light YAMAHA WR 250F 2009 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2009, Model line: WR 250F, Model: YAMAHA WR 250F 2009Pages: 224, PDF Size: 13.93 MB

Page 41 of 224

2-16

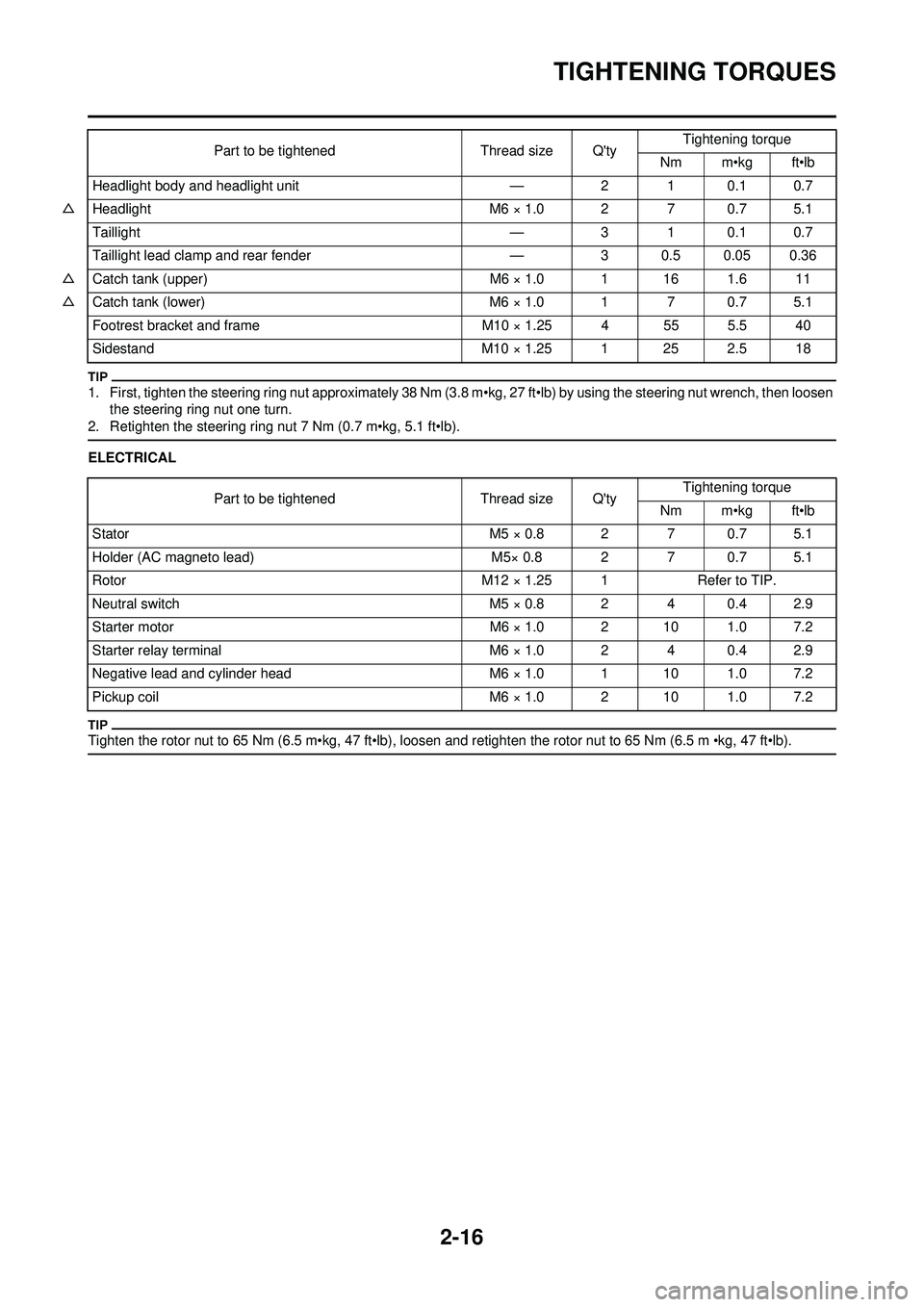

TIGHTENING TORQUES

1. First, tighten the steering ring nut approximately 38 Nm (3.8 m•kg, 27 ft•lb) by using the steering nut wrench, then loosen the steering ring nut one turn.

2. Retighten the steering ring nut 7 Nm (0.7 m•kg, 5.1 ft•lb).

ELECTRICAL

Tighten the rotor nut to 65 Nm (6.5 m•kg, 47 ft•lb), loosen and retighten the rotor nut to 65 Nm (6.5 m •kg, 47 ft•lb).

Headlight body and headlight unit —2 1 0.1 0.7

△ Headlight M6 × 1.0 2 7 0.7 5.1

Taillight —3 1 0.1 0.7

Taillight lead clamp and rear fender —3 0.5 0.05 0.36

△ Catch tank (upper) M6 × 1.0 1 16 1.6 11

△ Catch tank (lower) M6 × 1.0 1 7 0.7 5.1

Footrest bracket and frame M10 × 1.25 4 55 5.5 40

Sidestand M10 × 1.25 1 25 2.5 18

Part to be tightened

Thread size Q'tyTightening torque

Nm m•kg ft•lb

Part to be tightened Thread size Q'tyTightening torque

Nm m•kg ft•lb

Stator M5 × 0.8 2 7 0.7 5.1

Holder (AC magneto lead) M5× 0.8 2 7 0.7 5.1

Rotor M12 × 1.25 1Refer to TIP.

Neutral switch M5 × 0.8 2 4 0.4 2.9

Starter motor M6 × 1.0 2 10 1.0 7.2

Starter relay terminal M6 × 1.0 2 4 0.4 2.9

Negative lead and cylinder head M6 × 1.0 1 10 1.0 7.2

Pickup coil M6 × 1.0 2 10 1.0 7.2

Page 47 of 224

2-21

CABLE ROUTING DIAGRAM

A. Insert the end of the fuel tank breather hose into the hole in

the steering stem.

