check engine YAMAHA V1 2015 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2015, Model line: V1, Model: YAMAHA V1 2015Pages: 94, PDF Size: 3.01 MB

Page 5 of 94

Table of contents

General and important labels ........... 1

Identification numbers .................... 1

Primary Identification (PRI-ID)

number............................................ 1

Craft Identification Number (CIN) ....... 1

Engine serial number.......................... 1

Manufactured date label .................... 2

Model information ........................... 2

Builder’s plate .................................... 2

Important labels .............................. 4

Warning labels.................................... 5

Other labels ........................................ 8

Safety information ........................... 10

Limitations on who may operate

the watercraft ............................. 10

Cruising limitations ........................ 11

Operation requirements ................ 12

Recommended equipment ........... 14

Hazard information........................ 15

Watercraft characteristics ............. 15

Wakeboarding and water-skiing ... 17

Safe boating rules ......................... 18

Enjoy your watercraft

responsibly ................................. 19

Description....................................... 20

Watercraft glossary ....................... 20

Location of main components ...... 21

Control function operation ............. 25

Watercraft control functions ......... 25

Engine stop switch .......................... 25

Engine shut-off switch .................... 25

Start switch ..................................... 25

Throttle lever .................................... 26

Steering system ............................... 26

Cooling water pilot outlet ................. 27

Water separator................................ 27

Watercraft operation ...................... 28

Watercraft operation functions ..... 28

Reverse system (V1 Sport) ............... 28

Instrument operation ...................... 29

Multifunction information

center ......................................... 29

Information display ........................... 29

Equipment operation ...................... 34

Equipment..................................... 34

Seat .................................................. 34

Handgrip........................................... 34

Reboarding step (V1 Sport) .............. 35

Bow eye............................................ 35

Stern eyes ........................................ 36

Cleat ................................................. 36

Storage compartments .................... 36

Fire extinguisher holder and cover ... 38

Operation and handling

requirements ................................... 40

Fuel requirements ......................... 40

Fuel................................................... 40

Engine oil requirements ................ 42

Engine oil .......................................... 42

Draining the bilge water ................ 43

Draining the bilge water on land....... 43

Draining the bilge water on water .... 44

Transporting on a trailer................ 45

First-time operation ........................ 46

Engine break-in............................. 46

Pre-operation checks ..................... 47

Pre-operation checklist .................... 47

Pre-operation check points .......... 49

Pre-launch checks ........................... 49

Post-launch checks.......................... 54

Operation ......................................... 56

Operating your watercraft ............. 56

Getting to know your watercraft....... 56

UF2P72E0.book Page 1 Tuesday, August 26, 2014 10:08 AM

Page 19 of 94

Safety information

13

in certain kinds of accidents and that it

could injure you in others.

A helmet is designed to provide some head

protection. Although helmets cannot pro-

tect against all foreseeable impacts, a hel-

met might reduce your injuries in a collision

with a boat or other obstacle.

A helmet may have potential safety haz-

ards, as well. Falling into the water could

risk the chance of the helmet catching wa-

ter, commonly known as “bucketing”, and

the resulting strain on your neck could

cause choking, severe and permanent

neck injuries, or death. A helmet could also

increase the risk of an accident if it reduces

your vision or hearing, or if it distracts you

or increases your fatigue.

How should you decide if a helmet’s poten-

tial safety benefits outweigh its potential

risks for you? Consider your particular rid-

ing conditions. Consider factors such as

your riding environment and your riding

style and ability. Also consider the likeli-

hood of traffic congestion, and the water

surface conditions.

If you decide to wear a helmet based upon

your riding circumstances, choose one

carefully. Look for a helmet designed for

personal watercraft use, if possible. If you

will be engaging in closed-course competi-

tion, follow the helmet requirements of the

sanctioning organization.

Never operate the watercraft after consum-

ing alcohol or taking other drugs.

For reasons of safety and proper care of

the watercraft, always perform the pre-op-

eration checks listed on page 47 before op-

erating the watercraft.

