heating YAMAHA TTR90 2006 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: TTR90, Model: YAMAHA TTR90 2006Pages: 390, PDF Size: 9.12 MB

Page 24 of 390

CHAPTER 4

ENGINE

CARBURETOR ..........................................4-1

CYLINDER HEAD ......................................4-8

CAMSHAFT AND ROCKER ARMS ........4-13

VALVES AND VALVE SPRINGS ............4-16

CYLINDER AND PISTON ........................4-21

CLUTCH ...................................................4-27

KICK AXLE ..............................................4-33

SHIFT SHAFT ..........................................4-34

OIL PUMP ................................................4-36

CDI MAGNETO (TT-R90) ........................4-39

CDI MAGNETO AND

STARTER CLUTCH (TT-R90E) ...............4-41

CRANKCASE AND CRANKSHAFT ........4-45

SHIFT FORK, SHIFT CAM AND

TRANSMISSION ......................................4-48

CHAPTER 5

CHASSIS

FRONT WHEEL AND REAR WHEEL .......5-1

FRONT FORK ..........................................5-10

HANDLEBAR ...........................................5-13

STEERING ...............................................5-18

SWINGARM .............................................5-20

CHAPTER 6

ELECTRICAL

ELECTRICAL COMPONENTS AND

WIRING DIAGRAM ....................................6-1

IGNITION SYSTEM ....................................6-3

ELECTRIC STARTING SYSTEM

(TT-R90E) ..................................................6-7

CHARGING SYSTEM (TT-R90E) ............6-15

CARBURETOR HEATING SYSTEM .......6-17

MAINTENANCE RECORD ......................6-21

Page 112 of 390

2 - 18

SPECCABLE ROUTING DIAGRAM

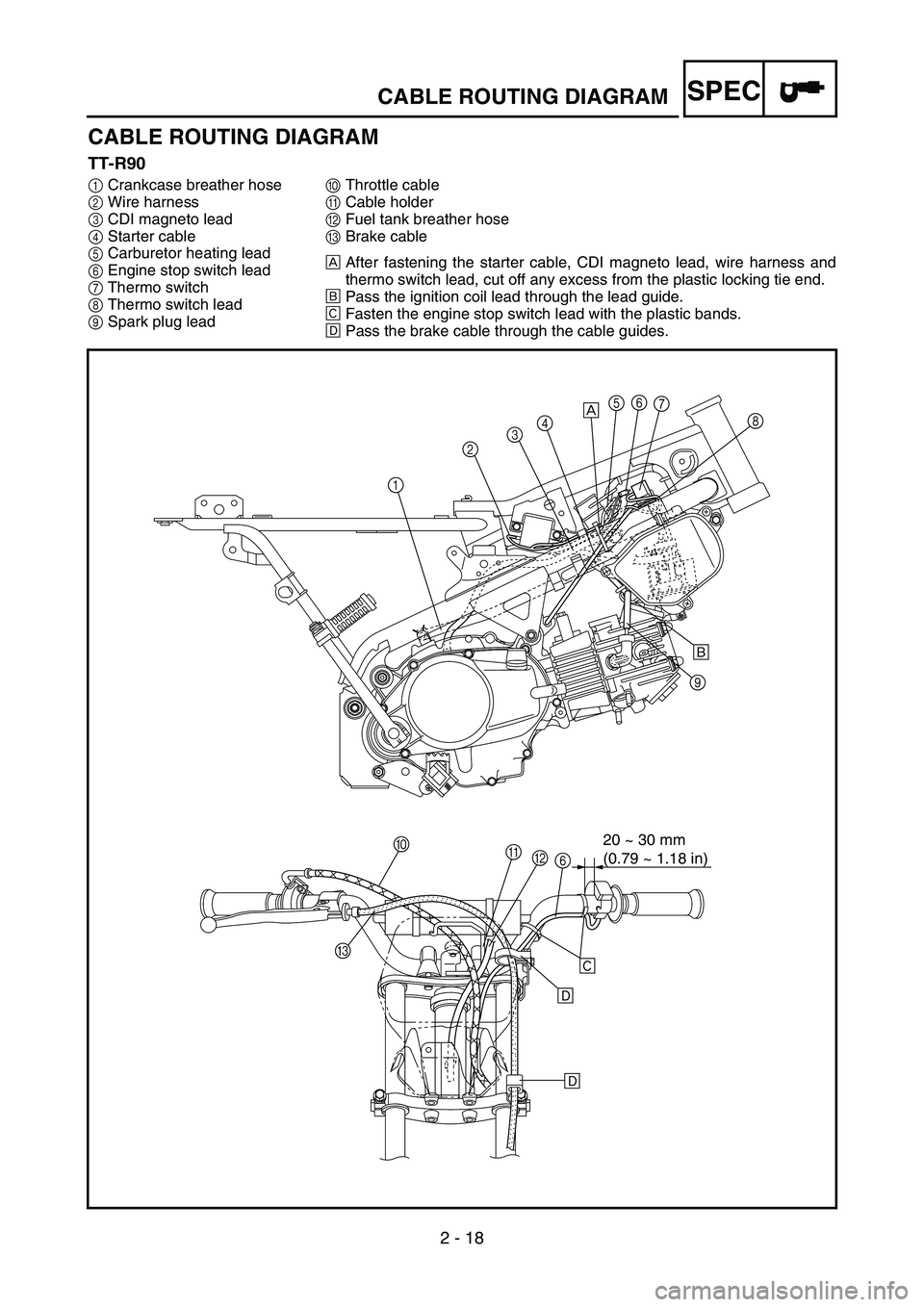

CABLE ROUTING DIAGRAM

TT-R90

1Crankcase breather hose

2Wire harness

3CDI magneto lead

4Starter cable

5Carburetor heating lead

6Engine stop switch lead

7Thermo switch

8Thermo switch lead

9Spark plug lead0Throttle cable

ACable holder

BFuel tank breather hose

CBrake cable

ÈAfter fastening the starter cable, CDI magneto lead, wire harness and

thermo switch lead, cut off any excess from the plastic locking tie end.

ÉPass the ignition coil lead through the lead guide.

ÊFasten the engine stop switch lead with the plastic bands.

ËPass the brake cable through the cable guides.

12345

9

0

B A

6

CÈ

É

Ê

Ë

Ë

67

8

20 ~ 30 mm

(0.79 ~ 1.18 in)

Page 182 of 390

3 - 26

INSP

ADJ

BATTERY INSPECTION AND CHARGING (TT-R90E)

