engine YAMAHA WR 250F 2007 Owner's Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2007, Model line: WR 250F, Model: YAMAHA WR 250F 2007Pages: 912, PDF Size: 23.95 MB

Page 212 of 912

3 - 1

INSP

ADJ

MAINTENANCE INTERVALS

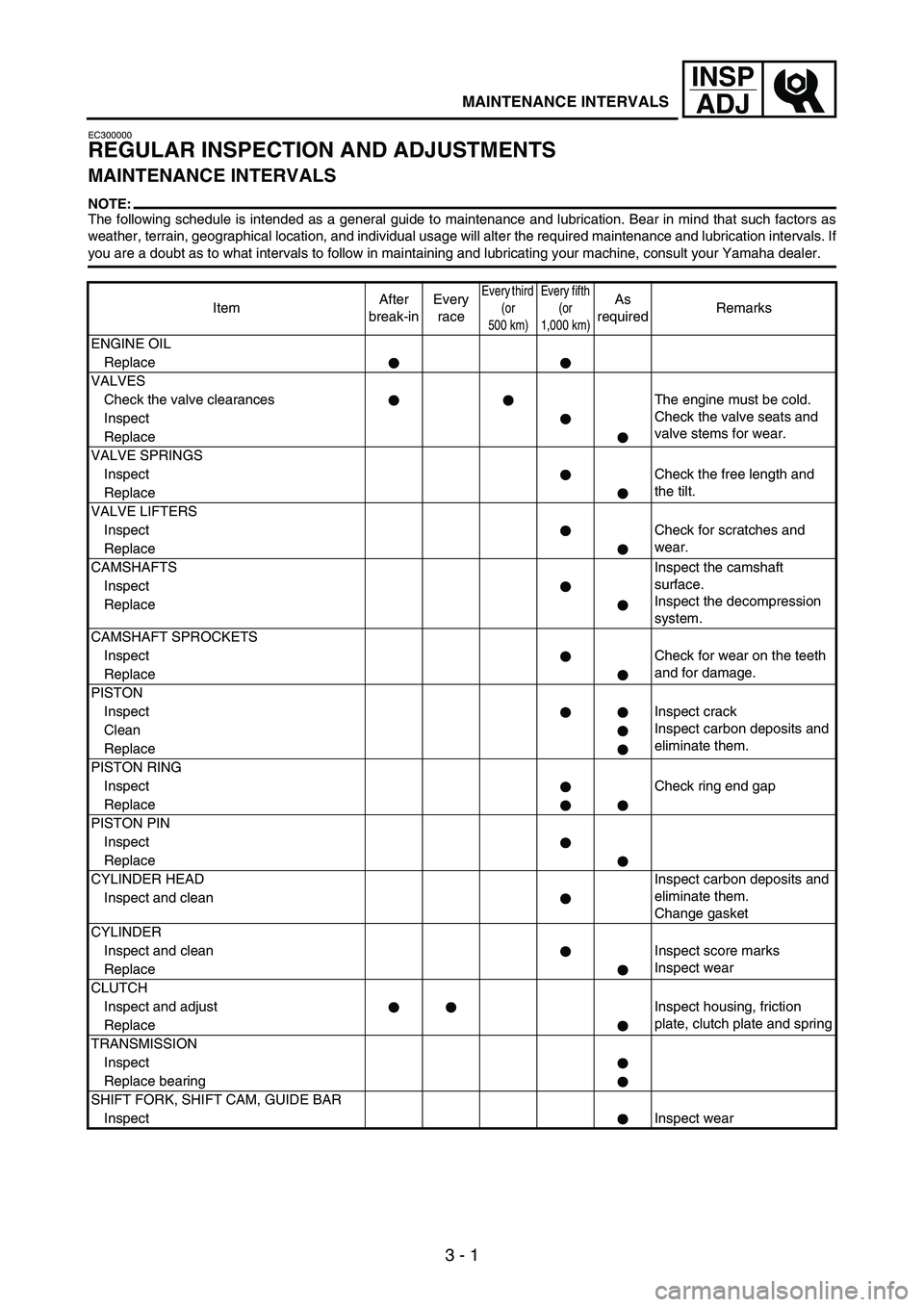

EC300000

REGULAR INSPECTION AND ADJUSTMENTS

MAINTENANCE INTERVALS

NOTE:The following schedule is intended as a general guide to maintenance and lubrication. Bear in mind that such factors as

weather, terrain, geographical location, and individual usage will alter the required maintenance and lubrication intervals. If

you are a doubt as to what intervals to follow in maintaining and lubricating your machine, consult your Yamaha dealer.

ItemAfter

break-inEvery

race

Every third

(or

500 km)Every fifth

(or

1,000 km)As

requiredRemarks

ENGINE OIL

Replace

VALVES

Check the valve clearances The engine must be cold.

Check the valve seats and

valve stems for wear. Inspect

Replace

VALVE SPRINGS

InspectCheck the free length and

the tilt.

Replace

VALVE LIFTERS

InspectCheck for scratches and

wear.

Replace

CAMSHAFTSInspect the camshaft

surface.

Inspect the decompression

system. Inspect

Replace

CAMSHAFT SPROCKETS

InspectCheck for wear on the teeth

and for damage.

Replace

PISTON

InspectInspect crack

Inspect carbon deposits and

eliminate them. Clean

Replace

PISTON RING

InspectCheck ring end gap

Replace

PISTON PIN

Inspect

Replace

CYLINDER HEADInspect carbon deposits and

eliminate them.

