torque YAMAHA WR 250F 2010 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2010, Model line: WR 250F, Model: YAMAHA WR 250F 2010Pages: 232, PDF Size: 13.94 MB

Page 86 of 232

3-27

CHASSIS

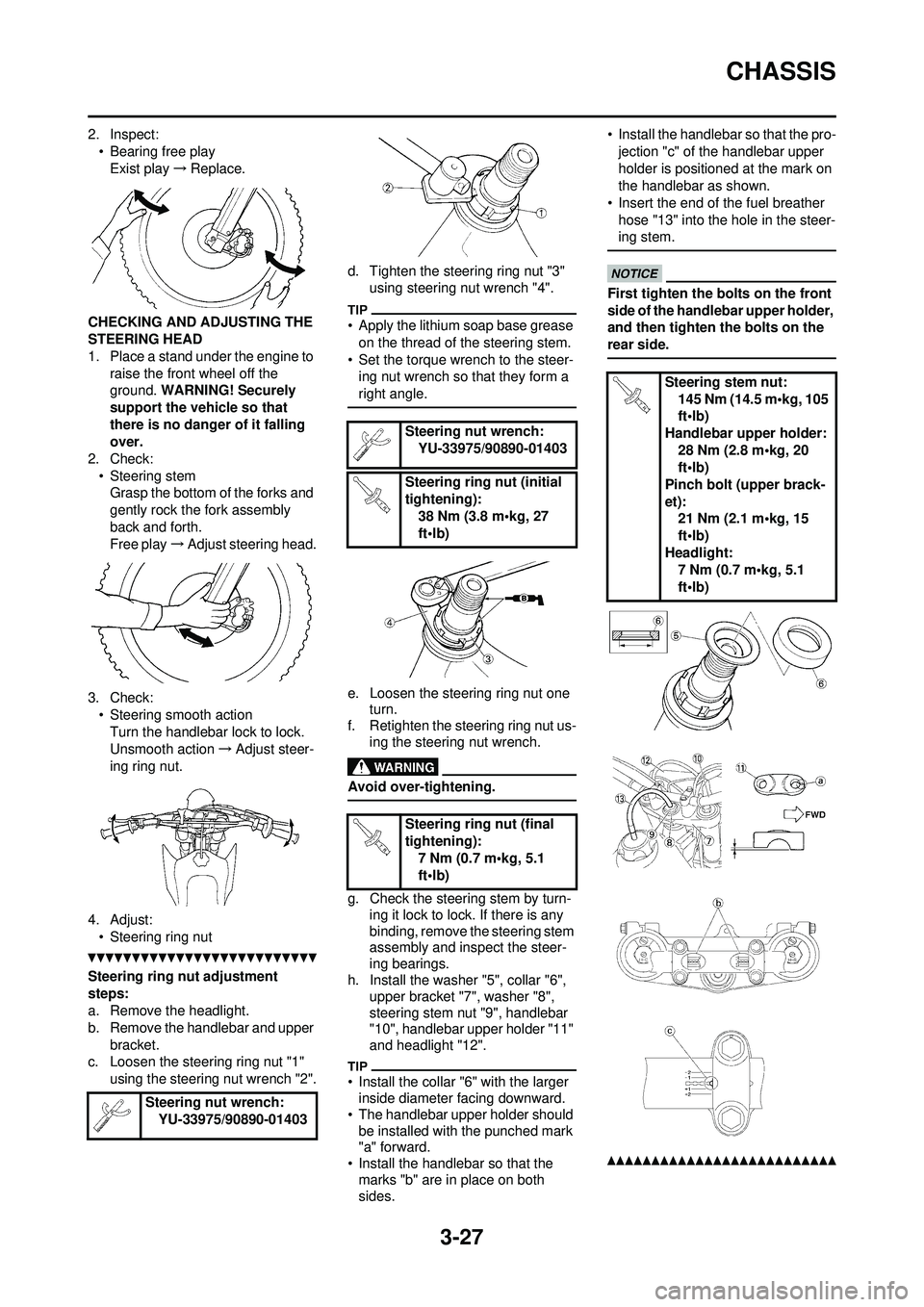

2. Inspect:• Bearing free playExist play →Replace.

CHECKING AND ADJUSTING THE

STEERING HEAD

1. Place a stand under the engine to raise the front wheel off the

ground. WARNING! Securely

support the vehicle so that

there is no danger of it falling

over.

2. Check: • Steering stemGrasp the bottom of the forks and

gently rock the fork assembly

back and forth.

Free play →Adjust steering head.

3. Check: • Steering smooth actionTurn the handlebar lock to lock.

Unsmooth action →Adjust steer-

ing ring nut.

4. Adjust: • Steering ring nut

Steering ring nut adjustment

steps:

a. Remove the headlight.

b. Remove the handlebar and upper

bracket.

c. Loosen the steering ring nut "1" using the steering nut wrench "2". d. Tighten the steering ring nut "3"

using steering nut wrench "4".

