display YAMAHA WR 250F 2010 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2010, Model line: WR 250F, Model: YAMAHA WR 250F 2010Pages: 232, PDF Size: 13.94 MB

Page 10 of 232

CONTENTS

CHAPTER 1

GENERAL INFOR-

MATION

LOCATION OF

IMPORTANT LABELS ..... 1-1

DESCRIPTION ................. 1-5

CONSUMER

INFORMATION................. 1-6

INCLUDED PARTS .......... 1-6

IMPORTANT

INFORMATION................. 1-6

CHECKING OF

CONNECTION .................. 1-7

SPECIAL TOOLS ............. 1-8

CONTROL FUNCTIONS.. 1-12

MULTI-FUNCTION

DISPLAY ........................ 1-13

STARTING AND

BREAK-IN ...................... 1-18

TORQUE-CHECK

POINTS........................... 1-20

CLEANING AND

STORAGE ...................... 1-21

CHAPTER 2

SPECIFICATIONS

GENERAL

SPECIFICATIONS ............ 2-1

MAINTENANCE

SPECIFICATIONS ............ 2-3

TIGHTENING

TORQUES ...................... 2-12

LUBRICATION

DIAGRAMS .................... 2-19

CABLE ROUTING

DIAGRAM ....................... 2-21

CHAPTER 3

REGULAR INSPEC-

TION AND AD-JUSTMENTS

PERIODIC MAINTENANCE

CHART FOR THE EMISSION

CONTROL SYSTEM (For

Canada) ............................ 3-1

GENERAL MAINTENANCE

AND LUBRICATION CHART

(For Canada) .................... 3-2

MAINTENANCE INTER-

VALS FOR COMPETITION

USE ................................... 3-3

PRE-OPERATION

INSPECTION AND

MAINTENANCE................ 3-7

ENGINE ............................ 3-8

CHASSIS ........................ 3-19

ELECTRICAL ................. 3-29

CHAPTER 4 TUNING

ENGINE

(Except for Canada) ........ 4-1

CHASSIS .......................... 4-5

CHAPTER 5

ENGINE

RADIATOR ....................... 5-1

CARBURETOR................. 5-4

AIR INDICTOIN

SYSTEM ......................... 5-12

CAMSHAFTS.................. 5-14

CYLINDER HEAD........... 5-19

VALVES AND VALVE

SPRINGS ........................ 5-21

CYLINDER AND

PISTON ........................... 5-25

CLUTCH ......................... 5-29 OIL FILTER ELEMENT

AND WATER PUMP .......5-34

BALANCER ....................5-39

OIL PUMP .......................5-41

KICK SHAFT AND SHIFT

SHAFT ............................5-44

AC MAGNETO AND

STARTER CLUTCH........5-49

ENGINE REMOVAL........5-54

CRANKCASE AND

CRANKSHAFT ...............5-58

TRANSMISSION,

SHIFT CAM AND

SHIFT FORK ...................5-64

CHAPTER 6

CHASSIS

FRONT WHEEL AND

REAR WHEEL ..................6-1

FRONT BRAKE AND

REAR BRAKE ..................6-6

FRONT FORK .................6-16

HANDLEBAR..................6-23

STEERING ......................6-27

SWINGARM ....................6-31

REAR SHOCK

ABSORBER ....................6-36

CHAPTER 7

ELECTRICAL

ELECTRICAL COMPO-

NENTS AND WIRING

DIAGRAM .........................7-1

IGNITION SYSTEM...........7-3

ELECTRIC STARTING

SYSTEM............................7-5

CHARGING SYSTEM .....7-13

THROTTLE POSITION

SENSOR SYSTEM .........7-15

LIGHTING SYSTEM .......7-18

SIGNALING SYSTEM.....7-20

Page 15 of 232

1-5

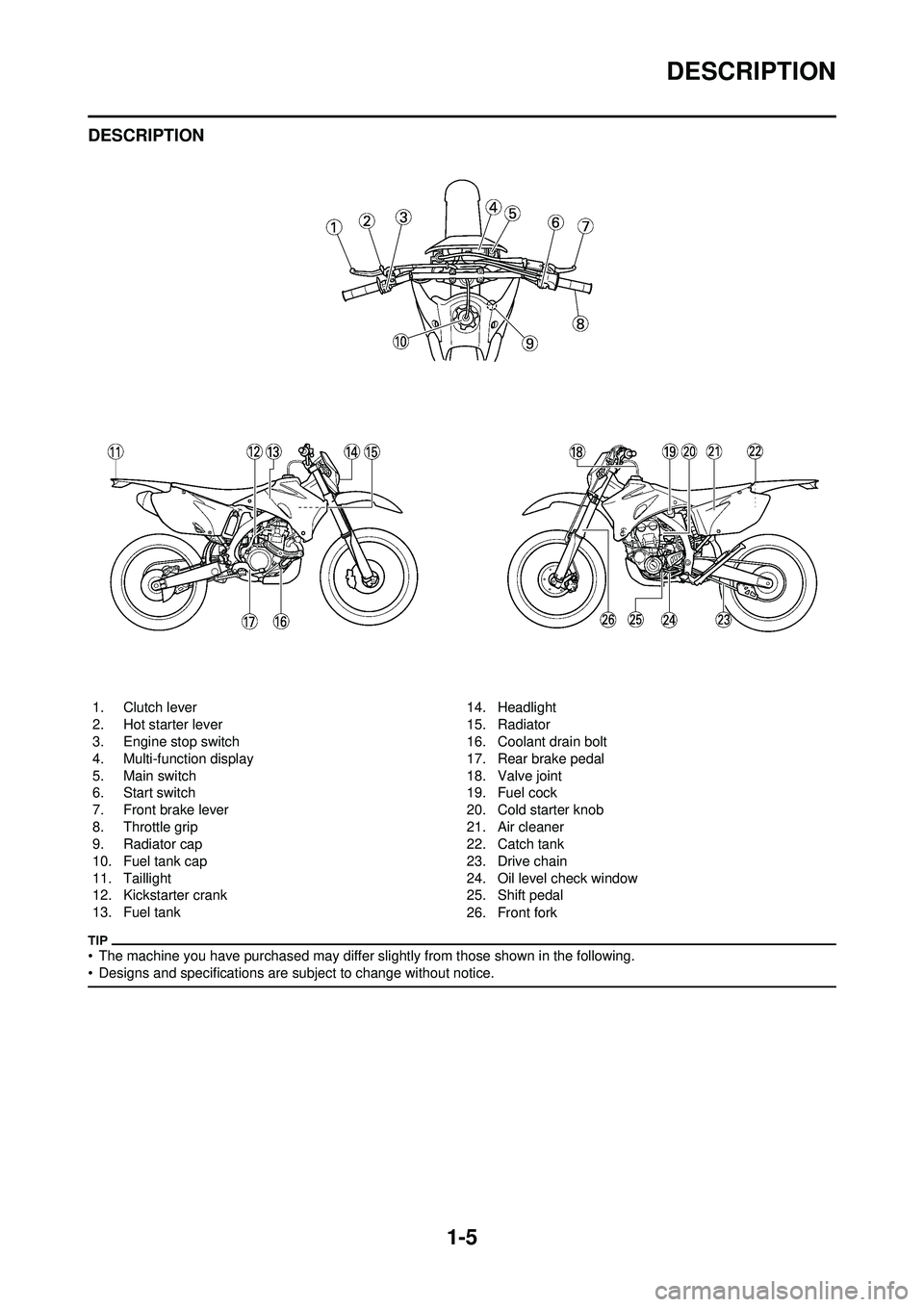

DESCRIPTION

DESCRIPTION

• The machine you have purchased may differ slightly from those shown in the following.

• Designs and specifications are subject to change without notice.

