oil filter YAMAHA TTR90 2006 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: TTR90, Model: YAMAHA TTR90 2006Pages: 390, PDF Size: 9.12 MB

Page 61 of 390

SPEC

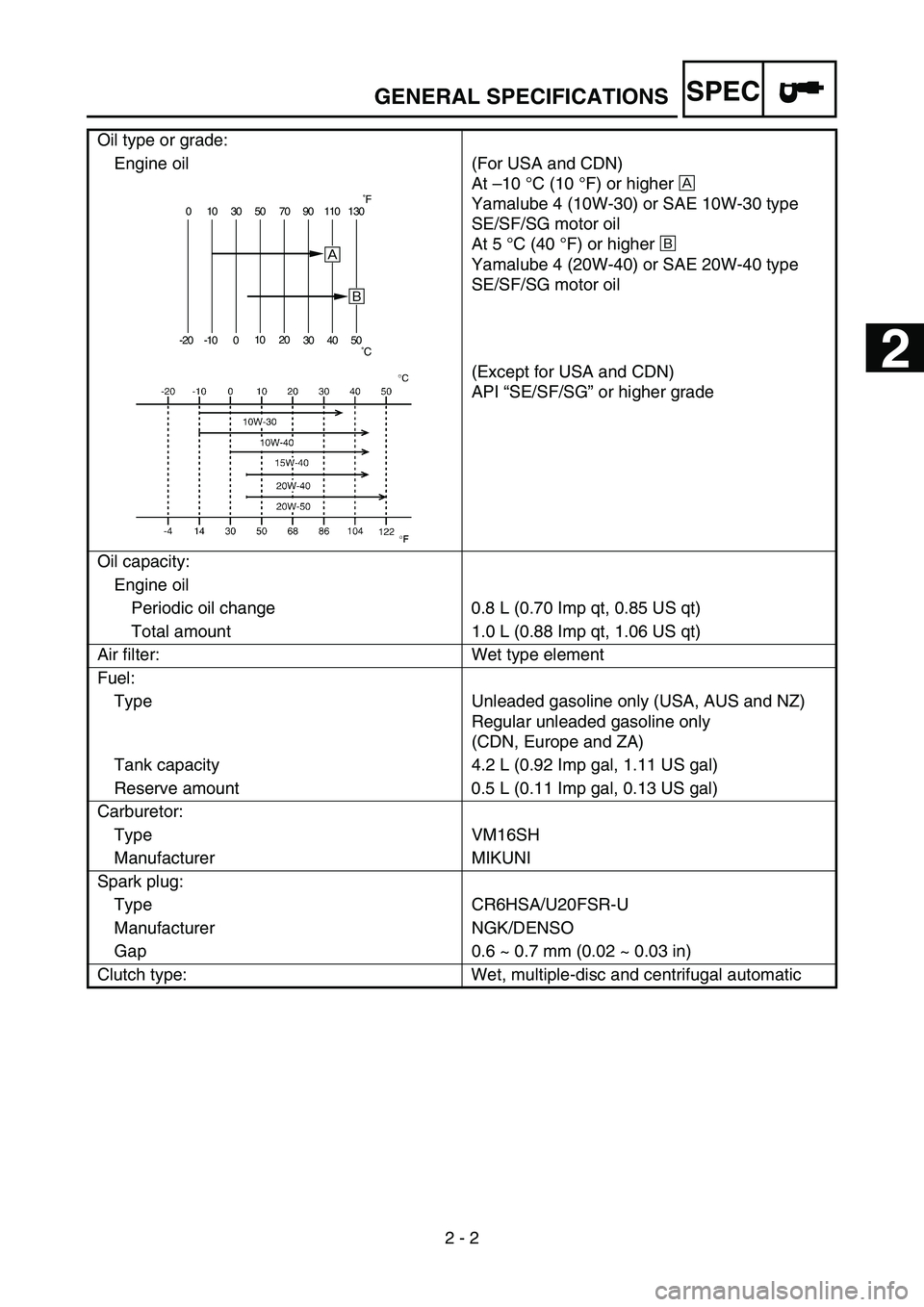

2 - 2 Oil type or grade:

Engine oil

(For USA and CDN)

At –10 °C (10 °F) or higher È

Yamalube 4 (10W-30) or SAE 10W-30 type

SE/SF/SG motor oil

At 5 °C (40 °F) or higher É

Yamalube 4 (20W-40) or SAE 20W-40 type

SE/SF/SG motor oil

(Except for USA and CDN)

API “SE/SF/SG” or higher grade

Oil capacity:

Engine oil

Periodic oil change 0.8 L (0.70 Imp qt, 0.85 US qt)

