lights YAMAHA WHY 50 2006 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: WHY 50, Model: YAMAHA WHY 50 2006Pages: 80, PDF Size: 1.18 MB

Page 17 of 80

EAU00027

INSTRUMENT AND CONTROL FUNCTIONS

Main switch / steering lock .................................................................. 3-1

Indicator and warning lights ................................................................ 3-2

Speedometer unit ................................................................................ 3-3

Fuel gauge .......................................................................................... 3-3

Handlebar switches ............................................................................. 3-4

Front brake lever ................................................................................. 3-5

Rear brake lever .................................................................................. 3-5

Fuel and 2-stroke engine oil tank caps ............................................... 3-5

Fuel ..................................................................................................... 3-6

Catalytic converter .............................................................................. 3-7

2-stroke engine oil ............................................................................... 3-7

Kickstarter ........................................................................................... 3-7

Rider seat ............................................................................................ 3-8

Storage compartment ......................................................................... 3-8

Carrier ................................................................................................. 3-9

Luggage hook ..................................................................................... 3-9

3

Page 19 of 80

INSTRUMENT AND CONTROL FUNCTIONS

312ZAUM0184

1. Turn signal indicator light ""

2. High beam indicator light "

`"

EAU00057

Turn signal indicator light ""

This indicator light flashes when the

turn signal switch is pushed to the left

or right.

EAU00063

High beam indicator light ""

This indicator light comes on when the

high beam of the headlight is switched

on.

1

ZAUM0357

1. Oil level indicator light ""

EAU02958

Oil level warning light ""

This warning light comes on when the

key is in the "

" position or when the

oil level in the 2-stroke engine oil tank

is low during operation. If the warning

light comes on during operation, stop

immediately and fill the oil tank with

Yamalube 2 or equivalent 2-stroke

engine oil of either JASO grade "FC"

or ISO grades "EG-C" or "EG-D". The

warning light should go off after the 2-

stroke engine oil tank has been refilled.

NOTE :

If the warning light does not come on

when the key is in the "

" position or

does not go off after the 2-stroke engine

oil tank has been refilled, have a

Yamaha dealer check the electrical cir-

cuit.

EC000000

Do not operate the scooter until you

know that the engine oil level is

sufficient.

3-2

EAU03034

Indicator and warning lights

Page 21 of 80

INSTRUMENT AND CONTROL FUNCTIONS

3

1

2

3

4

ZAUM0359

1

ZAUM0360

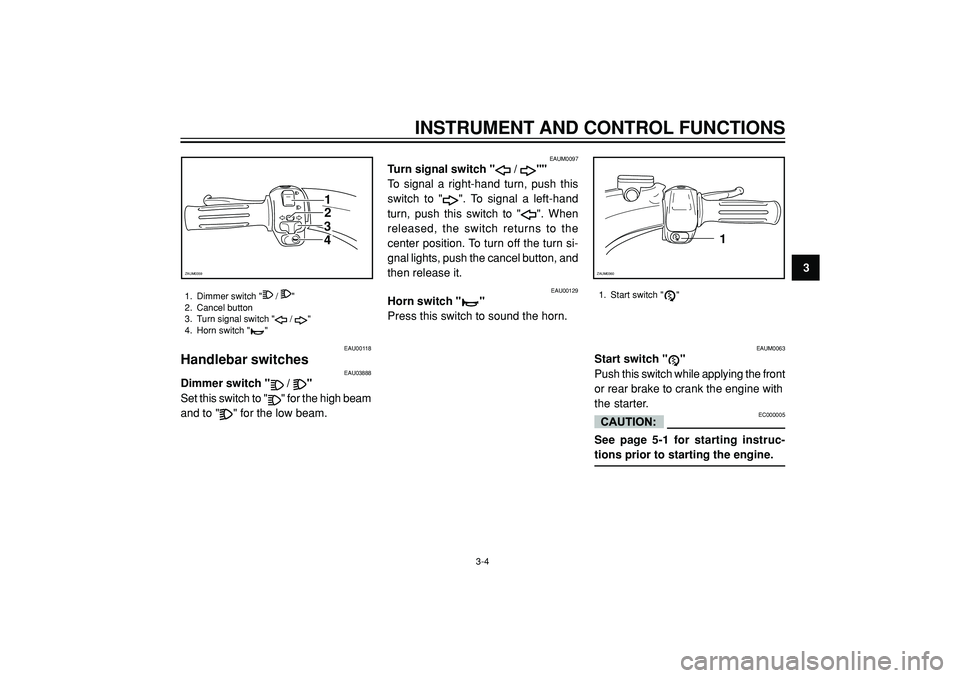

1. Dimmer switch " / "

2. Cancel button

3. Turn signal switch "

/ "

4. Horn switch "

"

EAU00118

Handlebar switchesEAU03888

Dimmer switch " / "

Set this switch to "

" for the high beam

and to "

" for the low beam.

