service YAMAHA VX110 2005 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: VX110, Model: YAMAHA VX110 2005Pages: 347, PDF Size: 14.17 MB

Page 16 of 347

1-7

E

GEN

INFO

SPECIAL SERVICE TOOLS

K

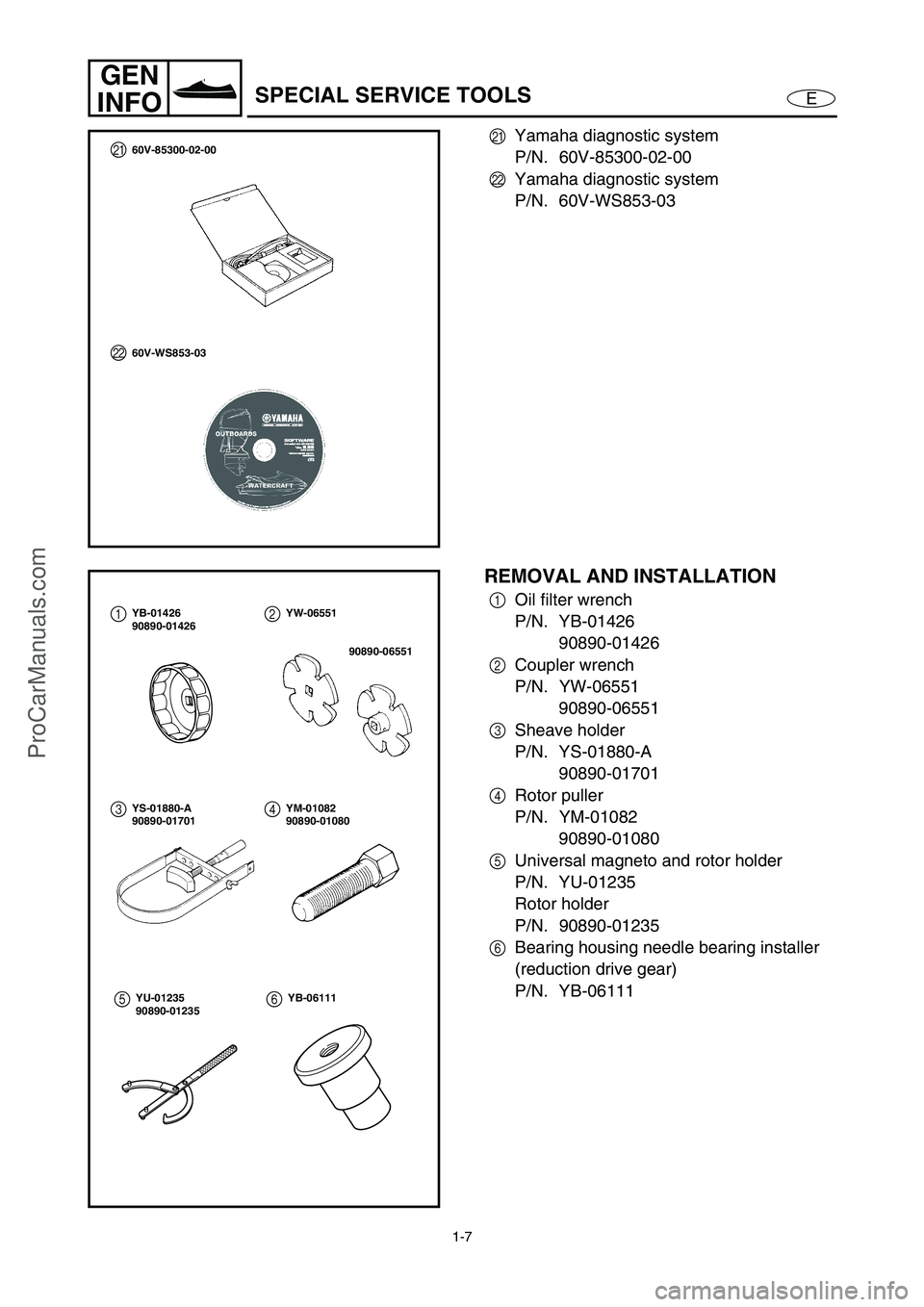

Yamaha diagnostic system

P/N. 60V-85300-02-00

L

Yamaha diagnostic system

P/N. 60V-WS853-03

L

60V-WS853-03

K60V-85300-02-00

REMOVAL AND INSTALLATION

1

Oil filter wrench

P/N. YB-01426

90890-01426

2

Coupler wrench

P/N. YW-06551

90890-06551

3

Sheave holder

P/N. YS-01880-A

90890-01701

4

Rotor puller

P/N. YM-01082

90890-01080

5

Universal magneto and rotor holder

P/N. YU-01235

Rotor holder

P/N. 90890-01235

6

Bearing housing needle bearing installer

(reduction drive gear)