Change gasket Inspect and clean

CYLINDER

Inspect and clean Inspect score marks

Inspect wear

Replace

CLUTCH

Inspect and adjust Inspect housing, friction

plate, clutch plate and spring

Replace

TRANSMISSION

Inspect

Replace bearing

SHIFT FORK, SHIFT CAM, GUIDE BAR

InspectInspect wear

Page 227 of 912

3 - 16

INSP

ADJ

PRE-OPERATION INSPECTION AND MAINTENANCE

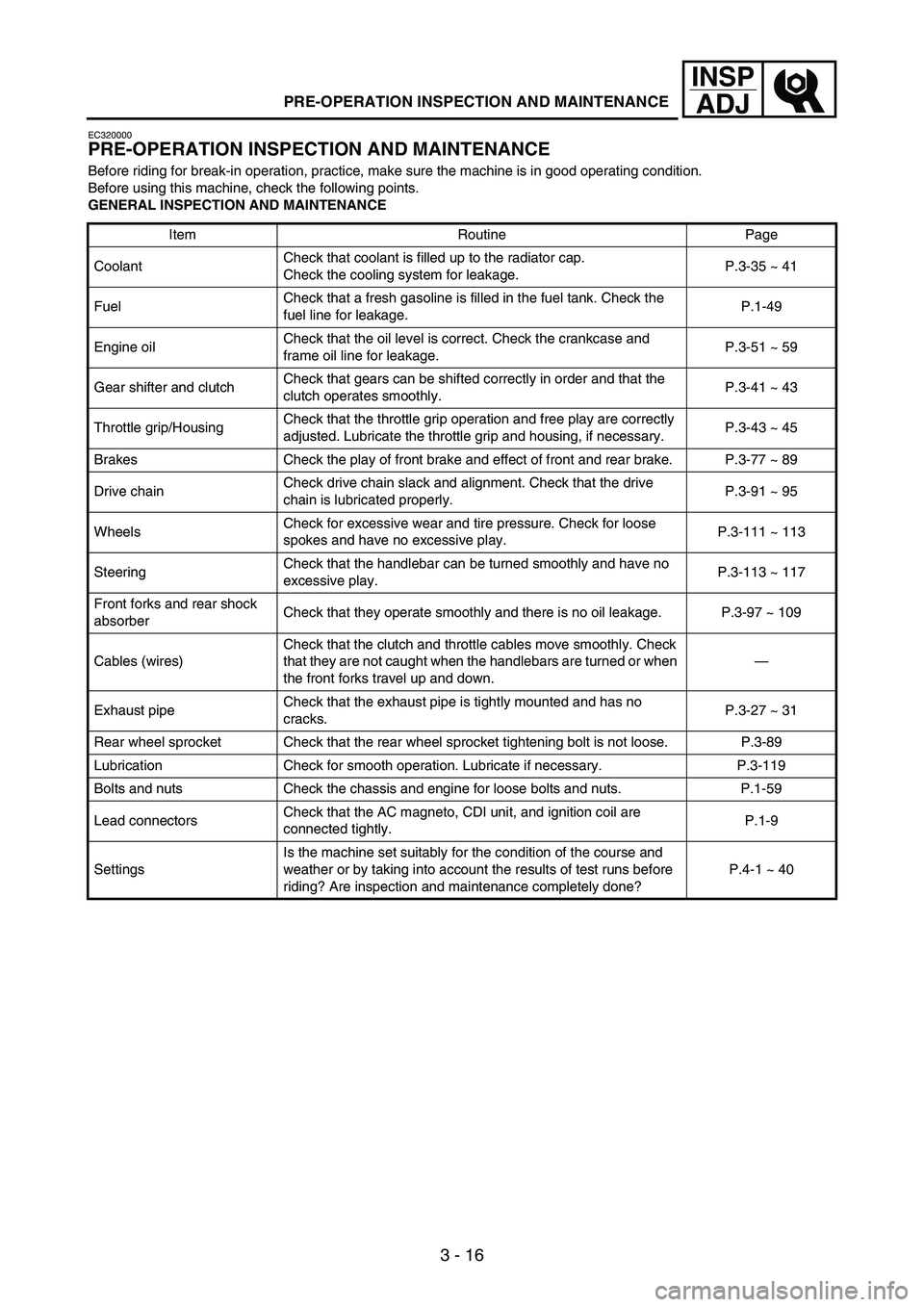

EC320000

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice, make sure the machine is in good operating condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCE

Item Routine Page

CoolantCheck that coolant is filled up to the radiator cap.

Check the cooling system for leakage.P.3-35 ~ 41

FuelCheck that a fresh gasoline is filled in the fuel tank. Check the

fuel line for leakage.P.1-49

Engine oilCheck that the oil level is correct. Check the crankcase and

frame oil line for leakage.P.3-51 ~ 59

Gear shifter and clutchCheck that gears can be shifted correctly in order and that the

clutch operates smoothly.P.3-41 ~ 43

Throttle grip/HousingCheck that the throttle grip operation and free play are correctly

adjusted. Lubricate the throttle grip and housing, if necessary.P.3-43 ~ 45

Brakes Check the play of front brake and effect of front and rear brake. P.3-77 ~ 89

Drive chainCheck drive chain slack and alignment. Check that the drive

chain is lubricated properly.P.3-91 ~ 95

WheelsCheck for excessive wear and tire pressure. Check for loose

spokes and have no excessive play.P.3-111 ~ 113

SteeringCheck that the handlebar can be turned smoothly and have no

excessive play.P.3-113 ~ 117

Front forks and rear shock

absorberCheck that they operate smoothly and there is no oil leakage. P.3-97 ~ 109

Cables (wires)Check that the clutch and throttle cables move smoothly. Check

that they are not caught when the handlebars are turned or when

the front forks travel up and down.—

Exhaust pipeCheck that the exhaust pipe is tightly mounted and has no

cracks.P.3-27 ~ 31

Rear wheel sprocket Check that the rear wheel sprocket tightening bolt is not loose. P.3-89