EAU00129

Horn switch ""

Press this switch to sound the horn.

EAUM0063

Start switch ""

Push this switch while applying the front

or rear brake to crank the engine with

the starter.

EC000005

See page 5-1 for starting instruc-

tions prior to starting the engine.

1. Start switch ""

3-4

EAUM0097

Turn signal switch " / ""

To signal a right-hand turn, push this

switch to "

". To signal a left-hand

turn, push this switch to "

". When

released, the switch returns to the

center position. To turn off the turn si-

gnal lights, push the cancel button, and

then release it.

Page 29 of 80

4

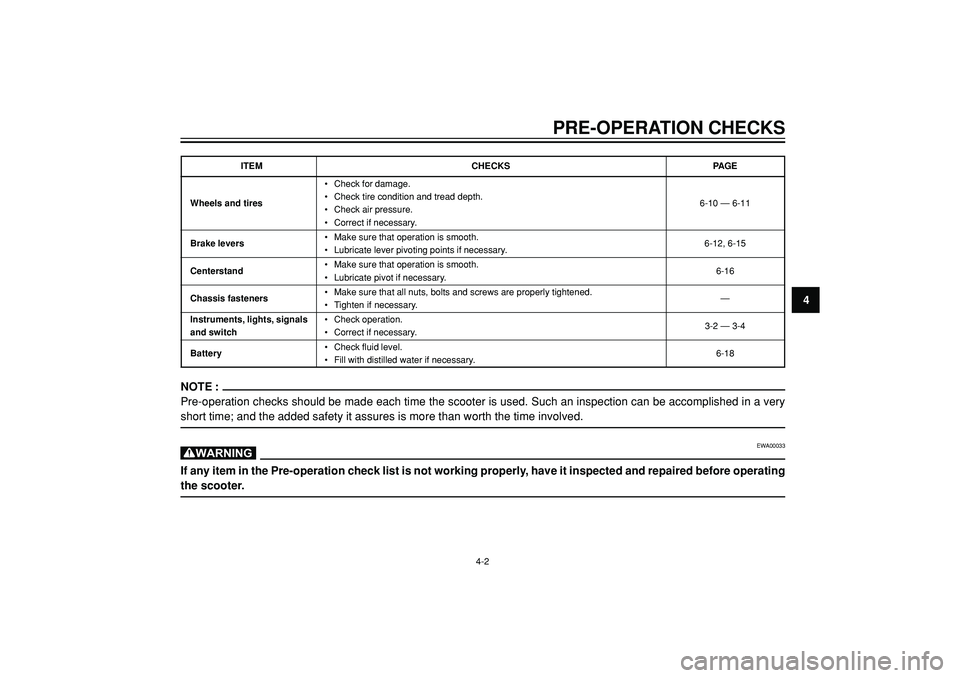

PRE-OPERATION CHECKS

NOTE :

Pre-operation checks should be made each time the scooter is used. Such an inspection can be accomplished in a very

short time; and the added safety it assures is more than worth the time involved.

EWA00033

If any item in the Pre-operation check list is not working properly, have it inspected and repaired before operating

the scooter.

ITEM CHECKS PAGE

•Check for damage.

Wheels and tires•Check tire condition and tread depth.

6-10 — 6-11

•Check air pressure.

•Correct if necessary.

Brake levers•Make sure that operation is smooth.

6-12, 6-15

•Lubricate lever pivoting points if necessary.

Centerstand•Make sure that operation is smooth.

6-16

•Lubricate pivot if necessary.

Chassis fasteners•Make sure that all nuts, bolts and screws are properly tightened.

—

•Tighten if necessary.

Instruments, lights, signals•Check operation.

3-2 — 3-4

and switch•Correct if necessary.

Battery•Check fluid level.

6-18

•Fill with distilled water if necessary.

