heater YAMAHA TTR90 2006 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: TTR90, Model: YAMAHA TTR90 2006Pages: 390, PDF Size: 9.12 MB

Page 120 of 390

2 - 22

SPECCABLE ROUTING DIAGRAM

1Clamp

2Engine stop switch lead

3Main switch lead

4Start switch lead

5Brake cable

6Throttle cable

7Fuel tank breather hose

8Ignition coil

9Wire harness

0Starter relay

AStarter motor leadBCrankcase breather hose

CStarter motor lead

DNeutral switch lead

ECDI magneto lead

FCDI unit

GFuel overflow hose

HSpark plug lead

IFuel hose

JCarburetor heater lead

KCarburetor breather hose

LCarburetor heater couplerMCDI magneto coupler

NCDI unit coupler

OCDI unit connector

PCDI unit lead

QThermo switch lead

RThermo switch

SStarting circuit cut-off relay

TStarting circuit cut-off relay lead

URectifier/regulator lead

VRectifier/regulator

WStarter relay lead

A AA

C C

D

B

B B

BF FF

EE

D

A - AB - BE - E

C

F - FG - GD

KK

QRÑ

8

E

H

Ô 2 3 4

6

5

4

3

2

1

J

I

H

G

F

E

D

CBA 0 Í 9 8 Ë K 7

S

W U

V

A

0

Ú T

99

QP

PT

9 Ò

Ó

Õ Ö

Ê É

È

Ï

Ø

Ù

E

GGA

P

O

NML 9

Ð

9

Î

Û

Ý

25 mm (1.0 in)

×

Ì

35 ~ 45 mm

(1.38 ~ 1.77 in)

30 ~ 40 mm

(1.18 ~ 1.57 in)

