ignition YAMAHA TTR90 2006 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: TTR90, Model: YAMAHA TTR90 2006Pages: 390, PDF Size: 9.12 MB

Page 206 of 390

4 - 6

ENGCARBURETOR

EC464600

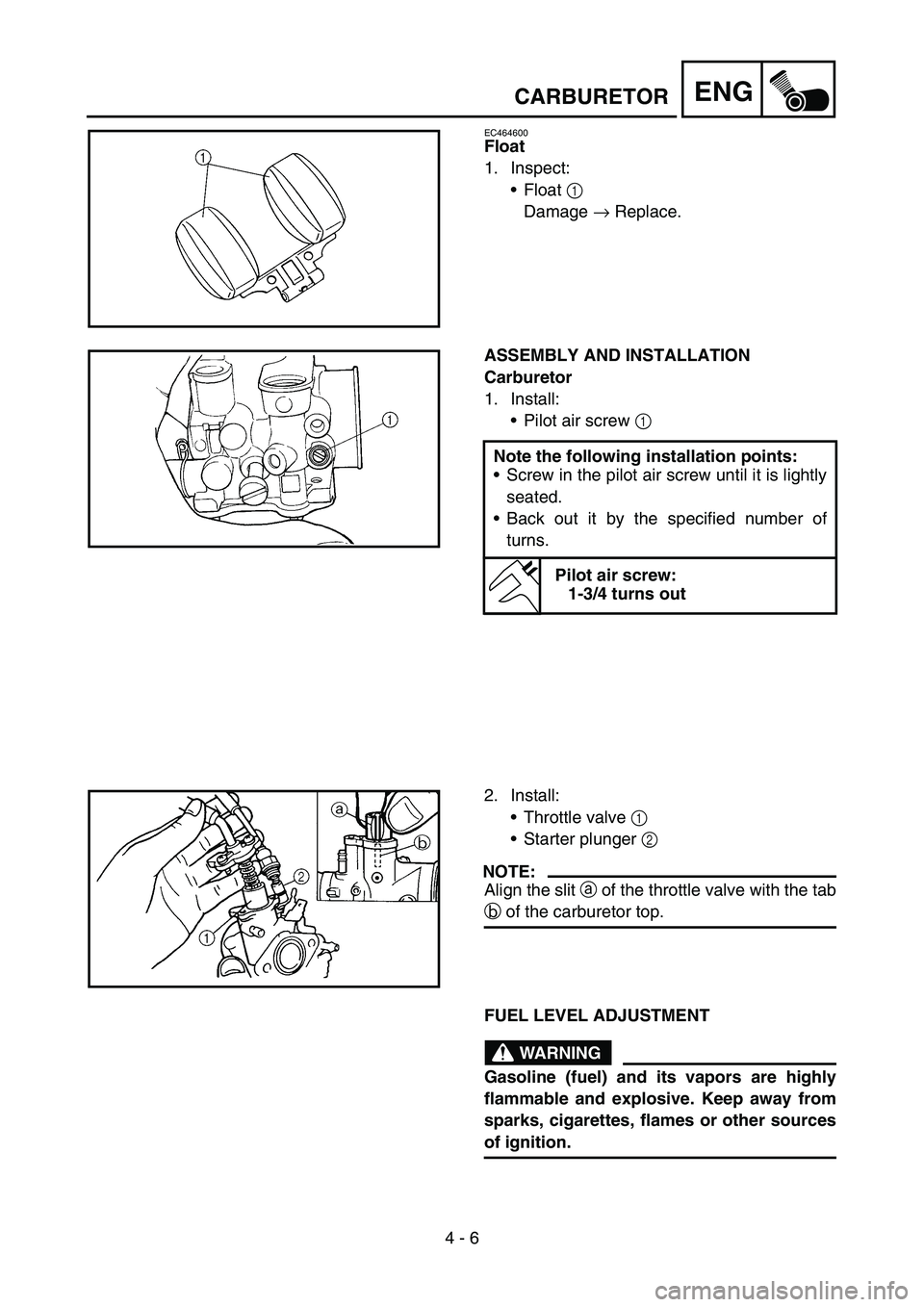

Float

1. Inspect:

Float 1

Damage → Replace.

ASSEMBLY AND INSTALLATION

Carburetor

1. Install:

Pilot air screw 1

Note the following installation points:

Screw in the pilot air screw until it is lightly

seated.

Back out it by the specified number of

turns.