Lubrication Check for smooth operation. Lubricate if necessary. P.3-119

Bolts and nuts Check the chassis and engine for loose bolts and nuts. P.1-59

Lead connectorsCheck that the AC magneto, CDI unit, and ignition coil are

connected tightly.P.1-9

SettingsIs the machine set suitably for the condition of the course and

weather or by taking into account the results of test runs before

riding? Are inspection and maintenance completely done?P.4-1 ~ 40

Page 232 of 912

INSP

ADJ

3 - 21

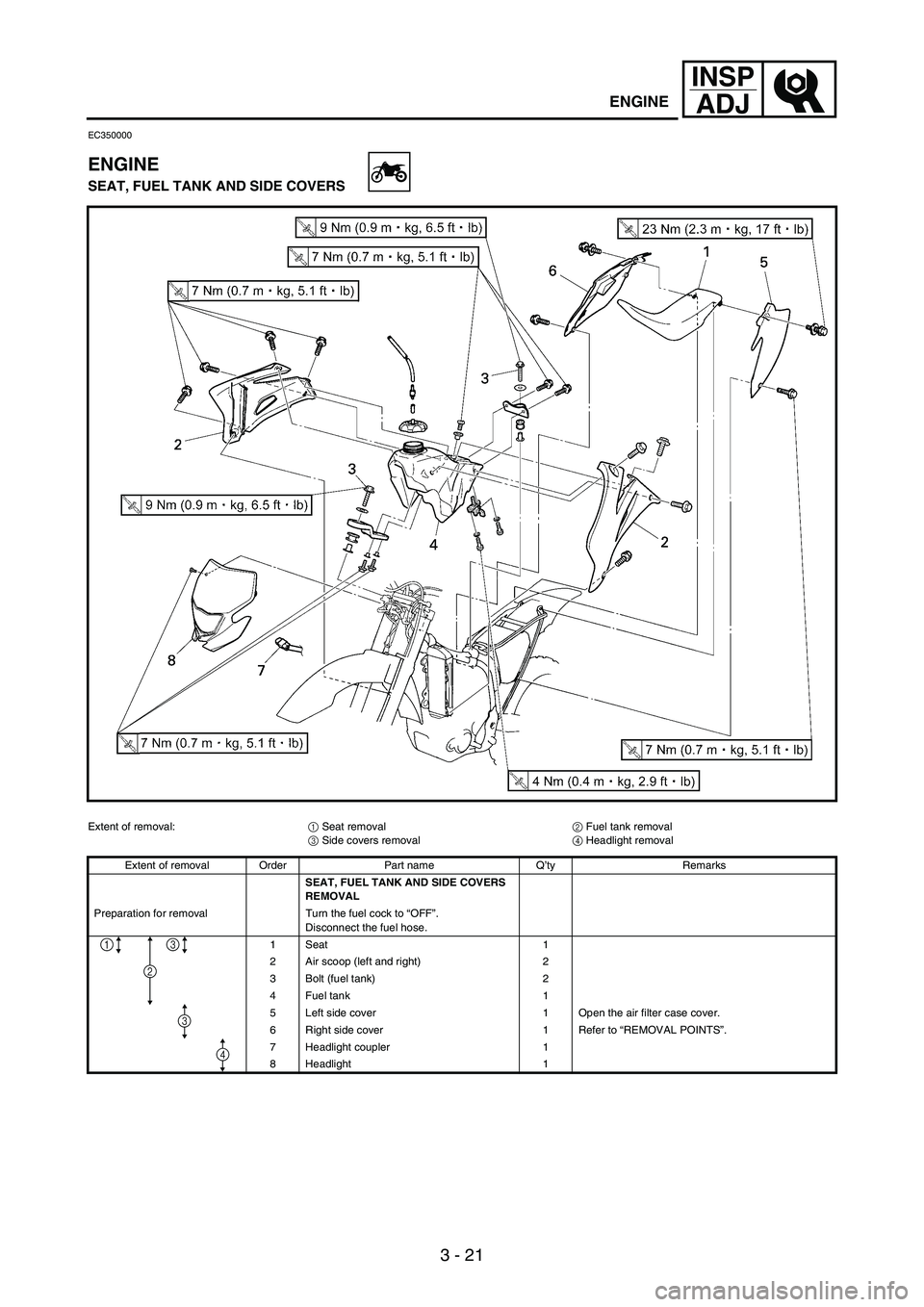

EC350000

ENGINE

SEAT, FUEL TANK AND SIDE COVERS

Extent of removal:

1 Seat removal

2 Fuel tank removal

3 Side covers removal

4 Headlight removal

Extent of removal Order Part name Q’ty Remarks

SEAT, FUEL TANK AND SIDE COVERS

REMOVAL

Preparation for removal Turn the fuel cock to “OFF”.

Disconnect the fuel hose.

