light YAMAHA WR 250F 2008 Owner's Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2008, Model line: WR 250F, Model: YAMAHA WR 250F 2008Pages: 224, PDF Size: 13.66 MB

Page 114 of 224

5-18

CAMSHAFTS

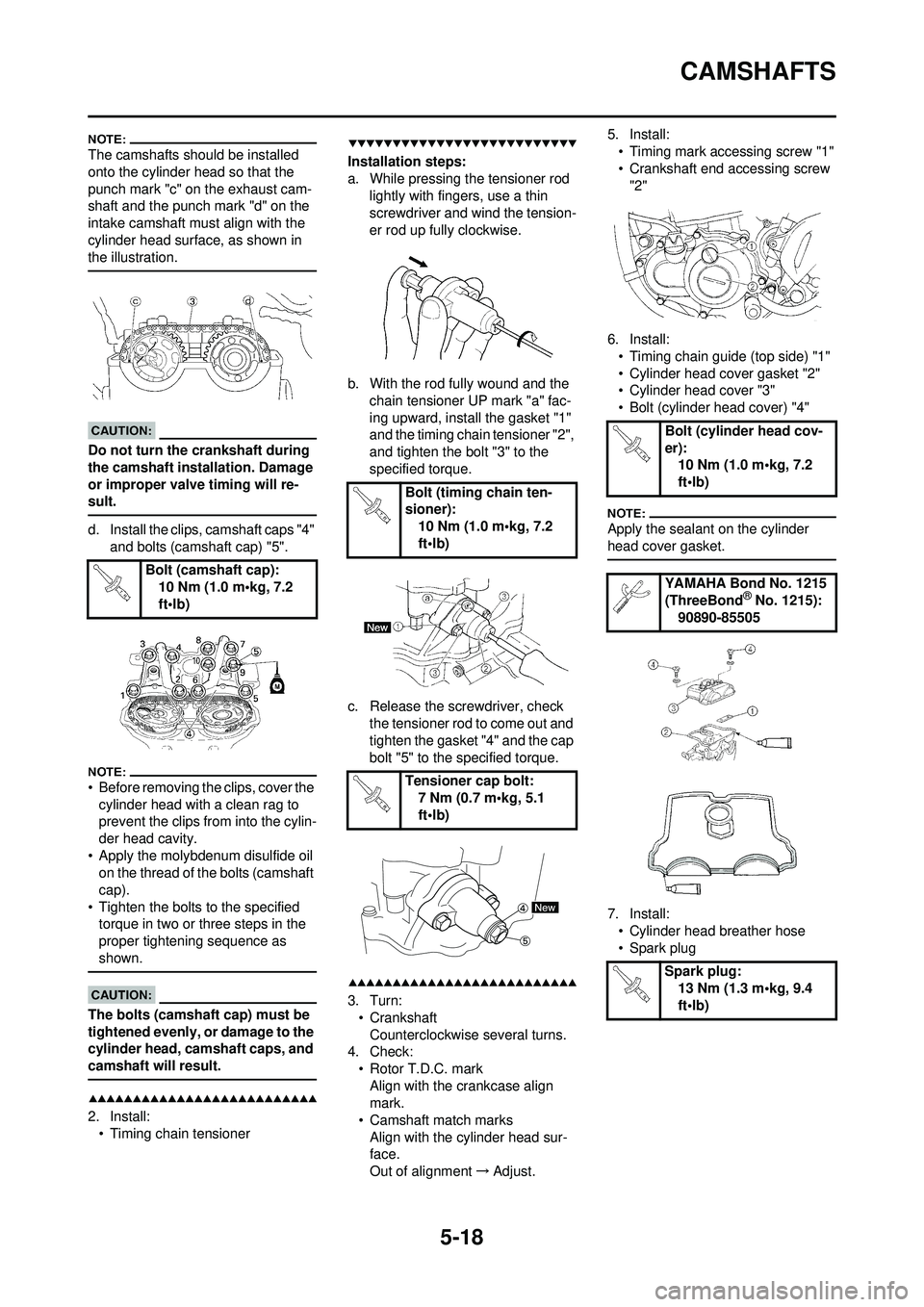

The camshafts should be installed

onto the cylinder head so that the

punch mark "c" on the exhaust cam-

shaft and the punch mark "d" on the

intake camshaft must align with the

cylinder head surface, as shown in

the illustration.

Do not turn the crankshaft during

the camshaft installation. Damage

or improper valve timing will re-

sult.

d. Install the clips, camshaft caps "4"

and bolts (camshaft cap) "5".

• Before removing the clips, cover the cylinder head with a clean rag to

prevent the clips from into the cylin-

der head cavity.

• Apply the molybdenum disulfide oil on the thread of the bolts (camshaft

cap).

• Tighten the bolts to the specified torque in two or three steps in the

proper tightening sequence as

shown.

The bolts (camshaft cap) must be

tightened evenly, or damage to the

cylinder head, camshaft caps, and

camshaft will result.

2. Install:• Timing chain tensioner

Installation steps:

a. While pressing the tensioner rod lightly with fingers, use a thin

screwdriver and wind the tension-

er rod up fully clockwise.

b. With the rod fully wound and the chain tensioner UP mark "a" fac-

ing upward, install the gasket "1"

and the timing chain tensioner "2",

and tighten the bolt "3" to the

specified torque.

c. Release the screwdriver, check the tensioner rod to come out and

tighten the gasket "4" and the cap

bolt "5" to the specified torque.

3. Turn:

• CrankshaftCounterclockwise several turns.

4. Check:

• Rotor T.D.C. markAlign with the crankcase align

mark.

• Camshaft match marks Align with the cylinder head sur-

face.

Out of alignment →Adjust. 5. Install:

• Timing mark accessing screw "1"

• Crankshaft end accessing screw "2"

6. Install: • Timing chain guide (top side) "1"

• Cylinder head cover gasket "2"

• Cylinder head cover "3"

• Bolt (cylinder head cover) "4"

Apply the sealant on the cylinder

head cover gasket.

7. Install:• Cylinder head breather hose

• Spark plug

Bolt (camshaft cap):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (timing chain ten-

sioner):10 Nm (1.0 m•kg, 7.2

ft•lb)

Tensioner cap bolt: 7 Nm (0.7 m•kg, 5.1

ft•lb)

Bolt (cylinder head cov-

er): 10 Nm (1.0 m•kg, 7.2

ft•lb)

YAMAHA Bond No. 1215

(ThreeBond

® No. 1215):

90890-85505

Spark plug: 13 Nm (1.3 m•kg, 9.4

ft•lb)