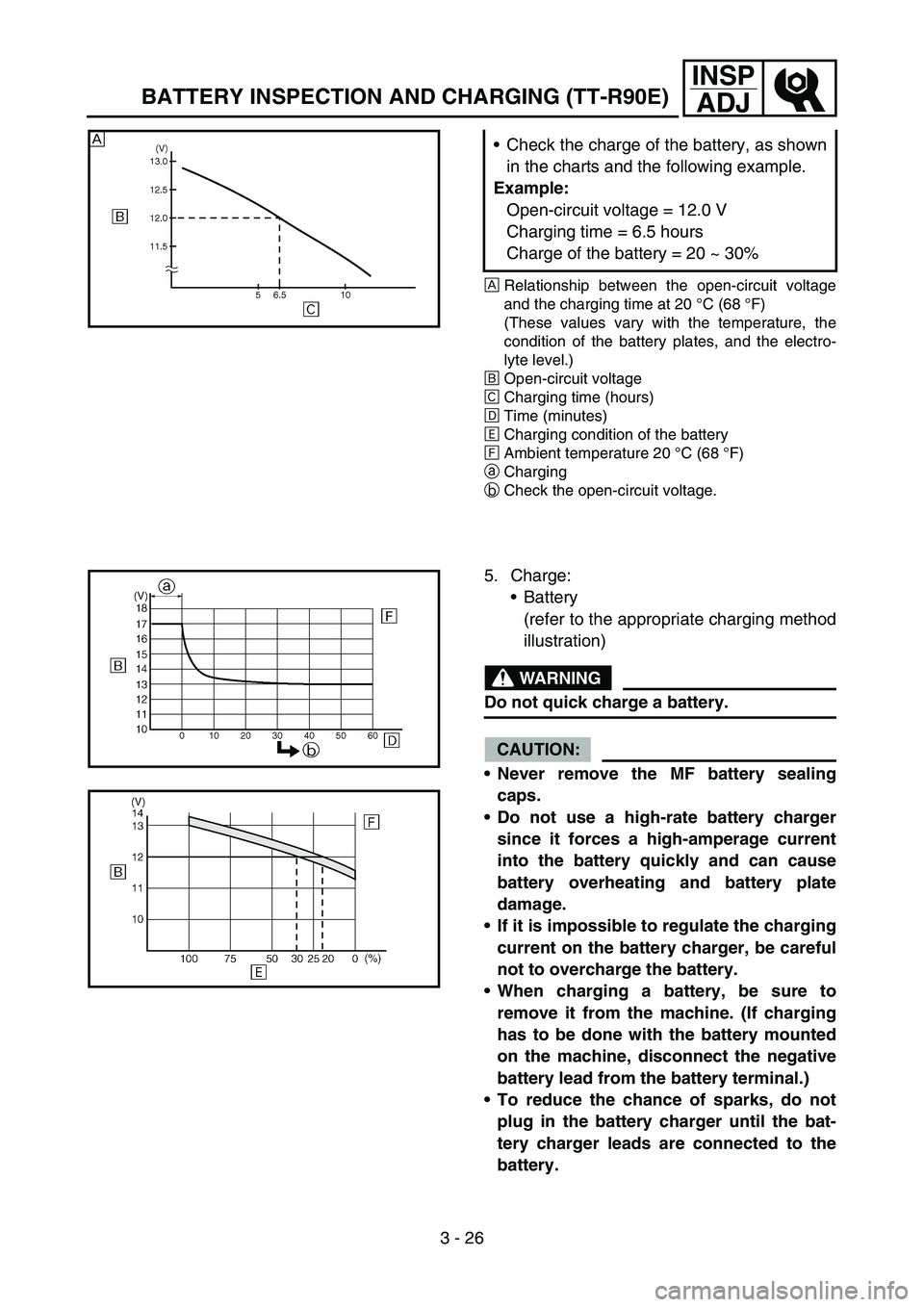

ÈRelationship between the open-circuit voltage

and the charging time at 20 °C (68 °F)

(These values vary with the temperature, the

condition of the battery plates, and the electro-

lyte level.)

ÉOpen-circuit voltage

ÊCharging time (hours)

ËTime (minutes)

ÌCharging condition of the battery

ÍAmbient temperature 20 °C (68 °F)

aCharging

bCheck the open-circuit voltage.

Check the charge of the battery, as shown

in the charts and the following example.

Example:

Open-circuit voltage = 12.0 V

Charging time = 6.5 hours

Charge of the battery = 20 ~ 30% È

5. Charge:

Battery

(refer to the appropriate charging method

illustration)

WARNING

Do not quick charge a battery.

CAUTION:

Never remove the MF battery sealing

caps.

Do not use a high-rate battery charger

since it forces a high-amperage current

into the battery quickly and can cause

battery overheating and battery plate

damage.

If it is impossible to regulate the charging

current on the battery charger, be careful

not to overcharge the battery.

When charging a battery, be sure to

remove it from the machine. (If charging

has to be done with the battery mounted

on the machine, disconnect the negative

battery lead from the battery terminal.)

To reduce the chance of sparks, do not

plug in the battery charger until the bat-

tery charger leads are connected to the

battery.

