YAMAHA WR 250F 2009 Owners Manual

Manufacturer: YAMAHA, Model Year: 2009, Model line: WR 250F, Model: YAMAHA WR 250F 2009Pages: 224, PDF Size: 13.93 MB

Page 211 of 224

7-10

ELECTRIC STARTING SYSTEM

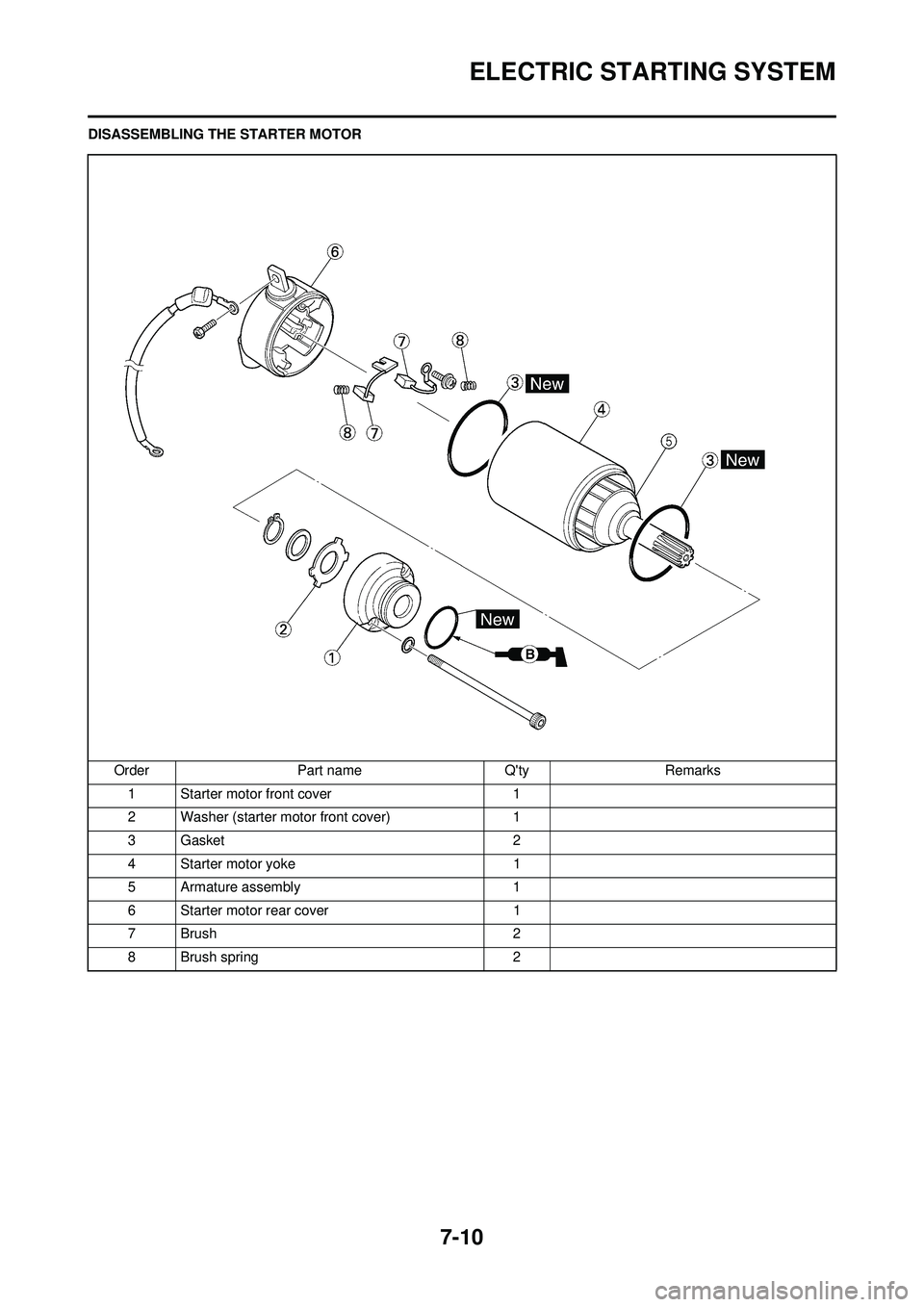

DISASSEMBLING THE STARTER MOTOROrder Part name Q'ty Remarks1 Starter motor front cover 1