Page 119 of 224

5-23

VALVES AND VALVE SPRINGS

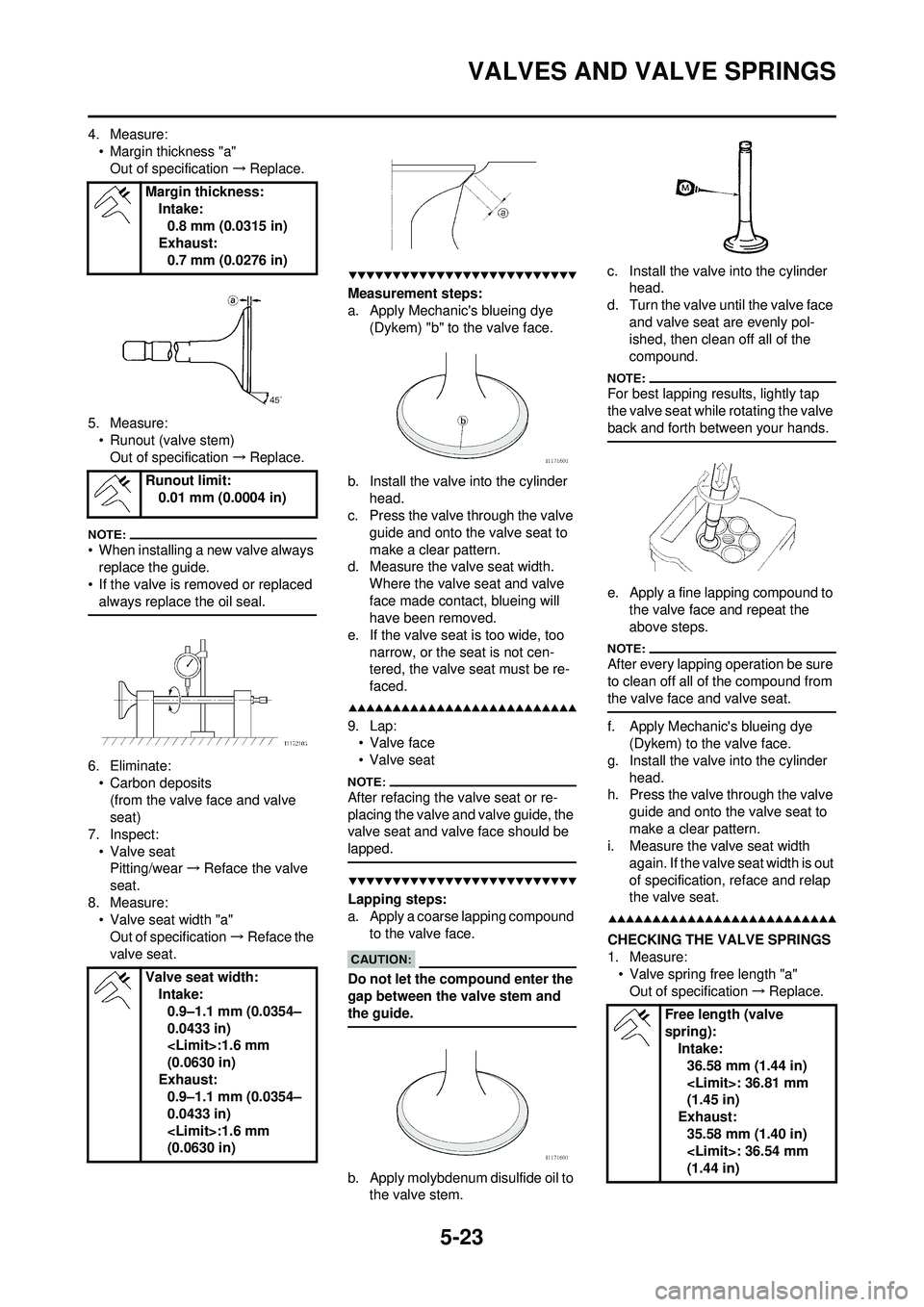

4. Measure:• Margin thickness "a"Out of specification →Replace.

5. Measure: • Runout (valve stem)Out of specification →Replace.

• When installing a new valve always

replace the guide.

• If the valve is removed or replaced

always replace the oil seal.

6. Eliminate:• Carbon deposits(from the valve face and valve

seat)

7. Inspect: • Valve seatPitting/wear →Reface the valve

seat.

8. Measure: • Valve seat width "a"

Out of specification →Reface the

valve seat.

Measurement steps:

a. Apply Mechanic's blueing dye (Dykem) "b" to the valve face.

b. Install the valve into the cylinder head.

c. Press the valve through the valve guide and onto the valve seat to

make a clear pattern.

d. Measure the valve seat width. Where the valve seat and valve

face made contact, blueing will

have been removed.

e. If the valve seat is too wide, too

narrow, or the seat is not cen-

tered, the valve se at must be re-

faced.

9. Lap: • Valve face

• Valve seat

After refacing the valve seat or re-

placing the valve and valve guide, the

valve seat and valve face should be

lapped.

Lapping steps:

a. Apply a coarse lapping compound

to the valve face.

Do not let the co mpound enter the

gap between the valve stem and

the guide.

b. Apply molybdenum disulfide oil to the valve stem. c. Install the valve into the cylinder

head.

d. Turn the valve until the valve face and valve seat are evenly pol-

ished, then clean off all of the

compound.

For best lapping results, lightly tap

the valve seat while rotating the valve

back and forth between your hands.

e. Apply a fine lapping compound to the valve face and repeat the

above steps.

After every lapping operation be sure

to clean off all of the compound from

the valve face and valve seat.

f. Apply Mechanic's blueing dye (Dykem) to the valve face.

g. Install the valve into the cylinder head.

h. Press the valve through the valve

guide and onto the valve seat to

make a clear pattern.

i. Measure the valve seat width

again. If the valve seat width is out

of specification, reface and relap

the valve seat.

CHECKING THE VALVE SPRINGS

1. Measure:• Valve spring free length "a"Out of specification →Replace.

Margin thickness:

Intake:

0.8 mm (0.0315 in)

Exhaust: 0.7 mm (0.0276 in)

Runout limit: 0.01 mm (0.0004 in)

Valve seat width: Intake:

0.9–1.1 mm (0.0354–

0.0433 in)

(0.0630 in)

Exhaust: 0.9–1.1 mm (0.0354–

0.0433 in)

(0.0630 in)

Free length (valve

spring): Intake:36.58 mm (1.44 in)

(1.45 in)

Exhaust:

35.58 mm (1.40 in)

(1.44 in)