Page 376 of 390

–+ELEC

6 - 17

CARBURETOR HEATING SYSTEM

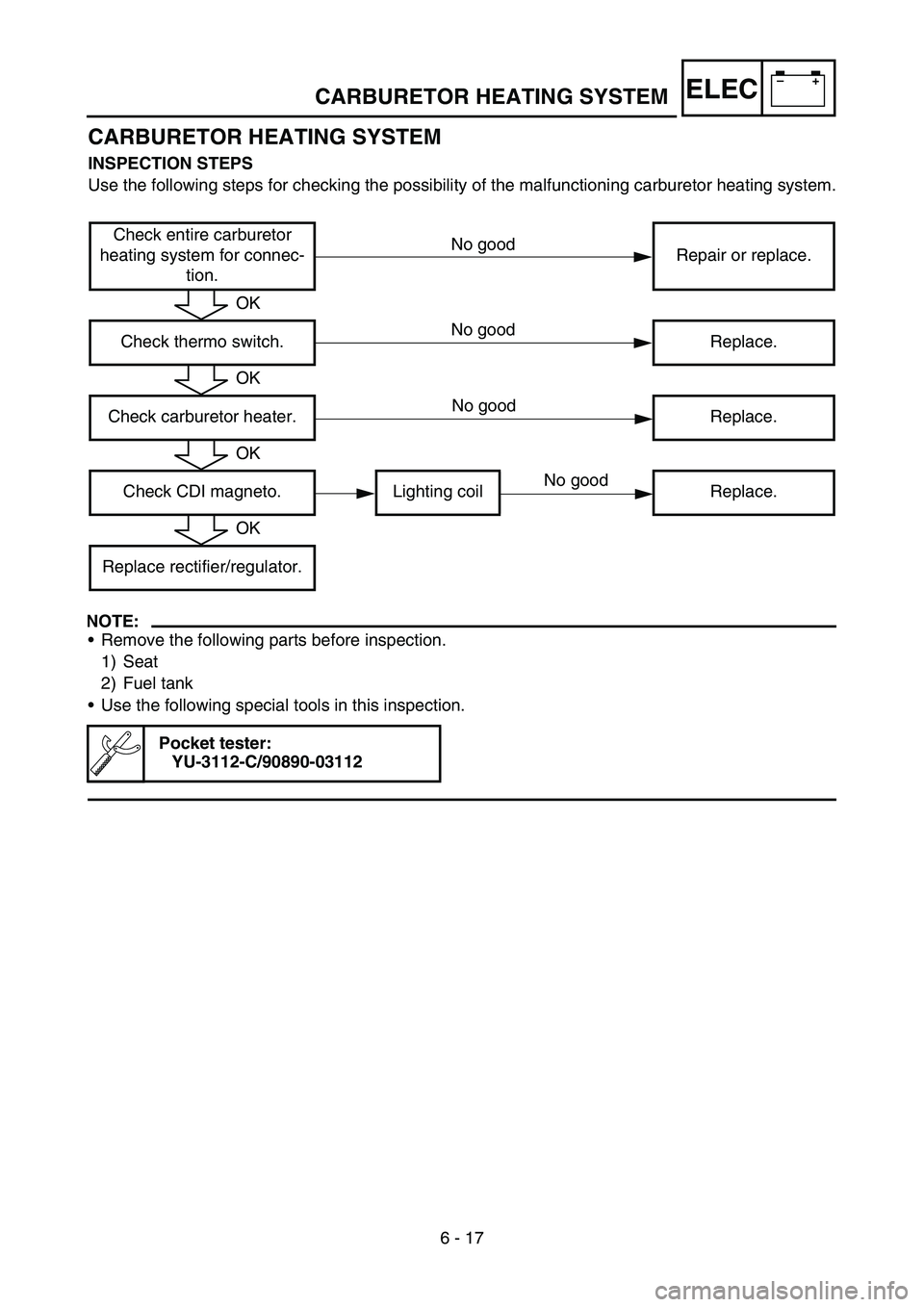

CARBURETOR HEATING SYSTEM

INSPECTION STEPS

Use the following steps for checking the possibility of the malfunctioning carburetor heating system.