2 Washer (starter motor front cover) 1

3Gasket 2

4 Starter motor yoke 1

5 Armature assembly 1

6 Starter motor rear cover 1

7Brush 2

8 Brush spring 2

Page 212 of 224

7-11

ELECTRIC STARTING SYSTEM

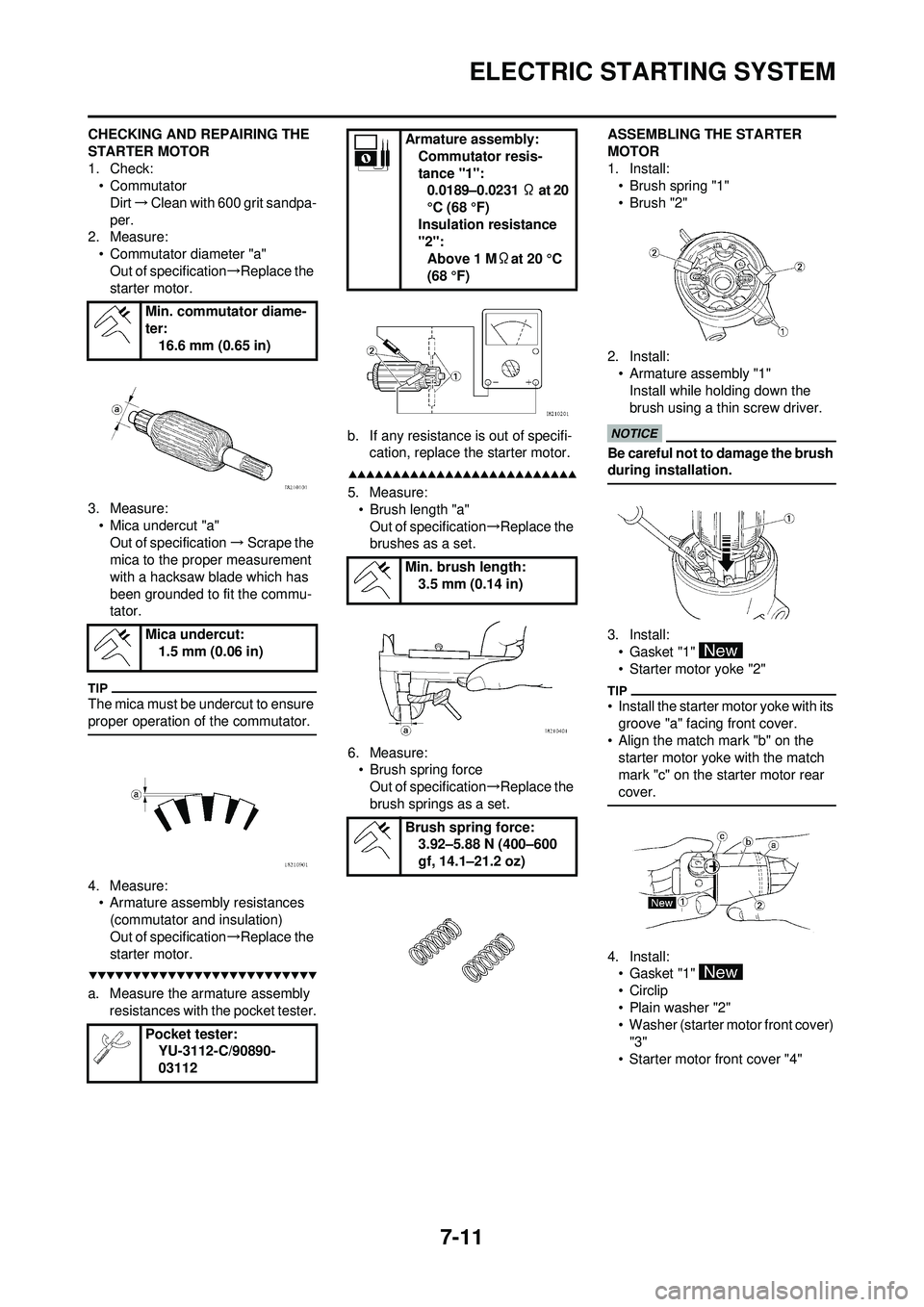

CHECKING AND REPAIRING THE

STARTER MOTOR

1. Check:• Commutator

Dirt →Clean with 600 grit sandpa-

per.

2. Measure:

• Commutator diameter "a"Out of specification →Replace the

starter motor.

3. Measure: • Mica undercut "a"Out of specification →Scrape the

mica to the proper measurement

with a hacksaw blade which has

been grounded to fit the commu-

tator.

The mica must be undercut to ensure

proper operation of the commutator.

4. Measure: • Armature assembly resistances

(commutator and insulation)

Out of specification →Replace the

starter motor.

a. Measure the armature assembly

resistances with the pocket tester. b. If any resistance is out of specifi-

cation, replace the starter motor.

5. Measure:

• Brush length "a"Out of specification →Replace the

brushes as a set.

6. Measure: • Brush spring force

Out of specification →Replace the

brush springs as a set. ASSEMBLING THE STARTER

MOTOR

1. Install:

• Brush spring "1"

•Brush "2"

2. Install: • Armature assembly "1"

Install while holding down the

brush using a thin screw driver.

Be careful not to damage the brush

during installation.

3. Install:• Gasket "1"

• Starter motor yoke "2"

• Install the starter motor yoke with its groove "a" facing front cover.

• Align the match mark "b" on the starter motor yoke with the match

mark "c" on the starter motor rear

cover.

4. Install:• Gasket "1"

•Circlip

• Plain washer "2"

• Washer (starter motor front cover)

"3"

• Starter motor front cover "4"

Min. commutator diame-

ter:

16.6 mm (0.65 in)

Mica undercut: 1.5 mm (0.06 in)

Pocket tester: YU-3112-C/90890-

03112

Armature assembly:

Commutator resis-

tance "1":0.0189–0.0231 Ω at 20

°C (68 °F)

Insulation resistance

"2": Above 1 M Ωat 20 °C

(68 °F)

Min. brush length: 3.5 mm (0.14 in)

Brush spring force: 3.92–5.88 N (400–600

gf, 14.1–21.2 oz)