Page 120 of 224

5-24

VALVES AND VALVE SPRINGS

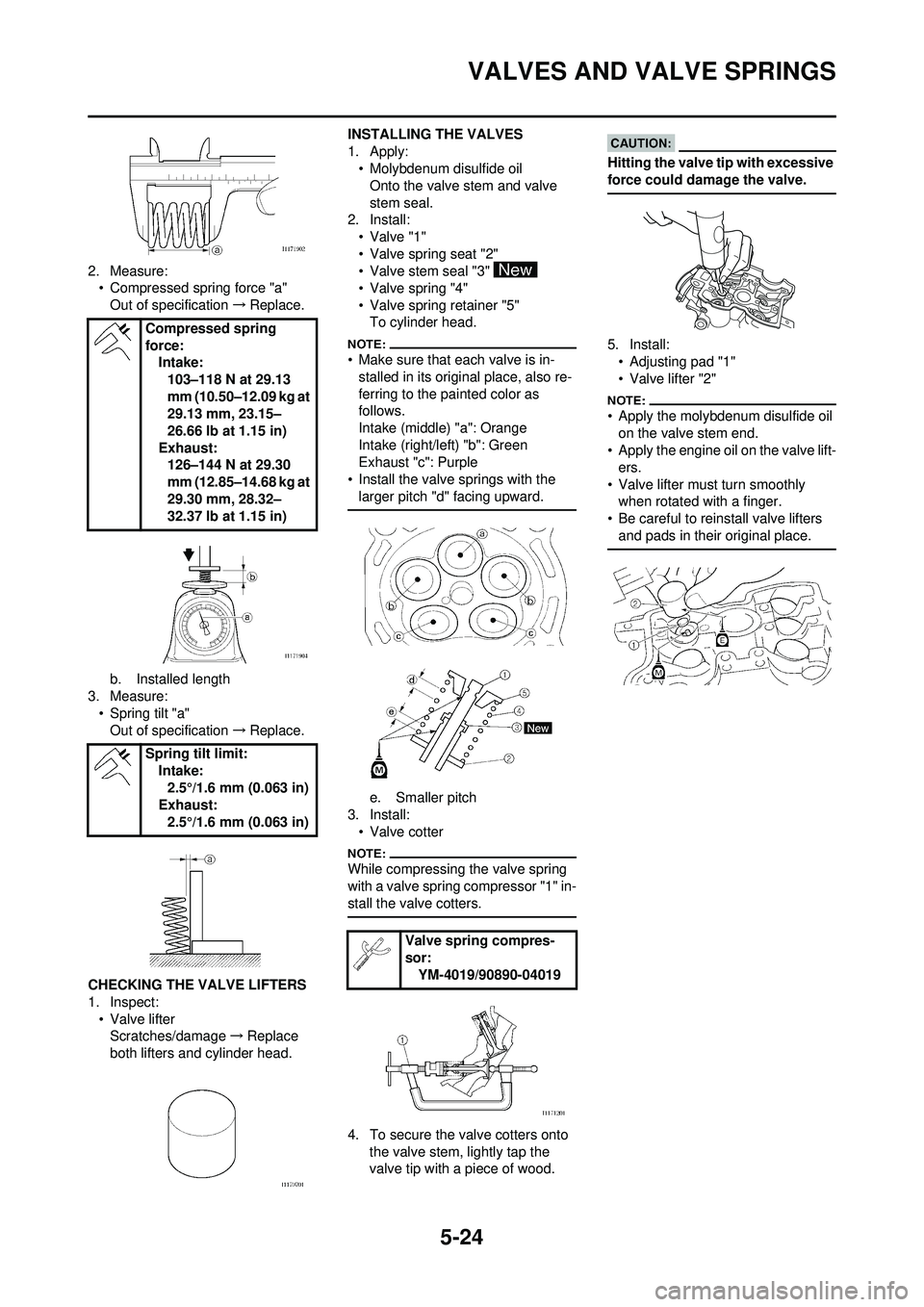

2. Measure:• Compressed spring force "a"

Out of specification →Replace.

b. Installed length

3. Measure: • Spring tilt "a"

Out of specification →Replace.

CHECKING THE VALVE LIFTERS

1. Inspect: • Valve lifterScratches/damage →Replace

both lifters and cylinder head. INSTALLING THE VALVES

1. Apply:

• Molybdenum disulfide oilOnto the valve stem and valve

stem seal.

2. Install: • Valve "1"

• Valve spring seat "2"

• Valve stem seal "3"

• Valve spring "4"

• Valve spring retainer "5"To cylinder head.

• Make sure that each valve is in-stalled in its original place, also re-

ferring to the painted color as

follows.

Intake (middle) "a": Orange

Intake (right/left) "b": Green

Exhaust "c": Purple

• Install the valve springs with the

larger pitch "d" facing upward.

e. Smaller pitch

3. Install:

• Valve cotter

While compressing the valve spring

with a valve spring compressor "1" in-

stall the valve cotters.

4. To secure the va lve cotters onto

the valve stem, lightly tap the

valve tip with a piece of wood.

Hitting the valve tip with excessive

force could damage the valve.

5. Install: • Adjusting pad "1"

• Valve lifter "2"

• Apply the molybdenum disulfide oil

on the valve stem end.

• Apply the engine oil on the valve lift- ers.

• Valve lifter must turn smoothly when rotated with a finger.

• Be careful to reinstall valve lifters and pads in their original place.

Compressed spring

force: Intake:

103–118 N at 29.13

mm (10.50–12.09 kg at

29.13 mm, 23.15–

26.66 lb at 1.15 in)

Exhaust: 126–144 N at 29.30

mm (12.85–14.68 kg at

29.30 mm, 28.32–

32.37 lb at 1.15 in)

Spring tilt limit: Intake:2.5°/1.6 mm (0.063 in)

Exhaust: 2.5°/1.6 mm (0.063 in)

Valve spring compres-

sor:

YM-4019/90890-04019

Page 156 of 224

5-60

CRANKCASE AND CRANKSHAFT

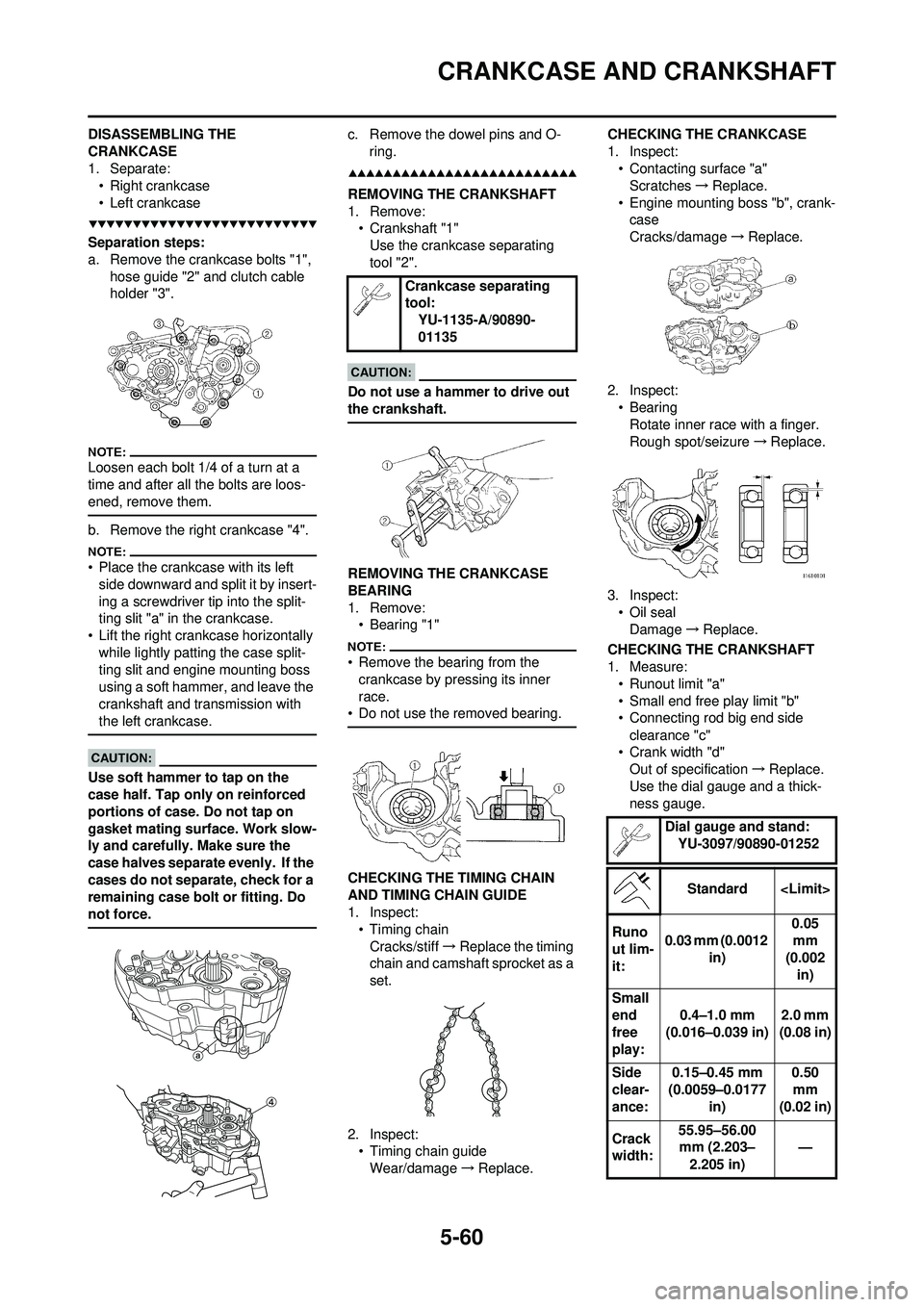

DISASSEMBLING THE

CRANKCASE

1. Separate:• Right crankcase

• Left crankcase

Separation steps:

a. Remove the crankcase bolts "1", hose guide "2" and clutch cable

holder "3".

Loosen each bolt 1/4 of a turn at a

time and after all the bolts are loos-

ened, remove them.

b. Remove the right crankcase "4".

• Place the crankcase with its left

side downward and split it by insert-

ing a screwdriver tip into the split-

ting slit "a" in the crankcase.

• Lift the right crankcase horizontally while lightly patting the case split-

ting slit and engine mounting boss

using a soft hammer, and leave the

crankshaft and transmission with

the left crankcase.

Use soft hammer to tap on the

case half. Tap only on reinforced

portions of case. Do not tap on

gasket mating surface. Work slow-

ly and carefully. Make sure the

case halves separate evenly. If the

cases do not separate, check for a

remaining case bolt or fitting. Do

not force.

c. Remove the dowel pins and O-

ring.

REMOVING THE CRANKSHAFT

1. Remove:• Crankshaft "1"

Use the crankcase separating

tool "2".

Do not use a hammer to drive out

the crankshaft.

REMOVING THE CRANKCASE

BEARING

1. Remove:•Bearing "1"

• Remove the bearing from the crankcase by pressing its inner

race.

• Do not use the removed bearing.

CHECKING THE TIMING CHAIN

AND TIMING CHAIN GUIDE

1. Inspect: • Timing chain

Cracks/stiff →Replace the timing

chain and camshaft sprocket as a

set.

2. Inspect: • Timing chain guideWear/damage →Replace. CHECKING THE CRANKCASE

1. Inspect:

• Contacting surface "a"Scratches →Replace.

• Engine mounting boss "b", crank- case

Cracks/damage →Replace.

2. Inspect: • BearingRotate inner race with a finger.

Rough spot/seizure →Replace.

3. Inspect: • Oil sealDamage →Replace.

CHECKING THE CRANKSHAFT

1. Measure: • Runout limit "a"

• Small end free play limit "b"

• Connecting rod big end side clearance "c"

• Crank width "d" Out of specification →Replace.

Use the dial gauge and a thick-

ness gauge.

Crankcase separating

tool: YU-1135-A/90890-

01135

Dial gauge and stand: YU-3097/90890-01252

Standard

Runo

ut lim-

it: 0.03 mm (0.0012

in) 0.05

mm

(0.002 in)

Small

end

free

play: 0.4–1.0 mm

(0.016–0.039 in) 2.0 mm

(0.08 in)

Side

clear-

ance: 0.15–0.45 mm

(0.0059–0.0177 in) 0.50

mm

(0.02 in)

Crack

width: 55.95–56.00

mm (2.203–

2.205 in) —

Page 158 of 224

5-62

CRANKCASE AND CRANKSHAFT

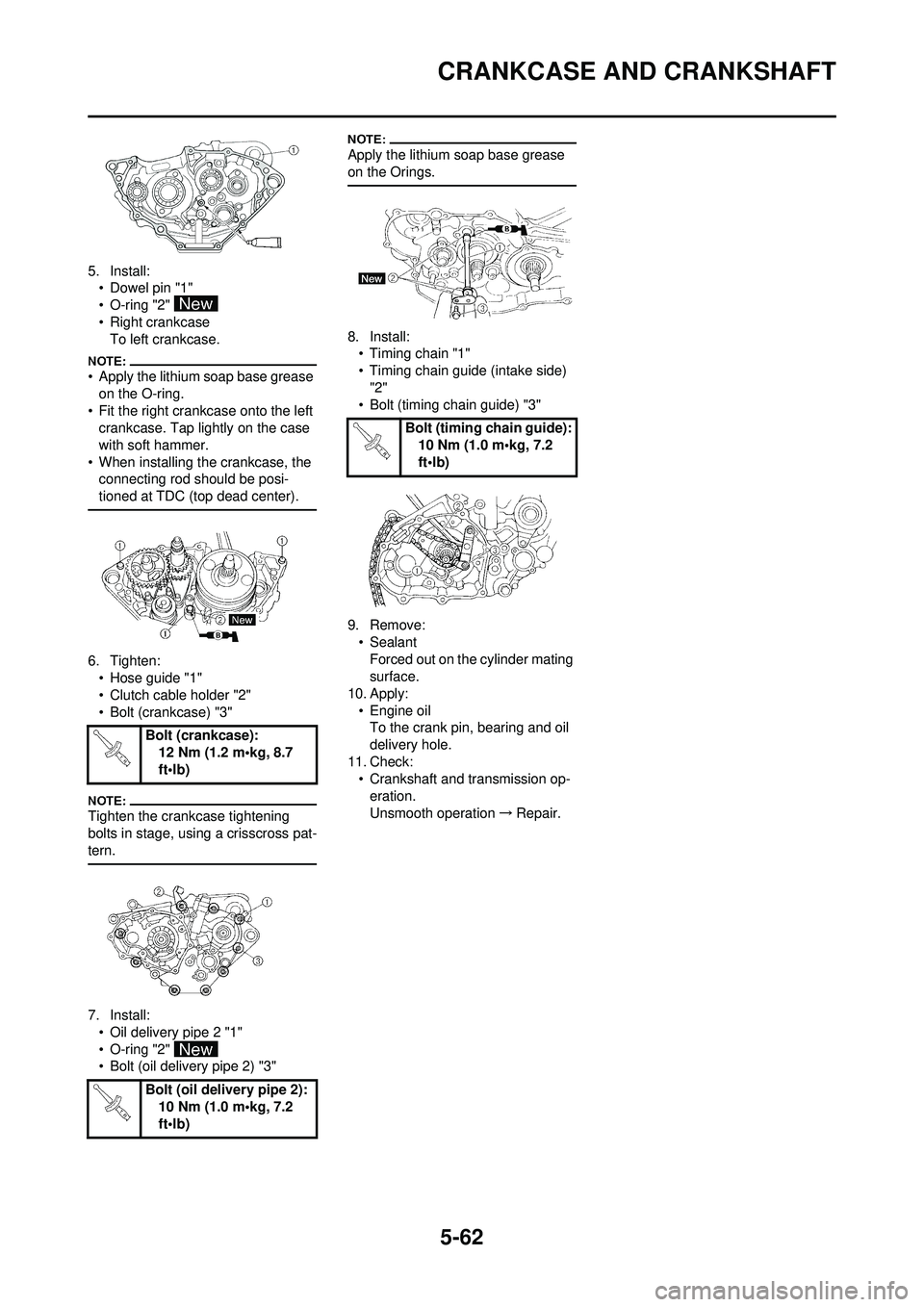

5. Install:• Dowel pin "1"

• O-ring "2"

• Right crankcaseTo left crankcase.