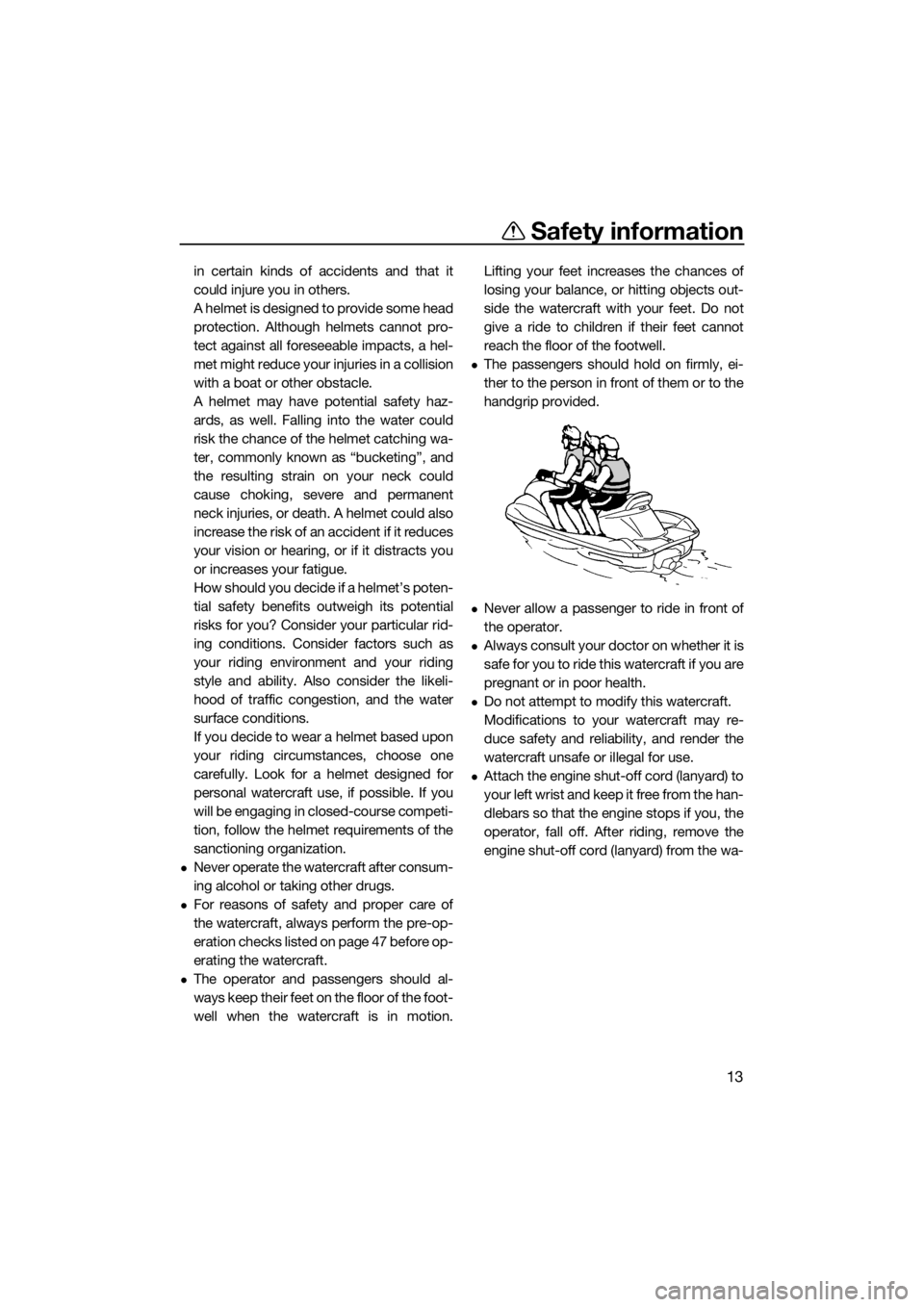

The operator and passengers should al-

ways keep their feet on the floor of the foot-

well when the watercraft is in motion.Lifting your feet increases the chances of

losing your balance, or hitting objects out-

side the watercraft with your feet. Do not

give a ride to children if their feet cannot

reach the floor of the footwell.

The passengers should hold on firmly, ei-

ther to the person in front of them or to the

handgrip provided.

Never allow a passenger to ride in front of

the operator.

Always consult your doctor on whether it is

safe for you to ride this watercraft if you are

pregnant or in poor health.

Do not attempt to modify this watercraft.

Modifications to your watercraft may re-

duce safety and reliability, and render the

watercraft unsafe or illegal for use.

