engine coolant YAMAHA WR 250F 2010 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2010, Model line: WR 250F, Model: YAMAHA WR 250F 2010Pages: 232, PDF Size: 13.94 MB

Page 15 of 232

1-5

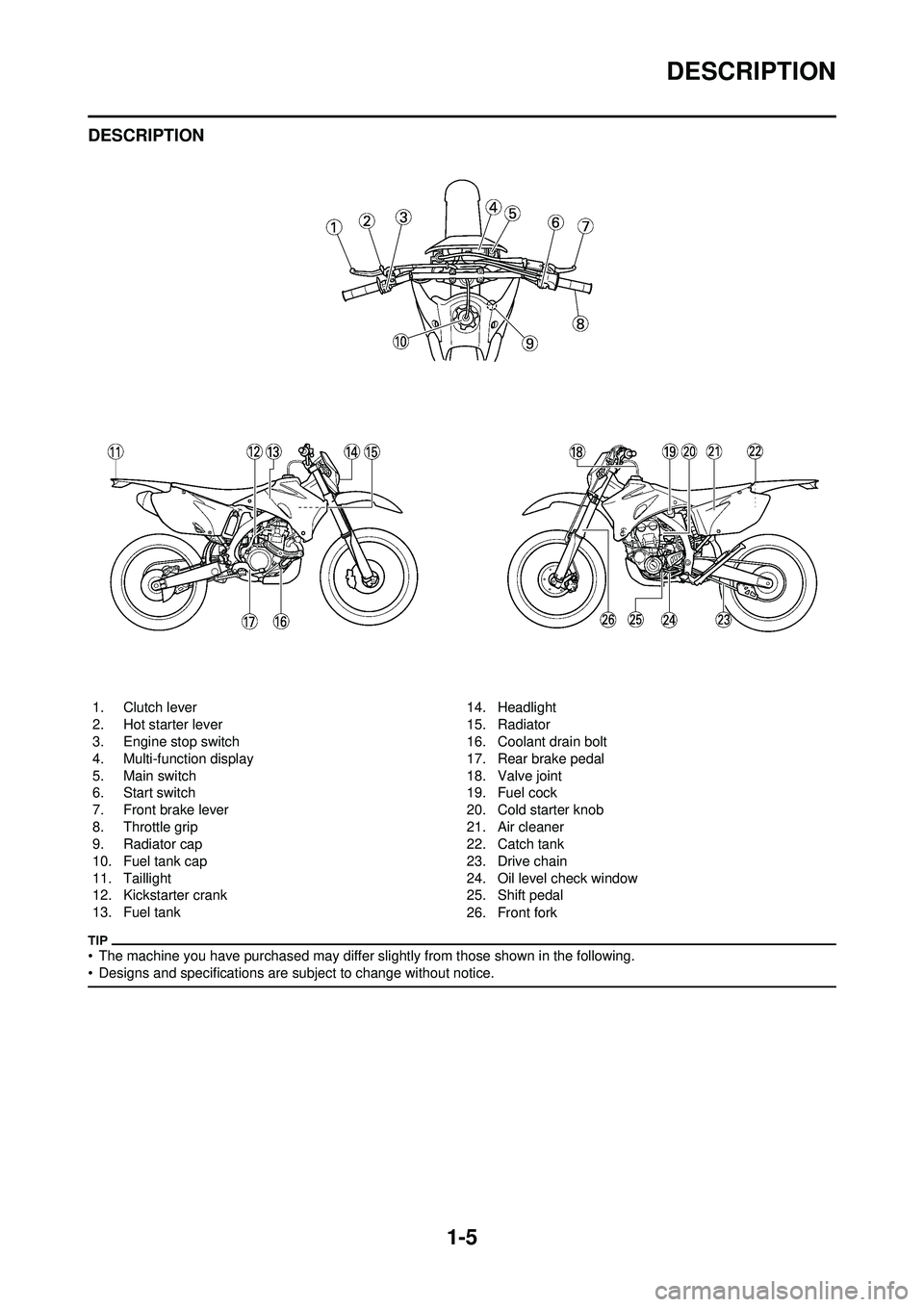

DESCRIPTION

DESCRIPTION

• The machine you have purchased may differ slightly from those shown in the following.

• Designs and specifications are subject to change without notice.

1. Clutch lever

2. Hot starter lever

3. Engine stop switch

4. Multi-function display

5. Main switch

6. Start switch

7. Front brake lever

8. Throttle grip

9. Radiator cap

10. Fuel tank cap

11. Taillight

12. Kickstarter crank

13. Fuel tank 14. Headlight

15. Radiator

16. Coolant drain bolt

17. Rear brake pedal

18. Valve joint

19. Fuel cock

20. Cold starter knob

21. Air cleaner

22. Catch tank

23. Drive chain

24. Oil level check window

25. Shift pedal

26. Front fork

Page 28 of 232

1-18

STARTING AND BREAK-IN

STARTING AND BREAK-IN

FUEL

Always use the recommended fuel as

stated below. Also, be sure to use

new gasoline.

Use only unleaded gasoline. The

use of leaded gasoline will cause

severe damage to the engine inter-

nal parts such as valves, piston

rings, and exhaust system, etc.

If knocking or pinging occurs, use a

different brand of gasoline or higher

octane grade.

• For refueling, be sure to stop the

engine and use enough care not

to spill any fuel. Also be sure to

avoid refueling close to a fire.

• Refuel after the engine, exhaust pipe, etc. have cooled off.

Gasohol (For Canada)

There are two types of gasohol: gas-

ohol containing ethanol and that con-

taining methanol. Gasohol containing

ethanol can be used if the ethanol

content does not exceed 10%. Gaso-

hol containing methanol is not recom-

mended by Yamaha because it can

cause damage to the fuel system or

vehicle performance problems.

HANDLING NOTE

Never start or run the engine in a

closed area. The exhaust fumes

are poisonous; they can cause

loss of consciousness and death

in a very short time. Always oper-

ate the machine in a well-ventilated

area.

• The carburetor on this machine has a built-in accelerator pump.

Therefore, when starting the en-

gine, do not operate the throttle

or the spark plug will foul.

• Unlike a two-stroke engine, this engine cannot be kick started

when the throttl e is open be-

cause the kickstarter may kick

back. Also, if the throttle is open

the air/fuel mixture may be too

lean for the engine to start.

• Before starting the machine, per- form the checks in the pre-opera-

tion check list.

AIR FILTER MAINTENANCE

According to "CLEANING THE AIR

FILTER ELEMENT" section in the

CHAPTER 3, apply the foam-air-filter

oil or its equivalent to the element.

(Excess oil in the element may ad-

versely affect engine starting.)

STARTING A COLD ENGINE

This model is equipped with an igni-

tion circuit cut-off system. The engine

can be started under the following

conditions.

• When the transmission is in neutral.

• When the clutch is disengaged with

the transmission in any position.

However, it is recommended to shift

into neutral before starting the en-

gine.

