brake light YAMAHA WR 250F 2003 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2003, Model line: WR 250F, Model: YAMAHA WR 250F 2003Pages: 860, PDF Size: 35.16 MB

Page 26 of 860

1 - 1

GEN

INFODESCRIPTION

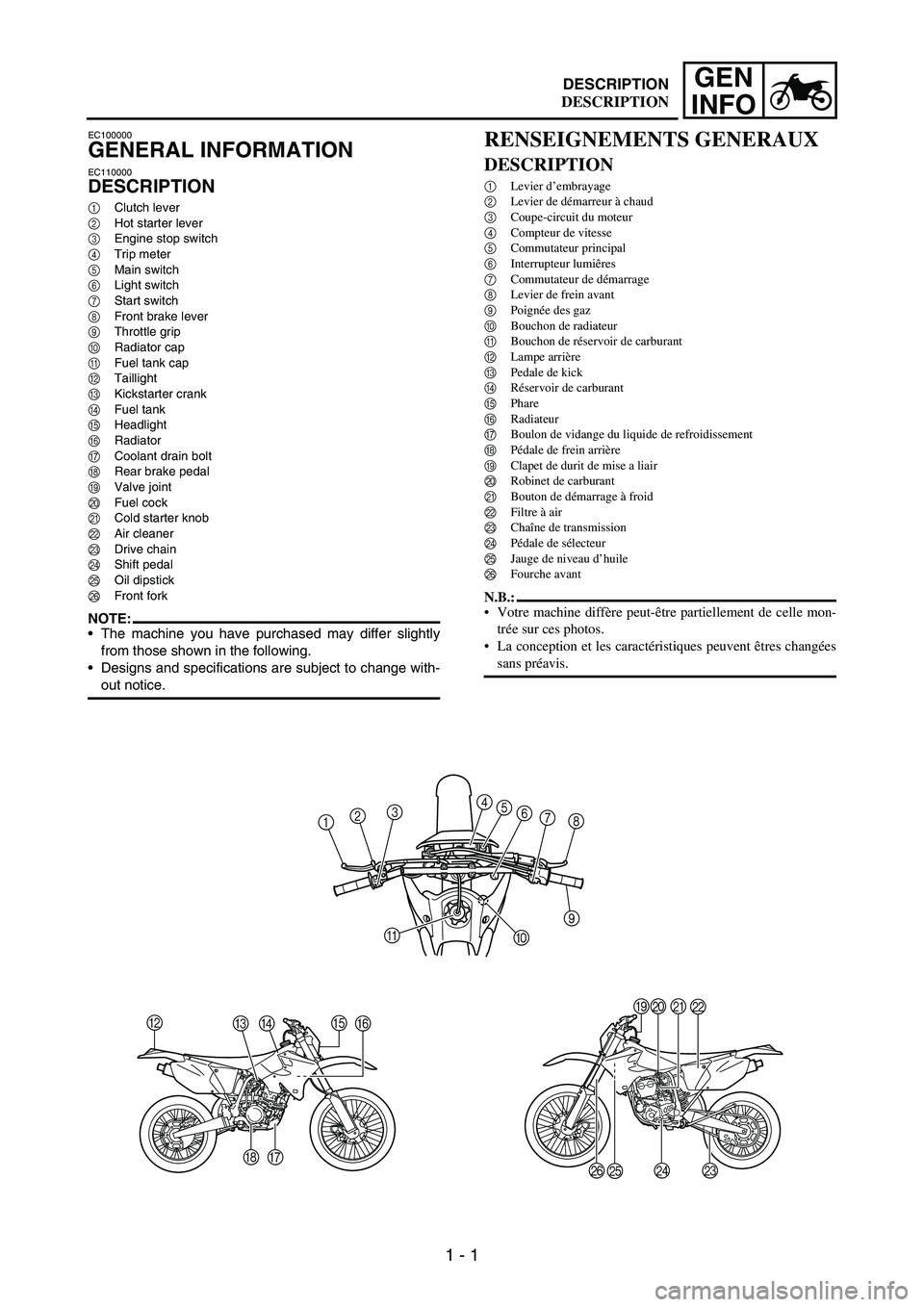

EC100000

GENERAL INFORMATION

EC110000

DESCRIPTION

1Clutch lever

2Hot starter lever

3Engine stop switch

4Trip meter

5Main switch

6Light switch

7Start switch

8Front brake lever

9Throttle grip

0Radiator cap

AFuel tank cap

BTaillight

CKickstarter crank

DFuel tank

EHeadlight

FRadiator

GCoolant drain bolt

HRear brake pedal

IValve joint

JFuel cock

KCold starter knob

LAir cleaner

MDrive chain

NShift pedal

OOil dipstick

PFront fork

NOTE:The machine you have purchased may differ slightly

from those shown in the following.

Designs and specifications are subject to change with-

out notice.

B

CDE

F

G H

1234

5

6

7

8

9

0 A

IJ

K

L

M N

O P

RENSEIGNEMENTS GENERAUX

DESCRIPTION

1Levier d’embrayage

2Levier de démarreur à chaud

3Coupe-circuit du moteur

4Compteur de vitesse

5Commutateur principal

6Interrupteur lumiêres

7Commutateur de démarrage

8Levier de frein avant

9Poignée des gaz

0Bouchon de radiateur

ABouchon de réservoir de carburant

BLampe arrière

CPedale de kick

DRéservoir de carburant

EPhare

FRadiateur

GBoulon de vidange du liquide de refroidissement

HPédale de frein arrière

IClapet de durit de mise a liair

JRobinet de carburant

KBouton de démarrage à froid

LFiltre à air

MChaîne de transmission

NPédale de sélecteur

OJauge de niveau d’huile

PFourche avant

N.B.:

Votre machine diffère peut-être partiellement de celle mon-

trée sur ces photos.