Total amount 1.0 L (0.88 Imp qt, 1.06 US qt)

Air filter: Wet type element

Fuel:

Type Unleaded gasoline only (USA, AUS and NZ)

Regular unleaded gasoline only

(CDN, Europe and ZA)

Tank capacity 4.2 L (0.92 Imp gal, 1.11 US gal)

Reserve amount 0.5 L (0.11 Imp gal, 0.13 US gal)

Carburetor:

Type VM16SH

Manufacturer MIKUNI

Spark plug:

Type CR6HSA/U20FSR-U

Manufacturer NGK/DENSO

Gap 0.6 ~ 0.7 mm (0.02 ~ 0.03 in)

Clutch type: Wet, multiple-disc and centrifugal automatic

0 10 30 50 70 90 110 130

-20 -10 01020

30 40 50

È

É

˚F

˚C

GENERAL SPECIFICATIONS

1

2

Page 68 of 390

SPEC

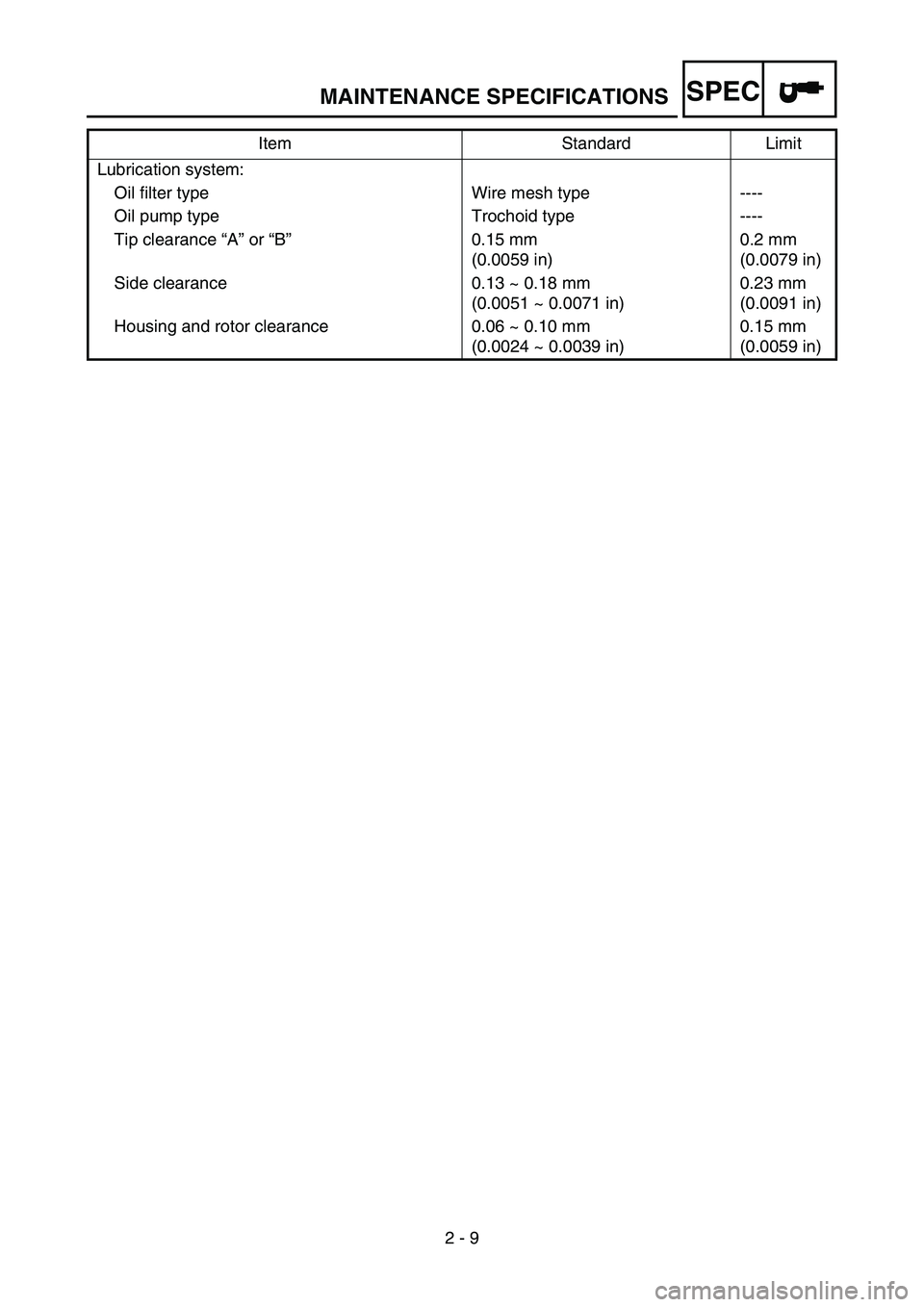

2 - 9 Lubrication system:

Oil filter type Wire mesh type ----

Oil pump type Trochoid type ----

Tip clearance “A” or “B”0.15 mm

(0.0059 in)0.2 mm

(0.0079 in)

Side clearance 0.13 ~ 0.18 mm

(0.0051 ~ 0.0071 in)0.23 mm

(0.0091 in)

Housing and rotor clearance 0.06 ~ 0.10 mm

(0.0024 ~ 0.0039 in)0.15 mm

(0.0059 in) Item Standard Limit

MAINTENANCE SPECIFICATIONS

Page 69 of 390

SPEC

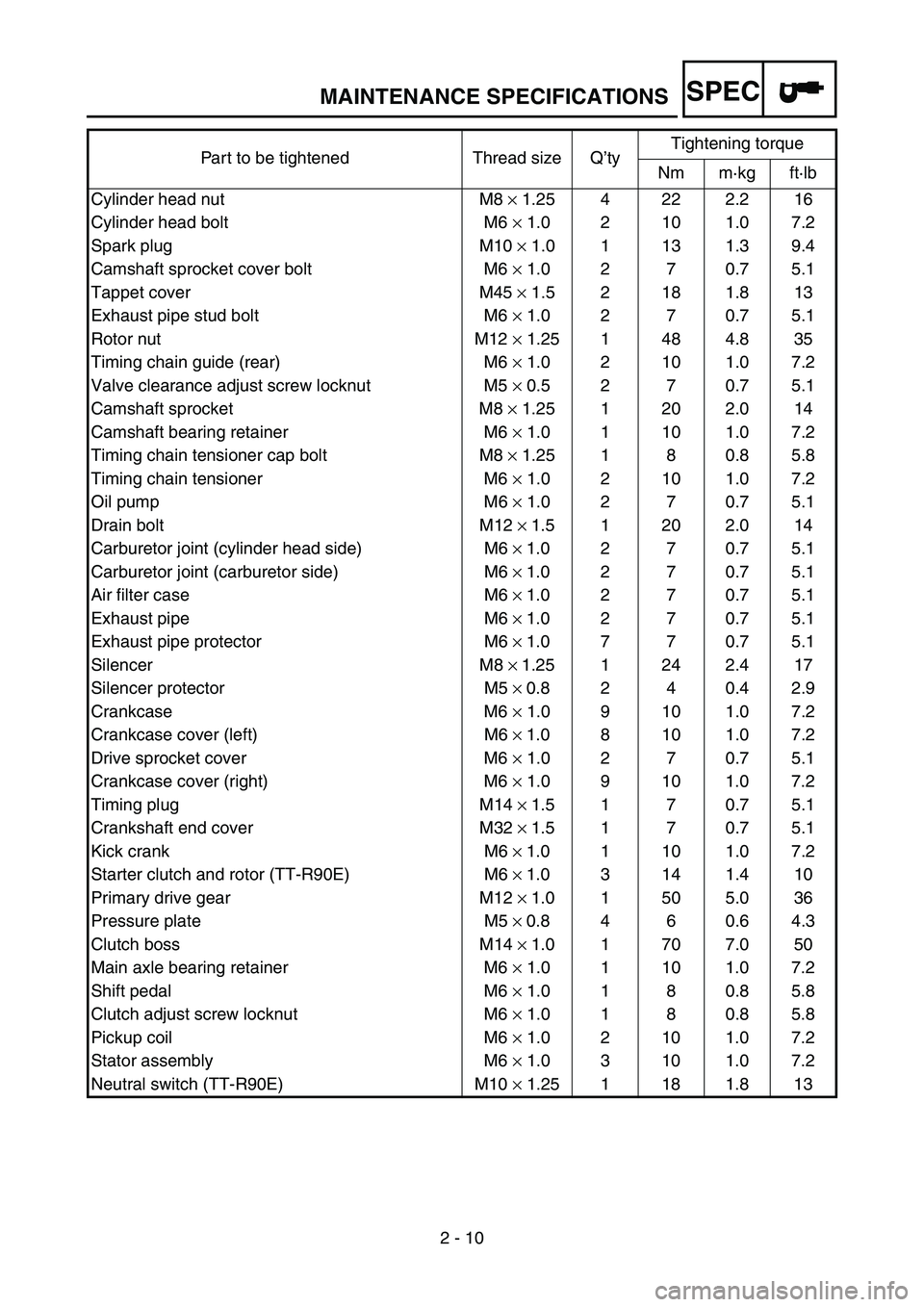

2 - 10 Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Cylinder head nut M8 × 1.25 4 22 2.2 16