B. Fasten the throttle cable, hot

starter cable and rectifier/regula-

tor lead onto the frame. Locate

the clamp end facing the lower

side of the hot starter cable and

cut off the tie end.

C. Fasten the diode (at the mark-

ing), throttle cable and hot start-

er cable onto the frame. Locate

the clamp end facing toward the

lower right of the frame and with

the tie end facing downward.

D. Fasten the wire harness, throttle

position sensor lead, starter mo-

tor lead and negative battery

lead onto the frame. Pass the

clamp through the hole in the

stay (air cut-off valve). Locate

the clamp end facing toward the

lower side of the frame and cut

off the tie end.

E. Pass the carburetor breather

hoses, carburetor overflow hose

and catch tank breather hose

between the connecting rod and

cross tube (frame).

F. Fasten the neutral switch lead and oil hose together with the

plastic locking ties and cut off

the tie ends.

G. Fasten the neutral switch lead

and AC magneto lead onto the

frame. Locate the clamp end

facing toward the outside of the

frame and tie end facing toward

the rear of the frame.

H. Pass the clutch cable through the cable guide.

I. Fasten the starter motor lead, AC magneto lead and neutral

switch lead onto the frame. Lo-

cate the clamp end facing to-

ward the rear of the frame and

cut off the tie end.

J. Fasten the clutch cable, starter motor lead, negative battery

lead, AC magneto lead and neu-

tral switch lead onto the frame.

Locate the clamp end facing to-

ward the rear of the frame and

cut off the tie end.

K. Pass the neutral switch lead and AC magneto lead on the inside

of the wire harness.

L. Fasten the clutch cable, AC magneto lead and neutral switch

lead onto the frame. Locate the

clamp end near the clutch cable

and cut off the tie end. M. Pass the clutch cable and wire

harness through the cable

guide.

N. Locate the couplers in the frame

recess.

O. Pass the carburetor breather hoses, carburetor overflow hose

and catch tank breather hose so

that the hoses do not contact the

rear shock absorber.

P. Secure the coupler by pushing it into the hole in the headlight

unit.

Q. Fasten the throttle position sen- sor lead and the hot starter ca-

ble.

R. Locate the clamp between the hot starter cable protector and

rubber cap.

Page 49 of 224

2-23

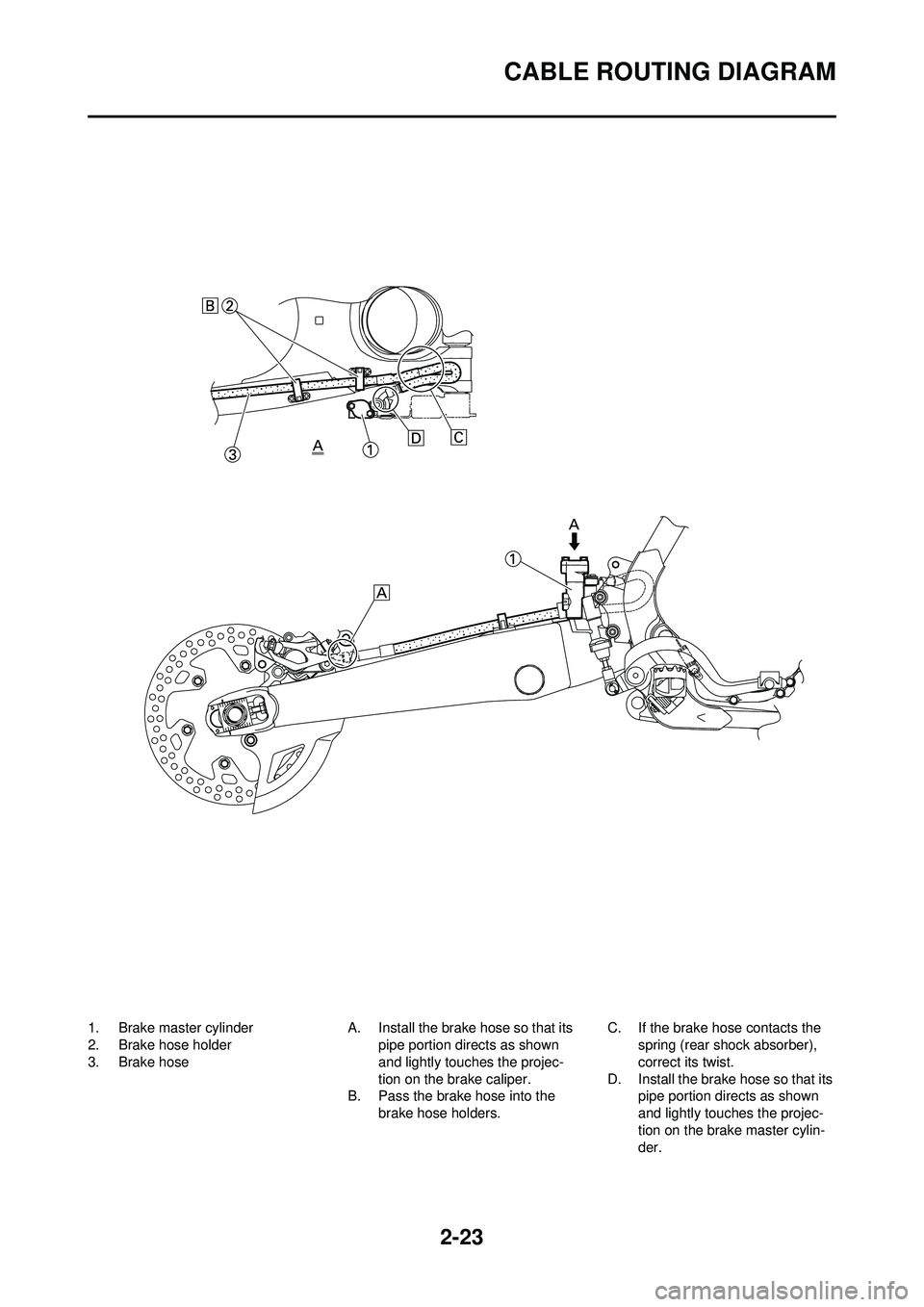

CABLE ROUTING DIAGRAM

1. Brake master cylinder

2. Brake hose holder

3. Brake hoseA. Install the brake hose so that its

pipe portion directs as shown

and lightly touches the projec-

tion on the brake caliper.