1. Inspect the coolant level.

2. Turn the fuel cock to "ON".

3. Push on the main switch to "ON".

4. Shift the transmission into neutral.

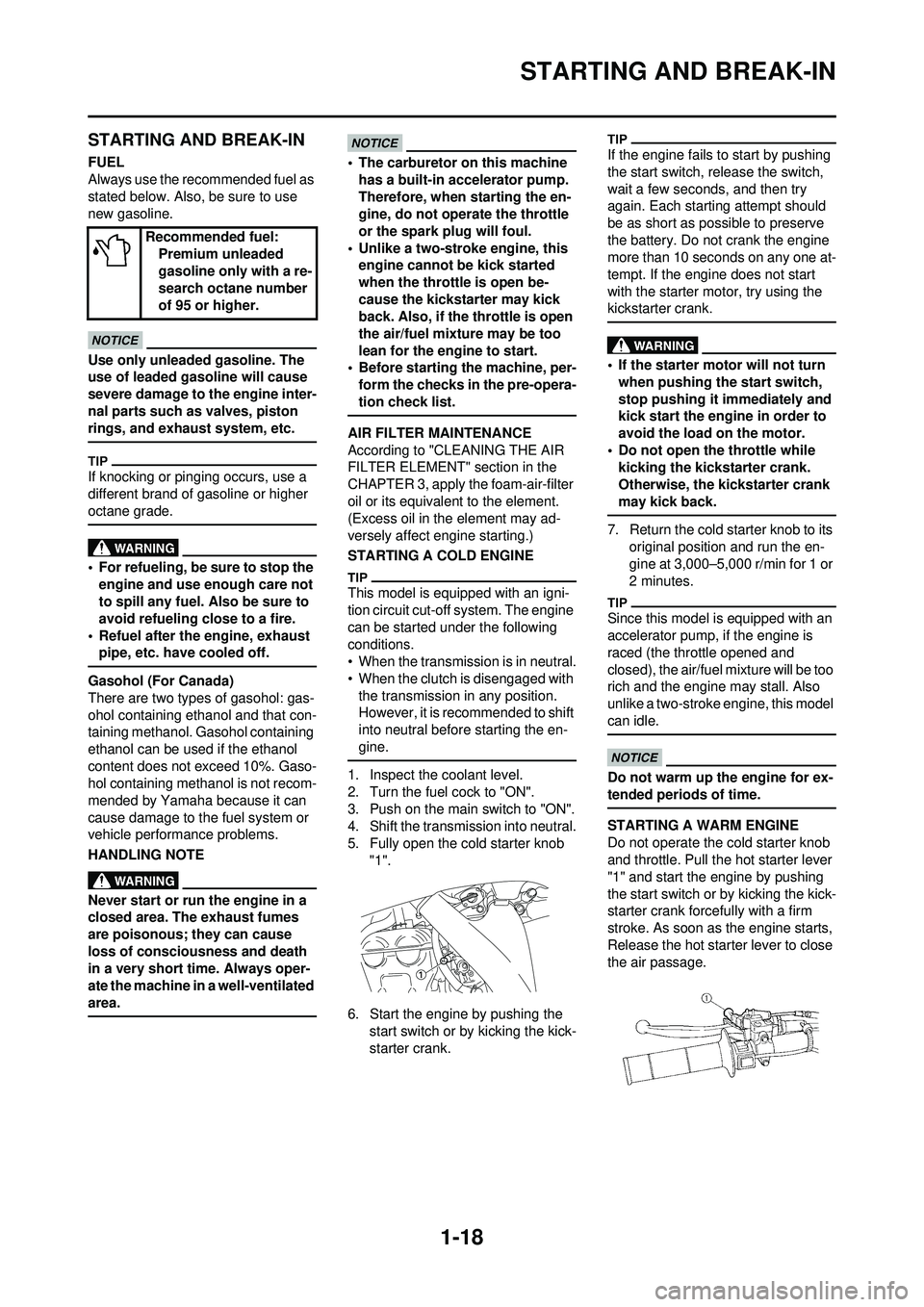

5. Fully open the cold starter knob "1".

6. Start the engine by pushing the start switch or by kicking the kick-

starter crank.

If the engine fails to start by pushing

the start switch, re lease the switch,

wait a few seconds, and then try

again. Each starting attempt should

be as short as possible to preserve

the battery. Do not crank the engine

more than 10 seconds on any one at-

tempt. If the engine does not start

with the starter motor, try using the

kickstarter crank.

• If the starter motor will no t turn

when pushing the start switch,

stop pushing it immediately and

kick start the engine in order to

avoid the load on the motor.

• Do not open the throttle while kicking the kickstarter crank.

Otherwise, the kickstarter crank

may kick back.

7. Return the cold starter knob to its original position and run the en-

gine at 3,000–5,000 r/min for 1 or

2 minutes.

Since this model is equipped with an

accelerator pump, if the engine is

raced (the throttle opened and

closed), the air/fuel mixture will be too

rich and the engine may stall. Also

unlike a two-stroke engine, this model

can idle.

Do not warm up th e engine for ex-

tended periods of time.

STARTING A WARM ENGINE

Do not operate the cold starter knob

and throttle. Pull the hot starter lever

"1" and start the engine by pushing

the start switch or by kicking the kick-

starter crank forcefully with a firm

stroke. As soon as the engine starts,

Release the hot starter lever to close

the air passage.

Recommended fuel:

Premium unleaded

gasoline only with a re-

search octane number

of 95 or higher.

Page 32 of 232

2-1

GENERAL SPECIFICATIONS

SPECIFICATIONS

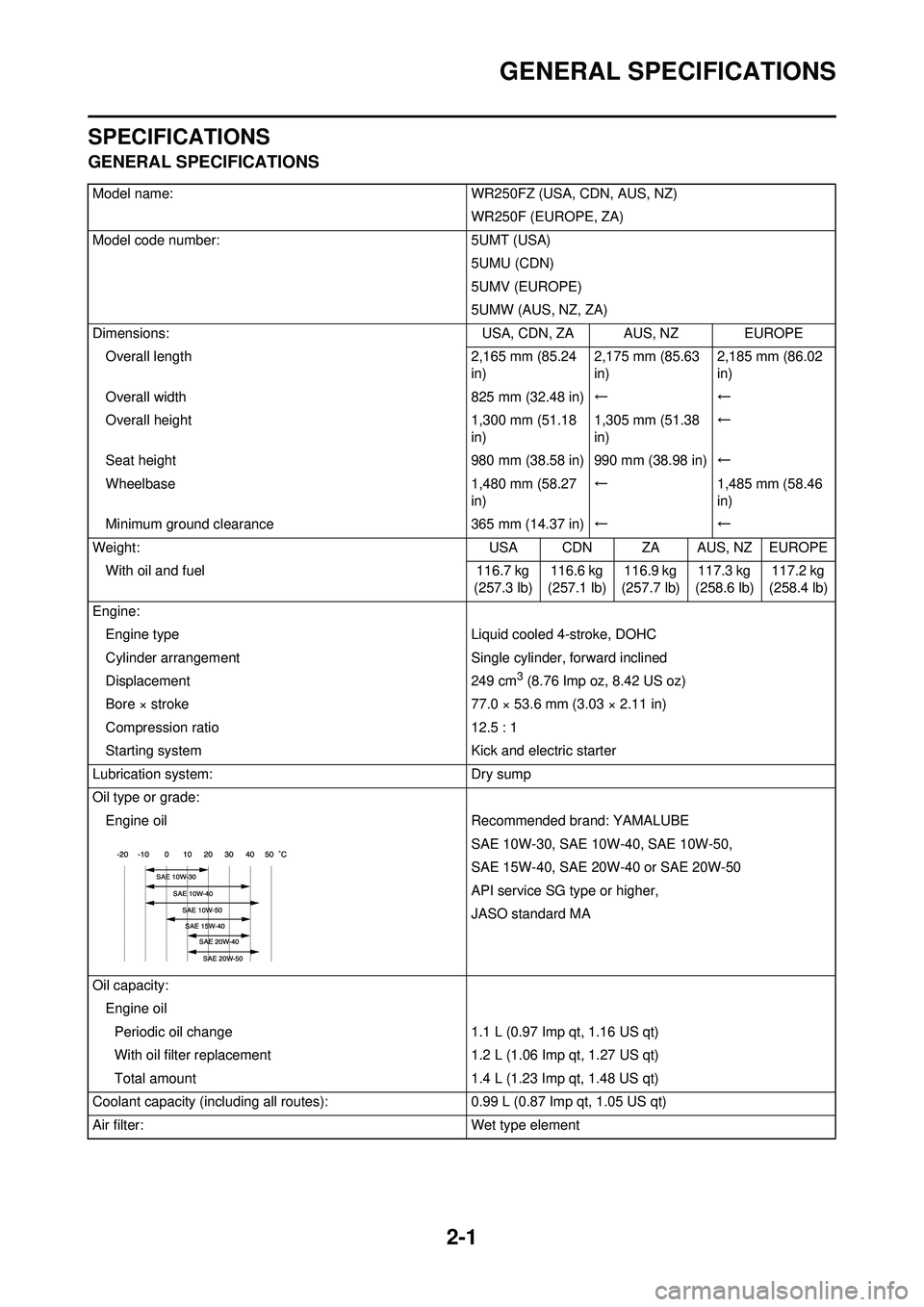

GENERAL SPECIFICATIONS

Model name:WR250FZ (USA, CDN, AUS, NZ)