Pilot air screw:

1-3/4 turns out

2. Install:

Throttle valve 1

Starter plunger 2

NOTE:

Align the slit a of the throttle valve with the tab

b of the carburetor top.

FUEL LEVEL ADJUSTMENT

WARNING

Gasoline (fuel) and its vapors are highly

flammable and explosive. Keep away from

sparks, cigarettes, flames or other sources

of ignition.

Page 338 of 390

6 - 1

–+ELECELECTRICAL COMPONENTS AND WIRING DIAGRAM

EC600000

ELECTRICAL

EC610000

ELECTRICAL COMPONENTS AND WIRING DIAGRAM

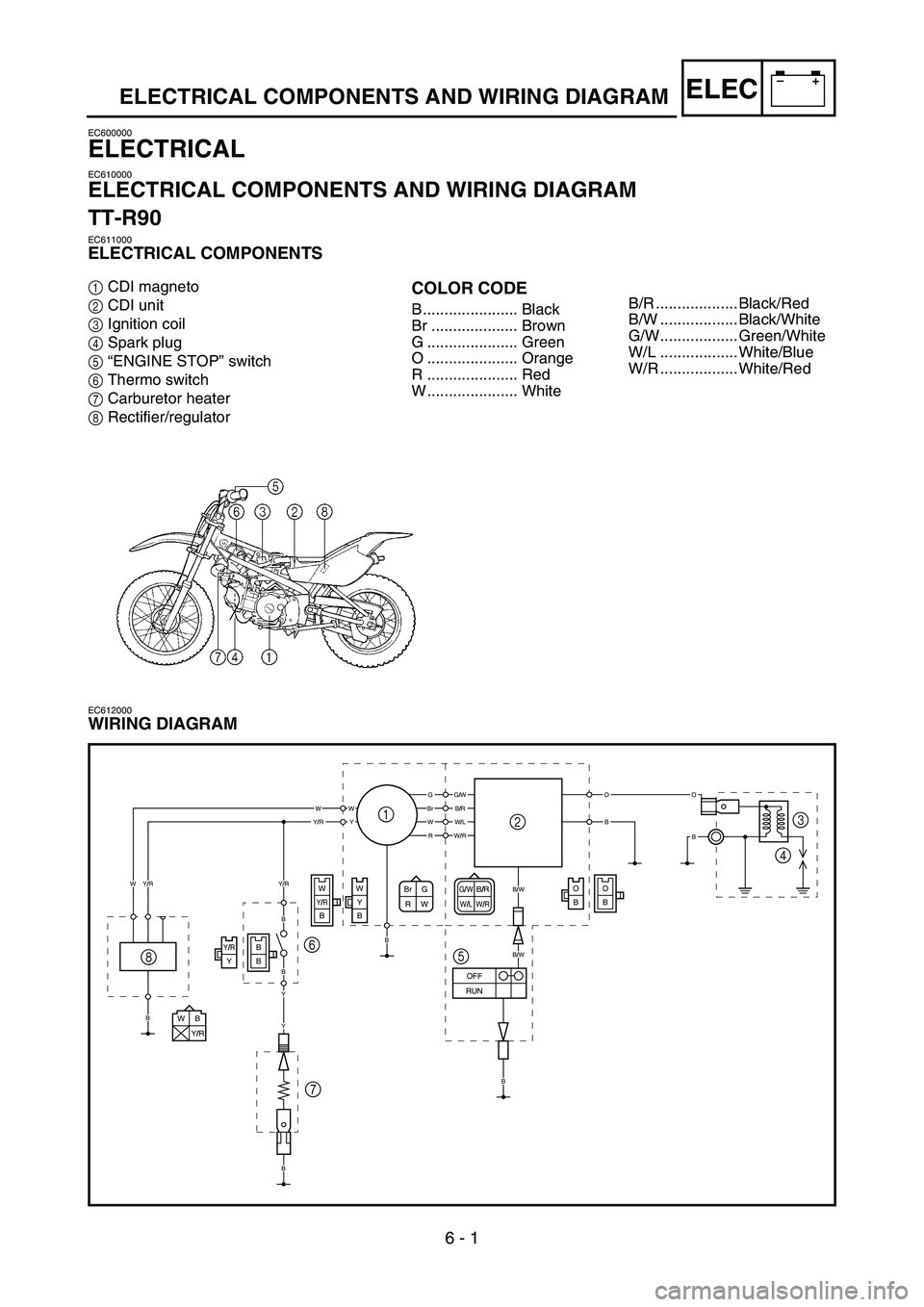

TT-R90

EC611000

ELECTRICAL COMPONENTS

1CDI magneto

2CDI unit

3Ignition coil

4Spark plug

5“ENGINE STOP” switch

6Thermo switch

7Carburetor heater

8Rectifier/regulatorCOLOR CODE

B ...................... Black

