clock YAMAHA VX110 2005 Service Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: VX110, Model: YAMAHA VX110 2005Pages: 347, PDF Size: 14.17 MB

Page 22 of 347

2-1

ESPECGENERAL SPECIFICATIONS

GENERAL SPECIFICATIONS

Item UnitModel

VX110 Sport VX110 Deluxe

Model code

Hull F1K

Engine/jet 6D3

Dimensions

Length mm (in) 3,220 (126.8)

Width mm (in) 1,170 (46.1)

Height mm (in) 1,150 (45.3)

Dry weight kg (lb) 325 (716)

Maximum capacity Person/kg (lb) 3/240 (530)

Performance

Maximum output kW (PS) @ r/min 81.0 (110) @ 8,000

Maximum fuel consumption l/h (US gal/h,

lmp gal/h)28.0 (7.4, 6.2)

Cruising range h 2.1

Engine

Engine type 4-stroke, L4, DOHC

Displacement cm

3 (cu. in) 1,052 (64.2)

Bore ×

stroke mm (in) 76.0 ×

58.0 (2.99 ×

2.28)

Compression ratio 11.4:1

Exhaust system Wet exhaust

Lubrication system Dry sump

Cooling system Water cooled

Starting system Electric starter

Ignition system TCI

Ignition timing Degree BTDC 5–BTDC 35

Spark plug model

(manufacturer)CR9EB (NGK)

Spark plug gap mm (in) 0.7–0.8 (0.028–0.031)

Battery capacity V/Ah 12/19

Generator output A @ r/min 12–21 @ 6,000

Drive unit

Propulsion system Jet pump

Jet pump type Axial flow, single stage

Impeller rotation Counterclockwise (viewed from rear)

Transmission Constant mesh 1-speed

Jet thrust nozzle horizontal

angleDegree 24 + 24

Jet thrust nozzle trim angle Degree 3

Reverse system—Reverse gate

ProCarManuals.com

Page 58 of 347

3-9

E

INSP

ADJ

POWER UNIT

3. Measure:

Valve clearance

Out of specification →

Adjust.

Valve clearance (cold):

Intake valve:

0.11–0.20 mm

(0.0043–0.0079 in)

Exhaust valve:

0.25–0.34 mm

(0.0098–0.0134 in)

Measurement steps:

Turn the drive coupling counterclockwise,

and then check if cylinder #1 is at TDC of

the compression stroke with a dial gauge.

NOTE:

TDC of the compression stroke can be

found when the camshaft lobes are turned

away from each other.

Measure the valve clearance with a thick-

ness gauge 1

.

NOTE:

If the valve clearance is incorrect, record

the measured reading.

Measure the valve clearance in the follow-

ing sequence.

Valve clearance measuring sequence:

Cylinder #1

→ #2

→ #4

→ #3

ÈBow end

To measure the valve clearances of the

other cylinders, starting with cylinder #1

at TDC, turn the drive coupling counter-

clockwise as specified in the following

table.

ÉDegrees that the crankshaft is turned clock-

wise

ÊCylinder

ËCombustion cycle

Cylinder #2 180°

Cylinder #4 360°

Cylinder #3 540°

INEX

1

7205403601800

#4 #3

#2

#1

É

Ê

Ë

Ë

Ë

Ë

ProCarManuals.com

Page 59 of 347

3-10

E

INSP

ADJ

POWER UNIT

4. Remove:

Timing chain tensioner cap bolt 1

Gasket

1

5. Turn the timing chain tensioner rod fully

clockwise with a thin screwdriver 1

.

NOTE:

Make sure that the tensioner rod has been fully

turned clockwise.

1

6. Remove:

Intake camshaft caps

Exhaust camshaft caps

Timing chain

(from the camshaft sprockets)

Intake camshaft

Exhaust camshaft

NOTE:

Refer to “CAMSHAFTS” in Chapter 5.