WR250F (EUROPE, ZA)

Model code number: 5UMT (USA)

5UMU (CDN)

5UMV (EUROPE)

5UMW (AUS, NZ, ZA)

Dimensions: USA, CDN, ZA AUS, NZ EUROPE

Overall length 2,165 mm (85.24

in) 2,175 mm (85.63

in)2,185 mm (86.02

in)

Overall width 825 mm (32.48 in)←←

Overall height 1,300 mm (51.18

in) 1,305 mm (51.38

in)←

Seat height 980 mm (38.58 in) 990 mm (38.98 in)←

Wheelbase 1,480 mm (58.27

in) ←

1,485 mm (58.46

in)

Minimum ground clearance 365 mm (14.37 in)←←

Weight: USA CDN ZA AUS, NZ EUROPE

With oil and fuel 116.7 kg

(257.3 lb) 116.6 kg

(257.1 lb) 116.9 kg

(257.7 lb) 117.3 kg

(258.6 lb) 117.2 kg

(258.4 lb)

Engine: Engine type Liquid cooled 4-stroke, DOHC

Cylinder arrangement Single cylinder, forward inclined

Displacement 249 cm

3 (8.76 Imp oz, 8.42 US oz)

Bore × stroke 77.0 × 53.6 mm (3.03 × 2.11 in)

Compression ratio 12.5 : 1

Starting system Kick and electric starter

Lubrication system: Dry sump

Oil type or grade: Engine oil Recommended brand: YAMALUBE

SAE 10W-30, SAE 10W-40, SAE 10W-50,

SAE 15W-40, SAE 20W-40 or SAE 20W-50

API service SG type or higher,

JASO standard MA

Oil capacity: Engine oilPeriodic oil change 1.1 L (0.97 Imp qt, 1.16 US qt)

With oil filter replacement 1.2 L (1.06 Imp qt, 1.27 US qt)

Total amount 1.4 L (1.23 Imp qt, 1.48 US qt)

Coolant capacity (including all routes ):0.99 L (0.87 Imp qt, 1.05 US qt)

Air filter: Wet type element

Page 43 of 232

2-12

TIGHTENING TORQUES

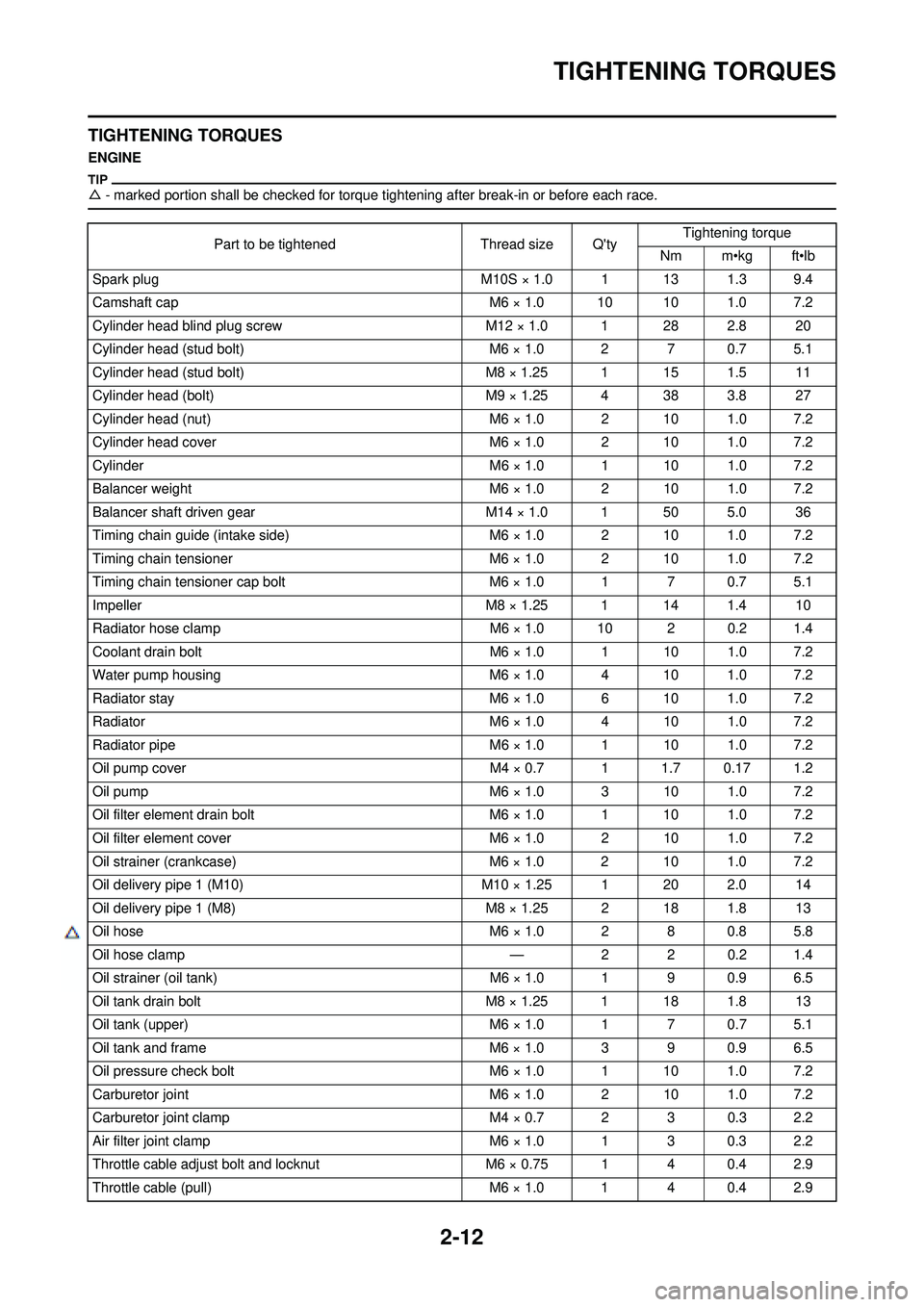

TIGHTENING TORQUES

ENGINE

△- marked portion shall be checked for torque ti ghtening after break-in or before each race.

