fuel pump YAMAHA WR 250F 2009 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2009, Model line: WR 250F, Model: YAMAHA WR 250F 2009Pages: 224, PDF Size: 13.93 MB

Page 10 of 224

1-2

MACHINE IDENTIFICATION

MACHINE IDENTIFICATION

There are two significant reasons for

knowing the serial number of your

machine:

1. When ordering parts, you can give the number to your Yamaha

dealer for positive identification of

the model you own.

2. If your machine is stolen, the au-

thorities will need the number to

search for and identify your ma-

chine.

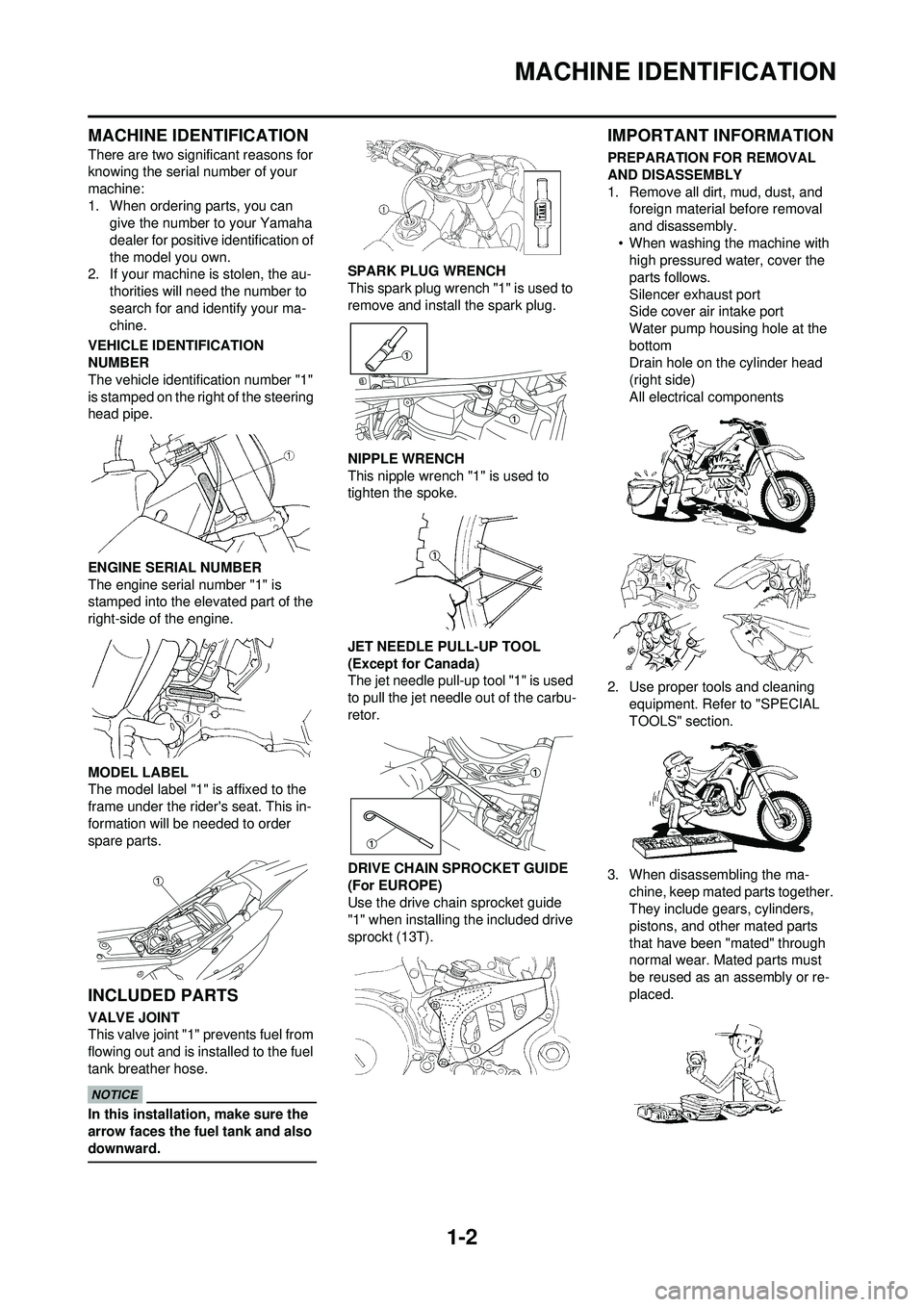

VEHICLE IDENTIFICATION

NUMBER

The vehicle identification number "1"

is stamped on the right of the steering

head pipe.

ENGINE SERIAL NUMBER

The engine serial number "1" is

stamped into the elevated part of the

right-side of the engine.

MODEL LABEL

The model label "1" is affixed to the

frame under the rider's seat. This in-

formation will be needed to order

spare parts.

INCLUDED PARTS

VALVE JOINT

This valve joint "1" prevents fuel from

flowing out and is installed to the fuel

tank breather hose.

In this installation, make sure the

arrow faces the fuel tank and also

downward.

SPARK PLUG WRENCH

This spark plug wrench "1" is used to

remove and install the spark plug.

NIPPLE WRENCH

This nipple wrench "1" is used to

tighten the spoke.