• Apply the lithium soap base grease

on the thread of the steering stem.

• Set the torque wrench to the steer- ing nut wrench so that they form a

right angle.

e. Loosen the steering ring nut one turn.

f. Retighten the steering ring nut us- ing the steering nut wrench.

Avoid over-tightening.

g. Check the steering stem by turn-ing it lock to lock. If there is any

binding, remove the steering stem

assembly and inspect the steer-

ing bearings.

h. Install the washer "5", collar "6", upper bracket "7", washer "8",

steering stem nut "9", handlebar

"10", handlebar upper holder "11"

and headlight "12".

• Install the collar "6" with the larger inside diameter facing downward.

• The handlebar upper holder should be installed with the punched mark

"a" forward.

• Install the handlebar so that the marks "b" are in place on both

sides. • Install the handlebar so that the pro-

jection "c" of the handlebar upper

holder is positioned at the mark on

the handlebar as shown.

• Insert the end of the fuel breather hose "13" into the hole in the steer-

ing stem.

First tighten the bolts on the front

side of the handlebar upper holder,

and then tighten the bolts on the

rear side.

Steering nut wrench:

YU-33975/90890-01403

Steering nut wrench:YU-33975/90890-01403

Steering ring nut (initial

tightening): 38 Nm (3.8 m•kg, 27

ft•lb)

Steering ring nut (final

tightening): 7 Nm (0.7 m•kg, 5.1

ft•lb)

Steering stem nut:

145 Nm (14.5 m•kg, 105

ft•lb)

Handlebar upper holder:

28 Nm (2.8 m•kg, 20

ft•lb)

Pinch bolt (upper brack-

et): 21 Nm (2.1 m•kg, 15

ft•lb)

Headlight: 7 Nm (0.7 m•kg, 5.1

ft•lb)

