sensor YAMAHA WR 250F 2010 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2010, Model line: WR 250F, Model: YAMAHA WR 250F 2010Pages: 232, PDF Size: 13.94 MB

Page 10 of 232

CONTENTS

CHAPTER 1

GENERAL INFOR-

MATION

LOCATION OF

IMPORTANT LABELS ..... 1-1

DESCRIPTION ................. 1-5

CONSUMER

INFORMATION................. 1-6

INCLUDED PARTS .......... 1-6

IMPORTANT

INFORMATION................. 1-6

CHECKING OF

CONNECTION .................. 1-7

SPECIAL TOOLS ............. 1-8

CONTROL FUNCTIONS.. 1-12

MULTI-FUNCTION

DISPLAY ........................ 1-13

STARTING AND

BREAK-IN ...................... 1-18

TORQUE-CHECK

POINTS........................... 1-20

CLEANING AND

STORAGE ...................... 1-21

CHAPTER 2

SPECIFICATIONS

GENERAL

SPECIFICATIONS ............ 2-1

MAINTENANCE

SPECIFICATIONS ............ 2-3

TIGHTENING

TORQUES ...................... 2-12

LUBRICATION

DIAGRAMS .................... 2-19

CABLE ROUTING

DIAGRAM ....................... 2-21

CHAPTER 3

REGULAR INSPEC-

TION AND AD-JUSTMENTS

PERIODIC MAINTENANCE

CHART FOR THE EMISSION

CONTROL SYSTEM (For

Canada) ............................ 3-1

GENERAL MAINTENANCE

AND LUBRICATION CHART

(For Canada) .................... 3-2

MAINTENANCE INTER-

VALS FOR COMPETITION

USE ................................... 3-3

PRE-OPERATION

INSPECTION AND

MAINTENANCE................ 3-7

ENGINE ............................ 3-8

CHASSIS ........................ 3-19

ELECTRICAL ................. 3-29

CHAPTER 4 TUNING

ENGINE

(Except for Canada) ........ 4-1

CHASSIS .......................... 4-5

CHAPTER 5

ENGINE

RADIATOR ....................... 5-1

CARBURETOR................. 5-4

AIR INDICTOIN

SYSTEM ......................... 5-12

CAMSHAFTS.................. 5-14

CYLINDER HEAD........... 5-19

VALVES AND VALVE

SPRINGS ........................ 5-21

CYLINDER AND

PISTON ........................... 5-25

CLUTCH ......................... 5-29 OIL FILTER ELEMENT

AND WATER PUMP .......5-34

BALANCER ....................5-39

OIL PUMP .......................5-41

KICK SHAFT AND SHIFT

SHAFT ............................5-44

AC MAGNETO AND

STARTER CLUTCH........5-49

ENGINE REMOVAL........5-54

CRANKCASE AND

CRANKSHAFT ...............5-58

TRANSMISSION,

SHIFT CAM AND

SHIFT FORK ...................5-64

CHAPTER 6

CHASSIS

FRONT WHEEL AND

REAR WHEEL ..................6-1

FRONT BRAKE AND

REAR BRAKE ..................6-6

FRONT FORK .................6-16

HANDLEBAR..................6-23

STEERING ......................6-27

SWINGARM ....................6-31

REAR SHOCK

ABSORBER ....................6-36

CHAPTER 7

ELECTRICAL

ELECTRICAL COMPO-

NENTS AND WIRING

DIAGRAM .........................7-1

IGNITION SYSTEM...........7-3

ELECTRIC STARTING

SYSTEM............................7-5

CHARGING SYSTEM .....7-13

THROTTLE POSITION

SENSOR SYSTEM .........7-15

LIGHTING SYSTEM .......7-18

SIGNALING SYSTEM.....7-20

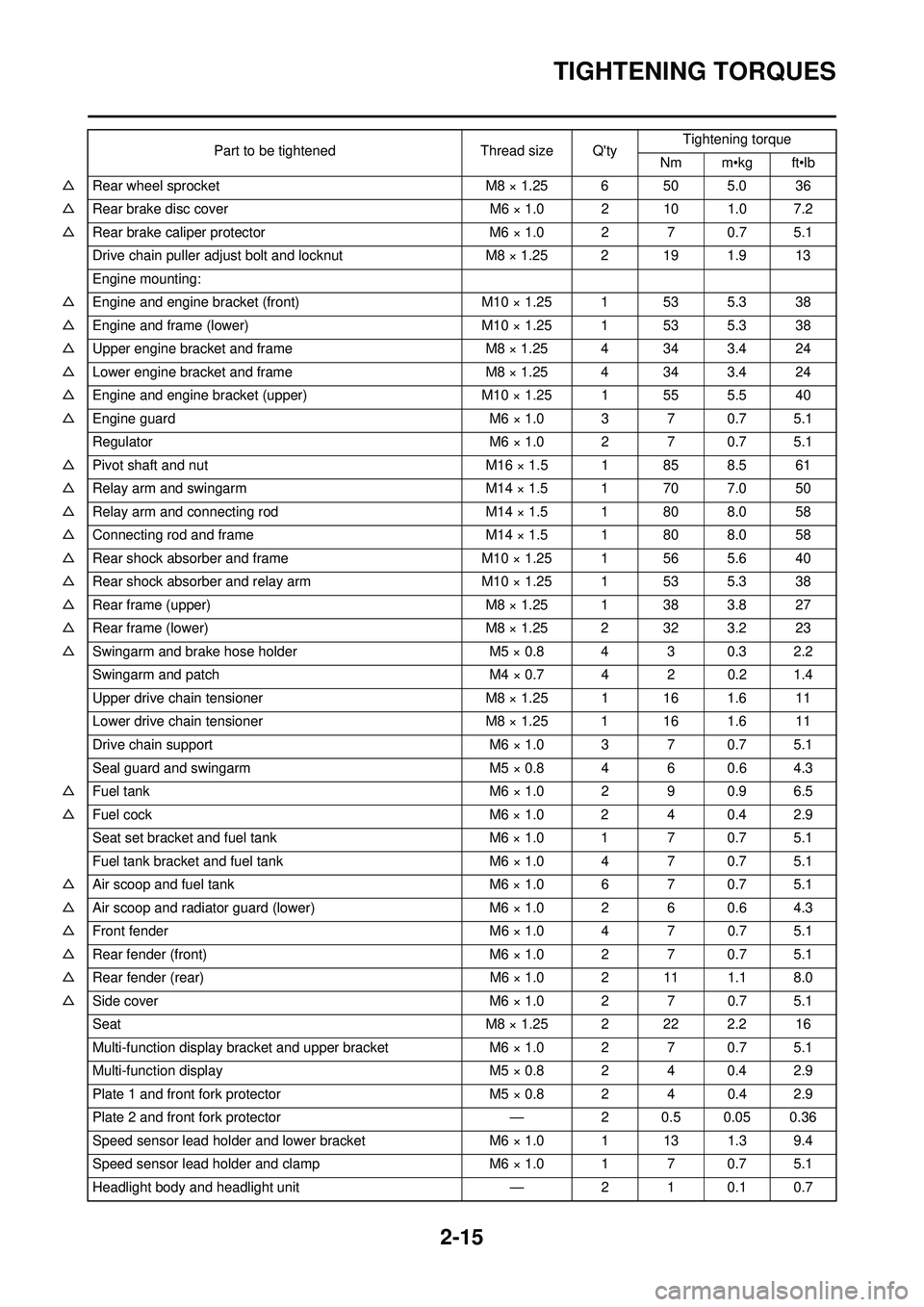

Page 46 of 232

2-15

TIGHTENING TORQUES

△Rear wheel sprocket M8 × 1.25 6 50 5.0 36

△ Rear brake disc cover M6 × 1.0 2 10 1.0 7.2

△ Rear brake caliper protector M6 × 1.0 2 7 0.7 5.1

Drive chain puller adjust bolt and locknut M8 × 1.25 2 19 1.9 13

Engine mounting:

△ Engine and engine bracket (front) M10 × 1.25 1 53 5.3 38

△ Engine and frame (lower) M10 × 1.25 1 53 5.3 38

△ Upper engine bracket and frame M8 × 1.25 4 34 3.4 24

△ Lower engine bracket and frame M8 × 1.25 4 34 3.4 24

△ Engine and engine bracket (upper) M10 × 1.25 1 55 5.5 40

△ Engine guard M6 × 1.0 3 7 0.7 5.1

Regulator M6 × 1.0 2 7 0.7 5.1

△ Pivot shaft and nut M16 × 1.5 1 85 8.5 61

△ Relay arm and swingarm M14 × 1.5 1 70 7.0 50

△ Relay arm and connecting rod M14 × 1.5 1 80 8.0 58

△ Connecting rod and frame M14 × 1.5 1 80 8.0 58

△ Rear shock absorber and frame M10 × 1.25 1 56 5.6 40

△ Rear shock absorber and relay arm M10 × 1.25 1 53 5.3 38

△ Rear frame (upper) M8 × 1.25 1 38 3.8 27

△ Rear frame (lower) M8 × 1.25 2 32 3.2 23

△ Swingarm and brake hose holder M5 × 0.8 4 3 0.3 2.2

Swingarm and patch M4 × 0.7 4 2 0.2 1.4

Upper drive chain tensioner M8 × 1.25 1 16 1.6 11

Lower drive chain tensioner M8 × 1.25 1 16 1.6 11

Drive chain support M6 × 1.0 3 7 0.7 5.1

Seal guard and swingarm M5 × 0.8 4 6 0.6 4.3

△ Fuel tank M6 × 1.0 2 9 0.9 6.5

△ Fuel cock M6 × 1.0 2 4 0.4 2.9

Seat set bracket and fuel tank M6 × 1.0 1 7 0.7 5.1

Fuel tank bracket and fuel tank M6 × 1.0 4 7 0.7 5.1

△ Air scoop and fuel tank M6 × 1.0 6 7 0.7 5.1

△ Air scoop and radiator guard (lower) M6 × 1.0 2 6 0.6 4.3

△ Front fender M6 × 1.0 4 7 0.7 5.1

△ Rear fender (front) M6 × 1.0 2 7 0.7 5.1

△ Rear fender (rear) M6 × 1.0 2 11 1.1 8.0

△ Side cover M6 × 1.0 2 7 0.7 5.1