Page 213 of 224

7-12

ELECTRIC STARTING SYSTEM

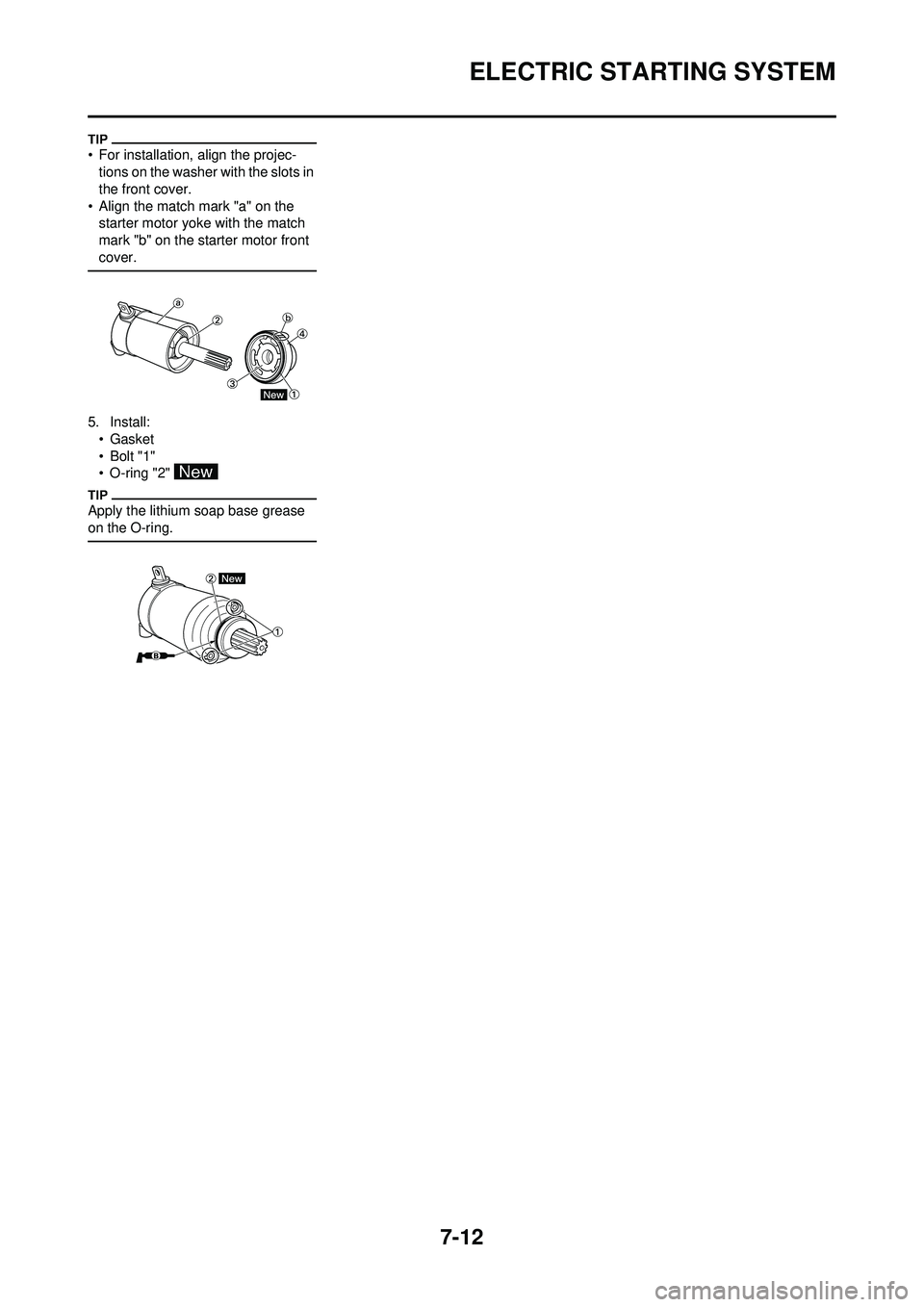

• For installation, align the projec-tions on the washer with the slots in

the front cover.

• Align the match mark "a" on the starter motor yoke with the match

mark "b" on the starter motor front

cover.

5. Install:

•Gasket

•Bolt "1"

• O-ring "2"

Apply the lithium soap base grease

on the O-ring.