La conception et les caractéristiques peuvent êtres changées

sans préavis.

DESCRIPTION

Page 54 of 860

1 - 29

GEN

INFO

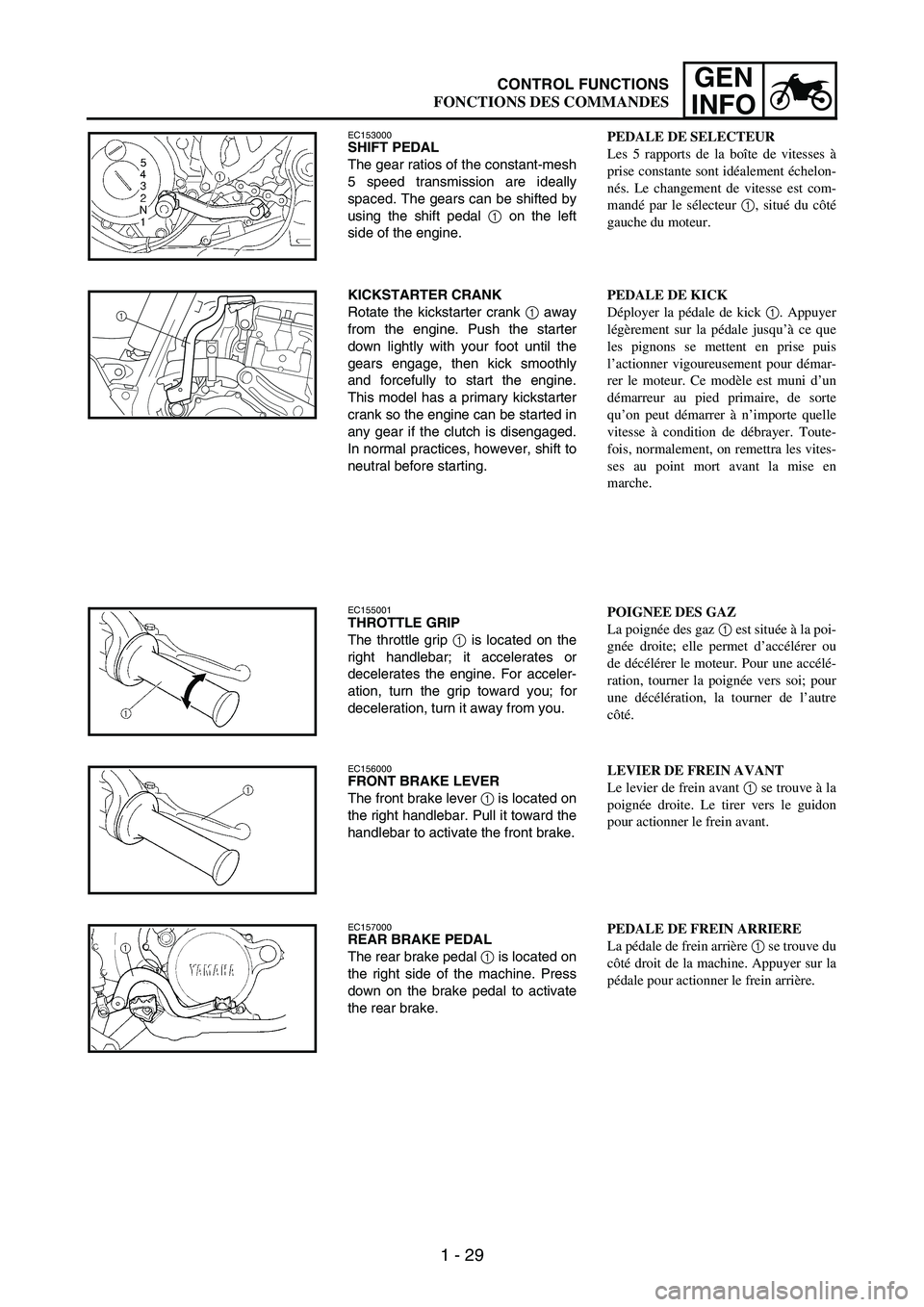

EC153000SHIFT PEDAL

The gear ratios of the constant-mesh

5 speed transmission are ideally

spaced. The gears can be shifted by

using the shift pedal

1 on the left

side of the engine.

KICKSTARTER CRANK

Rotate the kickstarter crank

1 away

from the engine. Push the starter

down lightly with your foot until the

gears engage, then kick smoothly

and forcefully to start the engine.

This model has a primary kickstarter

crank so the engine can be started in

any gear if the clutch is disengaged.

In normal practices, however, shift to

neutral before starting.

1

EC155001THROTTLE GRIP

The throttle grip

1 is located on the

right handlebar; it accelerates or

decelerates the engine. For acceler-

ation, turn the grip toward you; for

deceleration, turn it away from you.

EC156000FRONT BRAKE LEVER

The front brake lever

1 is located on

the right handlebar. Pull it toward the

handlebar to activate the front brake.

EC157000REAR BRAKE PEDAL

The rear brake pedal

1 is located on

the right side of the machine. Press

down on the brake pedal to activate

the rear brake.

PEDALE DE SELECTEUR

Les 5 rapports de la boîte de vitesses à

prise constante sont idéalement échelon-

nés. Le changement de vitesse est com-

mandé par le sélecteur 1, situé du côté

gauche du moteur.