4-2

Page 34 of 80

OPERATION AND IMPORTANT RIDING POINTS

5

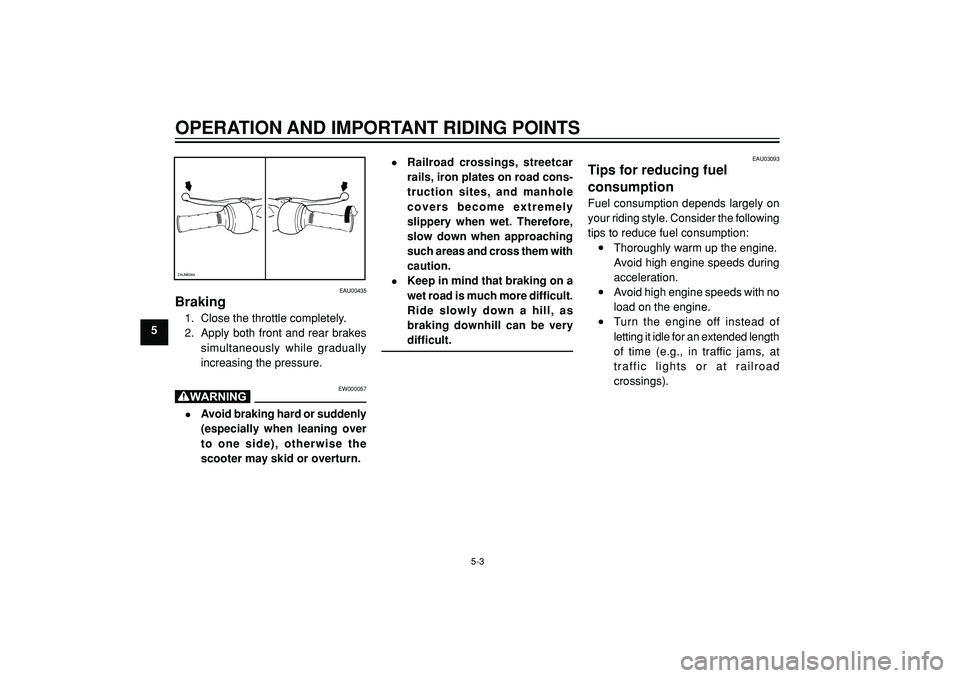

EAU00435

Braking

1. Close the throttle completely.

2. Apply both front and rear brakes

simultaneously while gradually

increasing the pressure.

EW000057

•Avoid braking hard or suddenly

(especially when leaning over

to one side), otherwise the

scooter may skid or overturn.

ZAUM0269

•Railroad crossings, streetcar

rails, iron plates on road cons-

truction sites, and manhole

covers become extremely

slippery when wet. Therefore,

slow down when approaching

such areas and cross them with

caution.

•Keep in mind that braking on a

wet road is much more difficult.

Ride slowly down a hill, as

braking downhill can be very

difficult.

EAU03093

Tips for reducing fuel

consumption

Fuel consumption depends largely on

your riding style. Consider the following

tips to reduce fuel consumption:

•Thoroughly warm up the engine.

Avoid high engine speeds during

acceleration.

•Avoid high engine speeds with no

load on the engine.

•Turn the engine off instead of

letting it idle for an extended length

of time (e.g., in traffic jams, at

traffic lights or at railroad

crossings).