When removing the timing chain and cam-

shafts, fasten the timing chain with a wire to

prevent it from falling into the crankcase.

ProCarManuals.com

Page 61 of 347

3-12

E

INSP

ADJ

POWER UNIT

NOTE:

The new valve pad number is only an

approximation. The valve clearance must

be measured again and the above steps

should be repeated if the measurement is

still incorrect.

Install the new valve pad 5

and the valve

lifter 6

.

NOTE:

Lubricate the valve pad with molybdenum

disulfide grease.

Lubricate the valve lifter with molybdenum

disulfide oil.

The valve lifter must turn smoothly when

rotated by hand.

Install the valve lifter and the valve pad in

the correct place.

Install the exhaust and intake camshafts,

timing chain, and camshaft caps.

T R..

Camshaft cap bolt:

10 N m (1.0 kgf m, 7.2 ft lb)

NOTE:

Refer to “Camshaft installation — CAM-

SHAFTS” in Chapter 5.

Lubricate the camshafts, camshaft lobes,

and camshaft journals.

Install the exhaust camshaft first.

Align the camshaft marks with the cam-

shaft cap marks.

Turn the crankshaft clockwise several full

turns to seat the parts.

Measure the valve clearance again.

If the valve clearance is still out of specifi-

cation, repeat all of the valve clearance

adjustment steps until the specified clear-

ance is obtained.

6

5

ProCarManuals.com

Page 138 of 347

5-39

EPOWRGENERATOR AND STARTER MOTOR

2. Check:

Starter clutch 1

Starter gear 2

Burrs/chips/roughness/wear →

Replace

the defective part(s).

3. Check:

Starter clutch gear’s contacting surfaces

a

Damage/pitting/wear →

Replace the

starter clutch gear.

12

a

4. Check:

Starter clutch operation

Checking steps:

Install the starter gear 1

onto the starter

clutch 2

and hold the starter clutch.

When turning the starter gear clockwise

È, it should turn freely, otherwise the

starter clutch is faulty and must be

replaced.

When turning the starter gear counter-

clockwise É, the starter clutch and the

starter gear should engage, otherwise

the starter clutch is faulty and must be

replaced.

ProCarManuals.com

Page 145 of 347

5-46

EPOWRCAMSHAFTS

SERVICE POINTS

Camshaft removal

1. Install:

Dial gauge needle

Dial gauge stand 1

(into spark plug hole #1)

Dial gauge 2

2. Turn the drive coupling counterclockwise,

and then check if cylinder #1 is at TDC of

the compression stroke with a dial gauge.

NOTE:

TDC on the compression stroke can be found

when the camshaft lobes are turned away from

each other.

Dial gauge stand:

90890-06583

Dial gauge needle:

90890-06584

Dial gauge stand set:

YB-06585/90890-06585

Dial indicator gauge:

YU-03097

Dial gauge set:

90890-01252

2

1

INEX

3. Make the alignment marks a on the timing

chain and camshaft sprockets.