P/N. YB-0611112

34YB-01426

90890-01426YW-06551

90890-06551

YS-01880-A

90890-01701YM-01082

90890-01080

56YU-01235

90890-01235YB-06111

ProCarManuals.com

Page 17 of 347

1-8

E

GEN

INFO

SPECIAL SERVICE TOOLS

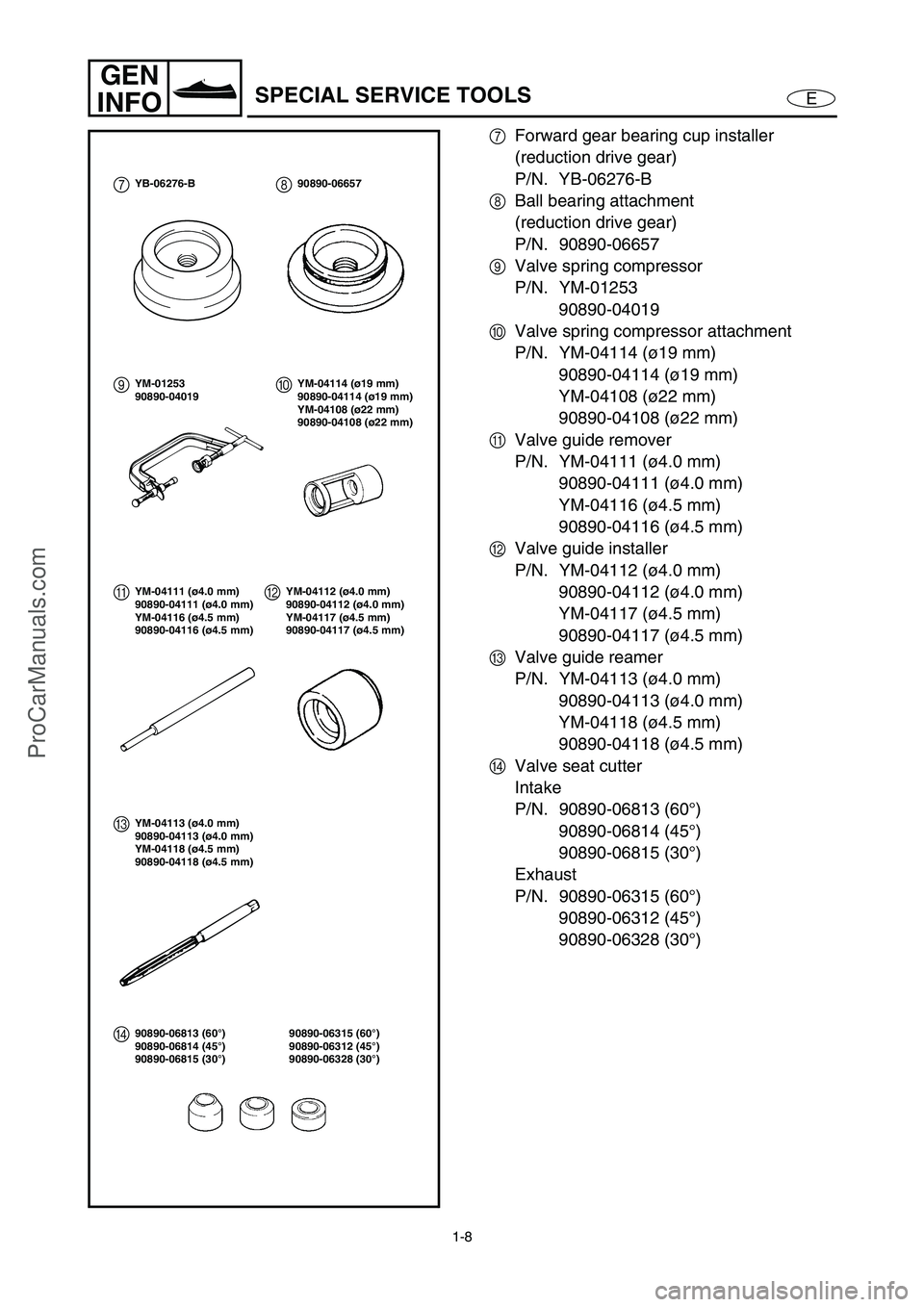

7

Forward gear bearing cup installer

(reduction drive gear)

P/N. YB-06276-B

8

Ball bearing attachment

(reduction drive gear)

P/N. 90890-06657

9

Valve spring compressor

P/N. YM-01253

90890-04019

0

Valve spring compressor attachment

P/N. YM-04114 (ø19 mm)

90890-04114 (ø19 mm)

YM-04108 (ø22 mm)

90890-04108 (ø22 mm)

A

Valve guide remover

P/N. YM-04111 (ø4.0 mm)

90890-04111 (ø4.0 mm)

YM-04116 (ø4.5 mm)

90890-04116 (ø4.5 mm)

B

Valve guide installer

P/N. YM-04112 (ø4.0 mm)

90890-04112 (ø4.0 mm)

YM-04117 (ø4.5 mm)

90890-04117 (ø4.5 mm)

C

Valve guide reamer

P/N. YM-04113 (ø4.0 mm)

90890-04113 (ø4.0 mm)

YM-04118 (ø4.5 mm)

90890-04118 (ø4.5 mm)

D

Valve seat cutter

Intake

P/N. 90890-06813 (60°)

90890-06814 (45°)

90890-06815 (30°)

Exhaust

P/N. 90890-06315 (60°)

90890-06312 (45°)

90890-06328 (30°)

0

AYM-04114 (ø19 mm)

90890-04114 (ø19 mm)

YM-04108 (ø22 mm)

90890-04108 (ø22 mm)

YM-04111 (ø4.0 mm)

90890-04111 (ø4.0 mm)

YM-04116 (ø4.5 mm)

90890-04116 (ø4.5 mm)

7YB-06276-B8

990890-06657

YM-01253

90890-04019

B

CYM-04112 (ø4.0 mm)

90890-04112 (ø4.0 mm)

YM-04117 (ø4.5 mm)

90890-04117 (ø4.5 mm)

YM-04113 (ø4.0 mm)

90890-04113 (ø4.0 mm)

YM-04118 (ø4.5 mm)

90890-04118 (ø4.5 mm)

90890-06315 (60°)

90890-06312 (45°)