5-3

Page 41 of 80

PERIODIC MAINTENANCE AND MINOR REPAIR

6

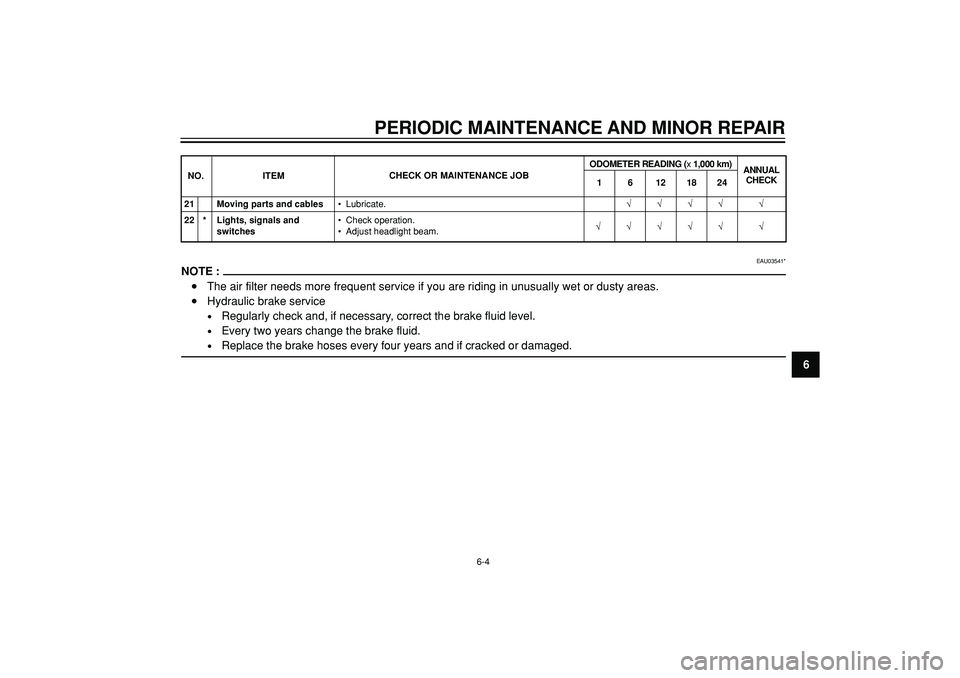

21 Moving parts and cables•Lubricate.√√√√ √

22 * Lights, signals and•Check operation.

√√√√√ √

switches•Adjust headlight beam.

ODOMETER READING (x 1,000 km)

NO. ITEMCHECK OR MAINTENANCE JOB

1

ANNUAL

CHECK

6121824

EAU03541*

NOTE :

•The air filter needs more frequent service if you are riding in unusually wet or dusty areas.

•Hydraulic brake service

•Regularly check and, if necessary, correct the brake fluid level.

•Every two years change the brake fluid.

•Replace the brake hoses every four years and if cracked or damaged.

6-4

Page 62 of 80

SCOOTER CARE AND STORAGE

7

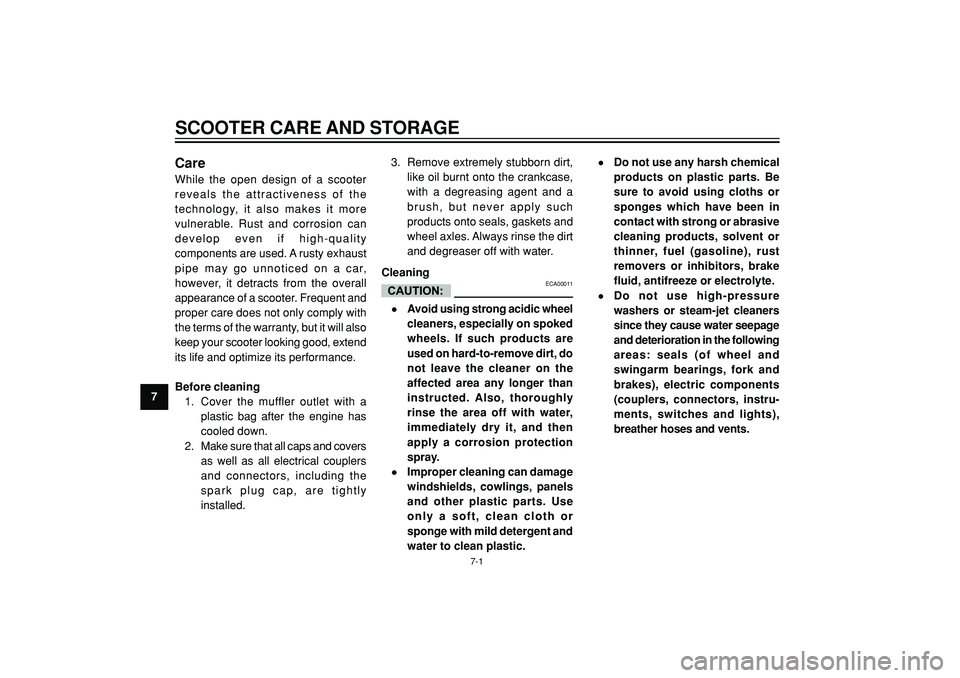

Care

While the open design of a scooter

reveals the attractiveness of the

technology, it also makes it more

vulnerable. Rust and corrosion can

develop even if high-quality

components are used. A rusty exhaust

pipe may go unnoticed on a car,

however, it detracts from the overall

appearance of a scooter. Frequent and

proper care does not only comply with

the terms of the warranty, but it will also

keep your scooter looking good, extend

its life and optimize its performance.