Br .................... Brown

G ..................... Green

O ..................... Orange

R ..................... Red

W ..................... White

EC612000

WIRING DIAGRAM

G/WB/RW/LW/RBr G

RW

WB

Y/R

O

BO

B

B

BY/RY

WY/RB

W

Y

B

GG/W

B/W

B/W

BrB/RWWWY

OO

BBW/LY/RR

W

B

B

B

W/R

Y/R

OFF

RUN

B

Y/R

B

B

Y

Y

1

23

4

5 6

7 8

B/R ................... Black/Red

B/W .................. Black/White

G/W.................. Green/White

W/L .................. White/Blue

W/R .................. White/Red

Page 340 of 390

6 - 2

–+ELEC

12

3

456

7

0

98

A

B

F

EC

D

ELECTRICAL COMPONENTS AND WIRING DIAGRAM

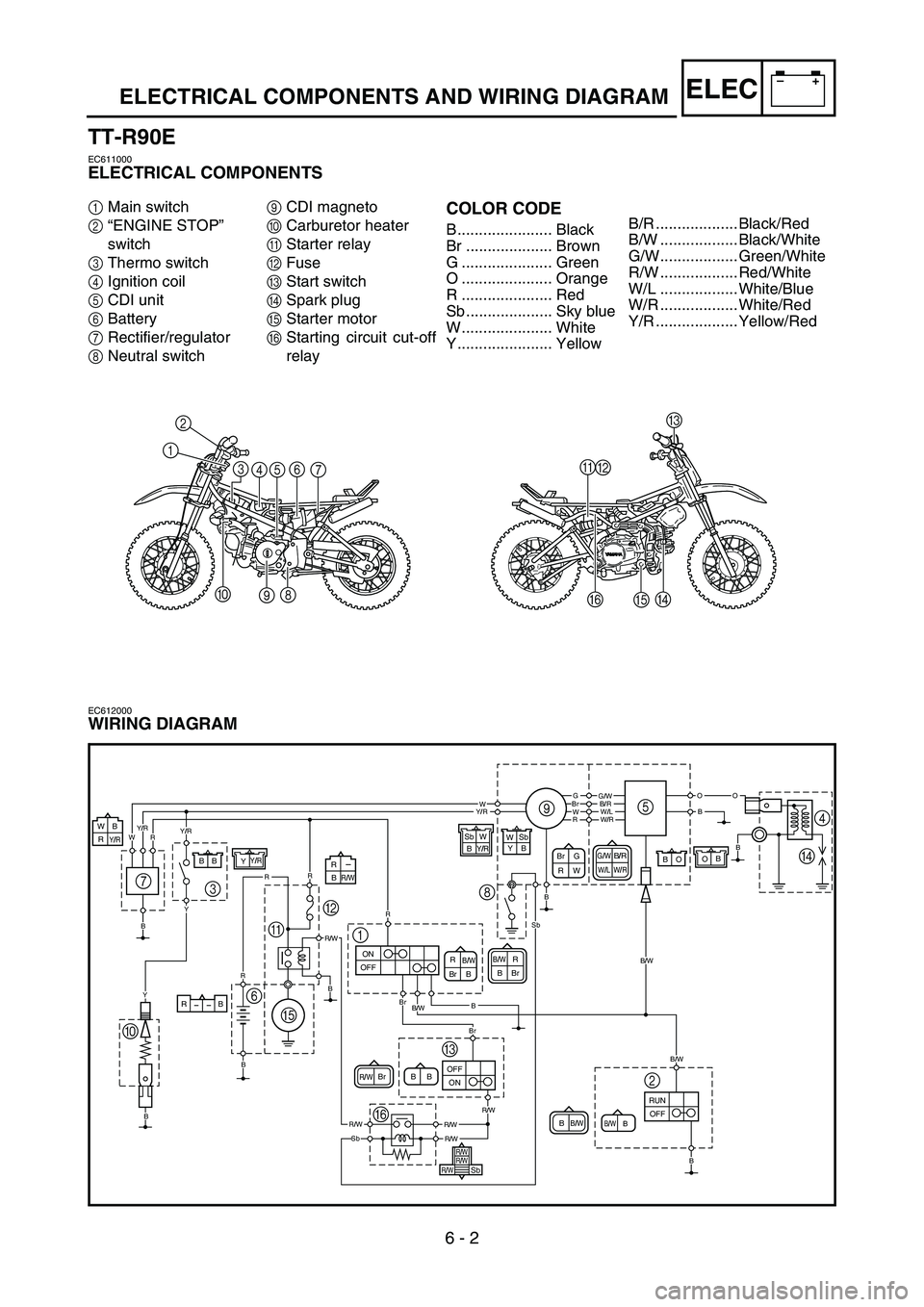

TT-R90E

EC611000

ELECTRICAL COMPONENTS

1Main switch

2“ENGINE STOP”

