lock YAMAHA WR 250F 2001 Service Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: WR 250F, Model: YAMAHA WR 250F 2001Pages: 686, PDF Size: 62.6 MB

Page 392 of 686

4 - 63

ENGBALANCER

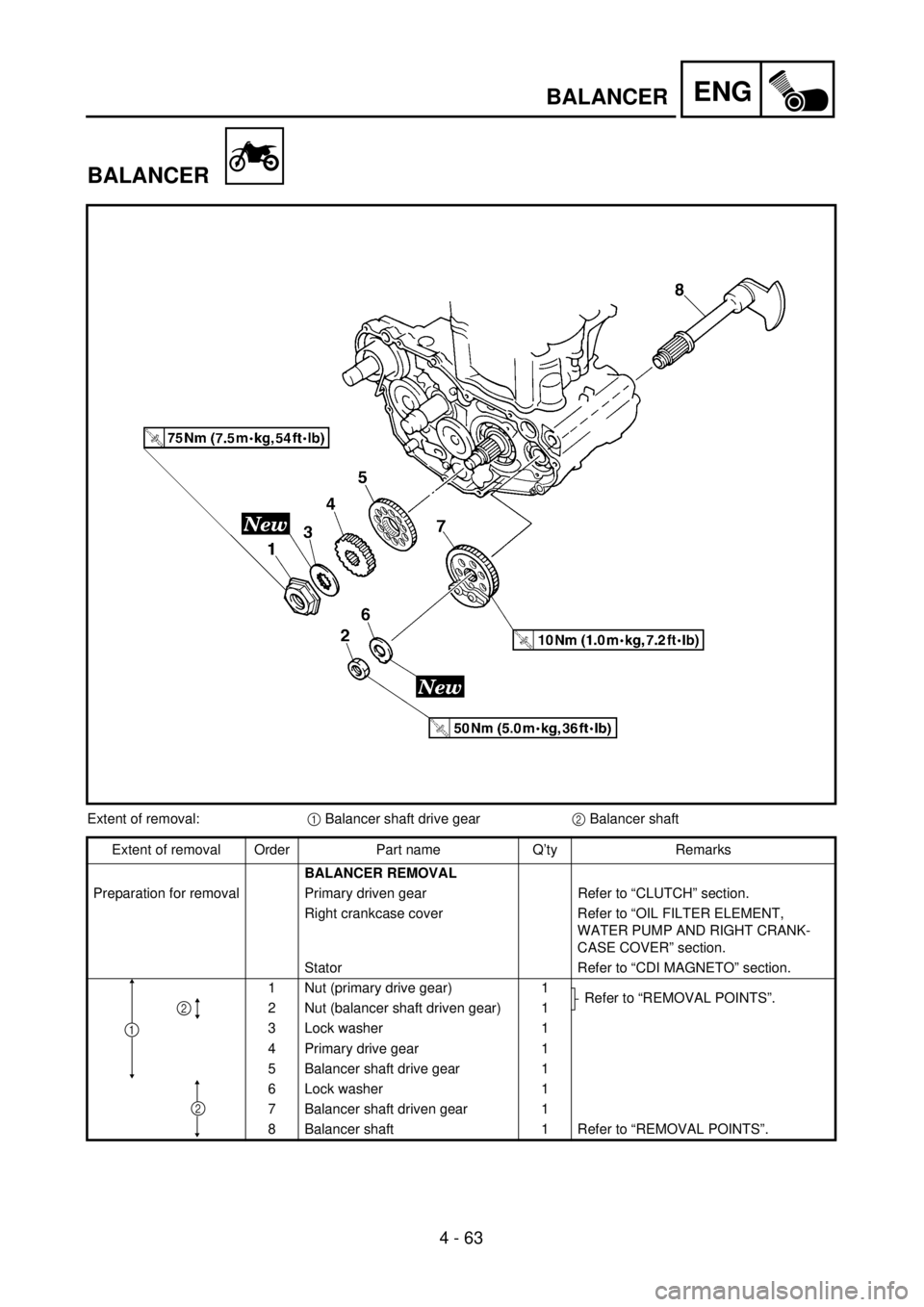

BALANCER

Extent of removal:1 Balancer shaft drive gear2 Balancer shaft

Extent of removal Order Part name Q’ty Remarks

BALANCER REMOVAL

Preparation for removal Primary driven gear Refer to “CLUTCH” section.

Right crankcase cover Refer to “OIL FILTER ELEMENT,

WATER PUMP AND RIGHT CRANK-

CASE COVER” section.

Stator Refer to “CDI MAGNETO” section.

1 Nut (primary drive gear) 1

Refer to “REMOVAL POINTS”.

