service YAMAHA VX110 2005 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: VX110, Model: YAMAHA VX110 2005Pages: 347, PDF Size: 14.17 MB

Page 81 of 347

4-4

EFUELFUEL TANK AND FUEL PUMP MODULE

SERVICE POINTS

Fuel hose disconnection

1. Disconnect:

Fuel hose

Refer to “FUEL INJECTION SYSTEM”.

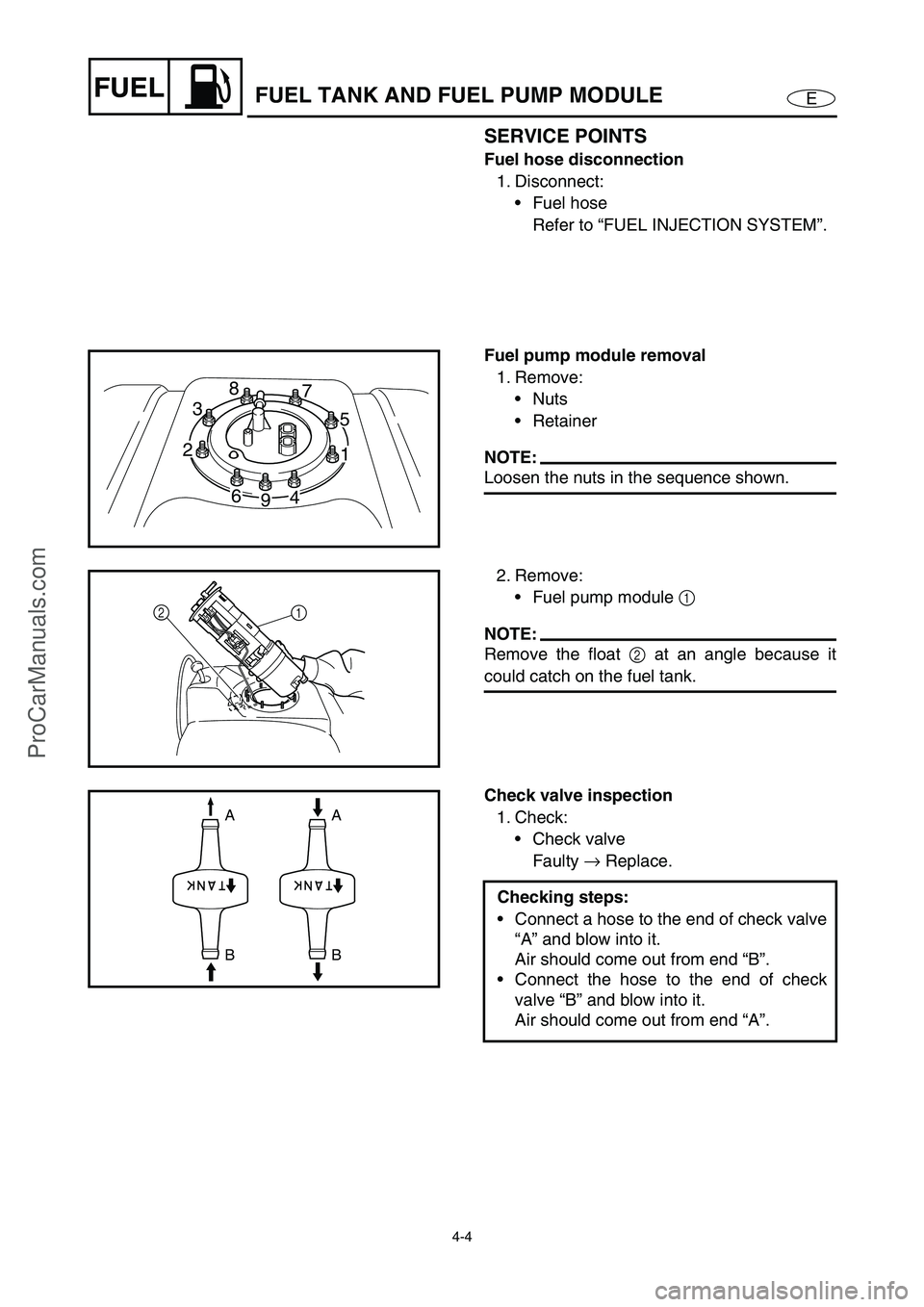

Fuel pump module removal

1. Remove:

Nuts

Retainer

NOTE:

Loosen the nuts in the sequence shown.