a

4. Remove:

Timing chain tensioner 1

Gasket

1

ProCarManuals.com

Page 148 of 347

5-49

EPOWRCAMSHAFTS

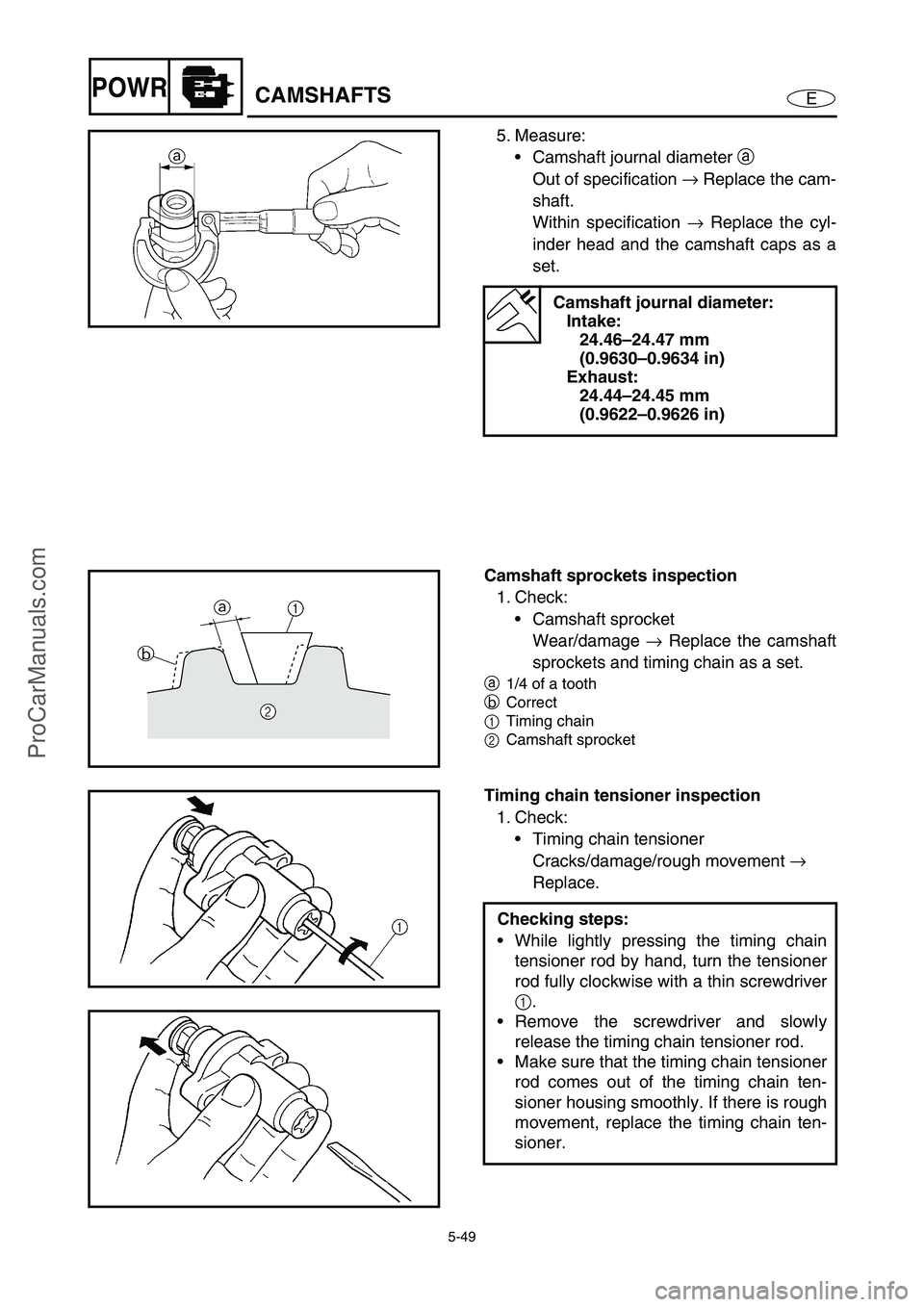

5. Measure:

Camshaft journal diameter a

Out of specification →

Replace the cam-

shaft.

Within specification →

Replace the cyl-

inder head and the camshaft caps as a

set.

Camshaft journal diameter:

Intake:

24.46–24.47 mm

(0.9630–0.9634 in)

Exhaust:

24.44–24.45 mm

(0.9622–0.9626 in)

Camshaft sprockets inspection

1. Check:

Camshaft sprocket

Wear/damage →

Replace the camshaft

sprockets and timing chain as a set.

a

1/4 of a tooth

b

Correct

1Timing chain

2Camshaft sprocket

Timing chain tensioner inspection

1. Check:

Timing chain tensioner

Cracks/damage/rough movement →

Replace.