2 Nut (balancer shaft driven gear) 1

3 Lock washer 1

4 Primary drive gear 1

5 Balancer shaft drive gear 1

6 Lock washer 1

7 Balancer shaft driven gear 1

8 Balancer shaft 1 Refer to “REMOVAL POINTS”.

2

1

2

Page 394 of 686

4 - 64

ENGBALANCER

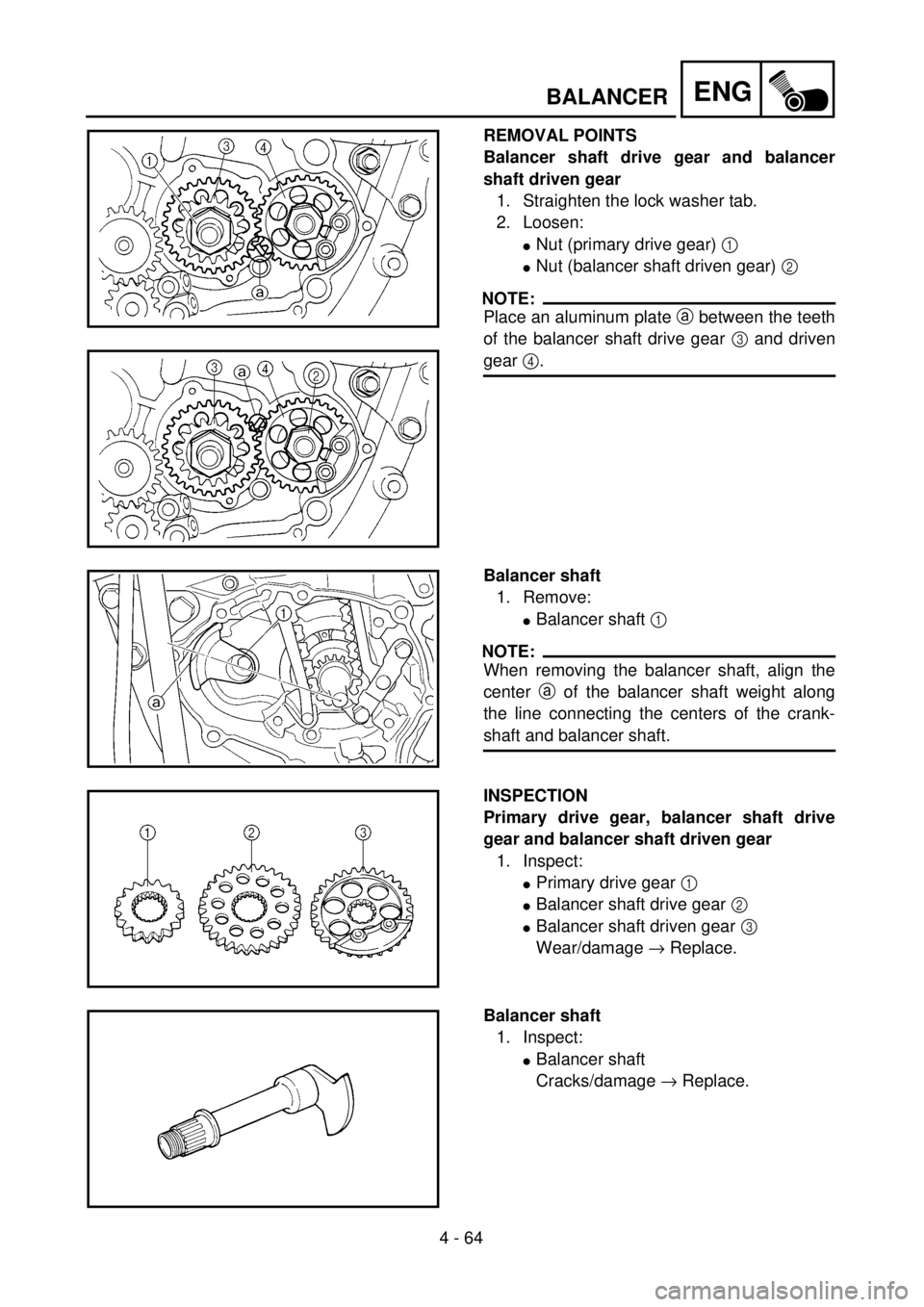

REMOVAL POINTS

Balancer shaft drive gear and balancer

shaft driven gear

1. Straighten the lock washer tab.

2. Loosen:

lNut (primary drive gear) 1

lNut (balancer shaft driven gear) 2

NOTE:

Place an aluminum plate a between the teeth

of the balancer shaft drive gear 3 and driven

gear 4.

Balancer shaft

1. Remove:

lBalancer shaft 1

NOTE:

When removing the balancer shaft, align the

center a of the balancer shaft weight along

the line connecting the centers of the crank-

shaft and balancer shaft.

INSPECTION

Primary drive gear, balancer shaft drive

gear and balancer shaft driven gear

1. Inspect:

lPrimary drive gear 1

lBalancer shaft drive gear 2

lBalancer shaft driven gear 3

Wear/damage ® Replace.

Balancer shaft

1. Inspect:

lBalancer shaft

Cracks/damage ® Replace.

Page 395 of 686

ENG

4 - 64

BALANCIER

AUSGLEICHSWELLE

BILANCIERE

AUSBAU

Ausgleichswellen-Antriebs- und -

Abtriebsräder

1. Die Lasche der Sicherungs-

scheibe umbiegen.

2. Lockern:

lMutter (Primärantriebsrad)

1

lMutter (Ausgleichswelle) 2

HINWEIS:

Ein Stückchen Aluminium a zwi-

schen die Zähne des Ausgleichswel-

len-Antriebsrades 3 und Aus-

gleichswellen-Abtriebrades 4 legen.

Ausgleichswelle

1. Demontieren:

lAusgleichswelle 1

HINWEIS:

Beim Ausbau der Ausgleichswelle

muß sich das Ausgleichsgewicht mit-

tig a auf der Fluchtlinie zwischen

den Mittelpunkten der Nockenwellen-

und Ausgleichswellen-Enden befin-

den.

