YAMAHA WR 250F 2008 Service Manual

Manufacturer: YAMAHA, Model Year: 2008, Model line: WR 250F, Model: YAMAHA WR 250F 2008Pages: 224, PDF Size: 13.66 MB

Page 41 of 224

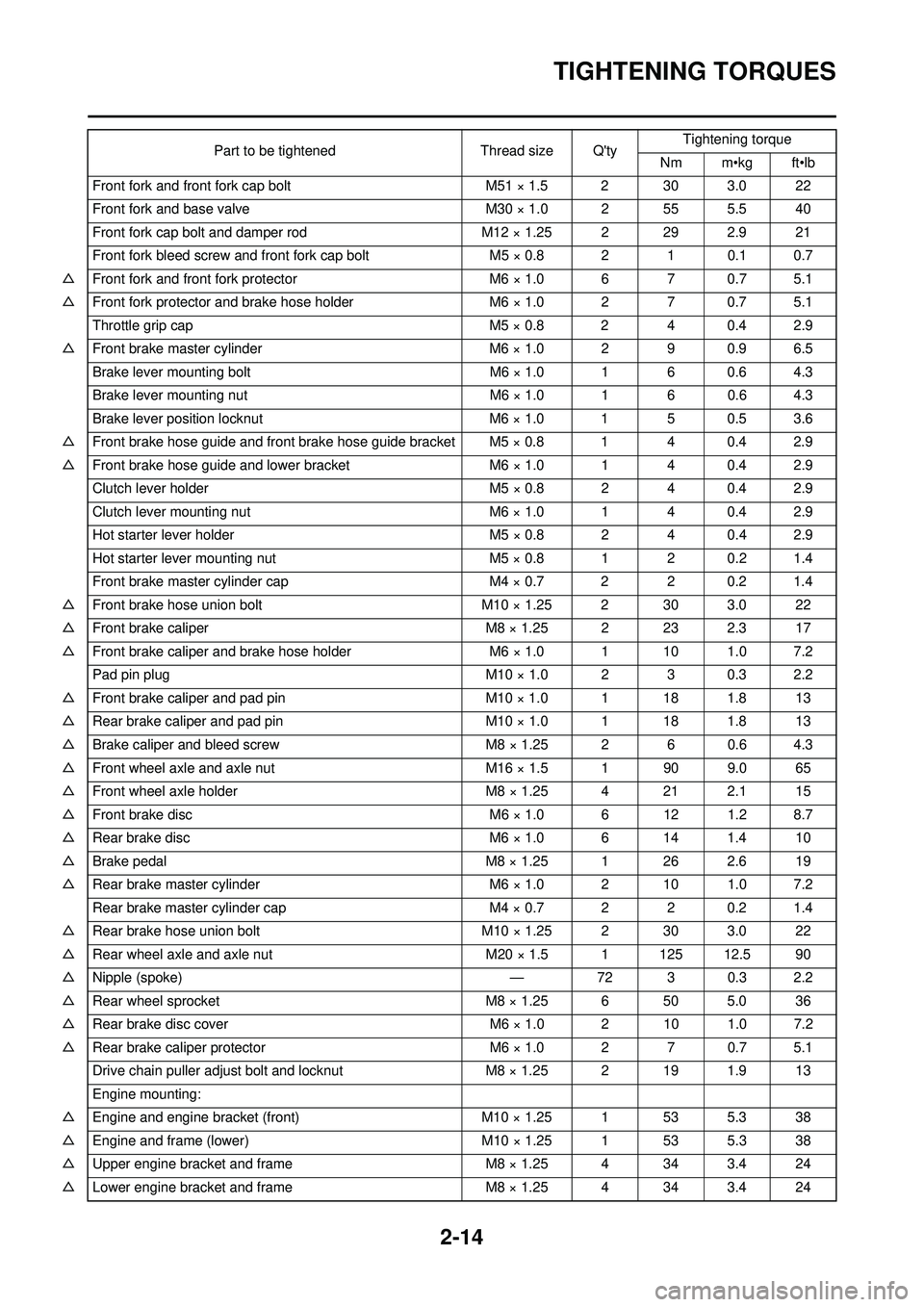

2-14

TIGHTENING TORQUES

Front fork and front fork cap boltM51 × 1.5 2 30 3.0 22

Front fork and base valve M30 × 1.0 2 55 5.5 40

Front fork cap bolt and damper rod M12 × 1.25 2 29 2.9 21

Front fork bleed screw and front fork cap bolt M5 × 0.8 2 1 0.1 0.7

△ Front fork and front fork protector M6 × 1.0 6 7 0.7 5.1

△ Front fork protector and brake hose holder M6 × 1.0 2 7 0.7 5.1

Throttle grip cap M5 × 0.8 2 4 0.4 2.9

△ Front brake master cylinder M6 × 1.0 2 9 0.9 6.5

Brake lever mounting bolt M6 × 1.0 1 6 0.6 4.3

Brake lever mounting nut M6 × 1.0 1 6 0.6 4.3

Brake lever position locknut M6 × 1.0 1 5 0.5 3.6

△ Front brake hose guide and front brake hose guide bracket M5 × 0.8 1 4 0.4 2.9

△ Front brake hose guide and lower bracket M6 × 1.0 1 4 0.4 2.9

Clutch lever holder M5 × 0.8 2 4 0.4 2.9

Clutch lever mounting nut M6 × 1.0 1 4 0.4 2.9

Hot starter lever holder M5 × 0.8 2 4 0.4 2.9