Seat M8 × 1.25 2 22 2.2 16

Multi-function display bracket and upper bracket M6 × 1.0 2 7 0.7 5.1

Multi-function display M5 × 0.8 2 4 0.4 2.9

Plate 1 and front fork protector M5 × 0.8 2 4 0.4 2.9

Plate 2 and front fork protector —2 0.5 0.05 0.36

Speed sensor lead holder and lower bracket M6 × 1.0 1 13 1.3 9.4

Speed sensor lead holder and clamp M6 × 1.0 1 7 0.7 5.1

Headlight body and headlight unit —2 1 0.1 0.7

Part to be tightened

Thread size Q'tyTightening torque

Nm m•kg ft•lb

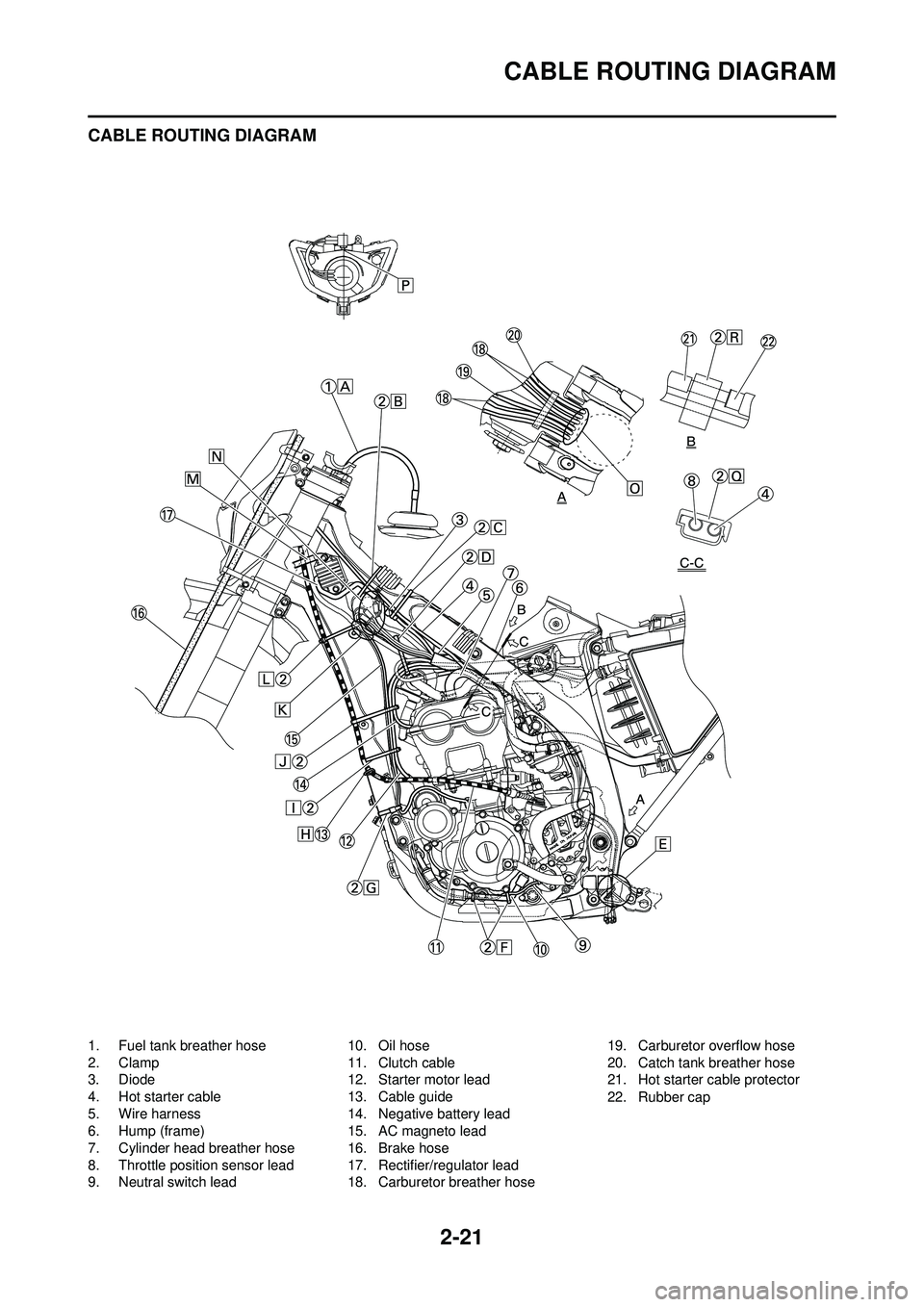

Page 52 of 232

2-21

CABLE ROUTING DIAGRAM

CABLE ROUTING DIAGRAM

1. Fuel tank breather hose

2. Clamp

3. Diode

4. Hot starter cable

5. Wire harness

6. Hump (frame)

7. Cylinder head breather hose

8. Throttle position sensor lead

9. Neutral switch lead10. Oil hose

11. Clutch cable

12. Starter motor lead

13. Cable guide

14. Negative battery lead

15. AC magneto lead

16. Brake hose

17. Rectifier/regulator lead

18. Carburetor breather hose 19. Carburetor overflow hose

20. Catch tank breather hose

21. Hot starter cable protector

22. Rubber cap

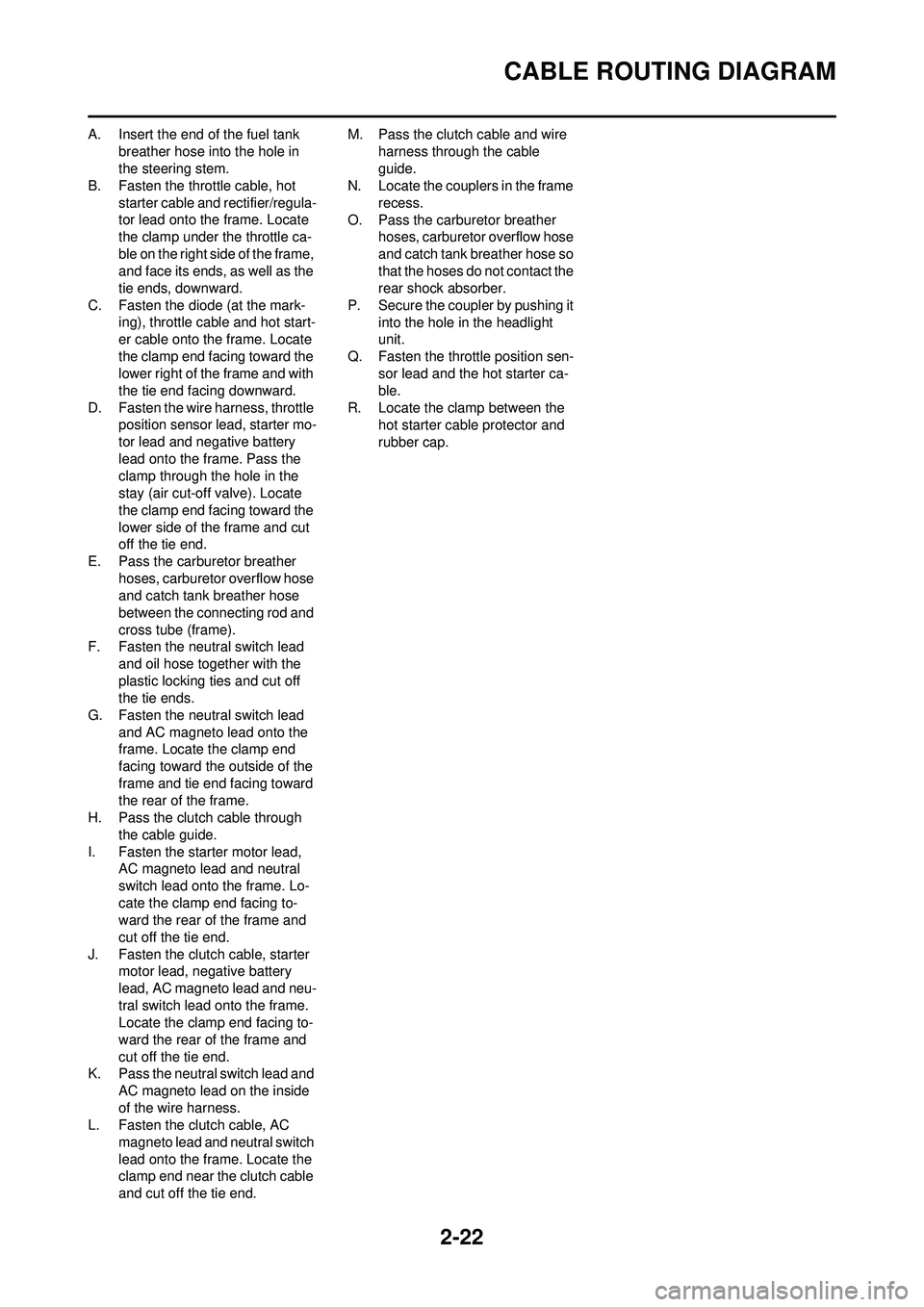

Page 53 of 232

2-22

CABLE ROUTING DIAGRAM

A. Insert the end of the fuel tank breather hose into the hole in

the steering stem.

B. Fasten the throttle cable, hot

starter cable and rectifier/regula-

tor lead onto the frame. Locate

the clamp under the throttle ca-

ble on the right side of the frame,

and face its ends, as well as the

tie ends, downward.