PRÜFUNG

Primär- und Ausgleichswellen-

Antriebs- und -Abtriebsräder

1. Kontrollieren:

lPrimärantriebsrad 1

lAusgleichswellen-Antriebs-

rad 2

lAusgleichswellen-Abtriebs-

rad 3

Verschleiß/Beschädigung ®

Erneuern.

Ausgleichswelle

1. Kontrollieren:

lAusgleichswelle

Rißbildung/Beschädigung

® Erneuern. POINTS DE DEPOSE

Pignon menant et pignon mené du

balancier

1. Redresser l’ongle de rondelle

d’arrêt.

2. Desserrer:

lEcrou (pignon menant pri-

maire) 1

lEcrou (pignon mené de balan-

cier) 2

N.B.:

Placer une plaquette en aluminium a

entre les dents du pignon menant 3 et le

pignon mené 4 du balancier.

Balancier

1. Déposer:

lBalancier 1

N.B.:

Avant de déposer l’arbre de balancier,

aligner le centre a du poids de l’arbre

de balancier avec la ligne reliant le cen-

tre du vilebrequin et le centre de l’arbre

de balancier.

CONTROLE

Pignon menant primaire, pignon

menant et pignon mené du balancier

1. Contrôler:

lPignon menant primaire 1

lPignon menant du balancier 2

lPignon mené du balancier 3

Usure/endommagements ®

Remplacer.

Balancier

1. Contrôler:

lBalancier

Craquelures/endommagement

® Remplacer.PUNTI DI RIMOZIONE

Ingranaggio conduttore dell’albero di

equilibratura e ingranaggio condotto

dell’albero di equilibratura

1. Spianare la linguetta della ron-

della di bloccaggio.

2. Allentare:

lDado (ingranaggio conduttore

della trasmissione primaria) 1

lDado (Ingranaggio condotto

dell’albero di equilibratura) 2

NOTA:

Inserire una piastra di alluminio a tra i

denti dell’ingranaggio conduttore 3 e

l’ingranaggio condotto 4 dell’albero di

equilibratura.

Albero di equilibratura

1. Rimuovere:

lAlbero di equilibratura 1

NOTA:

Nel rimuovere l’albero di equilibratura,

allineare il centro del peso dell’albero di

equilibratura a lungo la linea che col-

lega i punti centrali dell’albero motore e

dell’albero di equilibratura.

ISPEZIONE

Ingranaggio conduttore della trasmis-

sione primaria, ingranaggio condut-

tore dell’albero di equilibratura e

ingranaggio condotto dell’albero di

equilibratura

1. Ispezionare:

lIngranaggio conduttore della

trasmissione primaria 1

lIngranaggio conduttore

dell’albero di equilibratura 2

lIngranaggio condotto

dell’albero di equilibratura 3

Usura/danno ® Sostituire.

Albero di equilibratura

1. Ispezionare:

lAlbero di equilibratura

Incrinature/danno ® Sostitu-

ire.