Ü

Page 122 of 390

2 - 23

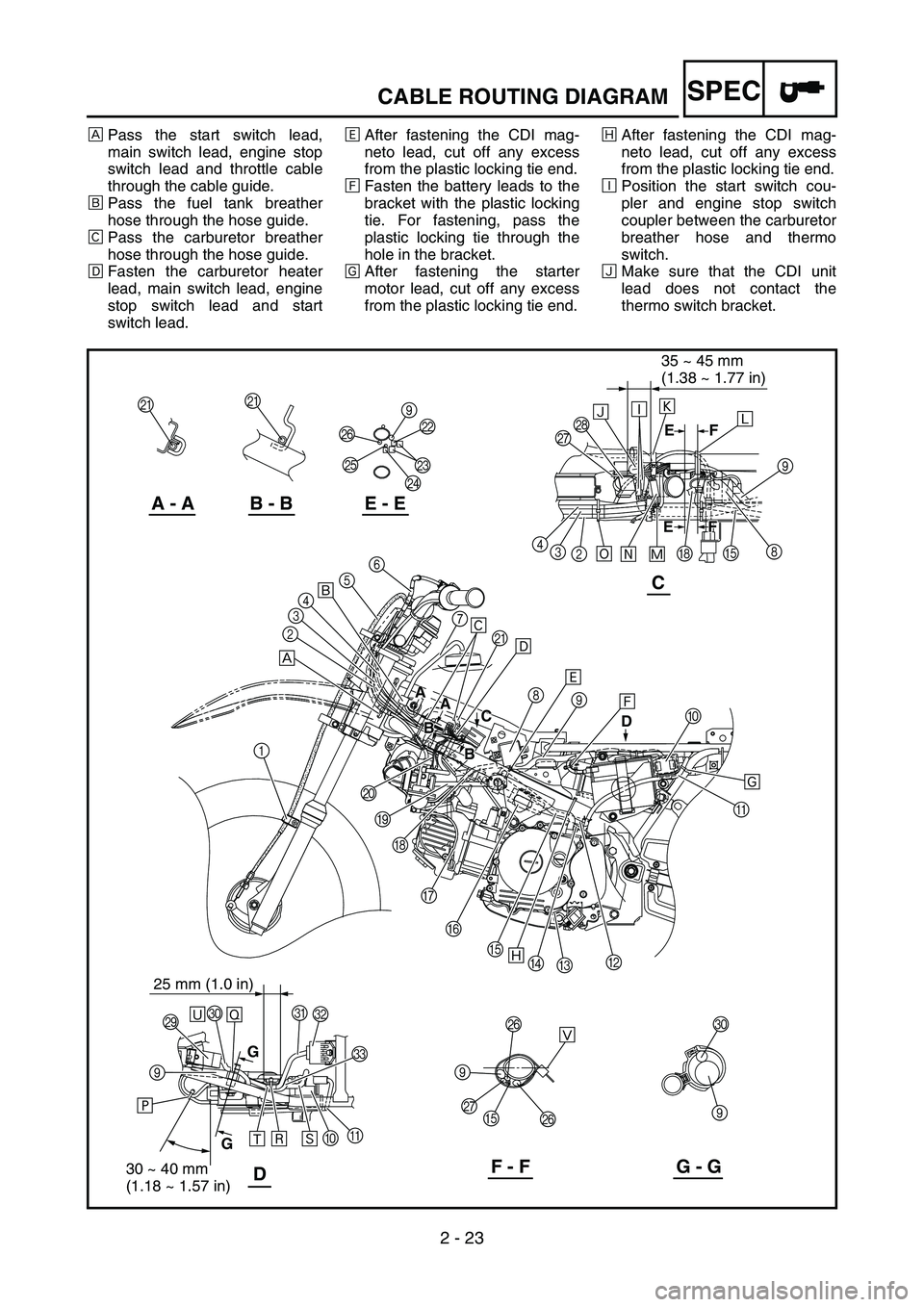

SPECCABLE ROUTING DIAGRAM

ÈPass the start switch lead,

main switch lead, engine stop

switch lead and throttle cable

through the cable guide.

ÉPass the fuel tank breather

hose through the hose guide.

ÊPass the carburetor breather

hose through the hose guide.

ËFasten the carburetor heater

lead, main switch lead, engine

stop switch lead and start

switch lead.ÌAfter fastening the CDI mag-

neto lead, cut off any excess

from the plastic locking tie end.

ÍFasten the battery leads to the

bracket with the plastic locking

tie. For fastening, pass the

plastic locking tie through the

hole in the bracket.

ÎAfter fastening the starter

motor lead, cut off any excess

from the plastic locking tie end.ÏAfter fastening the CDI mag-

neto lead, cut off any excess

from the plastic locking tie end.

ÐPosition the start switch cou-

pler and engine stop switch

coupler between the carburetor

breather hose and thermo

switch.

ÑMake sure that the CDI unit

lead does not contact the

thermo switch bracket.

A AA

C C

D

B

B B

BF FF

EE

D

A - AB - BE - E

C

F - FG - GD

KK

QRÑ

8

E

H

Ô 2 3 4

6

5

4

3

2

1

J

I

H

G

F

E

D

CBA 0 Í 9 8 Ë K 7

S

W U

V

A

0

Ú T

99

QP

PT

9 Ò

Ó

Õ Ö

Ê É

È

Ï

Ø

Ù

E

GGA

P

O

NML 9

Ð

9

Î

Û

Ý

25 mm (1.0 in)

×

Ì

35 ~ 45 mm

(1.38 ~ 1.77 in)

30 ~ 40 mm

(1.18 ~ 1.57 in)

Ü

Page 124 of 390

2 - 24

SPECCABLE ROUTING DIAGRAM

ÒFasten the starter cable,

thermo switch lead, CDI unit

lead, main switch lead, start

switch lead and engine stop

switch lead.

ÓFasten the wire harness, CDI

unit leads, thermo switch lead

and CDI magneto lead.

ÔPass the carburetor heater

lead between the carburetor

breather hose and air intake

duct.ÕPosition the main switch cou-

pler between the carburetor

breather hose and air intake

duct.

ÖFasten the start switch lead,

main switch lead and engine

stop switch lead at the tape

with the plastic locking tie.

×Fasten the battery leads.ØFasten the wire harness and

starting circuit cut-off relay lead

at the tape for the wire harness

with the plastic locking tie.

ÙFasten the rectifier/regulator

lead and starter relay leads.

For fastening, pass the plastic

locking tie through the hole in

the battery box.