C. Fasten the diode (at the mark- ing), throttle cable and hot start-

er cable onto the frame. Locate

the clamp end facing toward the

lower right of the frame and with

the tie end facing downward.

D. Fasten the wire harness, throttle position sensor lead, starter mo-

tor lead and negative battery

lead onto the frame. Pass the

clamp through the hole in the

stay (air cut-off valve). Locate

the clamp end facing toward the

lower side of the frame and cut

off the tie end.

E. Pass the carburetor breather hoses, carburetor overflow hose

and catch tank breather hose

between the connecting rod and

cross tube (frame).

F. Fasten the neutral switch lead

and oil hose together with the

plastic locking ties and cut off

the tie ends.

G. Fasten the neutral switch lead and AC magneto lead onto the

frame. Locate the clamp end

facing toward the outside of the

frame and tie end facing toward

the rear of the frame.

H. Pass the clutch cable through the cable guide.

I. Fasten the starter motor lead, AC magneto lead and neutral

switch lead onto the frame. Lo-

cate the clamp end facing to-

ward the rear of the frame and

cut off the tie end.

J. Fasten the clutch cable, starter motor lead, negative battery

lead, AC magneto lead and neu-

tral switch lead onto the frame.

Locate the clamp end facing to-

ward the rear of the frame and

cut off the tie end.

K. Pass the neutral switch lead and AC magneto lead on the inside

of the wire harness.

L. Fasten the clutch cable, AC magneto lead and neutral switch

lead onto the frame. Locate the

clamp end near the clutch cable

and cut off the tie end. M. Pass the clutch cable and wire

harness through the cable

guide.

N. Locate the couplers in the frame

recess.

O. Pass the carburetor breather hoses, carburetor overflow hose

and catch tank breather hose so

that the hoses do not contact the

rear shock absorber.

P. Secure the coupler by pushing it into the hole in the headlight

unit.

Q. Fasten the throttle position sen- sor lead and the hot starter ca-

ble.

R. Locate the clamp between the hot starter cable protector and

rubber cap.