1Seat 1

2 Air scoop (left and right) 2

3 Bolt (fuel tank) 2

4 Fuel tank 1

5 Left side cover 1 Open the air filter case cover.

6 Right side cover 1 Refer to “REMOVAL POINTS”.

7 Headlight coupler 1

8 Headlight 1

2

13

4

3

ENGINE

Page 236 of 912

3 - 25

INSP

ADJ

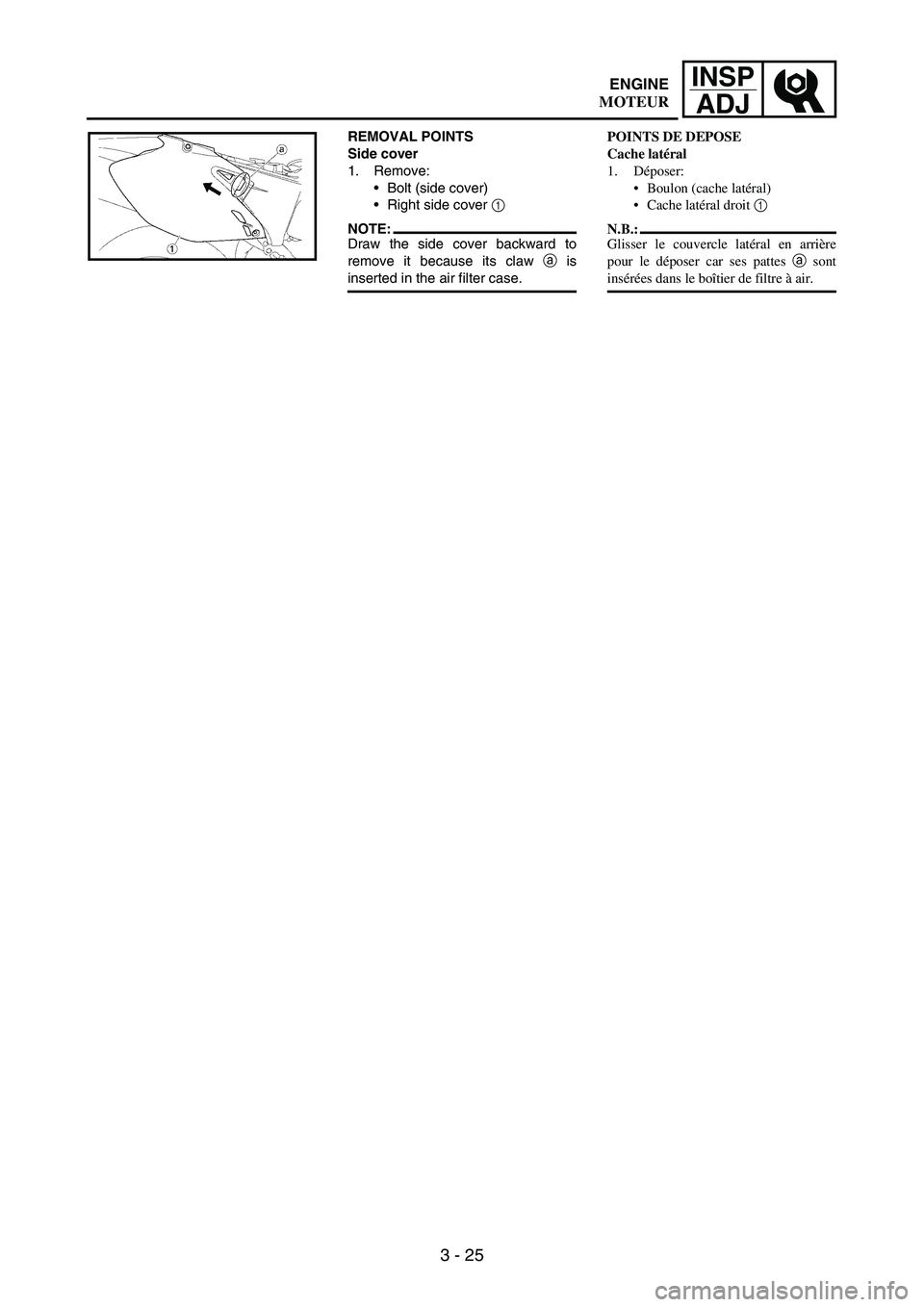

REMOVAL POINTS

Side cover

1. Remove:

Bolt (side cover)

Right side cover

1

NOTE:Draw the side cover backward to

remove it because its claw

a is

inserted in the air filter case.

POINTS DE DEPOSE

Cache latéral

1. Déposer:

Boulon (cache latéral)

Cache latéral droit 1

N.B.:

Glisser le couvercle latéral en arrière

pour le déposer car ses pattes a sont

insérées dans le boîtier de filtre à air.

ENGINE

MOTEUR

Page 238 of 912

INSP

ADJ

3 - 27

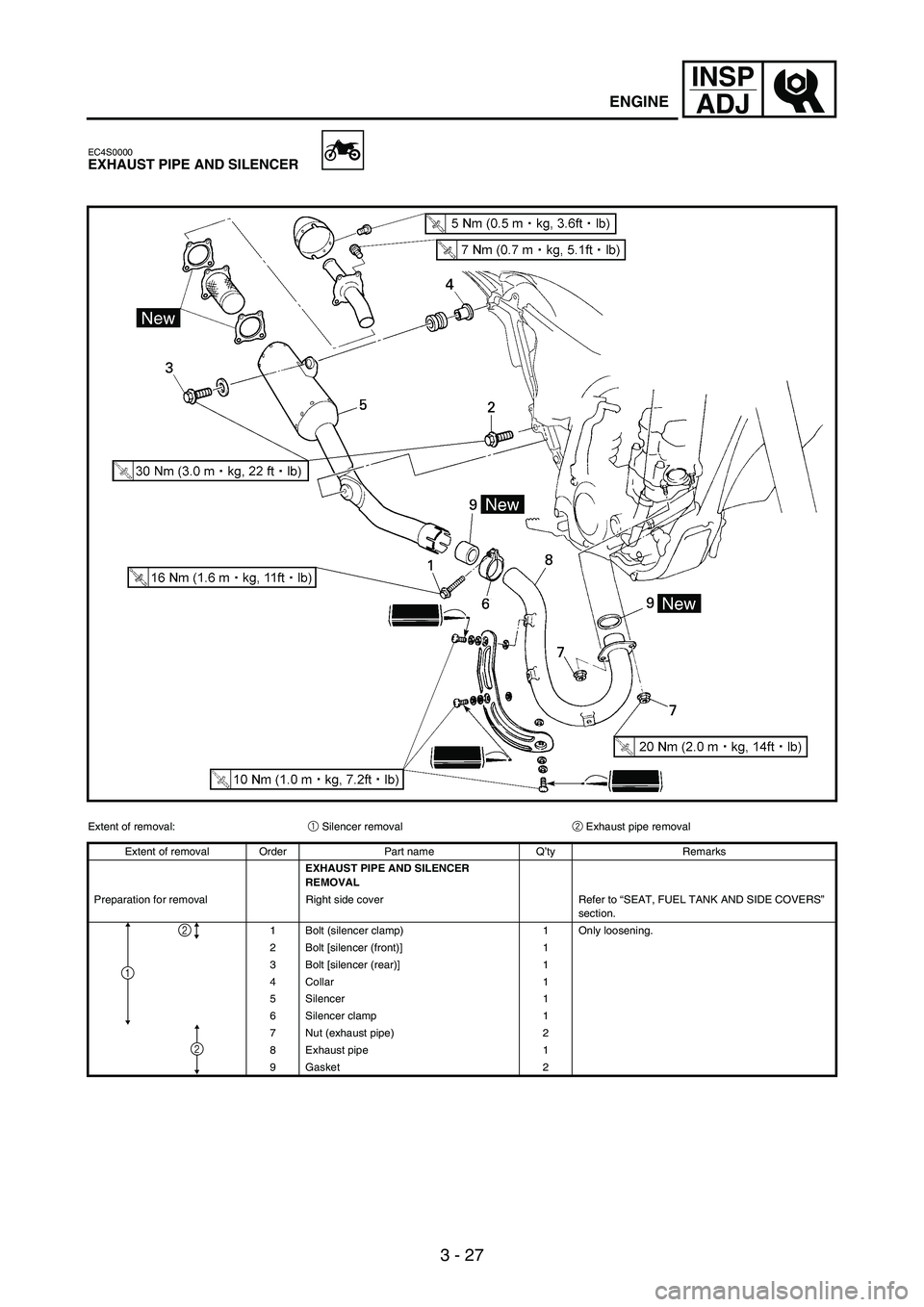

EC4S0000EXHAUST PIPE AND SILENCER

Extent of removal:

1 Silencer removal

2 Exhaust pipe removal

Extent of removal Order Part name Q’ty Remarks

EXHAUST PIPE AND SILENCER

REMOVAL

Preparation for removal Right side cover Refer to “SEAT, FUEL TANK AND SIDE COVERS”

section.