1. Clutch lever

2. Hot starter lever

3. Engine stop switch

4. Multi-function display

5. Main switch

6. Start switch

7. Front brake lever

8. Throttle grip

9. Radiator cap

10. Fuel tank cap

11. Taillight

12. Kickstarter crank

13. Fuel tank 14. Headlight

15. Radiator

16. Coolant drain bolt

17. Rear brake pedal

18. Valve joint

19. Fuel cock

20. Cold starter knob

21. Air cleaner

22. Catch tank

23. Drive chain

24. Oil level check window

25. Shift pedal

26. Front fork

Page 23 of 232

1-13

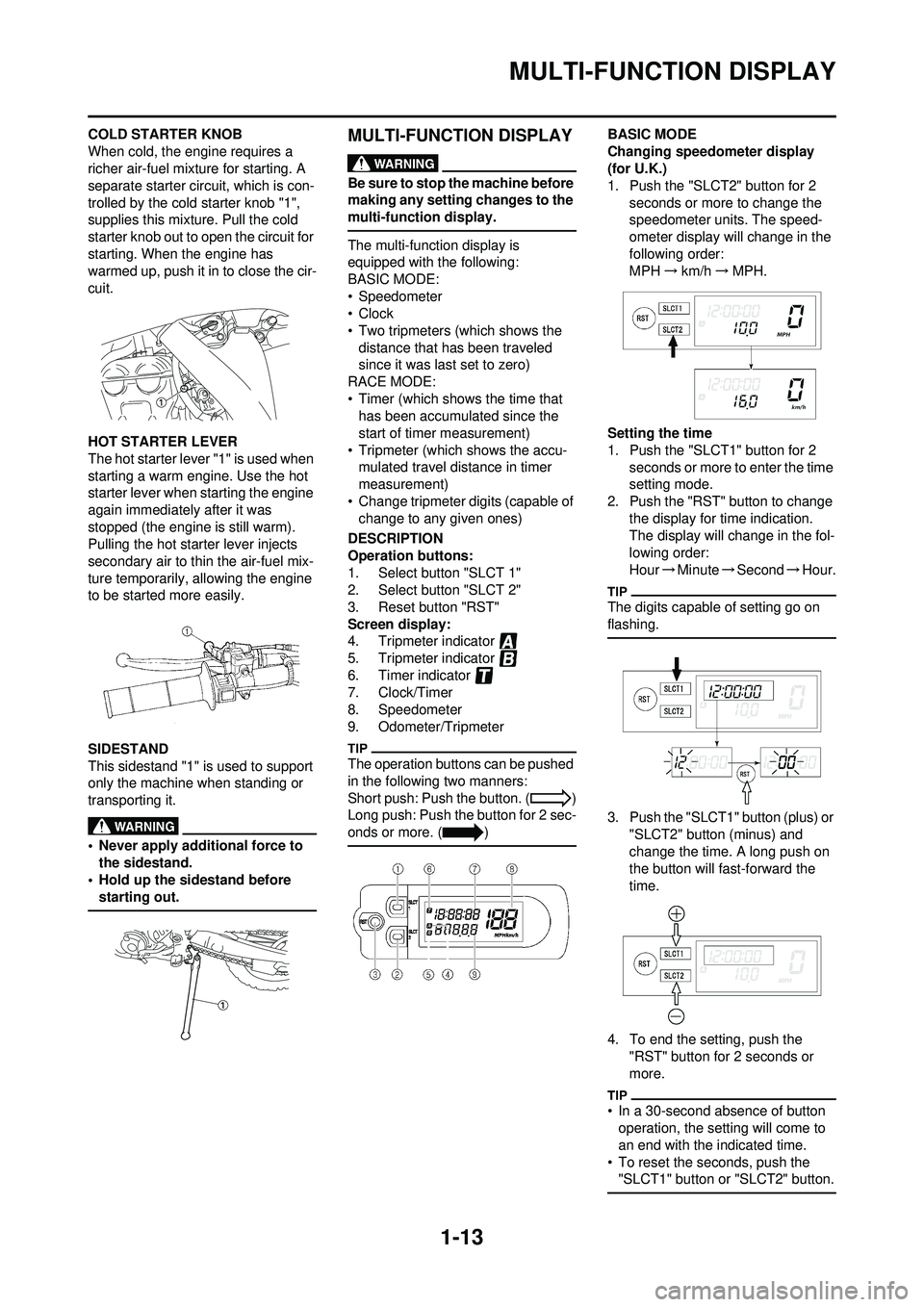

MULTI-FUNCTION DISPLAY

COLD STARTER KNOB

When cold, the engine requires a

richer air-fuel mixture for starting. A

separate starter circuit, which is con-

trolled by the cold starter knob "1",

supplies this mixture. Pull the cold

starter knob out to open the circuit for

starting. When the engine has

warmed up, push it in to close the cir-

cuit.

HOT STARTER LEVER

The hot starter lever "1" is used when

starting a warm engine. Use the hot

starter lever when starting the engine

again immediately after it was

stopped (the engine is still warm).

Pulling the hot starter lever injects

secondary air to thin the air-fuel mix-

ture temporarily, allowing the engine

to be started more easily.

SIDESTAND

This sidestand "1" is used to support

only the machine when standing or

transporting it.

• Never apply additional force to the sidestand.

• Hold up the sidestand before

starting out.

MULTI-FUNCTION DISPLAY

Be sure to stop the machine before

making any setting changes to the

multi-function display.

The multi-function display is

equipped with the following:

BASIC MODE:

• Speedometer

•Clock

• Two tripmeters (which shows the distance that has been traveled

since it was last set to zero)

RACE MODE:

• Timer (which shows the time that has been accumulated since the

start of timer measurement)

• Tripmeter (which shows the accu- mulated travel distance in timer

measurement)

• Change tripmeter digits (capable of change to any given ones)

DESCRIPTION

Operation buttons:

1. Select button "SLCT 1"

2. Select button "SLCT 2"

3. Reset button "RST"

Screen display:

4. Tripmeter indicator

5. Tripmeter indicator

6. Timer indicator

7. Clock/Timer

8. Speedometer

9. Odometer/Tripmeter

The operation buttons can be pushed

in the following two manners:

Short push: Push the button. ( )

Long push: Push the button for 2 sec-

onds or more. ( )

BASIC MODE

Changing speedometer display

(for U.K.)

1. Push the "SLCT2" button for 2 seconds or more to change the

speedometer units. The speed-

ometer display will change in the

following order:

MPH →km/h →MPH.

Setting the time

1. Push the "SLCT1" button for 2 seconds or more to enter the time

setting mode.

2. Push the "RST" button to change the display for time indication.

The display will change in the fol-

lowing order:

Hour →Minute →Second →Hour.

The digits capable of setting go on

flashing.

3. Push the "SLCT1" button (plus) or

"SLCT2" button (minus) and

change the time. A long push on

the button will fast-forward the

time.

4. To end the setting, push the "RST" button for 2 seconds or

more.

• In a 30-second absence of button operation, the setting will come to

an end with the indicated time.

• To reset the seconds, push the "SLCT1" button or "SLCT2" button.