238

7

5

1 238

7

5

1

4 4

9 6 6

2. Remove:

Fuel pump module 1

NOTE:

Remove the float 2

at an angle because it

could catch on the fuel tank.

12

Check valve inspection

1. Check:

Check valve

Faulty →

Replace.

Checking steps:

Connect a hose to the end of check valve

“A” and blow into it.

Air should come out from end “B”.

Connect the hose to the end of check

valve “B” and blow into it.

Air should come out from end “A”.

A A

B B

ProCarManuals.com

Page 84 of 347

4-7

EFUELFUEL INJECTION SYSTEM

FUEL INJECTION SYSTEM

EXPLODED DIAGRAM

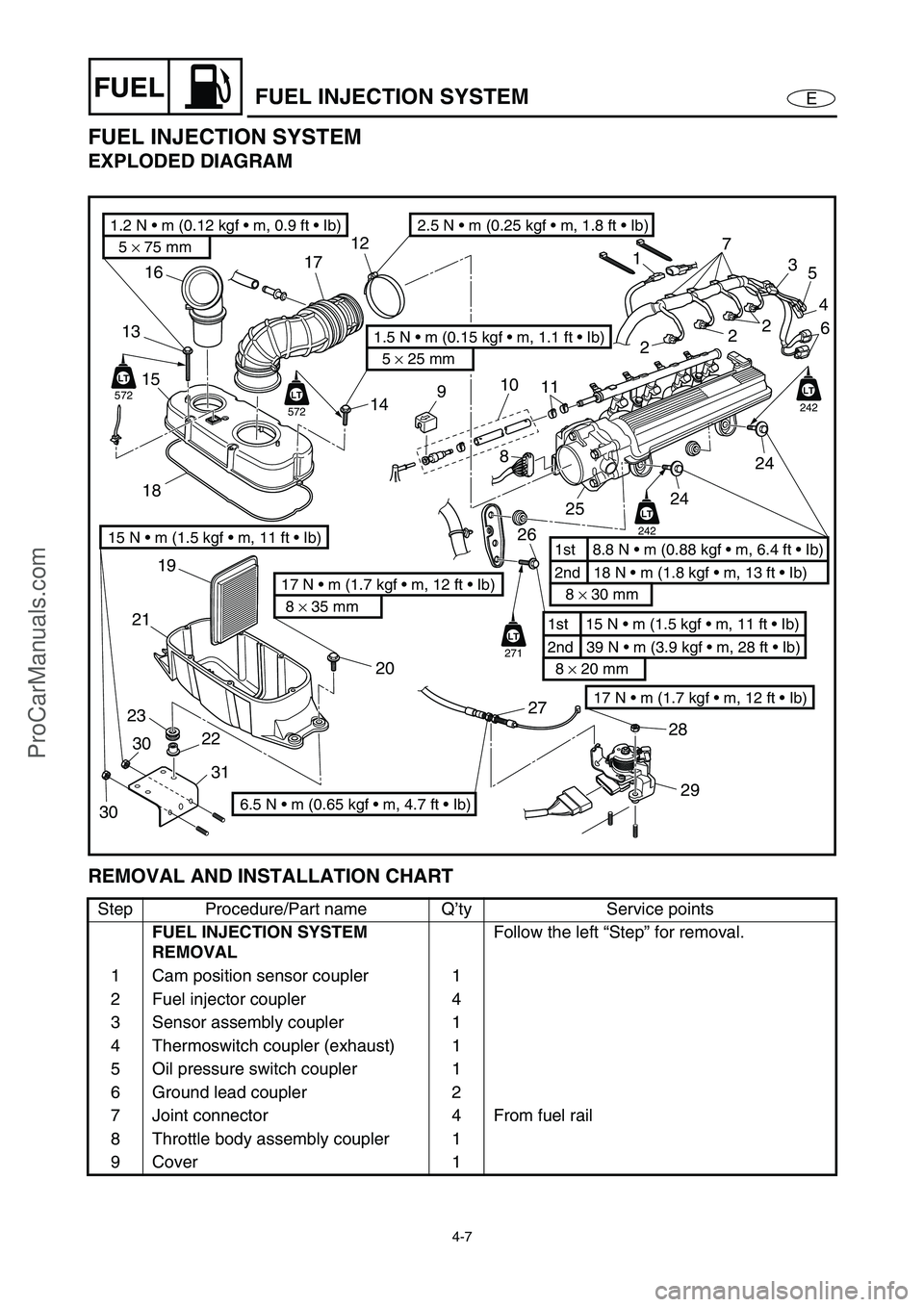

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

FUEL INJECTION SYSTEM

REMOVALFollow the left “Step” for removal.