Part to be tightenedThread size Q'tyTightening torque

Nm m•kg ft•lb

Spark plug M10S × 1.0 1 13 1.3 9.4

Camshaft cap M6 × 1.0 10 10 1.0 7.2

Cylinder head blind plug screw M12 × 1.0 1 28 2.8 20

Cylinder head (stud bolt) M6 × 1.0 2 7 0.7 5.1

Cylinder head (stud bolt) M8 × 1.25 1 15 1.5 11

Cylinder head (bolt) M9 × 1.25 4 38 3.8 27

Cylinder head (nut) M6 × 1.0 2 10 1.0 7.2

Cylinder head cover M6 × 1.0 2 10 1.0 7.2

Cylinder M6 × 1.0 1 10 1.0 7.2

Balancer weight M6 × 1.0 2 10 1.0 7.2

Balancer shaft driven gear M14 × 1.0 1 50 5.0 36

Timing chain guide (intake side) M6 × 1.0 2 10 1.0 7.2

Timing chain tensioner M6 × 1.0 2 10 1.0 7.2

Timing chain tensioner cap bolt M6 × 1.0 1 7 0.7 5.1

Impeller M8 × 1.25 1 14 1.4 10

Radiator hose clamp M6 × 1.0 10 2 0.2 1.4

Coolant drain bolt M6 × 1.0 1 10 1.0 7.2

Water pump housing M6 × 1.0 4 10 1.0 7.2

Radiator stay M6 × 1.0 6 10 1.0 7.2

Radiator M6 × 1.0 4 10 1.0 7.2

Radiator pipe M6 × 1.0 1 10 1.0 7.2

Oil pump cover M4 × 0.7 1 1.7 0.17 1.2

Oil pump M6 × 1.0 3 10 1.0 7.2

Oil filter element drain bolt M6 × 1.0 1 10 1.0 7.2

Oil filter element cover M6 × 1.0 2 10 1.0 7.2

Oil strainer (crankcase) M6 × 1.0 2 10 1.0 7.2

Oil delivery pipe 1 (M10) M10 × 1.25 1 20 2.0 14

Oil delivery pipe 1 (M8) M8 × 1.25 2 18 1.8 13

Oil hose M6 × 1.0 2 8 0.8 5.8

△ Oil hose clamp —2 2 0.2 1.4

Oil strainer (oil tank) M6 × 1.0 1 9 0.9 6.5

Oil tank drain bolt M8 × 1.25 1 18 1.8 13

Oil tank (upper) M6 × 1.0 1 7 0.7 5.1

Oil tank and frame M6 × 1.0 3 9 0.9 6.5

Oil pressure check bolt M6 × 1.0 1 10 1.0 7.2

Carburetor joint M6 × 1.0 2 10 1.0 7.2

Carburetor joint clamp M4 × 0.7 2 3 0.3 2.2

Air filter joint clamp M6 × 1.0 1 3 0.3 2.2

Throttle cable adjust bolt and locknut M6 × 0.75 1 4 0.4 2.9

Throttle cable (pull) M6 × 1.0 1 4 0.4 2.9

Page 64 of 232

3-5

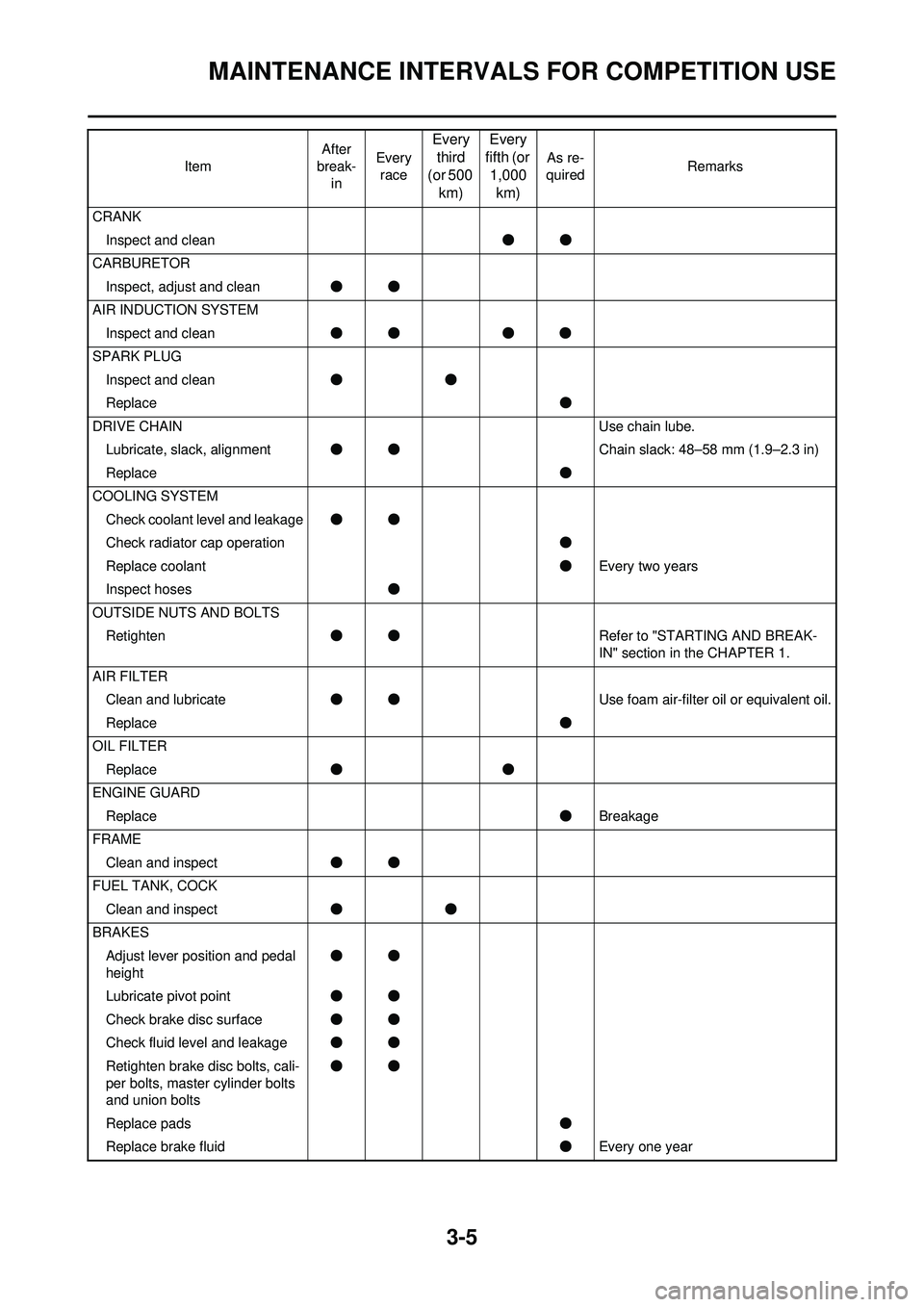

MAINTENANCE INTERVALS FOR COMPETITION USE

CRANKInspect and clean ●●

CARBURETOR Inspect, adjust and clean ●●

AIR INDUCTION SYSTEM Inspect and clean ●● ●●

SPARK PLUG Inspect and clean ●●

Replace ●

DRIVE CHAIN Use chain lube.

Lubricate, slack, alignment ●● Chain slack: 48–58 mm (1.9–2.3 in)

Replace ●

COOLING SYSTEM Check coolant level and leakage ●●

Check radiator cap operation ●

Replace coolant ●Every two years

Inspect hoses ●

OUTSIDE NUTS AND BOLTS Retighten ●● Refer to "STARTING AND BREAK-

IN" section in the CHAPTER 1.

AIR FILTER Clean and lubricate ●● Use foam air-filter oil or equivalent oil.

