wheel YAMAHA VMAX 2001 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: VMAX, Model: YAMAHA VMAX 2001Pages: 110, PDF Size: 11.88 MB

Page 26 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-11

3

EAU03414

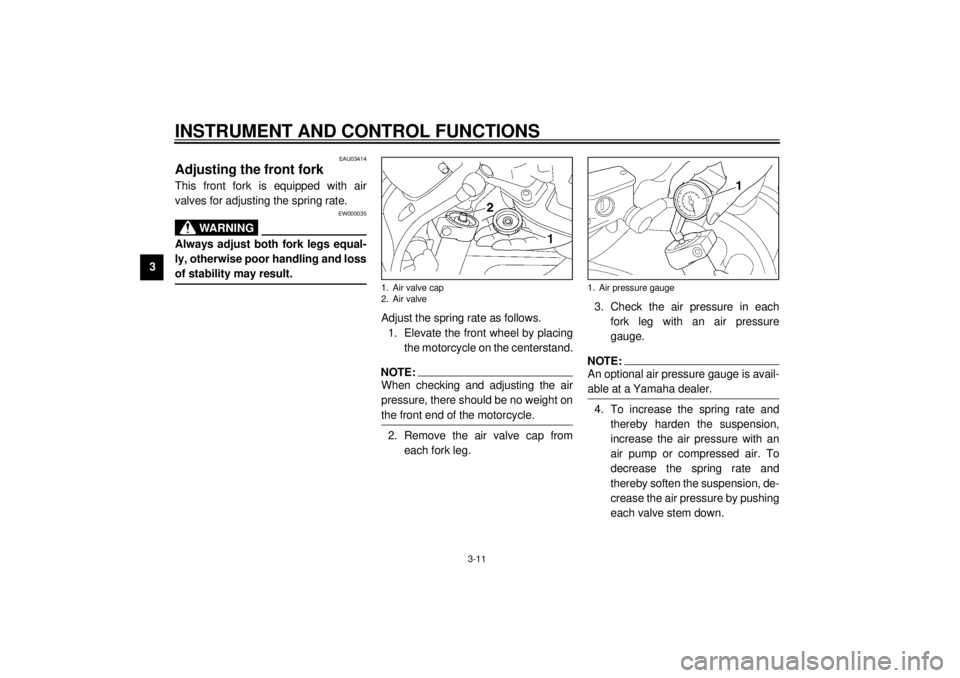

Adjusting the front fork This front fork is equipped with air

valves for adjusting the spring rate.

EW000035

WARNING

@ Always adjust both fork legs equal-

ly, otherwise poor handling and loss

of stability may result. @

Adjust the spring rate as follows.

1. Elevate the front wheel by placing

the motorcycle on the centerstand.NOTE:@ When checking and adjusting the air

pressure, there should be no weight on

the front end of the motorcycle. @2. Remove the air valve cap from

each fork leg.3. Check the air pressure in each

fork leg with an air pressure

gauge.

NOTE:@ An optional air pressure gauge is avail-

able at a Yamaha dealer. @4. To increase the spring rate and

thereby harden the suspension,

increase the air pressure with an

air pump or compressed air. To

decrease the spring rate and

thereby soften the suspension, de-

crease the air pressure by pushing

each valve stem down.