Page 396 of 686

4 - 65

ENGBALANCER

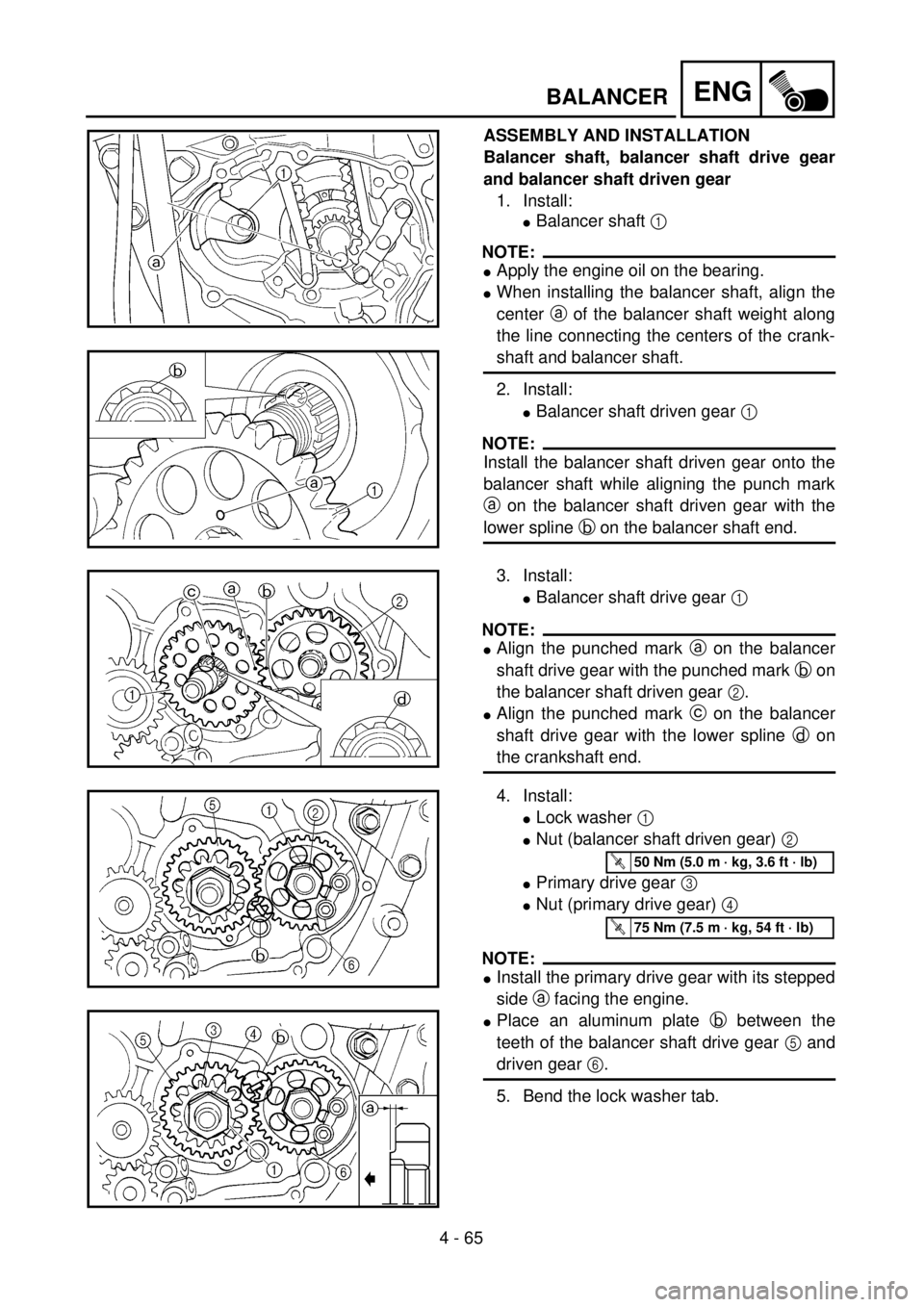

ASSEMBLY AND INSTALLATION

Balancer shaft, balancer shaft drive gear

and balancer shaft driven gear

1. Install:

lBalancer shaft 1

NOTE:

lApply the engine oil on the bearing.

lWhen installing the balancer shaft, align the

center a of the balancer shaft weight along

the line connecting the centers of the crank-

shaft and balancer shaft.

2. Install:

lBalancer shaft driven gear 1

NOTE:

Install the balancer shaft driven gear onto the

balancer shaft while aligning the punch mark

a on the balancer shaft driven gear with the

lower spline b on the balancer shaft end.

3. Install:

lBalancer shaft drive gear 1

NOTE:

lAlign the punched mark a on the balancer

shaft drive gear with the punched mark b on

the balancer shaft driven gear 2.

lAlign the punched mark c on the balancer

shaft drive gear with the lower spline d on

the crankshaft end.

4. Install:

lLock washer 1

lNut (balancer shaft driven gear) 2

lPrimary drive gear 3

lNut (primary drive gear) 4

NOTE:

lInstall the primary drive gear with its stepped

side a facing the engine.

lPlace an aluminum plate b between the

teeth of the balancer shaft drive gear 5 and

driven gear 6.

5. Bend the lock washer tab.

T R..50 Nm (5.0 m · kg, 3.6 ft · lb)

T R..75 Nm (7.5 m · kg, 54 ft · lb)

