warning YAMAHA TTR90 2006 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: TTR90, Model: YAMAHA TTR90 2006Pages: 390, PDF Size: 9.12 MB

Page 326 of 390

5 - 16

CHASHANDLEBAR

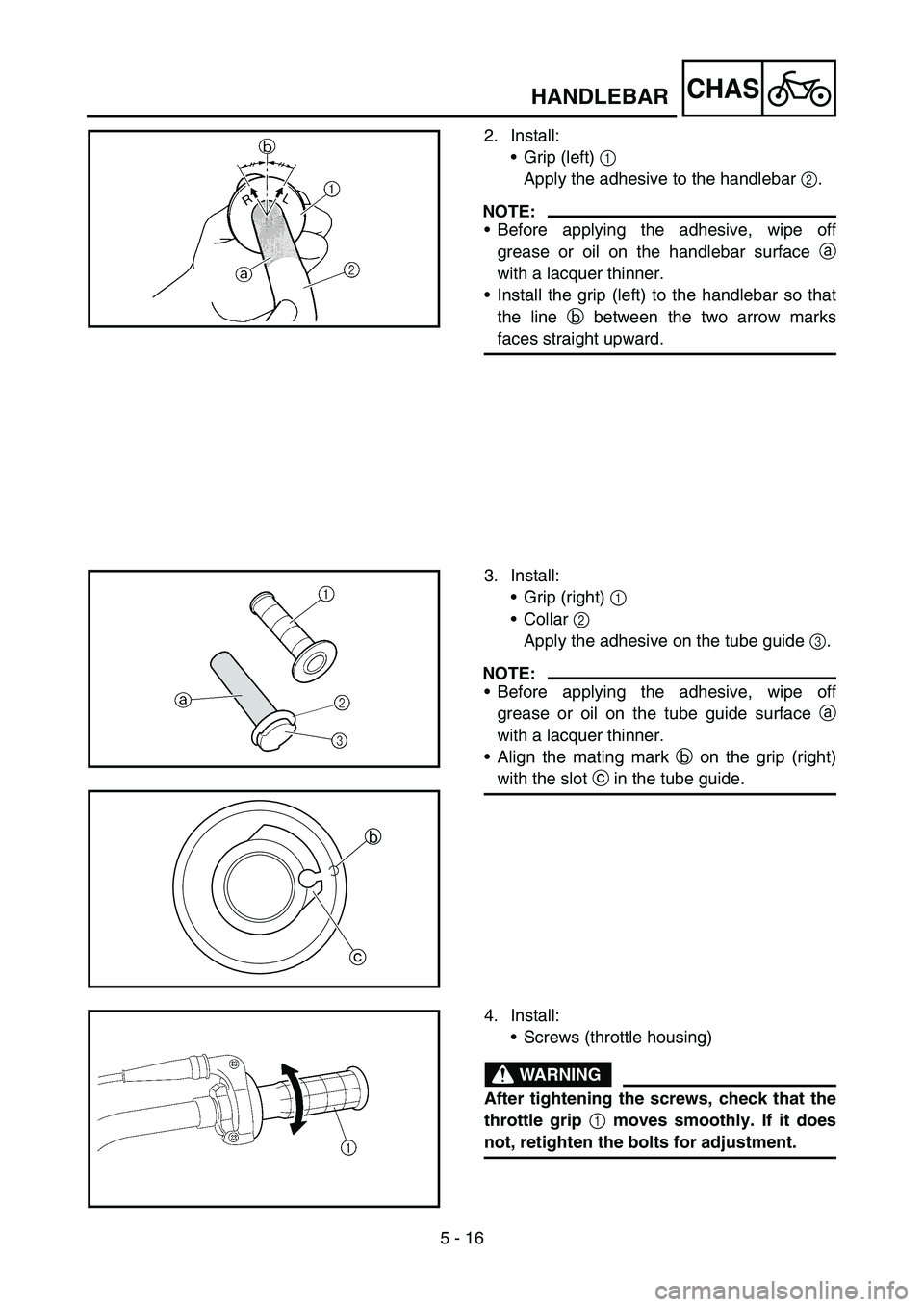

2. Install:

Grip (left) 1

Apply the adhesive to the handlebar 2.