90890-06328 (30°)

D90890-06813 (60°)

90890-06814 (45°)

90890-06815 (30°)

ProCarManuals.com

Page 18 of 347

1-9

E

GEN

INFO

SPECIAL SERVICE TOOLS

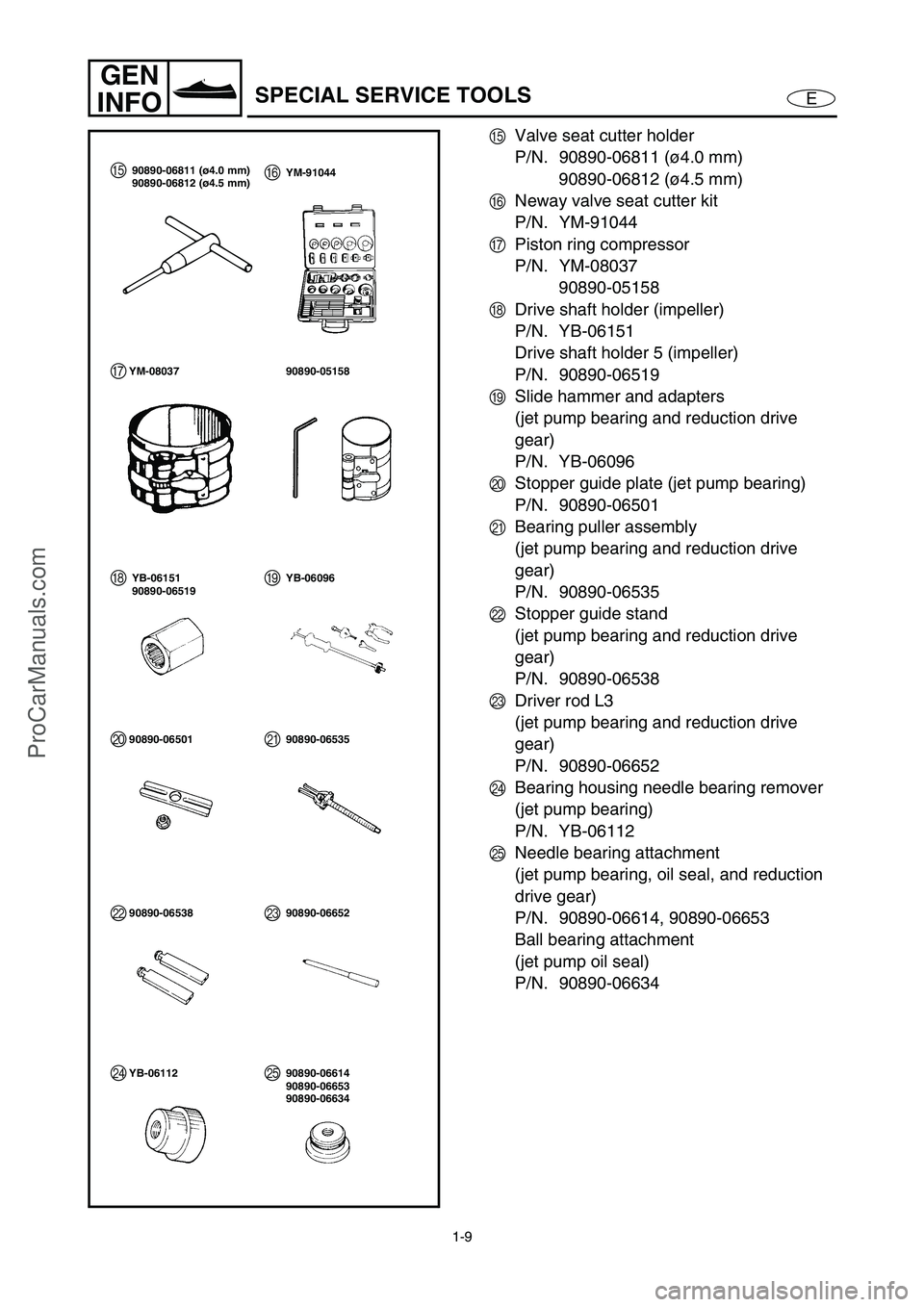

E

Valve seat cutter holder

P/N. 90890-06811 (ø4.0 mm)

90890-06812 (ø4.5 mm)

F

Neway valve seat cutter kit

P/N. YM-91044

G

Piston ring compressor

P/N. YM-08037

90890-05158

H

Drive shaft holder (impeller)

P/N. YB-06151

Drive shaft holder 5 (impeller)

P/N. 90890-06519

I

Slide hammer and adapters

(jet pump bearing and reduction drive

gear)

P/N. YB-06096

J

Stopper guide plate (jet pump bearing)

P/N. 90890-06501

K

Bearing puller assembly

(jet pump bearing and reduction drive

gear)

P/N. 90890-06535

L

Stopper guide stand

(jet pump bearing and reduction drive

gear)

P/N. 90890-06538

M

Driver rod L3

(jet pump bearing and reduction drive

gear)

P/N. 90890-06652

N

Bearing housing needle bearing remover

(jet pump bearing)

P/N. YB-06112

O

Needle bearing attachment

(jet pump bearing, oil seal, and reduction

drive gear)

P/N. 90890-06614, 90890-06653

Ball bearing attachment

(jet pump oil seal)

P/N. 90890-06634

YM-08037 90890-05158

YB-06096

90890-06501 90890-06535

E

G

HI

JK90890-06811 (ø4.0 mm)

90890-06812 (ø4.5 mm)