Page 412 of 686

4 - 73

ENGKICK SHAFT AND SHIFT SHAFT

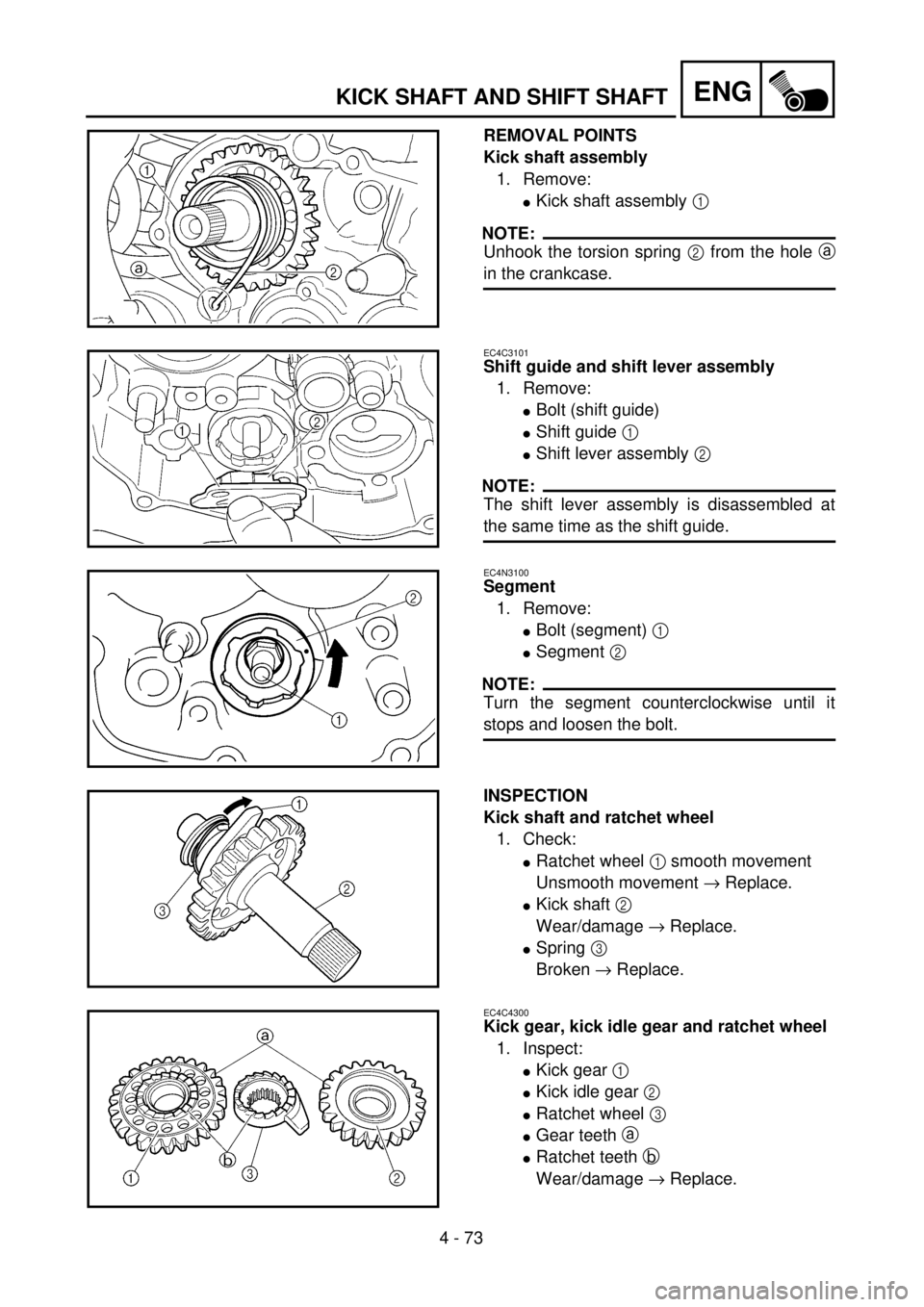

REMOVAL POINTS

Kick shaft assembly

1. Remove:

lKick shaft assembly 1

NOTE:

Unhook the torsion spring 2 from the hole a

in the crankcase.

EC4C3101

Shift guide and shift lever assembly

1. Remove:

lBolt (shift guide)

lShift guide 1

lShift lever assembly 2

NOTE:

The shift lever assembly is disassembled at

the same time as the shift guide.

EC4N3100

Segment

1. Remove:

lBolt (segment) 1

lSegment 2

NOTE:

Turn the segment counterclockwise until it

stops and loosen the bolt.

INSPECTION

Kick shaft and ratchet wheel

1. Check:

lRatchet wheel 1 smooth movement

Unsmooth movement ® Replace.

lKick shaft 2

Wear/damage ® Replace.

lSpring 3

Broken ® Replace.

EC4C4300

Kick gear, kick idle gear and ratchet wheel

1. Inspect:

lKick gear 1

lKick idle gear 2

lRatchet wheel 3

lGear teeth a

lRatchet teeth b

Wear/damage ® Replace.

Page 420 of 686

4 - 77

ENGKICK SHAFT AND SHIFT SHAFT

2. Install:

lTorsion spring 1

To kick shaft 2.

NOTE:

Make sure the stopper a of the torsion spring

fits into the hole b on the kick shaft.

3. Install:

lSpring guide 1

NOTE:

Slide the spring guide into the kick shaft, make

sure the groove a in the spring guide fits on

the stopper of the torsion spring.

4. Install:

lKick shaft assembly 1

lWasher 2

NOTE:

lApply the engine oil on the kick shaft.

lSlide the kick shaft assembly into the crank-

case, make sure the kick shaft stopper a fit

into their home position 3.

5. Hook:

lTorsion spring 1

NOTE:

Turn the torsion spring clockwise and hook

into the proper hole a in the crankcase.

Kick idle gear

1. Install:

lKick idle gear 1

lWasher 2

lCirclip 3

NOTE:

lApply the engine oil on the kick idle gear

inner circumference.

lInstall the kick idle gear with its depressed

side a toward you.