NOTE:

Before applying the adhesive, wipe off

grease or oil on the handlebar surface a

with a lacquer thinner.

Install the grip (left) to the handlebar so that

the line b between the two arrow marks

faces straight upward.

3. Install:

Grip (right) 1

Collar 2

Apply the adhesive on the tube guide 3.

NOTE:

Before applying the adhesive, wipe off

grease or oil on the tube guide surface a

with a lacquer thinner.

Align the mating mark b on the grip (right)

with the slot c in the tube guide.

cb

4. Install:

Screws (throttle housing)

WARNING

After tightening the screws, check that the

throttle grip

1 moves smoothly. If it does

not, retighten the bolts for adjustment.

Page 330 of 390

5 - 18

CHASSTEERING

EC560000

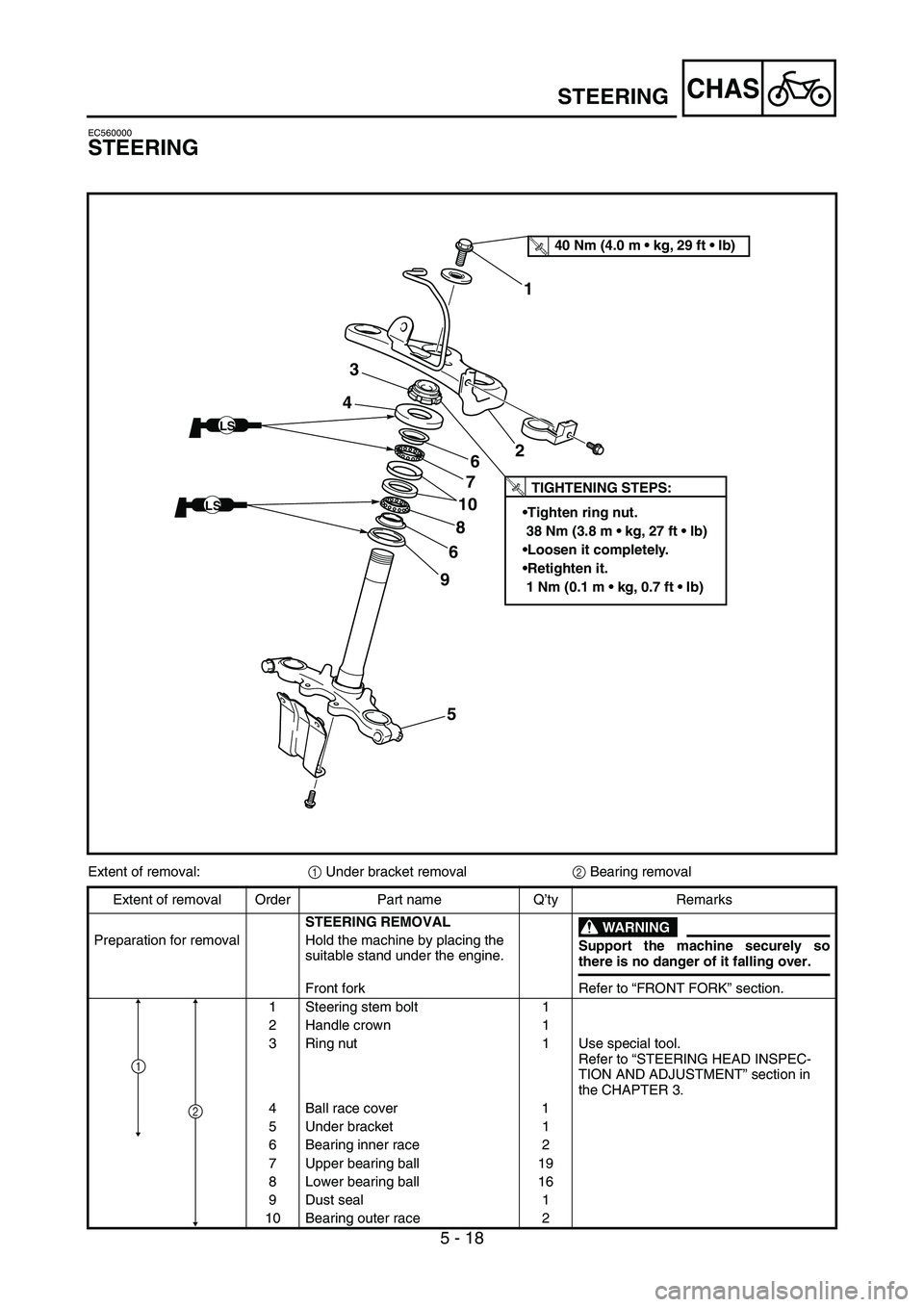

STEERING

LS

LS

T R..TIGHTENING STEPS:

Tighten ring nut.