Attach the engine shut-off cord (lanyard) to

y o u r l ef t w r is t an d k ee p i t fr e e f r o m t h e h an -

dlebars so that the engine stops if you, the

operator, fall off. After riding, remove the

engine shut-off cord (lanyard) from the wa-

UF2P72E0.book Page 13 Tuesday, August 26, 2014 10:08 AM

Page 33 of 94

Control function operation

27

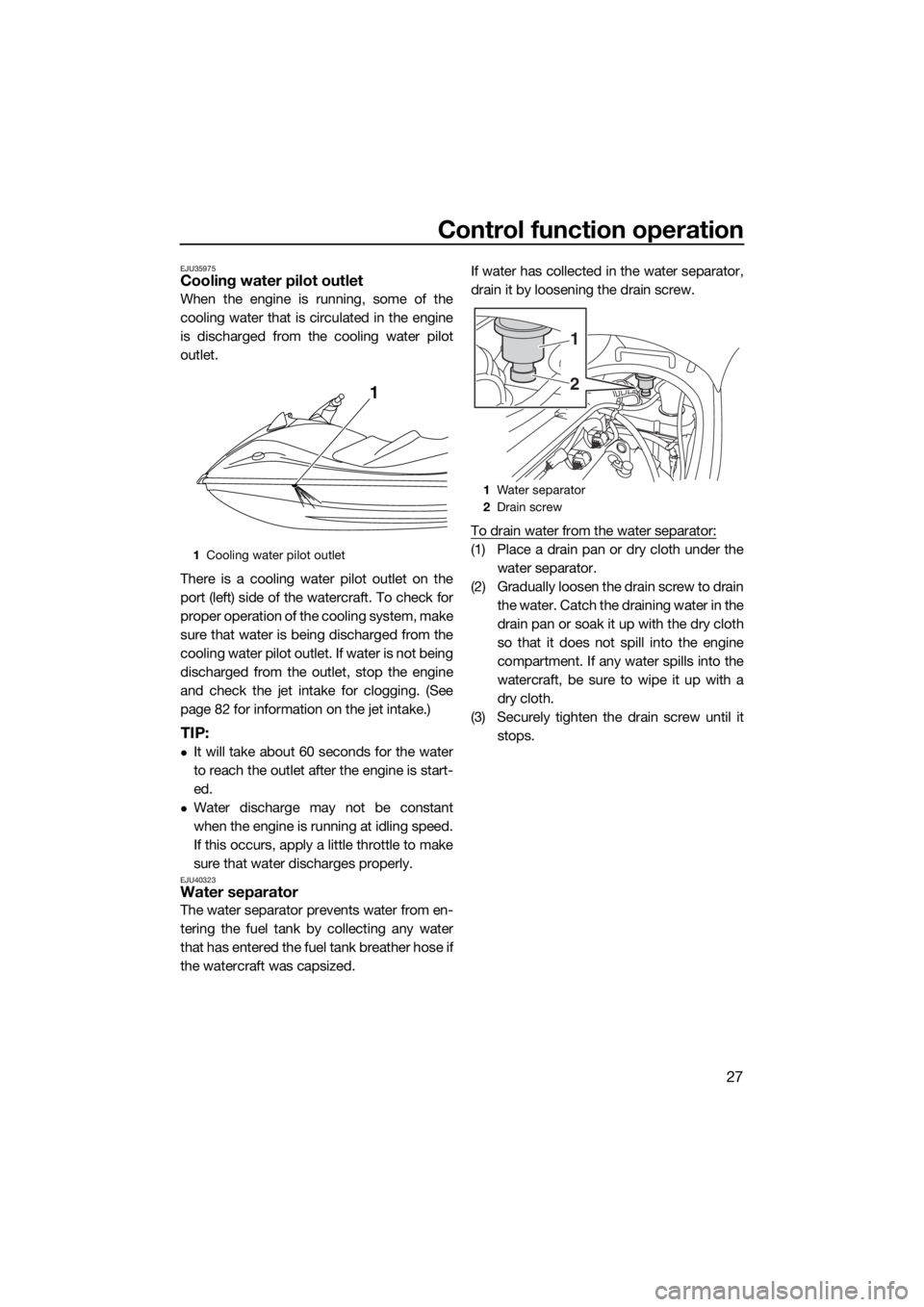

EJU35975Cooling water pilot outlet

When the engine is running, some of the

cooling water that is circulated in the engine

is discharged from the cooling water pilot

outlet.

There is a cooling water pilot outlet on the

port (left) side of the watercraft. To check for

proper operation of the cooling system, make

sure that water is being discharged from the

cooling water pilot outlet. If water is not being

discharged from the outlet, stop the engine

and check the jet intake for clogging. (See

page 82 for information on the jet intake.)

TIP:

It will take about 60 seconds for the water

to reach the outlet after the engine is start-

ed.

Water discharge may not be constant

when the engine is running at idling speed.

If this occurs, apply a little throttle to make

sure that water discharges properly.

EJU40323Water separator

The water separator prevents water from en-

tering the fuel tank by collecting any water

that has entered the fuel tank breather hose if

the watercraft was capsized.If water has collected in the water separator,

drain it by loosening the drain screw.

To drain water from the water separator:

(1) Place a drain pan or dry cloth under the

water separator.

(2) Gradually loosen the drain screw to drain

the water. Catch the draining water in the

drain pan or soak it up with the dry cloth

so that it does not spill into the engine

compartment. If any water spills into the

watercraft, be sure to wipe it up with a

dry cloth.