YB-06151

90890-06519YM-91044F

90890-06538 90890-06652LM

YB-06112 90890-06614NO90890-06653

90890-06634

ProCarManuals.com

Page 19 of 347

1-10

E

GEN

INFO

SPECIAL SERVICE TOOLS

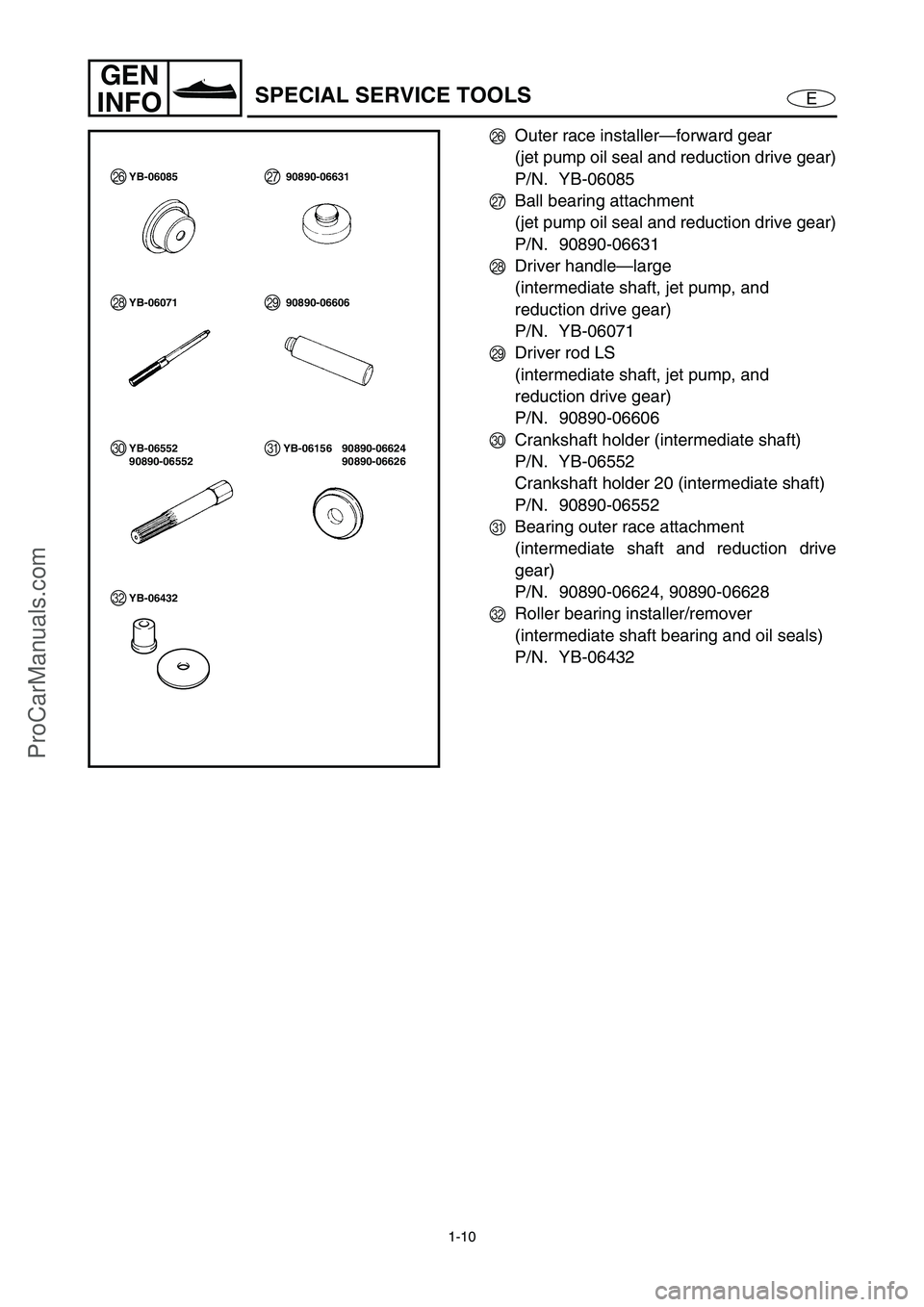

P

Outer race installer—forward gear

(jet pump oil seal and reduction drive gear)

P/N. YB-06085

Q

Ball bearing attachment

(jet pump oil seal and reduction drive gear)

P/N. 90890-06631

R

Driver handle—large

(intermediate shaft, jet pump, and

reduction drive gear)

P/N. YB-06071

S

Driver rod LS

(intermediate shaft, jet pump, and

reduction drive gear)

P/N. 90890-06606

T

Crankshaft holder (intermediate shaft)

P/N. YB-06552

Crankshaft holder 20 (intermediate shaft)

P/N. 90890-06552

U

Bearing outer race attachment

(intermediate shaft and reduction drive

gear)

P/N. 90890-06624, 90890-06628

V

Roller bearing installer/remover

(intermediate shaft bearing and oil seals)

P/N. YB-06432

YB-06071 90890-06606 RS

YB-06552

90890-06552T

YB-06085 P90890-06631Q

90890-06624 YB-06156U90890-06626

YB-06432V

ProCarManuals.com

Page 49 of 347

E

INSP

ADJ

1

2

3

4

5

6

7

8

9

CHAPTER 3

PERIODIC INSPECTION AND ADJUSTMENT

MAINTENANCE INTERVAL CHART .............................................................. 3-1

PERIODIC SERVICE ....................................................................................... 3-2

CONTROL SYSTEM ................................................................................. 3-2

Steering column inspection ................................................................. 3-2

Steering cable inspection and adjustment .......................................... 3-2