Page 102 of 232

4-9

CHASSIS

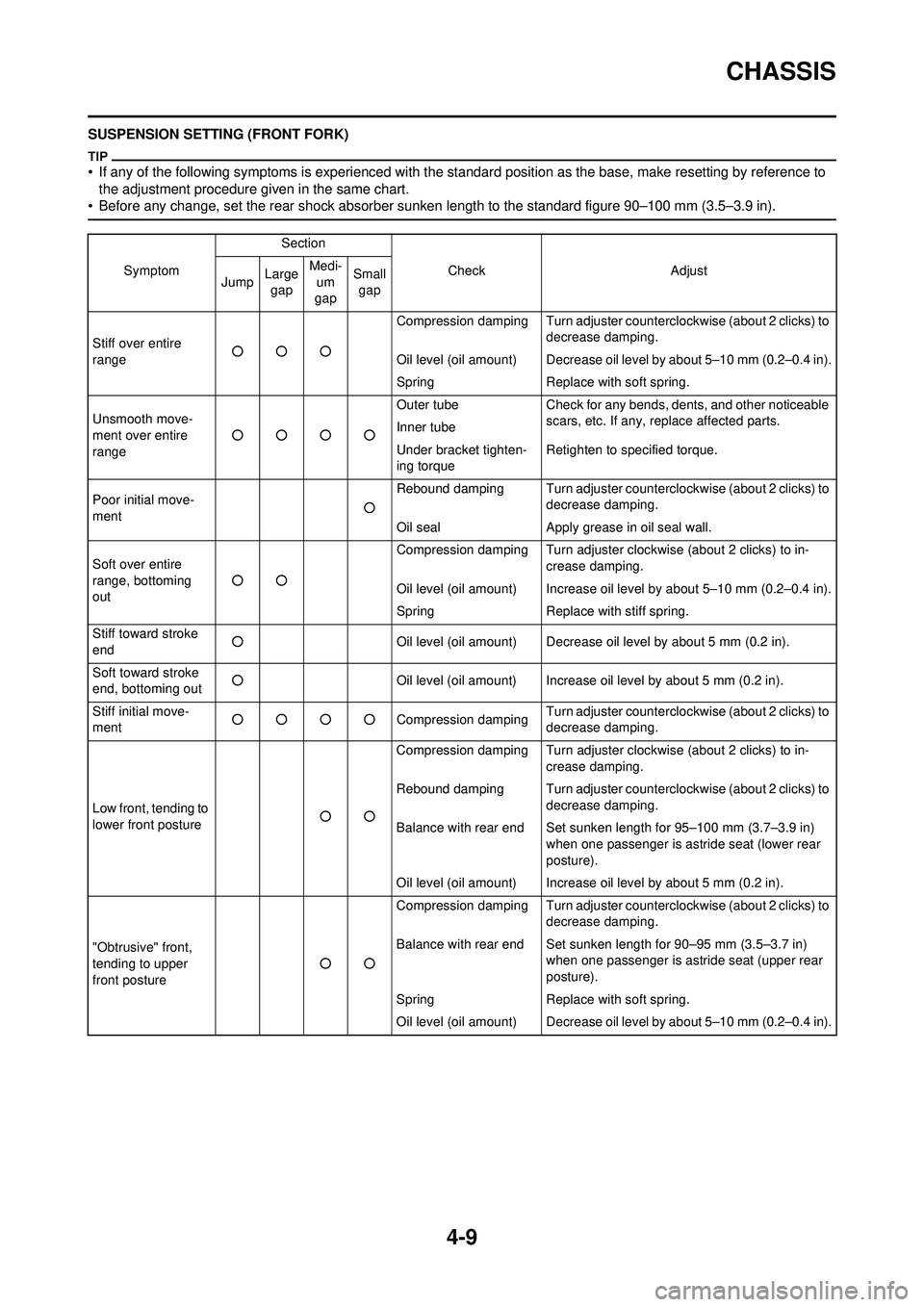

SUSPENSION SETTING (FRONT FORK)

• If any of the following symptoms is experienced with the standard position as the base, make resetting by reference to the adjustment procedure gi ven in the same chart.

• Before any change, set t he rear shock absorber sunken length to the standard figure 90–100 mm (3.5–3.9 in).

SymptomSection

Check Adjust

Jump Large

gap Medi-

um

gap Small

gap

Stiff over entire

range ○○○ Compression damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Oil level (oil amount) Decrease oil level by about 5–10 mm (0.2–0.4 in).

Spring Replace with soft spring.

Unsmooth move-

ment over entire

range ○○○○ Outer tube

Check for any bends, dents, and other noticeable

scars, etc. If any, replace affected parts.

Inner tube

Under bracket tighten-

ing torque Retighten to specified torque.

Poor initial move-

ment ○Rebound damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Oil seal Apply grease in oil seal wall.

Soft over entire

range, bottoming

out ○○ Compression damping Turn adjuster clockwise (about 2 clicks) to in-

crease damping.

Oil level (oil amount) Increase oil level by about 5–10 mm (0.2–0.4 in).

Spring Replace with stiff spring.

Stiff toward stroke

end ○

Oil level (oil amount) Decrease oil level by about 5 mm (0.2 in).

Soft toward stroke

end, bottoming out ○

Oil level (oil amount) Increase oil level by about 5 mm (0.2 in).

Stiff initial move-

ment ○○○○

Compression dampingTurn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Low front, tending to

lower front posture ○○Compression damping Turn adjuster clockwise (about 2 clicks) to in-

crease damping.

Rebound damping Turn adjuster counterclockwise (about 2 clicks) to decrease damping.

Balance with rear end Set sunken length for 95–100 mm (3.7–3.9 in) when one passenger is astride seat (lower rear

posture).

Oil level (oil amount) Increase oil level by about 5 mm (0.2 in).

"Obtrusive" front,

tending to upper

front posture ○○Compression damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Balance with rear end Set sunken length for 90–95 mm (3.5–3.7 in) when one passenger is astride seat (upper rear

posture).

Spring Replace with soft spring.

Oil level (oil amount) Decrease oil level by about 5–10 mm (0.2–0.4 in).