1. Air valve cap

2. Air valve

1. Air pressure gauge

E_3lr.book Page 11 Wednesday, November 22, 2000 4:10 PM

Page 34 of 110

4-1

4

EAU01114

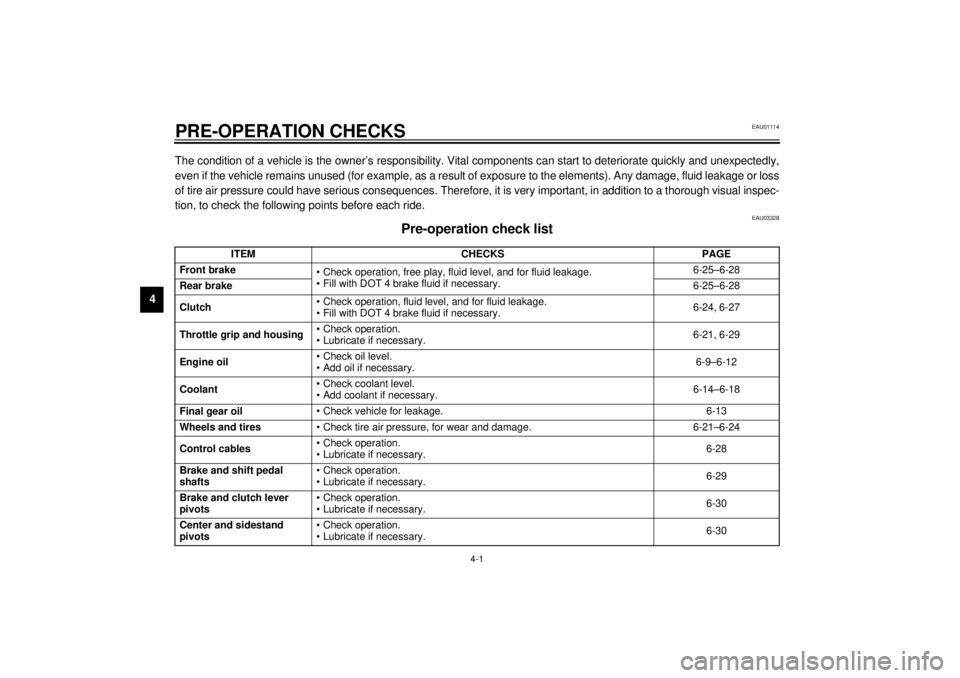

4-PRE-OPERATION CHECKSThe condition of a vehicle is the owner’s responsibility. Vital components can start to deteriorate quickly and unexpectedly,

even if the vehicle remains unused (for example, as a result of exposure to the elements). Any damage, fluid leakage or loss

of tire air pressure could have serious consequences. Therefore, it is very important, in addition to a thorough visual inspec-

tion, to check the following points before each ride.

EAU03328

Pre-operation check list

ITEM CHECKS PAGE

Front brake

• Check operation, free play, fluid level, and for fluid leakage.

• Fill with DOT 4 brake fluid if necessary.6-25–6-28

Rear brake6-25–6-28

Clutch• Check operation, fluid level, and for fluid leakage.

• Fill with DOT 4 brake fluid if necessary.6-24, 6-27

Throttle grip and housing• Check operation.

• Lubricate if necessary.6-21, 6-29

Engine oil• Check oil level.

• Add oil if necessary.6-9–6-12

Coolant• Check coolant level.

• Add coolant if necessary.6-14–6-18

Final gear oil• Check vehicle for leakage. 6-13

Wheels and tires• Check tire air pressure, for wear and damage. 6-21–6-24

Control cables• Check operation.

• Lubricate if necessary.6-28

Brake and shift pedal

shafts• Check operation.

• Lubricate if necessary.6-29

Brake and clutch lever

pivots• Check operation.

• Lubricate if necessary.6-30

Center and sidestand

pivots• Check operation.