Throttle cable inspection and adjustment............................................ 3-4

Shift cable inspection and adjustment (Deluxe model only)................ 3-5

Trolling speed inspection .................................................................... 3-6

FUEL SYSTEM.......................................................................................... 3-7

Fuel line inspection ............................................................................. 3-7

Water separator inspection ................................................................. 3-8

POWER UNIT............................................................................................ 3-8

Valve clearance adjustment ................................................................ 3-8

Engine oil level check........................................................................ 3-14

Engine oil change — using oil changer ............................................. 3-16

Air filter element clean....................................................................... 3-18

Spark plug inspection ........................................................................ 3-20

ELECTRICAL .......................................................................................... 3-22

Battery inspection.............................................................................. 3-22

JET PUMP UNIT ..................................................................................... 3-25

Impeller inspection ............................................................................ 3-25

Water inlet strainer inspection ........................................................... 3-25

BILGE PUMP........................................................................................... 3-26

Bilge strainer inspection .................................................................... 3-26

GENERAL ............................................................................................... 3-26

Drain plug inspection......................................................................... 3-26

Lubrication points .............................................................................. 3-26

ProCarManuals.com

Page 51 of 347

3-2

E

INSP

ADJ

CONTROL SYSTEM

PERIODIC SERVICE

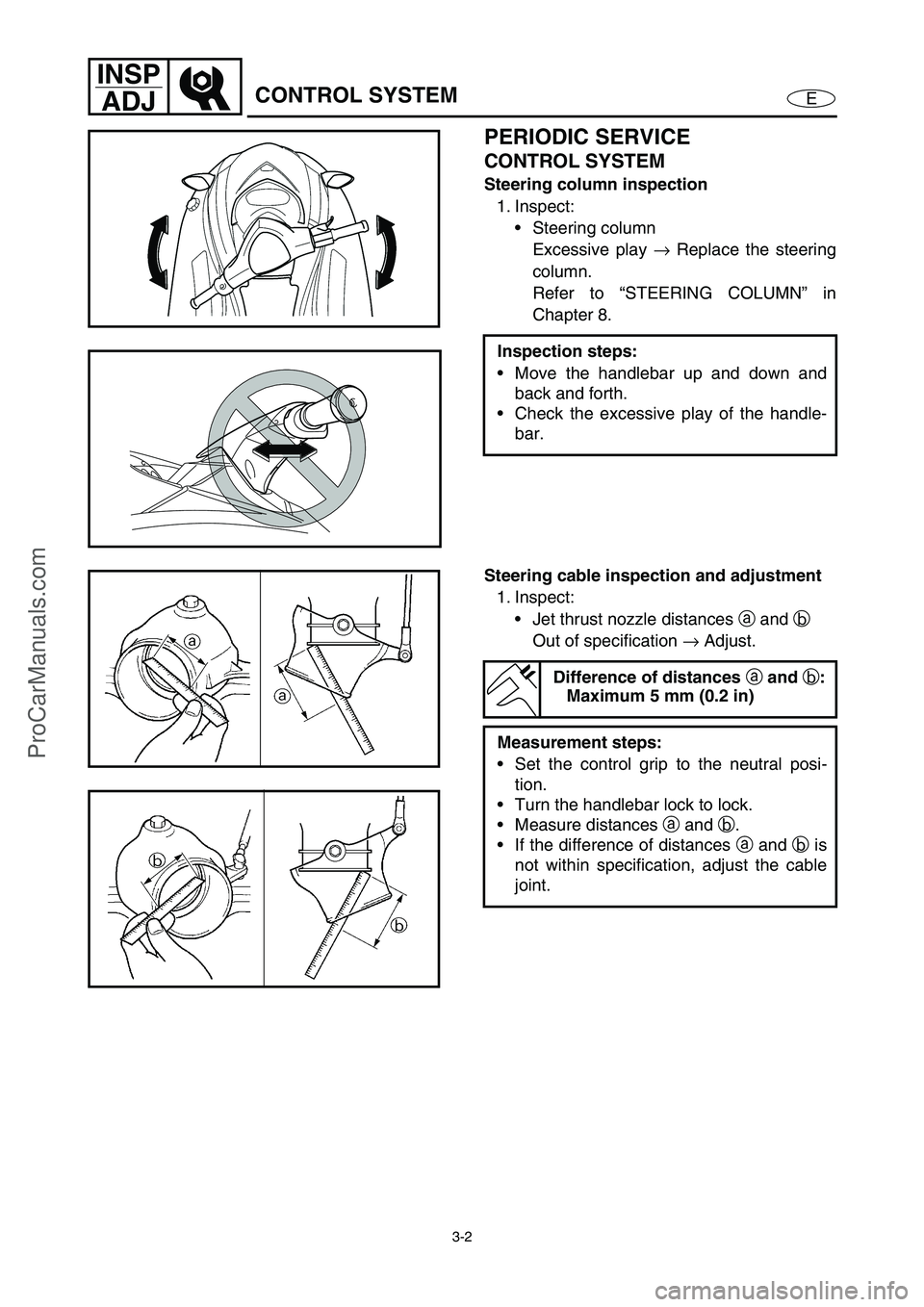

CONTROL SYSTEM

Steering column inspection

1. Inspect:

Steering column

Excessive play →

Replace the steering

column.

Refer to “STEERING COLUMN” in

Chapter 8.

Inspection steps:

Move the handlebar up and down and

back and forth.

Check the excessive play of the handle-

bar.

Steering cable inspection and adjustment

1. Inspect:

Jet thrust nozzle distances a

and b

Out of specification →

Adjust.

