lock YAMAHA WR 250F 2001 Owner's Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: WR 250F, Model: YAMAHA WR 250F 2001Pages: 686, PDF Size: 62.6 MB

Page 276 of 686

4 - 5

ENG

RADIATOR

EC456000

HANDLING NOTE

WARNING

Do not remove the radiator cap when the

engine and radiator are hot. Scalding hot

fluid and steam may be blown out under

pressure, which could cause serious

injury.

When the engine has cooled, open the radi-

ator cap by the following procedure:

Place a thick rag, like a towel, over the radi-

ator cap, slowly rotate the cap counter-

clockwise to the detent. This procedure

allows any residual pressure to escape.

When the hissing sound has stopped,

press down on the cap while turning coun-

terclockwise and remove it.

EC454000

INSPECTION

EC444100

Radiator

1. Inspect:

l

Radiator core

1

Obstruction

®

Blow out with com-

pressed air through rear of the radiator.

Bent fin

®

Repair/replace.

EC455000

ASSEMBLY AND INSTALLATION

Radiator

1. Install:

l

O-ring

1

l

Radiator pipe

2

l

Bolt (radiator pipe)

3

NOTE:

Apply the lithium soap base grease on the O-

ring.

2. Install:

l

Radiator hose 4 (longer)

1

l

Radiator hose 2 (shorter)

2

To right radiator 3.

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

Page 277 of 686

ENG

4 - 5

RADIATEUR

KÜHLER

RADIATORE

HANDHABUNGSHINWEIS

WARNUNG

Der heiße Kühler steht unter

Druck. Daher den Kühlerver-

schlußdeckel niemals bei heißem

Motor abnehmen, denn austreten-

der Dampf und heiße Kühlflüssig-

keit könnten ernsthafte Verbrü-

hungen verursachen.

Den Kühlerverschlußdeckel erst

nach Abkühlen des Motors öffnen.

Dazu einen dicken Lappen über

den Kühlerverschlußdeckel legen

und den Deckel langsam gegen

den Uhrzeigersinn bis zum An-

schlag drehen, damit der restliche

Druck entweichen kann. Wenn

kein Zischen mehr zu vernehmen

ist, auf den Deckel drücken und

ihn gegen den Uhrzeigersinn ab-

schrauben.

PRÜFUNG

Kühler

1. Kontrollieren:

lKühlerblock 1

Lamellen zugesetzt ® Von

hinten mit Druckluft ausbla-

sen.

Lamellen verformt ®

Instand setzen/erneuern.

ZUSAMMENBAU UND MONTAGE

Kühler

1. Montieren:

lO-Ring 1

lKühlerleitung 2

lSchraube (Kühlerleitung) 3

HINWEIS:

Lithiumfett auf den O-Ring auftragen.

T R..10 Nm (1,0 m · kg)

2. Montieren:

lKühlerschlauch 4 (länger) 1

lKühlerschlauch 2 (kürzer) 2

(zum Rechter Kühler 3) REMARQUES CONCERNANT LA

MANIPULATION

AVERTISSEMENT

Ne jamais enlever le bouchon du

radiateur quand le moteur et le radia-

teur sont chauds. Du liquide bouillon-

nant et de la vapeur risquent de jaillir

sous forte pression, ce qui est très dan-

gereux.

Une fois le moteur refroidi, enlever le

bouchon du radiateur en procédant

comme suit:

Quand le moteur est froid, mettre un

chiffon épais tel qu’une serviette sur

ce bouchon puis le tourner lentement

vers la gauche jusqu’au point de

détente. Cette procédure permet d’éli-

miner toute pression résiduelle.

Quand le sifflement s’est arrêté,

appuyer sur le bouchon tout en le

tournant vers la gauche puis l’enlever.

CONTROLE

Radiateur

1. Contrôler:

lCarcasse 1

Encrassé ® Nettoyer en souf-

flant de l’air comprimé par

l’arrière du radiateur.

Lamelle tordue ® Réparer/

changer.