JET NEEDLE PULL-UP TOOL

(Except for Canada)

The jet needle pull-up tool "1" is used

to pull the jet needle out of the carbu-

retor.

DRIVE CHAIN SPROCKET GUIDE

(For EUROPE)

Use the drive chain sprocket guide

"1" when installing the included drive

sprockt (13T).

IMPORTANT INFORMATION

PREPARATION FOR REMOVAL

AND DISASSEMBLY

1. Remove all dirt, mud, dust, and foreign material before removal

and disassembly.

• When washing the machine with high pressured water, cover the

parts follows.

Silencer exhaust port

Side cover air intake port

Water pump housing hole at the

bottom

Drain hole on the cylinder head

(right side)

All electrical components

2. Use proper tools and cleaning equipment. Refer to "SPECIAL

TOOLS" section.

3. When disassembling the ma- chine, keep mated parts together.

They include gears, cylinders,

pistons, and other mated parts

that have been "mated" through

normal wear. Mated parts must

be reused as an assembly or re-

placed.

Page 22 of 224

1-14

STARTING AND BREAK-IN

STARTING AND BREAK-IN

FUEL

Always use the recommended fuel as

stated below. Also, be sure to use

new gasoline.

Use only unleaded gasoline. The

use of leaded gasoline will cause

severe damage to the engine inter-

nal parts such as valves, piston

rings, and exhaust system, etc.

If knocking or pinging occurs, use a

different brand of gasoline or higher

octane grade.

• For refueling, be sure to stop the engine and use enough care not

to spill any fuel. Also be sure to

avoid refueling close to a fire.

• Refuel after the engine, exhaust

pipe, etc. have cooled off.

Gasohol (For Canada)

There are two types of gasohol: gas-

ohol containing ethanol and that con-

taining methanol. Gasohol containing

ethanol can be used if the ethanol

content does not exceed 10%. Gaso-

hol containing methanol is not recom-

mended by Yamaha because it can

cause damage to the fuel system or

vehicle performance problems.

HANDLING NOTE

Never start or run the engine in a

closed area. The exhaust fumes

are poisonous; they can cause

loss of consciousness and death

in a very short time. Always oper-

ate the machine in a well-ventilated

area.

• The carburetor on this machine has a built-in accelerator pump.

Therefore, when starting the en-

gine, do not operate the throttle

or the spark plug will foul.

• Unlike a two-stroke engine, this engine cannot be kick started

when the throttle is open be-

cause the kickstarter may kick

back. Also, if the throttle is open

the air/fuel mixture may be too

lean for the engine to start.

• Before starting the machine, per- form the checks in the pre-opera-

tion check list.

AIR FILTER MAINTENANCE

According to "CLEANING THE AIR

FILTER ELEMENT" section in the

CHAPTER 3, apply the foam-air-filter

oil or its equivalent to the element.

(Excess oil in the element may ad-

versely affect engine starting.)