Hot starter lever mounting nut M5 × 0.8 1 2 0.2 1.4

Front brake master cylinder cap M4 × 0.7 2 2 0.2 1.4

△ Front brake hose union bolt M10 × 1.25 2 30 3.0 22

△ Front brake caliper M8 × 1.25 2 23 2.3 17

△ Front brake caliper and brake hose holder M6 × 1.0 1 10 1.0 7.2

Pad pin plug M10 × 1.0 2 3 0.3 2.2

△ Front brake caliper and pad pin M10 × 1.0 1 18 1.8 13

△ Rear brake caliper and pad pin M10 × 1.0 1 18 1.8 13

△ Brake caliper and bleed screw M8 × 1.25 2 6 0.6 4.3

△ Front wheel axle and axle nut M16 × 1.5 1 90 9.0 65

△ Front wheel axle holder M8 × 1.25 4 21 2.1 15

△ Front brake disc M6 × 1.0 6 12 1.2 8.7

△ Rear brake disc M6 × 1.0 6 14 1.4 10

△ Brake pedal M8 × 1.25 1 26 2.6 19

△ Rear brake master cylinder M6 × 1.0 2 10 1.0 7.2

Rear brake master cylinder cap M4 × 0.7 2 2 0.2 1.4

△ Rear brake hose union bolt M10 × 1.25 2 30 3.0 22

△ Rear wheel axle and axle nut M20 × 1.5 1 125 12.5 90

△ Nipple (spoke) —72 3 0.3 2.2

△ Rear wheel sprocket M8 × 1.25 6 50 5.0 36

△ Rear brake disc cover M6 × 1.0 2 10 1.0 7.2

△ Rear brake caliper protector M6 × 1.0 2 7 0.7 5.1

Drive chain puller adjust bolt and locknut M8 × 1.25 2 19 1.9 13

Engine mounting:

△ Engine and engine bracket (front) M10 × 1.25 1 53 5.3 38

△ Engine and frame (lower) M10 × 1.25 1 53 5.3 38

△ Upper engine bracket and frame M8 × 1.25 4 34 3.4 24

△ Lower engine bracket and frame M8 × 1.25 4 34 3.4 24

Part to be tightened

Thread size Q'tyTightening torque

Nm m•kg ft•lb

Page 42 of 224

2-15

TIGHTENING TORQUES

△Engine and engine bracket (upper) M10 × 1.25 1 55 5.5 40

△ Engine guard M6 × 1.0 3 7 0.7 5.1

Regulator M6 × 1.0 2 7 0.7 5.1

△ Pivot shaft and nut M16 × 1.5 1 85 8.5 61

△ Relay arm and swingarm M14 × 1.5 1 70 7.0 50

△ Relay arm and connecting rod M14 × 1.5 1 80 8.0 58

△ Connecting rod and frame M14 × 1.5 1 80 8.0 58

△ Rear shock absorber and frame M10 × 1.25 1 56 5.6 40

△ Rear shock absorber and relay arm M10 × 1.25 1 53 5.3 38

△ Rear frame (upper) M8 × 1.25 1 38 3.8 27

△ Rear frame (lower) M8 × 1.25 2 32 3.2 23

△ Swingarm and brake hose holder M5 × 0.8 4 2 0.2 1.4

Swingarm and patch M4 × 0.7 4 2 0.2 1.4

Upper drive chain tensioner M8 × 1.25 1 16 1.6 11

Lower drive chain tensioner M8 × 1.25 1 16 1.6 11

Drive chain support M6 × 1.0 3 7 0.7 5.1

Seal guard and swingarm M5 × 0.8 4 6 0.6 4.3

△ Fuel tank M6 × 1.0 2 9 0.9 6.5

△ Fuel cock M6 × 1.0 2 4 0.4 2.9

Seat set bracket and fuel tank M6 × 1.0 1 7 0.7 5.1

Fuel tank bracket and fuel tank M6 × 1.0 4 7 0.7 5.1

△ Air scoop and fuel tank M6 × 1.0 6 7 0.7 5.1

△ Air scoop and radiator guard (lower) M6 × 1.0 2 6 0.6 4.3

△ Front fender M6 × 1.0 4 7 0.7 5.1

△ Rear fender (front) M6 × 1.0 2 7 0.7 5.1

△ Rear fender (rear) M6 × 1.0 2 11 1.1 8.0

△ Side cover M6 × 1.0 2 7 0.7 5.1

△ Seat M8 × 1.25 2 23 2.3 17

Multi-function display bracket and upper bracket M6 × 1.0 2 7 0.7 5.1

Multi-function display M5 × 0.8 2 4 0.4 2.9

Plate 1 and front fork protector M5 × 0.8 2 4 0.4 2.9

Plate 2 and front fork protector —2 0.5 0.05 0.36

Speed sensor lead holder and lower bracket M6 × 1.0 1 13 1.3 9.4

Speed sensor lead holder and clamp M6 × 1.0 1 7 0.7 5.1

Headlight body and headlight unit —2 1 0.1 0.7

△ Headlight M6 × 1.0 2 7 0.7 5.1

Taillight —3 1 0.1 0.7

Taillight lead clamp and rear fender —3 0.5 0.05 0.36

△ Catch tank (upper) M6 × 1.0 1 16 1.6 11

△ Catch tank (lower) M6 × 1.0 1 7 0.7 5.1

Footrest bracket and frame M10 × 1.25 4 55 5.5 40

Sidestand M10 × 1.25 1 25 2.5 18

Part to be tightened

Thread size Q'tyTightening torque

Nm m•kg ft•lb

Page 43 of 224

2-16

TIGHTENING TORQUES

1. First, tighten the steering ring nut approximately 38 Nm (3.8 m•kg, 27 ft•lb) by using the steering nut wrench, then loosen

the steering ring nut one turn.

2. Retighten the steering ring nut 7 Nm (0.7 m•kg, 5.1 ft•lb).

ELECTRICAL

Tighten the rotor nut to 65 Nm (6.5 m•kg, 47 ft•lb), loosen and retighten the rotor nut to 65 Nm (6.5 m •kg, 47 ft•lb).

Part to be tightened Thread size Q'tyTightening torque

Nm m•kg ft•lb

Stator M5 × 0.8 2 7 0.7 5.1

Holder (AC magneto lead) M5× 0.8 2 7 0.7 5.1

Rotor M12 × 1.25 1Refer to NOTE.