Replace ●

OIL FILTER Replace ●●

ENGINE GUARD Replace ●Breakage

FRAME Clean and inspect ●●

FUEL TANK, COCK Clean and inspect ●●

BRAKES Adjust lever position and pedal

height ●●

Lubricate pivot point ●●

Check brake disc surface ●●

Check fluid level and leakage ●●

Retighten brake disc bolts, cali-

per bolts, master cylinder bolts

and union bolts ●●

Replace pads ●

Replace brake fluid ●Every one year

Item

After

break- in Every

race

Every third

(or 500 km) Every

fifth (or

1,000 km)

As re-

quired Remarks

Page 66 of 232

3-7

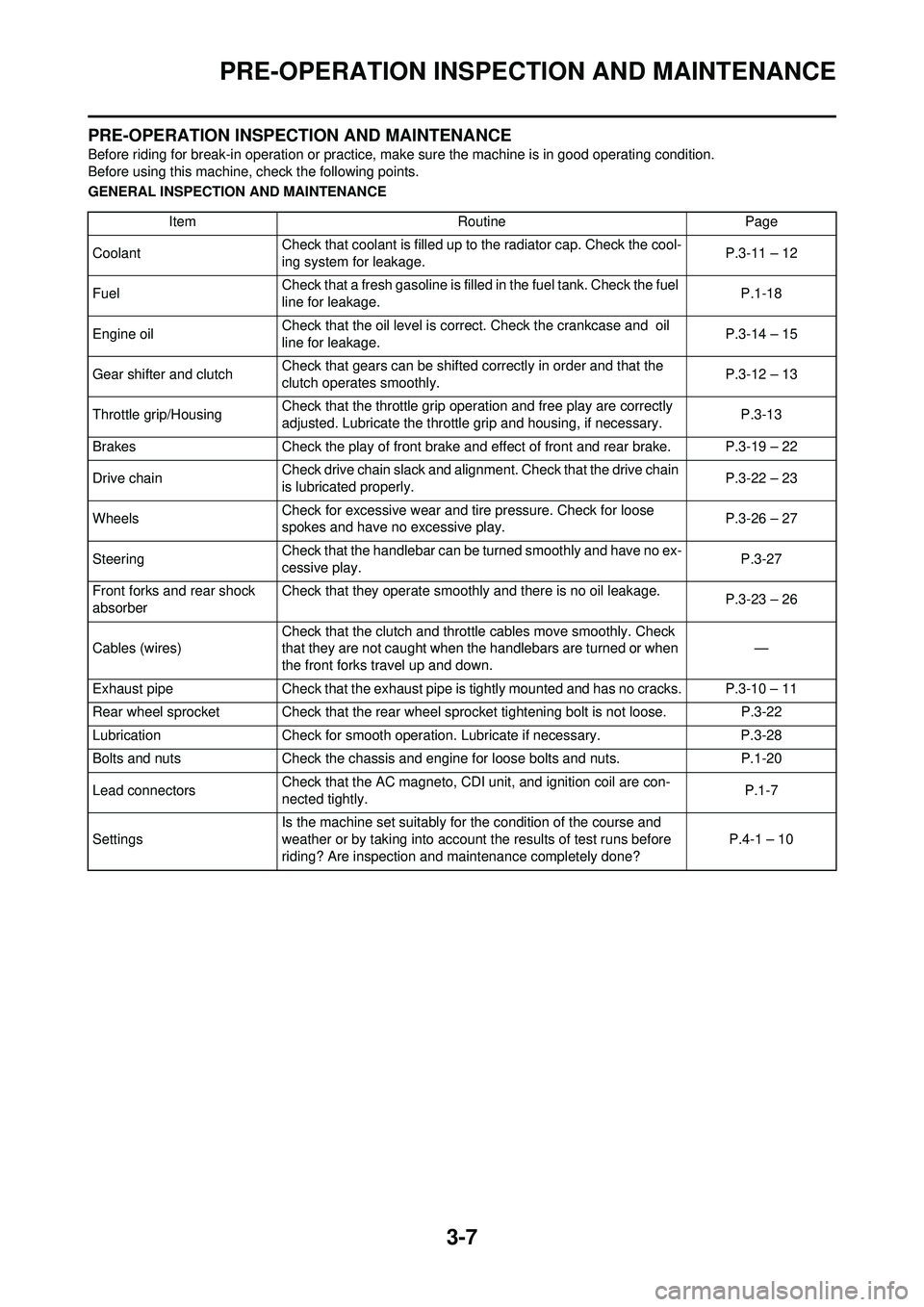

PRE-OPERATION INSPECTION AND MAINTENANCE

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation or practice, make sure the machine is in good operating condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCEItem RoutinePage

Coolant Check that coolant is filled up to the radiator cap. Check the cool-

ing system for leakage. P.3-11 – 12

Fuel Check that a fresh gasoline is filled in the fuel tank. Check the fuel

line for leakage.

P.1-18

Engine oil Check that the oil level is corre

ct. Check the crankcase and oil

line for leakage. P.3-14 – 15

Gear shifter and clutch Check that gears can be shifted correctly in order and that the

clutch operates smoothly. P.3-12 – 13

Throttle grip/Housing Check that the throttle grip operation and free play are correctly

adjusted. Lubricate the throttle grip and housing, if necessary.

P.3-13

Brakes Check the play of front brake and ef fect of front and rear brake. P.3-19 – 22

Drive chain Check drive chain slack and alignment. Check that the drive chain

is lubricated properly. P.3-22 – 23

Wheels Check for excessive wear and ti

re pressure. Check for loose

spokes and have no excessive play. P.3-26 – 27

Steering Check that the handlebar can be turned smoothly and have no ex-

cessive play.

P.3-27

Front forks and rear shock

absorber Check that they operate smoothly and there is no oil leakage.

P.3-23 – 26

Cables (wires) Check that the clutch and throttle cables move smoothly. Check

that they are not caught when the handlebars are turned or when

the front forks travel up and down. —

Exhaust pipe Check that the exhaust pipe is tightly mount ed and has no cracks. P.3-10 – 11

Rear wheel sprocket Check that the rear wheel sprocket tightening bolt is not loose. P.3-22