1 Cam position sensor coupler 1

2 Fuel injector coupler 4

3 Sensor assembly coupler 1

4 Thermoswitch coupler (exhaust) 1

5 Oil pressure switch coupler 1

6 Ground lead coupler 2

7 Joint connector 4 From fuel rail

8 Throttle body assembly coupler 1

9 Cover 1

17 N m (1.7 kgf m, 12 ft Ib)

5 × 75 mm

1.2 N m (0.12 kgf m, 0.9 ft Ib)

5 × 25 mm

1.5 N m (0.15 kgf m, 1.1 ft Ib)

8 × 35 mm

17 N m (1.7 kgf m, 12 ft Ib)2nd 18 N m (1.8 kgf m, 13 ft Ib) 1st 8.8 N m (0.88 kgf m, 6.4 ft Ib)

8 × 30 mm

2nd 39 N m (3.9 kgf m, 28 ft Ib) 1st 15 N m (1.5 kgf m, 11 ft Ib)

8 × 20 mm

LT

242

LT

242

LT

271

LT

572

LT

LT

572

LT

22 2320 19

2118 15 1316

14 1712

17

3

2

2

25

4

6

24

24

25 8

26

27

28

29

11 10

9

2.5 N m (0.25 kgf m, 1.8 ft Ib)