• Apply the lithium soap base grease

on the O-ring.

• Fit the right crankcase onto the left crankcase. Tap lightly on the case

with soft hammer.

• When installing the crankcase, the connecting rod should be posi-

tioned at TDC (top dead center).

6. Tighten:

• Hose guide "1"

• Clutch cable holder "2"

• Bolt (crankcase) "3"

Tighten the crankcase tightening

bolts in stage, using a crisscross pat-

tern.

7. Install:• Oil delivery pipe 2 "1"

• O-ring "2"

• Bolt (oil delivery pipe 2) "3"

Apply the lithium soap base grease

on the Orings.

8. Install:• Timing chain "1"

• Timing chain guide (intake side)

"2"

• Bolt (timing chain guide) "3"

9. Remove: • Sealant

Forced out on the cylinder mating

surface.

10. Apply:

• Engine oilTo the crank pin, bearing and oil

delivery hole.

11. Check: • Crankshaft and transmission op-eration.

Unsmooth operation →Repair.

Bolt (crankcase):

12 Nm (1.2 m•kg, 8.7

ft•lb)

Bolt (oil delivery pipe 2): 10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (timing chain guide):10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 160 of 224

5-64

TRANSMISSION, SHIFT CAM AND SHIFT FORK

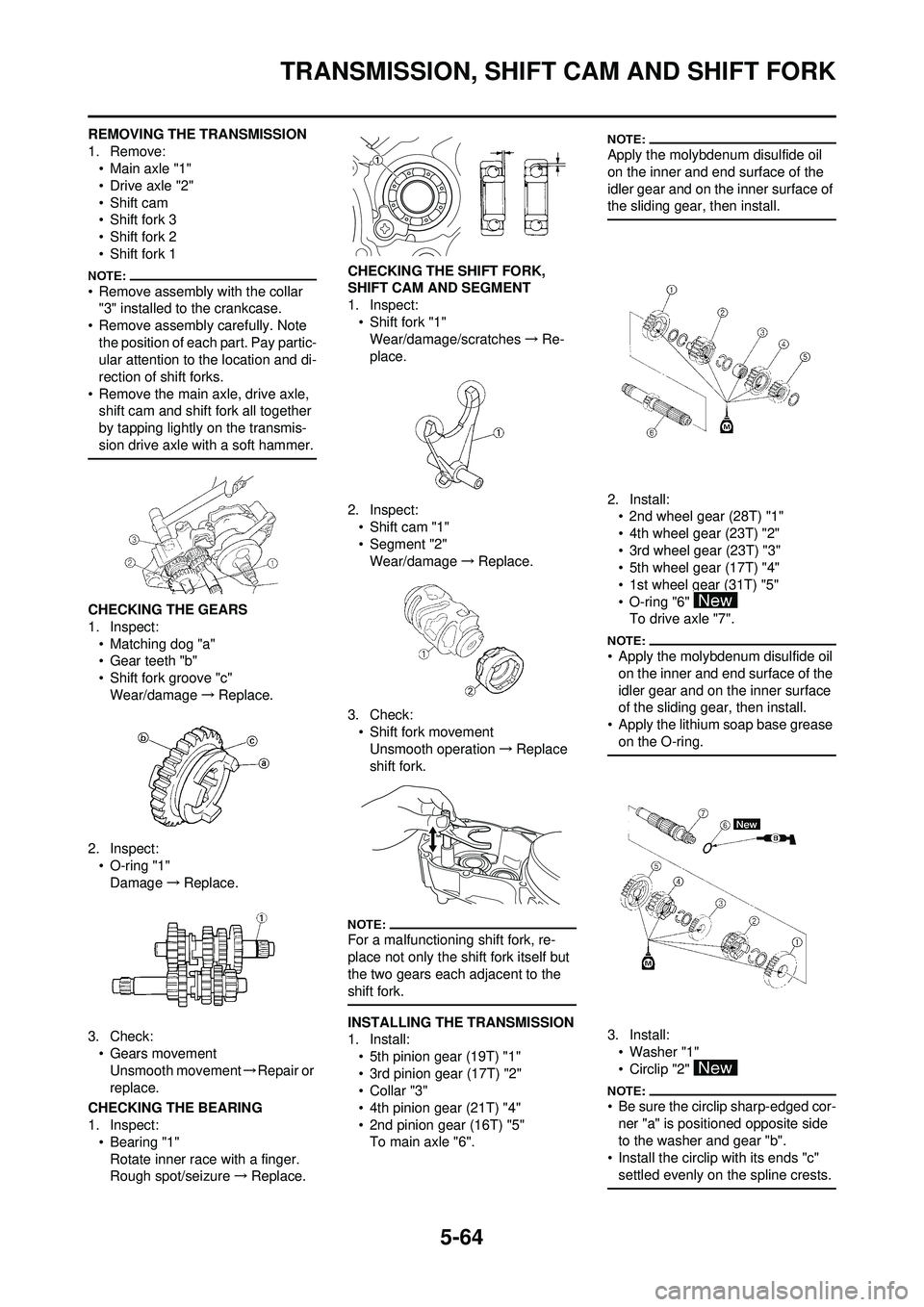

REMOVING THE TRANSMISSION

1. Remove:• Main axle "1"

• Drive axle "2"

• Shift cam

• Shift fork 3

• Shift fork 2

• Shift fork 1

• Remove assembly with the collar "3" installed to the crankcase.

• Remove assembly carefully. Note

the position of each part. Pay partic-

ular attention to the location and di-

rection of shift forks.

• Remove the main axle, drive axle, shift cam and shift fork all together

by tapping lightly on the transmis-

sion drive axle with a soft hammer.

CHECKING THE GEARS

1. Inspect:

• Matching dog "a"

• Gear teeth "b"

• Shift fork groove "c"Wear/damage →Replace.

2. Inspect: • O-ring "1"

Damage →Replace.

3. Check: • Gears movementUnsmooth movement →Repair or

replace.

CHECKING THE BEARING

1. Inspect: • Bearing "1"

Rotate inner race with a finger.

Rough spot/seizure →Replace. CHECKING THE SHIFT FORK,

SHIFT CAM AND SEGMENT

1. Inspect:

• Shift fork "1"Wear/damage/scratches →Re-

place.

2. Inspect: • Shift cam "1"

• Segment "2"Wear/damage →Replace.

3. Check: • Shift fork movement

Unsmooth operation →Replace

shift fork.

For a malfunctioning shift fork, re-

place not only the shift fork itself but

the two gears each adjacent to the

shift fork.

INSTALLING THE TRANSMISSION

1. Install:

• 5th pinion gear (19T) "1"

• 3rd pinion gear (17T) "2"

• Collar "3"

• 4th pinion gear (21T) "4"

• 2nd pinion gear (16T) "5"To main axle "6".

Apply the molybdenum disulfide oil

on the inner and end surface of the

idler gear and on the inner surface of

the sliding gear, then install.