Page 214 of 224

7-13

CHARGING SYSTEM

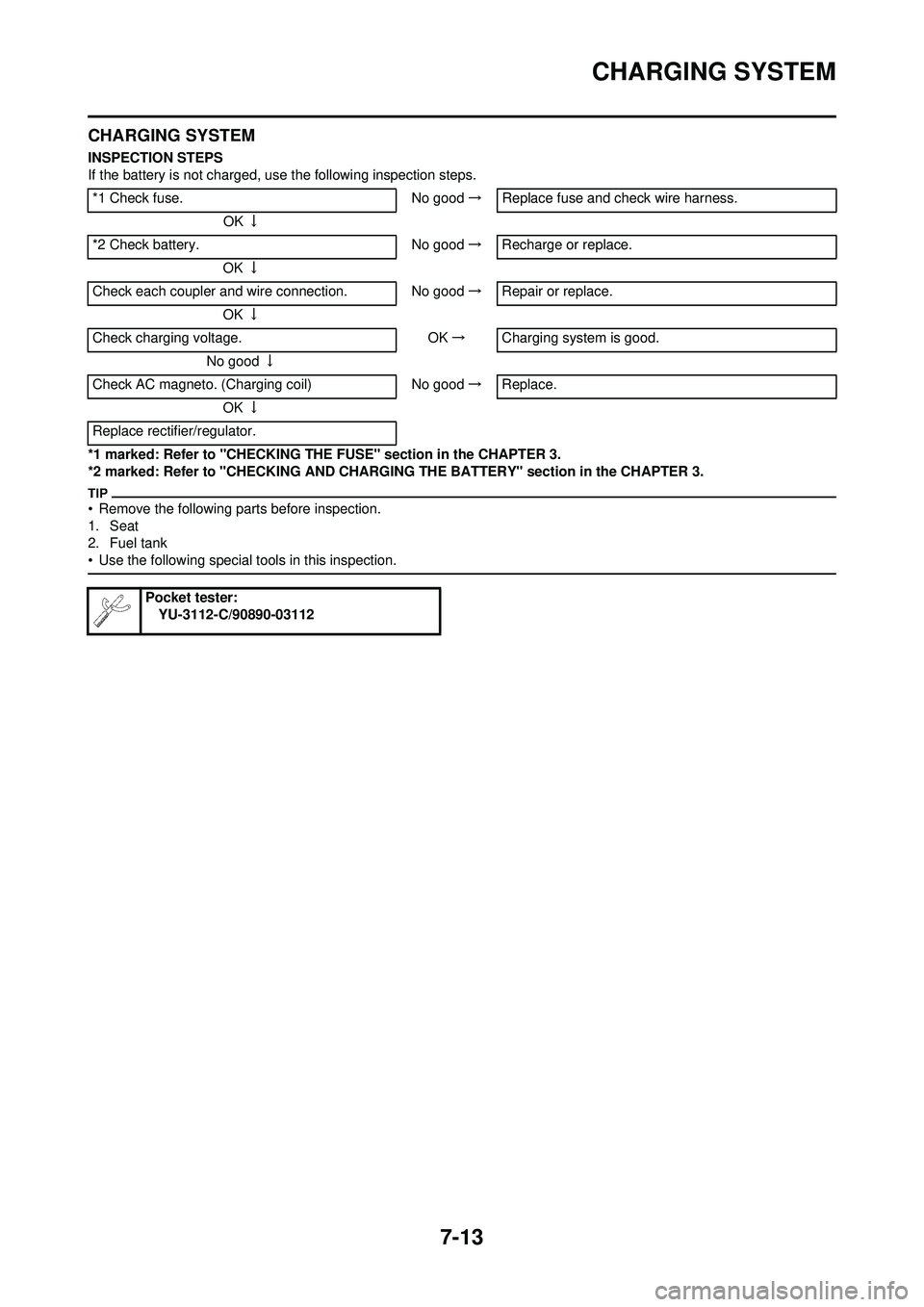

CHARGING SYSTEM

INSPECTION STEPS

If the battery is not charged, use the following inspection steps.

*1 marked: Refer to "CHECKING THE FUSE" section in the CHAPTER 3.

*2 marked: Refer to "CHECKING AND CHARGING THE BATTERY" section in the CHAPTER 3.

• Remove the following parts before inspection.

1. Seat

2. Fuel tank

• Use the following special tools in this inspection.

*1 Check fuse.No good→Replace fuse and check wire harness.

OK ↓

*2 Check battery. No good→Recharge or replace.

OK ↓

Check each coupler and wire connection. No good →Repair or replace.

OK ↓

Check charging voltage. OK→ Charging system is good.

No good ↓

Check AC magneto. (Charging coil) No good→Replace.

OK ↓

Replace rectifier/regulator.