6.5 N m (0.65 kgf m, 4.7 ft Ib)

15 N m (1.5 kgf m, 11 ft Ib)

3031

30

ProCarManuals.com

Page 85 of 347

4-8

EFUELFUEL INJECTION SYSTEM

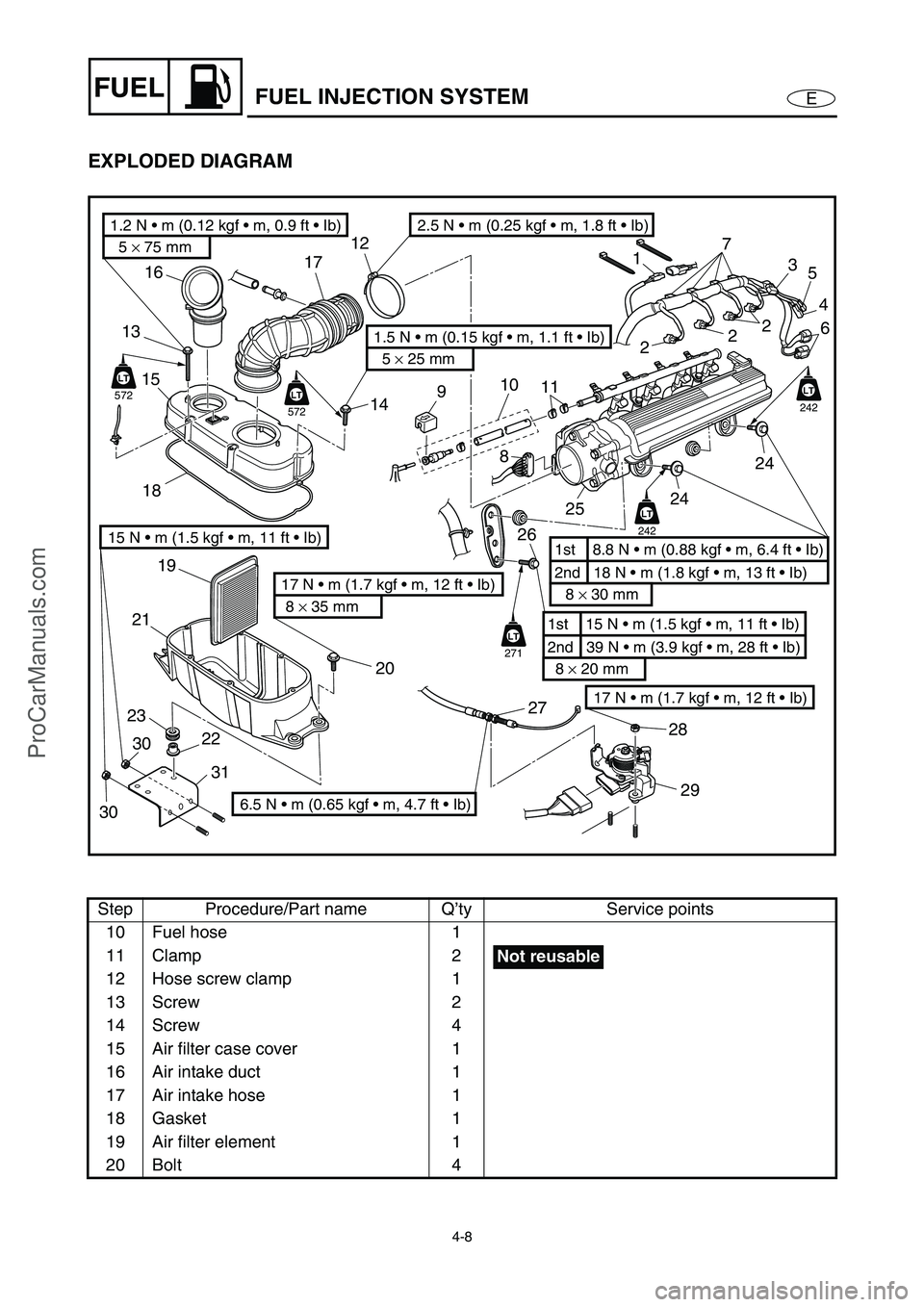

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

10 Fuel hose 1

11 Clamp 2

12 Hose screw clamp 1

13 Screw 2

14 Screw 4

15 Air filter case cover 1

16 Air intake duct 1

17 Air intake hose 1

18 Gasket 1

19 Air filter element 1

20 Bolt 4

17 N m (1.7 kgf m, 12 ft Ib)

5 × 75 mm

1.2 N m (0.12 kgf m, 0.9 ft Ib)

5 × 25 mm

1.5 N m (0.15 kgf m, 1.1 ft Ib)

8 × 35 mm

17 N m (1.7 kgf m, 12 ft Ib)2nd 18 N m (1.8 kgf m, 13 ft Ib) 1st 8.8 N m (0.88 kgf m, 6.4 ft Ib)

8 × 30 mm

2nd 39 N m (3.9 kgf m, 28 ft Ib) 1st 15 N m (1.5 kgf m, 11 ft Ib)