(3) Securely tighten the drain screw until it

stops.1Cooling water pilot outlet

1

1Water separator

2Drain screw

1

2

UF2P72E0.book Page 27 Tuesday, August 26, 2014 10:08 AM

Page 35 of 94

Instrument operation

29

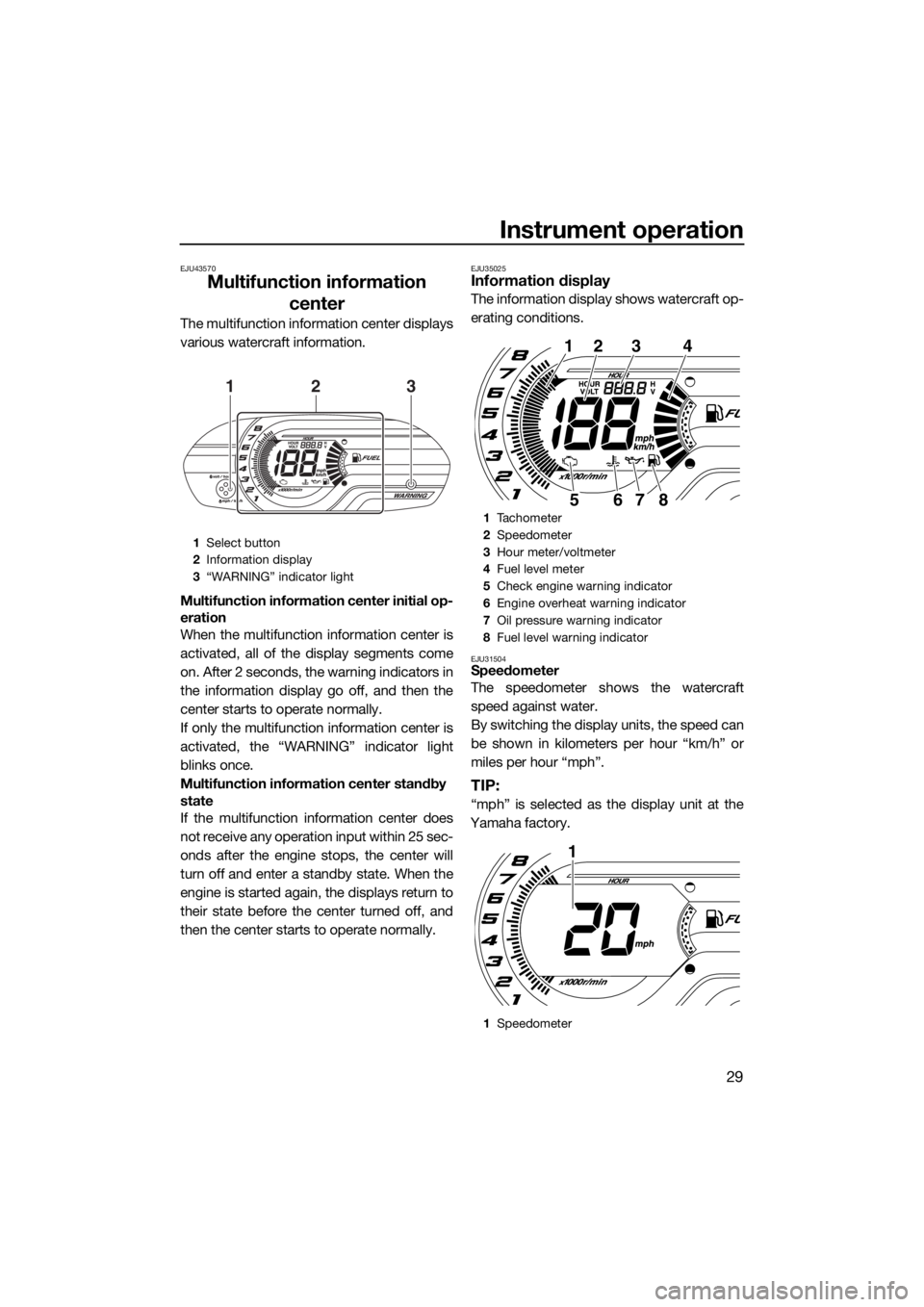

EJU43570

Multifunction information

center

The multifunction information center displays

various watercraft information.

Multifunction information center initial op-

eration

When the multifunction information center is

activated, all of the display segments come

on. After 2 seconds, the warning indicators in

the information display go off, and then the

center starts to operate normally.

If only the multifunction information center is

activated, the “WARNING” indicator light

blinks once.

Multifunction information center standby

state

If the multifunction information center does

not receive any operation input within 25 sec-

onds after the engine stops, the center will

turn off and enter a standby state. When the

engine is started again, the displays return to

their state before the center turned off, and

then the center starts to operate normally.

EJU35025Information display

The information display shows watercraft op-

erating conditions.

EJU31504Speedometer

The speedometer shows the watercraft

speed against water.

By switching the display units, the speed can

be shown in kilometers per hour “km/h” or

miles per hour “mph”.

TIP:

“mph” is selected as the display unit at the

Yamaha factory.

1Select button

2Information display

3“WARNING” indicator light

123

1Tachometer

2Speedometer

3Hour meter/voltmeter

4Fuel level meter

5Check engine warning indicator

6Engine overheat warning indicator

7Oil pressure warning indicator

8Fuel level warning indicator

1Speedometer

1234

8765

1

UF2P72E0.book Page 29 Tuesday, August 26, 2014 10:08 AM

Page 38 of 94

Instrument operation

32

TIP:

Push the select button on the multifunction

information center to stop the buzzer.