Difference of distances

a and

b:

Maximum 5 mm (0.2 in)

Measurement steps:

Set the control grip to the neutral posi-

tion.

Turn the handlebar lock to lock.

Measure distances a

and b

.

If the difference of distances a

and b

is

not within specification, adjust the cable

joint.

ProCarManuals.com

Page 77 of 347

EFUEL

1

2

3

4

5

6

7

8

9

CHAPTER 4

FUEL SYSTEM

FUEL TANK AND FUEL PUMP MODULE...................................................... 4-1

EXPLODED DIAGRAM ............................................................................. 4-1

REMOVAL AND INSTALLATION CHART ................................................ 4-1

SERVICE POINTS .................................................................................... 4-4

Fuel hose disconnection ..................................................................... 4-4

Fuel pump module removal................................................................. 4-4

Check valve inspection ....................................................................... 4-4

Fuel sender inspection ........................................................................ 4-5

Fuel tank inspection ............................................................................ 4-5

Fuel hose inspection ........................................................................... 4-5

Fuel pump filter inspection .................................................................. 4-5

Fuel pump module installation ............................................................ 4-6

Fuel hose connect ............................................................................... 4-6

FUEL INJECTION SYSTEM ............................................................................ 4-7

EXPLODED DIAGRAM ............................................................................. 4-7

REMOVAL AND INSTALLATION CHART ................................................ 4-7

THROTTLE BODY ASSEMBLY AND INTAKE MANIFOLD ........................ 4-10

EXPLODED DIAGRAM ........................................................................... 4-10

REMOVAL AND INSTALLATION CHART .............................................. 4-10

SERVICE POINTS .................................................................................. 4-12

Fuel hose clamps removal ................................................................ 4-12

Hose clamps installation ................................................................... 4-12

Fuel hose disconnection ................................................................... 4-12

Fuel line inspection ........................................................................... 4-13

Fuel hose installation (replacing with new fuel hose) ........................ 4-14

Fuel hose connection ........................................................................ 4-14

Fuel injectors inspection.................................................................... 4-15

Throttle body assembly inspection .................................................... 4-15

Accelerator position sensor inspection.............................................. 4-15

Intake assembly installation .............................................................. 4-16

Air filter case assembly installation ................................................... 4-17

Fuel pressure measurement ............................................................. 4-17