8 × 20 mm

LT

242

LT

242

LT

271

LT

572

LT

LT

572

LT

22 2320 19

2118 15 1316

14 1712

17

3

2

2

25

4

6

24

24

25 8

26

27

28

29

11 10

9

2.5 N m (0.25 kgf m, 1.8 ft Ib)

6.5 N m (0.65 kgf m, 4.7 ft Ib)

15 N m (1.5 kgf m, 11 ft Ib)

3031

30

Not reusable

ProCarManuals.com

Page 86 of 347

4-9

EFUELFUEL INJECTION SYSTEM

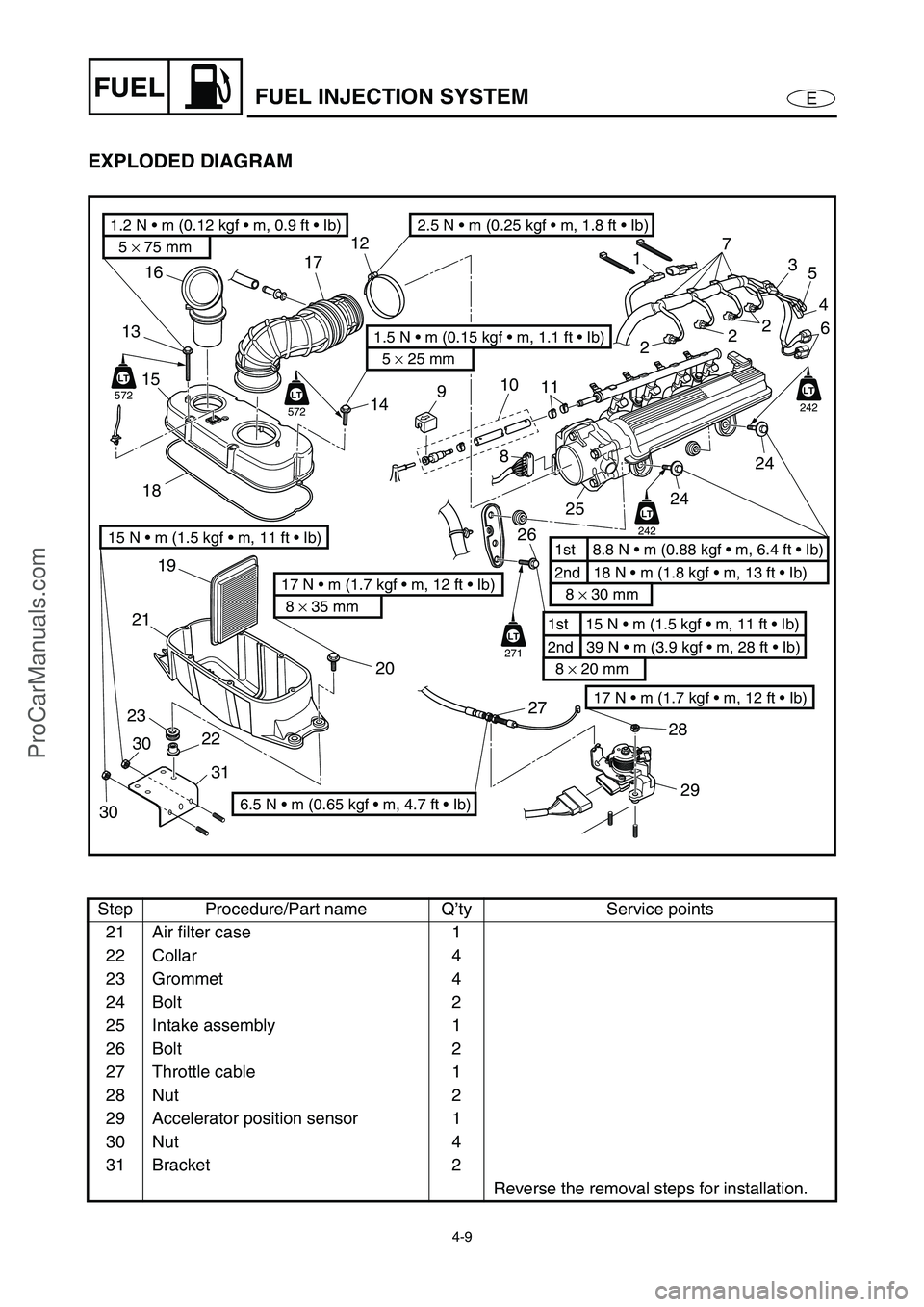

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

21 Air filter case 1

22 Collar 4

23 Grommet 4

24 Bolt 2

25 Intake assembly 1

26 Bolt 2

27 Throttle cable 1

28 Nut 2

29 Accelerator position sensor 1

30 Nut 4

31 Bracket 2

Reverse the removal steps for installation.

17 N m (1.7 kgf m, 12 ft Ib)

5 × 75 mm

1.2 N m (0.12 kgf m, 0.9 ft Ib)

5 × 25 mm

1.5 N m (0.15 kgf m, 1.1 ft Ib)

8 × 35 mm

17 N m (1.7 kgf m, 12 ft Ib)2nd 18 N m (1.8 kgf m, 13 ft Ib) 1st 8.8 N m (0.88 kgf m, 6.4 ft Ib)

8 × 30 mm

2nd 39 N m (3.9 kgf m, 28 ft Ib) 1st 15 N m (1.5 kgf m, 11 ft Ib)