ASSEMBLAGE ET MONTAGE

Radiateur

1. Monter:

lJoint torique 1

lTuyau de radiateur 2

lBoulon (tuyau de radiateur) 3

N.B.:

Enduire le joint torique de graisse à base

de savon au lithium.

T R..10 Nm (1,0 m · kg, 7,2 ft · lb)

2. Monter:

lDurit de radiateur 4 (plus lon-

gue) 1

lDurit de radiateur 2 (plus

courte) 2

Au radiateur droite 3.NOTA PER LA MANIPOLAZIONE

AVVERTENZA

Non rimuovere il tappo del radiatore a

motore e radiatore caldi. Si potrebbe

verificare la fuoriuscita di fluido bol-

lente, che potrebbe provocare infor-

tuni gravi.

Quando il motore si è raffreddato,

aprire il tappo del radiatore nel modo

seguente:

Posizionare uno straccio spesso, ad

esempio un asciugamano, sul tappo

del radiatore e far ruotare lentamente

il tappo in senso opposto al fermo.

Questa procedura consentirà la fuo-

riuscita della pressione residua.

Quando non si sente più il sibilo carat-

teristico, premere sul tappo del radia-

tore e svitarlo in senso antiorario per

rimuoverlo.

ISPEZIONE

Radiatore

1. Ispezionare:

lMassa radiante 1

Ostruzioni ® Pulire con aria

compressa insufflata dal retro

del radiatore.

Aletta piegata ® Riparare/

sostituire.

MONTAGGIO ED INSTALLAZIONE

Radiatore

1. Installare:

lO-ring 1

lTubazione del radiatore 2

lBullone (tubazione del radia-

tore) 3

NOTA:

Applicare grasso a base di sapone di litio

sull’O-ring.

T R..10 Nm (1,0 m · kg, 7,2 ft · lb)

2. Installare:

lTubo flessibile radiatore 4 (più

lungo) 1

lTubo flessibile radiatore 2 (più

corto) 2

Sul radiatore destro 3.

Page 281 of 686

4 - 7

ENG

CARBURATEUR

VERGASER

CARBURATORE

VERGASER

Demontage-Arbeiten:1 Vergaser demontieren

Demontage-ArbeitenReihen-

folgeBauteil Anz. Bemerkungen

VERGASER DEMONTIEREN

Vorbereitung für den Ausbau Sitzbank und Kraftstofftank Siehe unter “SITZBANK, KRAFTSTOFFTANK UND

SEITENABDECKUNGEN”.

1 Schlauchschelle 2

2 Gaspositionssensor-Leitungskoppler 1

3 Gaszug-Abdeckung 1

4 Gaszug 2

5 Gasseilzugkappe 1

6 Schlauchschelle (Luftfilteranschluß) 1 Die Schrauben (Luftfilterverbindung) lockern.

7 Schlauchschelle (Vergaseranschluß) 2 Die Schrauben (Vergaseranschluß) lockern.

8 Vergaser (komplett) 1

9 Vergaseranschluß 1

1

CARBURATEUR

Organisation de la dépose:1 Dépose du carburateur

Organisation de la dépose Ordre Nom de pièce Qté Remarques

DEPOSE DU CARBURATEUR

Préparation à la dépose Selle et réservoir de carburant Se reporter à la section “SELLE, RESERVOIR A

ESSENCE ET CACHES LATERAUX”.

1 Bride 2

2 Fiche rapide de fil de capteur de position de

papillon des gaz1

3 Cache du logement des câbles de gaz 1

4 Câble de gaz 2

5 Cache du logement des câbles d’accélération 1

6 Bride (raccord de filtre à air) 1 Desserrer la vis (conduit d’admission d’air).

7 Bride (raccord de carburateur) 2 Desserrer les vis (raccord de carburateur).

8 Rampe de carburateurs 1

9 Raccord de carburateur 1

1

CARBURATORE

Portata dello smontaggio:1 Rimozione del carburatore

Portata dello smontaggio Ordine Denominazione Quantità Osservazioni

RIMOZIONE DEL CARBURATORE

Preparazione per lo smontaggio Sella e serbatoio del carburante Fare riferimento al paragrafo “SELLA, SERBATOIO

DEL CARBURANTE E CARENATURA LATERALE”.