Pocket tester: YU-3112-C/90890-03112

Page 215 of 224

7-14

CHARGING SYSTEM

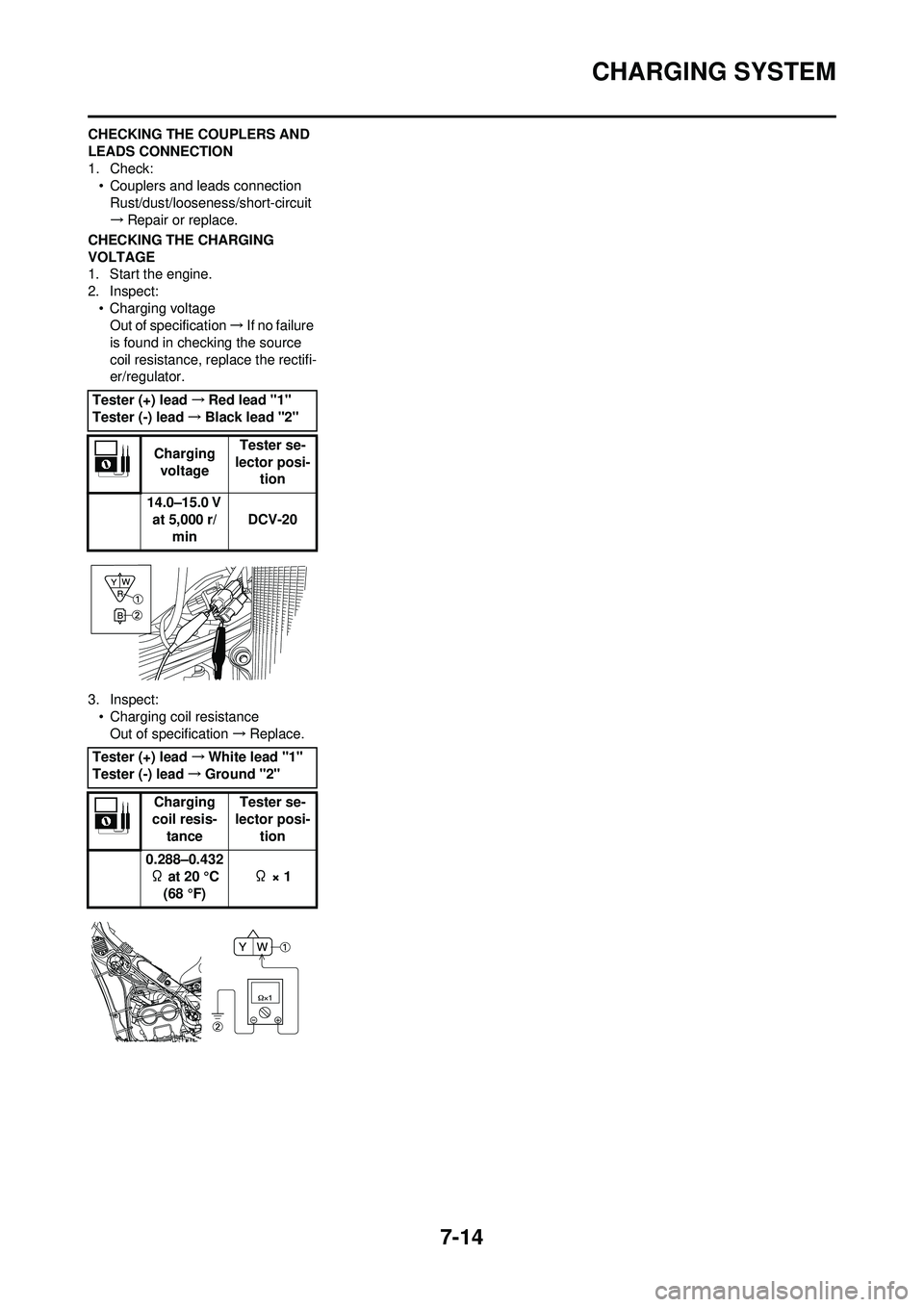

CHECKING THE COUPLERS AND

LEADS CONNECTION

1. Check:• Couplers and leads connection

Rust/dust/looseness/short-circuit

→ Repair or replace.

CHECKING THE CHARGING

VOLTAGE

1. Start the engine.

2. Inspect: • Charging voltageOut of specification →If no failure

is found in checking the source

coil resistance, replace the rectifi-

er/regulator.

3. Inspect: • Charging coil resistanceOut of specification →Replace.

Tester (+) lead

→Red lead "1"

Tester (-) lead →Black lead "2"

Charging voltage Tester se-

lector posi- tion

14.0–15.0 V at 5,000 r/ min DCV-20

Tester (+) lead →White lead "1"

Tester (-) lead →Ground "2"

Charging

coil resis- tance Tester se-

lector posi- tion

0.288–0.432 Ω at 20 °C

(68 °F) Ω × 1

Page 216 of 224

7-15

THROTTLE POSITION SENSOR SYSTEM

THROTTLE POSITION SENSOR SYSTEM

INSPECTION STEPS

If the throttle position sensor will not operate, use the following inspection steps.

Use the following special tools in this inspection.

Check entire ignition system for connection. No good→Repair or replace.

OK ↓

Check throttle position sensor.(Throttle position

sensor coil) No good

→

Replace.

OK ↓

Check CDI unit.(Throttle position sensor input

voltage) No good

→

Replace.

Pocket tester:

YU-3112-C/90890-03112

Page 217 of 224

7-16

THROTTLE POSITION SENSOR SYSTEM

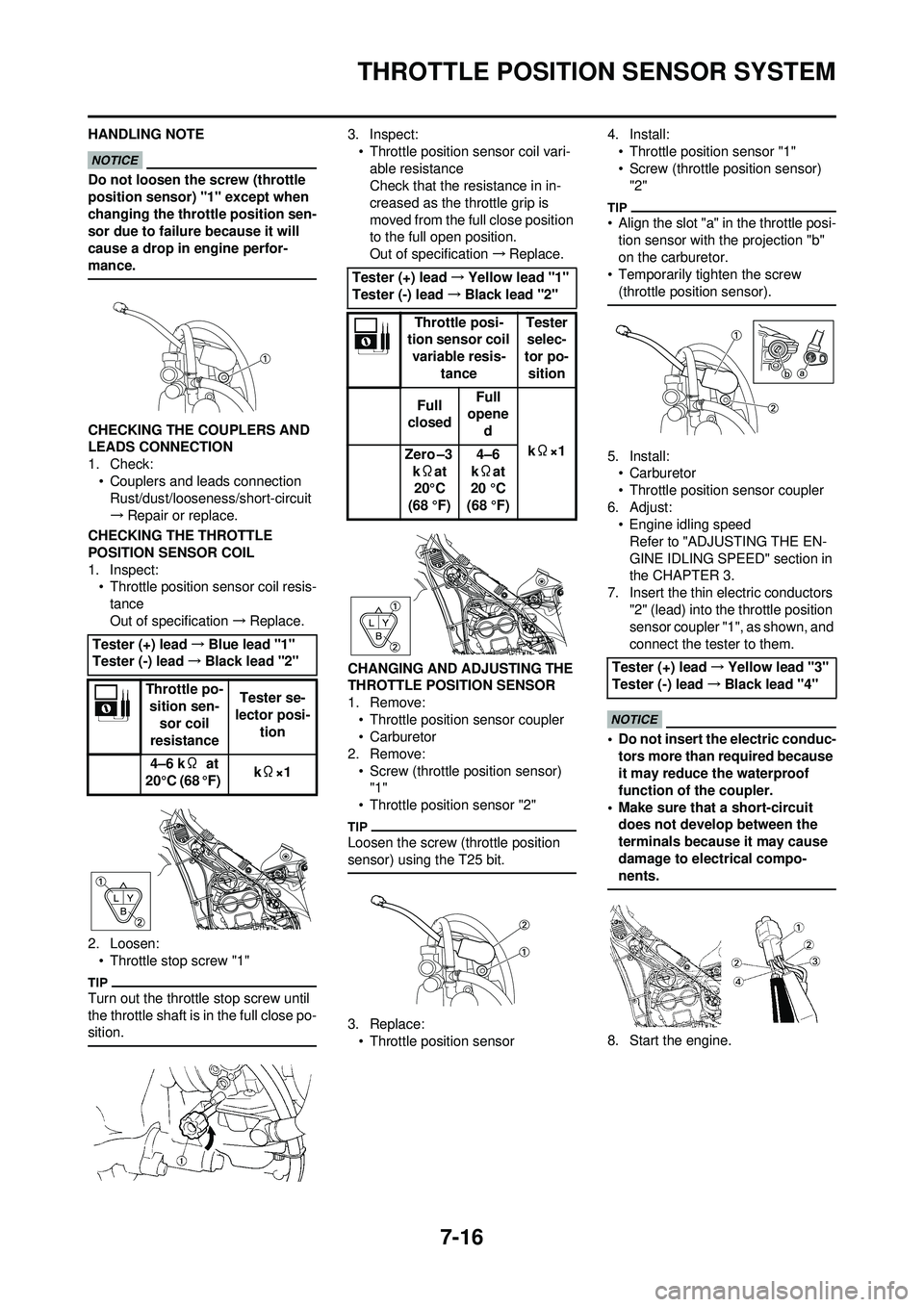

HANDLING NOTE

Do not loosen the screw (throttle

position sensor) "1" except when

changing the throttle position sen-

sor due to failure because it will

cause a drop in engine perfor-

mance.

CHECKING THE COUPLERS AND

LEADS CONNECTION

1. Check:• Couplers and leads connectionRust/dust/looseness/short-circuit

→ Repair or replace.

CHECKING THE THROTTLE

POSITION SENSOR COIL

1. Inspect: • Throttle position sensor coil resis-

tance

Out of specification →Replace.

2. Loosen: • Throttle stop screw "1"

Turn out the throttle stop screw until

the throttle shaft is in the full close po-

sition.

3. Inspect:• Throttle position sensor coil vari-able resistance

Check that the resistance in in-

creased as the throttle grip is

moved from the full close position

to the full open position.

Out of specification →Replace.

CHANGING AND ADJUSTING THE

THROTTLE POSITION SENSOR

1. Remove: • Throttle position sensor coupler

•Carburetor

2. Remove: • Screw (throttle position sensor) "1"

• Throttle position sensor "2"

Loosen the screw (throttle position

sensor) using the T25 bit.

3. Replace: • Throttle position sensor 4. Install:

• Throttle position sensor "1"

• Screw (throttle position sensor) "2"

• Align the slot "a" in the throttle posi-

tion sensor with the projection "b"

on the carburetor.

• Temporarily tighten the screw

(throttle position sensor).

5. Install:•Carburetor

• Throttle position sensor coupler

6. Adjust: • Engine idling speed

Refer to "ADJUSTING THE EN-

GINE IDLING SPEED" section in

the CHAPTER 3.

7. Insert the thin electric conductors "2" (lead) into the throttle position

sensor coupler "1", as shown, and

connect the tester to them.

• Do not insert the electric conduc-tors more than required because

it may reduce the waterproof

function of the coupler.

• Make sure that a short-circuit does not develop between the

terminals because it may cause

damage to electrical compo-

nents.

8. Start the engine.

Tester (+) lead

→Blue lead "1"

Tester (-) lead →Black lead "2"

Throttle po- sition sen- sor coil

resistance Tester se-

lector posi- tion

4–6 k Ω at

20°C (68 °F) k

Ω×1

Tester (+) lead →Yellow lead "1"

Tester (-) lead →Black lead "2"

Throttle posi-

tion sensor coil

variable resis- tance Tester

selec-

tor po- sition

Full

closed Full

opene

d

kΩ×1

Zero –3

kΩat

20°C

(68 °F) 4–6

k Ωat

20 °C

(68 °F)

Tester (+) lead →Yellow lead "3"

Tester (-) lead →Black lead "4"