B. Pass the brake hose into the

brake hose holders. C. If the brake hose contacts the

spring (rear shock absorber),

correct its twist.

D. Install the brake hose so that its pipe portion directs as shown

and lightly touches the projec-

tion on the brake master cylin-

der.

Page 50 of 224

2-24

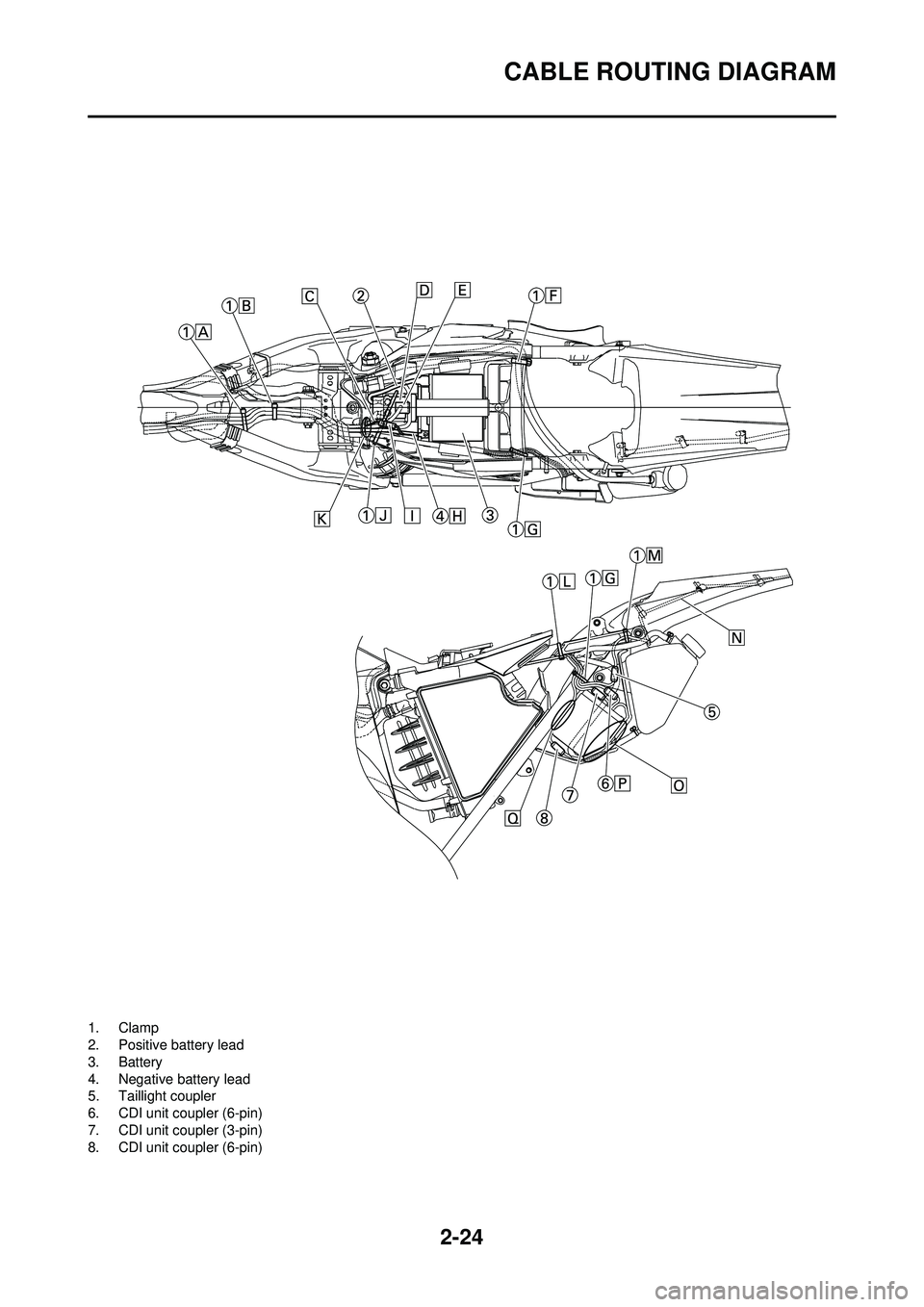

CABLE ROUTING DIAGRAM

1. Clamp

2. Positive battery lead

3. Battery

4. Negative battery lead

5. Taillight coupler

6. CDI unit coupler (6-pin)

7. CDI unit coupler (3-pin)

8. CDI unit coupler (6-pin)

Page 51 of 224

2-25

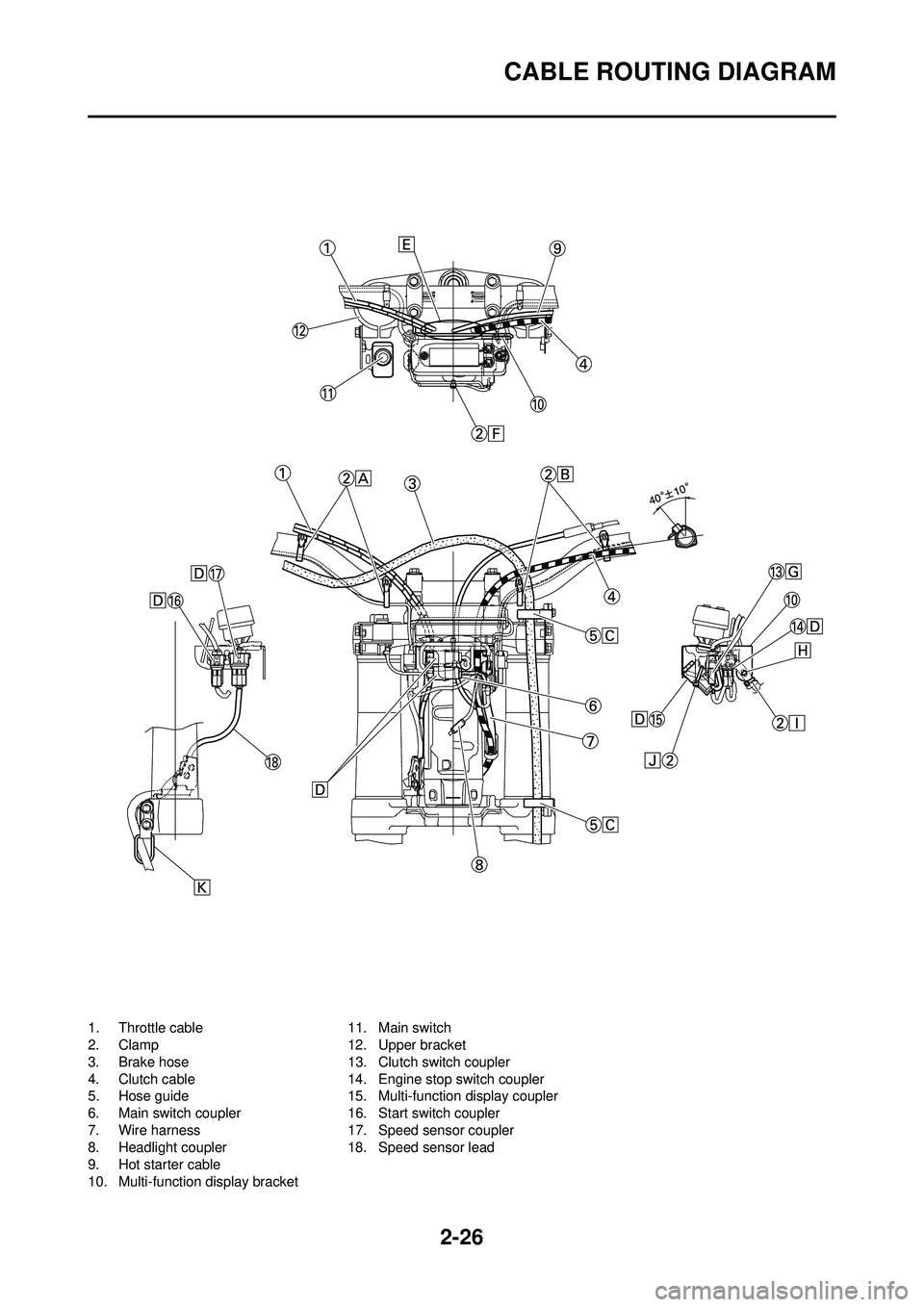

CABLE ROUTING DIAGRAM

A. Fasten the wire harness, nega-tive battery lead and starter mo-

tor lead to the upper engine

bracket (left side). Locate the

clamp end facing toward the up-

per side of the frame with the tie

end cut off on the inside of the

frame.

B. Fasten the wire harness, nega- tive battery lead and starter mo-

tor lead to the upper engine

bracket (left side). Locate the

clamp end facing toward the up-

per side of the frame with the tie

end cut off on the inside of the

frame. Clamp the wire harness

and negative lead at the mark-

ing.

C. Pass the starter motor lead

through the hole in the relay

holder.

D. Fit the cover securely.

E. Connect the wire harness to the

starter relay.

F. Fasten the catch tank breather

hose and catch tank hose to the

rear frame. Clamp them close to