Page 121 of 232

5-18

CAMSHAFTS

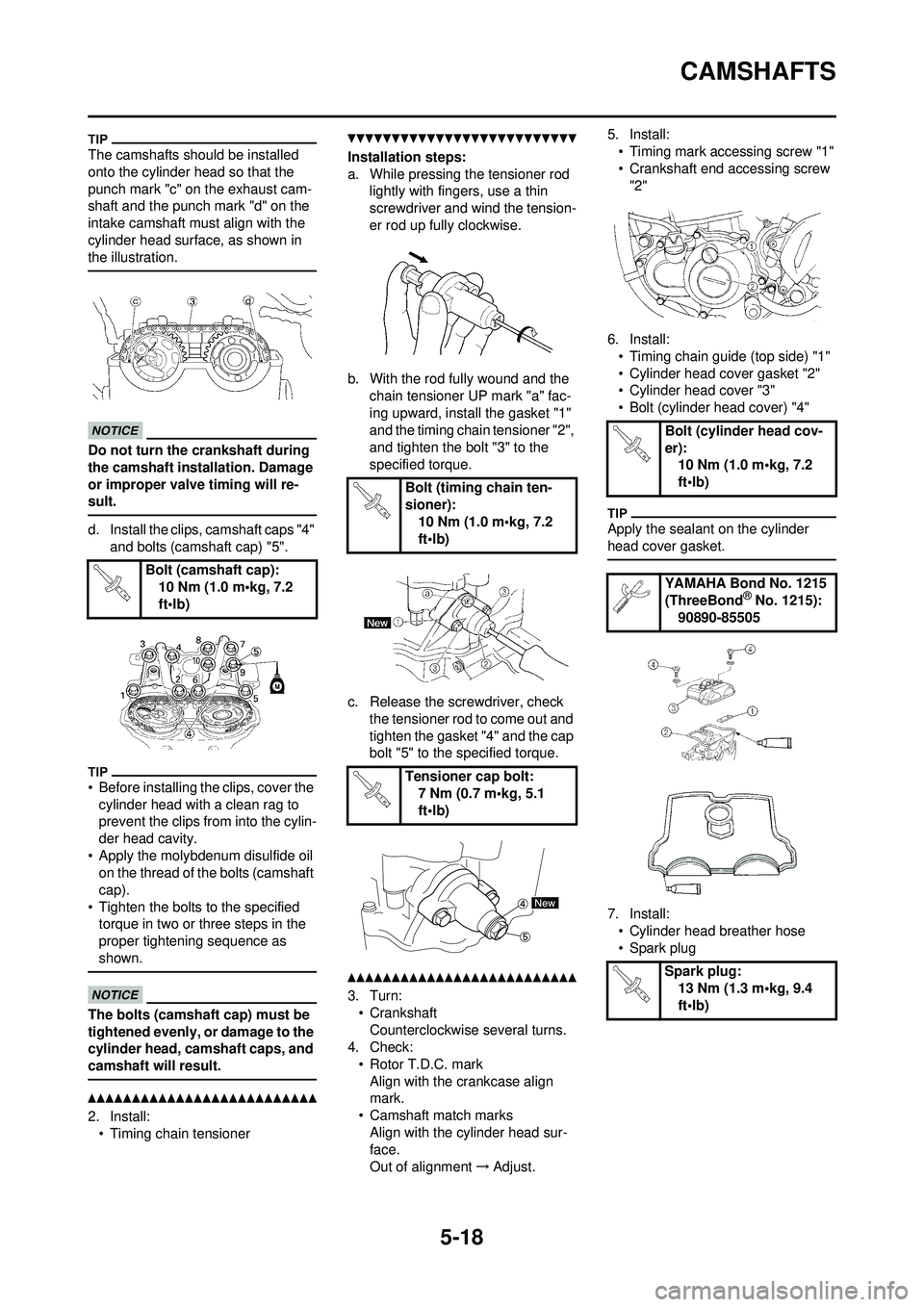

The camshafts should be installed

onto the cylinder head so that the

punch mark "c" on the exhaust cam-

shaft and the punch mark "d" on the

intake camshaft must align with the

cylinder head surface, as shown in

the illustration.

Do not turn the crankshaft during

the camshaft installation. Damage

or improper valve timing will re-

sult.

d. Install the clips, camshaft caps "4"

and bolts (camshaft cap) "5".

• Before installing the clips, cover the cylinder head with a clean rag to

prevent the clips from into the cylin-

der head cavity.

• Apply the molybdenum disulfide oil on the thread of the bolts (camshaft

cap).

• Tighten the bolts to the specified torque in two or three steps in the

proper tightening sequence as

shown.

The bolts (camshaft cap) must be

tightened evenly, or damage to the

cylinder head, camshaft caps, and

camshaft will result.

2. Install:• Timing chain tensioner

Installation steps:

a. While pressing the tensioner rod lightly with fingers, use a thin

screwdriver and wind the tension-

er rod up fully clockwise.

b. With the rod fully wound and the chain tensioner UP mark "a" fac-

ing upward, install the gasket "1"

and the timing chain tensioner "2",

and tighten the bolt "3" to the

specified torque.

c. Release the screwdriver, check the tensioner rod to come out and

tighten the gasket "4" and the cap

bolt "5" to the specified torque.

3. Turn:

• CrankshaftCounterclockwise several turns.

4. Check:

• Rotor T.D.C. markAlign with the crankcase align

mark.

• Camshaft match marks Align with the cylinder head sur-

face.

Out of alignment →Adjust. 5. Install:

• Timing mark accessing screw "1"

• Crankshaft end accessing screw "2"

6. Install: • Timing chain guide (top side) "1"

• Cylinder head cover gasket "2"

• Cylinder head cover "3"

• Bolt (cylinder head cover) "4"

Apply the sealant on the cylinder

head cover gasket.