switch

3Thermo switch

4Ignition coil

5CDI unit

6Battery

7Rectifier/regulator

8Neutral switch9CDI magneto

0Carburetor heater

AStarter relay

BFuse

CStart switch

DSpark plug

EStarter motor

FStarting circuit cut-off

relayCOLOR CODE

B ...................... Black

Br .................... Brown

G ..................... Green

O ..................... Orange

R ..................... Red

Sb .................... Sky blue

W ..................... White

Y ...................... Yellow

EC612000

WIRING DIAGRAM

G/WB/RW/LW/RBr G

RW

B/WBr BRB/WBBrR

B/WB/WBB

BR/WBr B

GG/W

B/W

B/W

BrB/RWWOO

B

BW/LY/RR

W

B

B

R

W/RY/R

OFF RUNB

Y/R

Y

Y

OBO BY/RYB B

Sb

W W

Sb

ON OFF

OFFON

Y

BBY/R

Br

Br

B

B

R

RR

R

B

R/WR/W

R/WR/W

R/W

Sb

Sb

RB

R/WB R

Y/RRB W

B/WB

R/W

R/W

R/W

Sb

9

8

1 B5

4

D

2 3

=A

E 6

C

F 7

B/R ................... Black/Red

B/W .................. Black/White

G/W.................. Green/White

R/W .................. Red/White