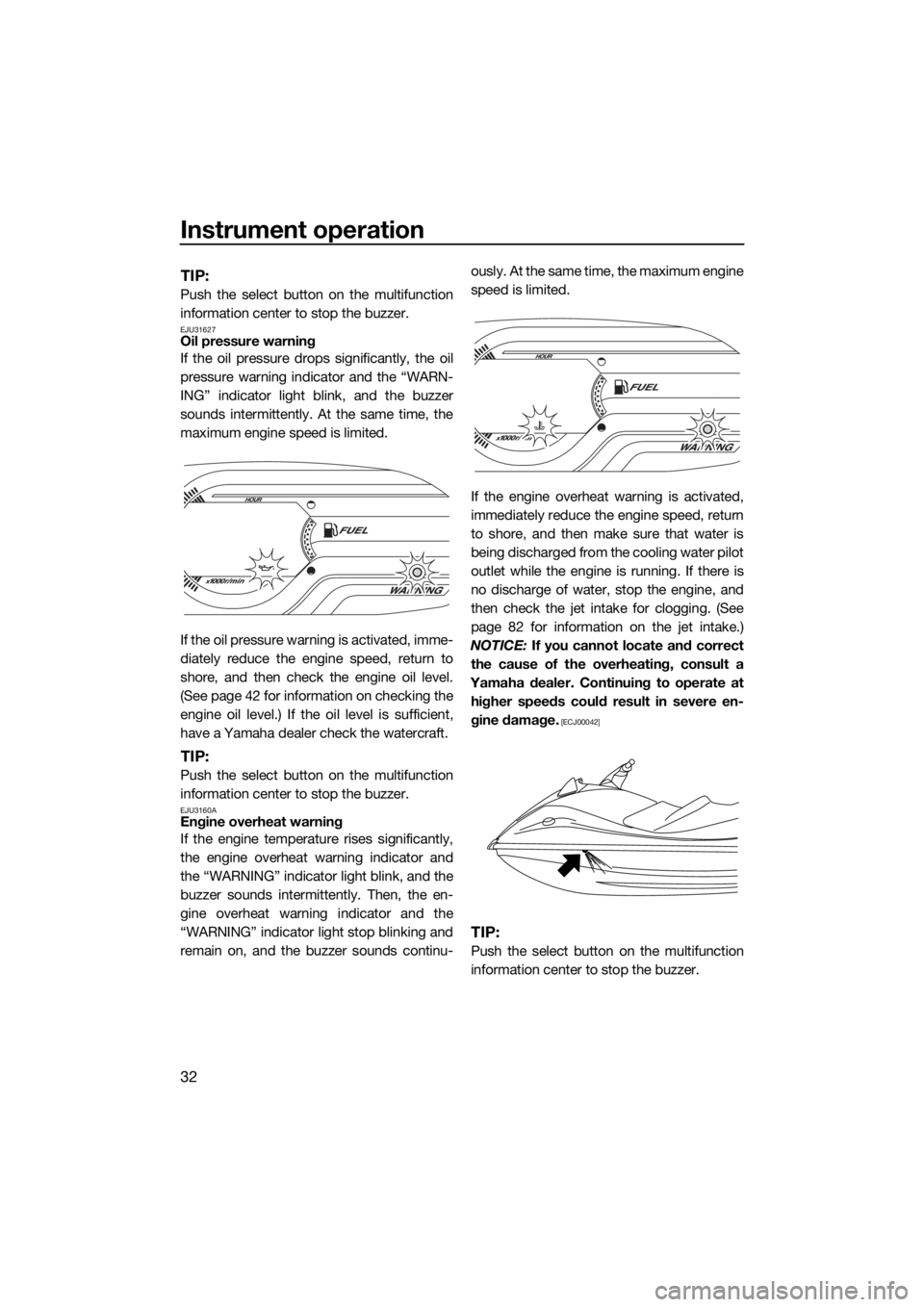

EJU31627Oil pressure warning

If the oil pressure drops significantly, the oil

pressure warning indicator and the “WARN-

ING” indicator light blink, and the buzzer

sounds intermittently. At the same time, the

maximum engine speed is limited.

If the oil pressure warning is activated, imme-

diately reduce the engine speed, return to

shore, and then check the engine oil level.

(See page 42 for information on checking the

engine oil level.) If the oil level is sufficient,

have a Yamaha dealer check the watercraft.

TIP:

Push the select button on the multifunction

information center to stop the buzzer.