7. Install:• Cylinder head breather hose

• Spark plug

Bolt (camshaft cap):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (timing chain ten-

sioner):10 Nm (1.0 m•kg, 7.2

ft•lb)

Tensioner cap bolt: 7 Nm (0.7 m•kg, 5.1

ft•lb)

Bolt (cylinder head cov-

er): 10 Nm (1.0 m•kg, 7.2

ft•lb)

YAMAHA Bond No. 1215

(ThreeBond

® No. 1215):

90890-85505

Spark plug: 13 Nm (1.3 m•kg, 9.4

ft•lb)

Page 152 of 232

5-49

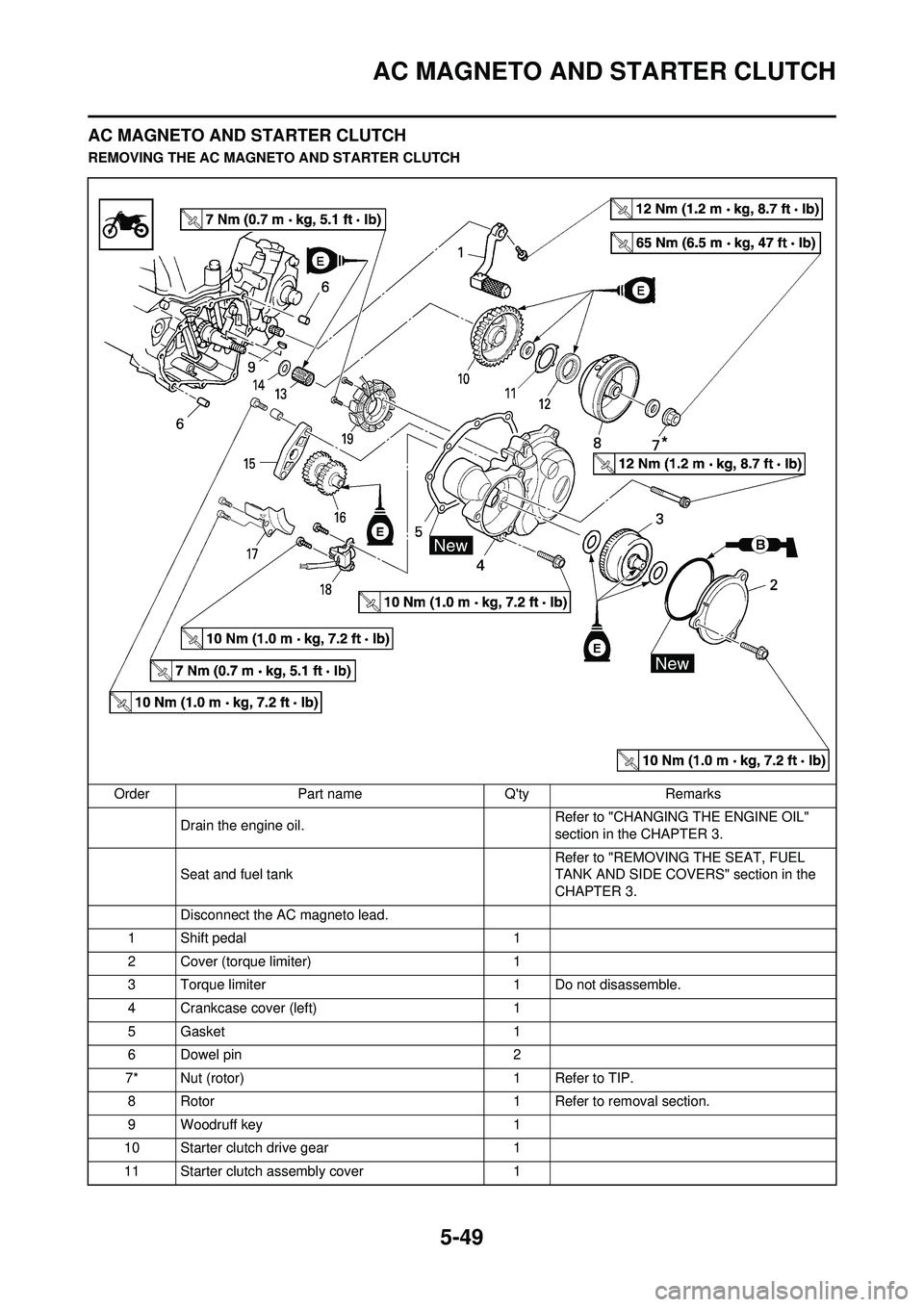

AC MAGNETO AND STARTER CLUTCH

AC MAGNETO AND STARTER CLUTCH

REMOVING THE AC MAGNETO AND STARTER CLUTCHOrder Part name Q'ty Remarks Drain the engine oil. Refer to "CHANGING THE ENGINE OIL"

section in the CHAPTER 3.

Seat and fuel tank Refer to "REMOVING THE SEAT, FUEL

TANK AND SIDE COVERS" section in the

CHAPTER 3.

Disconnect the AC magneto lead.

1 Shift pedal 1

2 Cover (torque limiter) 1

3 Torque limiter 1 Do not disassemble.

4 Crankcase cover (left) 1

5 Gasket 1

6 Dowel pin 2

7* Nut (rotor) 1 Refer to TIP.