W/L .................. White/Blue

W/R .................. White/Red

Y/R ................... Yellow/Red

Page 342 of 390

–+ELEC

6 - 3

IGNITION SYSTEM

EC620000

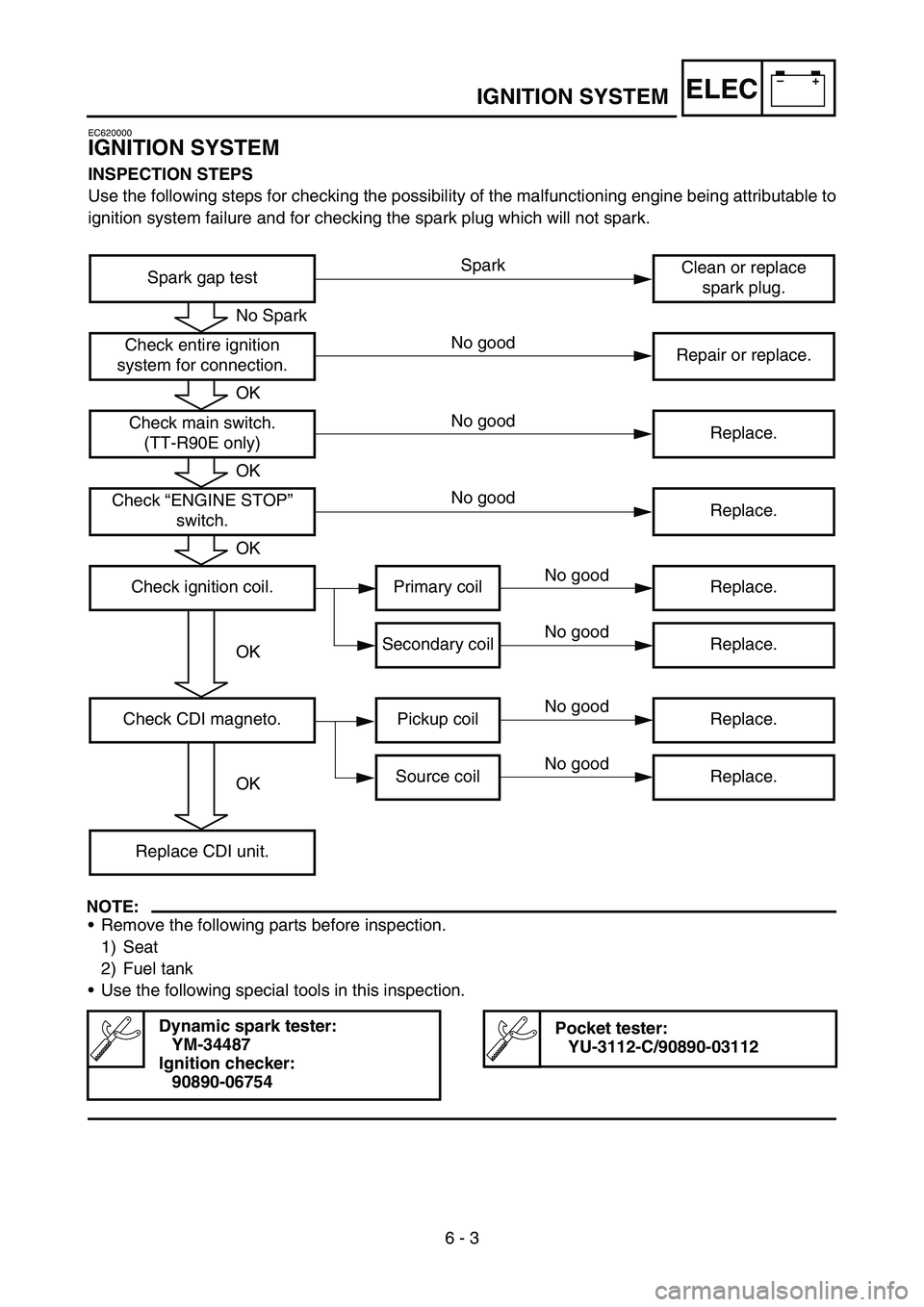

IGNITION SYSTEM

INSPECTION STEPS

Use the following steps for checking the possibility of the malfunctioning engine being attributable to

ignition system failure and for checking the spark plug which will not spark.

NOTE:

Remove the following parts before inspection.

1) Seat

2) Fuel tank

Use the following special tools in this inspection.

Dynamic spark tester:

YM-34487

Ignition checker:

90890-06754Pocket tester:

YU-3112-C/90890-03112

Spark gap testClean or replace

spark plug.

Check entire ignition

system for connection.Repair or replace.

Check main switch.

(TT-R90E only)Replace.

Check “ENGINE STOP”

switch.Replace.

Check ignition coil. Primary coil Replace.

Secondary coil Replace.

Check CDI magneto. Pickup coil Replace.

Source coil Replace.

Replace CDI unit.