• Lubricate if necessary.6-30

E_3lr.book Page 1 Wednesday, November 22, 2000 4:10 PM

Page 43 of 110

6

PERIODIC MAINTENANCE AND MINOR REPAIR

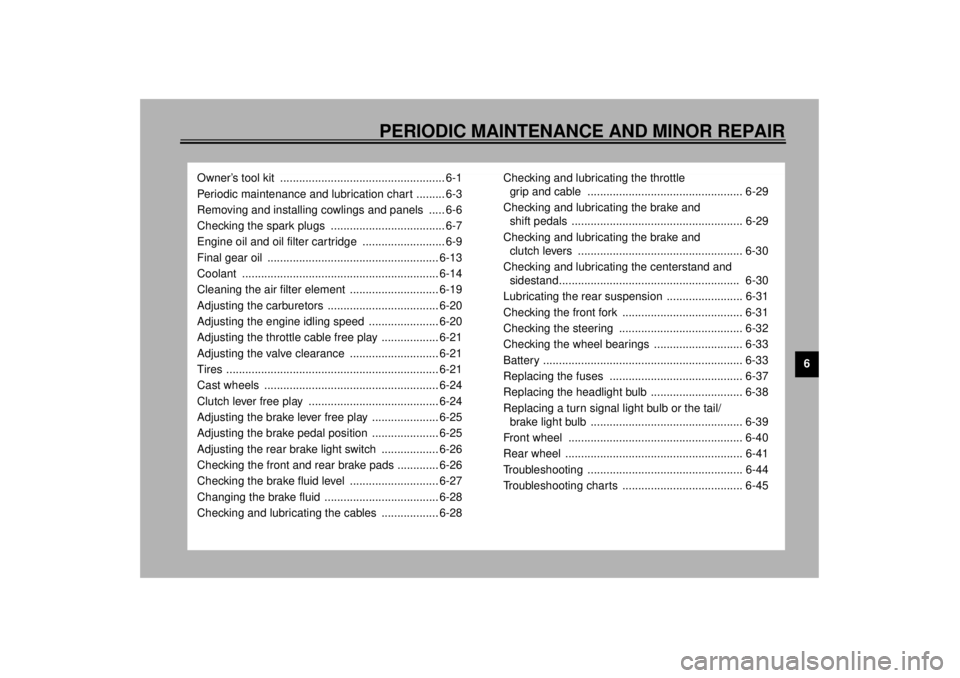

Owner’s tool kit .................................................... 6-1

Periodic maintenance and lubrication chart ......... 6-3

Removing and installing cowlings and panels ..... 6-6

Checking the spark plugs .................................... 6-7

Engine oil and oil filter cartridge .......................... 6-9

Final gear oil ...................................................... 6-13

Coolant .............................................................. 6-14

Cleaning the air filter element ............................ 6-19

Adjusting the carburetors ................................... 6-20

Adjusting the engine idling speed ...................... 6-20

Adjusting the throttle cable free play .................. 6-21

Adjusting the valve clearance ............................ 6-21

Tires ................................................................... 6-21

Cast wheels ....................................................... 6-24

Clutch lever free play ......................................... 6-24

Adjusting the brake lever free play ..................... 6-25

Adjusting the brake pedal position ..................... 6-25

Adjusting the rear brake light switch .................. 6-26

Checking the front and rear brake pads ............. 6-26

Checking the brake fluid level ............................ 6-27

Changing the brake fluid .................................... 6-28

Checking and lubricating the cables .................. 6-28Checking and lubricating the throttle

grip and cable ................................................. 6-29

Checking and lubricating the brake and

shift pedals ...................................................... 6-29

Checking and lubricating the brake and

clutch levers .................................................... 6-30

Checking and lubricating the centerstand and

sidestand......................................................... 6-30

Lubricating the rear suspension ........................ 6-31

Checking the front fork ...................................... 6-31

Checking the steering ....................................... 6-32

Checking the wheel bearings ............................ 6-33

Battery ............................................................... 6-33

Replacing the fuses .......................................... 6-37

Replacing the headlight bulb ............................. 6-38

Replacing a turn signal light bulb or the tail/

brake light bulb ................................................ 6-39

Front wheel ....................................................... 6-40

Rear wheel ........................................................ 6-41

Troubleshooting ................................................. 6-44

Troubleshooting charts ...................................... 6-45

E_3lr.book Page 1 Wednesday, November 22, 2000 4:10 PM

Page 47 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-4

6

10

*Brake hoses• Check for cracks or damage.ÖÖÖÖ Ö

• Replace. Every 4 years

11*Wheels• Check runout and for damage. ÖÖÖÖ

12*Tires• Check tread depth and for damage.

• Replace if necessary.

• Check air pressure.