38 Nm (3.8 m kg, 27 ft Ib)

Loosen it completely.

Retighten it.

1 Nm (0.1 m kg, 0.7 ft Ib)

T R..40 Nm (4.0 m kg, 29 ft Ib)

5 9681076 43

21

Extent of removal:

1 Under bracket removal

2 Bearing removal

Extent of removal Order Part name Q’ty Remarks

STEERING REMOVAL

WARNING

Support the machine securely so

there is no danger of it falling over. Preparation for removal Hold the machine by placing the

suitable stand under the engine.

Front fork Refer to “FRONT FORK” section.

1 Steering stem bolt 1

2 Handle crown 1

3 Ring nut 1 Use special tool.

Refer to “STEERING HEAD INSPEC-

TION AND ADJUSTMENT” section in

the CHAPTER 3.

4 Ball race cover 1

5 Under bracket 1

6 Bearing inner race 2

7 Upper bearing ball 19

8 Lower bearing ball 16

9 Dust seal 1

10 Bearing outer race 2

2

1

Page 332 of 390

5 - 19

CHAS

EC563000

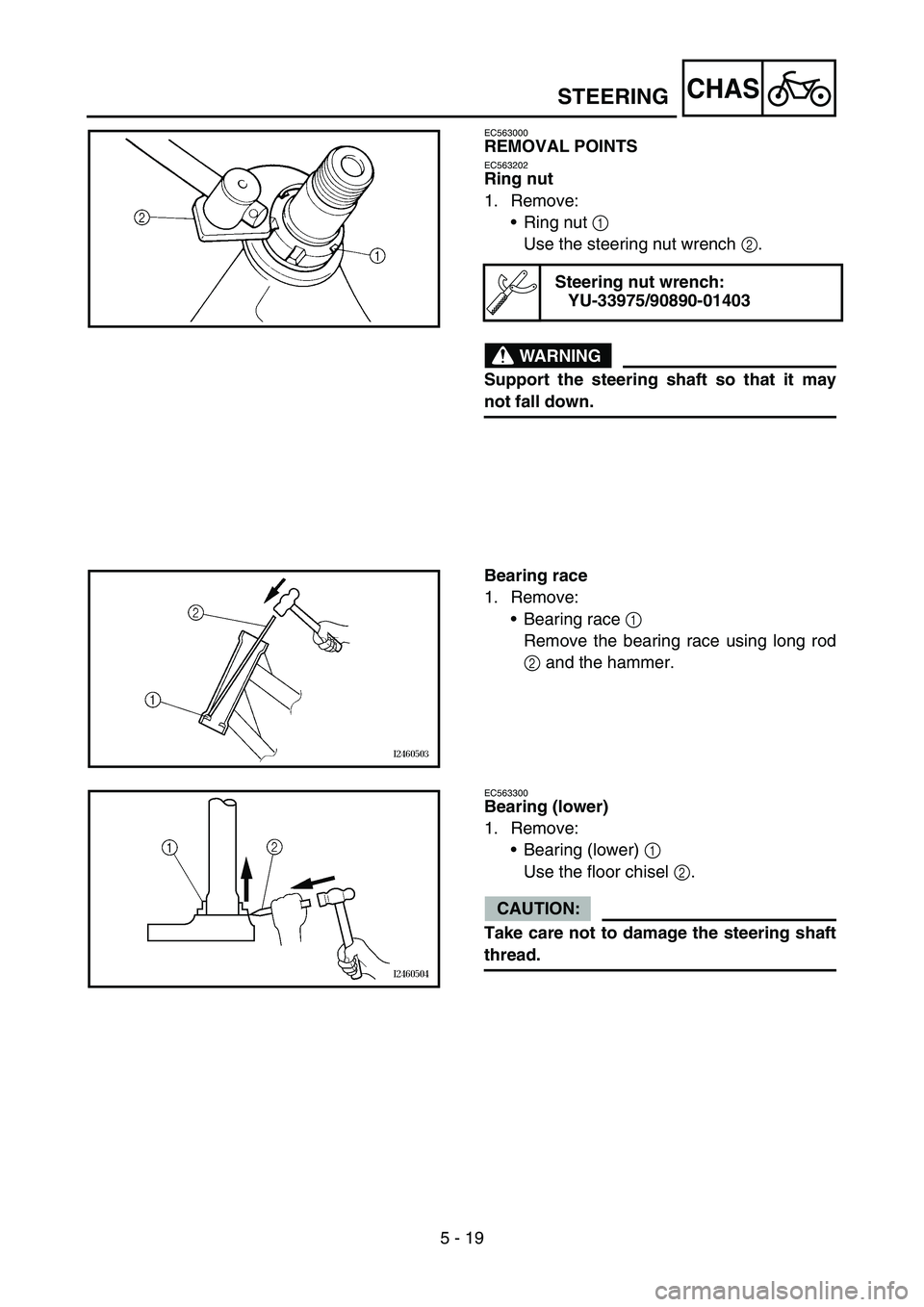

REMOVAL POINTS

EC563202

Ring nut

1. Remove:

Ring nut 1

Use the steering nut wrench 2.

WARNING

Support the steering shaft so that it may

not fall down.

Steering nut wrench:

YU-33975/90890-01403

Bearing race

1. Remove:

Bearing race 1

Remove the bearing race using long rod

2 and the hammer.

EC563300

Bearing (lower)

1. Remove:

Bearing (lower) 1

Use the floor chisel 2.

CAUTION:

Take care not to damage the steering shaft

thread.