PEDALE DE KICK

Déployer la pédale de kick 1. Appuyer

légèrement sur la pédale jusqu’à ce que

les pignons se mettent en prise puis

l’actionner vigoureusement pour démar-

rer le moteur. Ce modèle est muni d’un

démarreur au pied primaire, de sorte

qu’on peut démarrer à n’importe quelle

vitesse à condition de débrayer. Toute-

fois, normalement, on remettra les vites-

ses au point mort avant la mise en

marche.

POIGNEE DES GAZ

La poignée des gaz 1 est située à la poi-

gnée droite; elle permet d’accélérer ou

de décélérer le moteur. Pour une accélé-

ration, tourner la poignée vers soi; pour

une décélération, la tourner de l’autre

côté.

LEVIER DE FREIN AVANT

Le levier de frein avant 1 se trouve à la

poignée droite. Le tirer vers le guidon

pour actionner le frein avant.

PEDALE DE FREIN ARRIERE

La pédale de frein arrière 1 se trouve du

côté droit de la machine. Appuyer sur la

pédale pour actionner le frein arrière.

CONTROL FUNCTIONS

FONCTIONS DES COMMANDES

Page 82 of 860

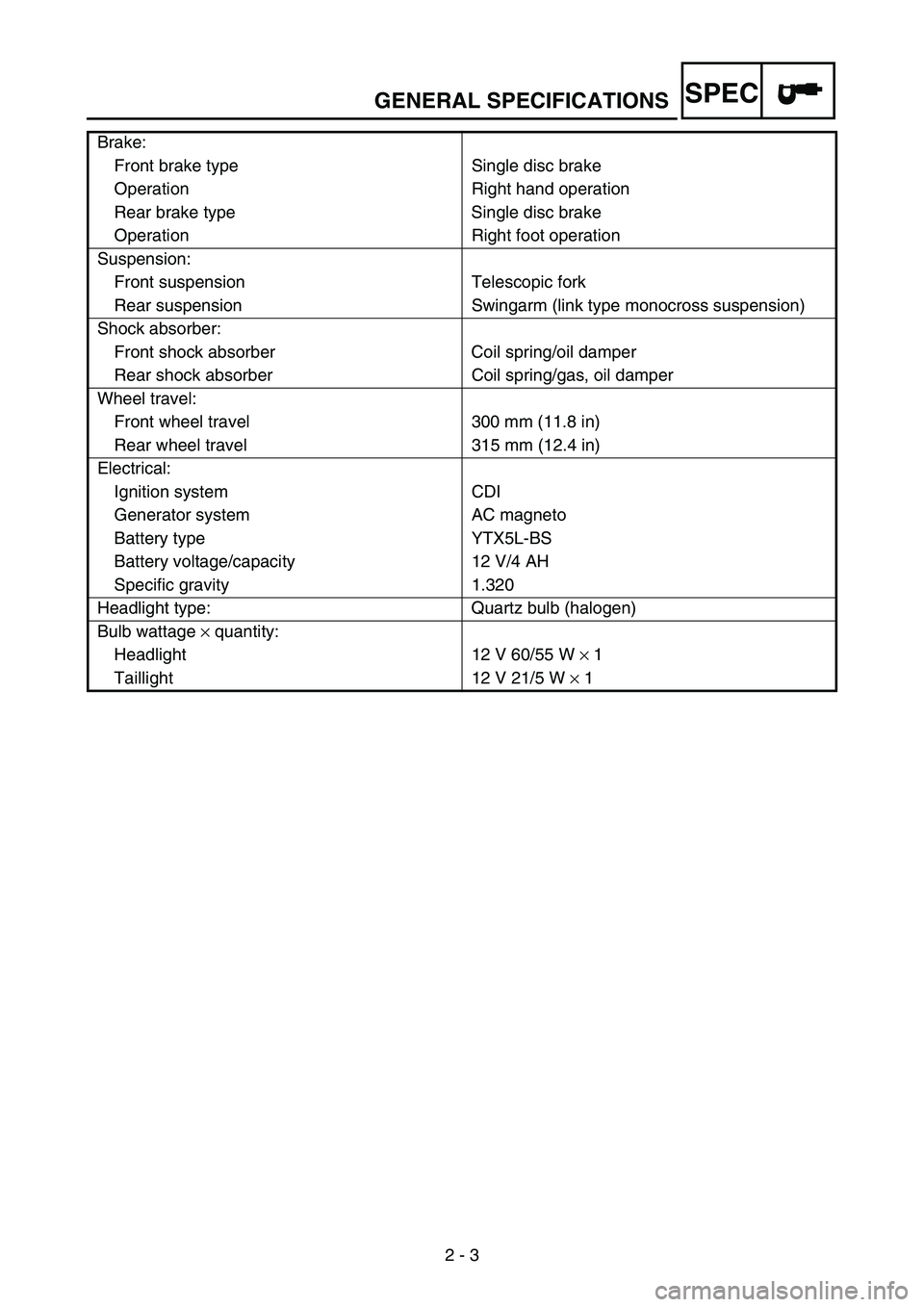

GENERAL SPECIFICATIONS

2 - 3

SPEC

Brake:

Front brake type Single disc brake

Operation Right hand operation

Rear brake type Single disc brake

Operation Right foot operation

Suspension:

Front suspension Telescopic fork

Rear suspension Swingarm (link type monocross suspension)

Shock absorber:

Front shock absorber Coil spring/oil damper

Rear shock absorber Coil spring/gas, oil damper

Wheel travel:

Front wheel travel 300 mm (11.8 in)

Rear wheel travel 315 mm (12.4 in)

Electrical:

Ignition system CDI

Generator system AC magneto

Battery type YTX5L-BS

Battery voltage/capacity 12 V/4 AH

Specific gravity 1.320

Headlight type: Quartz bulb (halogen)

Bulb wattage × quantity:

Headlight 12 V 60/55 W × 1

Taillight 12 V 21/5 W × 1

Page 93 of 860

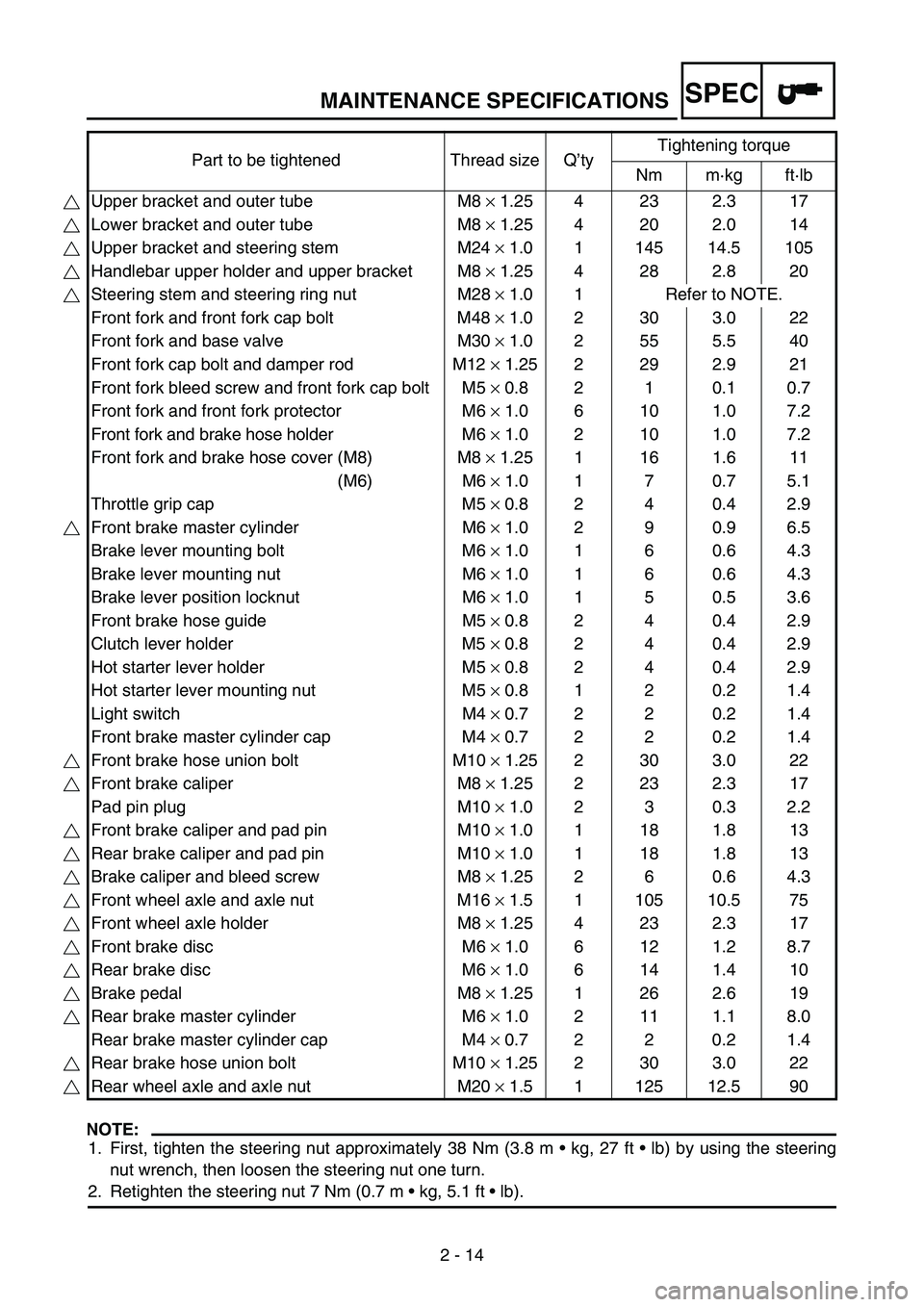

MAINTENANCE SPECIFICATIONS

2 - 14

SPEC

NOTE:

1. First, tighten the steering nut approximately 38 Nm (3.8 m kg, 27 ft lb) by using the steering

nut wrench, then loosen the steering nut one turn.

2. Retighten the steering nut 7 Nm (0.7 m kg, 5.1 ft lb). Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Upper bracket and outer tube M8 × 1.25 4 23 2.3 17

Lower bracket and outer tube M8 × 1.25 4 20 2.0 14

Upper bracket and steering stem M24 × 1.0 1 145 14.5 105

Handlebar upper holder and upper bracket M8 × 1.25 4 28 2.8 20

Steering stem and steering ring nut M28 × 1.0 1 Refer to NOTE.