• Correct if necessary.ÖÖÖÖ

13*Wheel bearings• Check bearings for looseness or damage. ÖÖÖÖ

14*Swingarm• Check swingarm pivoting point for play.ÖÖÖÖ

• Lubricate with molybdenum disulfide grease. Every 50,000 km

15*Steering bearings• Check bearing play and steering for roughness.ÖÖÖÖÖ

• Lubricate with lithium-soap-based grease. Every 50,000 km

16*Chassis fasteners• Make sure that all nuts, bolts and screws are properly

tightened.ÖÖÖÖ Ö

17 Sidestand/centerstand• Check operation.

• Lubricate.ÖÖÖÖ Ö

18*Sidestand switch• Check operation.ÖÖÖÖÖ Ö

19*Front fork• Check operation and for oil leakage.ÖÖÖÖ

20*Rear shock absorber

assemblies• Check operation and shock absorbers for oil leakage.ÖÖÖÖ

21*Carburetors• Check engine idling speed, synchronization and starter

operation.ÖÖÖÖÖ Ö

22 Engine oil• Change.ÖÖÖÖÖ Ö

23 Engine oil filter cartridge• Replace.ÖÖÖ

24*Cooling system• Check coolant level and vehicle for coolant leakage.ÖÖÖÖ Ö

• Change coolant. Every 3 years NO. ITEM CHECK OR MAINTENANCE JOBODOMETER READING (´1,000 km)

ANNUAL

CHECK

1 10203040

E_3lr.book Page 4 Wednesday, November 22, 2000 4:10 PM

Page 56 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-13

6

EAU02975

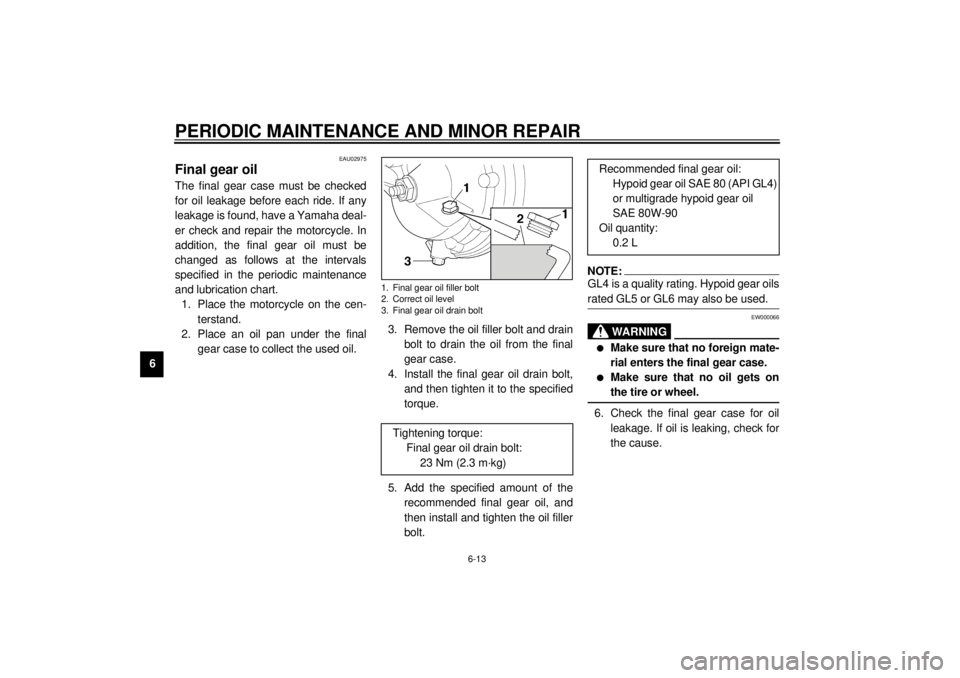

Final gear oil The final gear case must be checked

for oil leakage before each ride. If any

leakage is found, have a Yamaha deal-

er check and repair the motorcycle. In

addition, the final gear oil must be

changed as follows at the intervals

specified in the periodic maintenance

and lubrication chart.

1. Place the motorcycle on the cen-

terstand.