Checking steps:

While lightly pressing the timing chain

tensioner rod by hand, turn the tensioner

rod fully clockwise with a thin screwdriver

1

.

Remove the screwdriver and slowly

release the timing chain tensioner rod.

Make sure that the timing chain tensioner

rod comes out of the timing chain ten-

sioner housing smoothly. If there is rough

movement, replace the timing chain ten-

sioner.

ProCarManuals.com

Page 149 of 347

5-50

EPOWRCAMSHAFTS

Camshaft installation

1. Install:

Exhaust camshaft sprocket 1

Intake camshaft sprocket 2

(with the special service tool 3

)

NOTE:

Install the camshaft sprocket with the punch

mark a

facing outside.

Universal magneto and rotor

holder:

YU-01235

Rotor holder:

90890-01235

T R..

Camshaft sprocket bolt:

24 N m (2.4 kgf m, 17 ft lb)

2. Install:

Exhaust camshaft

Intake camshaft

Exhaust camshaft caps

Intake camshaft caps

Installation steps:

Turn the drive coupling counterclockwise,

and then check if cylinder #1 is at TDC of

the compression stroke with a dial gauge.

Install the timing chain onto both cam-

shaft sprockets, and then install the cam-

shaft.

CAUTION:

Do not turn the crankshaft when install-

ing the camshaft to avoid damage or

improper valve timing.

NOTE:

Make sure that the punch marks a

on the

camshafts face up.

Be sure to align the alignment marks b

made during removal to install the timing

chain and camshaft sprockets.

b

ProCarManuals.com

Page 150 of 347

5-51

EPOWRCAMSHAFTS

Install the exhaust and intake camshaft

caps.

NOTE:

Gradually tighten the intake and exhaust

camshaft cap bolts in 2–3 steps in the

sequence shown.

T R..

Camshaft cap bolt:

10 N m (1.0 kgf m, 7.2 ft lb)

NOTE:

Make sure that the punch marks c

on the

camshafts are aligned with the arrow marks

d

on the camshaft caps.

Out of alignment →

Reinstall.

Remove the wire from the timing chain.

10 1 4 5 8

17 5 1 4 8 15 9 12 149 3 2

7 6

18 7 3 2 6

13 11 10 16

3. Install:

Timing chain tensioner

Installation steps:

While lightly pressing the timing chain

tensioner rod by hand, turn the tensioner

rod fully clockwise with a thin screwdriver

1

.

NOTE:

Make sure that the tensioner rod has been

fully set clockwise.

With the timing chain tensioner rod

turned all the way into the timing chain

tensioner housing (with the thin screw-

driver still installed), install the gasket and

the timing chain tensioner 2

onto the cyl-

inder block.

WARNING

Always use a new gasket.

Tighten the timing chain tensioner bolts

3

to the specified torque.

NOTE:

The “UP” mark on the timing chain ten-

sioner should face up.

33

2

ProCarManuals.com

Page 151 of 347

5-52

EPOWRCAMSHAFTS

T R..

Timing chain tensioner bolt:

10 N m (1.0 kgf m, 7.2 ft lb)

Remove the screwdriver, make sure the

timing chain tensioner rod releases, and

then tighten the cap bolt to the specified

torque.

T R..

Cap bolt:

10 N m (1.0 kgf m, 7.2 ft lb)

4. Turn:

Drive coupling

(several turns counterclockwise)

5. Check:

Turn the drive coupling counterclock-

wise, and then check if cylinder #1 is at

TDC of the compression stroke with a

dial gauge.

Camshaft punch marks a

Make sure that the camshaft punch

marks are aligned with the arrow marks

b

on the camshaft caps.

Out of alignment →

Adjust.

Refer to the installation steps above.

6. Measure:

Valve clearance

Out of specification →

Adjust.

Refer to “POWER UNIT” in Chapter 3.

ProCarManuals.com