Page 432 of 686

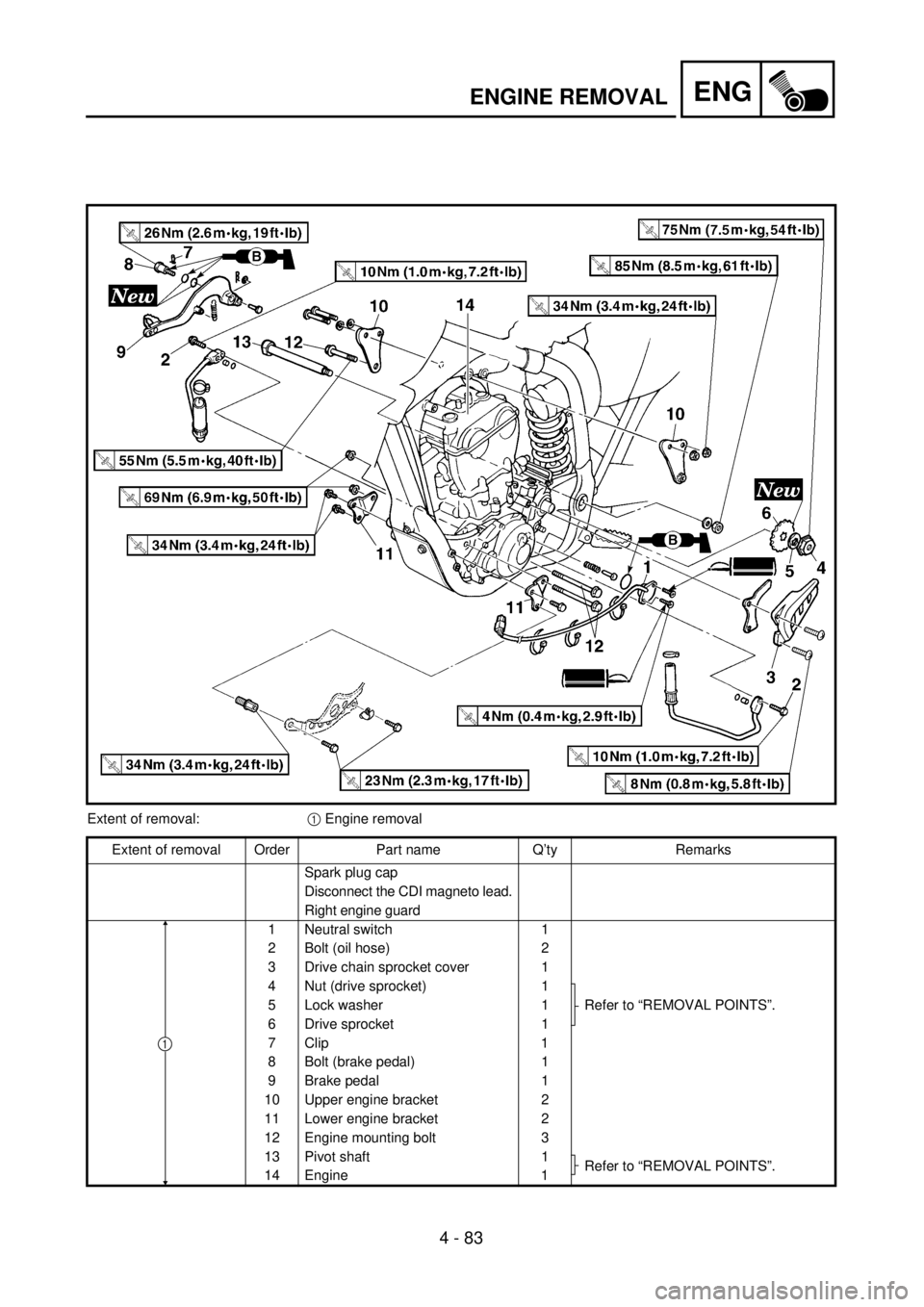

4 - 83

ENGENGINE REMOVAL

Extent of removal:1 Engine removal

Extent of removal Order Part name Q’ty Remarks

Spark plug cap

Disconnect the CDI magneto lead.

Right engine guard

1 Neutral switch 1

2 Bolt (oil hose) 2

3 Drive chain sprocket cover 1

4 Nut (drive sprocket) 1

Refer to “REMOVAL POINTS”. 5 Lock washer 1

6 Drive sprocket 1

7 Clip 1

8 Bolt (brake pedal) 1

9 Brake pedal 1

10 Upper engine bracket 2

11 Lower engine bracket 2

12 Engine mounting bolt 3

13 Pivot shaft 1

Refer to “REMOVAL POINTS”.