8 × 20 mm

LT

242

LT

242

LT

271

LT

572

LT

LT

572

LT

22 2320 19

2118 15 1316

14 1712

17

3

2

2

25

4

6

24

24

25 8

26

27

28

29

11 10

9

2.5 N m (0.25 kgf m, 1.8 ft Ib)

6.5 N m (0.65 kgf m, 4.7 ft Ib)

15 N m (1.5 kgf m, 11 ft Ib)

3031

30

ProCarManuals.com

Page 87 of 347

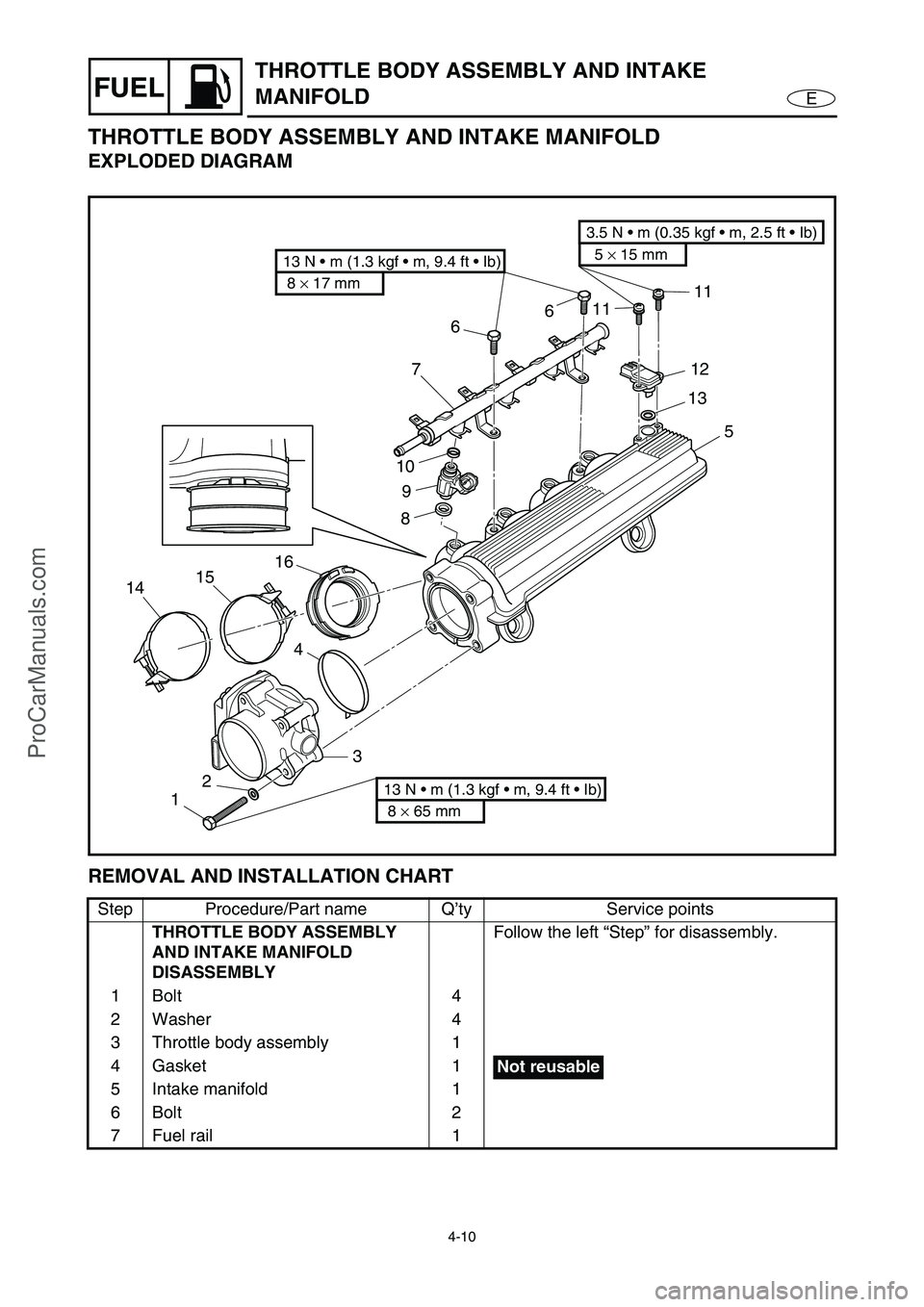

4-10

EFUEL

THROTTLE BODY ASSEMBLY AND INTAKE

MANIFOLD

THROTTLE BODY ASSEMBLY AND INTAKE MANIFOLD

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

THROTTLE BODY ASSEMBLY

AND INTAKE MANIFOLD

DISASSEMBLYFollow the left “Step” for disassembly.