Lubrication Check for smooth operation. Lubricate if necessary. P.3-28

Bolts and nuts Check the chassis and engine for loose bolts and nuts. P.1-20

Lead connectors Check that the AC magneto, CDI unit, and ignition coil are con-

nected tightly. P.1-7

Settings Is the machine set suitably for the condition of the course and

weather or by taking into account the results of test runs before

riding? Are inspection and maintenance completely done? P.4-1 – 10

Page 70 of 232

3-11

ENGINE

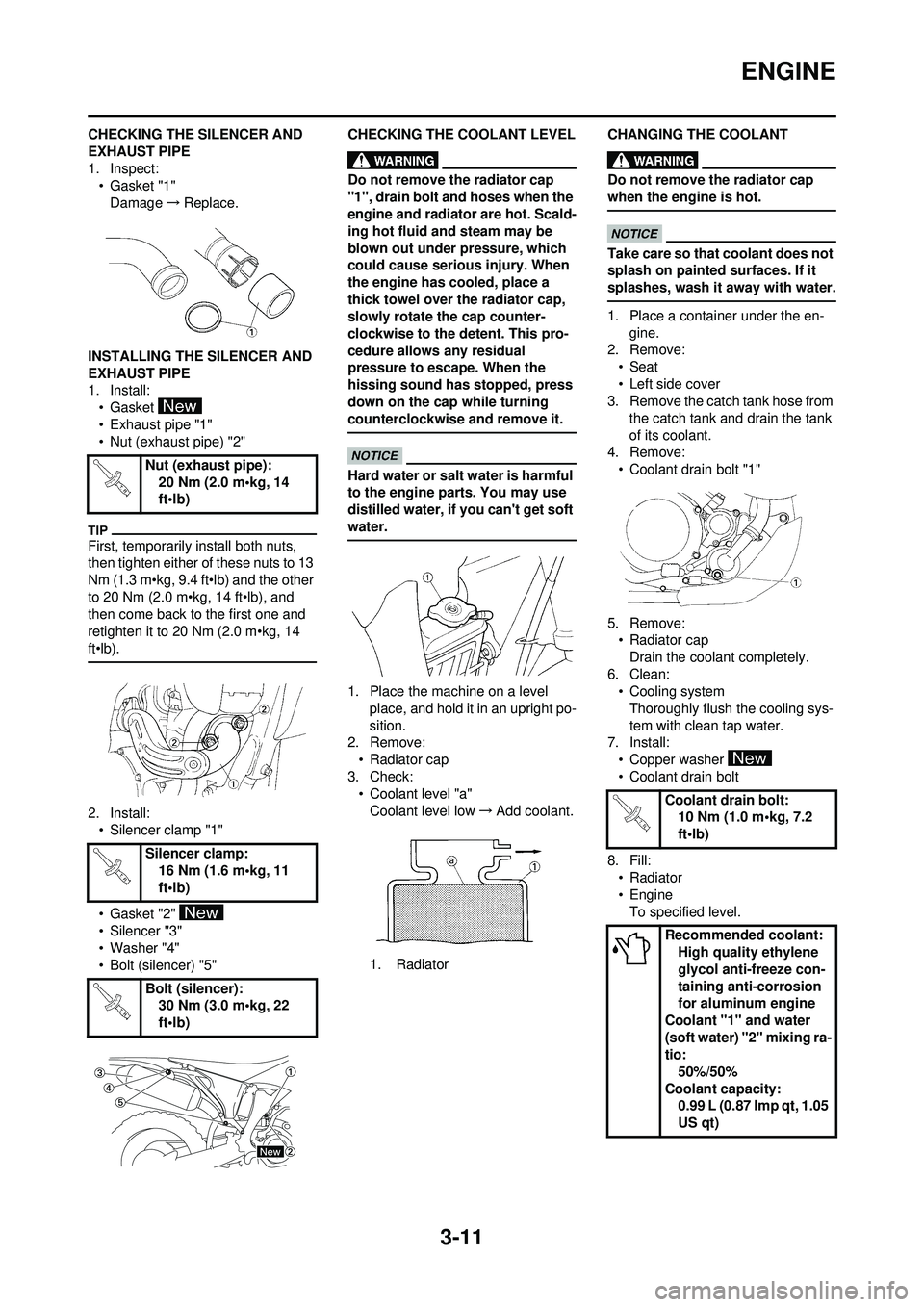

CHECKING THE SILENCER AND

EXHAUST PIPE

1. Inspect:• Gasket "1"

Damage →Replace.

INSTALLING THE SILENCER AND

EXHAUST PIPE

1. Install: • Gasket

• Exhaust pipe "1"

• Nut (exhaust pipe) "2"

First, temporarily install both nuts,

then tighten either of these nuts to 13

Nm (1.3 m•kg, 9.4 ft•lb) and the other

to 20 Nm (2.0 m•kg, 14 ft•lb), and

then come back to the first one and

retighten it to 20 Nm (2.0 m•kg, 14

ft•lb).

2. Install: • Silencer clamp "1"

• Gasket "2"

• Silencer "3"

• Washer "4"

• Bolt (silencer) "5" CHECKING THE COOLANT LEVEL

Do not remove the radiator cap

"1", drain bolt and hoses when the

engine and radiator are hot. Scald-

ing hot fluid and steam may be

blown out under pressure, which

could cause serious injury. When

the engine has cooled, place a

thick towel over the radiator cap,

slowly rotate the cap counter-

clockwise to the detent. This pro-

cedure allows any residual

pressure to escape. When the

hissing sound has stopped, press

down on the cap while turning

counterclockwise and remove it.

Hard water or salt water is harmful

to the engine parts. You may use

distilled water, if you can't get soft

water.

1. Place the machine on a level

place, and hold it in an upright po-

sition.

2. Remove: • Radiator cap

3. Check: • Coolant level "a"Coolant level low →Add coolant.

1. Radiator CHANGING THE COOLANT

Do not remove the radiator cap

when the engine is hot.

Take care so that coolant does not

splash on painted surfaces. If it

splashes, wash it away with water.

1. Place a container under the en-

gine.

2. Remove:

• Seat

• Left side cover

3. Remove the catch tank hose from

the catch tank and drain the tank

of its coolant.

4. Remove:

• Coolant drain bolt "1"

5. Remove: • Radiator capDrain the coolant completely.

6. Clean: • Cooling systemThoroughly flush the cooling sys-

tem with clean tap water.

7. Install: • Copper washer

• Coolant drain bolt

8. Fill: •Radiator

• Engine

To specified level.

Nut (exhaust pipe):

20 Nm (2.0 m•kg, 14

ft•lb)

Silencer clamp: 16 Nm (1.6 m•kg, 11

ft•lb)

Bolt (silencer): 30 Nm (3.0 m•kg, 22

ft•lb)

Coolant drain bolt:10 Nm (1.0 m•kg, 7.2

ft•lb)

Recommended coolant: High quality ethylene

glycol anti-freeze con-

taining anti-corrosion

for aluminum engine

Coolant "1" and water

(soft water) "2" mixing ra-

tio: 50%/50%

Coolant capacity: 0.99 L (0.87 Imp qt, 1.05

US qt)

Page 71 of 232

3-12

ENGINE

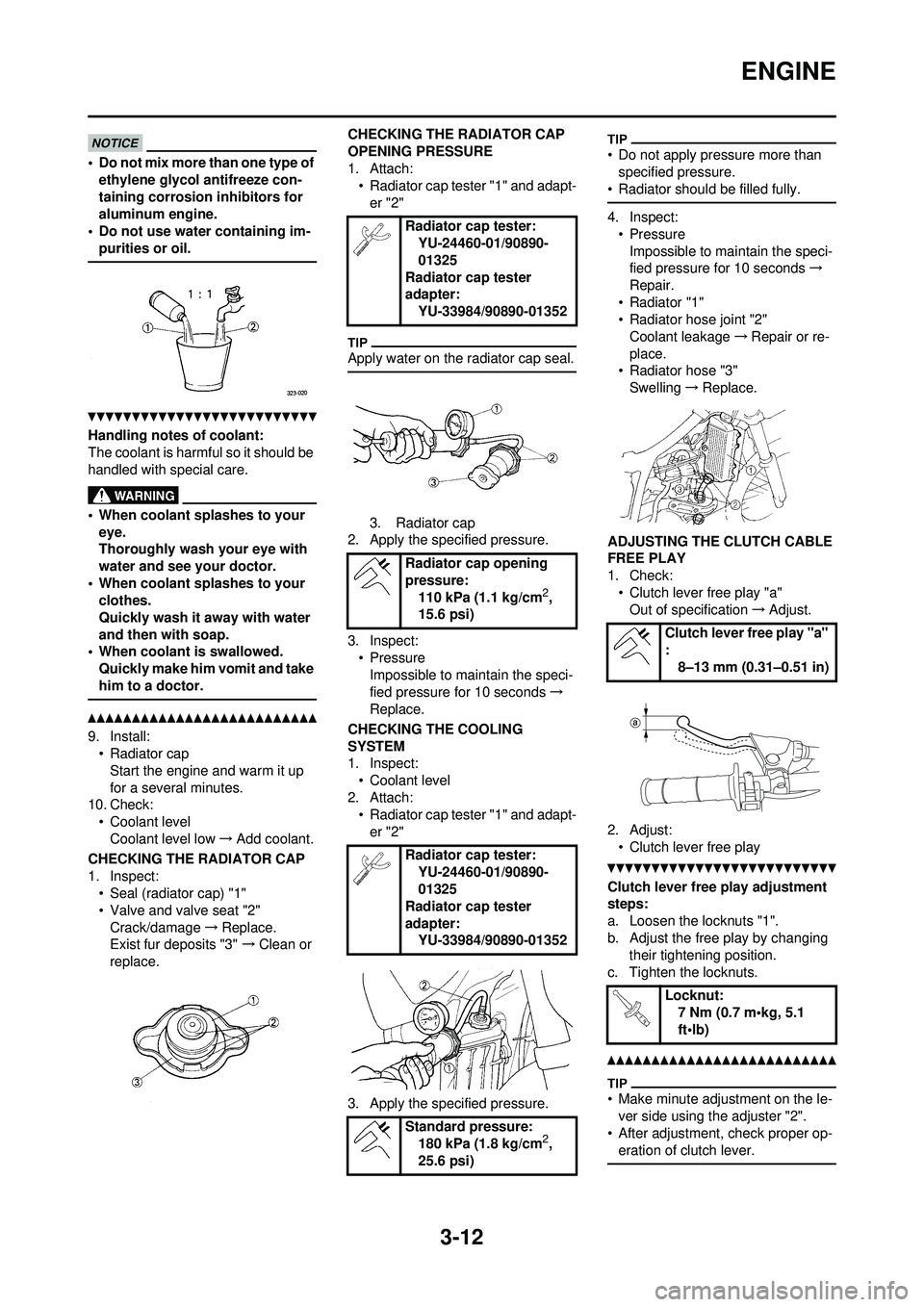

• Do not mix more than one type of ethylene glycol antifreeze con-

taining corrosion inhibitors for

aluminum engine.