8 Rotor 1 Refer to removal section.

9 Woodruff key 1

10 Starter clutch drive gear 1

11 Starter clutch assembly cover 1

Page 154 of 232

5-51

AC MAGNETO AND STARTER CLUTCH

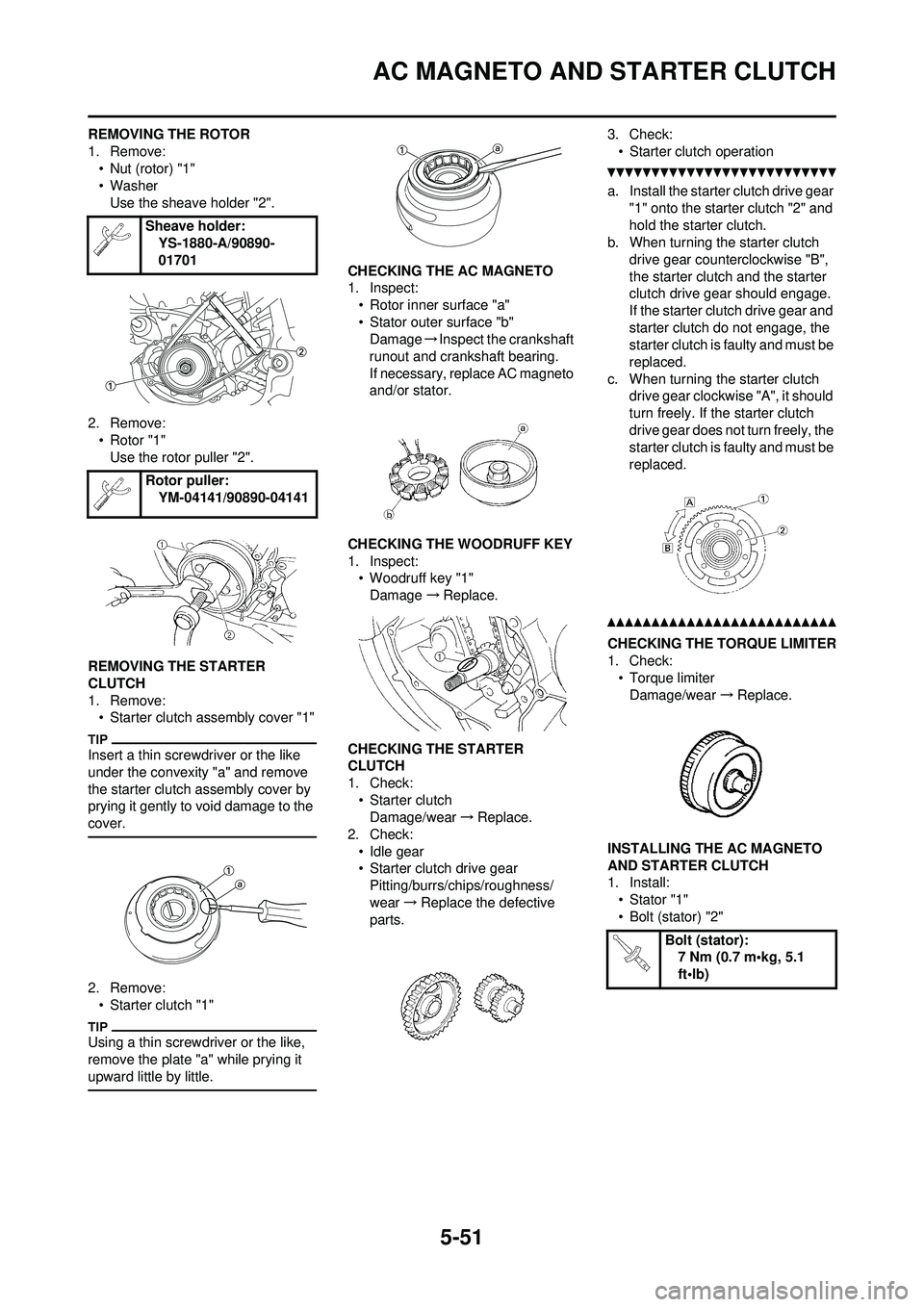

REMOVING THE ROTOR

1. Remove:• Nut (rotor) "1"

• Washer

Use the sheave holder "2".

2. Remove: • Rotor "1"Use the rotor puller "2".

REMOVING THE STARTER

CLUTCH

1. Remove: • Starter clutch a ssembly cover "1"

Insert a thin screwdriver or the like

under the convexity "a" and remove

the starter clutch assembly cover by

prying it gently to void damage to the

cover.

2. Remove:

• Starter clutch "1"

Using a thin screwdriver or the like,

remove the plate "a" while prying it

upward little by little.

CHECKING THE AC MAGNETO

1. Inspect:

• Rotor inner surface "a"

• Stator outer surface "b"Damage →Inspect the crankshaft

runout and crankshaft bearing.