1Bolt 4

2 Washer 4

3 Throttle body assembly 1

4Gasket 1

5 Intake manifold 1

6Bolt 2

7 Fuel rail 1

8 × 17 mm

13 N m (1.3 kgf m, 9.4 ft Ib)5 × 15 mm

3.5 N m (0.35 kgf m, 2.5 ft Ib)

8 × 65 mm

13 N m (1.3 kgf m, 9.4 ft Ib)123 4 14151689 107661111

12

13

5

Not reusable

ProCarManuals.com

Page 88 of 347

4-11

EFUEL

THROTTLE BODY ASSEMBLY AND INTAKE

MANIFOLD

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

8Gasket 4

9 Fuel injector 4

10 O-ring 4

11 Screw 2

12 Sensor assembly 1

13 O-ring 1

14 Clamp 4

15 Clamp 4

16 Intake manifold joint 4

Reverse the disassembly steps for

assembly.

8 × 17 mm

13 N m (1.3 kgf m, 9.4 ft Ib)5 × 15 mm

3.5 N m (0.35 kgf m, 2.5 ft Ib)

8 × 65 mm

13 N m (1.3 kgf m, 9.4 ft Ib)123 4 14151689 107661111

12

13

5

Not reusable

Not reusable

Not reusable

ProCarManuals.com

Page 89 of 347

4-12

EFUEL

THROTTLE BODY ASSEMBLY AND INTAKE

MANIFOLD

SERVICE POINTS

Fuel hose clamps removal

1. Remove:

Fuel hose clamps

CAUTION:

If the fuel hose clamps are removed with-

out cutting the joint first, the fuel hose will

be damaged.

Hose clamps installation

1. Install:

Fuel hose clamps

WARNING

Do not reuse the fuel hose clamps, always

replace them with new ones.

NOTE:

Crimp the fuel hose clamps properly to

securely fasten them.

Fuel hose disconnection

WARNING

Before disconnecting the hose, remove the

fuel tank filler cap to reduce any pressure

inside the fuel tank, and then disconnect

the battery negative lead to cut off the elec-

tric current to the electrical systems.

1. Wrap the quick connector with a cloth, and

then rotate the quick connector tab 1

to

the stopper position a

.

WARNING

If the quick connector is removed sud-

denly, pressurized fuel could spray out. To

gradually release the fuel pressure, be sure

to remove the quick connector slowly.

1

a

ProCarManuals.com

Page 97 of 347

EPOWR

1

2

3

4

5

6

7

8

9

CHAPTER 5

POWER UNIT

ENGINE UNIT .................................................................................................. 5-1

EXPLODED DIAGRAM ............................................................................. 5-1

REMOVAL AND INSTALLATION CHART ................................................ 5-1

SERVICE POINTS .................................................................................... 5-4

Compression pressure measurement ................................................. 5-4

Engine unit removal ............................................................................ 5-6

Shim removal ...................................................................................... 5-6

Engine mount inspection ..................................................................... 5-6

Coupling clearance inspection ............................................................ 5-7

EXHAUST PIPES 1 AND 2.............................................................................. 5-8

EXPLODED DIAGRAM ............................................................................. 5-8

REMOVAL AND INSTALLATION CHART ................................................ 5-8

EXHAUST MANIFOLD .................................................................................. 5-11

EXPLODED DIAGRAM ........................................................................... 5-11

REMOVAL AND INSTALLATION CHART .............................................. 5-11

OIL TANK ...................................................................................................... 5-12

EXPLODED DIAGRAM ........................................................................... 5-12

REMOVAL AND INSTALLATION CHART .............................................. 5-12

SERVICE POINTS .................................................................................. 5-17

Oil tank removal ................................................................................ 5-17

Oil strainer inspection........................................................................ 5-18

Oil tank installation ............................................................................ 5-18

OIL PUMP ...................................................................................................... 5-21

EXPLODED DIAGRAM ........................................................................... 5-21

REMOVAL AND INSTALLATION CHART .............................................. 5-21

SERVICE POINTS .................................................................................. 5-23

Oil strainer inspection........................................................................ 5-23

Oil pump installation .......................................................................... 5-23