1 Bolt (silencer clamp) 1 Only loosening.

2 Bolt [silencer (front)] 1

3 Bolt [silencer (rear)] 1

4 Collar 1

5 Silencer 1

6 Silencer clamp 1

7 Nut (exhaust pipe) 2

8 Exhaust pipe 1

9 Gasket 2

1

2

2

ENGINE

Page 242 of 912

3 - 31

INSP

ADJ

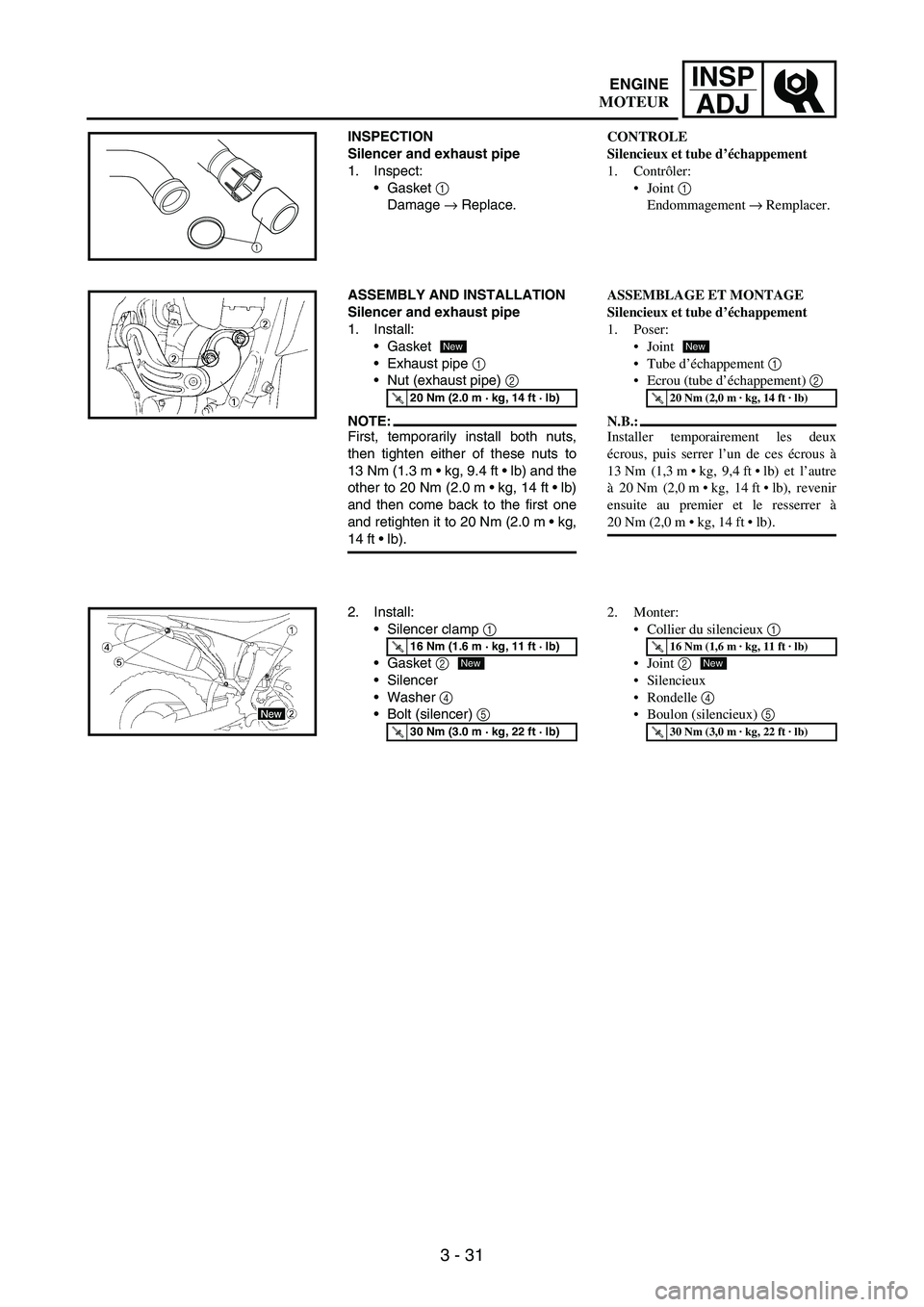

INSPECTION

Silencer and exhaust pipe

1. Inspect:

Gasket

1

Damage

→ Replace.

1

ASSEMBLY AND INSTALLATION

Silencer and exhaust pipe

1. Install:

Gasket

Exhaust pipe

1

Nut (exhaust pipe)

2

NOTE:First, temporarily install both nuts,

then tighten either of these nuts to

13 Nm (1.3 mkg, 9.4 ftlb) and the

other to 20 Nm (2.0 mkg, 14 ftlb)

and then come back to the first one

and retighten it to 20 Nm (2.0 mkg,

14 ftlb).

T R..20 Nm (2.0 m · kg, 14 ft · lb)

New

2. Install:

Silencer clamp 1

Gasket 2

Silencer

Washer 4

Bolt (silencer) 5

T R..16 Nm (1.6 m · kg, 11 ft · lb)

T R..30 Nm (3.0 m · kg, 22 ft · lb)

New

CONTROLE

Silencieux et tube d’échappement

1. Contrôler:

Joint 1

Endommagement → Remplacer.

ASSEMBLAGE ET MONTAGE

Silencieux et tube d’échappement

1. Poser:

Joint

Tube d’échappement 1

Ecrou (tube d’échappement) 2

N.B.:

Installer temporairement les deux

écrous, puis serrer l’un de ces écrous à

13 Nm (1,3 mkg, 9,4 ftlb) et l’autre

à 20 Nm (2,0 mkg, 14 ftlb), revenir

ensuite au premier et le resserrer à

20 Nm (2,0 mkg, 14 ftlb).

T R..20 Nm (2,0 m · kg, 14 ft · lb)

New

2. Monter:

Collier du silencieux 1

Joint 2

Silencieux

Rondelle 4

Boulon (silencieux) 5

T R..16 Nm (1,6 m · kg, 11 ft · lb)

T R..30 Nm (3,0 m · kg, 22 ft · lb)