2. Install:• 2nd wheel gear (28T) "1"

• 4th wheel gear (23T) "2"

• 3rd wheel gear (23T) "3"

• 5th wheel gear (17T) "4"

• 1st wheel gear (31T) "5"

• O-ring "6" To drive axle "7".

• Apply the molybdenum disulfide oil on the inner and end surface of the

idler gear and on the inner surface

of the sliding gear, then install.

• Apply the lithium soap base grease

on the O-ring.

3. Install:• Washer "1"

• Circlip "2"

• Be sure the circlip sharp-edged cor-ner "a" is positioned opposite side

to the washer and gear "b".

• Install the circlip with its ends "c" settled evenly on the spline crests.

Page 174 of 224

6-13

FRONT BRAKE AND REAR BRAKE

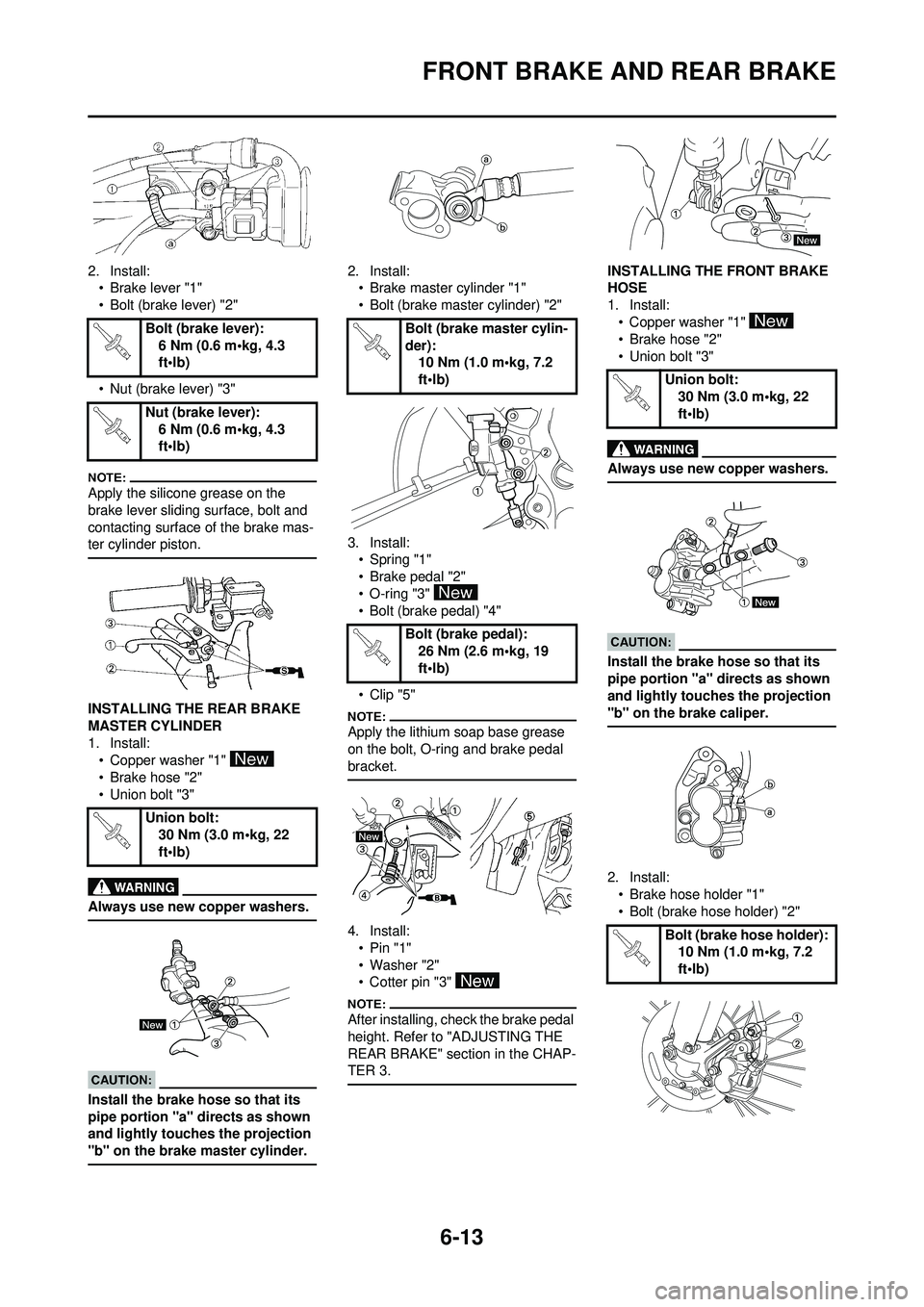

2. Install:• Brake lever "1"

• Bolt (brake lever) "2"

• Nut (brake lever) "3"

Apply the silicone grease on the

brake lever sliding surface, bolt and

contacting surface of the brake mas-

ter cylinder piston.

INSTALLING THE REAR BRAKE

MASTER CYLINDER

1. Install:• Copper washer "1"

• Brake hose "2"

• Union bolt "3"

Always use new copper washers.

Install the brake hose so that its

pipe portion "a" directs as shown

and lightly touches the projection

"b" on the brake master cylinder.

2. Install:• Brake master cylinder "1"

• Bolt (brake master cylinder) "2"

3. Install: • Spring "1"

• Brake pedal "2"

• O-ring "3"

• Bolt (brake pedal) "4"

• Clip "5"

Apply the lithium soap base grease

on the bolt, O-ring and brake pedal

bracket.

4. Install:

•Pin "1"

• Washer "2"

• Cotter pin "3"

After installing, check the brake pedal

height. Refer to "ADJUSTING THE

REAR BRAKE" section in the CHAP-

TER 3.

INSTALLING THE FRONT BRAKE

HOSE

1. Install:• Copper washer "1"

• Brake hose "2"

• Union bolt "3"

Always use new copper washers.

Install the brake hose so that its

pipe portion "a" directs as shown

and lightly touches the projection

"b" on the brake caliper.

2. Install:

• Brake hose holder "1"

• Bolt (brake hose holder) "2"

Bolt (brake lever):

6 Nm (0.6 m•kg, 4.3

ft•lb)

Nut (brake lever): 6 Nm (0.6 m•kg, 4.3

ft•lb)

Union bolt: 30 Nm (3.0 m•kg, 22

ft•lb)

Bolt (brake master cylin-

der):10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (brake pedal): 26 Nm (2.6 m•kg, 19

ft•lb)

Union bolt: 30 Nm (3.0 m•kg, 22

ft•lb)

Bolt (brake hose holder): 10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 175 of 224