Front fork and front fork cap bolt M48 × 1.0 2 30 3.0 22

Front fork and base valve M30 × 1.0 2 55 5.5 40

Front fork cap bolt and damper rod M12 × 1.25 2 29 2.9 21

Front fork bleed screw and front fork cap bolt M5 × 0.8 2 1 0.1 0.7

Front fork and front fork protector M6 × 1.0 6 10 1.0 7.2

Front fork and brake hose holder M6 × 1.0 2 10 1.0 7.2

Front fork and brake hose cover (M8) M8 × 1.25 1 16 1.6 11

(M6) M6 × 1.0 1 7 0.7 5.1

Throttle grip cap M5 × 0.8 2 4 0.4 2.9

Front brake master cylinder M6 × 1.0 2 9 0.9 6.5

Brake lever mounting bolt M6 × 1.0 1 6 0.6 4.3

Brake lever mounting nut M6 × 1.0 1 6 0.6 4.3

Brake lever position locknut M6 × 1.0 1 5 0.5 3.6

Front brake hose guide M5 × 0.8 2 4 0.4 2.9

Clutch lever holder M5 × 0.8 2 4 0.4 2.9

Hot starter lever holder M5 × 0.8 2 4 0.4 2.9

Hot starter lever mounting nut M5 × 0.8 1 2 0.2 1.4

Light switch M4 × 0.7 2 2 0.2 1.4

Front brake master cylinder cap M4 × 0.7 2 2 0.2 1.4

Front brake hose union bolt M10 × 1.25 2 30 3.0 22

Front brake caliper M8 × 1.25 2 23 2.3 17

Pad pin plug M10 × 1.0 2 3 0.3 2.2

Front brake caliper and pad pin M10 × 1.0 1 18 1.8 13

Rear brake caliper and pad pin M10 × 1.0 1 18 1.8 13

Brake caliper and bleed screw M8 × 1.25 2 6 0.6 4.3

Front wheel axle and axle nut M16 × 1.5 1 105 10.5 75

Front wheel axle holder M8 × 1.25 4 23 2.3 17

Front brake disc M6 × 1.0 6 12 1.2 8.7

Rear brake disc M6 × 1.0 6 14 1.4 10

Brake pedal M8 × 1.25 1 26 2.6 19

Rear brake master cylinder M6 × 1.0 2 11 1.1 8.0

Rear brake master cylinder cap M4 × 0.7 2 2 0.2 1.4

Rear brake hose union bolt M10 × 1.25 2 30 3.0 22

Rear wheel axle and axle nut M20 × 1.5 1 125 12.5 90

Page 94 of 860

MAINTENANCE SPECIFICATIONS

2 - 15

SPEC

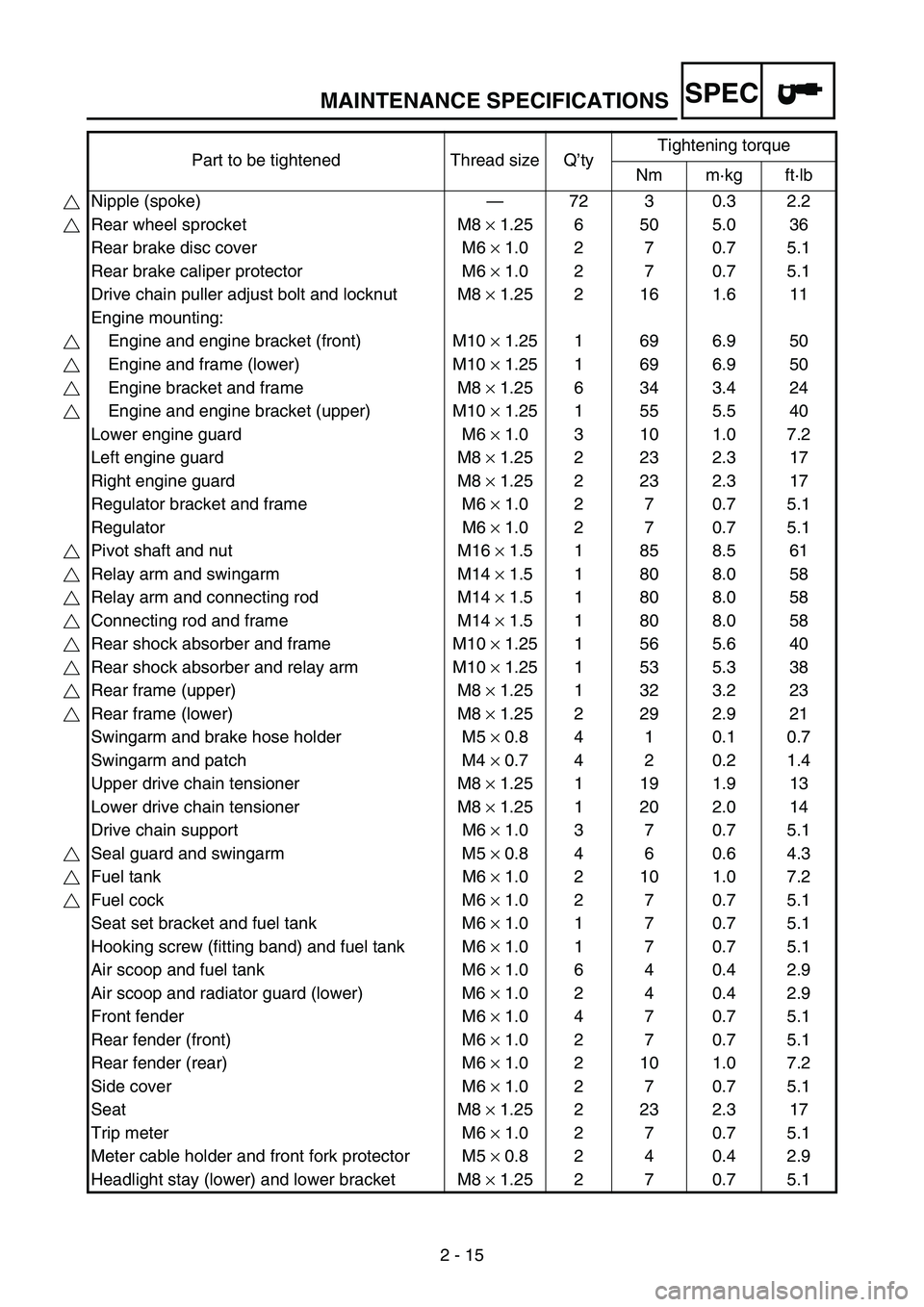

Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Nipple (spoke)—72 3 0.3 2.2

Rear wheel sprocket M8 × 1.25 6 50 5.0 36

Rear brake disc cover M6 × 1.0 2 7 0.7 5.1

Rear brake caliper protector M6 × 1.0 2 7 0.7 5.1

Drive chain puller adjust bolt and locknut M8 × 1.25 2 16 1.6 11

Engine mounting:

Engine and engine bracket (front) M10 × 1.25 1 69 6.9 50

Engine and frame (lower) M10 × 1.25 1 69 6.9 50

Engine bracket and frame M8 × 1.25 6 34 3.4 24

Engine and engine bracket (upper) M10 × 1.25 1 55 5.5 40

Lower engine guard M6 × 1.0 3 10 1.0 7.2

Left engine guard M8 × 1.25 2 23 2.3 17

Right engine guard M8 × 1.25 2 23 2.3 17

Regulator bracket and frame M6 × 1.0 2 7 0.7 5.1

Regulator M6 × 1.0 2 7 0.7 5.1

Pivot shaft and nut M16 × 1.5 1 85 8.5 61

Relay arm and swingarm M14 × 1.5 1 80 8.0 58

Relay arm and connecting rod M14 × 1.5 1 80 8.0 58

Connecting rod and frame M14 × 1.5 1 80 8.0 58

Rear shock absorber and frame M10 × 1.25 1 56 5.6 40

Rear shock absorber and relay arm M10 × 1.25 1 53 5.3 38

Rear frame (upper) M8 × 1.25 1 32 3.2 23

Rear frame (lower) M8 × 1.25 2 29 2.9 21

Swingarm and brake hose holder M5 × 0.8 4 1 0.1 0.7

Swingarm and patch M4 × 0.7 4 2 0.2 1.4

Upper drive chain tensioner M8 × 1.25 1 19 1.9 13

Lower drive chain tensioner M8 × 1.25 1 20 2.0 14

Drive chain support M6 × 1.0 3 7 0.7 5.1

Seal guard and swingarm M5 × 0.8 4 6 0.6 4.3

Fuel tank M6 × 1.0 2 10 1.0 7.2

Fuel cock M6 × 1.0 2 7 0.7 5.1

Seat set bracket and fuel tank M6 × 1.0 1 7 0.7 5.1

Hooking screw (fitting band) and fuel tank M6 × 1.0 1 7 0.7 5.1

Air scoop and fuel tank M6 × 1.0 6 4 0.4 2.9

Air scoop and radiator guard (lower) M6 × 1.0 2 4 0.4 2.9

Front fender M6 × 1.0 4 7 0.7 5.1

Rear fender (front) M6 × 1.0 2 7 0.7 5.1

Rear fender (rear) M6 × 1.0 2 10 1.0 7.2

Side cover M6 × 1.0 2 7 0.7 5.1

Seat M8 × 1.25 2 23 2.3 17

Trip meter M6 × 1.0 2 7 0.7 5.1

Meter cable holder and front fork protector M5 × 0.8 2 4 0.4 2.9

Headlight stay (lower) and lower bracket M8 × 1.25 2 7 0.7 5.1

Page 176 of 860

SPEC

2 - 97

CABLE ROUTING DIAGRAM

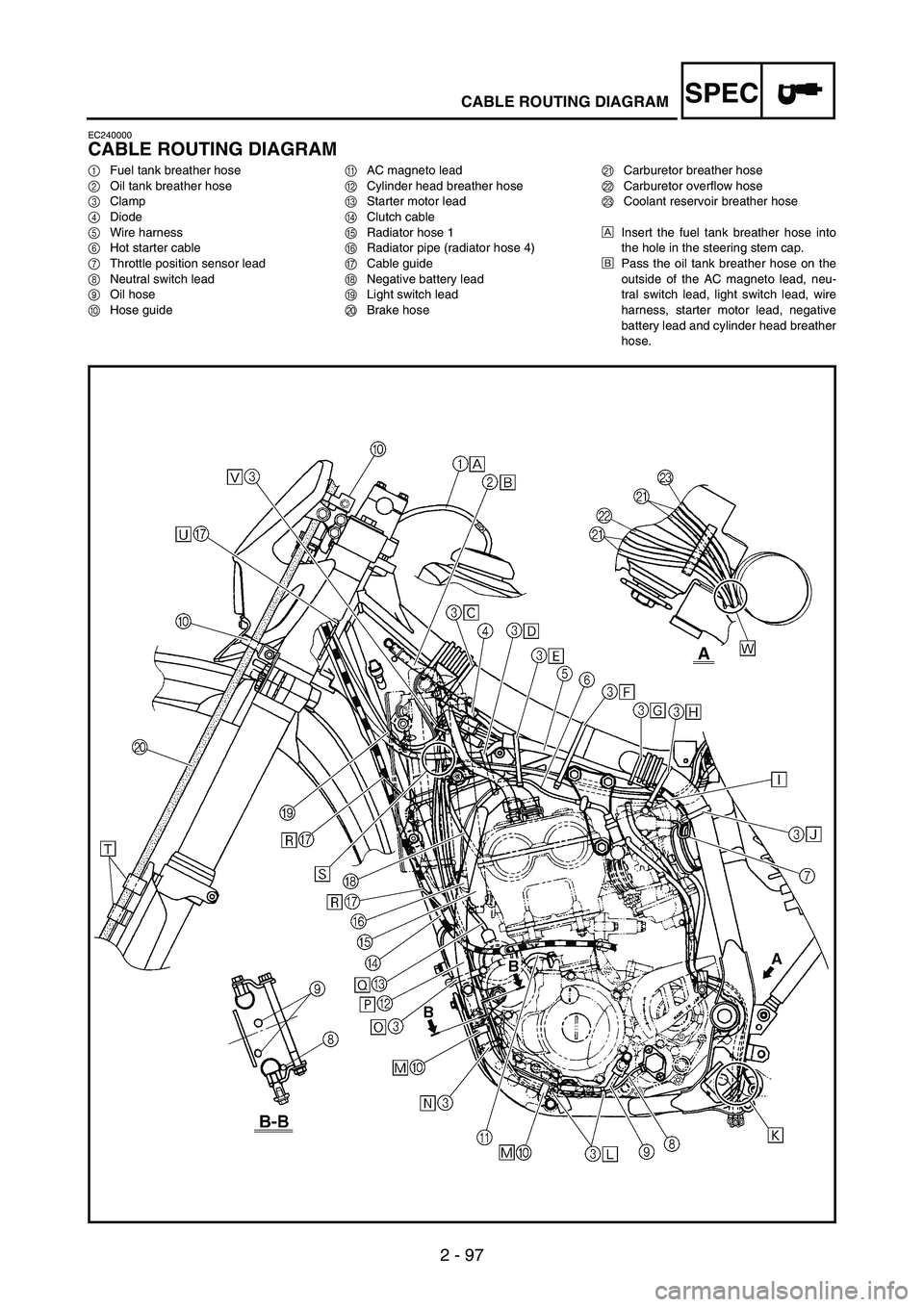

EC240000

CABLE ROUTING DIAGRAM

1Fuel tank breather hose

2Oil tank breather hose

3Clamp

4Diode

5Wire harness

6Hot starter cable

7Throttle position sensor lead

8Neutral switch lead

9Oil hose

0Hose guideAAC magneto lead

BCylinder head breather hose

CStarter motor lead

DClutch cable

ERadiator hose 1

FRadiator pipe (radiator hose 4)

GCable guide

HNegative battery lead

ILight switch lead

JBrake hoseKCarburetor breather hose

LCarburetor overflow hose

MCoolant reservoir breather hose

ÈInsert the fuel tank breather hose into

the hole in the steering stem cap.

ÉPass the oil tank breather hose on the

outside of the AC magneto lead, neu-

tral switch lead, light switch lead, wire