New

ENGINE

MOTEUR

Page 244 of 912

3 - 33

INSP

ADJ

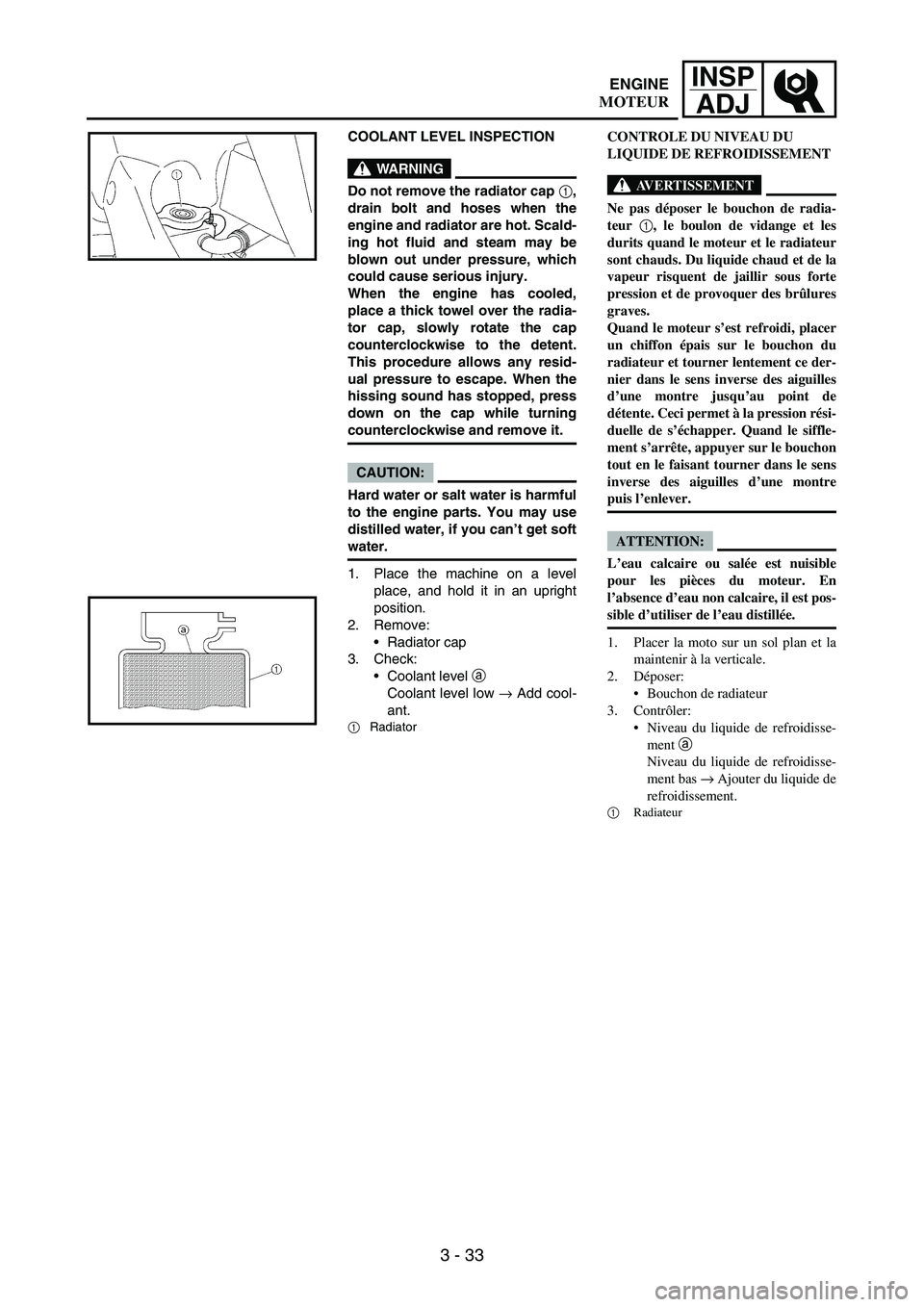

COOLANT LEVEL INSPECTION

WARNING

Do not remove the radiator cap 1,

drain bolt and hoses when the

engine and radiator are hot. Scald-

ing hot fluid and steam may be

blown out under pressure, which

could cause serious injury.

When the engine has cooled,

place a thick towel over the radia-

tor cap, slowly rotate the cap

counterclockwise to the detent.

This procedure allows any resid-

ual pressure to escape. When the

hissing sound has stopped, press

down on the cap while turning

counterclockwise and remove it.

CAUTION:

Hard water or salt water is harmful

to the engine parts. You may use

distilled water, if you can’t get soft

water.

1. Place the machine on a level

place, and hold it in an upright

position.

2. Remove:

Radiator cap

3. Check:

Coolant level

a

Coolant level low

→ Add cool-

ant.

1Radiator

CONTROLE DU NIVEAU DU

LIQUIDE DE REFROIDISSEMENT

AVERTISSEMENT

Ne pas déposer le bouchon de radia-

teur 1, le boulon de vidange et les

durits quand le moteur et le radiateur

sont chauds. Du liquide chaud et de la

vapeur risquent de jaillir sous forte

pression et de provoquer des brûlures

graves.

Quand le moteur s’est refroidi, placer

un chiffon épais sur le bouchon du

radiateur et tourner lentement ce der-

nier dans le sens inverse des aiguilles

d’une montre jusqu’au point de

détente. Ceci permet à la pression rési-

duelle de s’échapper. Quand le siffle-

ment s’arrête, appuyer sur le bouchon

tout en le faisant tourner dans le sens

inverse des aiguilles d’une montre

puis l’enlever.

ATTENTION:

L’eau calcaire ou salée est nuisible

pour les pièces du moteur. En

l’absence d’eau non calcaire, il est pos-

sible d’utiliser de l’eau distillée.

1. Placer la moto sur un sol plan et la

maintenir à la verticale.

2. Déposer:

Bouchon de radiateur

3. Contrôler:

Niveau du liquide de refroidisse-

ment a

Niveau du liquide de refroidisse-

ment bas → Ajouter du liquide de

refroidissement.