where they are joined to the

frame. Fasten the pipe tightly

enough not to crush it. Locate

the clamp end facing toward the

rear of the frame with the tie end

facing downward.

G. Fasten the (three) CDI unit leads

and taillight lead to the rear

frame. Locate the clamp end

facing toward the upper side of

the frame and cut off the tie end.

H. Connect the negative battery lead to the battery negative ter-

minal.

I. Connect the negative battery lead to the wire harness.

J. Fasten the wire harness to the

rear frame. Locate the clamp

end facing toward the upper side

of the frame and the tie end to-

ward the inside of the frame.

Clamp the wire harness at the

marking.

K. Pass the wire harness, starter relay lead, starting circuit cut-off

relay lead and negative battery

lead through the hole in the relay

holder.

L. Fasten the (three) CDI unit leads

and taillight lead to the rear

frame. Locate the clamp end

facing toward the lower side of

the frame and cut off the tie end. M. Fasten the taillight lead to the

rear frame. Locate the clamp

end facing toward the upper side

of the frame and cut off the tie

end.

N. Do not allow the taillight lead to slacken.

O. Locate the CDI unit lead be- tween the CDI unit and rear

fender.

P. Locate the CDI unit coupler in the clearance between the up-

per side of the CDI unit and low-

er side of the catch tank stay.

Q. Locate the CDI unit lead be- tween the CDI unit and rear

frame.