REDUCTION DRIVE GEAR .......................................................................... 5-24

EXPLODED DIAGRAM ........................................................................... 5-24

REMOVAL AND INSTALLATION CHART .............................................. 5-24

SERVICE POINTS .................................................................................. 5-28

Drive coupling removal...................................................................... 5-28

Drive shaft removal ........................................................................... 5-28

Bearing removal ................................................................................ 5-28

Oil pump drive shaft inspection ......................................................... 5-29

Drive shaft inspection ........................................................................ 5-29

Bearing installing ............................................................................... 5-30

Drive shaft installation ....................................................................... 5-32

Drive coupling installation ................................................................. 5-32

ProCarManuals.com

Page 98 of 347

EPOWR

GENERATOR AND STARTER MOTOR ....................................................... 5-33

EXPLODED DIAGRAM ........................................................................... 5-33

REMOVAL AND INSTALLATION CHART ............................................. 5-33

SERVICE POINTS .................................................................................. 5-38

Flywheel magneto removal ............................................................... 5-38

Starter clutch inspection .................................................................... 5-38

Flywheel magneto installation ........................................................... 5-40

CAMSHAFTS................................................................................................. 5-41

EXPLODED DIAGRAM ........................................................................... 5-41

REMOVAL AND INSTALLATION CHART .............................................. 5-41

SERVICE POINTS .................................................................................. 5-46

Camshaft removal ............................................................................. 5-46

Camshaft inspection.......................................................................... 5-47

Camshaft sprockets inspection ......................................................... 5-49

Timing chain tensioner inspection ..................................................... 5-49

Camshaft installation ......................................................................... 5-50

CYLINDER HEAD.......................................................................................... 5-54

EXPLODED DIAGRAM ........................................................................... 5-54

REMOVAL AND INSTALLATION CHART ............................................. 5-54

SERVICE POINTS .................................................................................. 5-56

Cylinder head removal ...................................................................... 5-56

Cylinder head inspection ................................................................... 5-56

Cylinder head installation .................................................................. 5-57

VALVES AND VALVE SPRINGS .................................................................. 5-59

EXPLODED DIAGRAM ........................................................................... 5-59

REMOVAL AND INSTALLATION CHART ............................................. 5-59

SERVICE POINTS .................................................................................. 5-61

Valve removal ................................................................................... 5-61

Valve spring inspection ..................................................................... 5-62

Valve inspection ................................................................................ 5-62

Valve guide inspection ...................................................................... 5-64

Valve guide replacement................................................................... 5-64

Valve seat inspection ........................................................................ 5-66

Valve seat reface .............................................................................. 5-67

Valve installation ............................................................................... 5-69

CRANKCASE ................................................................................................ 5-71

EXPLODED DIAGRAM ........................................................................... 5-71

REMOVAL AND INSTALLATION CHART .............................................. 5-71

SERVICE POINTS .................................................................................. 5-75

Crankcase disassembly .................................................................... 5-75

Crankcase inspection ........................................................................ 5-76

Timing chain inspection..................................................................... 5-76

Crankcase assembly ......................................................................... 5-77

ProCarManuals.com

Page 99 of 347

EPOWR

CONNECTING RODS AND PISTONS .......................................................... 5-80

EXPLODED DIAGRAM ........................................................................... 5-80

REMOVAL AND INSTALLATION CHART .............................................. 5-80

SERVICE POINTS .................................................................................. 5-82

Connecting rod and piston removal .................................................. 5-82

Cylinder and piston inspection .......................................................... 5-83

Piston ring inspection ........................................................................ 5-84

Piston pin inspection ......................................................................... 5-86

Connecting rod inspection................................................................. 5-87

Connecting rod and piston installation .............................................. 5-89

CRANKSHAFT .............................................................................................. 5-93

EXPLODED DIAGRAM ........................................................................... 5-93

REMOVAL AND INSTALLATION CHART .............................................. 5-93

SERVICE POINTS .................................................................................. 5-94

Crankshaft removal ........................................................................... 5-94

Crankshaft inspection........................................................................ 5-94

Crankshaft installation ....................................................................... 5-97

COOLING WATER HOSE ............................................................................. 5-98

EXPLODED DIAGRAM ........................................................................... 5-98

REMOVAL AND INSTALLATION CHART .............................................. 5-98

ProCarManuals.com