If necessary, replace AC magneto

and/or stator.

CHECKING THE WOODRUFF KEY

1. Inspect: • Woodruff key "1"

Damage →Replace.

CHECKING THE STARTER

CLUTCH

1. Check: • Starter clutchDamage/wear →Replace.

2. Check:

• Idle gear

• Starter clutch drive gearPitting/burrs/chips/roughness/

wear →Replace the defective

parts. 3. Check:

• Starter clutch operation

a. Install the starter clutch drive gear "1" onto the starter clutch "2" and

hold the starter clutch.

b. When turning the starter clutch

drive gear counterclockwise "B",

the starter clutch and the starter

clutch drive gear should engage.

If the starter clutch drive gear and

starter clutch do not engage, the

starter clutch is faulty and must be

replaced.

c. When turning the starter clutch drive gear clockwise "A", it should

turn freely. If the starter clutch

drive gear does not turn freely, the

starter clutch is faulty and must be

replaced.

CHECKING THE TORQUE LIMITER

1. Check:• Torque limiter

Damage/wear →Replace.

INSTALLING THE AC MAGNETO

AND STARTER CLUTCH

1. Install: • Stator "1"

• Bolt (stator) "2"

Sheave holder:

YS-1880-A/90890-

01701

Rotor puller: YM-04141/90890-04141

Bolt (stator):7 Nm (0.7 m•kg, 5.1

ft•lb)

Page 156 of 232

![YAMAHA WR 250F 2010 User Guide 5-53

AC MAGNETO AND STARTER CLUTCH

10. Install:• Dowel pin

• Gasket [crankcase cover (left)]

• Crankcase cover (left) "1"

• Bolt [crankcase cover (left)] "2"

• Bolt [crankcase cover (left)] YAMAHA WR 250F 2010 User Guide 5-53

AC MAGNETO AND STARTER CLUTCH

10. Install:• Dowel pin

• Gasket [crankcase cover (left)]

• Crankcase cover (left) "1"

• Bolt [crankcase cover (left)] "2"

• Bolt [crankcase cover (left)]](/img/51/52318/w960_52318-155.png)

5-53

AC MAGNETO AND STARTER CLUTCH

10. Install:• Dowel pin

• Gasket [crankcase cover (left)]

• Crankcase cover (left) "1"

• Bolt [crankcase cover (left)] "2"

• Bolt [crankcase cover (left)] "3"

Tighten the bolts in stage, using a

crisscross pattern.

11. Install:• Washer "1"

• Torque limiter "2"

• Washer "3"

Apply the engine oil to the shaft and

washers.

12. Install:• O-ring

• Cover (idle gear 1) "1"

•Bolt "2"

• Apply the lithium soap base grease on the O-ring.

• Install the cover (idle gear 1) with its

mark "a" facing upward.

13. Connect:• AC magneto lead

Refer to "CABLE ROUTING DIA-

GRAM" section in the CHAPTER

2.

14. Install: • Shift pedal "1"

• Bolt (shift pedal) "2"

When installing the shift pedal onto

the shift shaft, be sure that the center

of the shift pedal is about 1.4 mm

(0.06 in) "a" above the top of the foot-

rest.

Bolt [crankcase cover

(left)]: 10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt [crankcase cover

(left)]: 12 Nm (1.2 m•kg, 8.7

ft•lb)

Bolt: 10 Nm (1.0 m•kg, 7.2

ft•lb)

E

Bolt (shift pedal):

12 Nm (1.2 m•kg, 8.7

ft•lb)