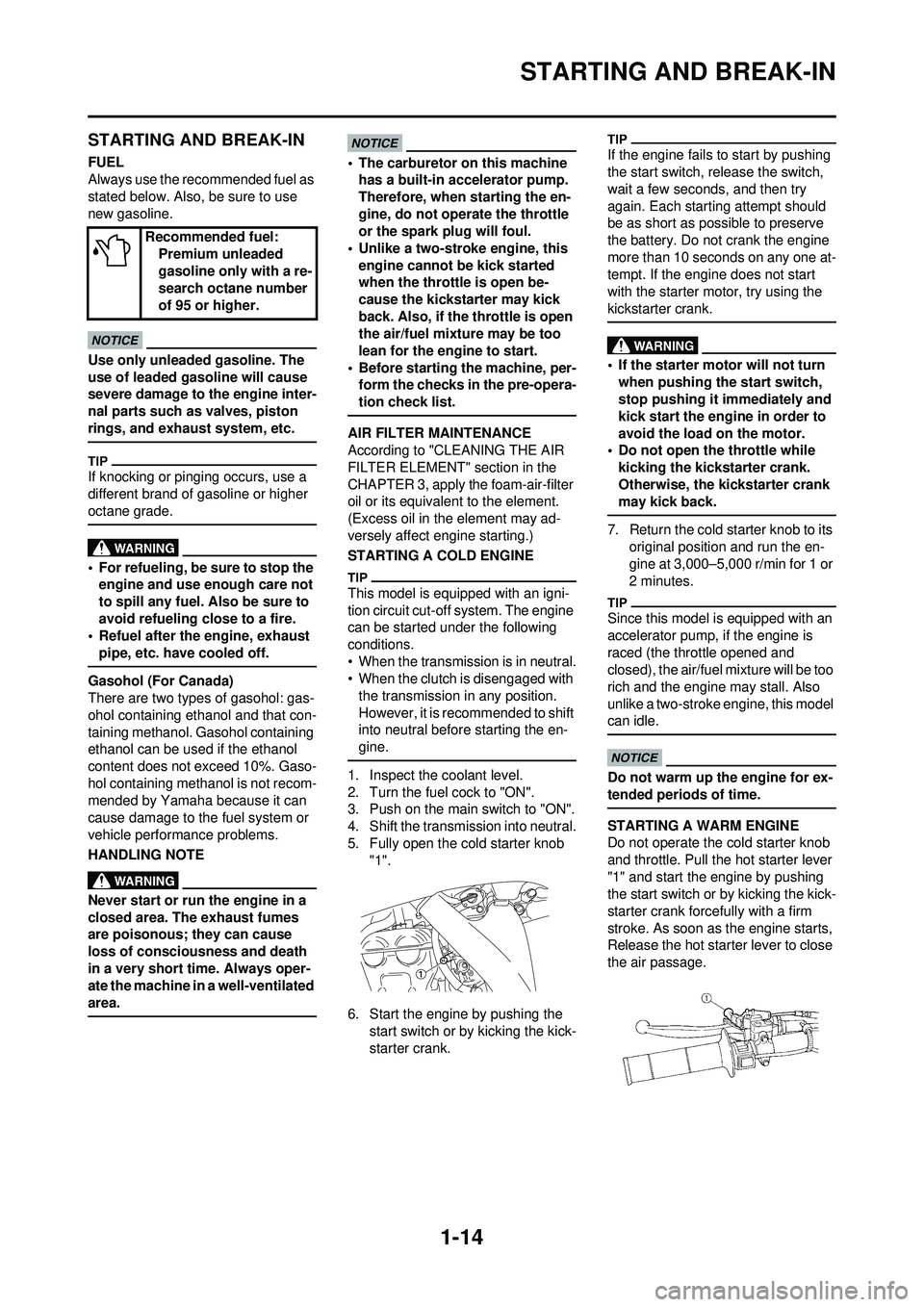

STARTING A COLD ENGINE

This model is equipped with an igni-

tion circuit cut-off system. The engine

can be started under the following

conditions.

• When the transmission is in neutral.

• When the clutch is disengaged with

the transmission in any position.

However, it is recommended to shift

into neutral before starting the en-

gine.

1. Inspect the coolant level.

2. Turn the fuel cock to "ON".

3. Push on the main switch to "ON".

4. Shift the transmission into neutral.

5. Fully open the cold starter knob "1".

6. Start the engine by pushing the start switch or by kicking the kick-

starter crank.

If the engine fails to start by pushing

the start switch, release the switch,

wait a few seconds, and then try

again. Each starting attempt should

be as short as possible to preserve

the battery. Do not crank the engine

more than 10 seconds on any one at-

tempt. If the engine does not start

with the starter motor, try using the

kickstarter crank.

• If the starter motor will not turn

when pushing the start switch,

stop pushing it immediately and

kick start the engine in order to

avoid the load on the motor.

• Do not open the throttle while

kicking the kickstarter crank.

Otherwise, the kickstarter crank

may kick back.

7. Return the cold starter knob to its original position and run the en-

gine at 3,000–5,000 r/min for 1 or

2 minutes.

Since this model is equipped with an

accelerator pump, if the engine is

raced (the throttle opened and

closed), the air/fuel mixture will be too

rich and the engine may stall. Also

unlike a two-stroke engine, this model

can idle.

Do not warm up the engine for ex-

tended periods of time.

STARTING A WARM ENGINE

Do not operate the cold starter knob

and throttle. Pull the hot starter lever

"1" and start the engine by pushing

the start switch or by kicking the kick-

starter crank forcefully with a firm

stroke. As soon as the engine starts,

Release the hot starter lever to close

the air passage.

Recommended fuel:

Premium unleaded

gasoline only with a re-

search octane number

of 95 or higher.