1

Radiateur

ENGINE

MOTEUR

Page 246 of 912

3 - 35

INSP

ADJ

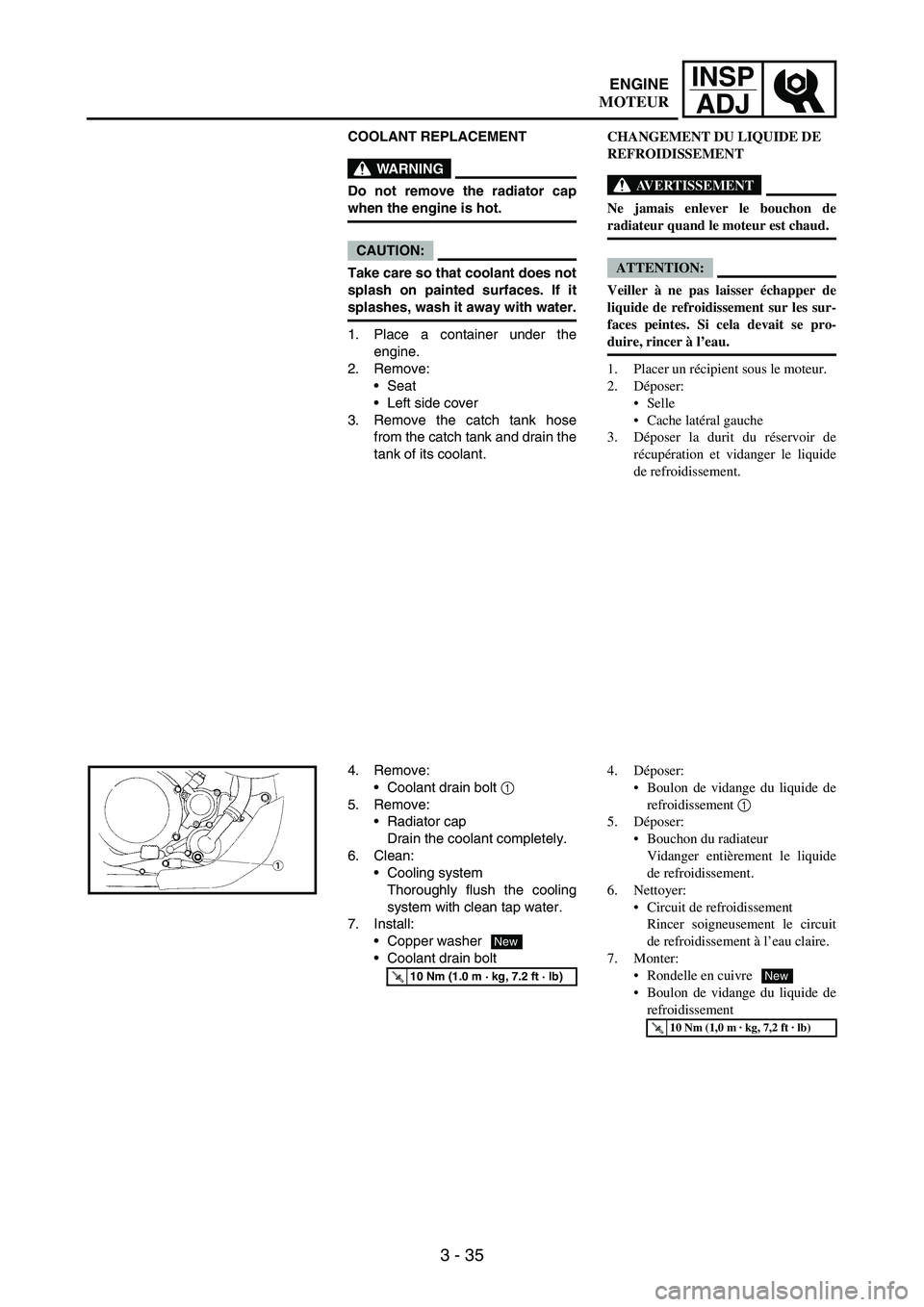

COOLANT REPLACEMENT

WARNING

Do not remove the radiator cap

when the engine is hot.

CAUTION:

Take care so that coolant does not

splash on painted surfaces. If it

splashes, wash it away with water.

1. Place a container under the

engine.

2. Remove:

Seat

Left side cover

3. Remove the catch tank hose

from the catch tank and drain the

tank of its coolant.

4. Remove:

Coolant drain bolt

1

5. Remove:

Radiator cap

Drain the coolant completely.

6. Clean:

Cooling system

Thoroughly flush the cooling

system with clean tap water.

7. Install:

Copper washer

Coolant drain bolt

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

New

CHANGEMENT DU LIQUIDE DE

REFROIDISSEMENT

AVERTISSEMENT

Ne jamais enlever le bouchon de

radiateur quand le moteur est chaud.

ATTENTION:

Veiller à ne pas laisser échapper de

liquide de refroidissement sur les sur-

faces peintes. Si cela devait se pro-

duire, rincer à l’eau.

1. Placer un récipient sous le moteur.

2. Déposer:

Selle

Cache latéral gauche

3. Déposer la durit du réservoir de

récupération et vidanger le liquide

de refroidissement.

4. Déposer:

Boulon de vidange du liquide de

refroidissement 1

5. Déposer:

Bouchon du radiateur

Vidanger entièrement le liquide

de refroidissement.

6. Nettoyer:

Circuit de refroidissement

Rincer soigneusement le circuit

de refroidissement à l’eau claire.

7. Monter:

Rondelle en cuivre

Boulon de vidange du liquide de

refroidissement

T R..10 Nm (1,0 m · kg, 7,2 ft · lb)

New

ENGINE

MOTEUR

Page 248 of 912

3 - 37

INSP

ADJ

8. Fill:

Radiator

Engine

To specified level.

CAUTION:

Do not mix more than one type

of ethylene glycol antifreeze

containing corrosion inhibitors

for aluminum engine.

Do not use water containing

impurities or oil.

9. Install:

Radiator cap

Start the engine and warm it

up for a several minutes.

10. Check:

Coolant level

Coolant level low

→ Add cool-

ant.

Recommended coolant:

High quality ethylene

glycol anti-freeze con-

taining anti-corrosion

for aluminum engine

Coolant 1 and water

(soft water) 2 mixing

ratio:

50%/50%

Coolant capacity:

0.99 L

(0.87 Imp qt,

1.05 US qt)

Handling notes of coolant:

The coolant is harmful so it should

be handled with special care.

WARNING

When coolant splashes to

your eye.

Thoroughly wash your eye

with water and see your doc-

tor.

When coolant splashes to

your clothes.

Quickly wash it away with

water and then with soap.

When coolant is swallowed.

Quickly make him vomit and

take him to a doctor.

8. Remplir:

Radiateur

Moteur

Au niveau spécifié.

ATTENTION:

Ne pas mélanger différents types

d’antigel à l’éthylène glycol conte-

nant un agent anticorrosion pour

moteurs en aluminium.

Ne pas utiliser de l’eau contenant

des impuretés ou de l’huile.

9. Monter:

Bouchon du radiateur

Mettre le moteur en marche et le

laisser chauffer pendant quelques

minutes.

10. Contrôler:

Niveau du liquide de refroidisse-

ment

Niveau du liquide de refroidisse-

ment bas → Ajouter du liquide de

refroidissement.

Liquide de refroidissement

recommandé:

Antigel à l’éthylène gly-

col de haute qualité con-

tenant un agent anticor-

rosion pour moteurs en

aluminium

Rapport de mélange liquide

de refroidissement 1 et

eau (eau douce) 2:

50%/50%

Quantité de liquide de

refroidissement:

0,99 L

(0,87 Imp qt, 1,05 US qt)

Notes concernant la manipulation

du liquide de refroidissement:

Le liquide de refroidissement étant

dangereux, il doit être manipulé avec

une attention particulière.