1 Morsetto 2

2 Accoppiatore cavo del sensore di posizione

dell’acceleratore1

3 Coperchio cavo dell’acceleratore 1

4 Cavo acceleratore 2

5 Tappo del cavo acceleratore 1

6 Morsetto (giunto filtro dell’aria) 1 Svitare la vite (giunto filtro dell’aria).

7 Morsetti (giunto carburatore) 2 Svitare le viti (giunto carburatore).

8 Gruppo carburatore 1

9 Giunto del carburatore 1

1

Page 310 of 686

4 - 22

ENGCAMSHAFTS

REMOVAL POINTS

Camshaft

1. Remove:

lTiming mark accessing screw 1

lCrankshaft end accessing screw 2

2. Align:

lT.D.C. mark

With align mark.

Checking steps:

lTurn the crankshaft counterclockwise with

a wrench.

NOTE:

Squeezing the decompression lever allows

the crankshaft to be turned easily.

lAlign the T.D.C. mark a on the rotor with

the align mark b on the crankcase cover

when piston is at T.D.C. on compression

stroke.

NOTE:

In order to be sure that the piston is at Top

Dead Center, the punch mark c on the

exhaust camshaft and the punch mark d on

the intake camshaft must align with the cyl-

inder head surface, as shown in the illustra-

tion.

3. Remove:

lTiming chain tensioner cap bolt 1

lTiming chain tensioner 2

lGasket

4. Remove:

lBolt (camshaft cap) 1

lCamshaft cap 2

lClip

NOTE:

Remove the bolts (camshaft cap) in a criss-

cross pattern, working from the outside in.

CAUTION:

The bolts (camshaft cap) must be removed

evenly to prevent damage to the cylinder

head, camshafts or camshaft caps.

Page 316 of 686

4 - 25

ENGCAMSHAFTS

Timing chain tensioner

1. Check:

lWhile pressing the tensioner rod lightly

with fingers, use a thin screwdriver 1

and wind the tensioner rod up fully

clockwise.

lWhen releasing the screwdriver by

pressing lightly with fingers, make sure

that the tensioner rod will come out

smoothly.

lIf not, replace the tensioner assembly.

ASSEMBLY AND INSTALLATION

Camshaft

1. Install:

lExhaust camshaft 1

lIntake camshaft 2

Installation steps:

lTurn the crankshaft counterclockwise with

a wrench.

NOTE:

Squeezing the decompression lever allows

the crankshaft to be turned easily.

lAlign the T.D.C. mark a on the rotor with

the align mark b on the crankcase cover

when piston is at T.D.C. on compression

stroke.

lFit the timing chain 3 onto both camshaft

sprockets and install the camshafts on the

cylinder head.

NOTE:

The camshafts should be installed onto the

cylinder head so that the punch mark c on

the exhaust camshaft and the punch mark

d on the intake camshaft must align with

the cylinder head surface, as shown in the

illustration.

Page 318 of 686

4 - 26

ENGCAMSHAFTS

CAUTION:

Do not turn the crankshaft during the

camshaft installation. Damage or

improper valve timing will result.

lInstall the clips, camshaft caps 4 and

bolts (camshaft cap) 5.

T R..

Bolt (camshaft cap):

10 Nm (1.0 m • kg, 7.2 ft • lb)

NOTE:

lBefore removing the clips, cover the cylin-

der head with a clean rag to prevent the

clips from into the cylinder head cavity.

lApply the engine oil on the thread and con-

tact surface of the bolts (camshaft cap).

lTighten the bolts (camshaft cap) 5 in a

crisscross pattern.

CAUTION:

The bolts (camshaft cap) must be tight-

ened evenly or damage to the cylinder

head, camshaft caps and camshaft will

result.