Page 69 of 224

3-16

ENGINE

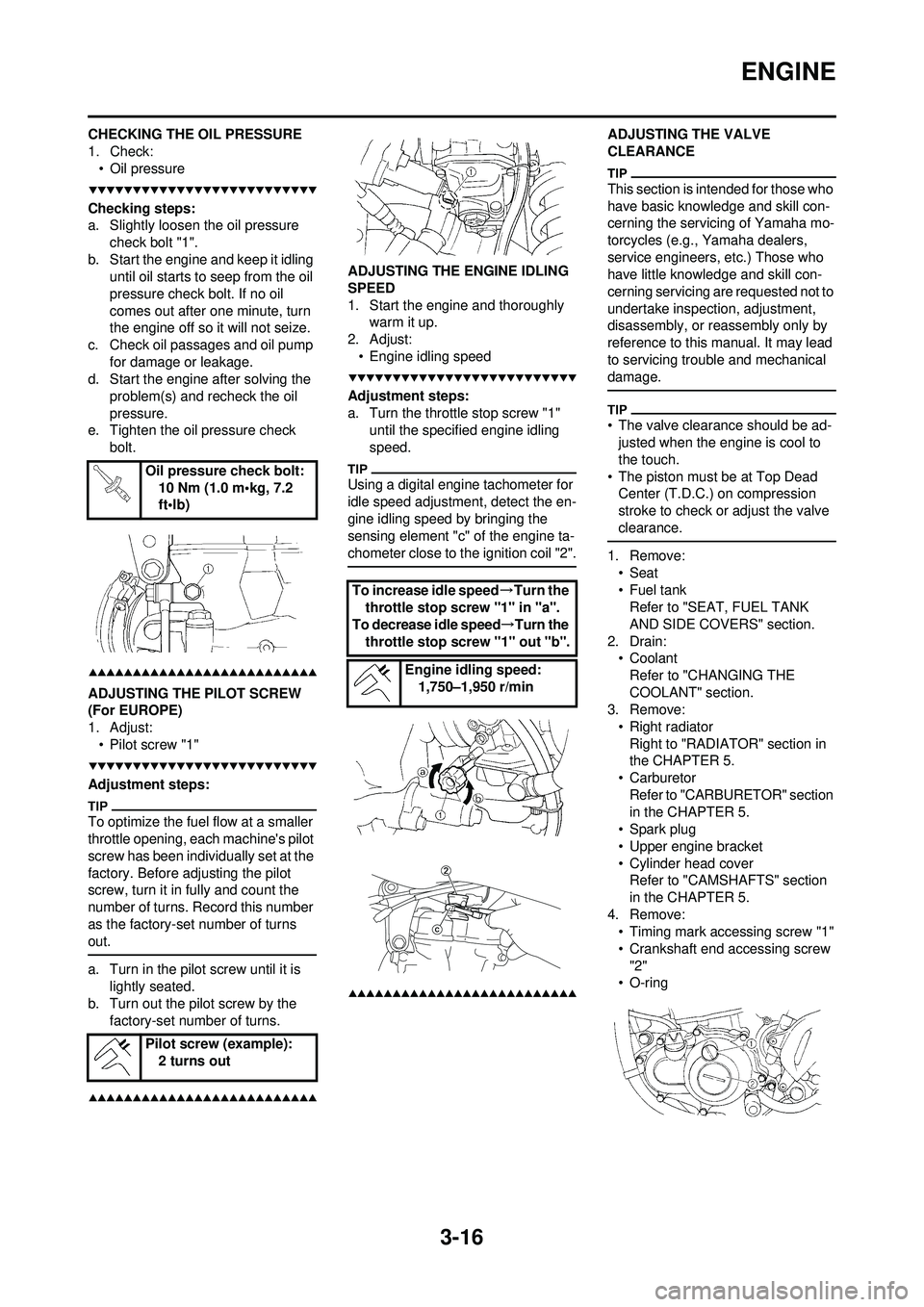

CHECKING THE OIL PRESSURE

1. Check:•Oil pressure

Checking steps:

a. Slightly loosen the oil pressure check bolt "1".

b. Start the engine and keep it idling until oil starts to seep from the oil

pressure check bolt. If no oil

comes out after one minute, turn

the engine off so it will not seize.

c. Check oil passages and oil pump for damage or leakage.

d. Start the engine after solving the

problem(s) and recheck the oil

pressure.

e. Tighten the oil pressure check

bolt.

ADJUSTING THE PILOT SCREW

(For EUROPE)

1. Adjust:• Pilot screw "1"

Adjustment steps:

To optimize the fuel flow at a smaller

throttle opening, each machine's pilot

screw has been individually set at the

factory. Before adjusting the pilot

screw, turn it in fully and count the

number of turns. Record this number

as the factory-set number of turns

out.

a. Turn in the pilot screw until it is lightly seated.

b. Turn out the pilot screw by the

factory-set number of turns.

ADJUSTING THE ENGINE IDLING

SPEED

1. Start the engine and thoroughly warm it up.

2. Adjust: • Engine idling speed

Adjustment steps:

a. Turn the throttle stop screw "1" until the specified engine idling

speed.

Using a digital engine tachometer for

idle speed adjustment, detect the en-

gine idling speed by bringing the

sensing element "c" of the engine ta-

chometer close to the ignition coil "2".

ADJUSTING THE VALVE

CLEARANCE

This section is intended for those who

have basic knowledge and skill con-

cerning the servicing of Yamaha mo-

torcycles (e.g., Yamaha dealers,

service engineers, etc.) Those who

have little knowledge and skill con-

cerning servicing are requested not to

undertake inspection, adjustment,

disassembly, or reassembly only by

reference to this manual. It may lead

to servicing trouble and mechanical

damage.

• The valve clearance should be ad-justed when the engine is cool to

the touch.

• The piston must be at Top Dead Center (T.D.C.) on compression

stroke to check or adjust the valve

clearance.

1. Remove:

•Seat

• Fuel tankRefer to "SEAT, FUEL TANK

AND SIDE COVERS" section.

2. Drain: • Coolant

Refer to "CHANGING THE

COOLANT" section.

3. Remove:

• Right radiatorRight to "RADIATOR" section in

the CHAPTER 5.

•Carburetor Refer to "CARBURETOR" section

in the CHAPTER 5.

• Spark plug

• Upper engine bracket

• Cylinder head cover Refer to "CAMSHAFTS" section

in the CHAPTER 5.

4. Remove: • Timing mark accessing screw "1"

• Crankshaft end accessing screw

"2"

• O-ring

Oil pressure check bolt:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Pilot screw (example): 2 turns out

To increase idle speed →Turn the

throttle stop screw "1" in "a".

To decrease idle speed→Turn the

throttle stop screw "1" out "b".

Engine idling speed:1,750–1,950 r/min

Page 88 of 224

4-1

ENGINE (Except for Canada)

TUNING

ENGINE (Except for Canada)

CARBURETOR SETTING

• The air/fuel mixture will vary de-pending on atmospheric conditions.

Therefore, it is necessary to take

into consideration the air pressure,

ambient temperature, humidity,

etc., when adjusting the carburetor.