STEERING

Page 334 of 390

5 - 20

CHASSWINGARM

EC570000

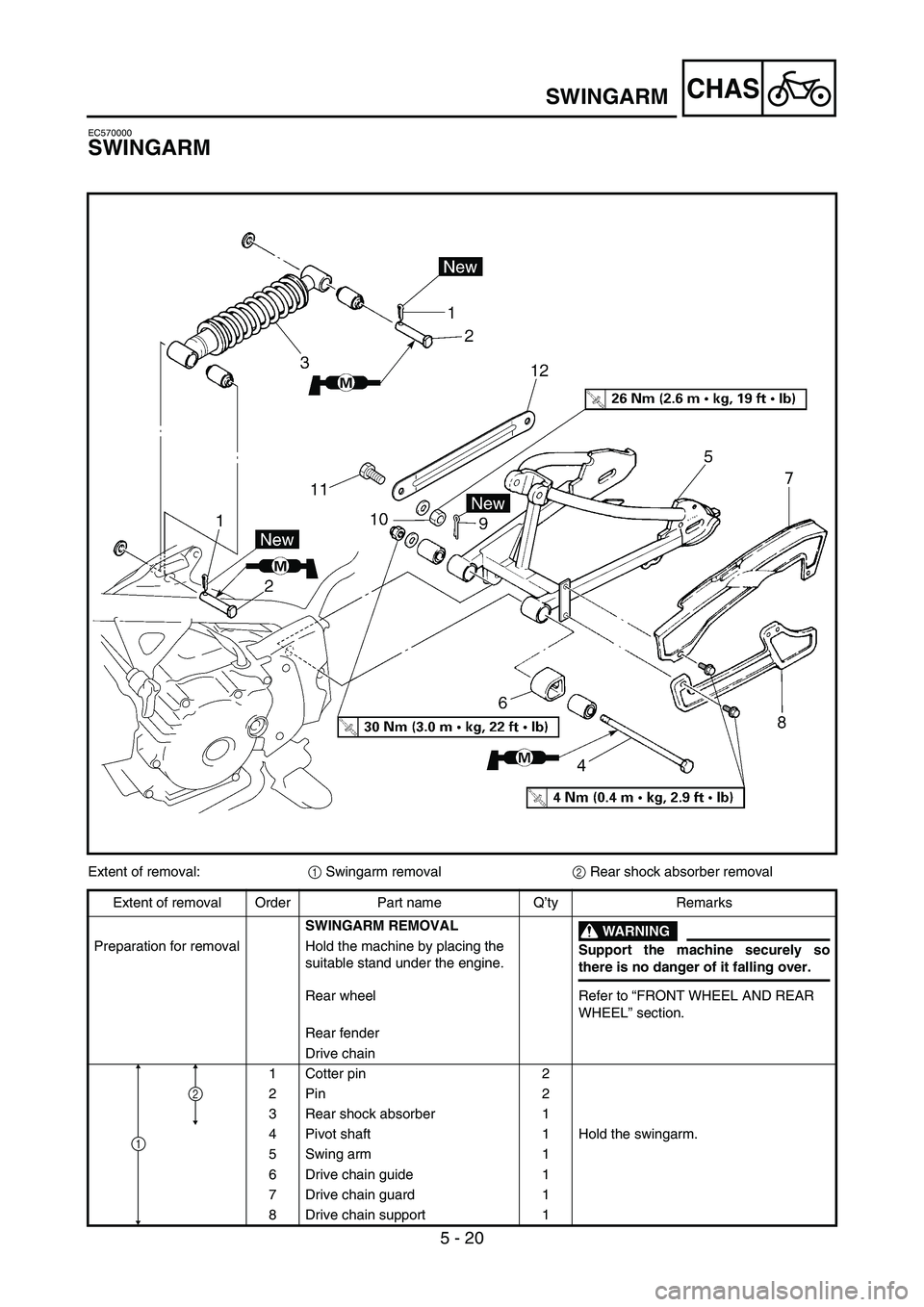

SWINGARM

Extent of removal:

1 Swingarm removal

2 Rear shock absorber removal

Extent of removal Order Part name Q’ty Remarks

SWINGARM REMOVAL

WARNING

Support the machine securely so

there is no danger of it falling over. Preparation for removal Hold the machine by placing the

suitable stand under the engine.

Rear wheel Refer to “FRONT WHEEL AND REAR

WHEEL” section.

Rear fender

Drive chain

1Cotter pin 2

2Pin 2

3 Rear shock absorber 1

4 Pivot shaft 1 Hold the swingarm.

5 Swing arm 1

6 Drive chain guide 1

7 Drive chain guard 1

8 Drive chain support 1

2

1

Page 358 of 390

6 - 9

–+ELEC

EC624000

COUPLERS AND LEADS CONNECTION

INSPECTION

1. Check:

Couplers and leads connection

Rust/dust/looseness/short-circuit →

Repair or replace.

STARTER MOTOR OPERATION

1. Connect the positive battery terminal 1

and starter motor lead 2 with a jumper

lead 3.

Not operate → Repair or replace the

starter motor.

WARNING

A wire that is used as a jumper lead must

have at least the same capacity or more

as that of the a battery lead, otherwise the

jumper lead may burn.

This check is likely to produce sparks,

therefore make sure nothing flammable is

in the vicinity.

STARTING CIRCUIT CUT-OFF RELAY

INSPECTION

1. Remove:

Starting circuit cut-off relay

2. Inspect:

Starting circuit cut-off relay conduct

Use 12 V battery.

Battery (+) lead → Red/White lead 1

Battery (–) lead → Sky blue lead 2

Tester (+) lead → Red/White lead 3

Tester (–) lead → Red/White lead 4

R/W

3 R/W

4 Tester selec-

tor position

Connected

to battery

Ω × 1

Not

connected

to battery

2 4

3

1

ELECTRIC STARTING SYSTEM (TT-R90E)