ProCarManuals.com

Page 78 of 347

4-1

EFUELFUEL TANK AND FUEL PUMP MODULE

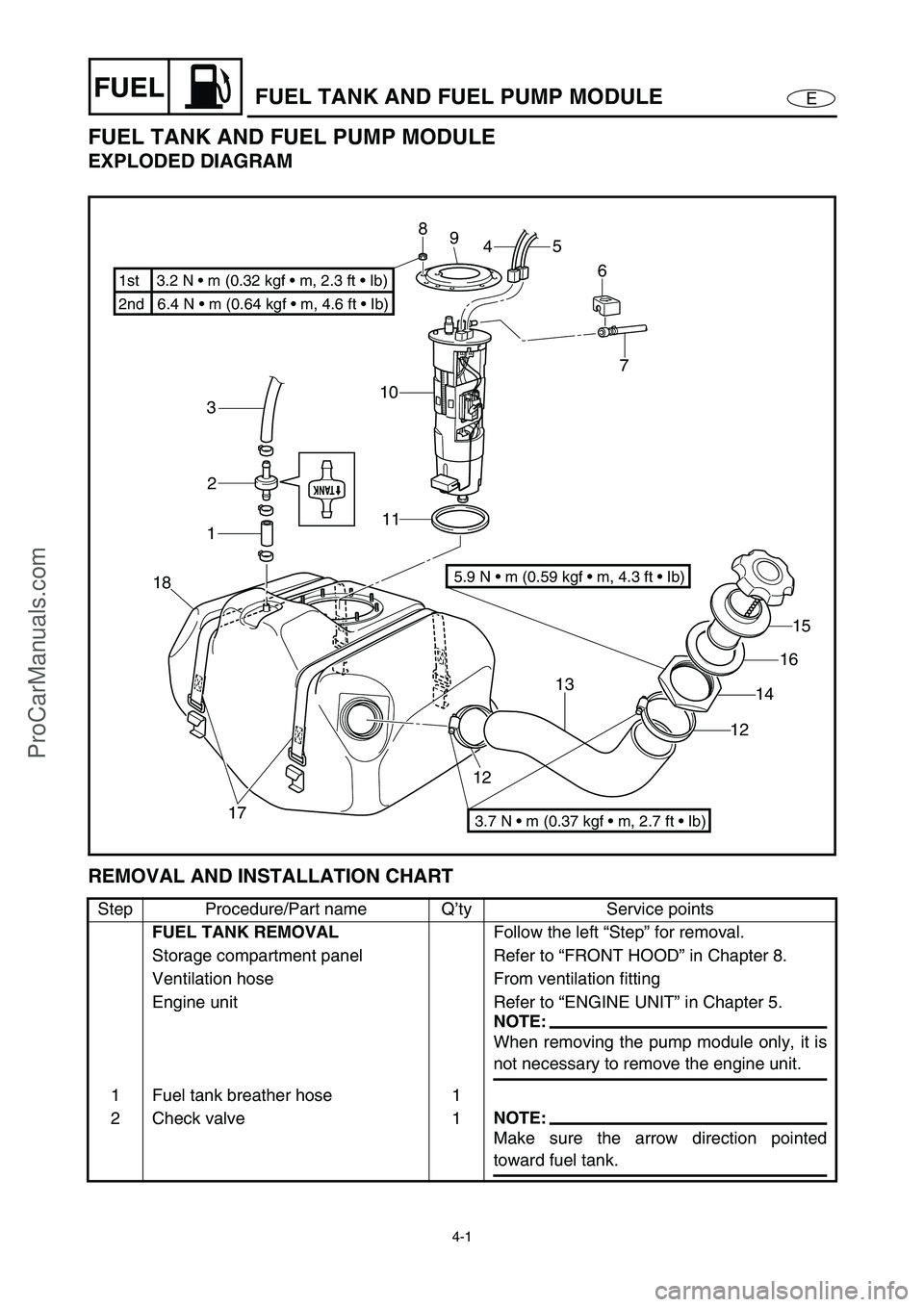

FUEL TANK AND FUEL PUMP MODULE

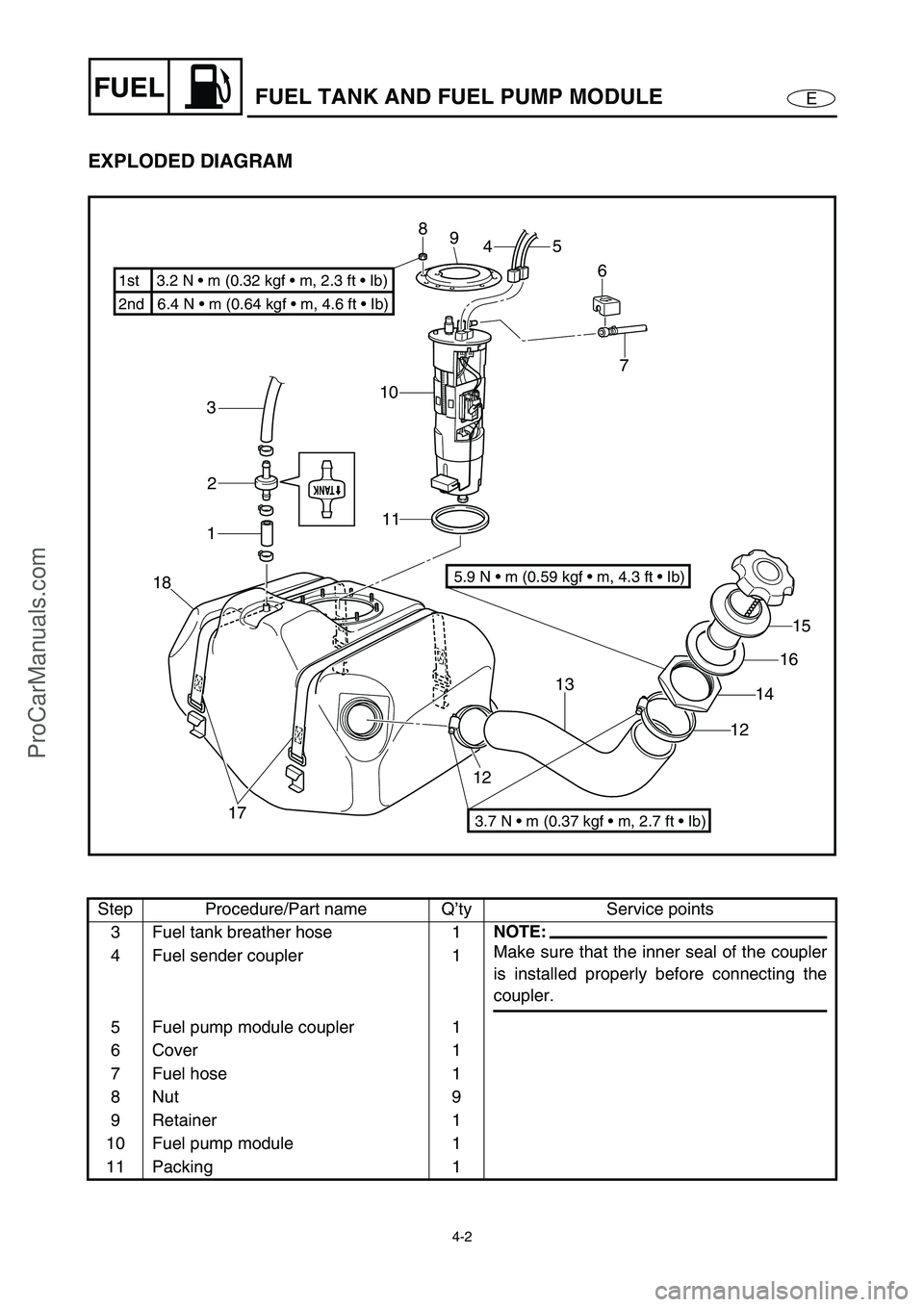

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

FUEL TANK REMOVAL

Follow the left “Step” for removal.

Storage compartment panel Refer to “FRONT HOOD” in Chapter 8.

Ventilation hose From ventilation fitting

Engine unit Refer to “ENGINE UNIT” in Chapter 5.

NOTE:

When removing the pump module only, it is

not necessary to remove the engine unit.

1 Fuel tank breather hose 1

2 Check valve 1

NOTE:

Make sure the arrow direction pointed

toward fuel tank.