• Perform a test run to check for prop- er engine performance (e.g., throt-

tle response) and spark plug(-s)

discoloration or fouling. Use these

readings to determine the best pos-

sible carburetor setting.

It is recommended to keep a record of

all carburetor settings and external

conditions (e.g., atmospheric condi-

tions, track/surface conditions, lap

times) to make future carburetor set-

ting easier.

• The carburetor is a part of the fuel line. Therefore, be sure to in-

stall it in a wellventilated area,

away from flammable objects

and any sources of fire.

• Never look into the carburetor in- take. Flames may shoot out from

the pipe if the engine backfires

while it is being started. Gasoline

may be discharged from the ac-

celerator pump nozzle when the

carburetor has been removed.

• The carburetor is extremely sen-sitive to foreign matter (dirt,

sand, water, etc.). During instal-

lation, do not allow foreign mat-

ter to get into the carburetor.

• Always handle the carburetor and its components carefully.

Even slight scratches, bends or

damage to carburetor parts may

prevent the carburetor from

functioning correctly. Carefully

perform all servicing with the ap-

propriate tools and without ap-

plying excessive force.

• When the engine is stopped or when riding at no load, do not

open and close the throttle un-

necessarily. Otherwise, too

much fuel may be discharged,

starting may become difficult or

the engine may not run well. • After installing the carburetor,

check that the throttle operates

correctly and opens and closes

smoothly.

ATMOSPHERIC CONDITIONS AND

CARBURETOR SETTINGS

The air density (i.e., concentration of

oxygen in the air) determines the rich-

ness or leanness of the air/fuel mix-

ture.

• Higher temperature expands the air with its resultant reduced density.

• Higher humidity reduces the

amount of oxygen in the air by so

much of the water vapor in the

same air.

• Lower atmospheric pressure (at a high altitude) reduces the density of

the air.