Page 52 of 224

2-26

CABLE ROUTING DIAGRAM

1. Throttle cable

2. Clamp

3. Brake hose

4. Clutch cable

5. Hose guide

6. Main switch coupler

7. Wire harness

8. Headlight coupler

9. Hot starter cable

10. Multi-function display bracket11. Main switch

12. Upper bracket

13. Clutch switch coupler

14. Engine stop switch coupler

15. Multi-function display coupler

16. Start switch coupler

17. Speed sensor coupler

18. Speed sensor lead

Page 55 of 224

3-2

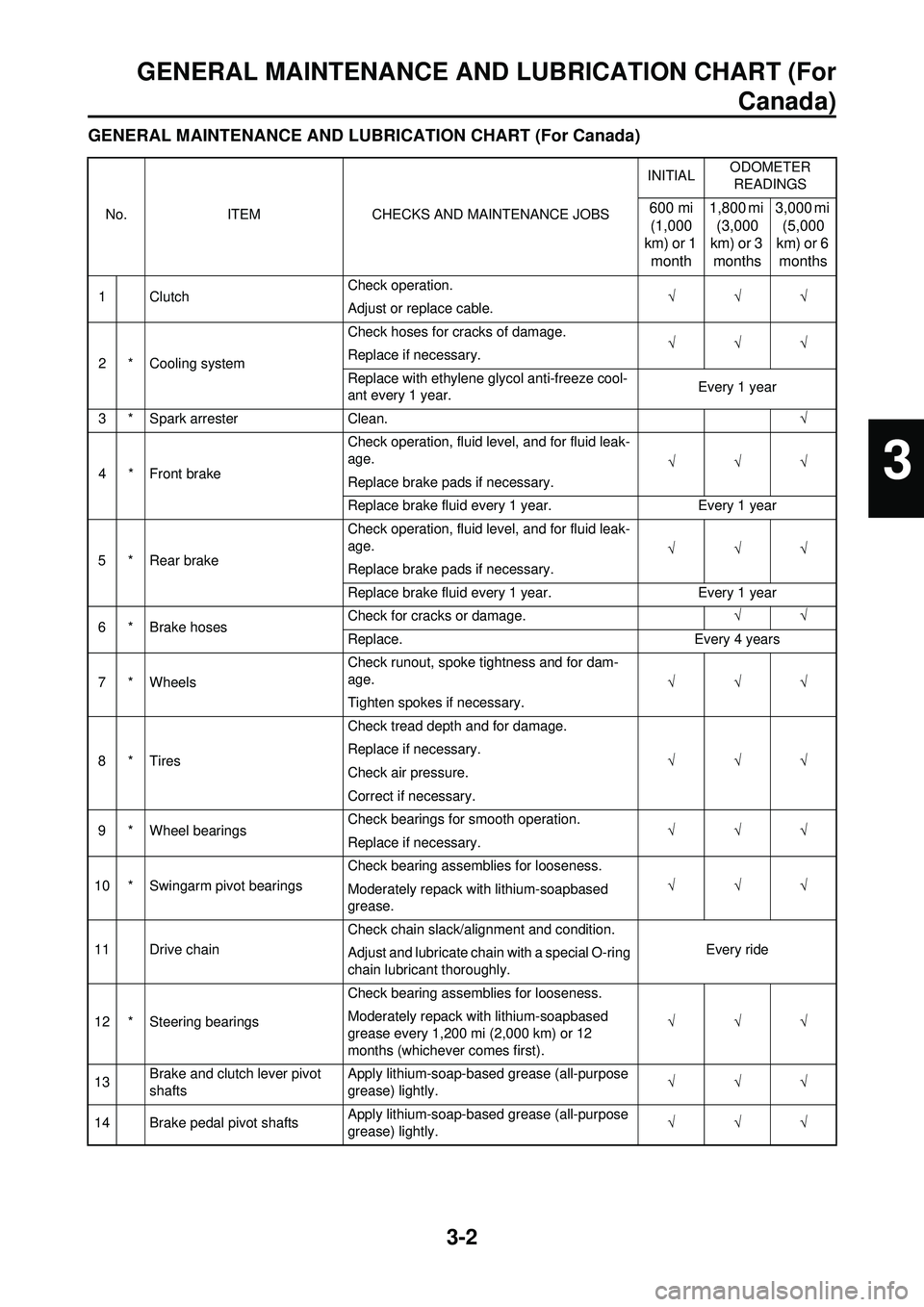

GENERAL MAINTENANCE AND LUBRICATION CHART (ForCanada)

GENERAL MAINTENANCE AND LUBRICATION CHART (For Canada)

No.ITEM CHECKS AND MAINTENANCE JOBS INITIAL

ODOMETER

READINGS600 mi (1,000

km) or 1

month 1,800 mi

(3,000

km) or 3

months 3,000 mi

(5,000

km) or 6

months

1Clutch Check operation.

√√√

Adjust or replace cable.

2 * Cooling system Check hoses for cracks of damage.

√√√

Replace if necessary.

Replace with ethylene glycol anti-freeze cool-

ant every 1 year. Every 1 year

3 * Spark arrester Clean. √

4 * Front brake Check operation, fluid level, and for fluid leak-

age.

√√√

Replace brake pads if necessary.

Replace brake fluid every 1 year. Every 1 year

5 * Rear brake Check operation, fluid level, and for fluid leak-

age.

√√√

Replace brake pads if necessary.

Replace brake fluid every 1 year. Every 1 year

6 * Brake hoses Check for cracks or damage.

√√

Replace. Every 4 years

7*Wheels Check runout, spoke tightness and for dam-

age.

√√√

Tighten spokes if necessary.

8*Tires Check tread depth and for damage.

√√√

Replace if necessary.

Check air pressure.

Correct if necessary.

9 * Wheel bearings Check bearings for smooth operation.

√√√

Replace if necessary.

10 * Swingarm pivot bearings Check bearing assemblies for looseness.

√√√

Moderately repack with lithium-soapbased

grease.

11 Drive chain Check chain slack/alignment and condition.

Every ride

Adjust and lubricate chain with a special O-ring

chain lubricant thoroughly.

12 * Steering bearings Check bearing assemblies for looseness.

√√√

Moderately repack with lithium-soapbased

grease every 1,200 mi (2,000 km) or 12

months (whichever comes first).

13 Brake and clutch lever pivot

shafts Apply lithium-soap-based grease (all-purpose

grease) lightly.