2. Install:

lTiming chain tensioner

Installation steps:

lWhile pressing the tensioner rod lightly

with fingers, use a thin screwdriver and

wind the tensioner rod up fully clockwise.

lWith the rod fully wound and the chain

tensioner UP mark a facing upward,

install the gasket 1 and the timing chain

tensioner 2, and tighten the bolt 3 to the

specified torque.

T R..

Bolt (timing chain tensioner):

10 Nm (1.0 m • kg, 7.2 ft • lb)

Page 320 of 686

4 - 27

ENG

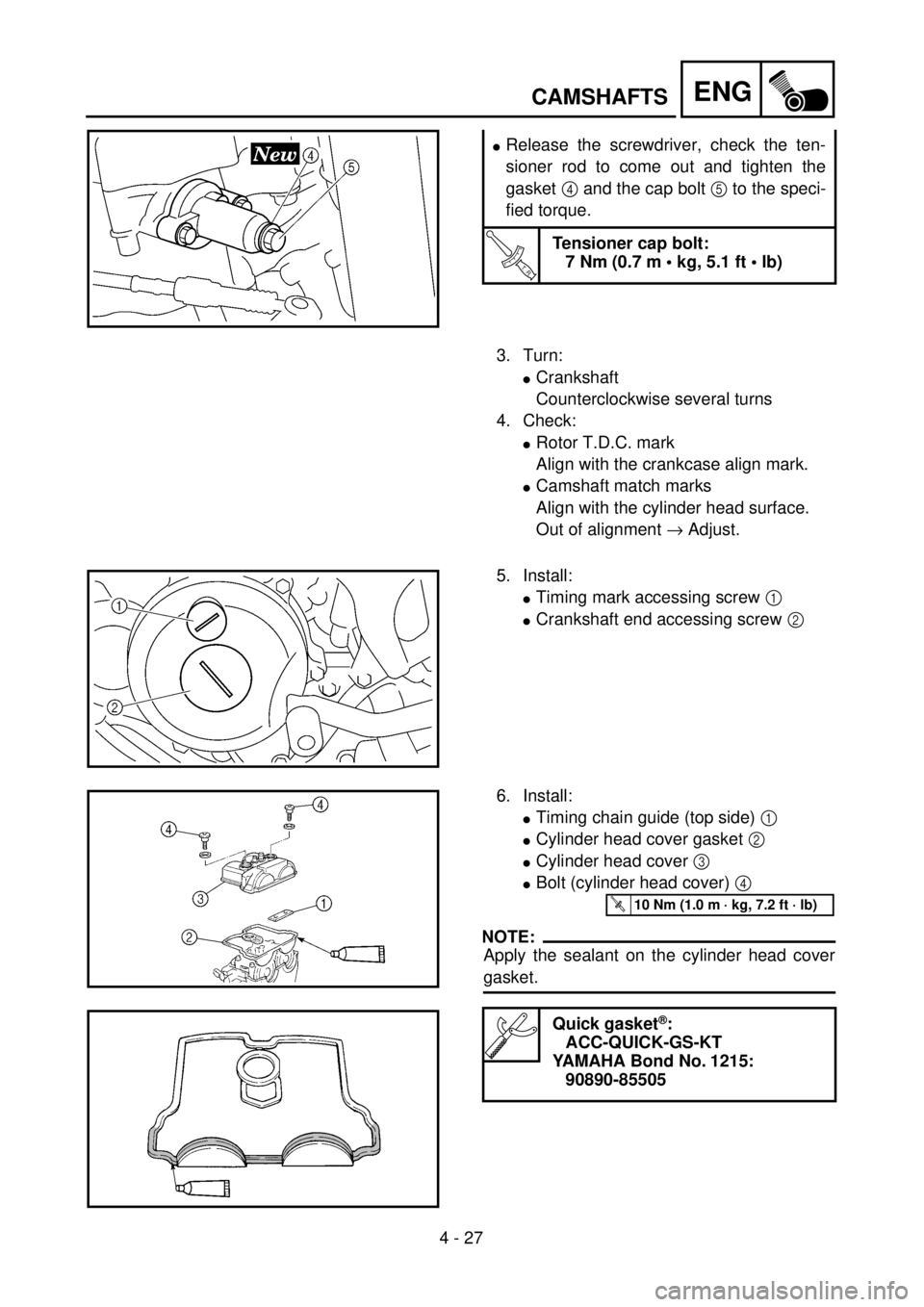

lRelease the screwdriver, check the ten-

sioner rod to come out and tighten the

gasket 4 and the cap bolt 5 to the speci-

fied torque.