Before cleaning

1. Cover the muffler outlet with a

plastic bag after the engine has

cooled down.

2. Make sure that all caps and covers

as well as all electrical couplers

and connectors, including the

spark plug cap, are tightly

installed.3. Remove extremely stubborn dirt,

like oil burnt onto the crankcase,

with a degreasing agent and a

brush, but never apply such

products onto seals, gaskets and

wheel axles. Always rinse the dirt

and degreaser off with water.

Cleaning

ECA00011

•Avoid using strong acidic wheel

cleaners, especially on spoked

wheels. If such products are

used on hard-to-remove dirt, do

not leave the cleaner on the

affected area any longer than

instructed. Also, thoroughly

rinse the area off with water,

immediately dry it, and then

apply a corrosion protection

spray.

•Improper cleaning can damage

windshields, cowlings, panels

and other plastic parts. Use

only a soft, clean cloth or

sponge with mild detergent and

water to clean plastic.

•Do not use any harsh chemical

products on plastic parts. Be

sure to avoid using cloths or

sponges which have been in

contact with strong or abrasive

cleaning products, solvent or

thinner, fuel (gasoline), rust

removers or inhibitors, brake

fluid, antifreeze or electrolyte.

•Do not use high-pressure

washers or steam-jet cleaners

since they cause water seepage

and deterioration in the following

areas: seals (of wheel and

swingarm bearings, fork and

brakes), electric components

(couplers, connectors, instru-

ments, switches and lights),

breather hoses and vents.

7-1

Page 70 of 80

SPECIFICATIONS

8

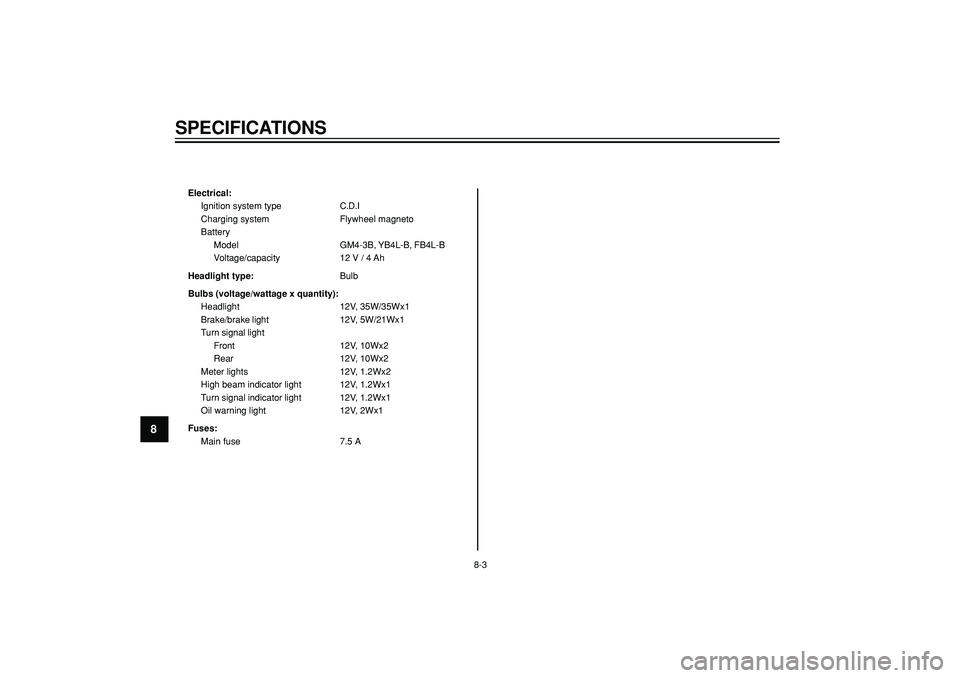

Electrical:

Ignition system typeC.D.I

Charging system Flywheel magneto

Battery

Model GM4-3B, YB4L-B, FB4L-B

Voltage/capacity 12 V / 4 Ah

Headlight type:Bulb

Bulbs (voltage/wattage x quantity):

Headlight 12V, 35W/35Wx1

Brake/brake light 12V, 5W/21Wx1

Turn signal light

Front 12V, 10Wx2

Rear 12V, 10Wx2

Meter lights 12V, 1.2Wx2

High beam indicator light 12V, 1.2Wx1

Turn signal indicator light 12V, 1.2Wx1

Oil warning light 12V, 2Wx1

Fuses:

Main fuse 7.5 A

8-3