Page 24 of 232

1-14

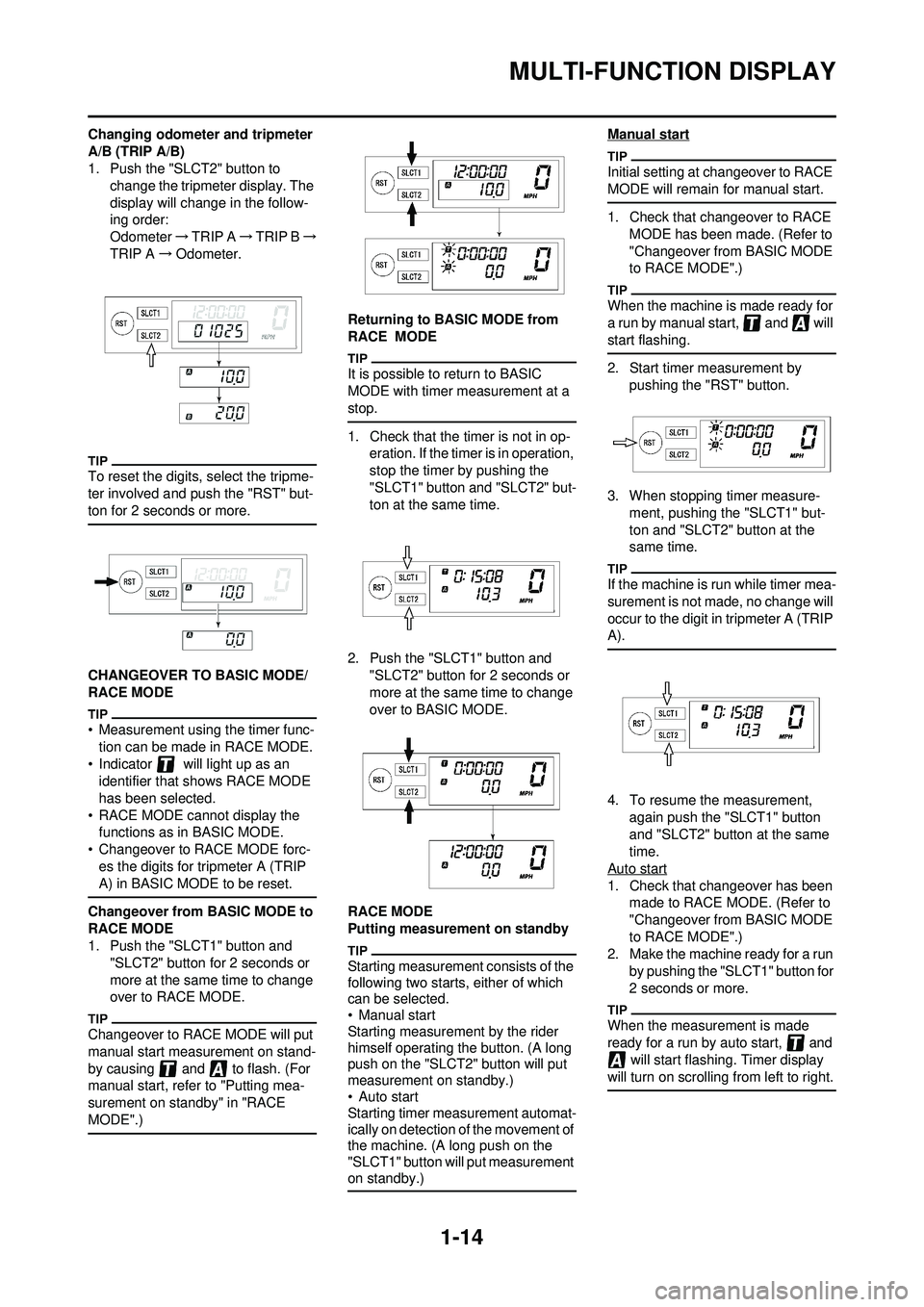

MULTI-FUNCTION DISPLAY

Changing odometer and tripmeter

A/B (TRIP A/B)

1. Push the "SLCT2" button to change the tripmeter display. The

display will change in the follow-

ing order:

Odometer →TRIP A →TRIP B →

TRIP A →Odometer.

To reset the digits, select the tripme-

ter involved and push the "RST" but-

ton for 2 seconds or more.

CHANGEOVER TO BASIC MODE/

RACE MODE

• Measurement using the timer func-

tion can be made in RACE MODE.

• Indicator will light up as an identifier that shows RACE MODE

has been selected.

• RACE MODE cannot display the functions as in BASIC MODE.

• Changeover to RACE MODE forc-

es the digits for tripmeter A (TRIP

A) in BASIC MODE to be reset.

Changeover from BASIC MODE to

RACE MODE

1. Push the "SLCT1" button and "SLCT2" button for 2 seconds or

more at the same time to change

over to RACE MODE.

Changeover to RACE MODE will put

manual start measurement on stand-

by causing and to flash. (For

manual start, refer to "Putting mea-

surement on standby" in "RACE

MODE".)

Returning to BASIC MODE from

RACE MODE

It is possible to return to BASIC

MODE with timer measurement at a

stop.

1. Check that the timer is not in op- eration. If the timer is in operation,

stop the timer by pushing the

"SLCT1" button and "SLCT2" but-

ton at the same time.

2. Push the "SLCT1" button and "SLCT2" button for 2 seconds or

more at the same time to change

over to BASIC MODE.

RACE MODE

Putting measurement on standby

Starting measurement consists of the

following two starts, either of which

can be selected.

• Manual start

Starting measurement by the rider

himself operating the button. (A long

push on the "SLCT2" button will put

measurement on standby.)

• Auto start

Starting timer measurement automat-

ically on detection of the movement of

the machine. (A long push on the

"SLCT1" button will put measurement

on standby.)

Manual start

Initial setting at changeover to RACE

MODE will remain for manual start.

1. Check that changeover to RACE

MODE has been made. (Refer to

"Changeover from BASIC MODE

to RACE MODE".)

When the machine is made ready for

a run by manual start, and will

start flashing.

2. Start timer measurement by pushing the "RST" button.

3. When stopping timer measure- ment, pushing the "SLCT1" but-

ton and "SLCT2" button at the

same time.

If the machine is run while timer mea-

surement is not made, no change will

occur to the digit in tripmeter A (TRIP

A).

4. To resume the measurement, again push the "SLCT1" button

and "SLCT2" button at the same

time.

Auto start

1. Check that changeover has been made to RACE MODE. (Refer to

"Changeover from BASIC MODE

to RACE MODE".)

2. Make the machine ready for a run by pushing the "SLCT1" button for

2 seconds or more.

When the measurement is made

ready for a run by auto start, and will start flashing. Timer display

will turn on scrolling from left to right.