2. Place an oil pan under the final

gear case to collect the used oil.3. Remove the oil filler bolt and drain

bolt to drain the oil from the final

gear case.

4. Install the final gear oil drain bolt,

and then tighten it to the specified

torque.

5. Add the specified amount of the

recommended final gear oil, and

then install and tighten the oil filler

bolt.

NOTE:@ GL4 is a quality rating. Hypoid gear oils

rated GL5 or GL6 may also be used. @

EW000066

WARNING

@ l

Make sure that no foreign mate-

rial enters the final gear case.

l

Make sure that no oil gets on

the tire or wheel.

@6. Check the final gear case for oil

leakage. If oil is leaking, check for

the cause.

1. Final gear oil filler bolt

2. Correct oil level

3. Final gear oil drain bolt

Tightening torque:

Final gear oil drain bolt:

23 Nm (2.3 m·kg)

Recommended final gear oil:

Hypoid gear oil SAE 80 (API GL4)

or multigrade hypoid gear oil

SAE 80W-90

Oil quantity:

0.2 L

E_3lr.book Page 13 Wednesday, November 22, 2000 4:10 PM

Page 66 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-23

6

EW000079

WARNING

@ l

Have a Yamaha dealer replace

excessively worn tires. Besides

being illegal, operating the

motorcycle with excessively

worn tires decreases riding sta-

bility and can lead to loss of

control.

l

The replacement of all wheel-

and brake-related parts, includ-

ing the tires, should be left to a

Yamaha dealer, who has the

necessary professional knowl-

edge and experience.

@

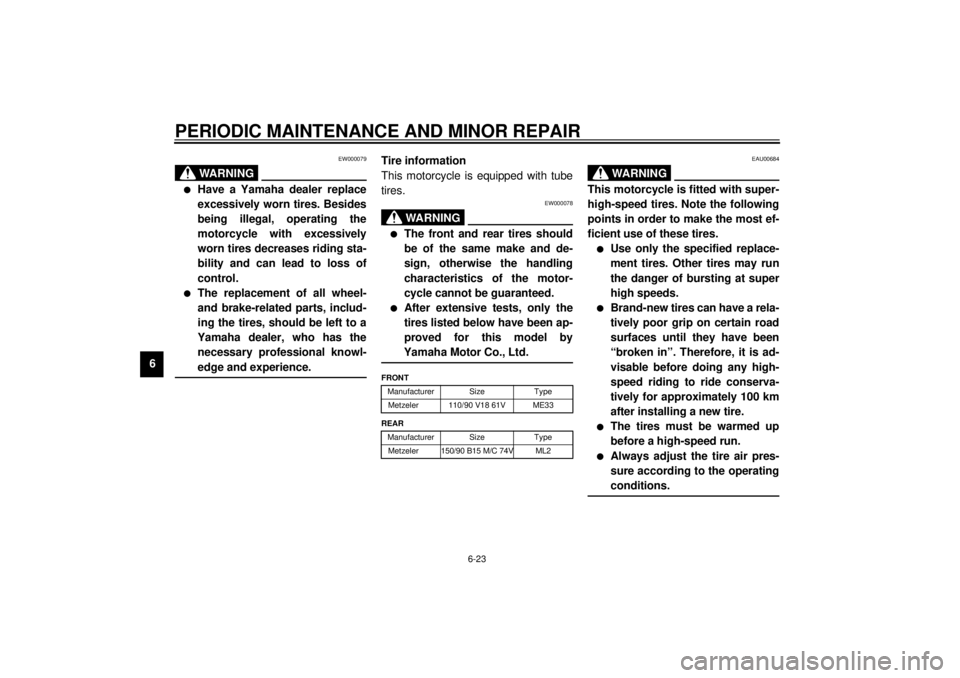

Tire information

This motorcycle is equipped with tube

tires.

EW000078

WARNING

@ l

The front and rear tires should

be of the same make and de-

sign, otherwise the handling

characteristics of the motor-

cycle cannot be guaranteed.

l

After extensive tests, only the

tires listed below have been ap-

proved for this model by

Yamaha Motor Co., Ltd.