T R..

Tensioner cap bolt:

7 Nm (0.7 m • kg, 5.1 ft • lb)

3. Turn:

lCrankshaft

Counterclockwise several turns

4. Check:

lRotor T.D.C. mark

Align with the crankcase align mark.

lCamshaft match marks

Align with the cylinder head surface.

Out of alignment ® Adjust.

5. Install:

lTiming mark accessing screw 1

lCrankshaft end accessing screw 2

6. Install:

lTiming chain guide (top side) 1

lCylinder head cover gasket 2

lCylinder head cover 3

lBolt (cylinder head cover) 4

NOTE:

Apply the sealant on the cylinder head cover

gasket.

Quick gasket®:

ACC-QUICK-GS-KT

YAMAHA Bond No. 1215:

90890-85505

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

CAMSHAFTS

Page 368 of 686

4 - 51

ENGCLUTCH

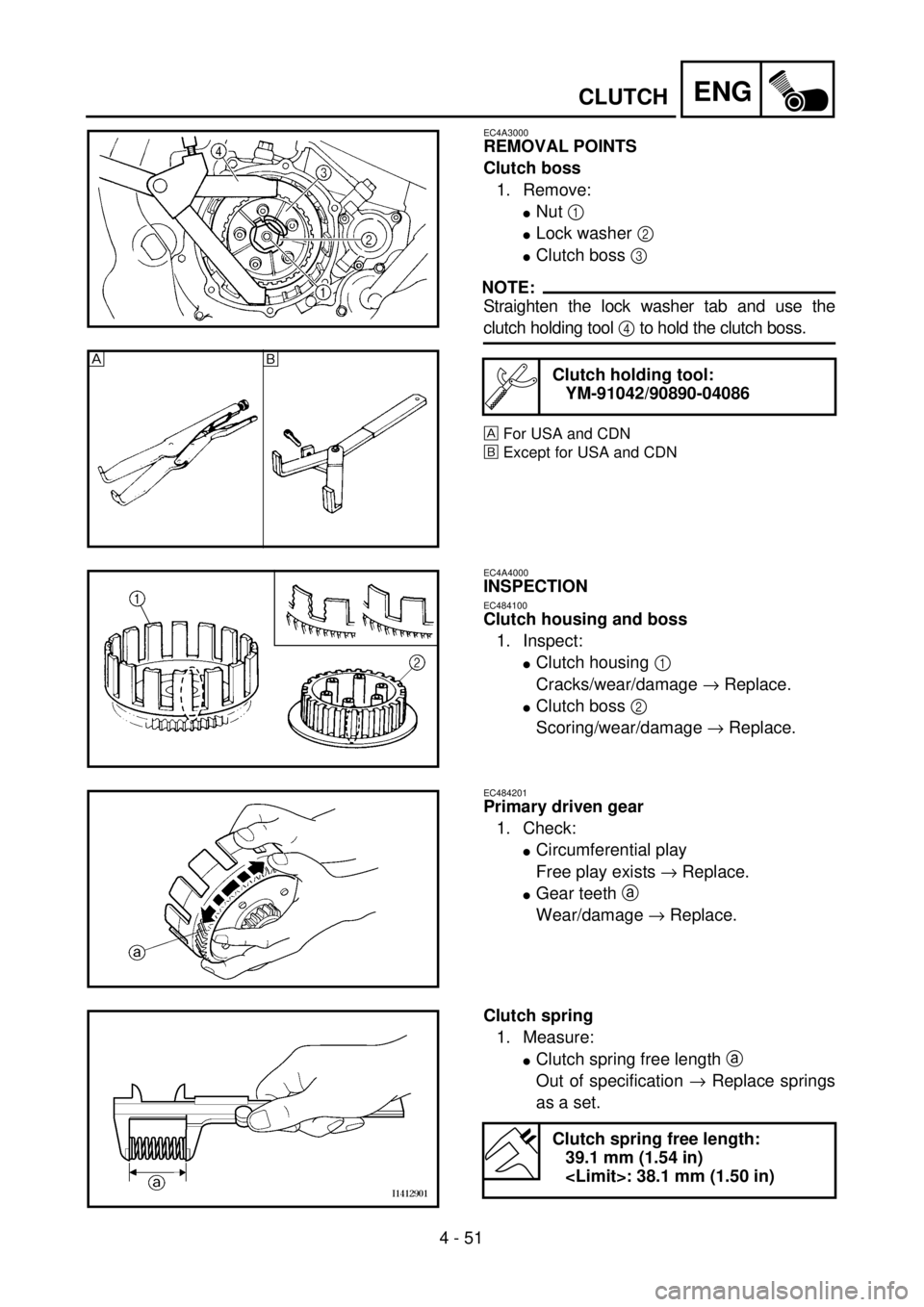

EC4A3000

REMOVAL POINTS

Clutch boss

1. Remove:

lNut 1

lLock washer 2

lClutch boss 3

NOTE:

Straighten the lock washer tab and use the

clutch holding tool 4 to hold the clutch boss.

For USA and CDN

õExcept for USA and CDN

Clutch holding tool:

YM-91042/90890-04086

õ

EC4A4000

INSPECTION

EC484100

Clutch housing and boss

1. Inspect:

lClutch housing 1

Cracks/wear/damage ® Replace.

lClutch boss 2

Scoring/wear/damage ® Replace.

EC484201

Primary driven gear

1. Check:

lCircumferential play

Free play exists ® Replace.

lGear teeth a

Wear/damage ® Replace.

Clutch spring

1. Measure:

lClutch spring free length a

Out of specification ® Replace springs

as a set.

Clutch spring free length:

39.1 mm (1.54 in)