AVERTISSEMENT

En cas de projection de liquide

de refroidissement dans les yeux:

rincer soigneusement les yeux à

l’eau et consulter un médecin.

En cas de projection de liquide

de refroidissement sur les vête-

ments:

rincer rapidement à l’eau claire

puis laver à l’eau savonneuse.

En cas d’ingestion de liquide de

refroidissement:

faire immédiatement vomir et

consulter un médecin dans les

plus brefs délais.

ENGINE

MOTEUR

Page 250 of 912

3 - 39

INSP

ADJ

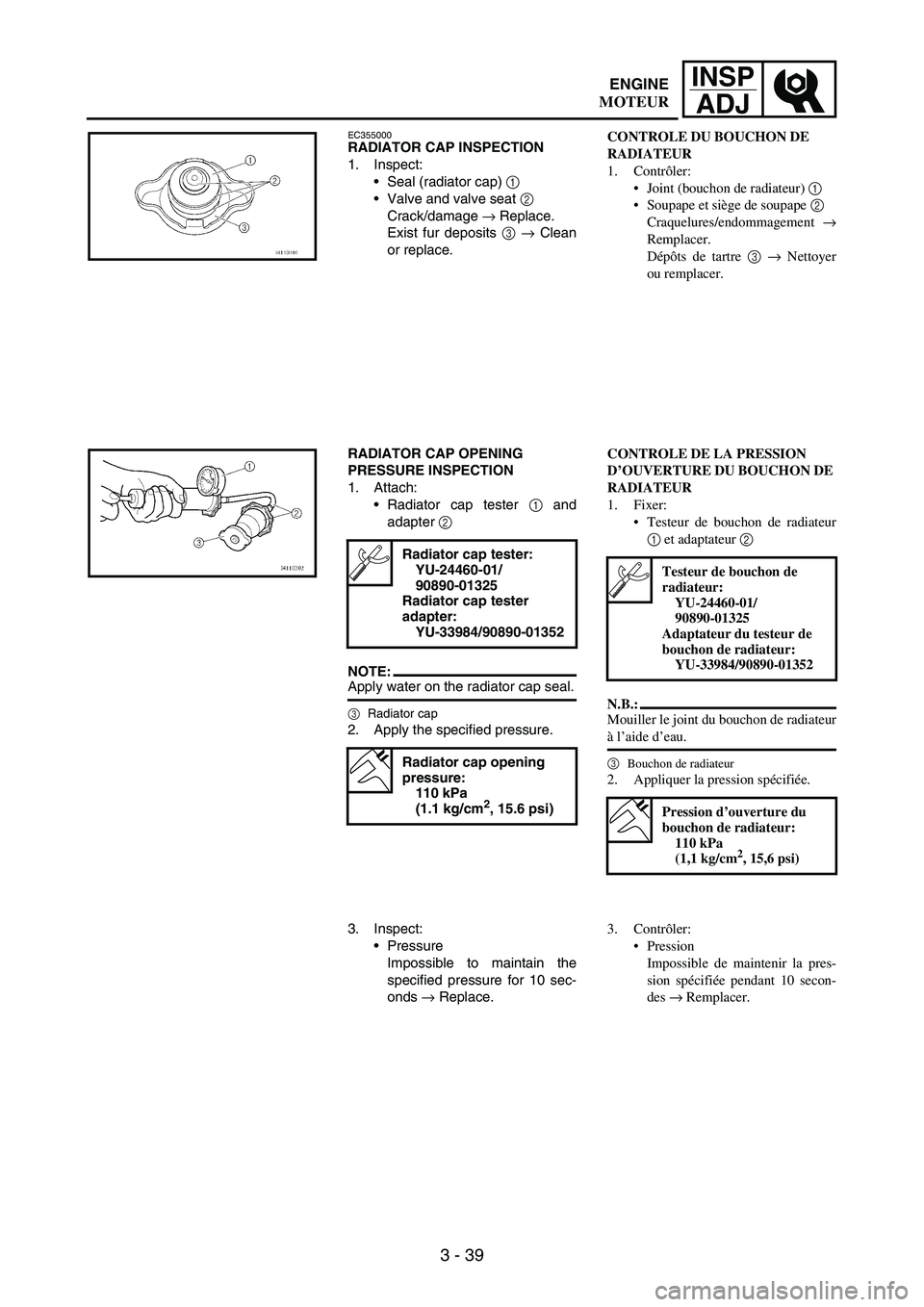

EC355000RADIATOR CAP INSPECTION

1. Inspect:

Seal (radiator cap)

1

Valve and valve seat

2

Crack/damage

→ Replace.

Exist fur deposits

3

→ Clean

or replace.

RADIATOR CAP OPENING

PRESSURE INSPECTION

1. Attach:

Radiator cap tester

1 and

adapter

2

NOTE:Apply water on the radiator cap seal.

3Radiator cap

2. Apply the specified pressure.

Radiator cap tester:

YU-24460-01/

90890-01325

Radiator cap tester

adapter:

YU-33984/90890-01352

Radiator cap opening

pressure:

110 kPa

(1.1 kg/cm

2, 15.6 psi)

3. Inspect:

Pressure

Impossible to maintain the

specified pressure for 10 sec-

onds

→ Replace.CONTROLE DU BOUCHON DE

RADIATEUR

1. Contrôler:

Joint (bouchon de radiateur) 1

Soupape et siège de soupape 2

Craquelures/endommagement →

Remplacer.

Dépôts de tartre 3 → Nettoyer

ou remplacer.

CONTROLE DE LA PRESSION

D’OUVERTURE DU BOUCHON DE

RADIATEUR

1. Fixer:

Testeur de bouchon de radiateur

1 et adaptateur 2

N.B.:

Mouiller le joint du bouchon de radiateur

à l’aide d’eau.

3

Bouchon de radiateur

2. Appliquer la pression spécifiée.

Testeur de bouchon de

radiateur:

YU-24460-01/

90890-01325

Adaptateur du testeur de

bouchon de radiateur:

YU-33984/90890-01352

Pression d’ouverture du

bouchon de radiateur:

110 kPa

(1,1 kg/cm

2, 15,6 psi)

3. Contrôler:

Pression

Impossible de maintenir la pres-

sion spécifiée pendant 10 secon-

des → Remplacer.

ENGINE

MOTEUR