Page 58 of 232

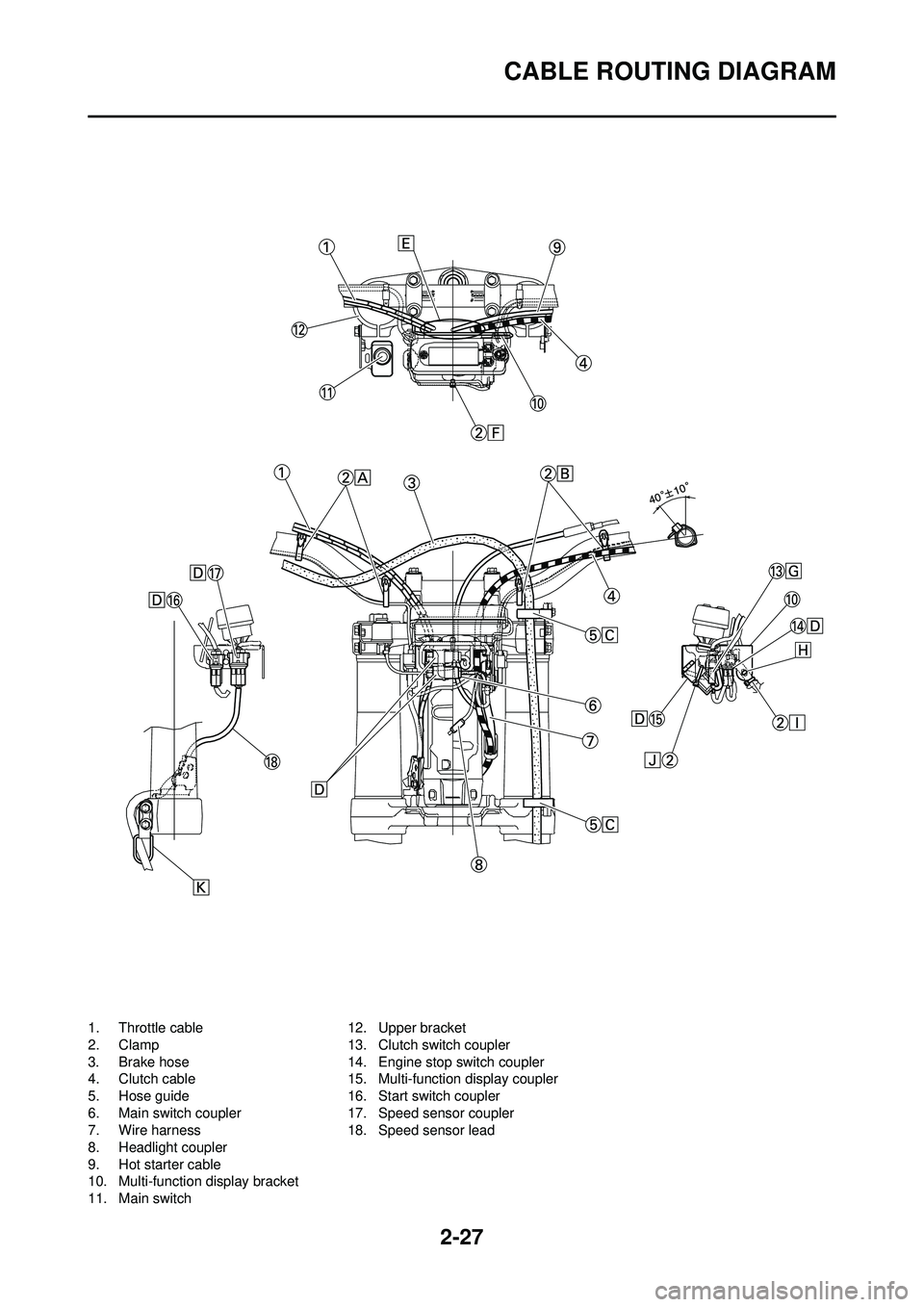

2-27

CABLE ROUTING DIAGRAM

1. Throttle cable

2. Clamp

3. Brake hose

4. Clutch cable

5. Hose guide

6. Main switch coupler

7. Wire harness

8. Headlight coupler

9. Hot starter cable

10. Multi-function display bracket

11. Main switch12. Upper bracket

13. Clutch switch coupler

14. Engine stop switch coupler

15. Multi-function display coupler

16. Start switch coupler

17. Speed sensor coupler

18. Speed sensor lead

Page 59 of 232

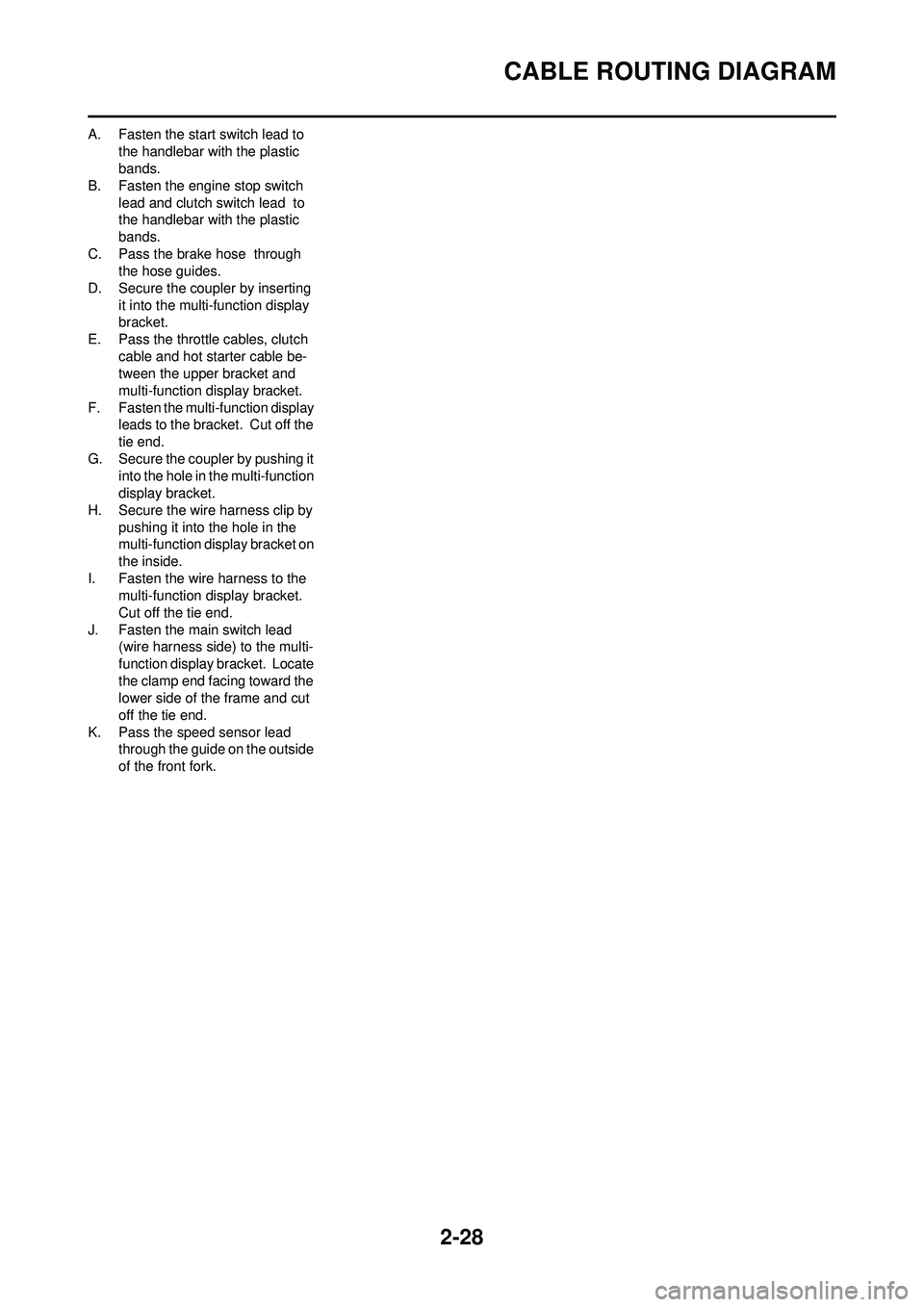

2-28

CABLE ROUTING DIAGRAM

A. Fasten the start switch lead to the handlebar with the plastic

bands.

B. Fasten the engine stop switch

lead and clutch switch lead to

the handlebar with the plastic

bands.

C. Pass the brake hose through the hose guides.

D. Secure the coupler by inserting

it into the multi-function display

bracket.

E. Pass the throttle cables, clutch

cable and hot starter cable be-

tween the upper bracket and

multi-function display bracket.

F. Fasten the multi-function display leads to the bracket. Cut off the

tie end.

G. Secure the coupler by pushing it into the hole in the multi-function

display bracket.

H. Secure the wire harness clip by pushing it into the hole in the

multi-function display bracket on

the inside.

I. Fasten the wire harness to the multi-function display bracket.

Cut off the tie end.

J. Fasten the main switch lead (wire harness side) to the multi-

function display br acket. Locate

the clamp end facing toward the

lower side of the frame and cut

off the tie end.

K. Pass the speed sensor lead through the guide on the outside

of the front fork.