14Engine

1

1

Page 434 of 686

4 - 84

ENGENGINE REMOVAL

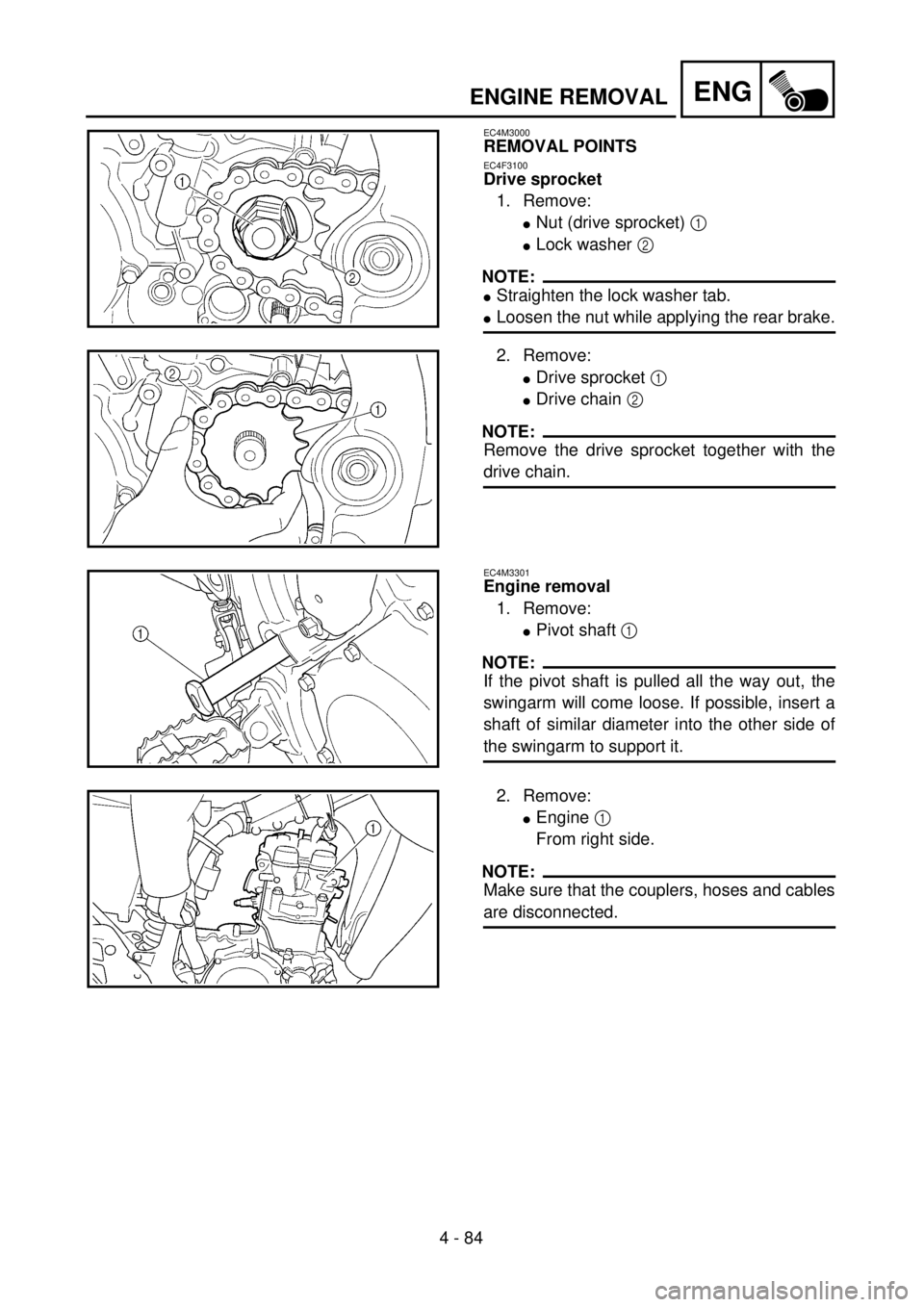

EC4M3000

REMOVAL POINTS

EC4F3100

Drive sprocket

1. Remove:

lNut (drive sprocket) 1

lLock washer 2

NOTE:

lStraighten the lock washer tab.

lLoosen the nut while applying the rear brake.

2. Remove:

lDrive sprocket 1

lDrive chain 2

NOTE:

Remove the drive sprocket together with the

drive chain.

EC4M3301

Engine removal

1. Remove:

lPivot shaft 1

NOTE:

If the pivot shaft is pulled all the way out, the

swingarm will come loose. If possible, insert a

shaft of similar diameter into the other side of

the swingarm to support it.

2. Remove:

lEngine 1

From right side.

NOTE:

Make sure that the couplers, hoses and cables

are disconnected.

Page 435 of 686

ENG

4 - 84

DEPOSE DU MOTEUR

MOTOR DEMONTIEREN

RIMOZIONE DEL MOTORE

AUSBAU

Antriebsritzel

1. Demontieren:

lMutter (Antriebsritzel) 1

lSicherungsscheibe 2

HINWEIS:

lDie Lasche der Sicherungsscheibe

umbiegen.

lBeim Lockern der Mutter die Hin-

terradbremse betätigen.

2. Demontieren:

lAntriebsritzel 1

lAntriebskette 2

HINWEIS:

Antriebsritzel und Antriebskette

gleichzeitig ausbauen.

Motor demontieren

1. Demontieren:

lSchwingenachse 1

HINWEIS:

Durch Herausziehen der Schwingen-

achse wird die Schwinge gelöst. Um

dies zu vermeiden, eine Schraube

gleichen Durchmessers an der ande-

ren Seite einstecken.

2. Demontieren:

lMotor 1

(von der rechten Seite)

HINWEIS:

Sicherstellen, daß zuvor alle Steck-

verbinder, Schläuche und Seilzüge

gelöst worden sind. POINTS DE DEPOSE

Pignon d’entraînement

1. Déposer:

lEcrou (pignon d’entraînement)

1

lRondelle-frein 2

N.B.:

lRedresser la languette de la rondelle-

frein.

lDesserrer l’écrou tout en actionnant le

frein arrière.

2. Déposer:

lPignon d’entraînement 1

lChaîne de transmission 2

N.B.:

Déposer le pignon d’entraînement avec

la chaîne de transmission.

Dépose du moteur

1. Déposer:

lAxe de pivot 1

N.B.:

Si l’on sort complètement l’axe de pivot,

le bras oscillant va tomber. Si possible,

introduire une tige de diamètre équiva-

lent de l’autre côté du bras pour le soute-

nir.

2. Déposer:

lMoteur 1

Du côté droit.

N.B.:

Vérifier que les fiches rapides, tuyaux et

câbles sont déconnectés.PUNTI DI RIMOZIONE

Corona dentata trasmissione

1. Rimuovere:

lDado (corona dentata trasmis-

sione) 1

lRondella di bloccaggio 2

NOTA:

lSpianare la linguetta della rondella di

bloccaggio.

lSvitare il dado agendo sul freno poste-

riore.

2. Rimuovere:

lCorona dentata trasmissione 1

lCatena di trasmissione 2

NOTA:

Rimuovere la corona dentata della tra-

smissione insieme alla catena di trasmis-

sione.