Cylinder head bolt M6 × 1.0 2 10 1.0 7.2

Spark plug M10 × 1.0 1 13 1.3 9.4

Camshaft sprocket cover bolt M6 × 1.0 2 7 0.7 5.1

Tappet cover M45 × 1.5 2 18 1.8 13

Exhaust pipe stud bolt M6 × 1.0 2 7 0.7 5.1

Rotor nut M12 × 1.25 1 48 4.8 35

Timing chain guide (rear) M6 × 1.0 2 10 1.0 7.2

Valve clearance adjust screw locknut M5 × 0.5 2 7 0.7 5.1

Camshaft sprocket M8 × 1.25 1 20 2.0 14

Camshaft bearing retainer M6 × 1.0 1 10 1.0 7.2

Timing chain tensioner cap bolt M8 × 1.25 1 8 0.8 5.8

Timing chain tensioner M6 × 1.0 2 10 1.0 7.2

Oil pump M6 × 1.0 2 7 0.7 5.1

Drain bolt M12 ×

1.5 1 20 2.0 14

Carburetor joint (cylinder head side) M6 ×

1.0 2 7 0.7 5.1

Carburetor joint (carburetor side) M6 ×

1.0 2 7 0.7 5.1

Air filter case M6 ×

1.0 2 7 0.7 5.1

Exhaust pipe M6 ×

1.0 2 7 0.7 5.1

Exhaust pipe protector M6 ×

1.0 7 7 0.7 5.1

Silencer M8 ×

1.25 1 24 2.4 17

Silencer protector M5 ×

0.8 2 4 0.4 2.9

Crankcase M6 × 1.0 9 10 1.0 7.2

Crankcase cover (left) M6 ×

1.0 8 10 1.0 7.2

Drive sprocket cover M6 × 1.0 2 7 0.7 5.1

Crankcase cover (right) M6 × 1.0 9 10 1.0 7.2

Timing plug M14 ×

1.5 1 7 0.7 5.1

Crankshaft end cover M32 ×

1.5 1 7 0.7 5.1

Kick crank M6 ×

1.0 1 10 1.0 7.2

Starter clutch and rotor (TT-R90E) M6 ×

1.0 3 14 1.4 10

Primary drive gear M12 ×

1.0 1 50 5.0 36

Pressure plate M5 ×

0.8 4 6 0.6 4.3

Clutch boss M14 ×

1.0 1 70 7.0 50

Main axle bearing retainer M6 × 1.0 1 10 1.0 7.2

Shift pedal M6 × 1.0 1 8 0.8 5.8

Clutch adjust screw locknut M6 × 1.0 1 8 0.8 5.8

Pickup coil M6 × 1.0 2 10 1.0 7.2

Stator assembly M6 × 1.0 3 10 1.0 7.2

Neutral switch (TT-R90E) M10 × 1.25 1 18 1.8 13

MAINTENANCE SPECIFICATIONS

Page 128 of 390

3 - 1

INSP

ADJ

MAINTENANCE INTERVALS

EC300000

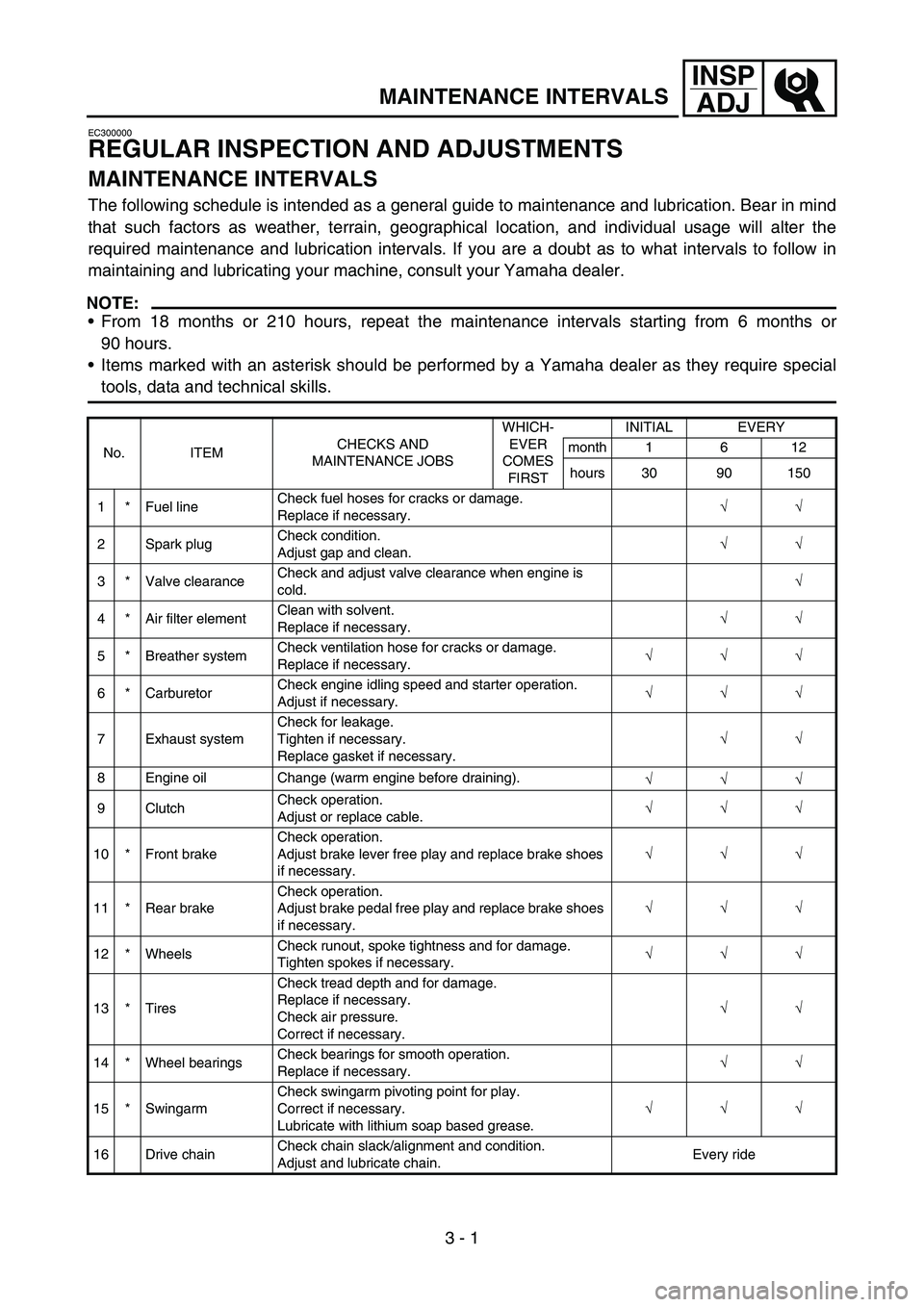

REGULAR INSPECTION AND ADJUSTMENTS

MAINTENANCE INTERVALS