Page 25 of 232

1-15

MULTI-FUNCTION DISPLAY

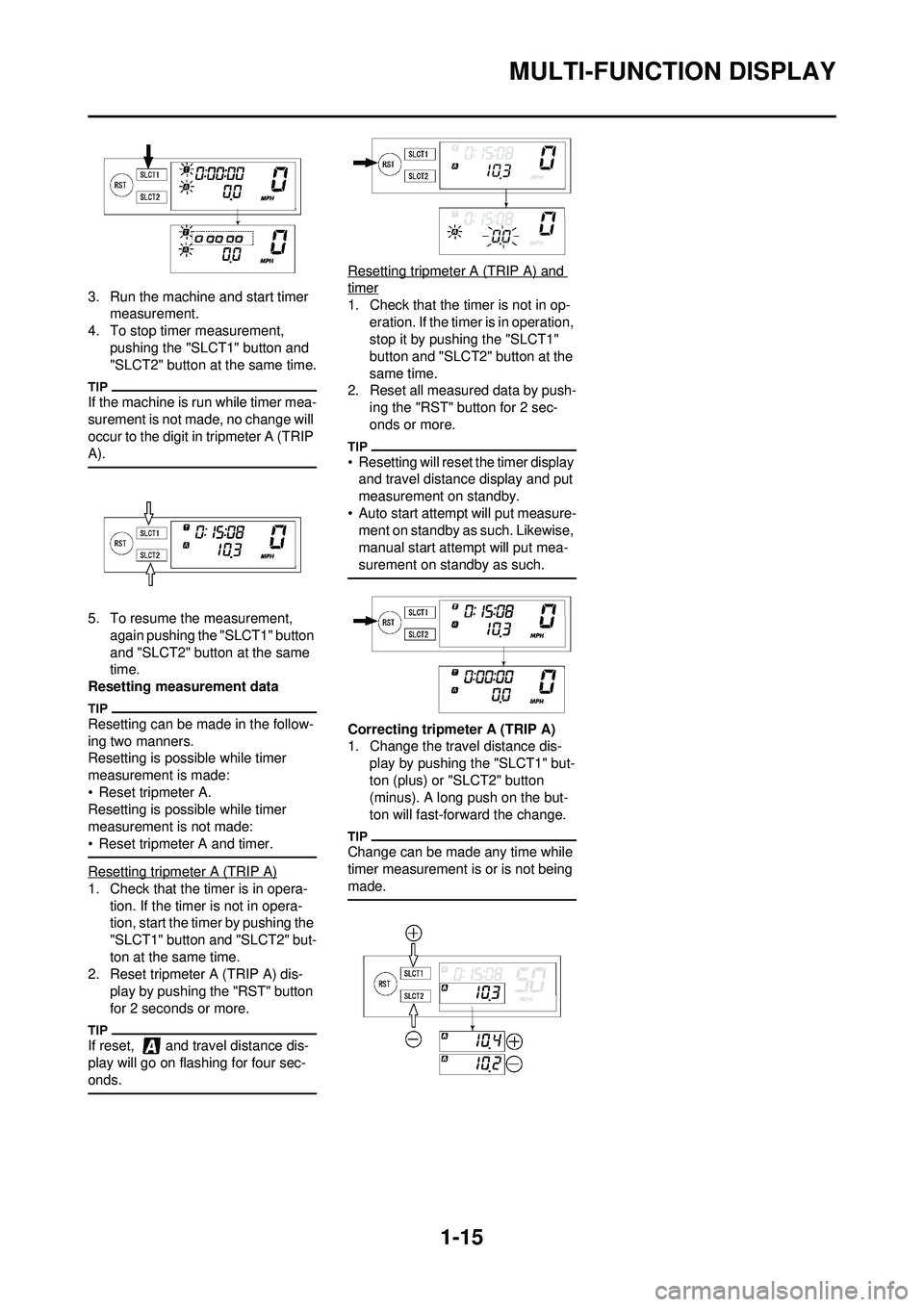

3. Run the machine and start timer measurement.

4. To stop timer measurement, pushing the "SLCT1" button and

"SLCT2" button at the same time.

If the machine is run while timer mea-

surement is not made, no change will

occur to the digit in tripmeter A (TRIP

A).

5. To resume the measurement, again pushing the "SLCT1" button

and "SLCT2" button at the same

time.

Resetting measurement data

Resetting can be made in the follow-

ing two manners.

Resetting is possible while timer

measurement is made:

• Reset tripmeter A.

Resetting is possible while timer

measurement is not made:

• Reset tripmeter A and timer.

Resetting tripmeter A (TRIP A)

1. Check that the timer is in opera- tion. If the timer is not in opera-

tion, start the timer by pushing the

"SLCT1" button and "SLCT2" but-

ton at the same time.

2. Reset tripmeter A (TRIP A) dis-

play by pushing the "RST" button

for 2 seconds or more.

If reset, and travel distance dis-

play will go on flashing for four sec-

onds.

Resetting tripmeter A (TRIP A) and

timer

1. Check that the timer is not in op-eration. If the timer is in operation,

stop it by pushing the "SLCT1"

button and "SLCT2" button at the

same time.

2. Reset all measured data by push-

ing the "RST" button for 2 sec-

onds or more.

• Resetting will reset the timer display and travel distance display and put

measurement on standby.

• Auto start attempt will put measure- ment on standby as such. Likewise,

manual start attempt will put mea-

surement on standby as such.

Correcting tripmeter A (TRIP A)

1. Change the travel distance dis- play by pushing the "SLCT1" but-

ton (plus) or "SLCT2" button

(minus). A long push on the but-

ton will fast-forward the change.

Change can be made any time while

timer measurement is or is not being

made.