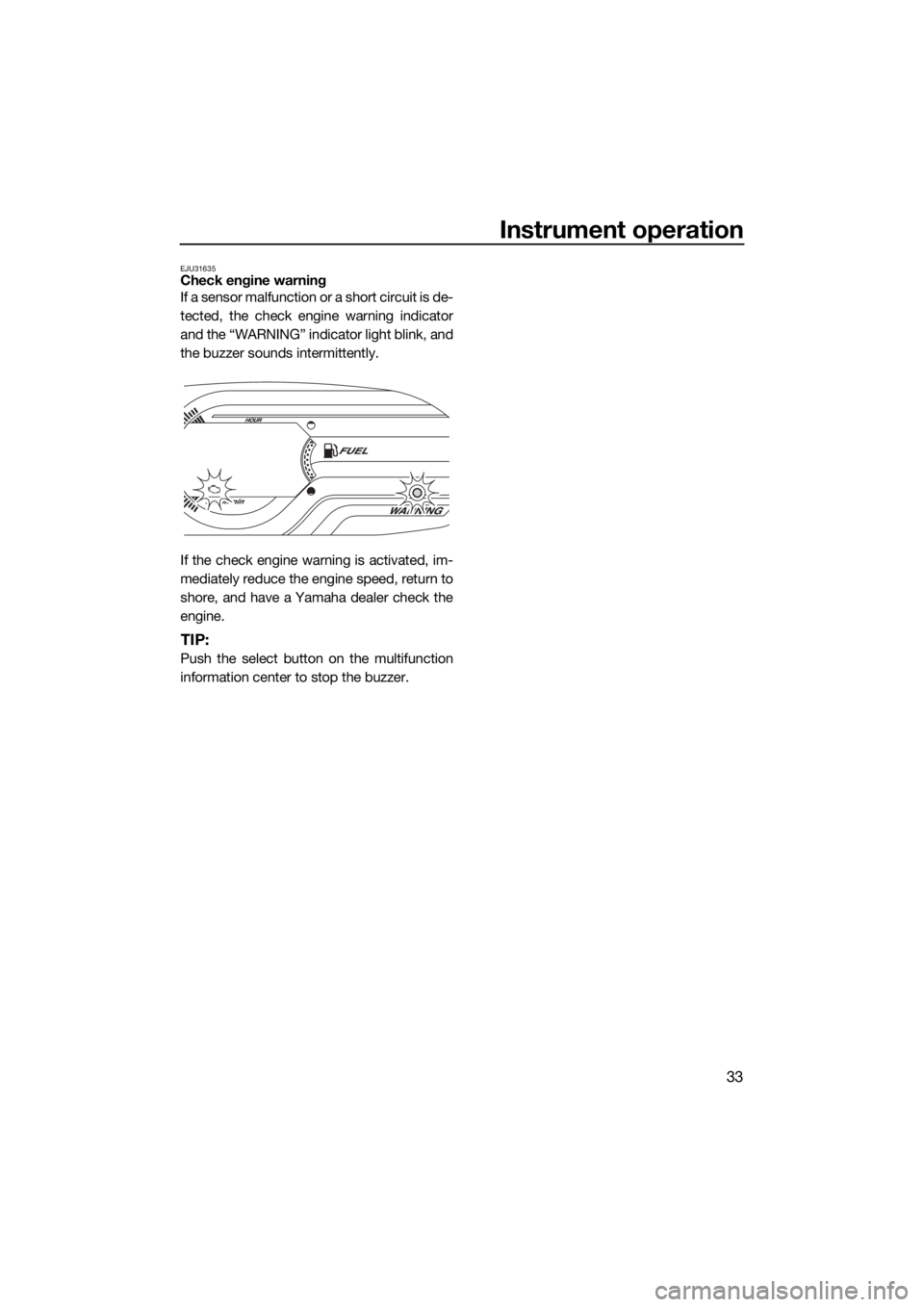

EJU3160AEngine overheat warning

If the engine temperature rises significantly,

the engine overheat warning indicator and

the “WARNING” indicator light blink, and the

buzzer sounds intermittently. Then, the en-

gine overheat warning indicator and the

“WARNING” indicator light stop blinking and

remain on, and the buzzer sounds continu-ously. At the same time, the maximum engine

speed is limited.

If the engine overheat warning is activated,

immediately reduce the engine speed, return

to shore, and then make sure that water is

being discharged from the cooling water pilot

outlet while the engine is running. If there is

no discharge of water, stop the engine, and

then check the jet intake for clogging. (See

page 82 for information on the jet intake.)

NOTICE: If you cannot locate and correct

the cause of the overheating, consult a

Yamaha dealer. Continuing to operate at

higher speeds could result in severe en-

gine damage.

[ECJ00042]

TIP:

Push the select button on the multifunction

information center to stop the buzzer.

UF2P72E0.book Page 32 Tuesday, August 26, 2014 10:08 AM

Page 39 of 94

Instrument operation

33

EJU31635Check engine warning

If a sensor malfunction or a short circuit is de-

tected, the check engine warning indicator

and the “WARNING” indicator light blink, and

the buzzer sounds intermittently.

If the check engine warning is activated, im-

mediately reduce the engine speed, return to

shore, and have a Yamaha dealer check the

engine.

TIP:

Push the select button on the multifunction

information center to stop the buzzer.

UF2P72E0.book Page 33 Tuesday, August 26, 2014 10:08 AM

Page 46 of 94

Operation and handling requirements

40

EJU31823

Fuel requirementsEJU37167Fuel

WARNING

EWJ00283

Gasoline and gasoline vapors are ex-

tremely flammable. To avoid fires and

explosions and to reduce the risk of in-

jury when refueling, follow these in-

structions.

Gasoline is poisonous and can cause in-

jury or death. Handle gasoline with care.

Never siphon gasoline by mouth. If you

should swallow some gasoline, inhale a

lot of gasoline vapor, or get some gaso-

line in your eyes, see your doctor imme-

diately. If gasoline spills on your skin,

wash with soap and water. If gasoline

spills on your clothing, change your

clothes.

NOTICE

ECJ00322

Do not use leaded gasoline. Leaded

gasoline can seriously damage the en-

gine.

Avoid getting water and contaminants in

the fuel tank. Contaminated fuel can

cause poor performance and engine

damage. Use only fresh gasoline that

has been stored in clean containers.

Gasohol

There are two types of gasohol: gasohol con-

taining ethanol and that containing methanol.Gasohol containing ethanol can be used if

ethanol content does not exceed 10% and

the fuel meets the minimum octane ratings.

E-85 is a fuel blend containing 85% ethanol

and therefore must not be used in this water-

craft. All ethanol blends containing more than

10% ethanol can cause fuel system damage

or engine performance problems.

Yamaha does not recommend gasohol con-

taining methanol because it can cause fuel

system damage and engine performance

problems.