The following schedule is intended as a general guide to maintenance and lubrication. Bear in mind

that such factors as weather, terrain, geographical location, and individual usage will alter the

required maintenance and lubrication intervals. If you are a doubt as to what intervals to follow in

maintaining and lubricating your machine, consult your Yamaha dealer.

NOTE:

From 18 months or 210 hours, repeat the maintenance intervals starting from 6 months or

90 hours.

Items marked with an asterisk should be performed by a Yamaha dealer as they require special

tools, data and technical skills.

No. ITEMCHECKS AND

MAINTENANCE JOBSWHICH-

EVER

COMES

FIRSTINITIAL EVERY

month 1 6 12

hours 30 90 150

1 * Fuel lineCheck fuel hoses for cracks or damage.

Replace if necessary.√

√

2 Spark plugCheck condition.

Adjust gap and clean.√

√

3 * Valve clearanceCheck and adjust valve clearance when engine is

cold.√

4 * Air filter elementClean with solvent.

Replace if necessary.√

√

5 * Breather systemCheck ventilation hose for cracks or damage.

Replace if necessary.√

√

√

6 * CarburetorCheck engine idling speed and starter operation.

Adjust if necessary.√

√

√

7 Exhaust systemCheck for leakage.

Tighten if necessary.

Replace gasket if necessary.√

√

8 Engine oil Change (warm engine before draining).

√

√

√

9 ClutchCheck operation.

Adjust or replace cable.√

√

√

10 * Front brakeCheck operation.

Adjust brake lever free play and replace brake shoes

if necessary.√

√

√

11 * Rear brakeCheck operation.

Adjust brake pedal free play and replace brake shoes

if necessary.√

√

√

12 * WheelsCheck runout, spoke tightness and for damage.

Tighten spokes if necessary.√

√

√

13 * TiresCheck tread depth and for damage.

Replace if necessary.

Check air pressure.

Correct if necessary.√

√

14 * Wheel bearingsCheck bearings for smooth operation.