harness, starter motor lead, negative

battery lead and cylinder head breather

hose.

Page 180 of 860

SPEC

2 - 101

CABLE ROUTING DIAGRAM

ÖFasten the neutral switch lead and AC magneto lead.

×Pass the cylinder head breather hose on the inside of the radi-

ator hose 1 and on the outside of the radiator pipe (radiator

hose 4). Make sure that the cylinder head breather hose does

not go forward of the chassis.

ØPass the starter motor lead in front of the radiator hose 4.

ÙPass the clutch cable through the cable guide.

ÚPass the wire harness on the outside of the neutral switch lead

and AC magneto lead.

ÛFit the brake hose into the guides on the protector.

ÜPass the wire harness, clutch cable and light switch lead

through the cable guide.ÝFasten the AC magneto lead, neutral switch lead and light

switch lead to the cable guide at their protecting tube with a

plastic locking tie and cut off the tie end.

ÞPass the carburetor breather hoses, carburetor overflow hose

and coolant reservoir breather hose so that the hoses do not

contact the rear shock absorber.

Page 186 of 860

SPEC

2 - 107

CABLE ROUTING DIAGRAM

1Brake master cylinder

2Brake hose holder

3Brake hoseÈInstall the brake hose so that its pipe portion directs as shown

and lightly touches the projection on the brake caliper.

ÉPass the brake hose into the brake hose holders.

ÊIf the brake hose contacts the spring (rear shock absorber),

correct its twist.

ËInstall the brake hose so that its pipe portion directs as shown

and lightly touches the projection on the brake master cylinder.

Page 190 of 860

SPEC

2 - 111

CABLE ROUTING DIAGRAM

1Throttle cable

2Brake hose

3Clamp

4Light switch lead

5Hot starter cable

6Clutch cable

7Hose guide

8Clutch switch lead

9Engine stop switch lead

0Trip meter cable

AMain switch lead

BTrip meter

CMain switchDLight switch

EStart switch lead

ÈFasten the start switch lead and light switch lead.

ÉFasten the engine stop switch lead and clutch switch lead.

ÊPass the brake hose through the hose guide.

ËPass the start switch lead in front of the main switch lead.

ÌFasten the start switch lead.

ÍPass the hot starter cable, clutch cable and light switch lead

between the upper bracket and coupler bracket.

ÎPass the throttle cables between the upper bracket and trip

meter.

Page 296 of 860

3 - 105

INSP

ADJ

GRAISSAGE

Pour assurer le bon fonctionnement de

tous les organes, graisser la machine lors

du montage, après le rodage et après cha-

que course.