Page 26 of 232

1-16

MULTI-FUNCTION DISPLAY

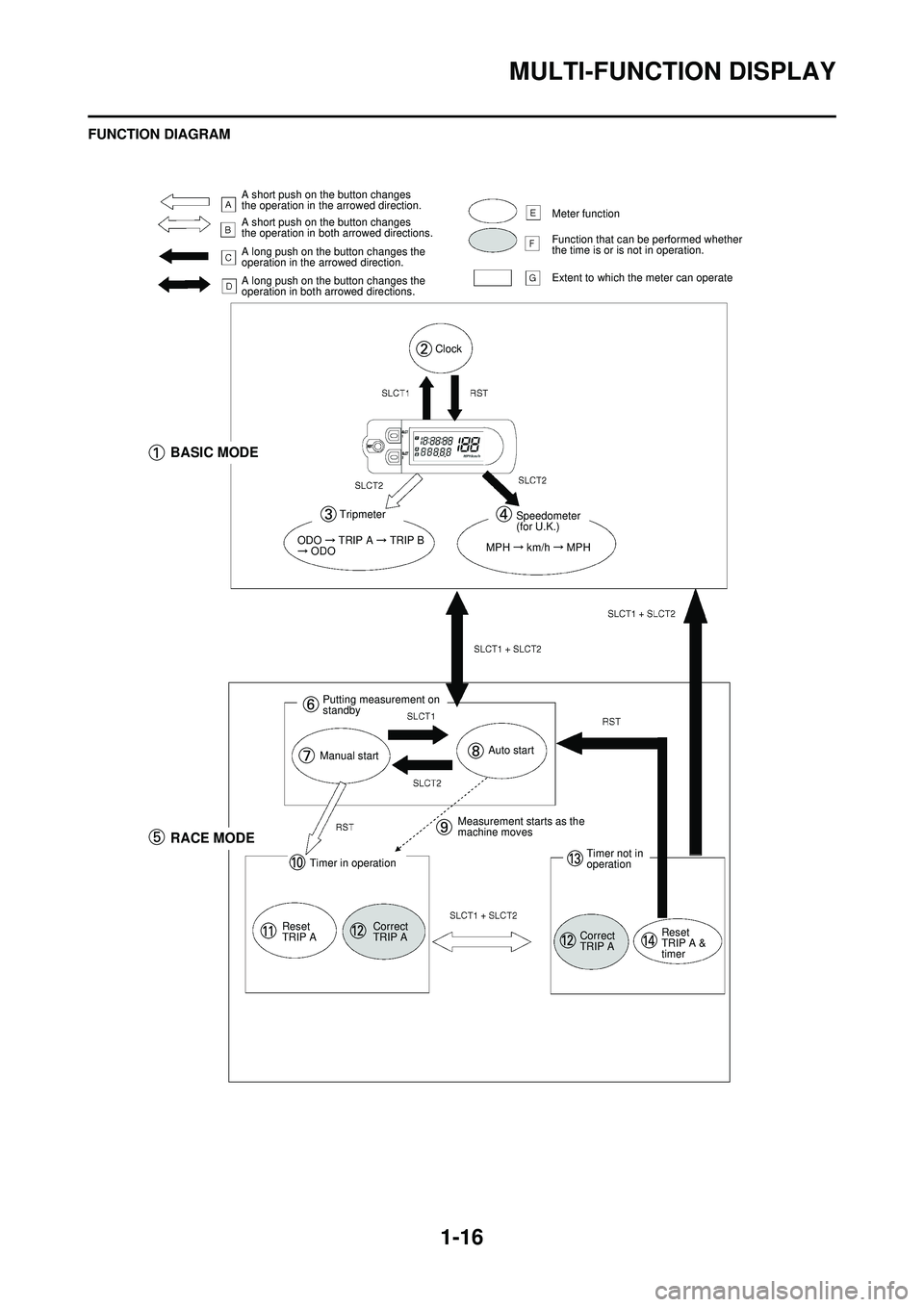

FUNCTION DIAGRAM

A short push on the button changes

the operation in the arrowed direction.

A short push on the button changes

the operation in both arrowed directions.

A long push on the button changes the

operation in the arrowed direction.

A long push on the button changes the

operation in both arrowed directions.Meter function

Function that can be performed whether

the time is or is not in operation.

Extent to which the meter can operate

Clock

BASIC MODE

Tripmeter

ODO TRIP A TRIP B ODO

Speedometer

(for U.K.)

MPH

km/h MPH

Putting measurement on

standby

Manual startAuto start

RACE MODE

Timer in operation

Reset

TRIP A Correct

TRIP AMeasurement starts as the

machine moves

Timer not in

operation

Correct

TRIP A Reset

TRIP A &

timer

Page 27 of 232

1-17

MULTI-FUNCTION DISPLAY

The following diagram illustrates the

multi-function display regarding the

direction and operation condition in-

volved in each of its functions.

A. A short push on the button changes the operation in the ar-

rowed direction.

B. A short push on the button changes the operation in both

arrowed directions.

C. A long push on the button changes the operation in the ar-

rowed direction.

D. A long push on the button changes the operation in both

arrowed directions.

E. Meter function

F. Function that can be performed whether the time is or is not in

operation.