Replace if necessary.√

√

15 * SwingarmCheck swingarm pivoting point for play.

Correct if necessary.

Lubricate with lithium soap based grease.√

√

√

16 Drive chainCheck chain slack/alignment and condition.

Adjust and lubricate chain.Every ride

3

Page 129 of 390

3 - 2

INSP

ADJ

MAINTENANCE INTERVALS

NOTE:

The air filter needs more frequent service if you are riding in unusually wet or dusty areas.

17 * Steering bearingsCheck bearing assemblies for looseness.

Lubricate with lithium soap based grease every or

120 hours or 12 months (whichever comes first).√

√

18Brake and clutch

lever pivot shaftsApply lithium soap based grease lightly.

√

√

√

19Brake pedal pivot

shaftApply lithium soap based grease lightly.

√

√

√

20 Sidestand pivotCheck operation.

Apply lithium soap based grease lightly.√

√

21 * Front forkCheck operation and for oil leakage.

Replace if necessary.√

√

22 *Shock absorber

assemblyCheck operation and for oil leakage.

Replace if necessary.√

√

23 * Control cablesApply Yamaha chain and cable lube or engine oil

10W-30 thoroughly.√

√

√

24 *Throttle grip hous-

ing and cableCheck operation and free play.

Adjust the throttle cable free play if necessary.

Lubricate the throttle grip housing and cable.√

√

√

25 * Chassis fastenersCheck all chassis fitting and fasteners.

Correct if necessary.√

√

√

26Battery (TT-R90E

only)Check terminal for looseness and corrosion.

√ No. ITEMCHECKS AND

MAINTENANCE JOBSWHICH-

EVER

COMES

FIRSTINITIAL EVERY

month 1 6 12

hours 30 90 150

3

Page 130 of 390

3 - 3

INSP

ADJ

PRE-OPERATION INSPECTION AND MAINTENANCE

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation or practice, make sure the machine is in good operating condi-

tion.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCE

Item Routine Page

Brake Check operation/adjustment. P3-12

Engine oil Change oil as required. P3-6 ~ 8

Drive chain Check alignment/adjustment/lubrication. P3-13 ~ 15

Spark plug Check color/condition. P3-23

Throttle Check for proper throttle cable operation. P3-4

Air filter Foam type – must be clean and damp oil always P3-4 ~ 5

Wheels and tires Check pressure/runout/spoke tightness/bead stopper/axle nuts. P3-17 ~ 20