1

Tous les câbles de commande

2

Pivot de levier d’embrayage

3

Pivot de pédale de changement de

vitesse

4

Pivots de repose-pied

5

Surface de contact entre le guidon et la

poignée des gaz

6

Chaîne de transmission

7

Partie d’enroulement du câble dans le

guide de tube

8

Extrémité de câble des gaz

9

Extrémités des câbles d’embrayage

0

Extrémité du câble de démarreur à chaud

È

Mettre du lubrifiant Yamaha pour câbles,

ou équivalent sur ces parties.

É

Utiliser de l’huile moteur SAE 10W-30

ou un lubrifiant pour chaînes adéquat.

Ê

Lubrifier les emplacements suivants à

l’aide d’un détergent gras léger à base de

lithium et de haute qualité.

ATTENTION:

Eliminer tout excès de graisse, et évi-

ter d’enduire de graisse les disques de

frein.

CHASSIS

PARTIE CYCLE

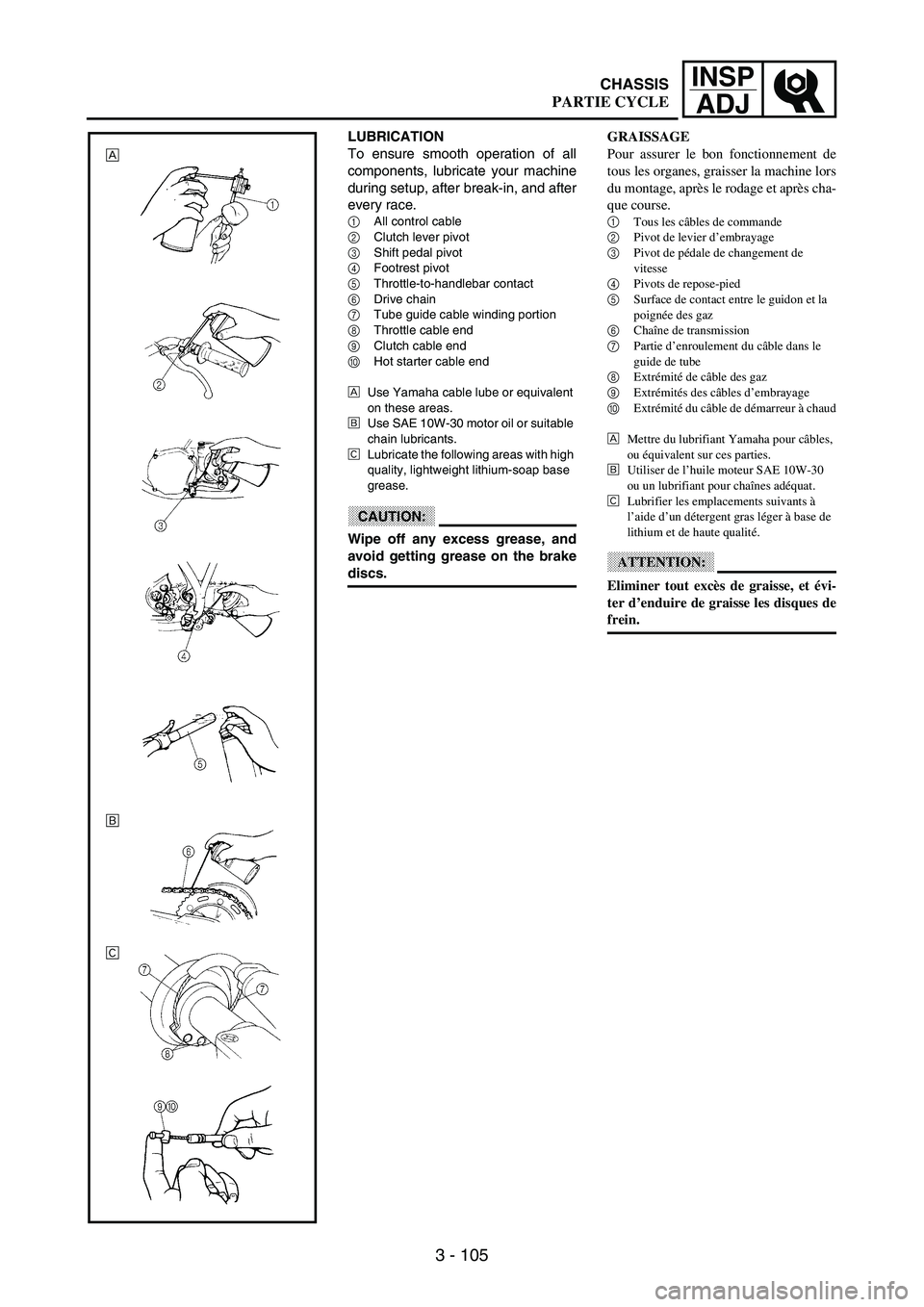

LUBRICATION

To ensure smooth operation of all

components, lubricate your machine

during setup, after break-in, and after

every race.

1All control cable

2Clutch lever pivot

3Shift pedal pivot

4Footrest pivot

5Throttle-to-handlebar contact

6Drive chain

7Tube guide cable winding portion

8Throttle cable end

9Clutch cable end

0Hot starter cable end

ÈUse Yamaha cable lube or equivalent

on these areas.

ÉUse SAE 10W-30 motor oil or suitable

chain lubricants.

ÊLubricate the following areas with high

quality, lightweight lithium-soap base

grease.

CAUTION:

Wipe off any excess grease, and

avoid getting grease on the brake

discs.

È

É

Ê