√√√

14 Brake pedal pivot shafts Apply lithium-soap-based grease (all-purpose

grease) lightly. √√√

3

Page 56 of 224

3-3

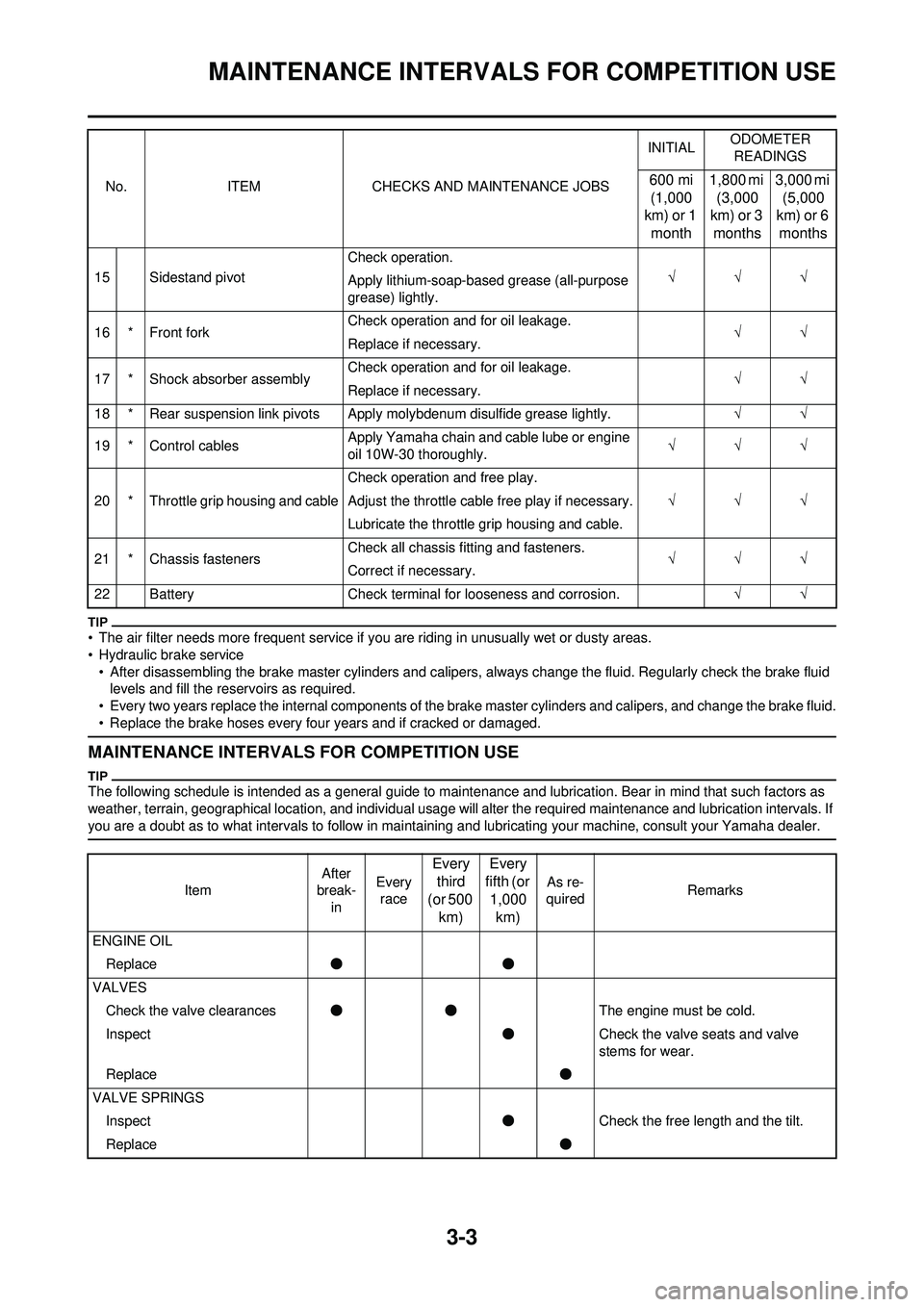

MAINTENANCE INTERVALS FOR COMPETITION USE

• The air filter needs more frequent service if you are riding in unusually wet or dusty areas.

• Hydraulic brake service• After disassembling the brake master cylinders and calipers, always change the fluid. Regularly check the brake fluid levels and fill the reservoirs as required.

• Every two years replace the internal components of the brake master cylinders and calipers, and change the brake fluid.

• Replace the brake hoses every four years and if cracked or damaged.

MAINTENANCE INTERVALS FOR COMPETITION USE

The following schedule is intended as a general guide to maintenance and lubrication. Bear in mind that such factors as

weather, terrain, geographical location, and individual usage will alter the required maintenance and lubrication intervals. If

you are a doubt as to what intervals to follow in maintaining and lubricating your machine, consult your Yamaha dealer.

15 Sidestand pivot Check operation.

√√√

Apply lithium-soap-based grease (all-purpose

grease) lightly.

16 * Front fork Check operation and for oil leakage.

√√

Replace if necessary.

17 * Shock absorber assembly Check operation and for oil leakage.

√√

Replace if necessary.

18 * Rear suspension link pivots Apply molybdenum disulfide grease lightly. √√

19 * Control cables Apply Yamaha chain and cable lube or engine

oil 10W-30 thoroughly. √√√

20 * Throttle grip housing and cable Check operation and free play.

√√√

Adjust the throttle cable free play if necessary.

Lubricate the throttle grip housing and cable.

21 * Chassis fasteners Check all chassis fitting and fasteners.

√√√

Correct if necessary.

22 Battery Check terminal for looseness and corrosion. √√

No.