Page 218 of 224

7-17

THROTTLE POSITION SENSOR SYSTEM

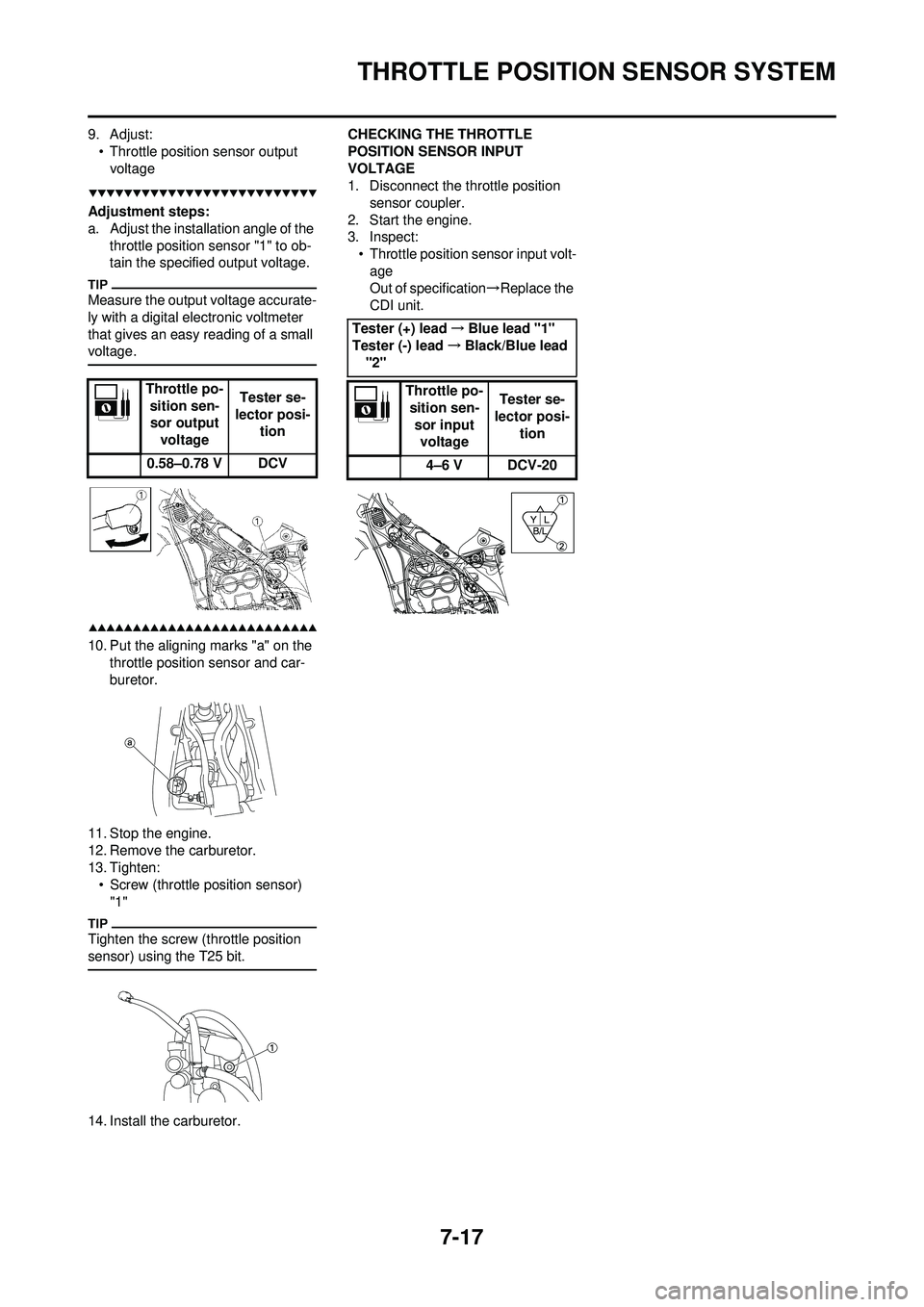

9. Adjust:• Throttle position sensor output voltage

Adjustment steps:

a. Adjust the installation angle of the throttle position sensor "1" to ob-

tain the specified output voltage.

Measure the output voltage accurate-

ly with a digital electronic voltmeter

that gives an easy reading of a small

voltage.

10. Put the aligning marks "a" on the throttle position sensor and car-

buretor.

11. Stop the engine.

12. Remove the carburetor.

13. Tighten: • Screw (throttle position sensor) "1"

Tighten the screw (throttle position

sensor) using the T25 bit.

14. Install the carburetor. CHECKING THE THROTTLE

POSITION SENSOR INPUT

VOLTAGE

1. Disconnect the throttle position

sensor coupler.

2. Start the engine.

3. Inspect: • Throttle position sensor input volt-age

Out of specification→Replace the

CDI unit.

Throttle po- sition sen-sor output

voltage Tester se-

lector posi- tion

0.58–0.78 V DCV

Tester (+) lead →Blue lead "1"

Tester (-) lead →Black/Blue lead

"2"

Throttle po-sition sen- sor input voltage Tester se-

lector posi- tion

4–6 V DCV-20

Page 219 of 224

7-18

LIGHTING SYSTEM

LIGHTING SYSTEM

INSPECTION STEPS

Refer to the following flow chart when inspecting the lighting system for possible problems.

• Remove the following parts before inspection.

1. Seat

2. Fuel tank

3. Left side cover

• Use the following special tools in this inspection.

Check the bulb and bulb socket.No good→Replace the bulb and/or bulb socket.

OK ↓

Check the taillight (LEDs). No good→Replace the taillight assembly.

OK ↓

Check the AC magneto. (Lighting coil) No good→Replace.

OK ↓

Check the entire lighting system proper for con-

nections. Improperly

connected →Repair or replace.

OK ↓

Check the rectifier/regulator. (Out-put voltage) No good →Replace.