G. Extent to which the meter can operate

1. BASIC MODE

2. Clock

3. Trip meter

4. Speedometer (for U.K.)

5. RACE MODE

6. Putting measurement on stand-

by

7. Manual start

8. Auto start

9. Measurement starts as the ma- chine moves

10. Timer in operation

11. Reset TRIP A

12. Correct TRIP A

13. Timer not in operation

14. Reset TRIP A & timer

Page 46 of 232

2-15

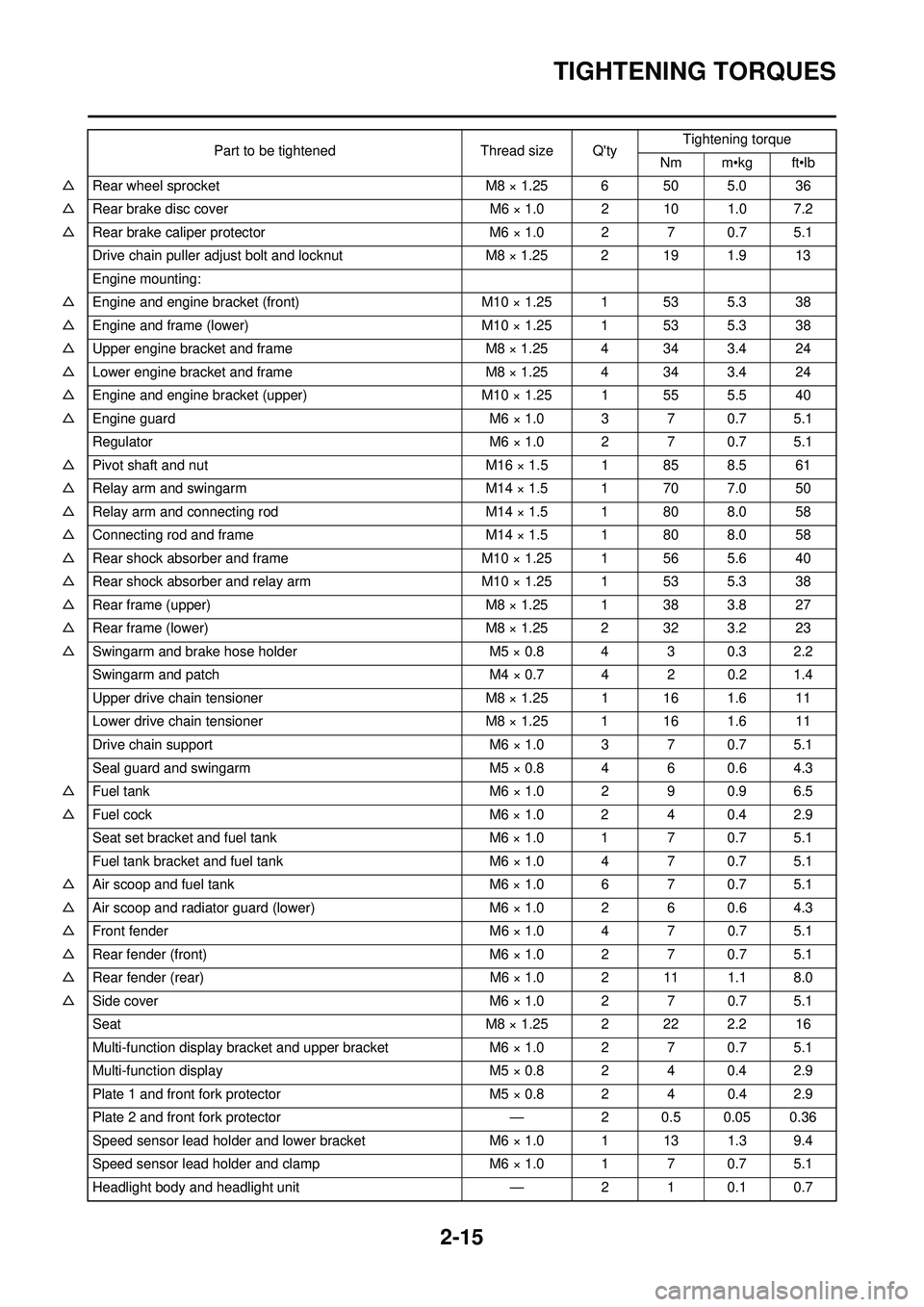

TIGHTENING TORQUES

△Rear wheel sprocket M8 × 1.25 6 50 5.0 36

△ Rear brake disc cover M6 × 1.0 2 10 1.0 7.2

△ Rear brake caliper protector M6 × 1.0 2 7 0.7 5.1

Drive chain puller adjust bolt and locknut M8 × 1.25 2 19 1.9 13

Engine mounting:

△ Engine and engine bracket (front) M10 × 1.25 1 53 5.3 38

△ Engine and frame (lower) M10 × 1.25 1 53 5.3 38

△ Upper engine bracket and frame M8 × 1.25 4 34 3.4 24

△ Lower engine bracket and frame M8 × 1.25 4 34 3.4 24

△ Engine and engine bracket (upper) M10 × 1.25 1 55 5.5 40

△ Engine guard M6 × 1.0 3 7 0.7 5.1

Regulator M6 × 1.0 2 7 0.7 5.1

△ Pivot shaft and nut M16 × 1.5 1 85 8.5 61

△ Relay arm and swingarm M14 × 1.5 1 70 7.0 50

△ Relay arm and connecting rod M14 × 1.5 1 80 8.0 58

△ Connecting rod and frame M14 × 1.5 1 80 8.0 58

△ Rear shock absorber and frame M10 × 1.25 1 56 5.6 40

△ Rear shock absorber and relay arm M10 × 1.25 1 53 5.3 38

△ Rear frame (upper) M8 × 1.25 1 38 3.8 27

△ Rear frame (lower) M8 × 1.25 2 32 3.2 23

△ Swingarm and brake hose holder M5 × 0.8 4 3 0.3 2.2

Swingarm and patch M4 × 0.7 4 2 0.2 1.4

Upper drive chain tensioner M8 × 1.25 1 16 1.6 11

Lower drive chain tensioner M8 × 1.25 1 16 1.6 11

Drive chain support M6 × 1.0 3 7 0.7 5.1

Seal guard and swingarm M5 × 0.8 4 6 0.6 4.3

△ Fuel tank M6 × 1.0 2 9 0.9 6.5

△ Fuel cock M6 × 1.0 2 4 0.4 2.9

Seat set bracket and fuel tank M6 × 1.0 1 7 0.7 5.1

Fuel tank bracket and fuel tank M6 × 1.0 4 7 0.7 5.1

△ Air scoop and fuel tank M6 × 1.0 6 7 0.7 5.1

△ Air scoop and radiator guard (lower) M6 × 1.0 2 6 0.6 4.3

△ Front fender M6 × 1.0 4 7 0.7 5.1

△ Rear fender (front) M6 × 1.0 2 7 0.7 5.1

△ Rear fender (rear) M6 × 1.0 2 11 1.1 8.0

△ Side cover M6 × 1.0 2 7 0.7 5.1

Seat M8 × 1.25 2 22 2.2 16

Multi-function display bracket and upper bracket M6 × 1.0 2 7 0.7 5.1

Multi-function display M5 × 0.8 2 4 0.4 2.9

Plate 1 and front fork protector M5 × 0.8 2 4 0.4 2.9

Plate 2 and front fork protector —2 0.5 0.05 0.36

Speed sensor lead holder and lower bracket M6 × 1.0 1 13 1.3 9.4