No Spark

OK

OK

OK

OK

OK

Spark

No good

No good

No good

No good

No good

No good

No good

Page 346 of 390

6 - 4

–+ELECIGNITION SYSTEM

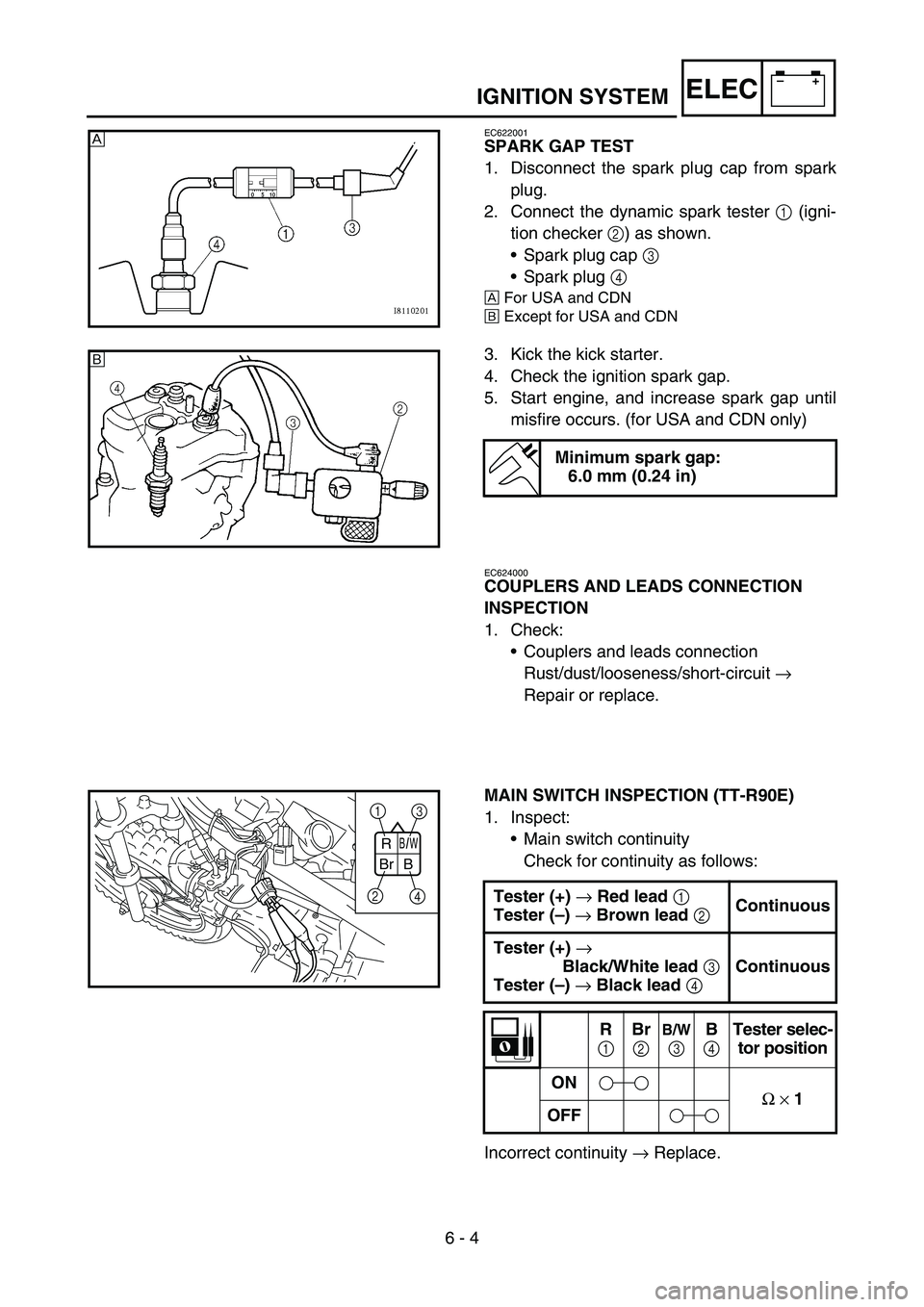

EC622001

SPARK GAP TEST

1. Disconnect the spark plug cap from spark

plug.

2. Connect the dynamic spark tester 1 (igni-

tion checker 2) as shown.

Spark plug cap 3

Spark plug 4

ÈFor USA and CDN

ÉExcept for USA and CDN

3. Kick the kick starter.

4. Check the ignition spark gap.

5. Start engine, and increase spark gap until

misfire occurs. (for USA and CDN only)

Minimum spark gap:

6.0 mm (0.24 in)

È

É

EC624000

COUPLERS AND LEADS CONNECTION

INSPECTION

1. Check:

Couplers and leads connection

Rust/dust/looseness/short-circuit →

Repair or replace.

MAIN SWITCH INSPECTION (TT-R90E)

1. Inspect:

Main switch continuity

Check for continuity as follows:

Incorrect continuity → Replace. Tester (+)

→ Red lead

1

Tester (–)

→ Brown lead

2 Continuous

Tester (+)

→

Black/White lead

3

Tester (–)