Page 372 of 686

4 - 53

ENGCLUTCH

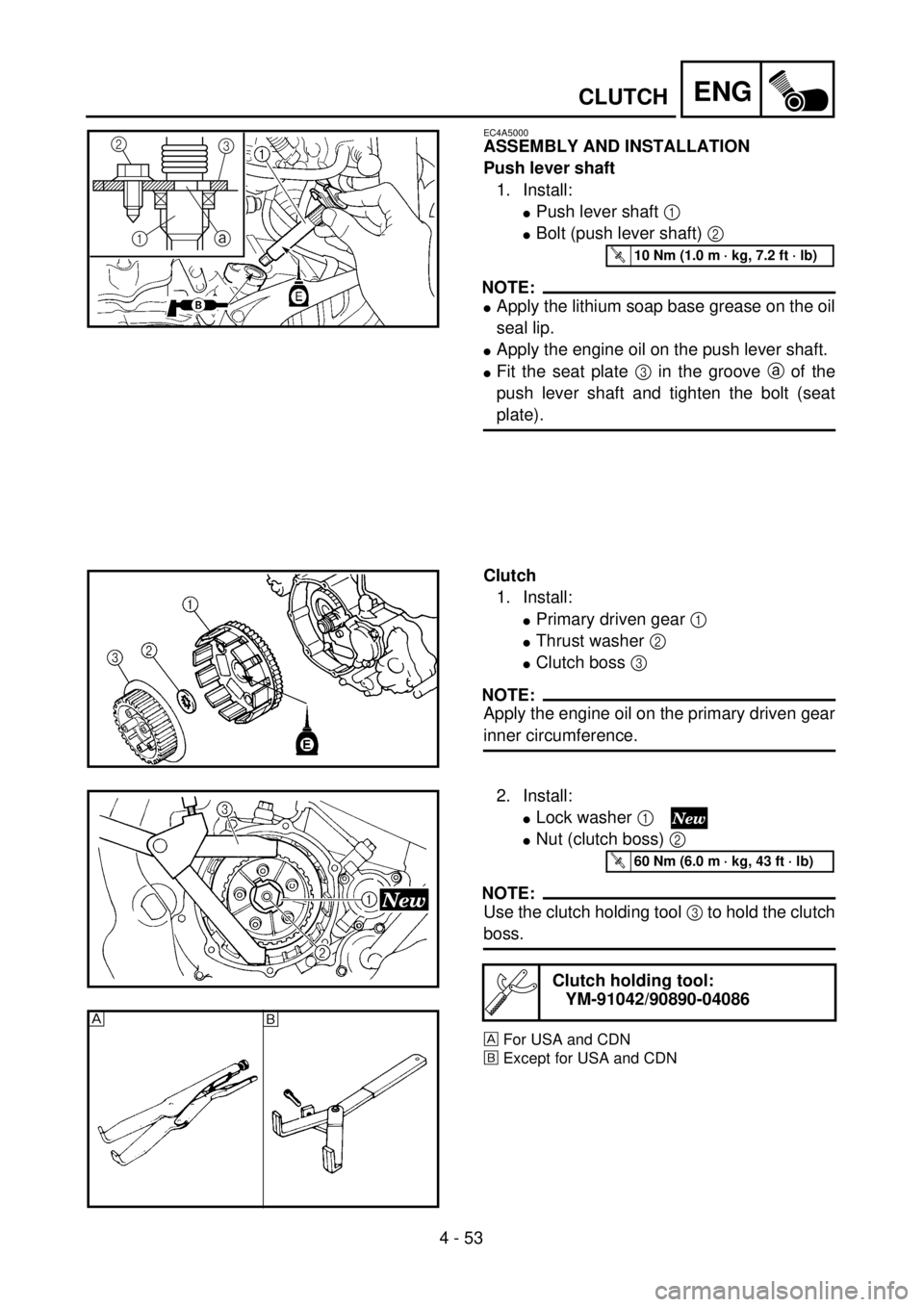

EC4A5000

ASSEMBLY AND INSTALLATION

Push lever shaft

1. Install:

lPush lever shaft 1

lBolt (push lever shaft) 2

NOTE:

lApply the lithium soap base grease on the oil

seal lip.

lApply the engine oil on the push lever shaft.

lFit the seat plate 3 in the groove a of the

push lever shaft and tighten the bolt (seat

plate).

3

1

a2

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

Clutch

1. Install:

lPrimary driven gear 1

lThrust washer 2

lClutch boss 3

NOTE:

Apply the engine oil on the primary driven gear

inner circumference.

2. Install:

lLock washer 1

lNut (clutch boss) 2

NOTE:

Use the clutch holding tool 3 to hold the clutch

boss.

For USA and CDN

õExcept for USA and CDN

Clutch holding tool:

YM-91042/90890-04086

T R..60 Nm (6.0 m · kg, 43 ft · lb)