Page 107 of 232

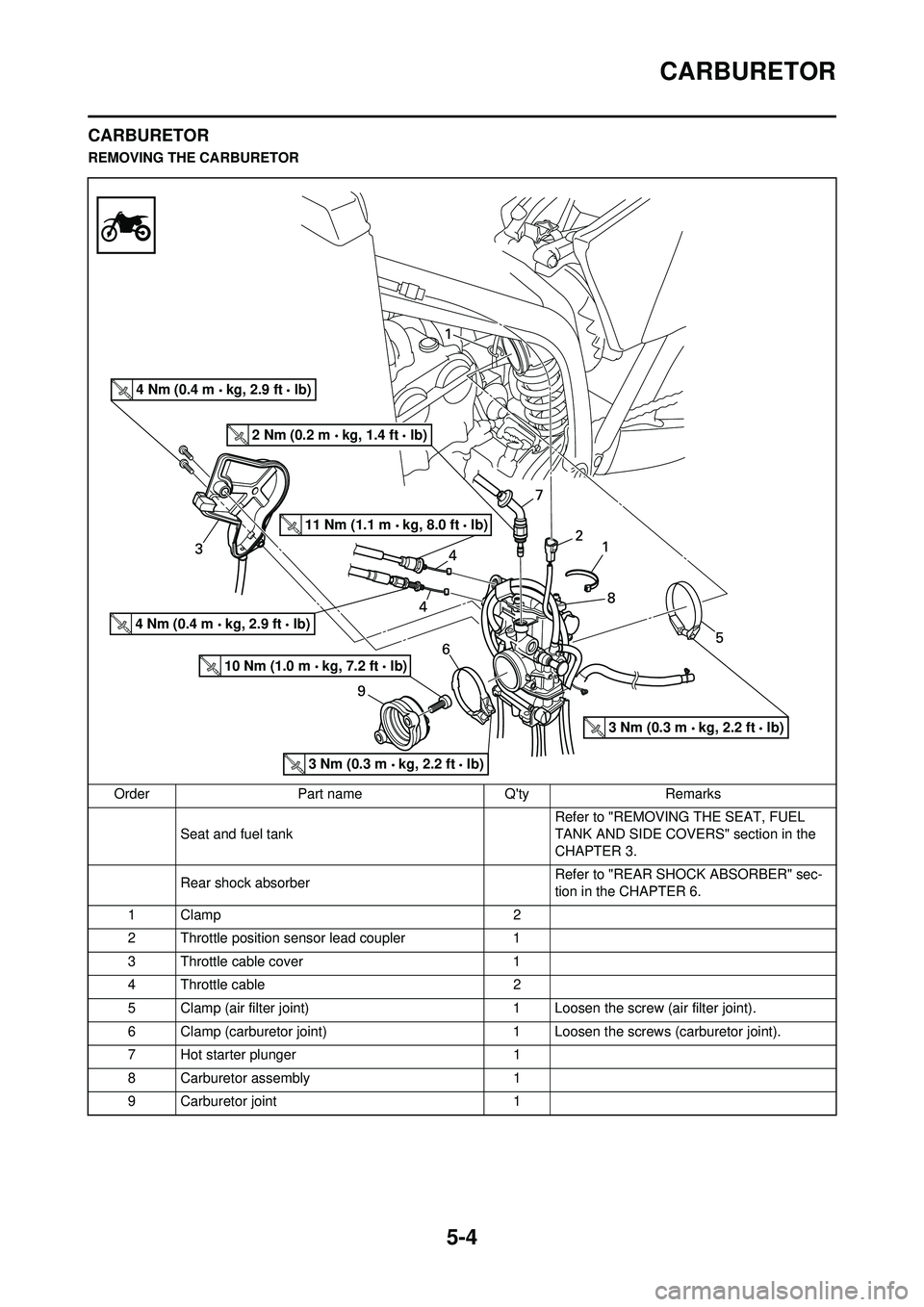

5-4

CARBURETOR

CARBURETOR

REMOVING THE CARBURETOROrder Part name Q'ty Remarks Seat and fuel tank Refer to "REMOVING THE SEAT, FUEL

TANK AND SIDE COVERS" section in the

CHAPTER 3.

Rear shock absorber Refer to "REAR SHOCK ABSORBER" sec-

tion in the CHAPTER 6.

1Clamp 2

2 Throttle position sensor lead coupler 1

3 Throttle cable cover 1

4 Throttle cable 2

5 Clamp (air filter joint) 1 Loosen the screw (air filter joint).

6 Clamp (carburetor joint) 1 Loosen the screws (carburetor joint).

7 Hot starter plunger 1

8 Carburetor assembly 1

9 Carburetor joint 1

4 Nm (0.4 m kg, 2.9 ft lb)

2 Nm (0.2 m kg, 1.4 ft lb)

11 Nm (1.1 m kg, 8.0 ft lb)

4 Nm (0.4 m kg, 2.9 ft lb)

10 Nm (1.0 m kg, 7.2 ft lb)

3 Nm (0.3 m kg, 2.2 ft lb)

3 Nm (0.3 m kg, 2.2 ft lb)

Page 110 of 232

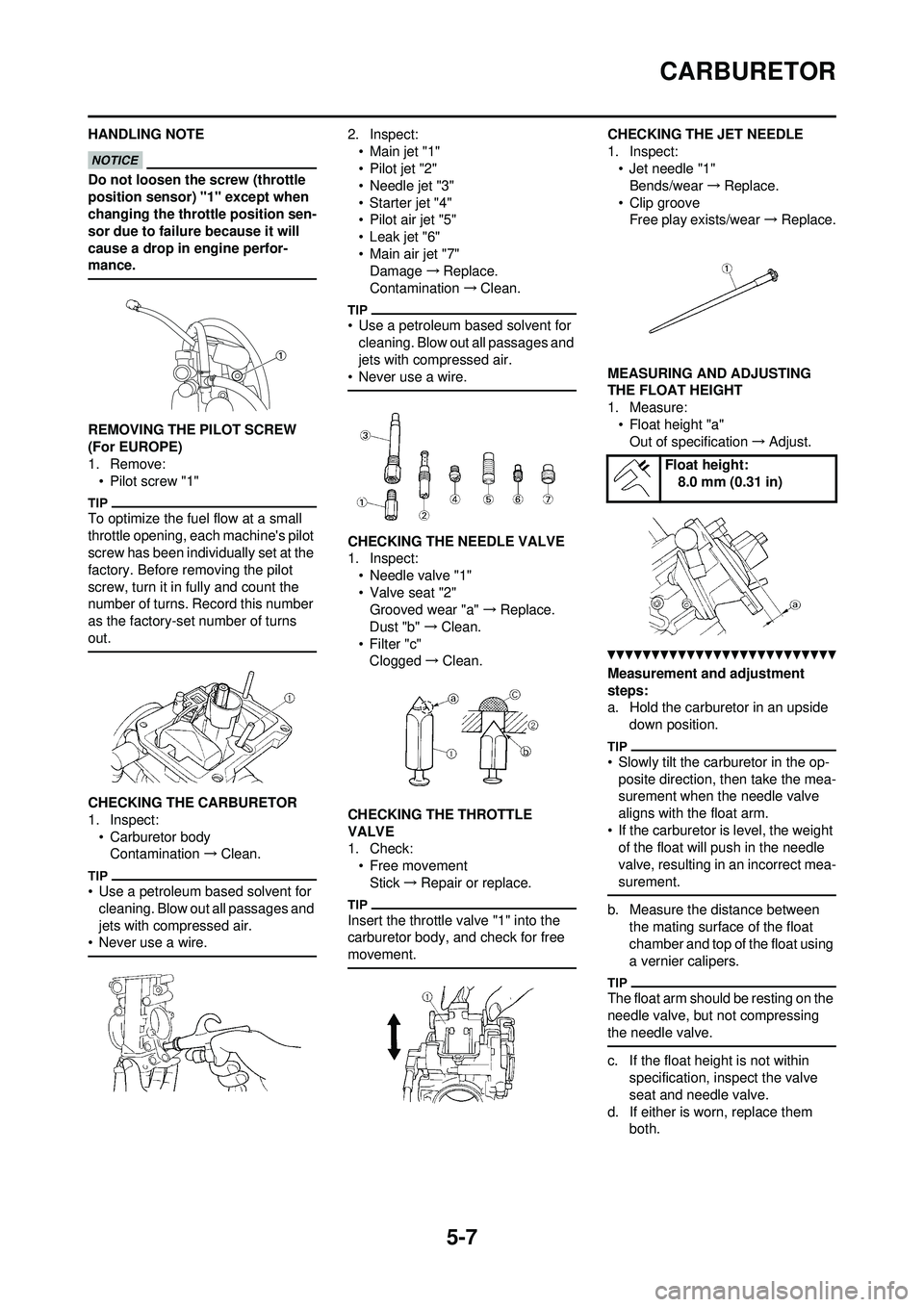

5-7

CARBURETOR

HANDLING NOTE

Do not loosen the screw (throttle

position sensor) "1" except when

changing the throttle position sen-

sor due to failure because it will

cause a drop in engine perfor-

mance.