@CE-10EEAU00684

WARNING

@ This motorcycle is fitted with super-

high-speed tires. Note the following

points in order to make the most ef-

ficient use of these tires.l

Use only the specified replace-

ment tires. Other tires may run

the danger of bursting at super

high speeds.

l

Brand-new tires can have a rela-

tively poor grip on certain road

surfaces until they have been

“broken in”. Therefore, it is ad-

visable before doing any high-

speed riding to ride conserva-

tively for approximately 100 km

after installing a new tire.

l

The tires must be warmed up

before a high-speed run.

l

Always adjust the tire air pres-

sure according to the operating

conditions.

@

FRONT

Manufacturer Size Type

Metzeler 110/90 V18 61V ME33

REAR

Manufacturer Size Type

Metzeler 150/90 B15 M/C 74V ML2

E_3lr.book Page 23 Wednesday, November 22, 2000 4:10 PM

Page 67 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-24

6

EAU00689

Cast wheels To maximize the performance, durabil-

ity, and safe operation of your motor-

cycle, note the following points

regarding the specified wheels.l

The wheel rims should be checked

for cracks, bends, warpage or

damage before each ride. If any

damage is found, have a Yamaha

dealer replace the wheel. Do not

attempt even the smallest repair to

the wheel. A deformed or cracked

wheel must be replaced.

l

The wheel should be balanced

whenever either the tire or wheel

has been changed or replaced. An

unbalanced wheel can result in

poor performance, adverse han-

dling characteristics, and a short-

ened tire life.

l

Ride at moderate speeds after

changing a tire since the tire sur-

face must first be “broken in” for it

to develop its optimal characteris-

tics.

l

After repairing or replacing a tire,

tighten the valve stem nut and

locknut to the specified torques.

EAU00695

Clutch lever free play Since this model is equipped with a hy-

draulic clutch, adjusting the clutch lever

free play is not needed. However, it is

necessary to check the clutch fluid lev-

el and check the hydraulic system for

leakage before each ride. If the clutch

lever free play does become exces-

sive, and shifting becomes rough or

clutch slippage occurs, causing poor

acceleration, there may be air in the

clutch system. If there is air in the hy-

draulic system, have a Yamaha dealer

bleed the system before operating the

motorcycle. Tightening torques:

Valve stem nut:

1.6 Nm (0.16 m·kg)

Valve stem locknut:

1.6 Nm (0.16 m·kg)

E_3lr.book Page 24 Wednesday, November 22, 2000 4:10 PM

Page 75 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-32

6

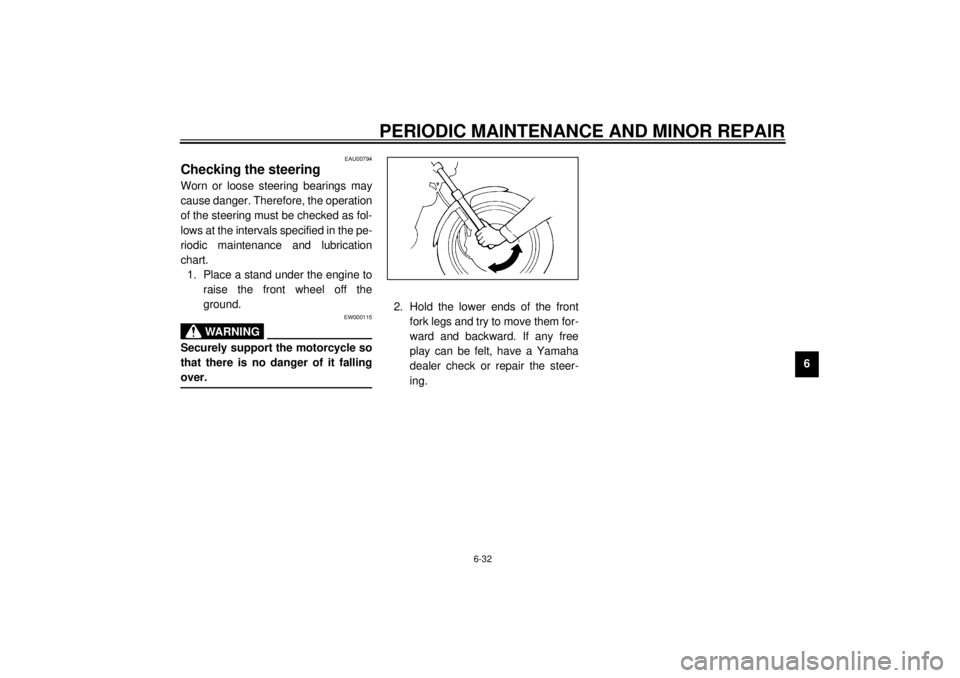

EAU00794

Checking the steering Worn or loose steering bearings may

cause danger. Therefore, the operation

of the steering must be checked as fol-

lows at the intervals specified in the pe-

riodic maintenance and lubrication

chart.

1. Place a stand under the engine to

raise the front wheel off the

ground.

EW000115

WARNING

@ Securely support the motorcycle so

that there is no danger of it falling

over. @

2. Hold the lower ends of the front

fork legs and try to move them for-

ward and backward. If any free

play can be felt, have a Yamaha

dealer check or repair the steer-

ing.

E_3lr.book Page 32 Wednesday, November 22, 2000 4:10 PM

Page 76 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-33

6

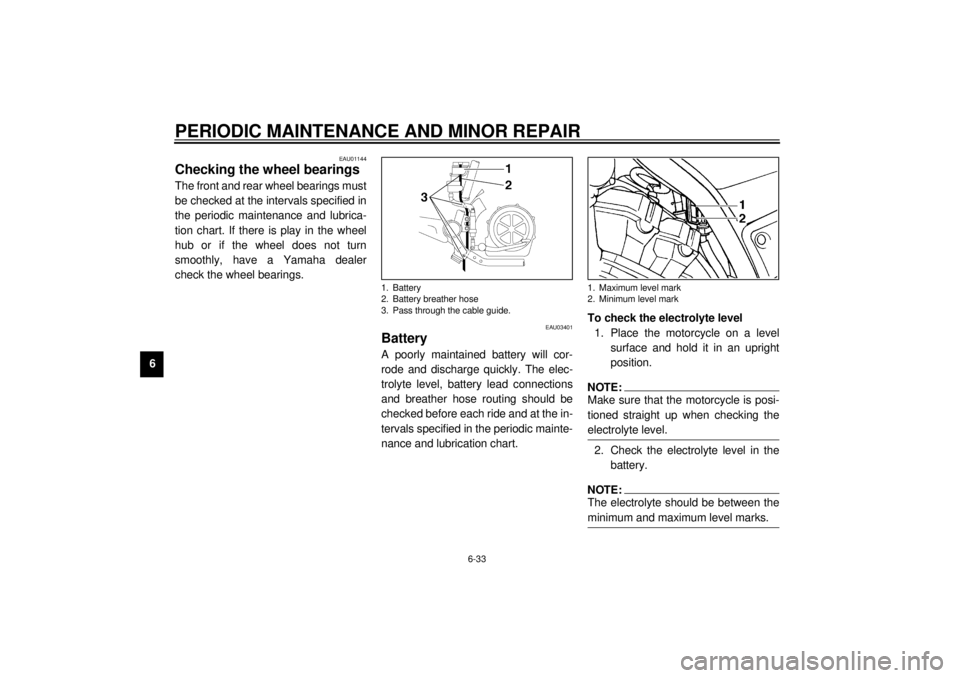

EAU01144

Checking the wheel bearings The front and rear wheel bearings must

be checked at the intervals specified in

the periodic maintenance and lubrica-

tion chart. If there is play in the wheel

hub or if the wheel does not turn

smoothly, have a Yamaha dealer

check the wheel bearings.