6-14

FRONT BRAKE AND REAR BRAKE

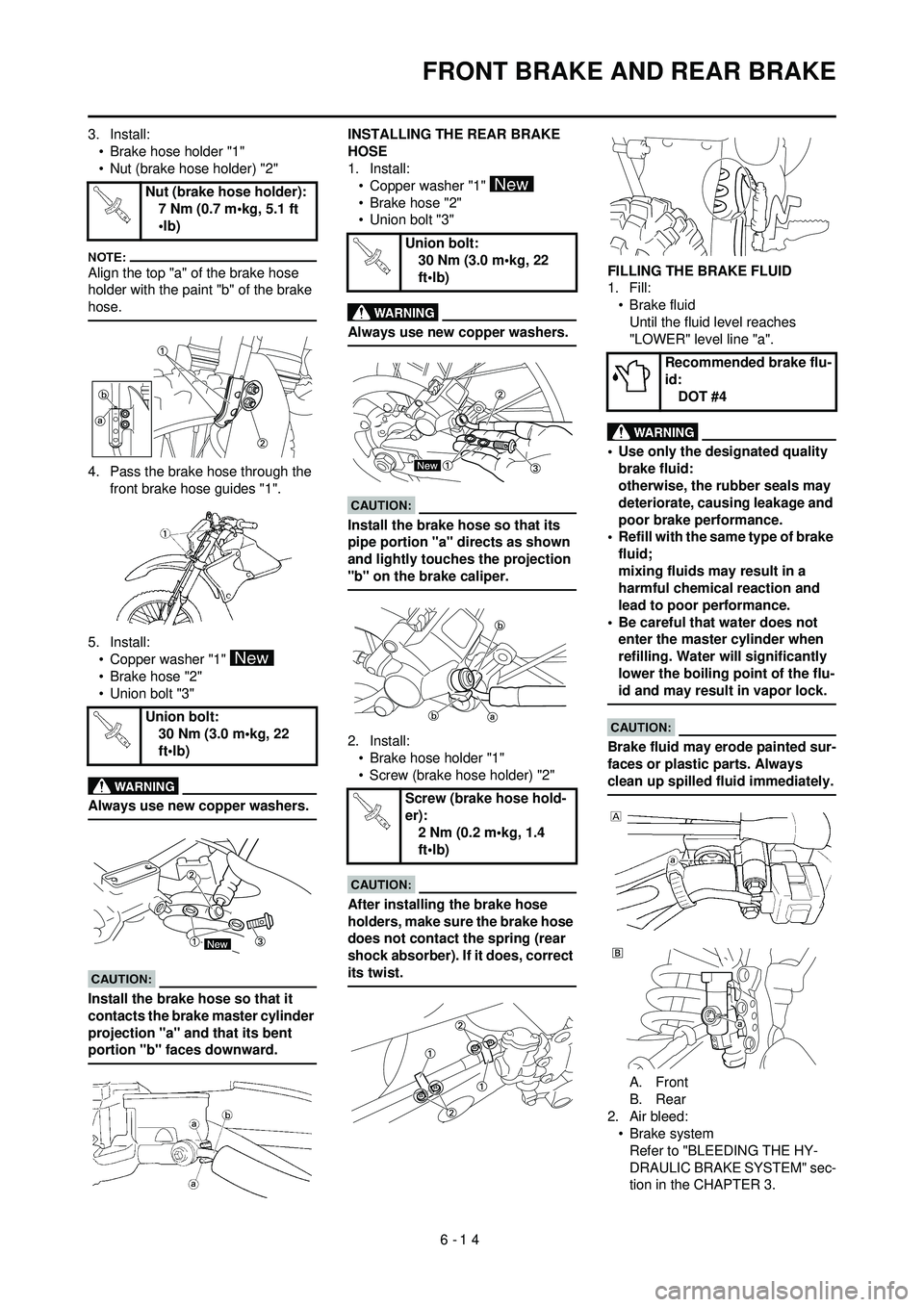

3. Install:• Brake hose holder "1"

• Nut (brake hose holder) "2"

Align the top "a" of the brake hose

holder with the paint "b" of the brake

hose.

4. Pass the brake hose through the front brake hose guides "1".

5. Install: • Copper washer "1"

• Brake hose "2"

• Union bolt "3"

Always use new copper washers.

Install the brake hose so that it

contacts the brake master cylinder

projection "a" and that its bent

portion "b" faces downward.

INSTALLING THE REAR BRAKE

HOSE

1. Install:• Copper washer "1"

• Brake hose "2"

• Union bolt "3"

Always use new copper washers.

Install the brake hose so that its

pipe portion "a" directs as shown

and lightly touches the projection

"b" on the brake caliper.

2. Install:

• Brake hose holder "1"

• Screw (brake hose holder) "2"

After installing the brake hose

holders, make sure the brake hose

does not contact the spring (rear

shock absorber). If it does, correct

its twist.

FILLING THE BRAKE FLUID

1. Fill:• Brake fluidUntil the fluid level reaches

"LOWER" level line "a".

• Use only the designated quality brake fluid:

otherwise, the rubber seals may

deteriorate, causi ng leakage and

poor brake performance.

• Refill with the same type of brake fluid;

mixing fluids may result in a

harmful chemical reaction and

lead to poor performance.

• Be careful that water does not enter the master cylinder when

refilling. Water will significantly

lower the boiling point of the flu-

id and may result in vapor lock.

Brake fluid may erode painted sur-

faces or plastic parts. Always

clean up spilled fluid immediately.

A. Front

B. Rear

2. Air bleed: • Brake system

Refer to "BLEEDING THE HY-

DRAULIC BRAKE SYSTEM" sec-

tion in the CHAPTER 3.

Nut (brake hose holder):

7 Nm (0.7 m•kg, 5.1 ft

•lb)

Union bolt: 30 Nm (3.0 m•kg, 22

ft•lb)

Union bolt:30 Nm (3.0 m•kg, 22

ft•lb)

Screw (brake hose hold-

er): 2 Nm (0.2 m•kg, 1.4

ft•lb)