• Do not use water containing im-

purities or oil.

Handling notes of coolant:

The coolant is harmful so it should be

handled with special care.

• When coolant splashes to your eye.

Thoroughly wash your eye with

water and see your doctor.

• When coolant splashes to your clothes.

Quickly wash it away with water

and then with soap.

• When coolant is swallowed. Quickly make him vomit and take

him to a doctor.

9. Install:• Radiator cap

Start the engine and warm it up

for a several minutes.

10. Check:

• Coolant levelCoolant level low →Add coolant.

CHECKING THE RADIATOR CAP

1. Inspect: • Seal (radiator cap) "1"

• Valve and valve seat "2"Crack/damage →Replace.

Exist fur deposits "3" →Clean or

replace. CHECKING THE RADIATOR CAP

OPENING PRESSURE

1. Attach:

• Radiator cap tester "1" and adapt-

er "2"

Apply water on the radiator cap seal.

3. Radiator cap

2. Apply the specified pressure.

3. Inspect:

•PressureImpossible to maintain the speci-

fied pressure for 10 seconds →

Replace.

CHECKING THE COOLING

SYSTEM

1. Inspect: • Coolant level

2. Attach: • Radiator cap tester "1" and adapt-

er "2"

3. Apply the specified pressure.

• Do not apply pressure more than specified pressure.

• Radiator should be filled fully.

4. Inspect: • PressureImpossible to maintain the speci-

fied pressure for 10 seconds →

Repair.

•Radiator "1"

• Radiator hose joint "2"

Coolant leakage →Repair or re-

place.

• Radiator hose "3"

Swelling →Replace.

ADJUSTING THE CLUTCH CABLE

FREE PLAY

1. Check: • Clutch lever free play "a"Out of specification →Adjust.

2. Adjust: • Clutch lever free play

Clutch lever free play adjustment

steps:

a. Loosen the locknuts "1".

b. Adjust the free play by changing their tightening position.

c. Tighten the locknuts.

• Make minute adjustment on the le- ver side using the adjuster "2".

• After adjustment, check proper op- eration of clutch lever.

Radiator cap tester: YU-24460-01/90890-

01325

Radiator cap tester

adapter: YU-33984/90890-01352

Radiator cap opening

pressure: 110 kPa (1.1 kg/cm

2,

15.6 psi)

Radiator cap tester: YU-24460-01/90890-

01325

Radiator cap tester

adapter: YU-33984/90890-01352

Standard pressure: 180 kPa (1.8 kg/cm

2,

25.6 psi)

Clutch lever free play "a"

: 8–13 mm (0.31–0.51 in)

Locknut: 7 Nm (0.7 m•kg, 5.1

ft•lb)

Page 75 of 232

3-16

ENGINE

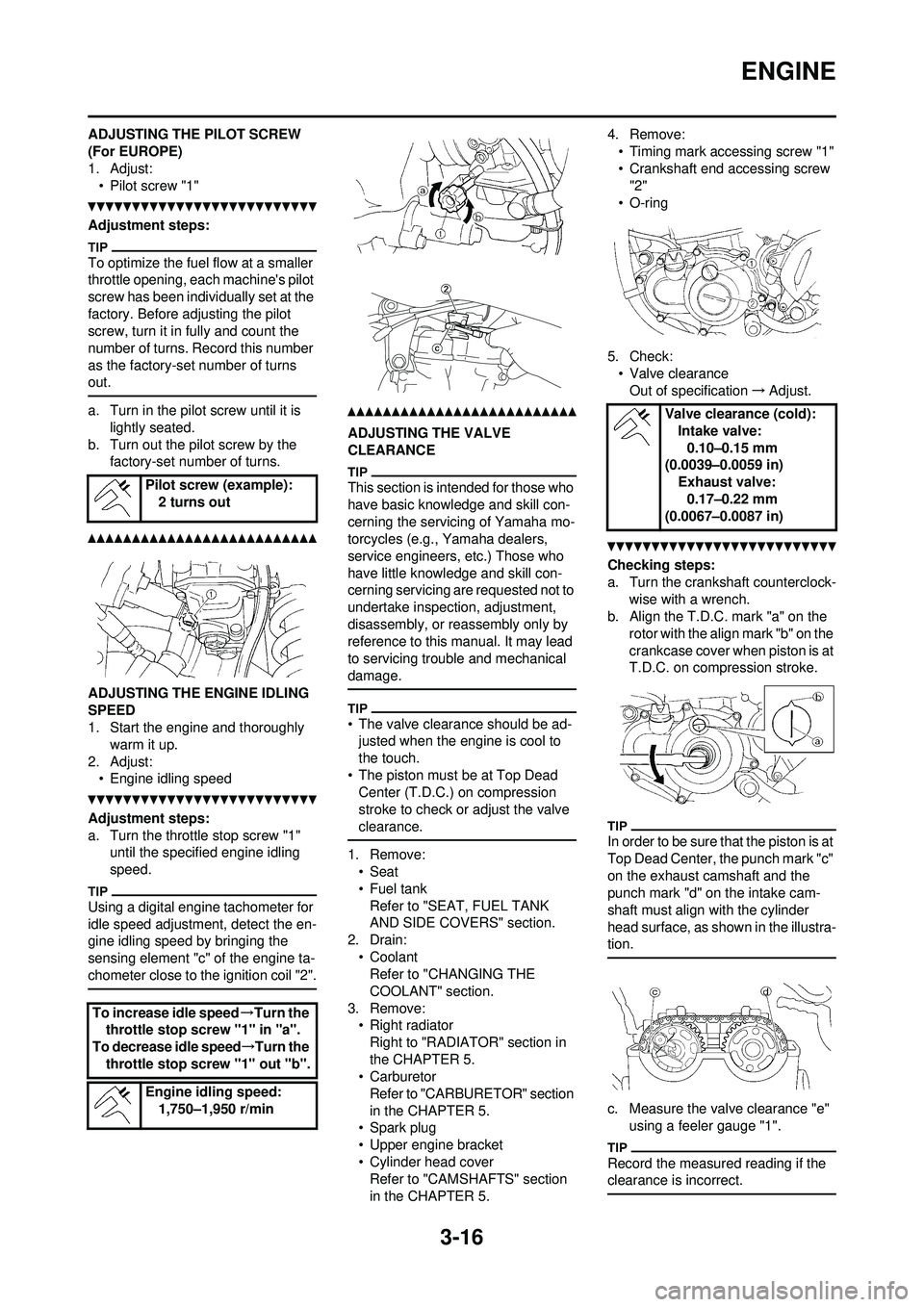

ADJUSTING THE PILOT SCREW

(For EUROPE)

1. Adjust:• Pilot screw "1"

Adjustment steps:

To optimize the fuel flow at a smaller

throttle opening, each machine's pilot

screw has been individually set at the

factory. Before adjusting the pilot

screw, turn it in fully and count the

number of turns. Record this number

as the factory-set number of turns

out.

a. Turn in the pilot screw until it is lightly seated.

b. Turn out the pilot screw by the factory-set number of turns.