Neutral switch M5 × 0.8 2 4 0.4 2.9

Starter motor M6 × 1.0 2 10 1.0 7.2

Starter relay terminal M6 × 1.0 2 4 0.4 2.9

Negative lead and cylinder head M6 × 1.0 1 10 1.0 7.2

Pickup coil M6 × 1.0 2 10 1.0 7.2

Page 44 of 224

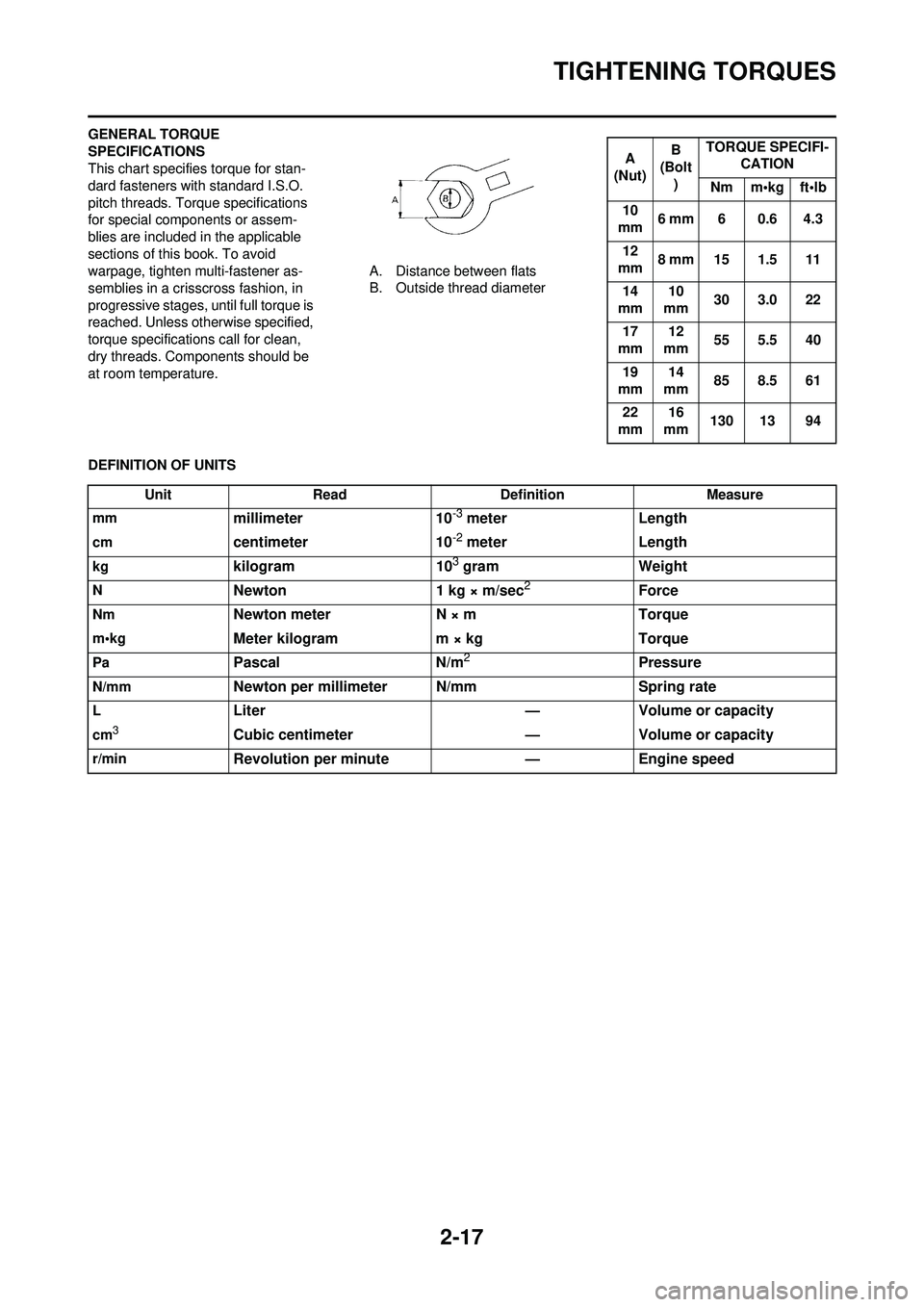

2-17

TIGHTENING TORQUES

GENERAL TORQUE

SPECIFICATIONS

This chart specifies torque for stan-

dard fasteners with standard I.S.O.