ITEM CHECKS AND MAINTENANCE JOBS INITIAL

ODOMETER

READINGS

600 mi (1,000

km) or 1

month 1,800 mi

(3,000

km) or 3

months 3,000 mi

(5,000

km) or 6

months

Item After

break-

in Every

race

Every

third

(or 500 km) Every

fifth (or 1,000 km)

As re-

quired Remarks

ENGINE OIL Replace ●●

VALVES Check the valve clearances ●● The engine must be cold.

Inspect ●Check the valve seats and valve

stems for wear.

Replace ●

VALVE SPRINGS Inspect ●Check the free length and the tilt.

Replace ●

Page 61 of 224

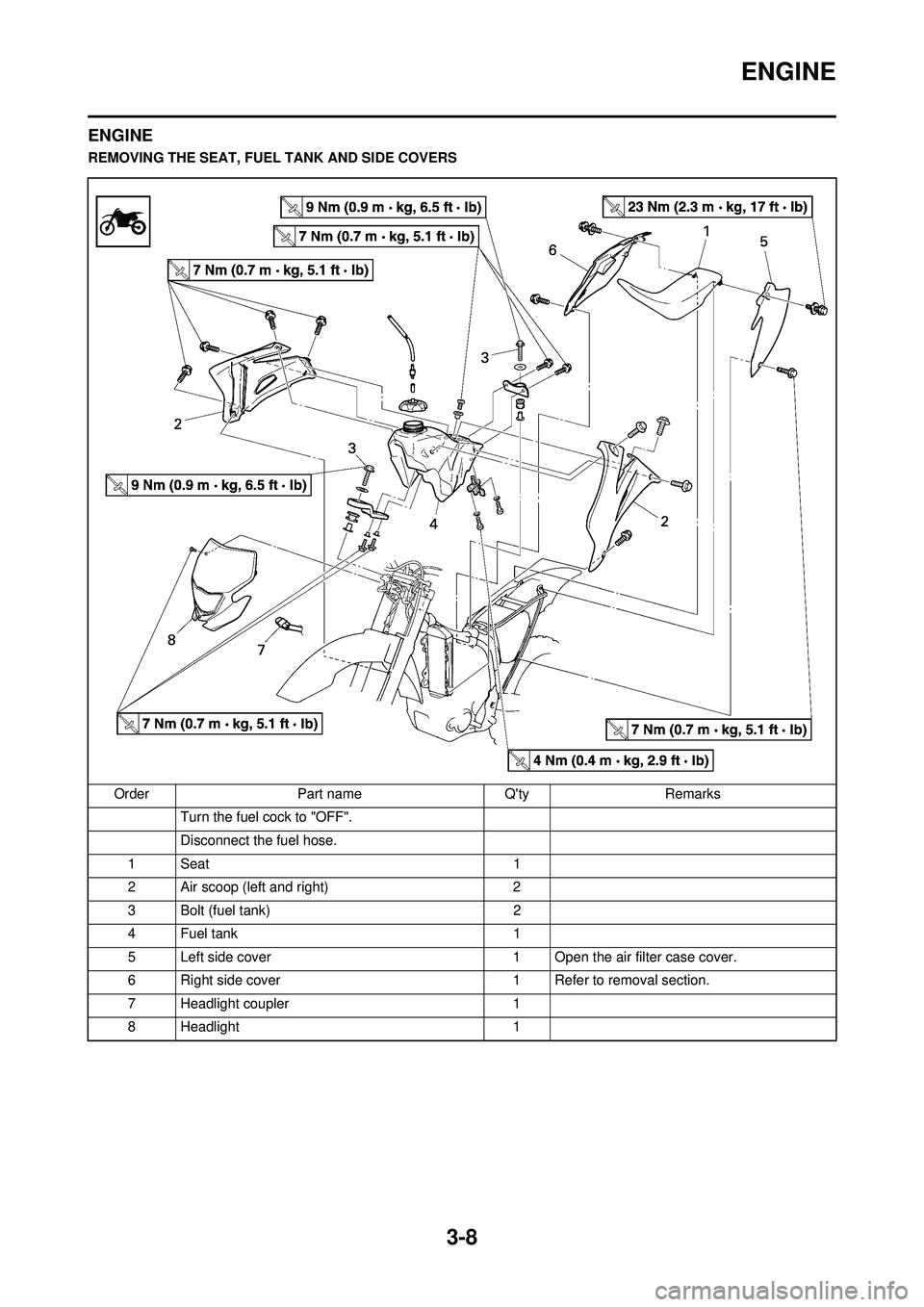

3-8

ENGINE

ENGINE

REMOVING THE SEAT, FUEL TANK AND SIDE COVERSOrder Part name Q'ty Remarks Turn the fuel cock to "OFF".

Disconnect the fuel hose.