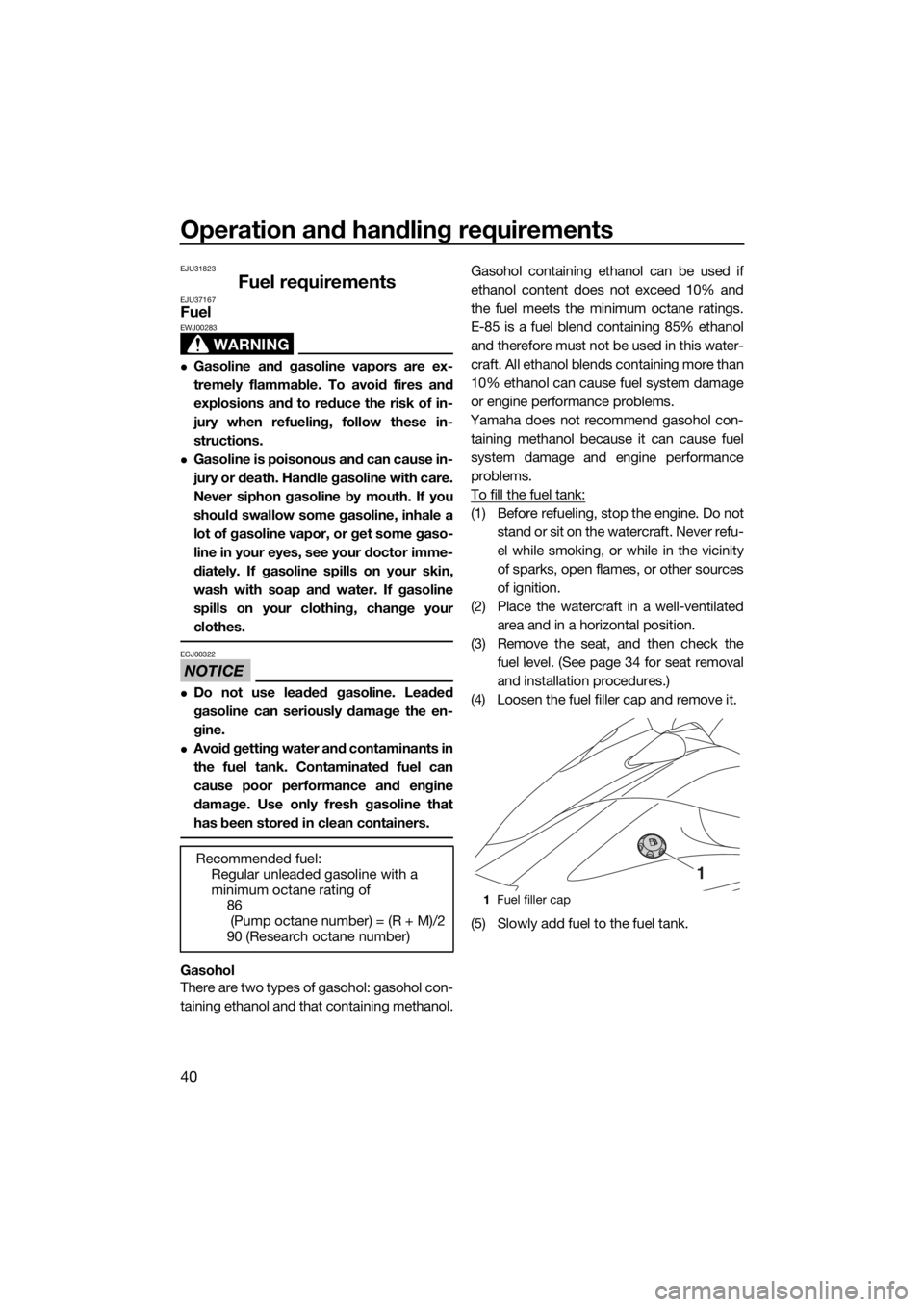

To fill the fuel tank:

(1) Before refueling, stop the engine. Do not

stand or sit on the watercraft. Never refu-

el while smoking, or while in the vicinity

of sparks, open flames, or other sources

of ignition.

(2) Place the watercraft in a well-ventilated

area and in a horizontal position.

(3) Remove the seat, and then check the

fuel level. (See page 34 for seat removal

and installation procedures.)

(4) Loosen the fuel filler cap and remove it.

(5) Slowly add fuel to the fuel tank. Recommended fuel:

Regular unleaded gasoline with a

minimum octane rating of

86

(Pump octane number) = (R + M)/2

90 (Research octane number)

1Fuel filler cap

1

UF2P72E0.book Page 40 Tuesday, August 26, 2014 10:08 AM

Page 48 of 94

Operation and handling requirements

42

EJU40291

Engine oil requirementsEJU41543Engine oil

NOTICE

ECJ00282

Use only 4-stroke engine oil. Usage of 2-

stroke engine oil could result in severe en-

gine damage.

Checking the engine oil level

WARNING

EWJ00341

Engine oil is extremely hot immediately af-

ter the engine is turned off. Coming in con-

tact with or getting any engine oil on your

clothes could result in burns.

NOTICE

ECJ00392

Do not run the engine with too much or

not enough oil in the oil tank, otherwise

the engine could be damaged.

Make sure that debris and water do not

enter the oil tank filler hole. Debris and

water in the engine oil can cause serious

engine damage.

TIP:

When checking the engine oil level on land,

the engine must be running while water is

being supplied to the cooling water pas-

sages. (See “Flushing the cooling water

passeges” on page 69 for information on

supplying water.)