Page 382 of 390

6 - 19

–+ELEC

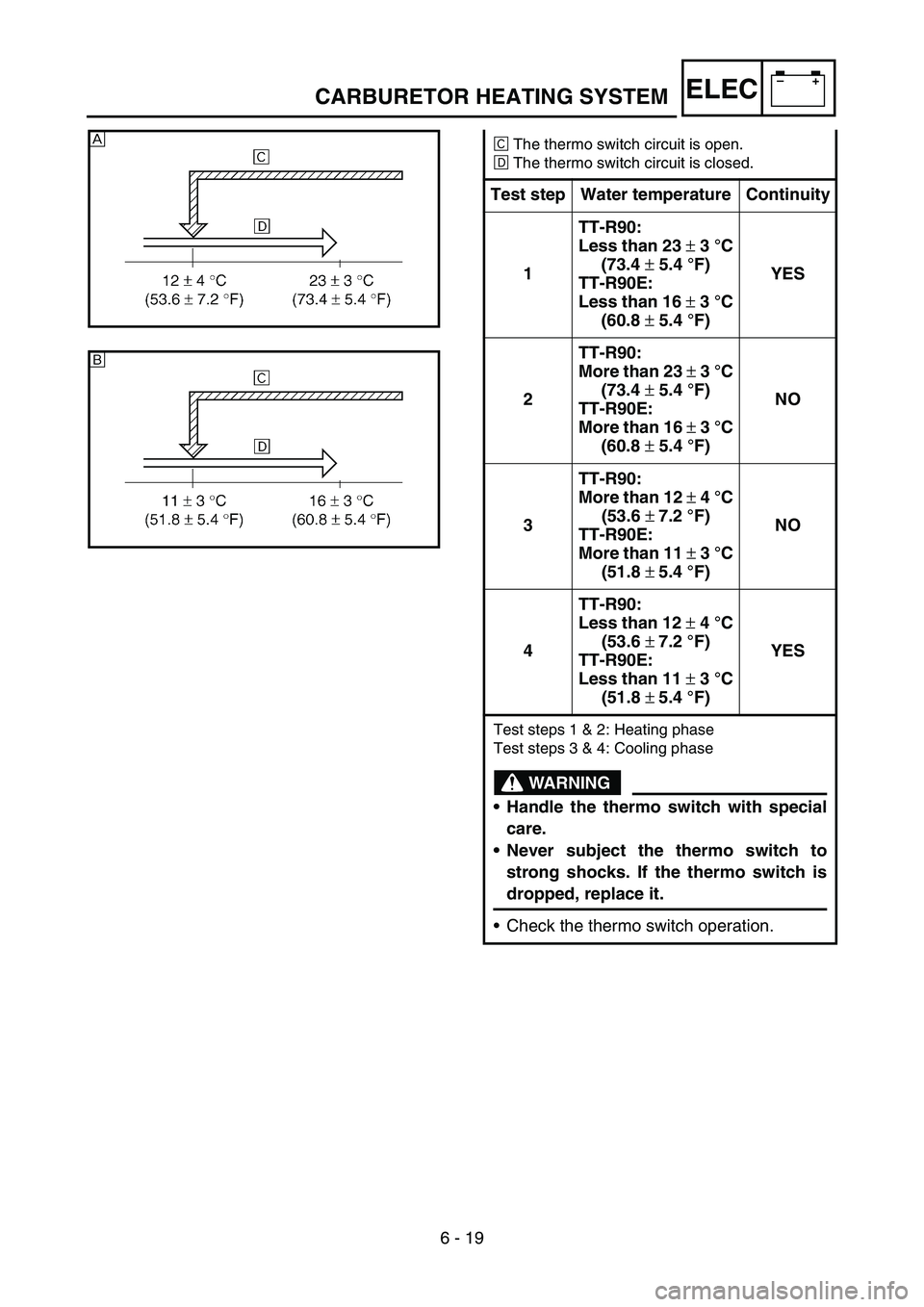

ÊThe thermo switch circuit is open.

ËThe thermo switch circuit is closed.

Test step Water temperature Continuity

1TT-R90:

Less than 23 ± 3 °C

(73.4 ± 5.4 °F)

TT-R90E:

Less than 16 ± 3 °C

(60.8 ± 5.4 °F)YES

2TT-R90:

More than 23 ± 3 °C

(73.4 ± 5.4 °F)

TT-R90E:

More than 16 ± 3 °C

(60.8 ± 5.4 °F)NO

3TT-R90:

More than 12 ± 4 °C

(53.6 ± 7.2 °F)

TT-R90E:

More than 11 ± 3 °C

(51.8 ± 5.4 °F)NO

4TT-R90:

Less than 12 ± 4 °C

(53.6 ± 7.2 °F)

TT-R90E:

Less than 11 ± 3 °C

(51.8 ± 5.4 °F)YES

Test steps 1 & 2: Heating phase

Test steps 3 & 4: Cooling phase

WARNING

Handle the thermo switch with special

care.

Never subject the thermo switch to

strong shocks. If the thermo switch is

dropped, replace it.

Check the thermo switch operation.

È

É

CARBURETOR HEATING SYSTEM