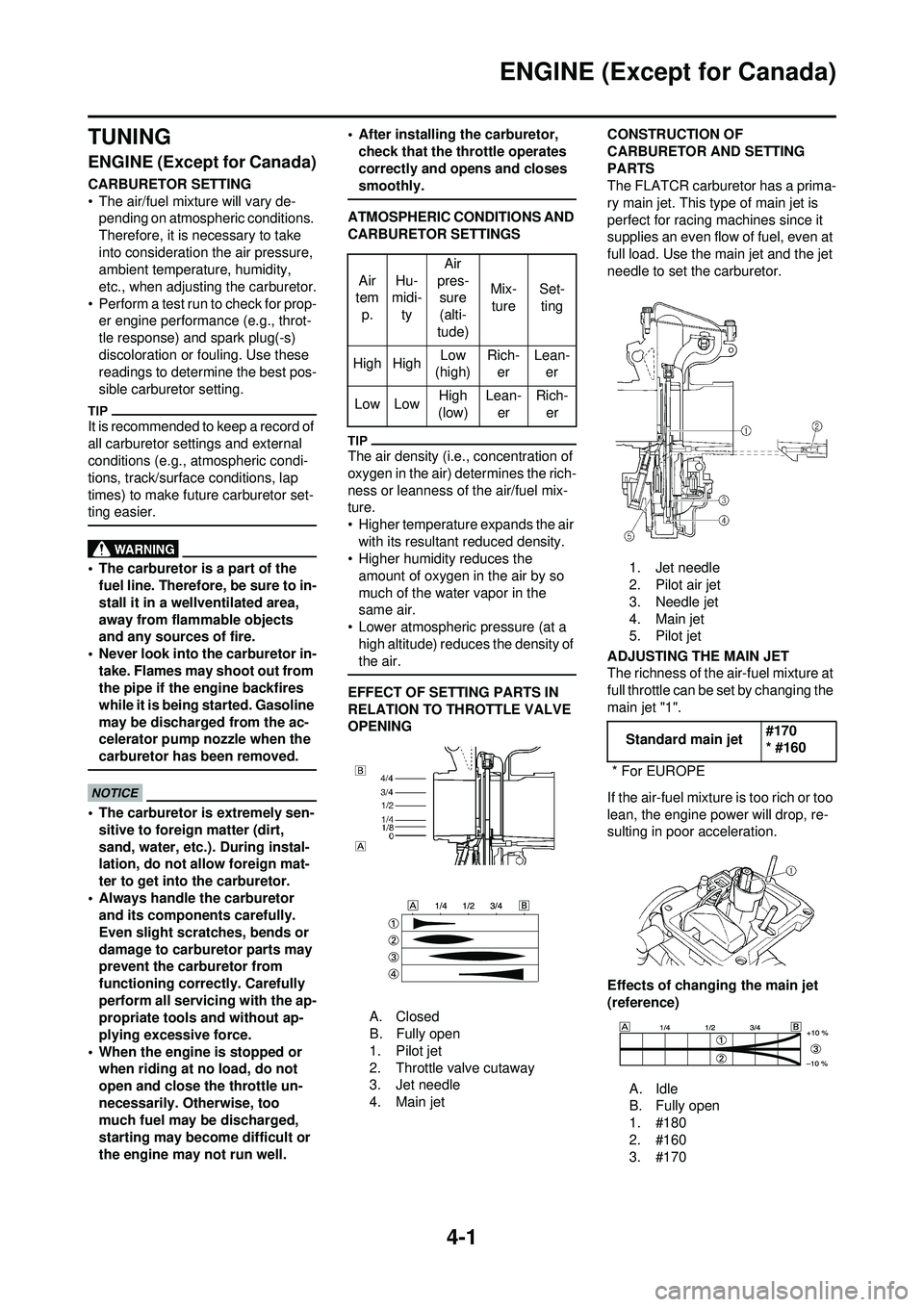

EFFECT OF SETTING PARTS IN

RELATION TO THROTTLE VALVE

OPENING

A. Closed

B. Fully open

1. Pilot jet

2. Throttle valve cutaway

3. Jet needle

4. Main jet CONSTRUCTION OF

CARBURETOR AND SETTING

PARTS

The FLATCR carburetor has a prima-

ry main jet. This type of main jet is

perfect for racing machines since it

supplies an even flow of fuel, even at

full load. Use the main jet and the jet

needle to set the carburetor.

1. Jet needle

2. Pilot air jet

3. Needle jet

4. Main jet

5. Pilot jet

ADJUSTING THE MAIN JET

The richness of the air-fuel mixture at

full throttle can be set by changing the

main jet "1".

If the air-fuel mixture is too rich or too

lean, the engine power will drop, re-

sulting in poor acceleration.

Effects of changing the main jet

(reference)

A. Idle

B. Fully open

1. #180

2. #160

3. #170

Air

tem

p. Hu-

midi-

ty Air

pres- sure

(alti-

tude) Mix-

ture Set-

ting

High High Low

(high) Rich-

er Lean-

er

Low Low High

(low) Lean-

er Rich-

er

Standard main jet #170

* #160

* For EUROPE

Page 89 of 224

4-2

ENGINE (Except for Canada)

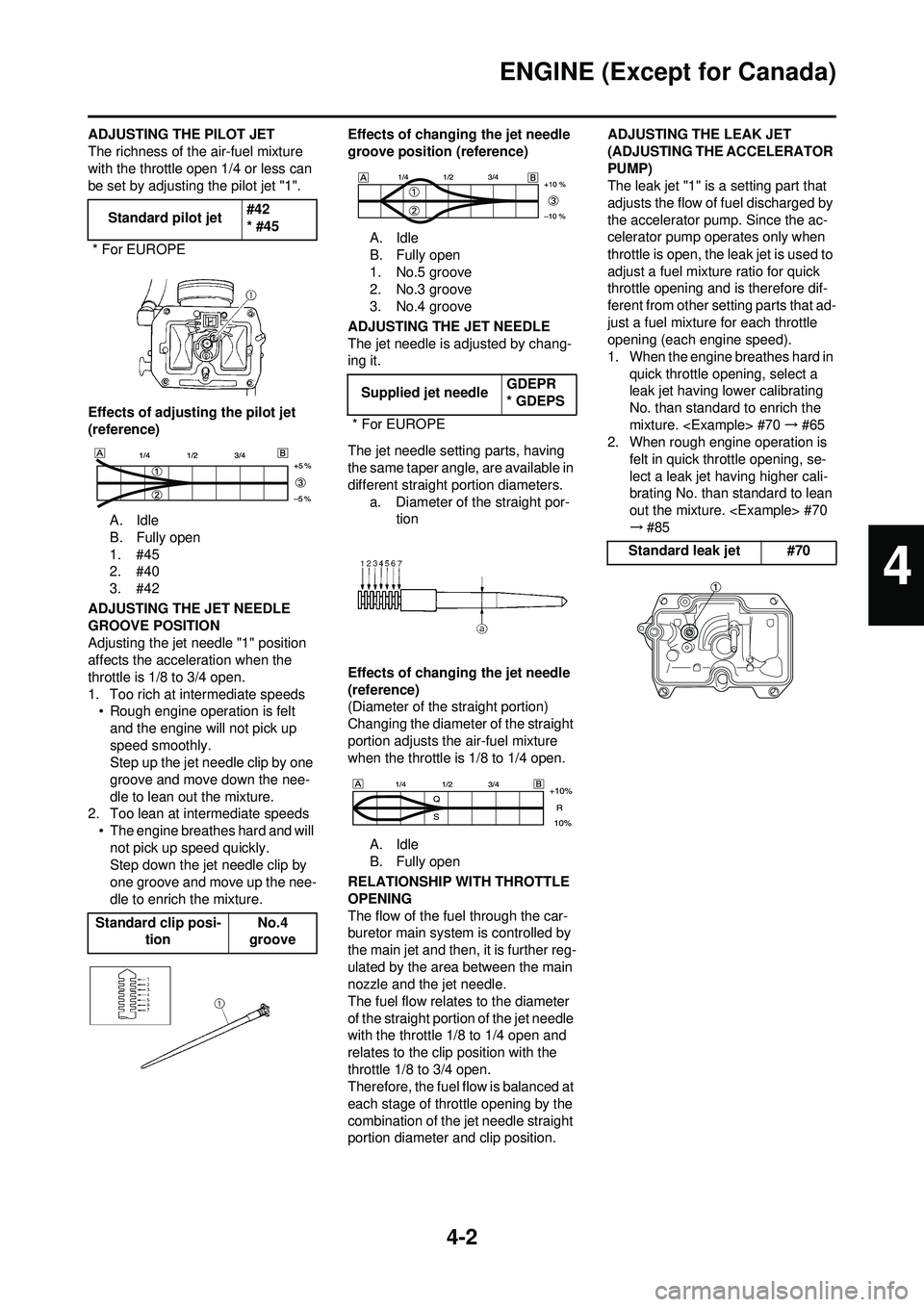

ADJUSTING THE PILOT JET

The richness of the air-fuel mixture

with the throttle open 1/4 or less can

be set by adjusting the pilot jet "1".