→ Black lead

4 Continuous

R

1Br

2B/W

3B

4Tester selec-

tor position

ON

Ω

× 1

OFF

B/W

BrR

B

1

3

2

4

Page 348 of 390

6 - 5

–+ELECIGNITION SYSTEM

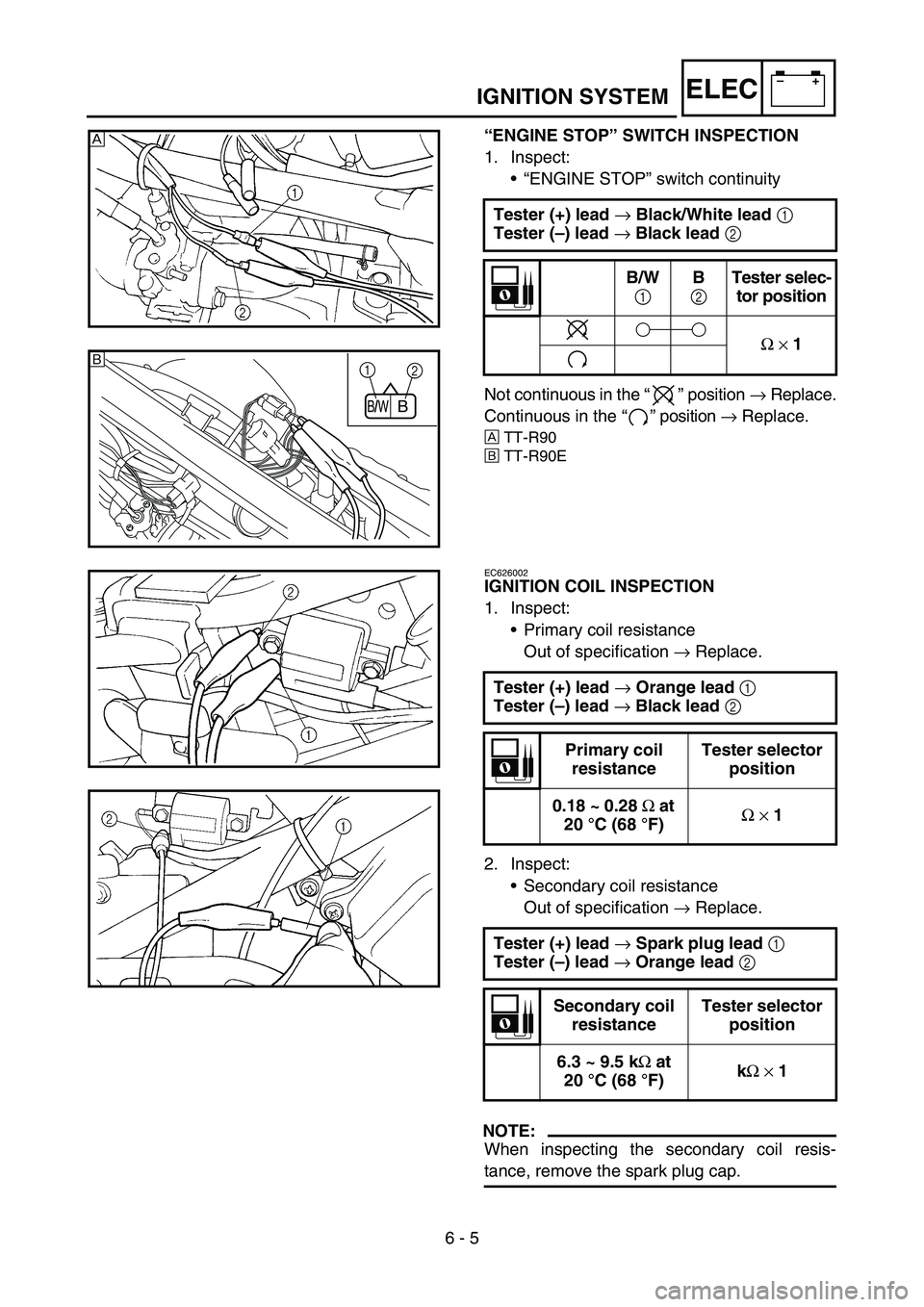

“ENGINE STOP” SWITCH INSPECTION

1. Inspect:

“ENGINE STOP” switch continuity

Not continuous in the “” position → Replace.

Continuous in the “” position → Replace.

ÈTT-R90

ÉTT-R90E

Tester (+) lead

→ Black/White lead

1

Tester (–) lead

→ Black lead

2

B/W

1 B

2 Tester selec-

tor position

Ω

× 1

È

BB/W

1

2É

EC626002

IGNITION COIL INSPECTION

1. Inspect:

Primary coil resistance

Out of specification → Replace.

2. Inspect:

Secondary coil resistance

Out of specification → Replace.

NOTE:

When inspecting the secondary coil resis-

tance, remove the spark plug cap.Tester (+) lead

→ Orange lead

1

Tester (–) lead

→ Black lead

2

Primary coil

resistanceTester selector

position

0.18 ~ 0.28

Ω at

20 °C (68 °F)Ω

× 1

Tester (+) lead

→ Spark plug lead

1

Tester (–) lead

→ Orange lead

2

Secondary coil

resistanceTester selector

position

6.3 ~ 9.5 k

Ω at

20 °C (68 °F)k

Ω

× 1

Page 350 of 390

6 - 6

–+ELECIGNITION SYSTEM

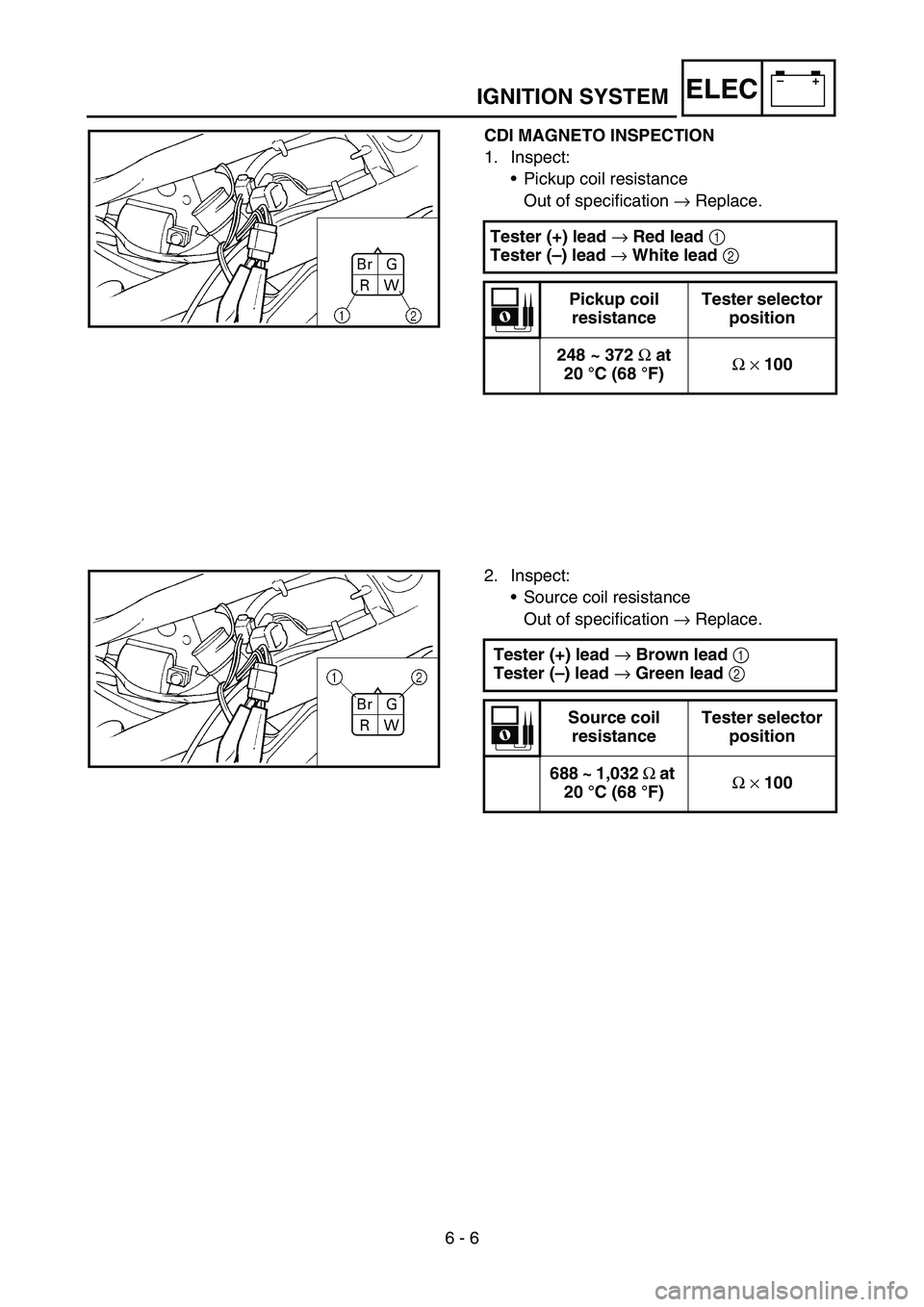

CDI MAGNETO INSPECTION

1. Inspect:

Pickup coil resistance

Out of specification → Replace.

Tester (+) lead

→ Red lead

1

Tester (–) lead

→ White lead

2

Pickup coil

resistanceTester selector

position

248 ~ 372

Ω at

20 °C (68 °F)Ω

× 100

2. Inspect:

Source coil resistance

Out of specification → Replace.

Tester (+) lead

→ Brown lead

1

Tester (–) lead

→ Green lead

2

Source coil

resistanceTester selector

position

688 ~ 1,032

Ω at

20 °C (68 °F)Ω

× 100