pitch threads. Torque specifications

for special components or assem-

blies are included in the applicable

sections of this book. To avoid

warpage, tighten multi-fastener as-

semblies in a crisscross fashion, in

progressive stages, until full torque is

reached. Unless otherwise specified,

torque specifications call for clean,

dry threads. Components should be

at room temperature. A. Distance between flats

B. Outside thread diameter

DEFINITION OF UNITS

A

(Nut) B

(Bolt

) TORQUE SPECIFI-

CATION

Nm m•kg ft•lb

10

mm 6 mm 6 0.6 4.3

12

mm 8 mm 15 1.5 11

14

mm 10

mm 30 3.0 22

17

mm 12

mm 55 5.5 40

19

mm 14

mm 85 8.5 61

22

mm 16

mm 130 13 94

Unit

Read Definition Measure

mm

millimeter 10-3 meterLength

cmcentimeter 10-2 meterLength

kgkilogram 103 gramWeight

NNewton 1 kg × m/sec2Force

NmNewton meter N × mTorque

m•kgMeter kilogram m × kg Torque

PaPascalN/m2Pressure

N/mmNewton per millimeter N/mm Spring rate

LLiter—Volume or capacity

cm3Cubic centimeter —Volume or capacity

r/minRevolution per minute —Engine speed

Page 45 of 224

2-18

LUBRICATION DIAGRAMS

LUBRICATION DIAGRAMS

1. Oil filter element

2. Oil pump

3. Drive axle

4. Main axle

5. Intake camshaft

6. Exhaust camshaft

7. Oil tank

8. Oil delivery pipe

A. To oil tank

Page 46 of 224

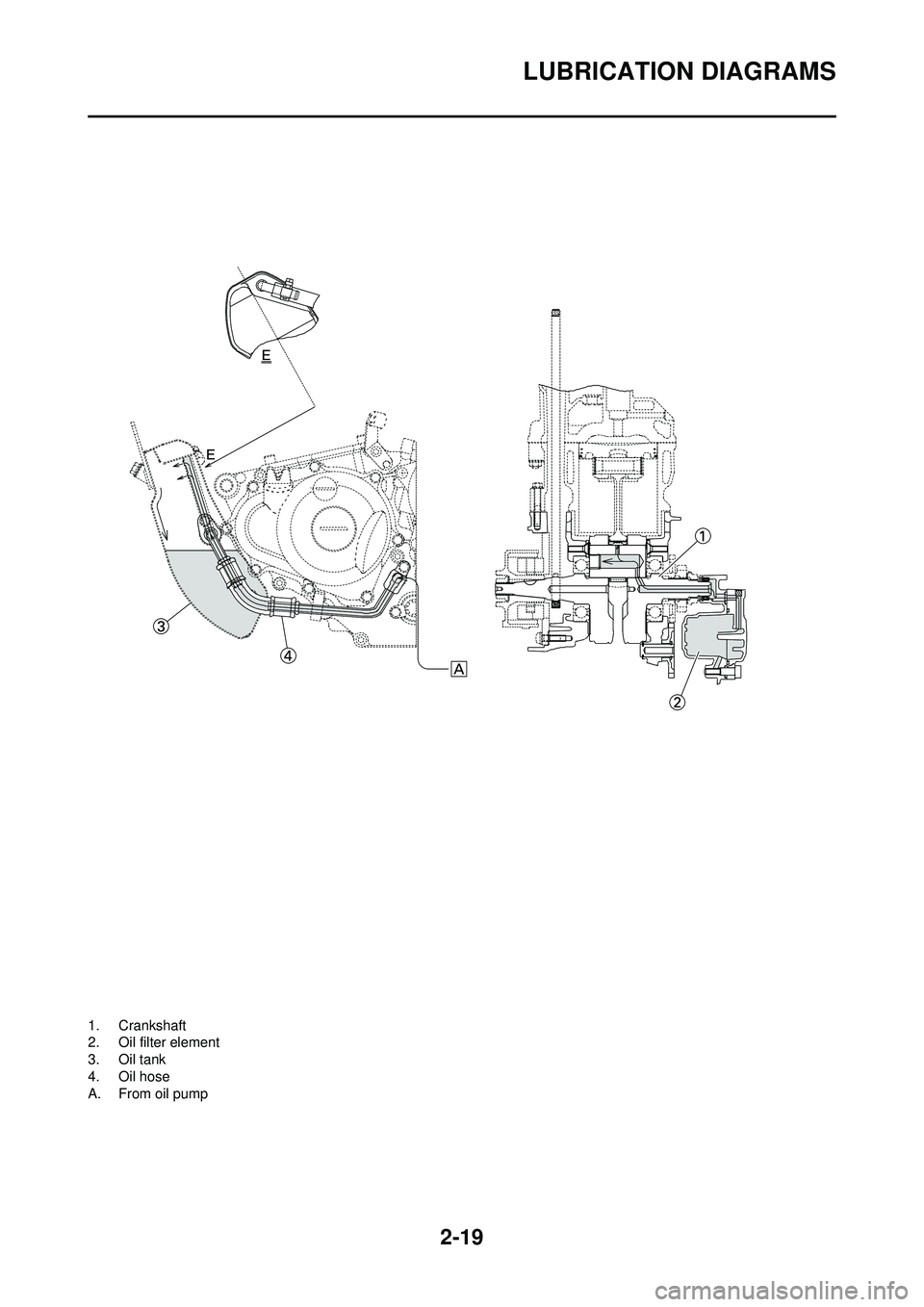

2-19

LUBRICATION DIAGRAMS

1. Crankshaft

2. Oil filter element

3. Oil tank

4. Oil hose

A. From oil pump

Page 47 of 224

2-20

LUBRICATION DIAGRAMS

Page 48 of 224

2-21

CABLE ROUTING DIAGRAM

CABLE ROUTING DIAGRAM

1. Fuel tank breather hose

2. Clamp

3. Diode

4. Hot starter cable

5. Wire harness

6. Hump (frame)

7. Cylinder head breather hose

8. Throttle position sensor lead

9. Neutral switch lead10. Oil hose

11. Clutch cable

12. Starter motor lead

13. Cable guide

14. Negative battery lead

15. AC magneto lead

16. Brake hose

17. Rectifier/regulator lead

18. Carburetor breather hose 19. Carburetor overflow hose

20. Catch tank breather hose

Page 49 of 224

2-22

CABLE ROUTING DIAGRAM

A. Insert the end of the fuel tank breather hose into the hole in

the steering stem.

B. Fasten the throttle cable, hot

starter cable and rectifier/regula-

tor lead onto the frame. Locate