NOTE:

Remove the following parts before inspection.

1) Seat

2) Fuel tank

Use the following special tools in this inspection.

Pocket tester:

YU-3112-C/90890-03112

Check entire carburetor

heating system for connec-

tion.Repair or replace.

Check thermo switch. Replace.

Check carburetor heater. Replace.

Check CDI magneto. Lighting coil Replace.

Replace rectifier/regulator.

OK

OK

OK

OK

No good

No good

No good

No good

Page 380 of 390

6 - 18

–+ELECCARBURETOR HEATING SYSTEM

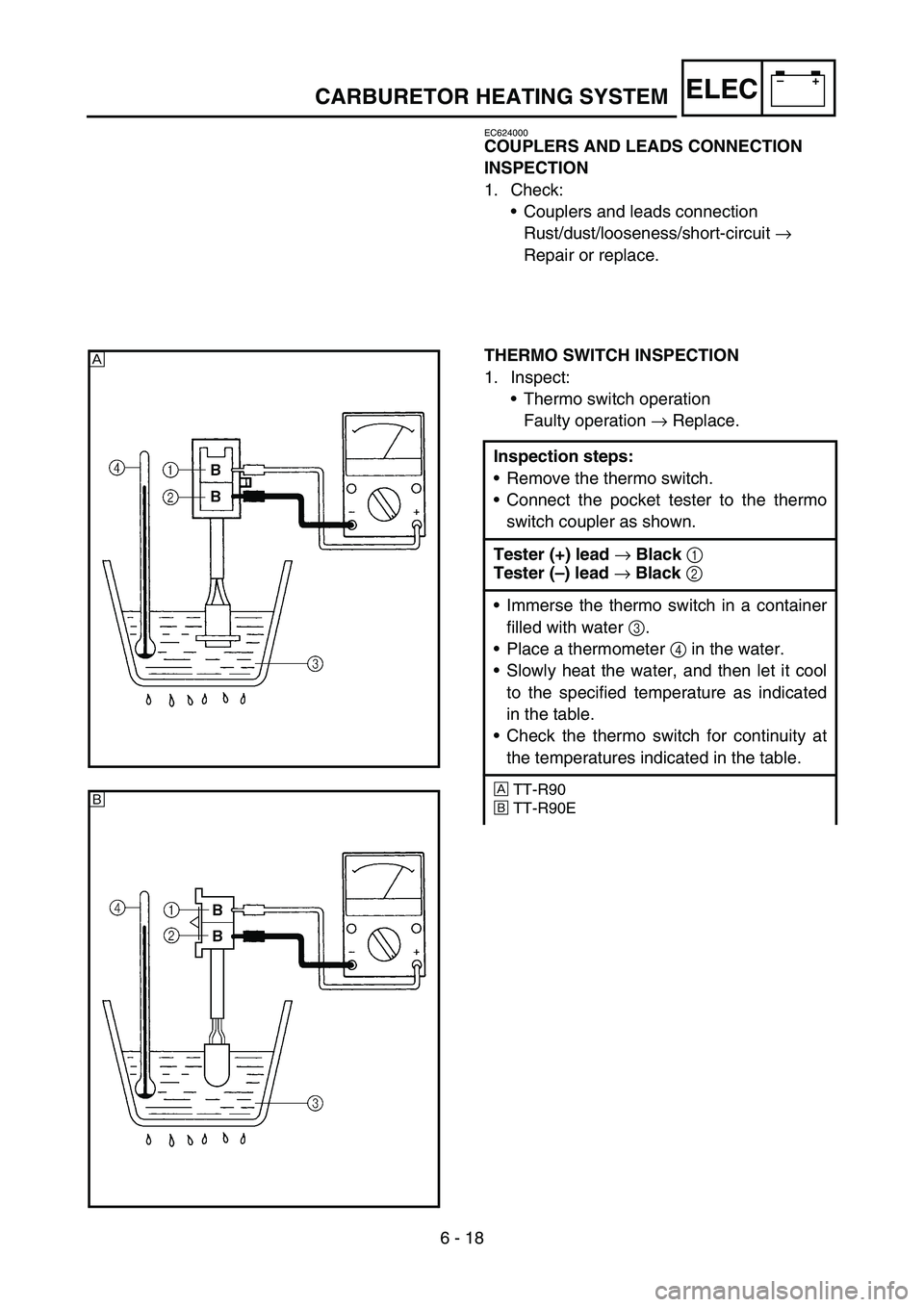

EC624000

COUPLERS AND LEADS CONNECTION

INSPECTION

1. Check:

Couplers and leads connection

Rust/dust/looseness/short-circuit →

Repair or replace.

THERMO SWITCH INSPECTION

1. Inspect:

Thermo switch operation

Faulty operation → Replace.

Inspection steps:

Remove the thermo switch.

Connect the pocket tester to the thermo

switch coupler as shown.

Tester (+) lead

→ Black

1

Tester (–) lead

→ Black

2

Immerse the thermo switch in a container

filled with water 3.

Place a thermometer 4 in the water.

Slowly heat the water, and then let it cool

to the specified temperature as indicated

in the table.

Check the thermo switch for continuity at

the temperatures indicated in the table.