ADJUSTING THE ENGINE IDLING

SPEED

1. Start the engine and thoroughly warm it up.

2. Adjust: • Engine idling speed

Adjustment steps:

a. Turn the throttle stop screw "1" until the specified engine idling

speed.

Using a digital engine tachometer for

idle speed adjustment, detect the en-

gine idling speed by bringing the

sensing element "c" of the engine ta-

chometer close to the ignition coil "2".

ADJUSTING THE VALVE

CLEARANCE

This section is intended for those who

have basic knowledge and skill con-

cerning the servicing of Yamaha mo-

torcycles (e.g., Yamaha dealers,

service engineers, etc.) Those who

have little knowledge and skill con-

cerning servicing are requested not to

undertake inspection, adjustment,

disassembly, or reassembly only by

reference to this manual. It may lead

to servicing trouble and mechanical

damage.

• The valve clearance should be ad-justed when the engine is cool to

the touch.

• The piston must be at Top Dead Center (T.D.C.) on compression

stroke to check or adjust the valve

clearance.

1. Remove:•Seat

•Fuel tank

Refer to "SEAT, FUEL TANK

AND SIDE COVERS" section.

2. Drain:

• CoolantRefer to "CHANGING THE

COOLANT" section.

3. Remove: • Right radiatorRight to "RADIATOR" section in

the CHAPTER 5.

• Carburetor Refer to "CARBU RETOR" section

in the CHAPTER 5.

• Spark plug

• Upper engine bracket

• Cylinder head cover Refer to "CAMSHAFTS" section

in the CHAPTER 5. 4. Remove:

• Timing mark accessing screw "1"

• Crankshaft end accessing screw "2"

• O-ring

5. Check: • Valve clearanceOut of specification →Adjust.

Checking steps:

a. Turn the crankshaft counterclock-

wise with a wrench.

b. Align the T.D.C. mark "a" on the

rotor with the align mark "b" on the

crankcase cover when piston is at

T.D.C. on compression stroke.

In order to be sure t hat the piston is at

Top Dead Center, the punch mark "c"

on the exhaust camshaft and the

punch mark "d" on the intake cam-

shaft must align with the cylinder

head surface, as shown in the illustra-

tion.

c. Measure the valve clearance "e" using a feeler gauge "1".

Record the measured reading if the

clearance is incorrect.

Pilot screw (example):2 turns out

To increase idle speed →Turn the

throttle stop screw "1" in "a".

To decrease idle speed →Turn the

throttle stop screw "1" out "b".

Engine idling speed:1,750–1,950 r/min

Valve clearance (cold):

Intake valve:0.10–0.15 mm

(0.0039–0.0059 in)

Exhaust valve:0.17–0.22 mm

(0.0067–0.0087 in)

Page 104 of 232

5-1

RADIATOR

ENGINE

This section is intended for those who have basic knowledge and skill concerning the servicing of Yamaha motorcycles

(e.g., Yamaha dealers, service engineers, etc.) Those who have little knowledge and skill concerning servicing are request-

ed not to undertake inspection, adjustment, disassembly, or reassembly only by reference to this manual. It may lead to

servicing trouble and mechanical damage.

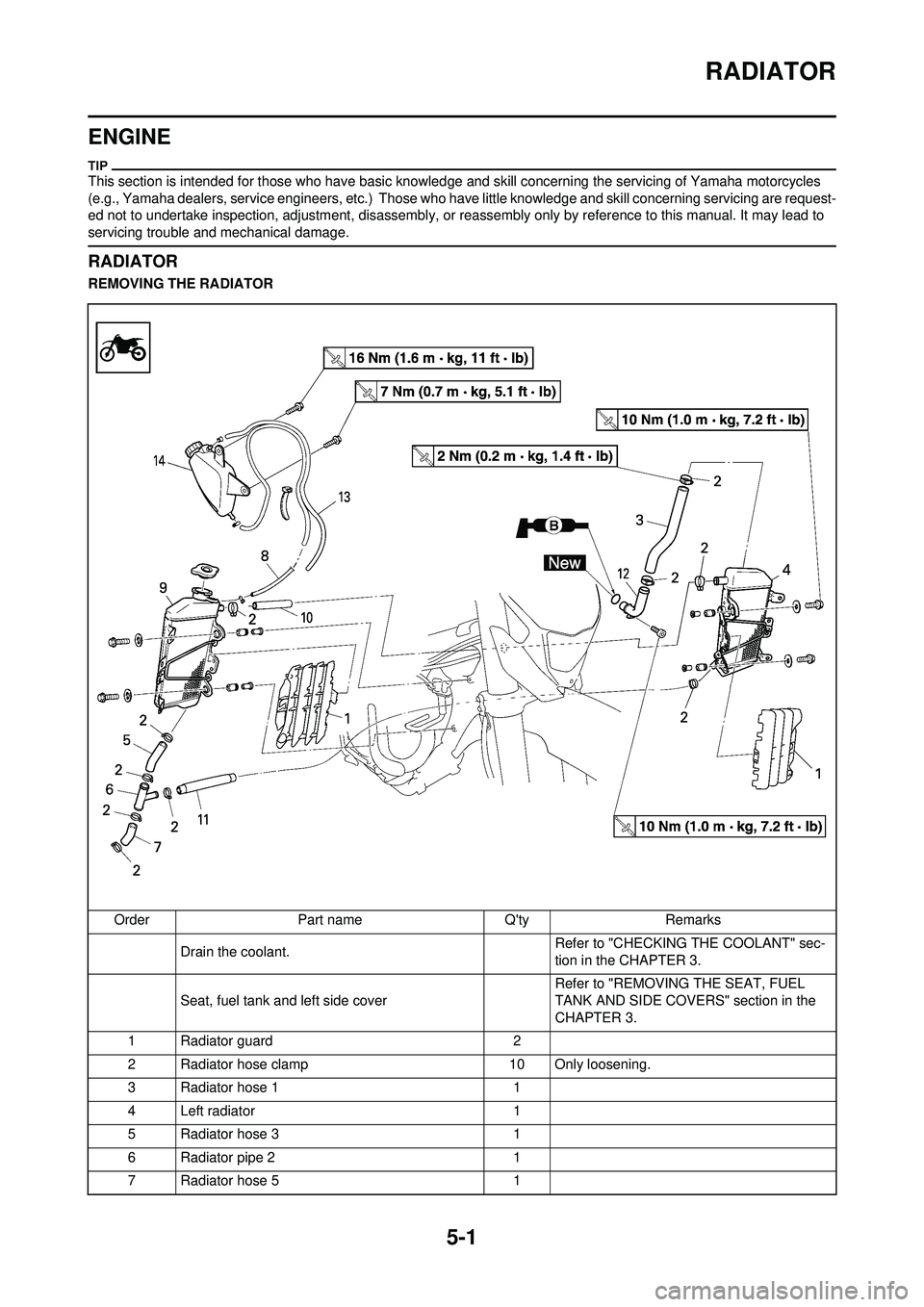

RADIATOR

REMOVING THE RADIATOR

Order Part name Q'ty Remarks Drain the coolant. Refer to "CHECKING THE COOLANT" sec-

tion in the CHAPTER 3.

Seat, fuel tank and left side cover Refer to "REMOVING THE SEAT, FUEL

TANK AND SIDE COVERS" section in the

CHAPTER 3.

1 Radiator guard 2

2 Radiator hose clamp 10 Only loosening.

3 Radiator hose 1 1

4 Left radiator 1

5 Radiator hose 3 1

6 Radiator pipe 2 1

7 Radiator hose 5 1