Effects of adjusting the pilot jet

(reference)A. Idle

B. Fully open

1. #45

2. #40

3. #42

ADJUSTING THE JET NEEDLE

GROOVE POSITION

Adjusting the jet needle "1" position

affects the acceleration when the

throttle is 1/8 to 3/4 open.

1. Too rich at intermediate speeds • Rough engine operation is felt

and the engine will not pick up

speed smoothly.

Step up the jet needle clip by one

groove and move down the nee-

dle to lean out the mixture.

2. Too lean at intermediate speeds

• The engine breathes hard and will not pick up speed quickly.

Step down the jet needle clip by

one groove and move up the nee-

dle to enrich the mixture. Effects of changing the jet needle

groove position (reference)

A. Idle

B. Fully open

1. No.5 groove

2. No.3 groove

3. No.4 groove

ADJUSTING THE JET NEEDLE

The jet needle is adjusted by chang-

ing it.

The jet needle setting parts, having

the same taper angle, are available in

different straight portion diameters. a. Diameter of the straight por- tion

Effects of changing the jet needle

(reference)

(Diameter of the straight portion)

Changing the diameter of the straight

portion adjusts the air-fuel mixture

when the throttle is 1/8 to 1/4 open. A. Idle

B. Fully open

RELATIONSHIP WITH THROTTLE

OPENING

The flow of the fuel through the car-

buretor main system is controlled by

the main jet and then, it is further reg-

ulated by the area between the main

nozzle and the jet needle.

The fuel flow relates to the diameter

of the straight portion of the jet needle

with the throttle 1/8 to 1/4 open and

relates to the clip position with the

throttle 1/8 to 3/4 open.

Therefore, the fuel flow is balanced at

each stage of throttle opening by the

combination of the jet needle straight

portion diameter and clip position. ADJUSTING THE LEAK JET

(ADJUSTING THE ACCELERATOR

PUMP)

The leak jet "1" is a setting part that

adjusts the flow of fuel discharged by

the accelerator pump. Since the ac-

celerator pump operates only when

throttle is open, the leak jet is used to

adjust a fuel mixture ratio for quick

throttle opening and is therefore dif-

ferent from other setting parts that ad-

just a fuel mixture for each throttle

opening (each engine speed).

1. When the engine breathes hard in

quick throttle opening, select a

leak jet having lower calibrating

No. than standard to enrich the

mixture.

2. When rough engine operation is

felt in quick throttle opening, se-

lect a leak jet having higher cali-

brating No. than standard to lean

out the mixture.

→#85

Standard pilot jet

#42

* #45

* For EUROPE

Standard clip posi- tion No.4

groove

Supplied jet needle GDEPR

* GDEPS

* For EUROPE

Standard leak jet #70

4

Page 91 of 224

4-4

ENGINE (Except for Canada)