REMOVING THE PILOT SCREW

(For EUROPE)

1. Remove: • Pilot screw "1"

To optimize the fuel flow at a small

throttle opening, each machine's pilot

screw has been individually set at the

factory. Before removing the pilot

screw, turn it in fully and count the

number of turns. Record this number

as the factory-set number of turns

out.

CHECKING THE CARBURETOR

1. Inspect:• Carburetor bodyContamination →Clean.

• Use a petroleum based solvent for

cleaning. Blow out all passages and

jets with compressed air.

• Never use a wire.

2. Inspect:

•Main jet "1"

• Pilot jet "2"

• Needle jet "3"

• Starter jet "4"

•Pilot air jet "5"

• Leak jet "6"

• Main air jet "7"Damage →Replace.

Contamination →Clean.

• Use a petroleum based solvent for

cleaning. Blow out all passages and

jets with compressed air.

• Never use a wire.

CHECKING THE NEEDLE VALVE

1. Inspect: • Needle valve "1"

• Valve seat "2"Grooved wear "a" →Replace.

Dust "b" →Clean.

• Filter "c" Clogged →Clean.

CHECKING THE THROTTLE

VALVE

1. Check: • Free movement

Stick →Repair or replace.

Insert the throttle valve "1" into the

carburetor body, and check for free

movement.

CHECKING THE JET NEEDLE

1. Inspect: • Jet needle "1"Bends/wear →Replace.

• Clip groove Free play exists/wear →Replace.

MEASURING AND ADJUSTING

THE FLOAT HEIGHT

1. Measure: • Float height "a"Out of specification →Adjust.

Measurement and adjustment

steps:

a. Hold the carburetor in an upside

down position.

• Slowly tilt the ca rburetor in the op-

posite direction, then take the mea-

surement when the needle valve

aligns with the float arm.

• If the carburetor is level, the weight of the float will push in the needle

valve, resulting in an incorrect mea-

surement.

b. Measure the distance between the mating surface of the float

chamber and top of the float using

a vernier calipers.

The float arm should be resting on the

needle valve, but not compressing

the needle valve.

c. If the float height is not within specification, inspect the valve

seat and needle valve.

d. If either is worn, replace them both.

Float height:

8.0 mm (0.31 in)

Page 112 of 232

5-9

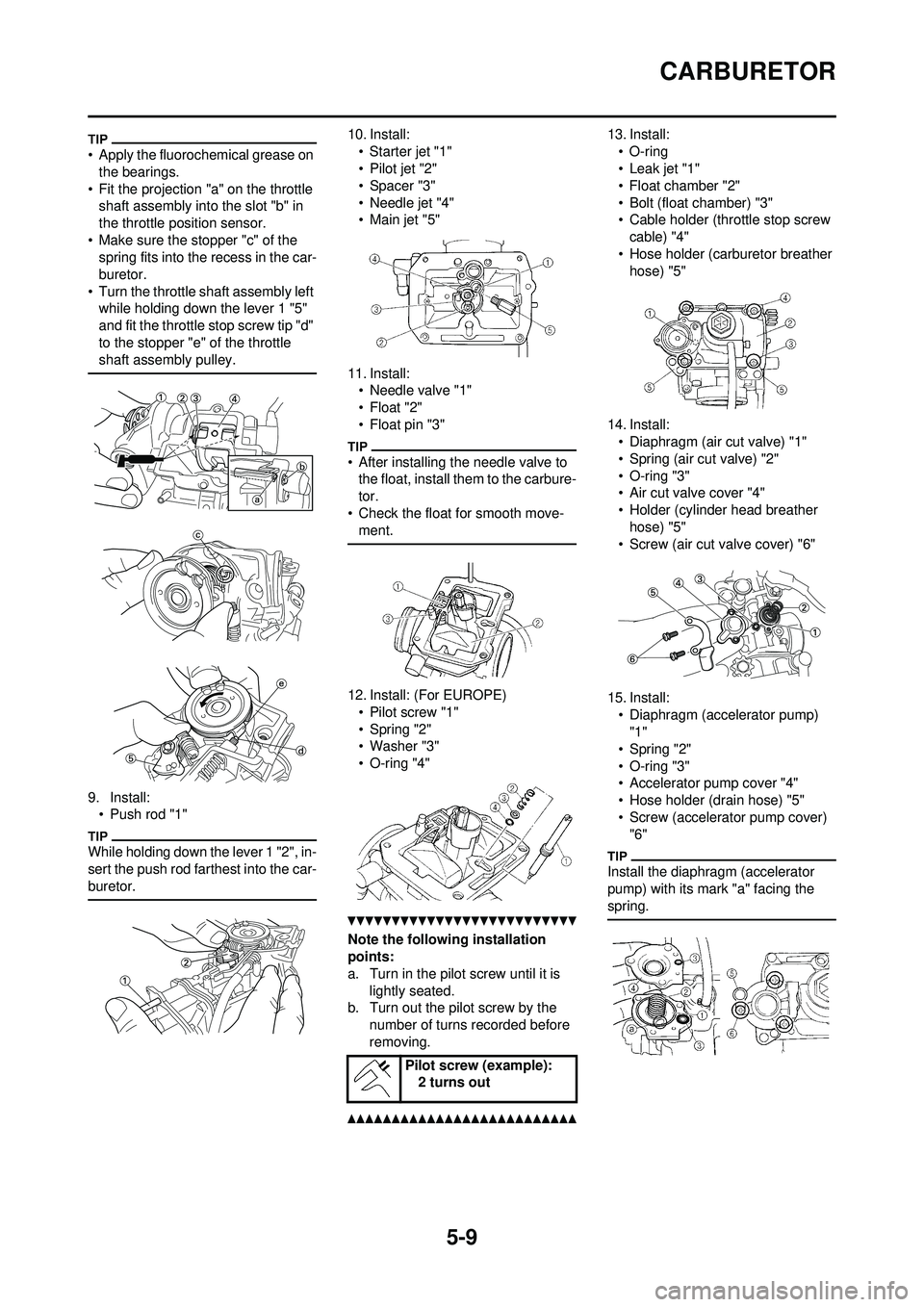

CARBURETOR

• Apply the fluorochemical grease on the bearings.