A AA

C C

D

B

B B

BF FF

EE

D

A - AB - BE - E

C

F - FG - GD

KK

QRÑ

8

E

H

Ô 2 3 4

6

5

4

3

2

1

J

I

H

G

F

E

D

CBA 0 Í 9 8 Ë K 7

S

W U

V

A

0

Ú T

99

QP

PT

9 Ò

Ó

Õ Ö

Ê É

È

Ï

Ø

Ù

E

GGA

P

O

NML 9

Ð

9

Î

Û

Ý

25 mm (1.0 in)

×

Ì

35 ~ 45 mm

(1.38 ~ 1.77 in)

30 ~ 40 mm

(1.18 ~ 1.57 in)

Ü

Page 196 of 390

4 - 1

ENG

ENGINE

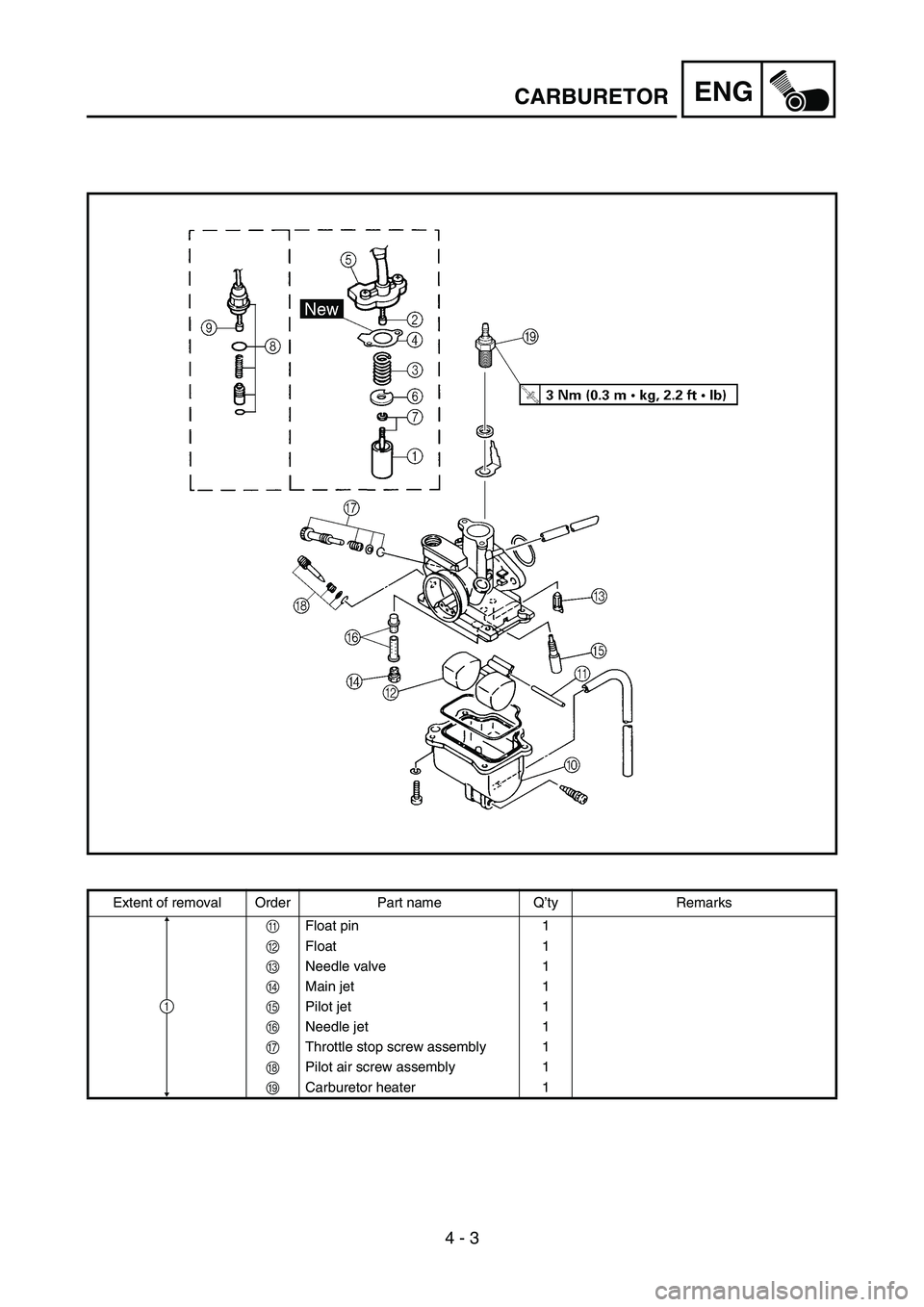

CARBURETOR

Extent of removal:

1 Carburetor removal

Extent of removal Order Part name Q’ty Remarks

CARBURETOR REMOVAL

Preparation for removal Fuel tank

1 Clamp (air filter joint) 1 Loosen the screw (air filter joint).

2 Carburetor heater lead 1

3 Air vent hose 1

4 Fuel hose 1

5Bolt 2

6 Carburetor assembly 1

7O-ring 2

8Spacer 1

9 Carburetor top 1

10 Starter plunger assembly 1

1

CARBURETOR

Page 200 of 390

4 - 3

ENGCARBURETOR

Extent of removal Order Part name Q’ty Remarks

A Float pin 1

B Float 1

C Needle valve 1

D Main jet 1

E Pilot jet 1

F Needle jet 1

G Throttle stop screw assembly 1

H Pilot air screw assembly 1

I Carburetor heater 1

1

Page 338 of 390

6 - 1

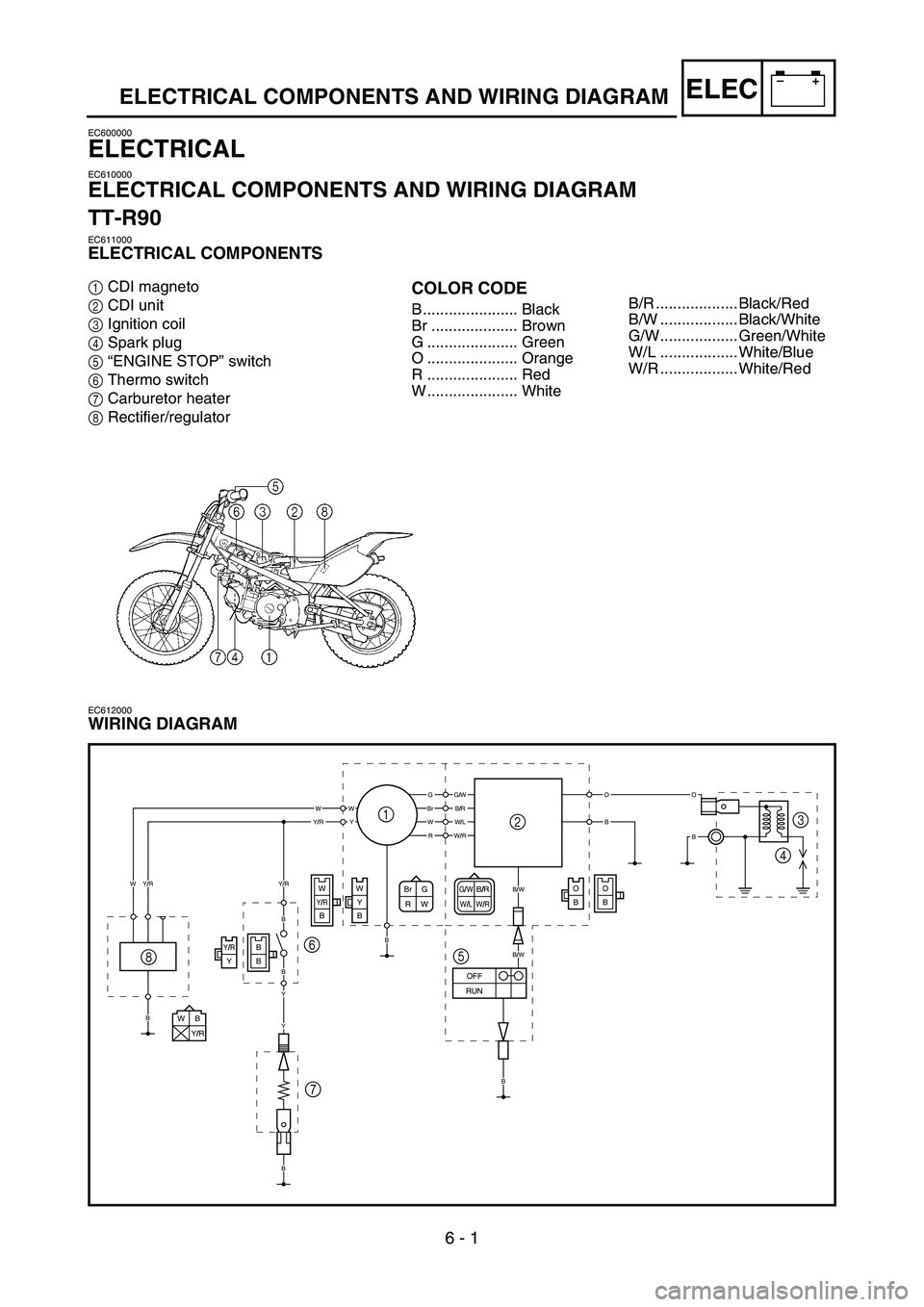

–+ELECELECTRICAL COMPONENTS AND WIRING DIAGRAM

EC600000

ELECTRICAL

EC610000

ELECTRICAL COMPONENTS AND WIRING DIAGRAM

TT-R90

EC611000

ELECTRICAL COMPONENTS

1CDI magneto

2CDI unit

3Ignition coil