Rimozione del motore

1. Rimuovere:

lAlbero snodato 1

NOTA:

Se l’albero snodato viene spinto comple-

tamente fuori, il forcellone oscillante si

allenta. Se possibile, inserire un albero di

diametro simile nell’altro lato del forcel-

lone oscillante per sostenerlo.

2. Rimuovere:

lMotore 1

Dal lato destro.

NOTA:

Accertarsi che gli accoppiatori, i flessi-

bili ed i cavi siano scollegati.

Page 438 of 686

4 - 86

ENGENGINE REMOVAL

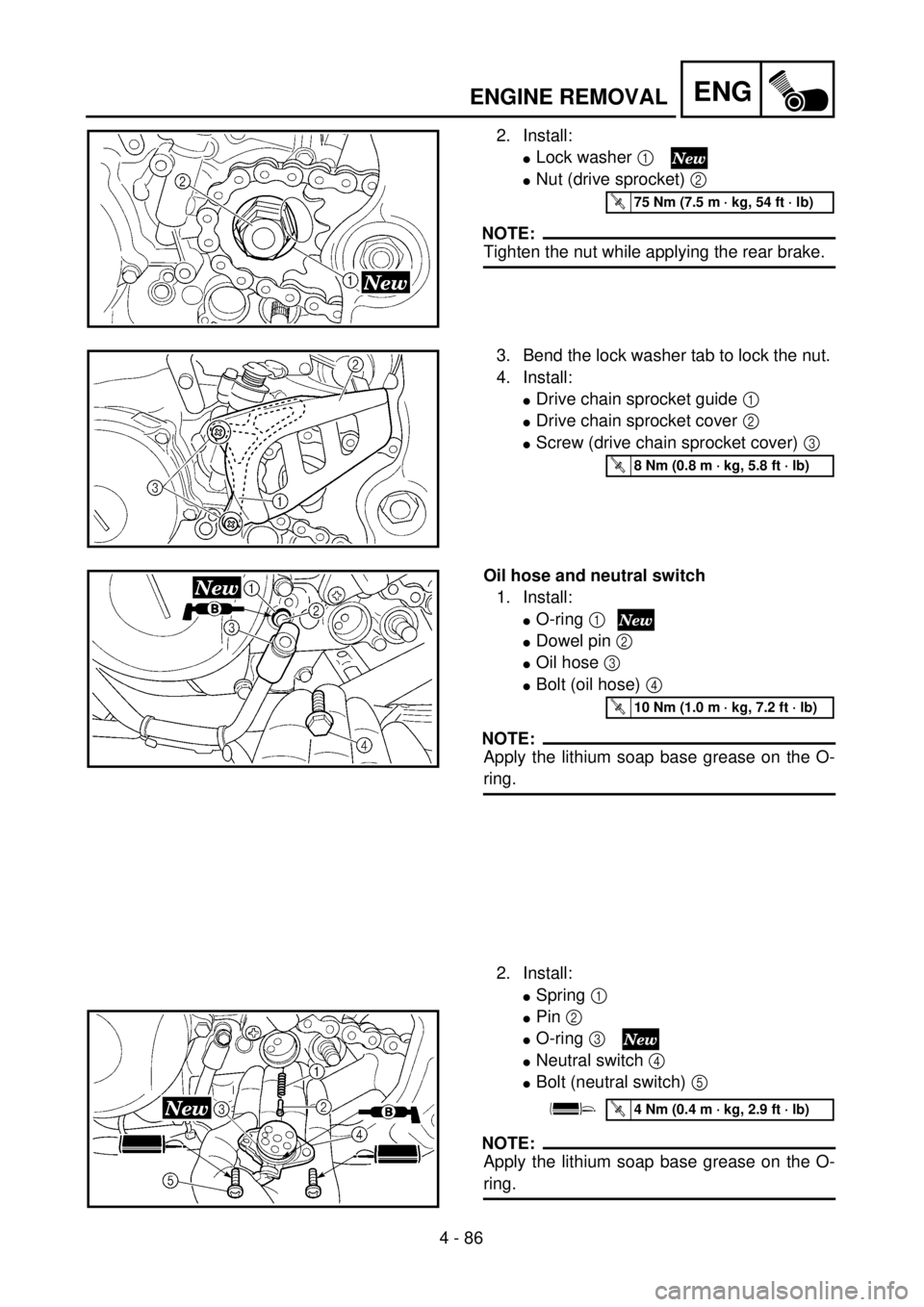

2. Install:

lLock washer 1

lNut (drive sprocket) 2

NOTE:

Tighten the nut while applying the rear brake.

T R..75 Nm (7.5 m · kg, 54 ft · lb)

3. Bend the lock washer tab to lock the nut.

4. Install:

lDrive chain sprocket guide 1

lDrive chain sprocket cover 2

lScrew (drive chain sprocket cover) 3

T R..8 Nm (0.8 m · kg, 5.8 ft · lb)

Oil hose and neutral switch

1. Install:

lO-ring 1

lDowel pin 2

lOil hose 3

lBolt (oil hose) 4

NOTE:

Apply the lithium soap base grease on the O-

ring.

2. Install:

lSpring 1

lPin 2

lO-ring 3

lNeutral switch 4

lBolt (neutral switch) 5

NOTE:

Apply the lithium soap base grease on the O-

ring.

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

T R..4 Nm (0.4 m · kg, 2.9 ft · lb)