Recommended brake flu-

id: DOT #4

Page 177 of 224

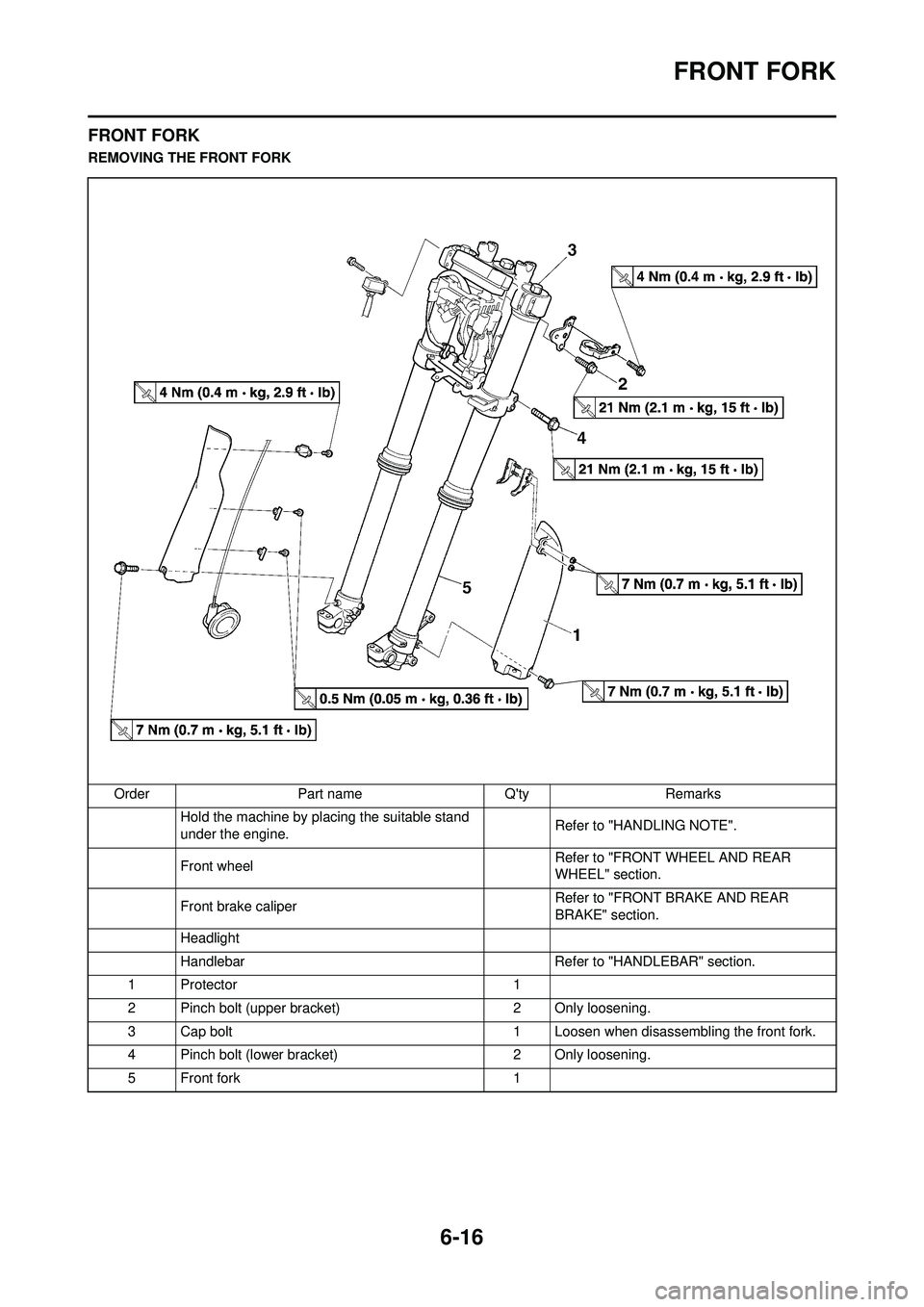

6-16

FRONT FORK

FRONT FORK

REMOVING THE FRONT FORKOrder Part name Q'ty Remarks Hold the machine by placing the suitable stand

under the engine. Refer to "HANDLING NOTE".

Front wheel Refer to "FRONT WHEEL AND REAR

WHEEL" section.

Front brake caliper Refer to "FRONT BRAKE AND REAR

BRAKE" section.

Headlight

Handlebar Refer to "HANDLEBAR" section.

1 Protector 1

2 Pinch bolt (upper bracket) 2 Only loosening.

3 Cap bolt 1 Loosen when disassembling the front fork.

4 Pinch bolt (lower bracket) 2 Only loosening.

5 Front fork 1

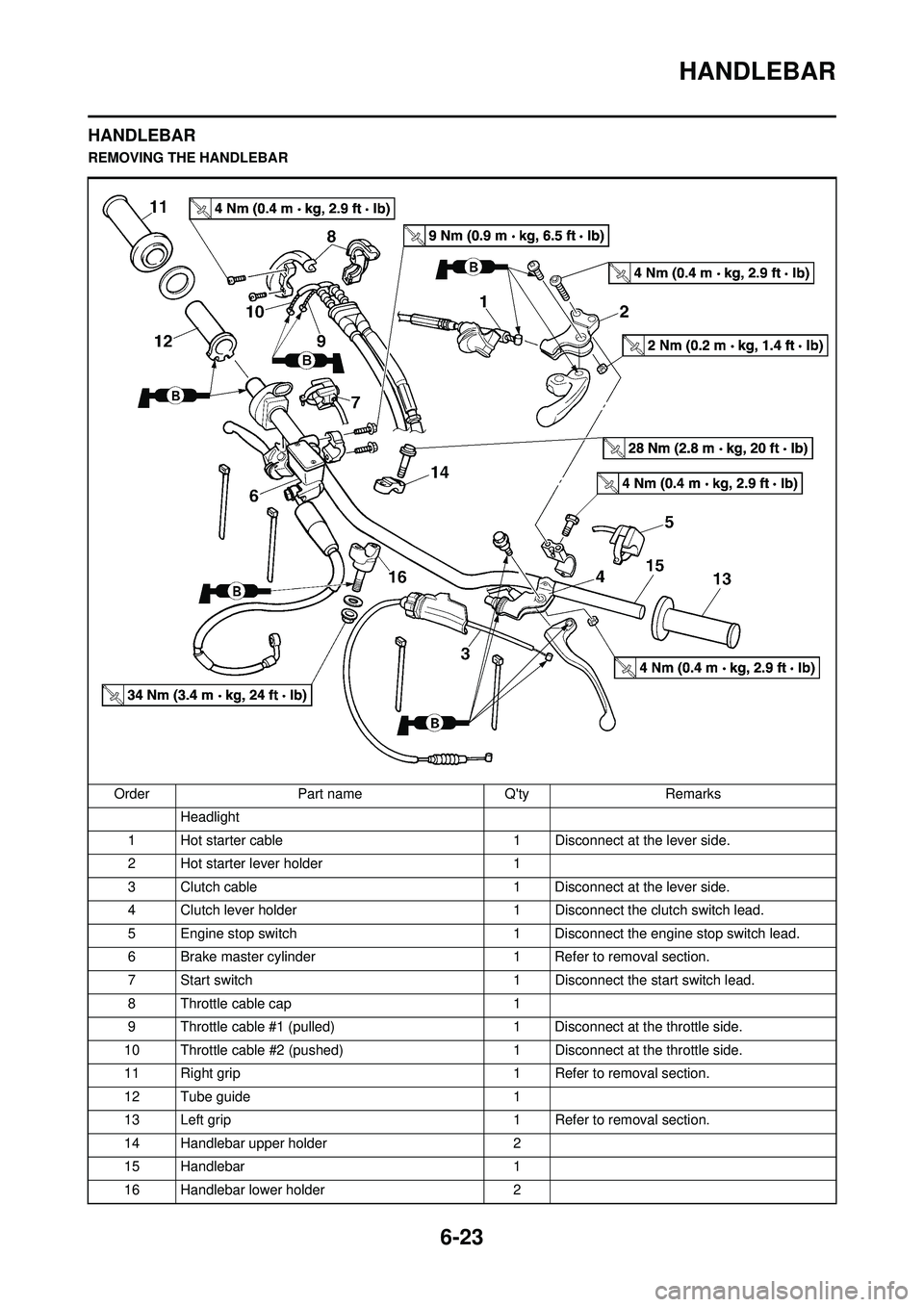

Page 184 of 224

6-23

HANDLEBAR

HANDLEBAR

REMOVING THE HANDLEBAROrder Part name Q'ty Remarks Headlight

1 Hot starter cable 1 Disconnect at the lever side.

2 Hot starter lever holder 1

3 Clutch cable 1 Disconnect at the lever side.

4 Clutch lever holder 1 Disconnect the clutch switch lead.

5 Engine stop switch 1 Disconnect the engine stop switch lead.

6 Brake master cylinder 1 Refer to removal section.

7 Start switch 1 Disconnect the start switch lead.

8 Throttle cable cap 1

9 Throttle cable #1 (pulled) 1 Disconnect at the throttle side.

10 Throttle cable #2 (pushed) 1 Disconnect at the throttle side.

11 Right grip 1 Refer to removal section.

12 Tube guide 1

13 Left grip 1 Refer to removal section.

14 Handlebar upper holder 2

15 Handlebar 1

16 Handlebar lower holder 2