õ

Page 374 of 686

4 - 54

ENGCLUTCH

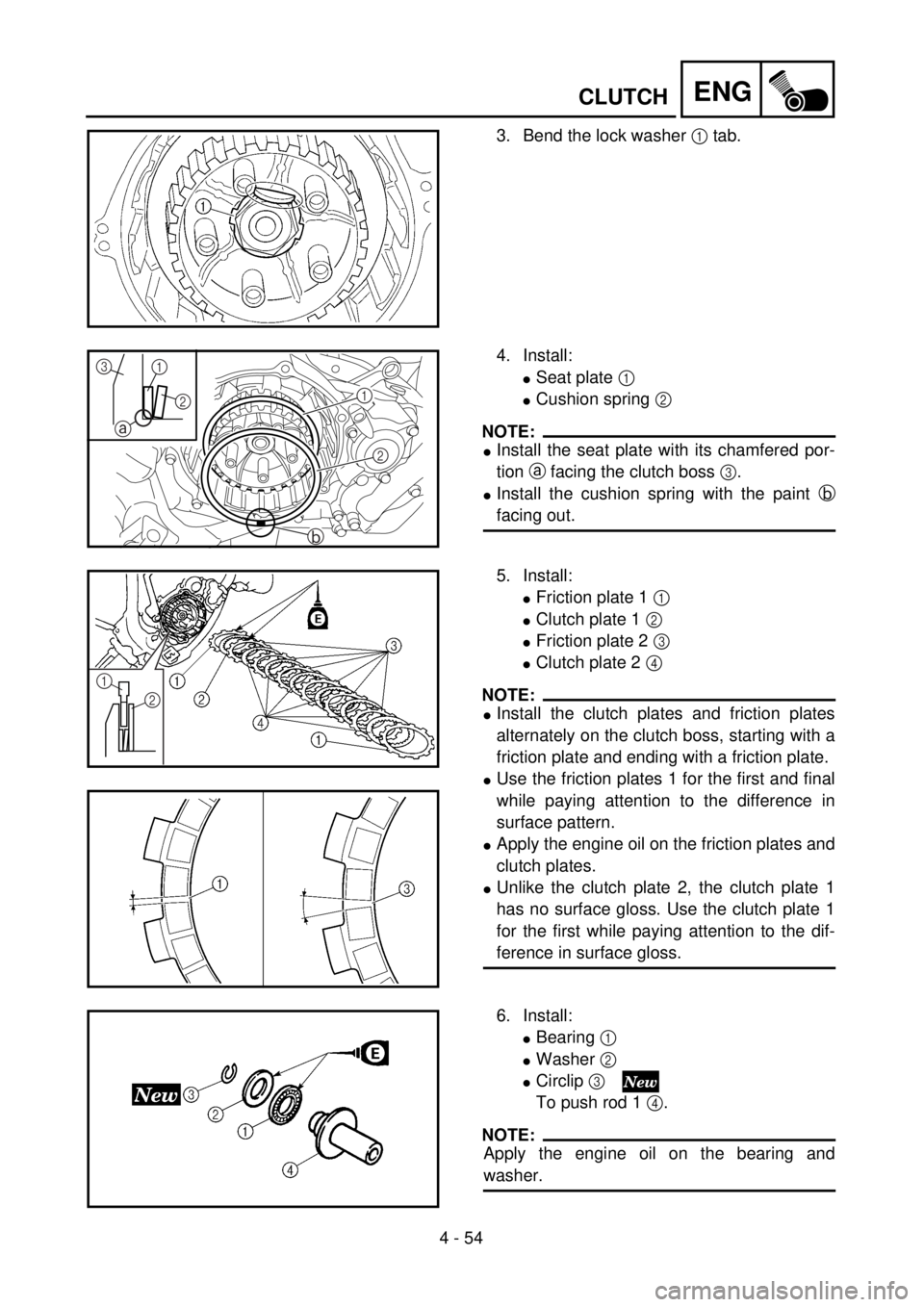

3. Bend the lock washer 1 tab.

4. Install:

lSeat plate 1

lCushion spring 2

NOTE:

lInstall the seat plate with its chamfered por-

tion a facing the clutch boss 3.

lInstall the cushion spring with the paint b

facing out.

1

2 1

2 3

a

b

5. Install:

lFriction plate 1 1

lClutch plate 1 2

lFriction plate 2 3

lClutch plate 2 4

NOTE:

lInstall the clutch plates and friction plates

alternately on the clutch boss, starting with a

friction plate and ending with a friction plate.

lUse the friction plates 1 for the first and final

while paying attention to the difference in

surface pattern.

lApply the engine oil on the friction plates and

clutch plates.

lUnlike the clutch plate 2, the clutch plate 1

has no surface gloss. Use the clutch plate 1

for the first while paying attention to the dif-

ference in surface gloss.

1

2

6. Install:

lBearing 1

lWasher 2

lCirclip 3

To push rod 1 4.

NOTE:

Apply the engine oil on the bearing and

washer.