ÈTT-R90

ÉTT-R90E

È

É

Page 382 of 390

6 - 19

–+ELEC

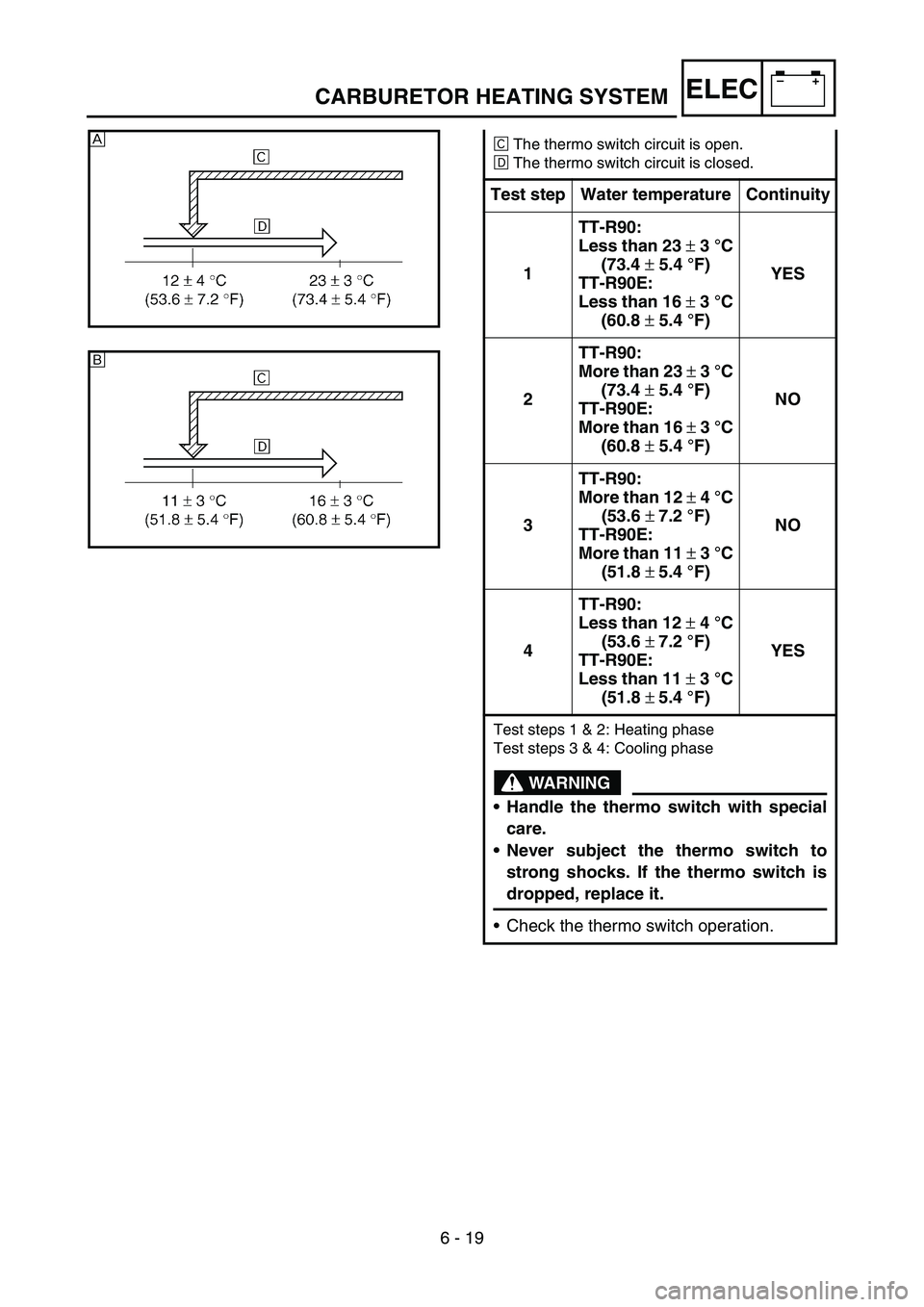

ÊThe thermo switch circuit is open.

ËThe thermo switch circuit is closed.

Test step Water temperature Continuity

1TT-R90:

Less than 23 ± 3 °C

(73.4 ± 5.4 °F)

TT-R90E:

Less than 16 ± 3 °C

(60.8 ± 5.4 °F)YES

2TT-R90:

More than 23 ± 3 °C

(73.4 ± 5.4 °F)

TT-R90E:

More than 16 ± 3 °C

(60.8 ± 5.4 °F)NO

3TT-R90:

More than 12 ± 4 °C

(53.6 ± 7.2 °F)

TT-R90E:

More than 11 ± 3 °C

(51.8 ± 5.4 °F)NO

4TT-R90:

Less than 12 ± 4 °C

(53.6 ± 7.2 °F)

TT-R90E:

Less than 11 ± 3 °C

(51.8 ± 5.4 °F)YES

Test steps 1 & 2: Heating phase

Test steps 3 & 4: Cooling phase

WARNING

Handle the thermo switch with special

care.

Never subject the thermo switch to

strong shocks. If the thermo switch is

dropped, replace it.

Check the thermo switch operation.