Pocket tester:

YU-3112-C/90890-03112

Page 220 of 224

7-19

LIGHTING SYSTEM

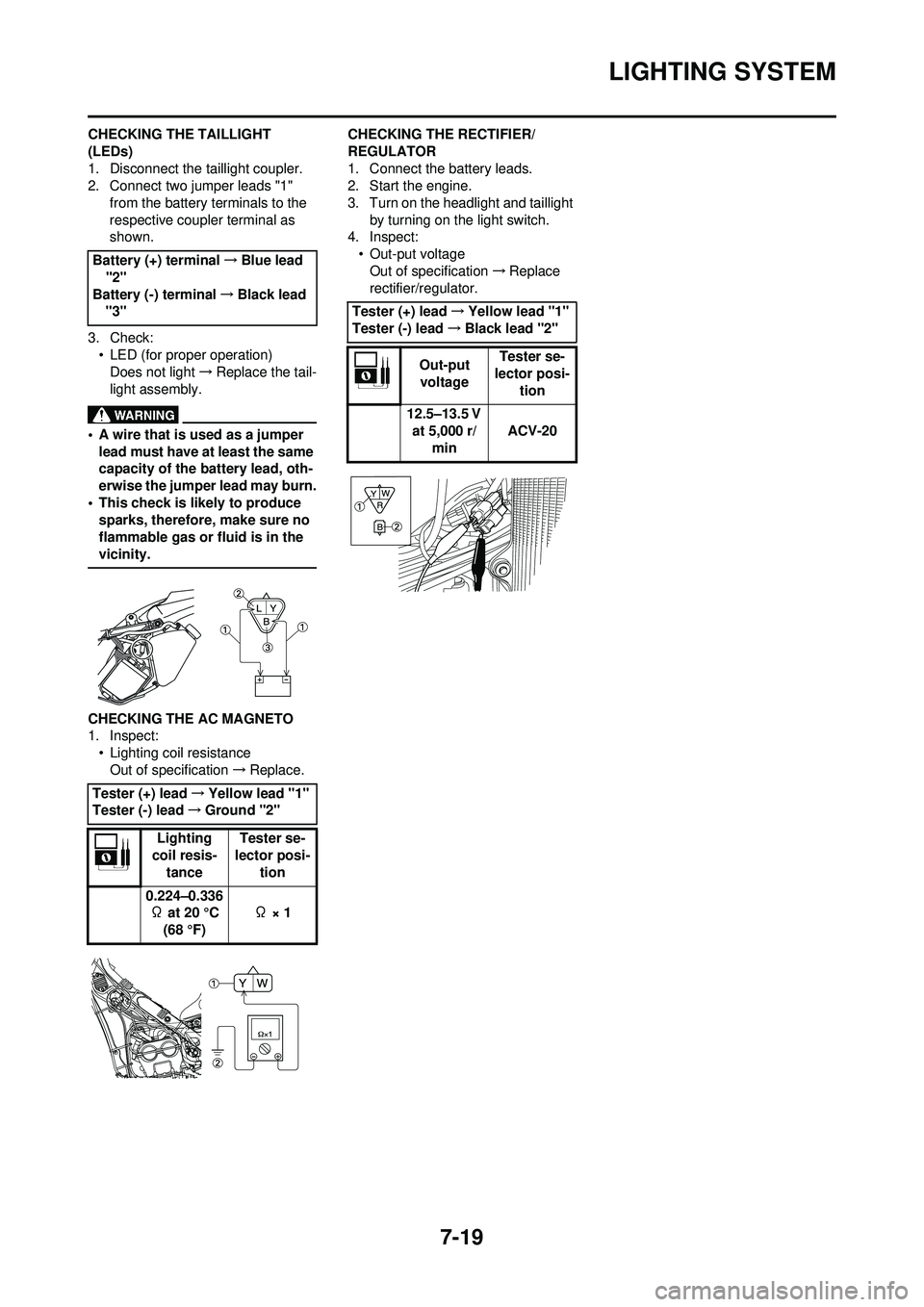

CHECKING THE TAILLIGHT

(LEDs)

1. Disconnect the taillight coupler.

2. Connect two jumper leads "1" from the battery terminals to the

respective coupler terminal as

shown.

3. Check: • LED (for proper operation)Does not light →Replace the tail-

light assembly.

• A wire that is used as a jumper lead must have at least the same

capacity of the battery lead, oth-

erwise the jumper lead may burn.

• This check is likely to produce sparks, therefore, make sure no

flammable gas or fluid is in the

vicinity.

CHECKING THE AC MAGNETO

1. Inspect:

• Lighting coil resistanceOut of specification →Replace. CHECKING THE RECTIFIER/

REGULATOR

1. Connect the battery leads.

2. Start the engine.

3. Turn on the headlight and taillight

by turning on the light switch.

4. Inspect:

• Out-put voltageOut of specification →Replace

rectifier/regulator.

Battery (+) terminal

→Blue lead

"2"

Battery (-) terminal →Black lead

"3"

Tester (+) lead →Yellow lead "1"

Tester (-) lead →Ground "2"

Lighting

coil resis- tance Tester se-

lector posi- tion

0.224–0.336 Ω at 20 °C

(68 °F) Ω × 1

Tester (+) lead

→Yellow lead "1"

Tester (-) lead →Black lead "2"

Out-put voltage Tester se-

lector posi- tion

12.5–13.5 V at 5,000 r/ min ACV-20