1 Seat 1

2 Air scoop (left and right) 2

3 Bolt (fuel tank) 2

4 Fuel tank 1

5 Left side cover 1 Open the air filter case cover.

6 Right side cover 1 Refer to removal section.

7 Headlight coupler 1

8 Headlight 1

Page 69 of 224

3-16

ENGINE

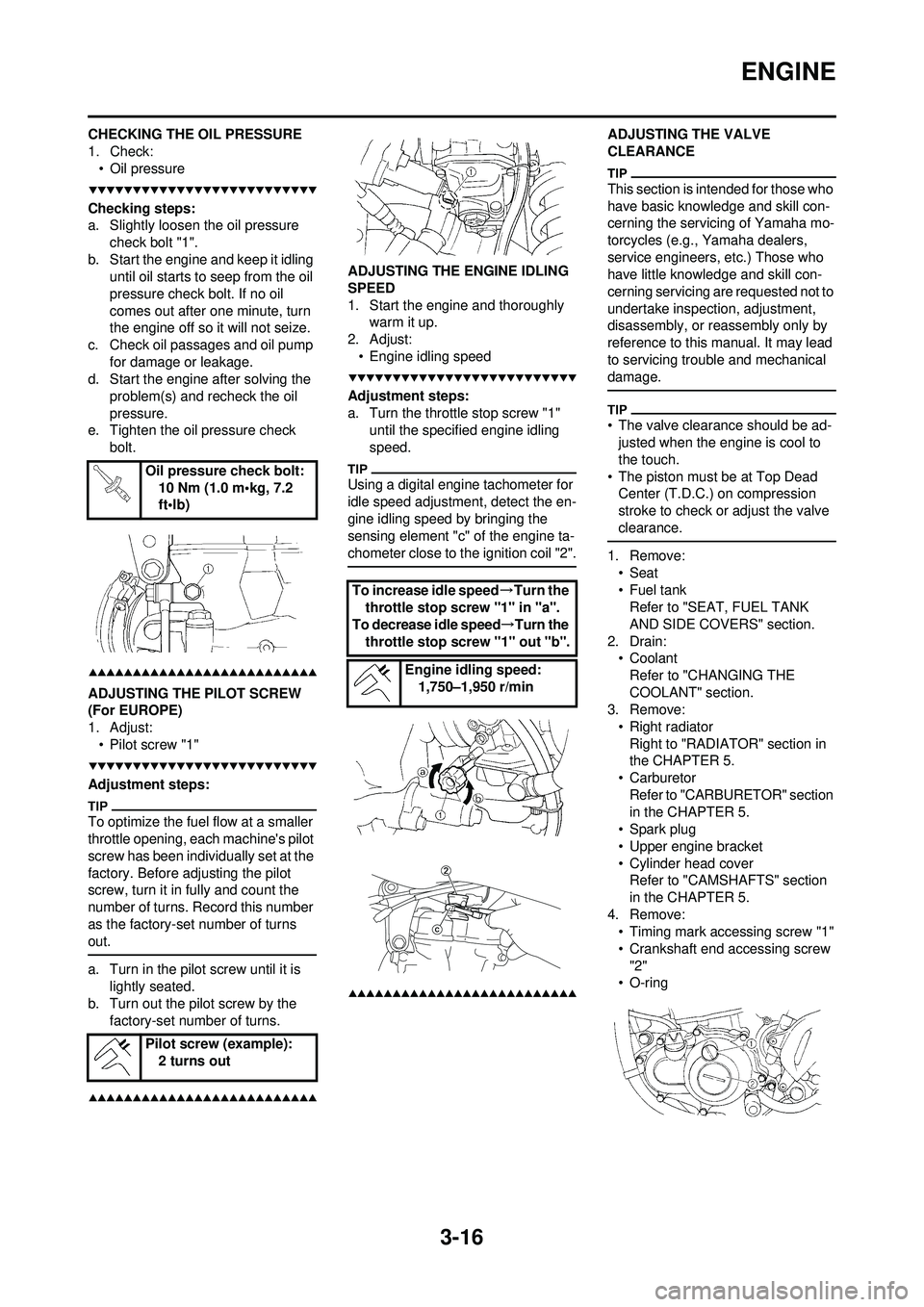

CHECKING THE OIL PRESSURE

1. Check:•Oil pressure

Checking steps:

a. Slightly loosen the oil pressure check bolt "1".

b. Start the engine and keep it idling until oil starts to seep from the oil

pressure check bolt. If no oil

comes out after one minute, turn

the engine off so it will not seize.

c. Check oil passages and oil pump for damage or leakage.

d. Start the engine after solving the

problem(s) and recheck the oil

pressure.

e. Tighten the oil pressure check

bolt.

ADJUSTING THE PILOT SCREW

(For EUROPE)

1. Adjust:• Pilot screw "1"

Adjustment steps:

To optimize the fuel flow at a smaller

throttle opening, each machine's pilot

screw has been individually set at the

factory. Before adjusting the pilot

screw, turn it in fully and count the

number of turns. Record this number

as the factory-set number of turns

out.

a. Turn in the pilot screw until it is lightly seated.

b. Turn out the pilot screw by the

factory-set number of turns.

ADJUSTING THE ENGINE IDLING

SPEED

1. Start the engine and thoroughly warm it up.

2. Adjust: • Engine idling speed

Adjustment steps:

a. Turn the throttle stop screw "1" until the specified engine idling

speed.

Using a digital engine tachometer for

idle speed adjustment, detect the en-

gine idling speed by bringing the

sensing element "c" of the engine ta-

chometer close to the ignition coil "2".

ADJUSTING THE VALVE

CLEARANCE

This section is intended for those who

have basic knowledge and skill con-

cerning the servicing of Yamaha mo-

torcycles (e.g., Yamaha dealers,

service engineers, etc.) Those who

have little knowledge and skill con-

cerning servicing are requested not to

undertake inspection, adjustment,

disassembly, or reassembly only by

reference to this manual. It may lead

to servicing trouble and mechanical

damage.

• The valve clearance should be ad-justed when the engine is cool to

the touch.

• The piston must be at Top Dead Center (T.D.C.) on compression

stroke to check or adjust the valve

clearance.

1. Remove:

•Seat

• Fuel tankRefer to "SEAT, FUEL TANK

AND SIDE COVERS" section.

2. Drain: • Coolant

Refer to "CHANGING THE

COOLANT" section.

3. Remove:

• Right radiatorRight to "RADIATOR" section in

the CHAPTER 5.

•Carburetor Refer to "CARBURETOR" section

in the CHAPTER 5.

• Spark plug

• Upper engine bracket

• Cylinder head cover Refer to "CAMSHAFTS" section

in the CHAPTER 5.

4. Remove: • Timing mark accessing screw "1"

• Crankshaft end accessing screw

"2"

• O-ring

Oil pressure check bolt:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Pilot screw (example): 2 turns out

To increase idle speed →Turn the

throttle stop screw "1" in "a".

To decrease idle speed→Turn the

throttle stop screw "1" out "b".

Engine idling speed:1,750–1,950 r/min