Speed sensor lead holder and clamp M6 × 1.0 1 7 0.7 5.1

Headlight body and headlight unit —2 1 0.1 0.7

Part to be tightened

Thread size Q'tyTightening torque

Nm m•kg ft•lb

Page 58 of 232

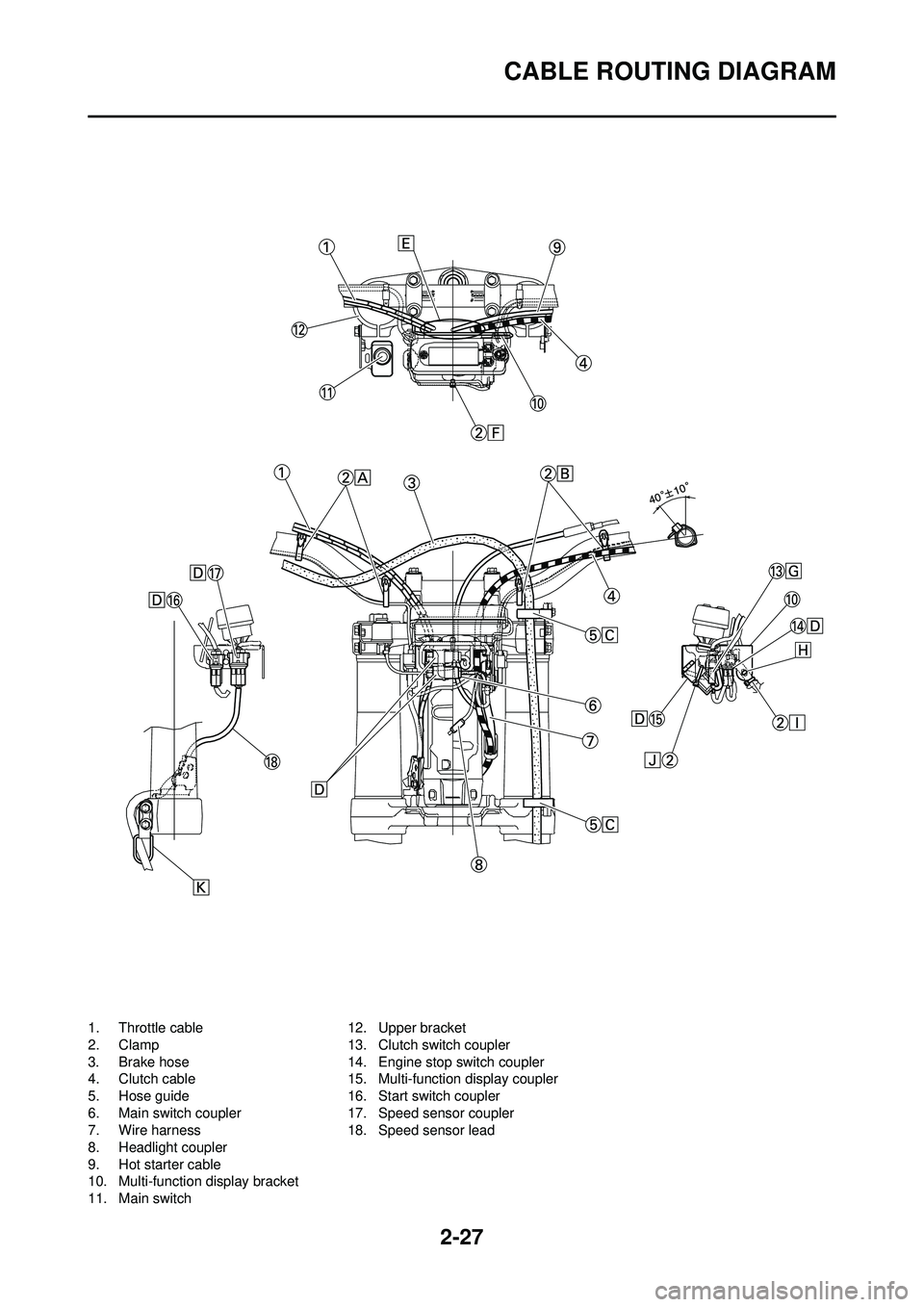

2-27

CABLE ROUTING DIAGRAM

1. Throttle cable

2. Clamp

3. Brake hose

4. Clutch cable

5. Hose guide

6. Main switch coupler

7. Wire harness

8. Headlight coupler

9. Hot starter cable

10. Multi-function display bracket

11. Main switch12. Upper bracket

13. Clutch switch coupler

14. Engine stop switch coupler

15. Multi-function display coupler

16. Start switch coupler

17. Speed sensor coupler

18. Speed sensor lead

Page 59 of 232

2-28

CABLE ROUTING DIAGRAM

A. Fasten the start switch lead to the handlebar with the plastic

bands.

B. Fasten the engine stop switch

lead and clutch switch lead to

the handlebar with the plastic

bands.

C. Pass the brake hose through the hose guides.

D. Secure the coupler by inserting

it into the multi-function display

bracket.

E. Pass the throttle cables, clutch

cable and hot starter cable be-

tween the upper bracket and

multi-function display bracket.

F. Fasten the multi-function display leads to the bracket. Cut off the

tie end.

G. Secure the coupler by pushing it into the hole in the multi-function

display bracket.

H. Secure the wire harness clip by pushing it into the hole in the

multi-function display bracket on

the inside.

I. Fasten the wire harness to the multi-function display bracket.

Cut off the tie end.

J. Fasten the main switch lead (wire harness side) to the multi-

function display br acket. Locate

the clamp end facing toward the

lower side of the frame and cut

off the tie end.

K. Pass the speed sensor lead through the guide on the outside

of the front fork.