EAU03401

Battery A poorly maintained battery will cor-

rode and discharge quickly. The elec-

trolyte level, battery lead connections

and breather hose routing should be

checked before each ride and at the in-

tervals specified in the periodic mainte-

nance and lubrication chart.To check the electrolyte level

1. Place the motorcycle on a level

surface and hold it in an upright

position.

NOTE:@ Make sure that the motorcycle is posi-

tioned straight up when checking the

electrolyte level. @2. Check the electrolyte level in the

battery.NOTE:@ The electrolyte should be between the

minimum and maximum level marks. @

1. Battery

2. Battery breather hose

3. Pass through the cable guide.

1. Maximum level mark

2. Minimum level mark

E_3lr.book Page 33 Wednesday, November 22, 2000 4:10 PM

Page 83 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-40

6

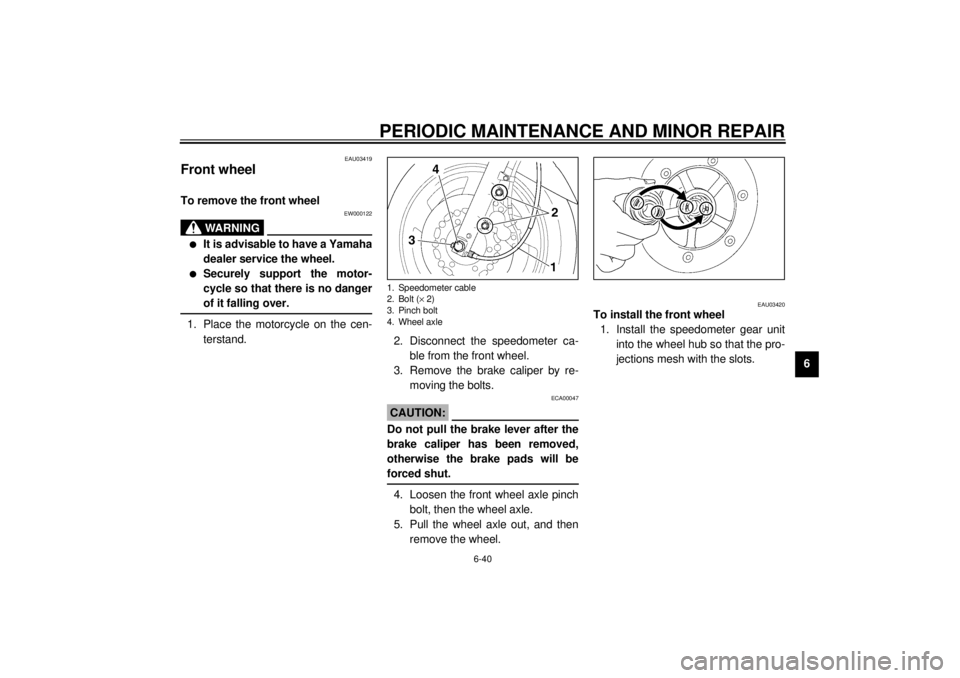

EAU03419

Front wheel To remove the front wheel

EW000122

WARNING

@ l

It is advisable to have a Yamaha

dealer service the wheel.

l

Securely support the motor-

cycle so that there is no danger

of it falling over.

@1. Place the motorcycle on the cen-

terstand.

2. Disconnect the speedometer ca-

ble from the front wheel.

3. Remove the brake caliper by re-

moving the bolts.

ECA00047

CAUTION:@ Do not pull the brake lever after the

brake caliper has been removed,

otherwise the brake pads will be

forced shut. @4. Loosen the front wheel axle pinch

bolt, then the wheel axle.

5. Pull the wheel axle out, and then

remove the wheel.

EAU03420

To install the front wheel

1. Install the speedometer gear unit

into the wheel hub so that the pro-

jections mesh with the slots.

1. Speedometer cable

2. Bolt (´ 2)

3. Pinch bolt

4. Wheel axle

E_3lr.book Page 40 Wednesday, November 22, 2000 4:10 PM