4Spark plug

5“ENGINE STOP” switch

6Thermo switch

7Carburetor heater

8Rectifier/regulatorCOLOR CODE

B ...................... Black

Br .................... Brown

G ..................... Green

O ..................... Orange

R ..................... Red

W ..................... White

EC612000

WIRING DIAGRAM

G/WB/RW/LW/RBr G

RW

WB

Y/R

O

BO

B

B

BY/RY

WY/RB

W

Y

B

GG/W

B/W

B/W

BrB/RWWWY

OO

BBW/LY/RR

W

B

B

B

W/R

Y/R

OFF

RUN

B

Y/R

B

B

Y

Y

1

23

4

5 6

7 8

B/R ................... Black/Red

B/W .................. Black/White

G/W.................. Green/White

W/L .................. White/Blue

W/R .................. White/Red

Page 340 of 390

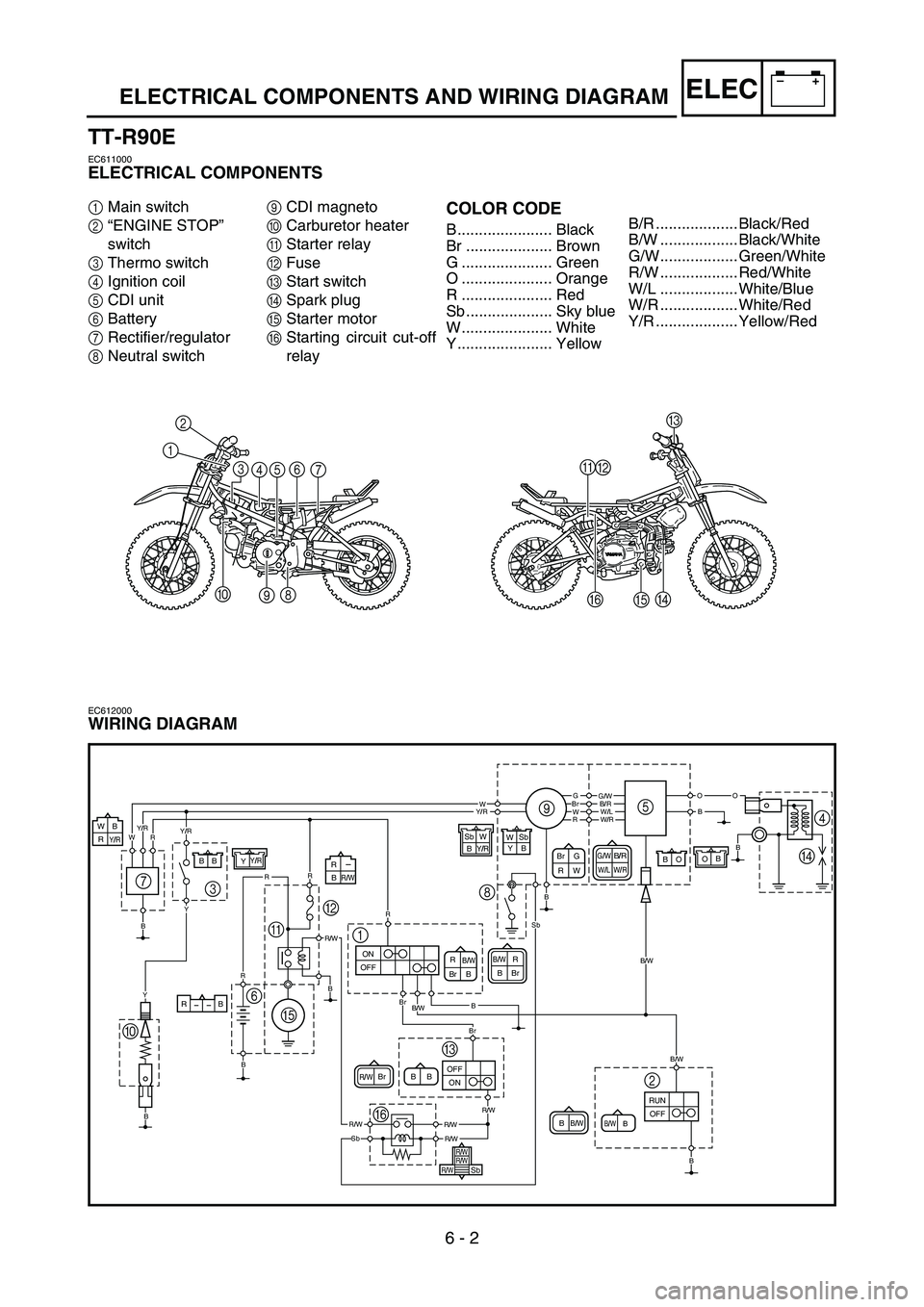

6 - 2

–+ELEC

12

3

456

7

0

98

A

B

F

EC

D

ELECTRICAL COMPONENTS AND WIRING DIAGRAM

TT-R90E

EC611000

ELECTRICAL COMPONENTS

1Main switch

2“ENGINE STOP”