Fittings/fasteners Check all – tighten as necessary. P2-13

Page 140 of 390

3 - 5

INSP

ADJ

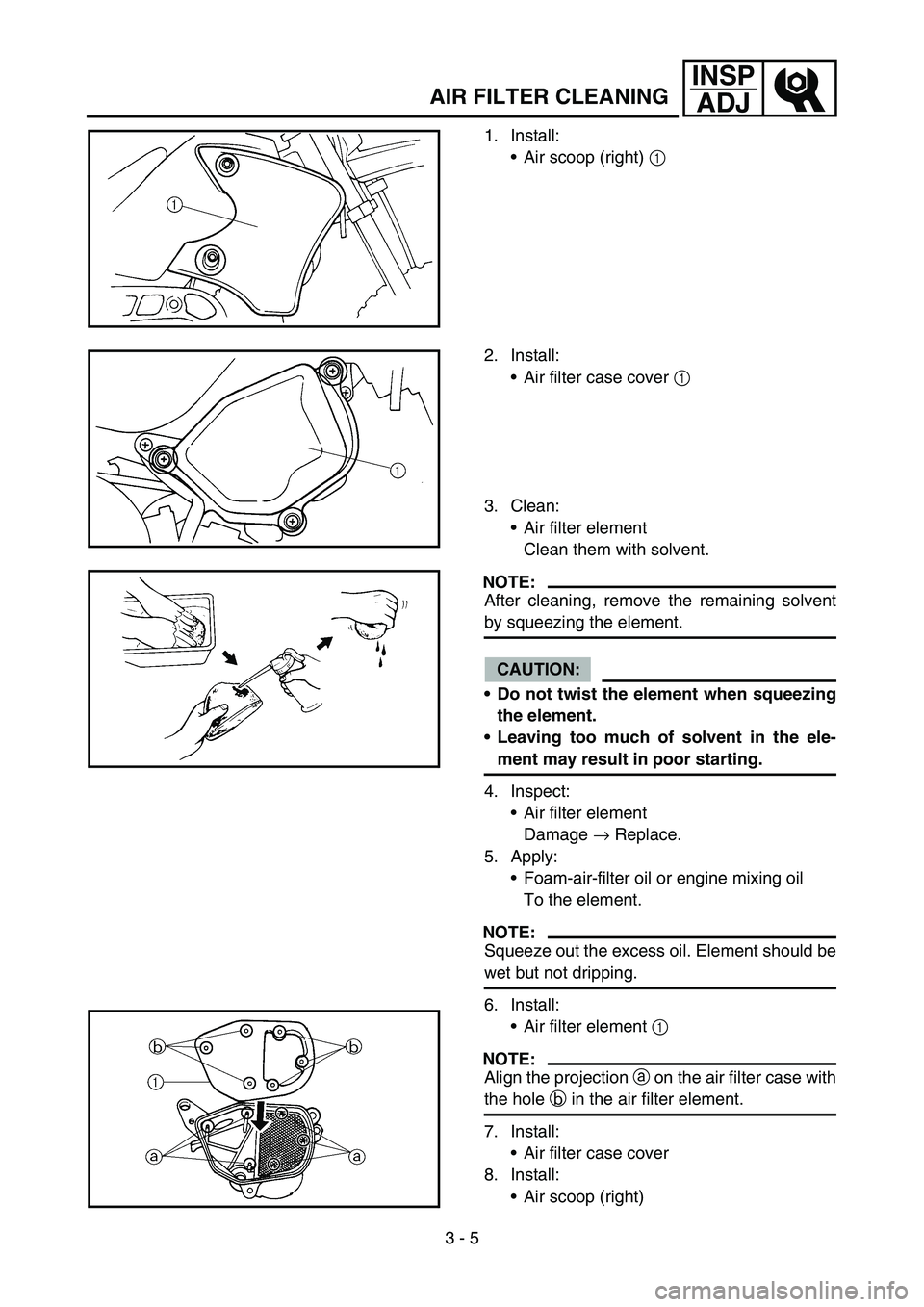

AIR FILTER CLEANING

1. Install:

Air scoop (right) 1

2. Install:

Air filter case cover 1

3. Clean:

Air filter element

Clean them with solvent.

NOTE:

After cleaning, remove the remaining solvent

by squeezing the element.

CAUTION:

Do not twist the element when squeezing

the element.

Leaving too much of solvent in the ele-

ment may result in poor starting.

4. Inspect:

Air filter element

Damage → Replace.

5. Apply:

Foam-air-filter oil or engine mixing oil

To the element.

NOTE:

Squeeze out the excess oil. Element should be

wet but not dripping.

6. Install:

Air filter element 1

NOTE:

Align the projection a on the air filter case with

the hole b in the air filter element.

7. Install:

Air filter case cover

8. Install:

Air scoop (right)