the clamp end facing the lower

side of the hot starter cable and

cut off the tie end.

C. Fasten the diode (at the mark-

ing), throttle cable and hot start-

er cable onto the frame. Locate

the clamp end facing toward the

lower right of the frame and with

the tie end facing downward.

D. Fasten the wire harness, throttle

position sensor lead, starter mo-

tor lead and negative battery

lead onto the frame. Pass the

clamp through the hole in the

stay (air cut-off valve). Locate

the clamp end facing toward the

lower side of the frame and cut

off the tie end.

E. Fasten the throttle position sen-

sor lead onto the frame. Locate

the clamp end facing toward the

lower side of the frame and cut

off the tie end.

F. Pass the carburetor breather hoses, carburetor overflow hose

and catch tank breather hose

between the connecting rod and

cross tube (frame).

G. Fasten the neutral switch lead and oil hose together with the

plastic locking ties and cut off

the tie ends.

H. Fasten the neutral switch lead

and AC magneto lead onto the

frame. Locate the clamp end

facing toward the outside of the

frame and tie end facing toward

the rear of the frame.

I. Pass the clutch cable through

the cable guide.

J. Fasten the starter motor lead, AC magneto lead and neutral

switch lead onto the frame. Lo-

cate the clamp end facing to-

ward the rear of the frame and

cut off the tie end.

K. Fasten the clutch cable, starter motor lead, negative battery

lead, AC magneto lead and neu-

tral switch lead onto the frame.

Locate the clamp end facing to-

ward the rear of the frame and

cut off the tie end.

L. Pass the neutral switch lead and

AC magneto lead on the inside

of the wire harness. M. Fasten the clutch cable, AC

magneto lead and neutral switch

lead onto the frame. Locate the

clamp end near the clutch cable

and cut off the tie end.

N. Pass the clutch cable and wire harness through the cable

guide.

O. Locate the couplers in the frame recess.

P. Pass the carburetor breather hoses, carburetor overflow hose

and catch tank breather hose so

that the hoses do not contact the

rear shock absorber.

Q. Secure the coupler by pushing it

into the hole in the headlight

unit.