È

É

CARBURETOR HEATING SYSTEM

Page 384 of 390

6 - 20

–+ELECCARBURETOR HEATING SYSTEM

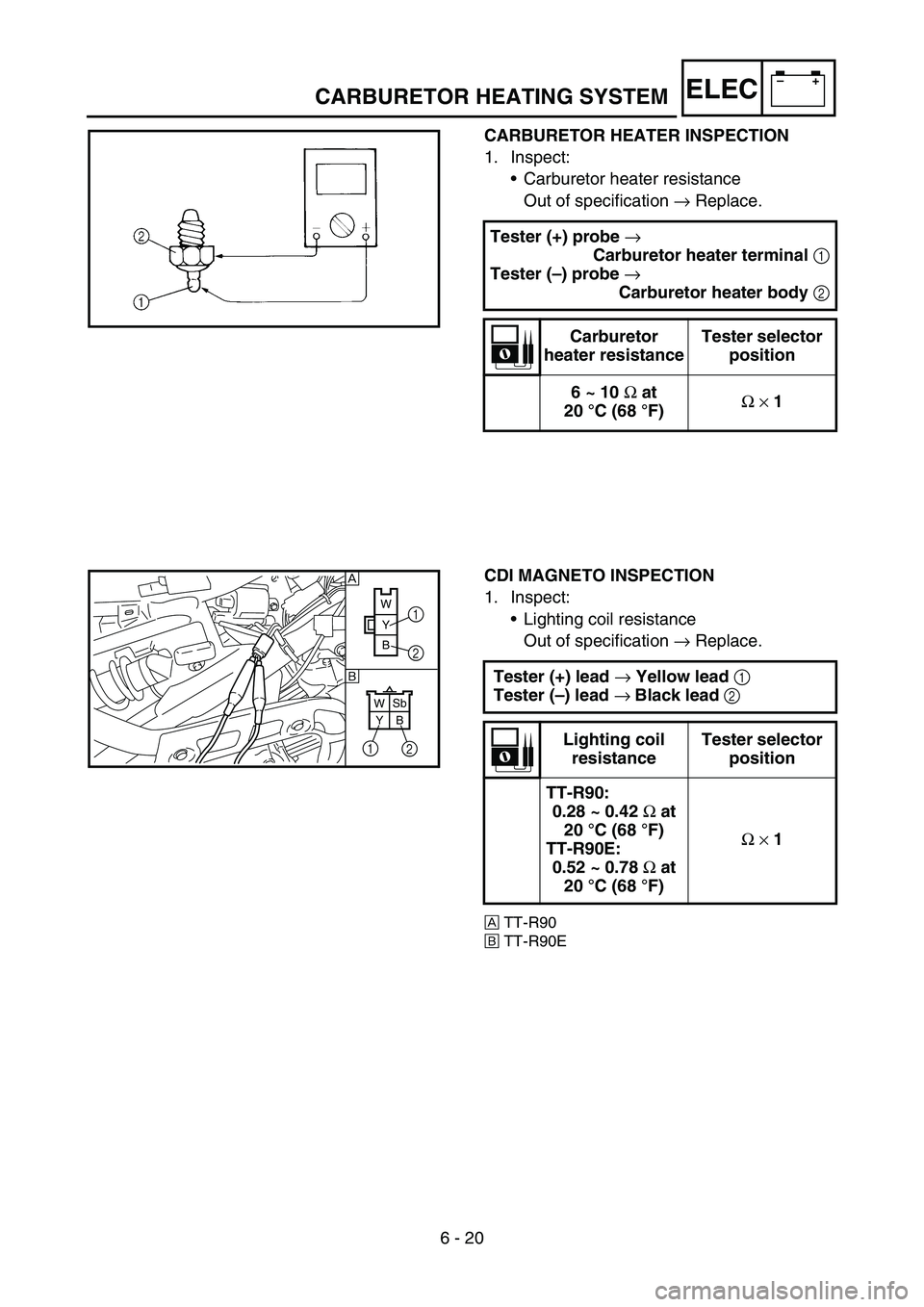

CARBURETOR HEATER INSPECTION

1. Inspect:

Carburetor heater resistance

Out of specification → Replace.

Tester (+) probe

→

Carburetor heater terminal

1

Tester (–) probe

→

Carburetor heater body

2

Carburetor

heater resistanceTester selector

position

6 ~ 10

Ω at

20 °C (68 °F)Ω

× 1

CDI MAGNETO INSPECTION

1. Inspect:

Lighting coil resistance

Out of specification → Replace.

ÈTT-R90

ÉTT-R90E

Tester (+) lead

→ Yellow lead

1

Tester (–) lead

→ Black lead

2

Lighting coil

resistanceTester selector

position

TT-R90:

0.28 ~ 0.42

Ω at

20 °C (68 °F)

TT-R90E:

0.52 ~ 0.78

Ω at

20 °C (68 °F)Ω

× 1

W

Y

B

WSb

YB

1

2

1

2

È

É