switch

3Thermo switch

4Ignition coil

5CDI unit

6Battery

7Rectifier/regulator

8Neutral switch9CDI magneto

0Carburetor heater

AStarter relay

BFuse

CStart switch

DSpark plug

EStarter motor

FStarting circuit cut-off

relayCOLOR CODE

B ...................... Black

Br .................... Brown

G ..................... Green

O ..................... Orange

R ..................... Red

Sb .................... Sky blue

W ..................... White

Y ...................... Yellow

EC612000

WIRING DIAGRAM

G/WB/RW/LW/RBr G

RW

B/WBr BRB/WBBrR

B/WB/WBB

BR/WBr B

GG/W

B/W

B/W

BrB/RWWOO

B

BW/LY/RR

W

B

B

R

W/RY/R

OFF RUNB

Y/R

Y

Y

OBO BY/RYB B

Sb

W W

Sb

ON OFF

OFFON

Y

BBY/R

Br

Br

B

B

R

RR

R

B

R/WR/W

R/WR/W

R/W

Sb

Sb

RB

R/WB R

Y/RRB W

B/WB

R/W

R/W

R/W

Sb

9

8

1 B5

4

D

2 3

=A

E 6

C

F 7

B/R ................... Black/Red

B/W .................. Black/White

G/W.................. Green/White

R/W .................. Red/White

W/L .................. White/Blue

W/R .................. White/Red

Y/R ................... Yellow/Red

Page 376 of 390

–+ELEC

6 - 17

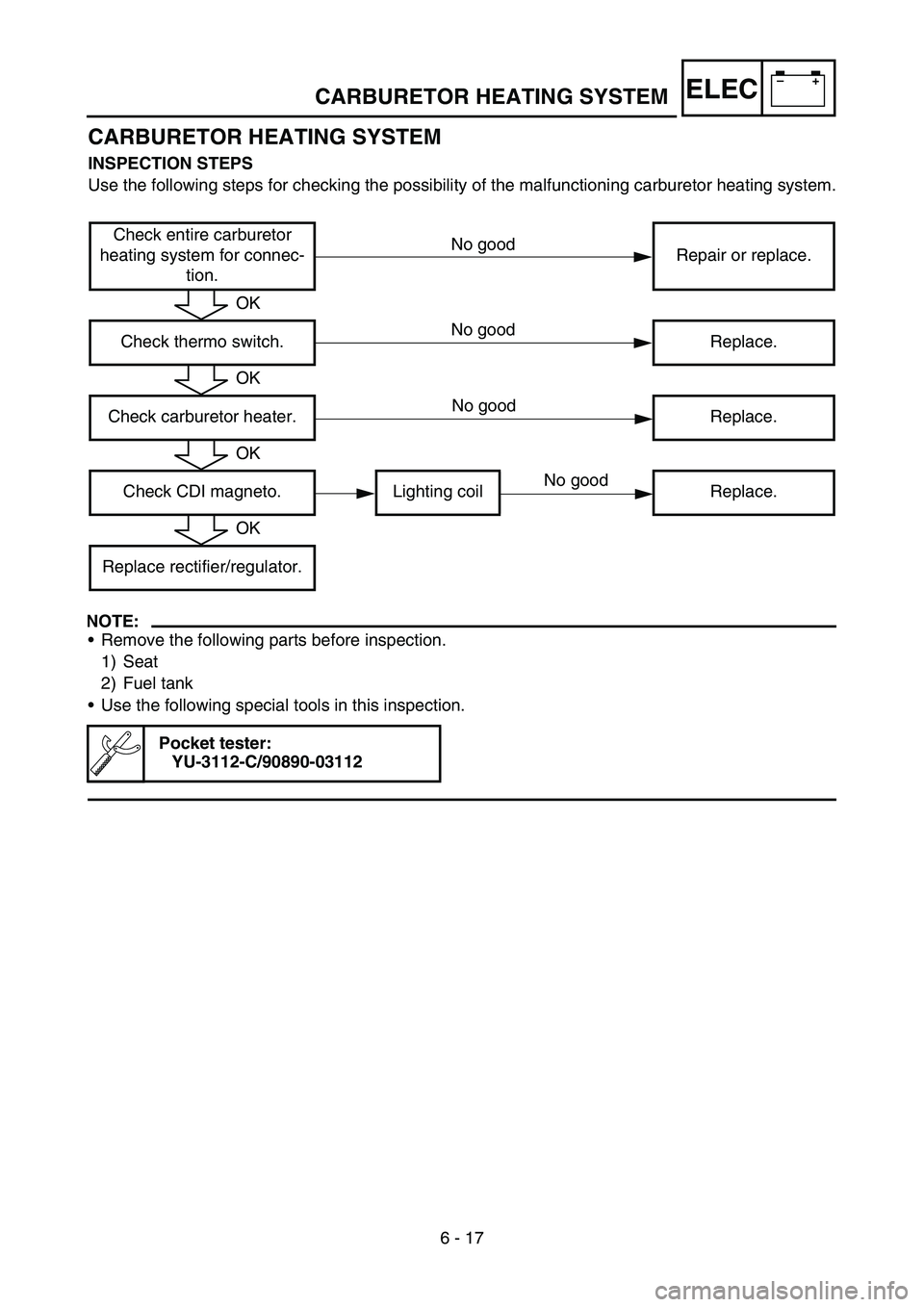

CARBURETOR HEATING SYSTEM

CARBURETOR HEATING SYSTEM

INSPECTION STEPS