• Fit the projection "a" on the throttle shaft assembly into the slot "b" in

the throttle position sensor.

• Make sure the stopper "c" of the spring fits into the recess in the car-

buretor.

• Turn the throttle shaft assembly left while holding down the lever 1 "5"

and fit the throttle stop screw tip "d"

to the stopper "e" of the throttle

shaft assembly pulley.

9. Install:• Push rod "1"

While holding down the lever 1 "2", in-

sert the push rod farthest into the car-

buretor.

10. Install:

• Starter jet "1"

• Pilot jet "2"

• Spacer "3"

• Needle jet "4"

•Main jet "5"

11. Install: • Needle valve "1"

•Float "2"

• Float pin "3"

• After installing the needle valve to the float, install them to the carbure-

tor.

• Check the float for smooth move- ment.

12. Install: (For EUROPE)• Pilot screw "1"

• Spring "2"

• Washer "3"

• O-ring "4"

Note the following installation

points:

a. Turn in the pilot screw until it is

lightly seated.

b. Turn out the pilot screw by the

number of turns recorded before

removing.

13. Install:• O-ring

• Leak jet "1"

• Float chamber "2"

• Bolt (float chamber) "3"

• Cable holder (throttle stop screw cable) "4"

• Hose holder (carburetor breather hose) "5"

14. Install: • Diaphragm (air cut valve) "1"

• Spring (air cut valve) "2"

• O-ring "3"

• Air cut valve cover "4"

• Holder (cylinder head breather hose) "5"

• Screw (air cut valve cover) "6"

15. Install: • Diaphragm (accelerator pump) "1"

• Spring "2"

• O-ring "3"

• Accelerator pump cover "4"

• Hose holder (drain hose) "5"

• Screw (accelerator pump cover) "6"

Install the diaphragm (accelerator

pump) with its mark "a" facing the

spring.

Pilot screw (example): 2 turns out

Page 114 of 232

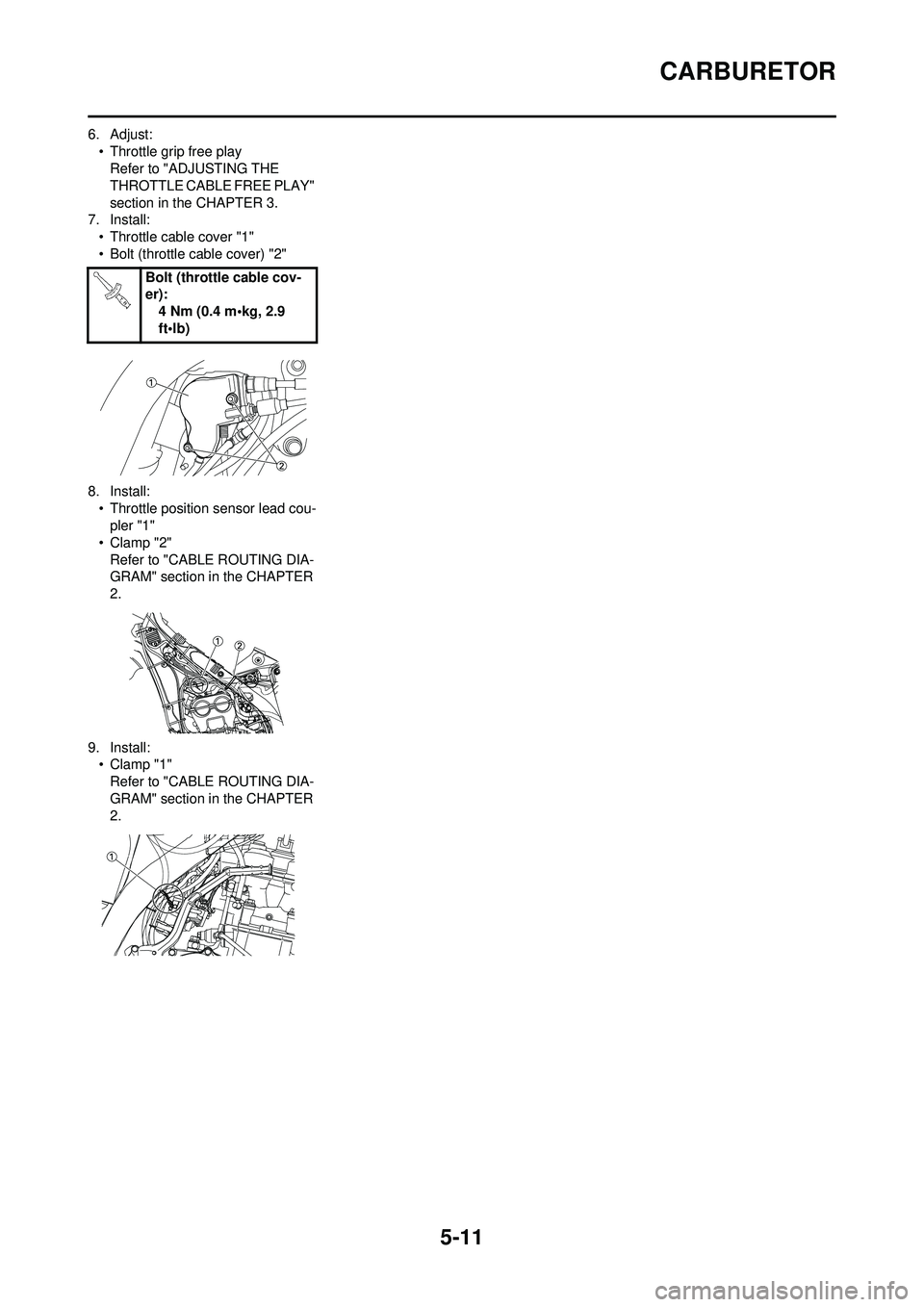

5-11

CARBURETOR

6. Adjust:• Throttle grip free playRefer to "ADJUSTING THE

THROTTLE CABLE FREE PLAY"

section in the CHAPTER 3.

7. Install: • Throttle cable cover "1"

• Bolt (throttle cable cover) "2"

8. Install: • Throttle position sensor lead cou-pler "1"

• Clamp "2" Refer to "CABLE ROUTING DIA-

GRAM" section in the CHAPTER

2.

9. Install: • Clamp "1"

Refer to "CABLE ROUTING DIA-

GRAM" section in the CHAPTER

2. Bolt (throttle cable cov-

er):

4 Nm (0.4 m•kg, 2.9

ft•lb)