7

10

11 3

2

1

18

17121315

16

14

12 6 5

4 8

9

2nd 6.4 N • m (0.64 kgf m, 4.6 ft Ib) 1st 3.2 N m (0.32 kgf m, 2.3 ft Ib)

3.7 N m (0.37 kgf m, 2.7 ft Ib)

5.9 N m (0.59 kgf m, 4.3 ft Ib)

ProCarManuals.com

Page 79 of 347

4-2

EFUELFUEL TANK AND FUEL PUMP MODULE

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

3 Fuel tank breather hose 1

NOTE:

Make sure that the inner seal of the coupler

is installed properly before connecting the

coupler. 4 Fuel sender coupler 1

5 Fuel pump module coupler 1

6 Cover 1

7 Fuel hose 1

8Nut 9

9 Retainer 1

10 Fuel pump module 1

11 Packing 1

7

10

11 3

2

1

18

17121315

16

14

12 6 5

4 8

9

2nd 6.4 N m (0.64 kgf m, 4.6 ft Ib) 1st 3.2 N m (0.32 kgf m, 2.3 ft Ib)

3.7 N m (0.37 kgf m, 2.7 ft Ib)

5.9 N m (0.59 kgf m, 4.3 ft Ib)

ProCarManuals.com

Page 80 of 347

4-3

EFUELFUEL TANK AND FUEL PUMP MODULE

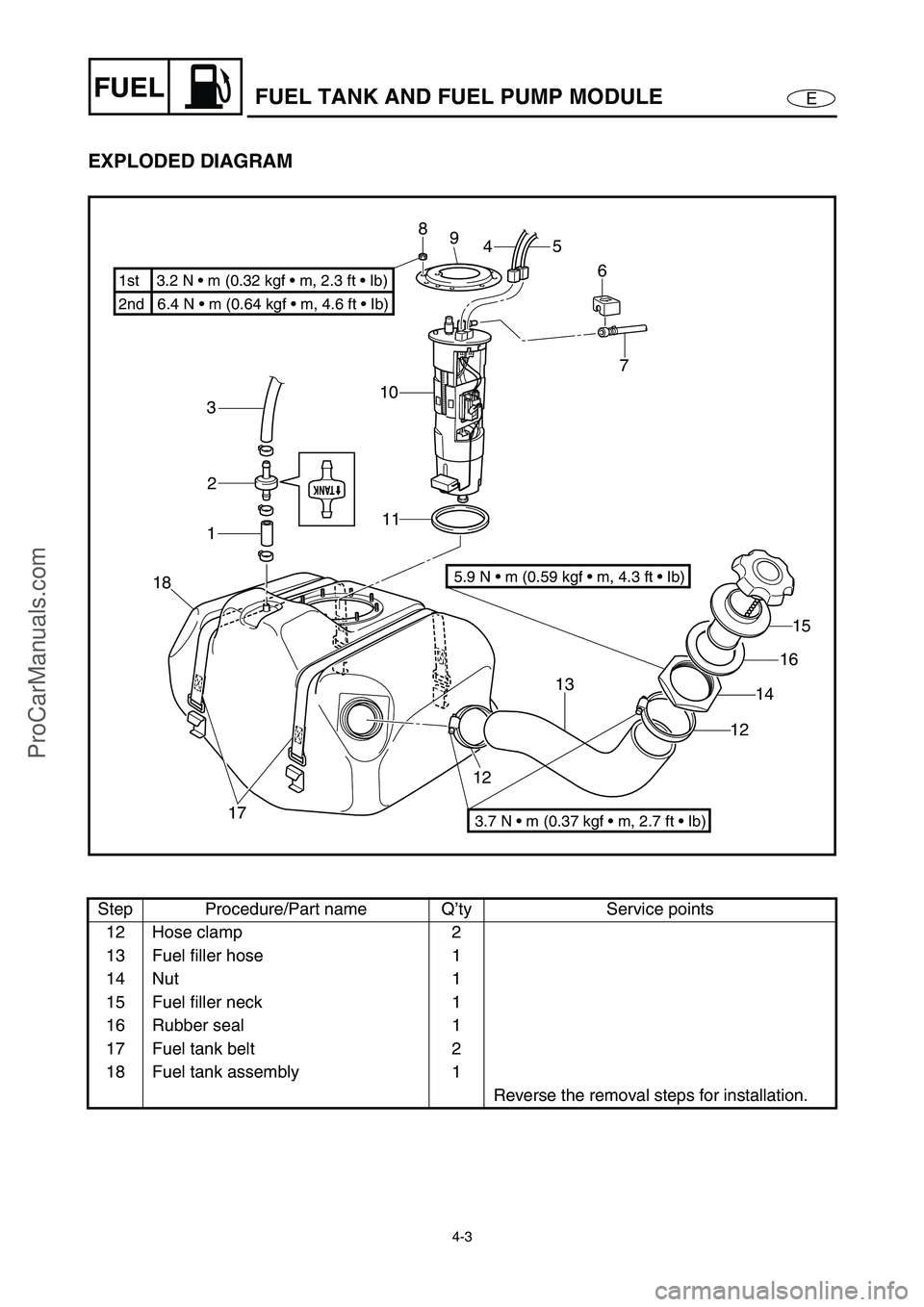

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

12 Hose clamp 2

13 Fuel filler hose 1

14 Nut 1

15 Fuel filler neck 1

16 Rubber seal 1

17 Fuel tank belt 2

18 Fuel tank assembly 1

Reverse the removal steps for installation.

7

10

11 3

2

1

18

17121315

16

14

12 6 5

4 8

9

2nd 6.4 N m (0.64 kgf m, 4.6 ft Ib) 1st 3.2 N m (0.32 kgf m, 2.3 ft Ib)

3.7 N m (0.37 kgf m, 2.7 ft Ib)

5.9 N m (0.59 kgf m, 4.3 ft Ib)

ProCarManuals.com