Page 50 of 224

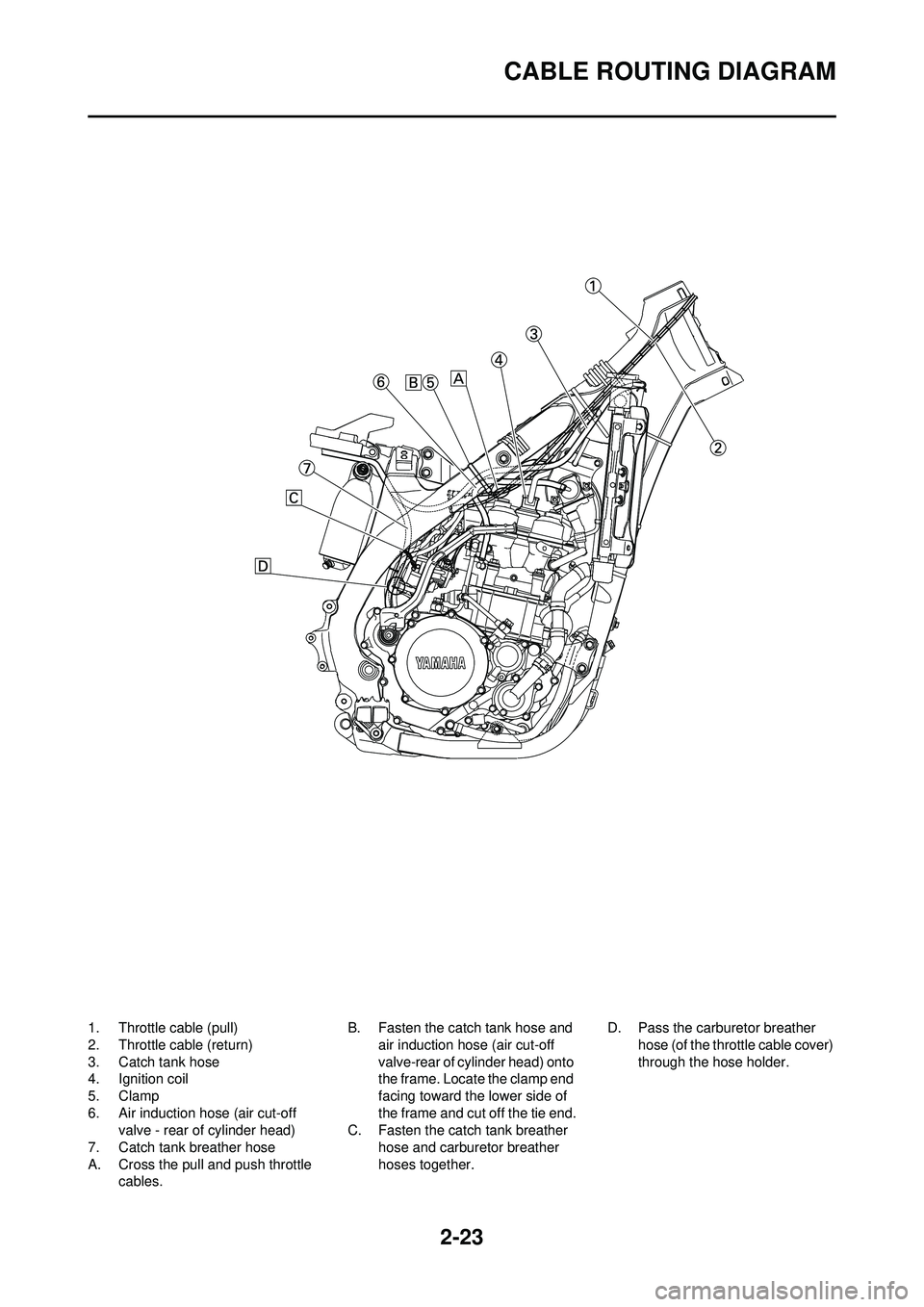

2-23

CABLE ROUTING DIAGRAM

1. Throttle cable (pull)

2. Throttle cable (return)

3. Catch tank hose

4. Ignition coil

5. Clamp

6. Air induction hose (air cut-off valve - rear of cylinder head)

7. Catch tank breather hose

A. Cross the pull and push throttle cables. B. Fasten the catch tank hose and

air induction hose (air cut-off

valve-rear of cylinder head) onto

the frame. Locat e the clamp end

facing toward the lower side of

the frame and cut off the tie end.

C. Fasten the catch tank breather hose and carburetor breather

hoses together. D. Pass the carburetor breather

hose (of the throttle cable cover)

through the hose holder.