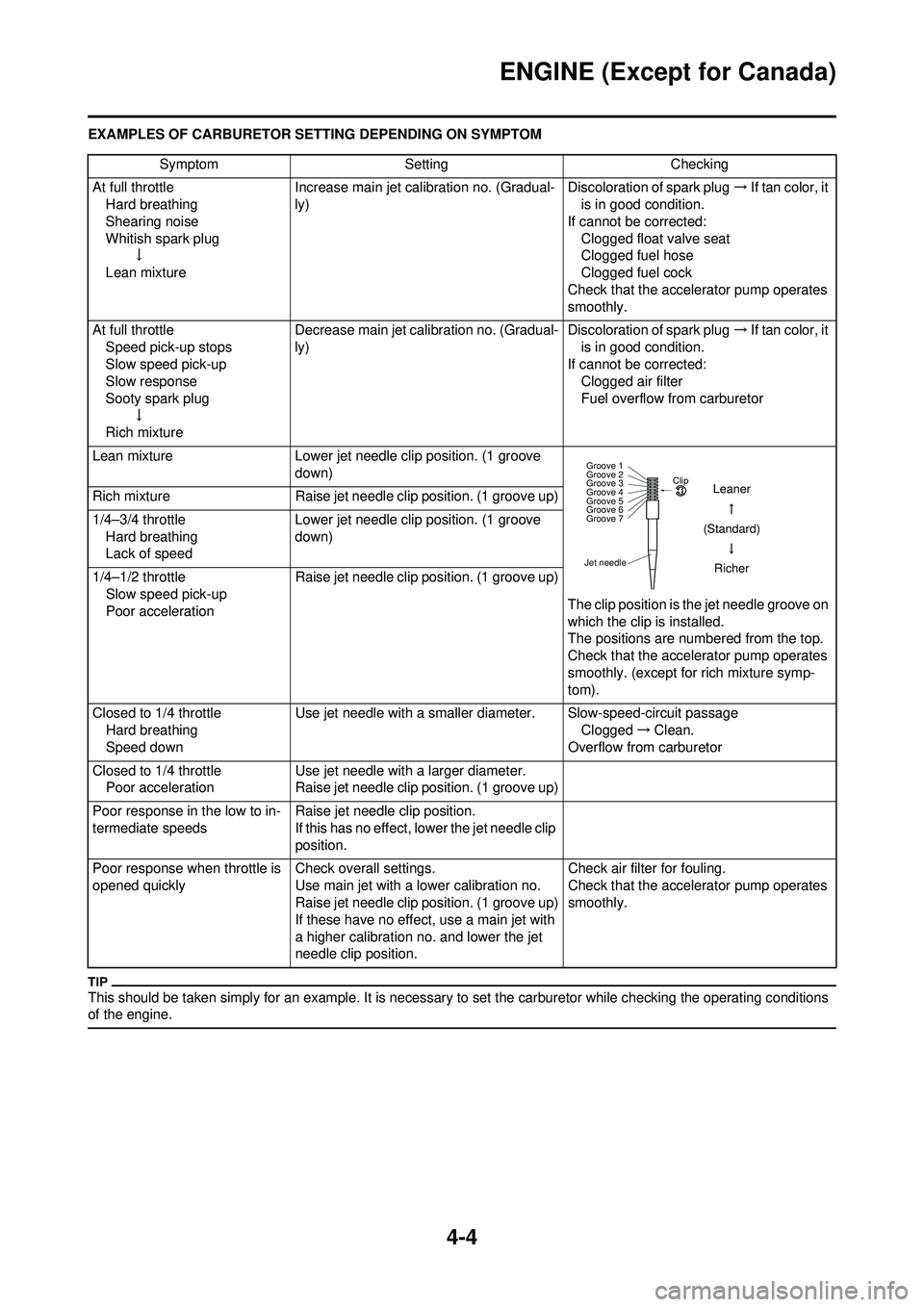

EXAMPLES OF CARBURETOR SETTING DEPENDING ON SYMPTOM

This should be taken simply for an example. It is necessary to set the carburetor while checking the operating conditions

of the engine.

SymptomSetting Checking

At full throttle Hard breathing

Shearing noise

Whitish spark plug ↓

Lean mixture Increase main jet calibration no. (Gradual-

ly)

Discoloration of spark plug

→If tan color, it

is in good condition.

If cannot be corrected: Clogged float valve seat

Clogged fuel hose

Clogged fuel cock

Check that the accelerator pump operates

smoothly.

At full throttle Speed pick-up stops

Slow speed pick-up

Slow response

Sooty spark plug ↓

Rich mixture Decrease main jet calibration no. (Gradual-

ly)

Discoloration of spark plug

→If tan color, it

is in good condition.

If cannot be corrected: Clogged air filter

Fuel overflow from carburetor

Lean mixture Lower jet needle clip position. (1 groove

down)

The clip position is the jet needle groove on

which the clip is installed.

The positions are numbered from the top.

Check that the accelerator pump operates

smoothly. (except for rich mixture symp-

tom).

Rich mixture

Raise jet needle clip position. (1 groove up)

1/4–3/4 throttle Hard breathing

Lack of speed Lower jet needle clip position. (1 groove

down)

1/4–1/2 throttle Slow speed pick-up

Poor acceleration Raise jet needle clip position. (1 groove up)

Closed to 1/4 throttle Hard breathing

Speed down Use jet needle with a smaller diameter. Slow-speed-circuit passage

Clogged→Clean.

Overflow from carburetor

Closed to 1/4 throttle Poor acceleration Use jet needle with a larger diameter.

Raise jet needle clip position. (1 groove up)

Poor response in the low to in-

termediate speeds Raise jet needle clip position.

If this has no effect, lower the jet needle clip

position.

Poor response when throttle is

opened quickly Check overall settings.

Use main jet with a lower calibration no.

Raise jet needle clip position. (1 groove up)

If these have no effect, use a main jet with

a higher calibration no. and lower the jet

needle clip position. Check air filter for fouling.

Check that the accelerator pump operates

smoothly.

Jet needleClip

Groove 7 Groove 6

Groove 5

Groove 4

Groove 3

Groove 2

Groove 1

Leaner

(Standard) Richer

Page 149 of 224

5-53

ENGINE REMOVAL

ENGINE REMOVAL

REMOVING THE ENGINEOrder Part name Q'ty Remarks Hold the machine by placing the suitable stand

under the frame. Refer to "HANDLING NOTE".

Drain the engine oil. Refer to "CHANGING THE ENGINE OIL"

section in the CHAPTER 3.

Seat and fuel tank Refer to "REMOVING THE SEAT, FUEL

TANK AND SIDE COVERS" section in the

CHAPTER 3.

Carburetor Refer to "CARBURETOR" section.

Exhaust pipe and silencer Refer to "REMOVING THE EXHAUST PIPE

AND SILENCER" section in the CHAPTER 3.

Air cut-off valve assembly Refer to "AIR INDUCTION SYSTEM" section.

Clutch cable Disconnect at the engine side.

Radiator Refer to "RADIATOR" section.

Shift pedal Refer to "AC MAGNETO AND STARTER

CLUTCH" section.

Cylinder head breather hose Refer to "CAMSHAFTS" section.

Oil hose and oil tank breather hose Refer to "OIL PUMP" section.

Ignition coil