When checking the engine oil level on wa-

ter, moor the watercraft so that it will not

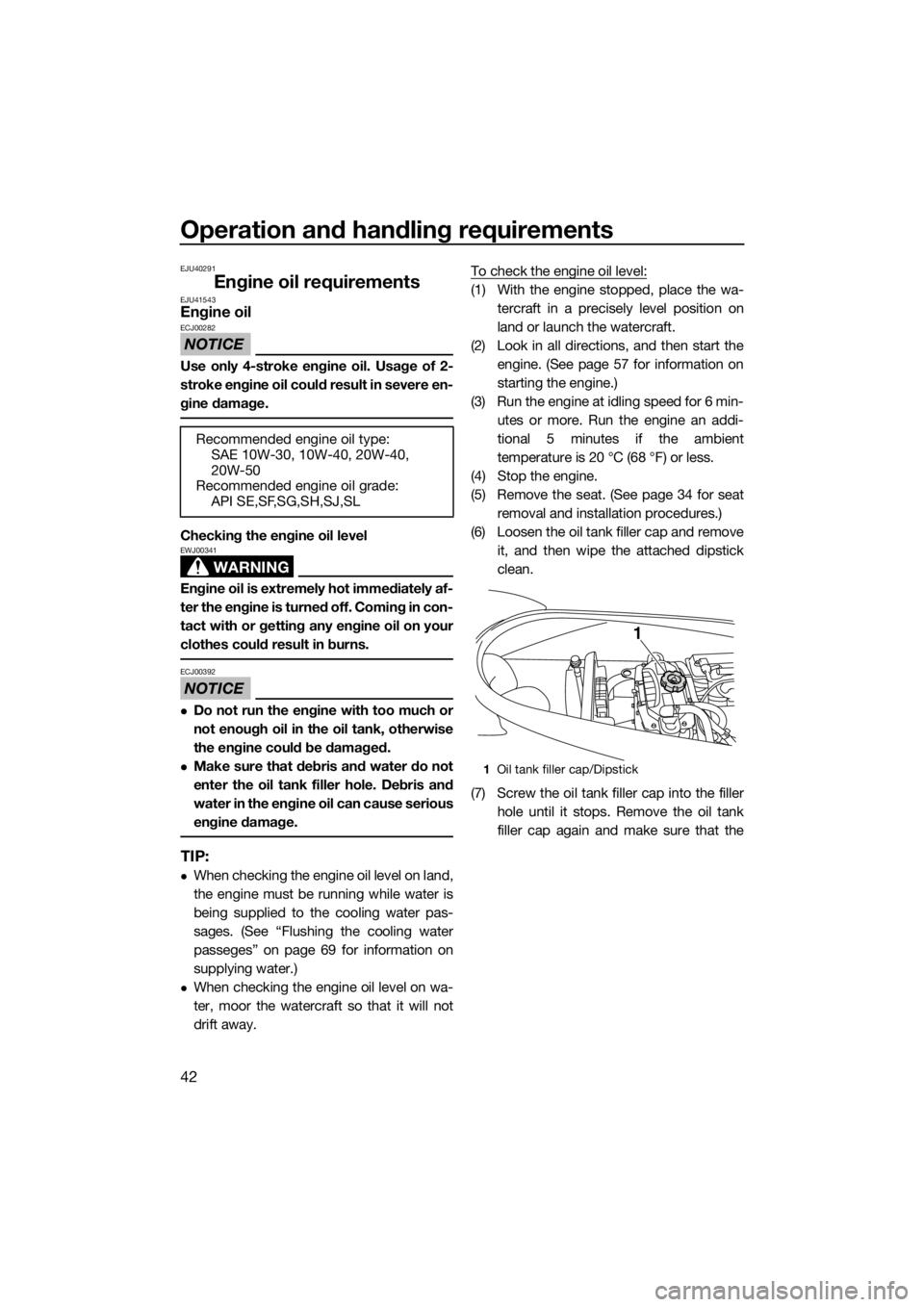

drift away.To check the engine oil level:

(1) With the engine stopped, place the wa-

tercraft in a precisely level position on

land or launch the watercraft.

(2) Look in all directions, and then start the

engine. (See page 57 for information on

starting the engine.)

(3) Run the engine at idling speed for 6 min-

utes or more. Run the engine an addi-

tional 5 minutes if the ambient

temperature is 20 °C (68 °F) or less.

(4) Stop the engine.

(5) Remove the seat. (See page 34 for seat

removal and installation procedures.)

(6) Loosen the oil tank filler cap and remove

it, and then wipe the attached dipstick

clean.

(7) Screw the oil tank filler cap into the filler

hole until it stops. Remove the oil tank

filler cap again and make sure that the Recommended engine oil type:

SAE 10W-30, 10W-40, 20W-40,

20W-50

Recommended engine oil grade:

API SE,SF,SG,SH,SJ,SL

1Oil tank filler cap/Dipstick

1

UF2P72E0.book Page 42 Tuesday, August 26, 2014 10:08 AM

Page 50 of 94

Operation and handling requirements

44

maining moisture in the engine compart-

ment with a dry cloth.

(4) Securely install the stern drain plugs by

tightening them until they stop. NOTICE:

Before installing the stern drain plugs,

clean the drain plug threads and the

O-rings on the plugs to remove any

foreign materials, such as dirt or sand.

Otherwise, the stern drain plugs could

be damaged, allowing water to enter

the engine compartment. Check the

O-rings on the stern drain plugs and

make sure that the plugs are tightened

securely before launching the water-

craft. Otherwise, water may flood the

engine compartment and cause the

watercraft to submerge.

[ECJ00363]

EJU40535

Draining the bilge water on water

A small quantity of bilge water will remain in

the engine compartment even after the bilge

water is drained on water. To completely

drain the bilge water, remove the watercraft

from the water and drain the bilge water on

land.

Jet vacuum bilge draining system

While the watercraft is operating, bilge water

in the engine compartment is drawn in by the

vacuum that is generated in the jet pump and

discharged from the watercraft through the

jet thrust nozzle.

To drain the bilge water on water:

Operate the watercraft as straight as possible

and above planing speed for at least 2 min-

utes. NOTICE: Do not run the engine at full

throttle for at least 1 minute after the en-

gine has been restarted. Bilge water in the

engine compartment can splash into theengine, which can result in severe dam-

age.

[ECJ00554]

UF2P72E0.book Page 44 Tuesday, August 26, 2014 10:08 AM

Page 52 of 94

First-time operation

46

EJU32786

Engine break-in

NOTICE

ECJ00432

Failure to perform the engine break-in

could result in reduced engine life or even

severe engine damage.

The engine break-in is essential to allow the

various components of the engine to wear

and polish themselves to the correct operat-

ing clearances. This ensures proper perfor-

mance and promotes longer component life.

To perform the engine break-in:

(1) Check the engine oil level. (See page 42

for information on checking the engine

oil level.)

(2) Launch the watercraft and start the en-

gine. (See page 57 for information on

starting the engine.)

(3) For the first 5 minutes, operate with the

engine at idling speed.

(4) For the next 30 minutes, operate with the

engine speed below 5000 r/min.

(5) For the next 1 hour, operate with the en-

gine speed below 6500 r/min.

After the engine break-in is complete, the wa-

tercraft can be operated normally.

UF2P72E0.book Page 46 Tuesday, August 26, 2014 10:08 AM