Use the following steps for checking the possibility of the malfunctioning carburetor heating system.

NOTE:

Remove the following parts before inspection.

1) Seat

2) Fuel tank

Use the following special tools in this inspection.

Pocket tester:

YU-3112-C/90890-03112

Check entire carburetor

heating system for connec-

tion.Repair or replace.

Check thermo switch. Replace.

Check carburetor heater. Replace.

Check CDI magneto. Lighting coil Replace.

Replace rectifier/regulator.

OK

OK

OK

OK

No good

No good

No good

No good

Page 384 of 390

6 - 20

–+ELECCARBURETOR HEATING SYSTEM

CARBURETOR HEATER INSPECTION

1. Inspect:

Carburetor heater resistance

Out of specification → Replace.

Tester (+) probe

→

Carburetor heater terminal

1

Tester (–) probe

→

Carburetor heater body

2

Carburetor

heater resistanceTester selector

position

6 ~ 10

Ω at

20 °C (68 °F)Ω

× 1

CDI MAGNETO INSPECTION

1. Inspect:

Lighting coil resistance

Out of specification → Replace.

ÈTT-R90

ÉTT-R90E

Tester (+) lead

→ Yellow lead

1

Tester (–) lead

→ Black lead

2

Lighting coil

resistanceTester selector

position

TT-R90:

0.28 ~ 0.42

Ω at

20 °C (68 °F)

TT-R90E:

0.52 ~ 0.78

Ω at

20 °C (68 °F)Ω

× 1

W

Y

B

WSb

YB

1

2

1

2

È

É