Page 266 of 390

4 - 36

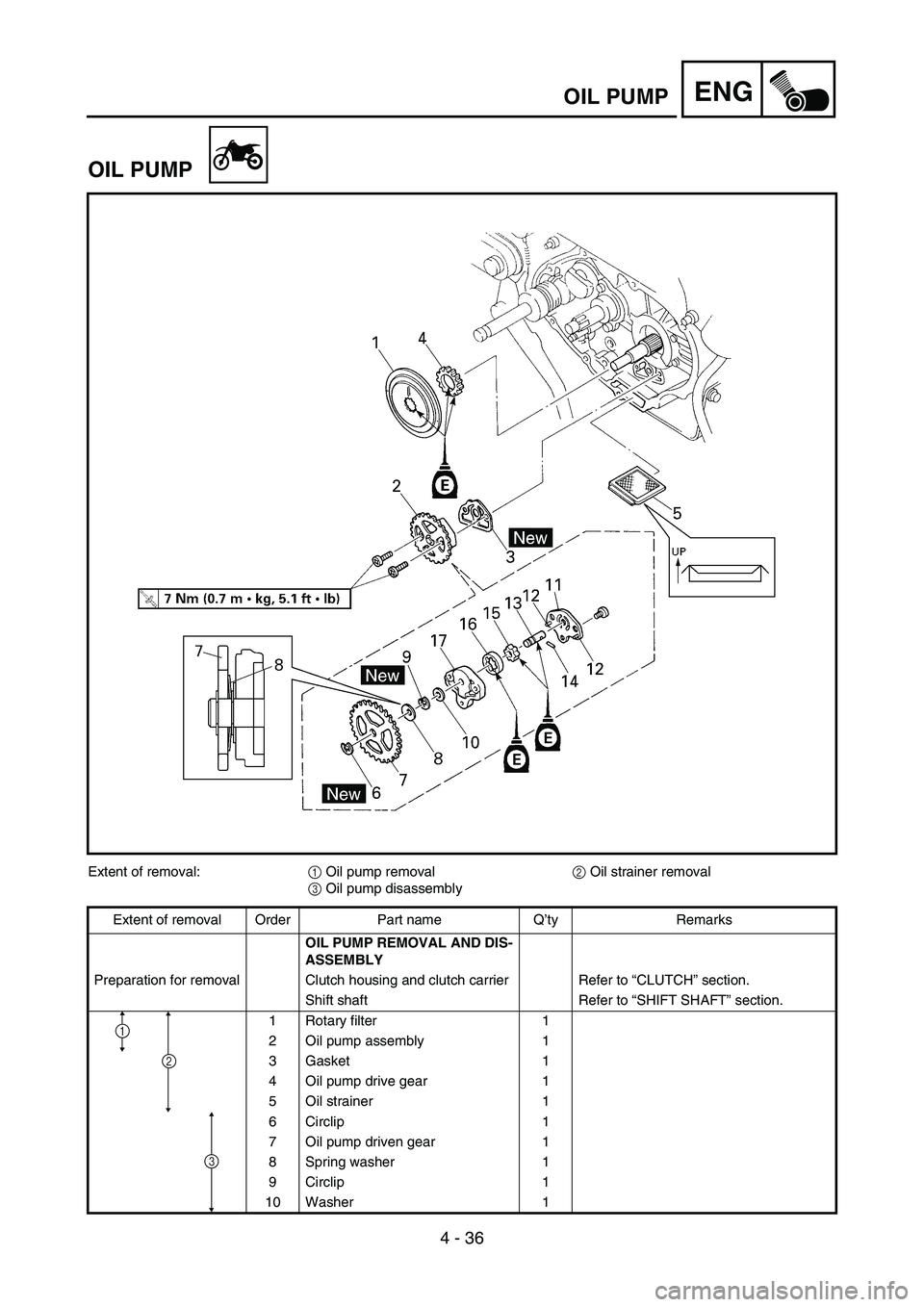

ENGOIL PUMP

OIL PUMP

Extent of removal:

1 Oil pump removal

2 Oil strainer removal

3 Oil pump disassembly

Extent of removal Order Part name Q’ty Remarks

OIL PUMP REMOVAL AND DIS-

ASSEMBLY

Preparation for removal Clutch housing and clutch carrier Refer to “CLUTCH” section.

Shift shaft Refer to “SHIFT SHAFT” section.

1 Rotary filter 1

2 Oil pump assembly 1

3 Gasket 1

4 Oil pump drive gear 1

5 Oil strainer 1

6 Circlip 1

7 Oil pump driven gear 1

8 Spring washer 1

9 Circlip 1

10 Washer 1

2

1

3

Page 270 of 390

4 - 38

ENGOIL PUMP

INSPECTION

Oil pump

1. Measure:

Tip clearance a

(between the inner rotor 1 and the outer

rotor 2)

Side clearance b

(between the outer rotor 2 and the rotor

housing 3)

Out of specification → Replace the oil

pump assembly.

Rotor housing and rotor clearance c

(between the rotor housing 3 and the

rotors 1 2)

Out of specification → Replace the oil

pump assembly.

Tip clearance

a:

0.15 mm (0.0059 in)

Side clearance

b:

0.13 ~ 0.18 mm

(0.0051 ~ 0.0071 in)

Rotor housing and rotor clear-

ance

c:

0.06 ~ 0.10 mm

(0.0024 ~ 0.0039 in)

Rotary filter and oil strainer

1. Inspect:

Rotary filter 1

Oil strainer 2

Damage → Replace.

3Upper side

4Lower side

ASSEMBLY AND INSTALLATION

Rotary filter

1. Install:

Rotary filter 1

NOTE:

When installing the rotary filter, align the match

mark a on the rotary filter with the hole b of

the crankshaft.

Page 284 of 390

4 - 45

ENGCRANKCASE AND CRANKSHAFT

CRANKCASE AND CRANKSHAFT

Extent of removal Order Part name Q’ty Remarks

CRANKCASE SEPARATION

AND CRANKSHAFT REMOVAL

Preparation for removal Seat, fuel tank and rear fender

Exhaust pipe

Air filter case

Carburetor Refer to “CARBURETOR” section.

Drain the engine oil Refer to “ENGINE OIL REPLACEMENT”

section in the CHAPTER 3.

Engine guard and drive sprocket

Engine assembly From the chassis.

Cylinder head Refer to “CYLINDER HEAD” section.

Cylinder and piston Refer to “CYLINDER AND PISTON” sec-

tion.

Clutch housing and clutch carrier Refer to “CLUTCH” section.

Kick axle assembly Refer to “KICK AXLE” section.