Page 190 of 232

6-21

FRONT FORK

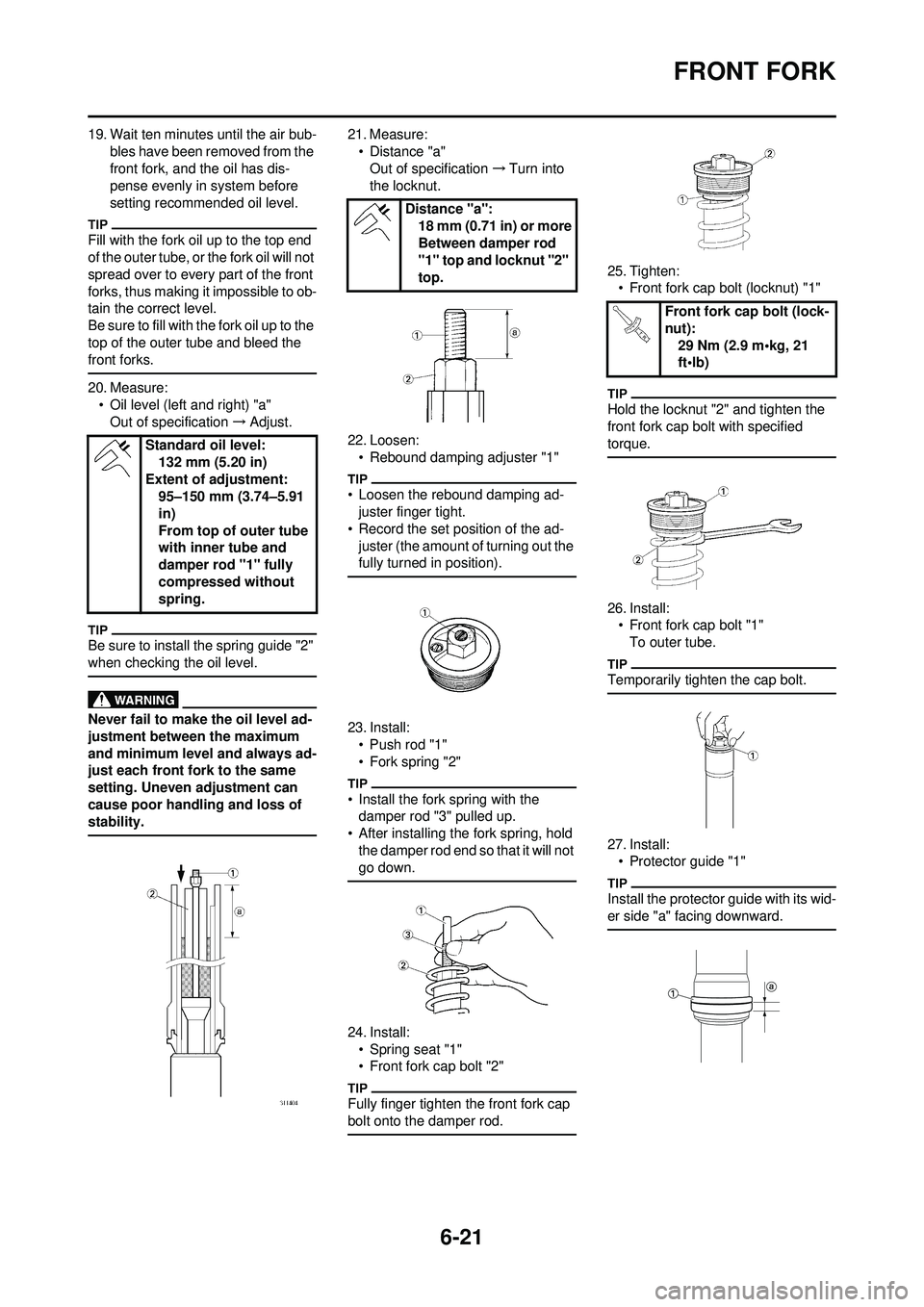

19. Wait ten minutes until the air bub-bles have been removed from the

front fork, and the oil has dis-

pense evenly in system before

setting recommended oil level.

Fill with the fork oil up to the top end

of the outer tube, or the fork oil will not

spread over to every part of the front

forks, thus making it impossible to ob-

tain the correct level.

Be sure to fill with the fork oil up to the

top of the outer tube and bleed the

front forks.

20. Measure:• Oil level (left and right) "a" Out of specification →Adjust.

Be sure to install the spring guide "2"

when checking the oil level.

Never fail to make the oil level ad-

justment between the maximum

and minimum level and always ad-

just each front fork to the same

setting. Uneven adjustment can

cause poor handling and loss of

stability.

21. Measure:

• Distance "a"Out of specification →Turn into

the locknut.

22. Loosen: • Rebound damping adjuster "1"

• Loosen the rebound damping ad-juster finger tight.

• Record the set position of the ad- juster (the amount of turning out the

fully turned in position).

23. Install:• Push rod "1"

• Fork spring "2"

• Install the fork spring with the damper rod "3" pulled up.

• After installing the fork spring, hold

the damper rod end so that it will not

go down.

24. Install:• Spring seat "1"

• Front fork cap bolt "2"

Fully finger tighten the front fork cap

bolt onto the damper rod.

25. Tighten:• Front fork cap bolt (locknut) "1"

Hold the locknut "2" and tighten the

front fork cap bolt with specified

torque.

26. Install:• Front fork cap bolt "1"To outer tube.

Temporarily tighten the cap bolt.

27. Install:• Protector guide "1"

Install the protector guide with its wid-

er side "a" facing downward.

Standard oil level:

132 mm (5.20 in)

Extent of adjustment: 95–150 mm (3.74–5.91

in)

From top of outer tube

with inner tube and

damper rod "1" fully

compressed without

spring.

Distance "a":

18 mm (0.71 in) or more

Between damper rod

"1" top and locknut "2"

top.

Front fork cap bolt (lock-

nut): 29 Nm (2.9 m•kg, 21

ft•lb)

Page 191 of 232

6-22

FRONT FORK

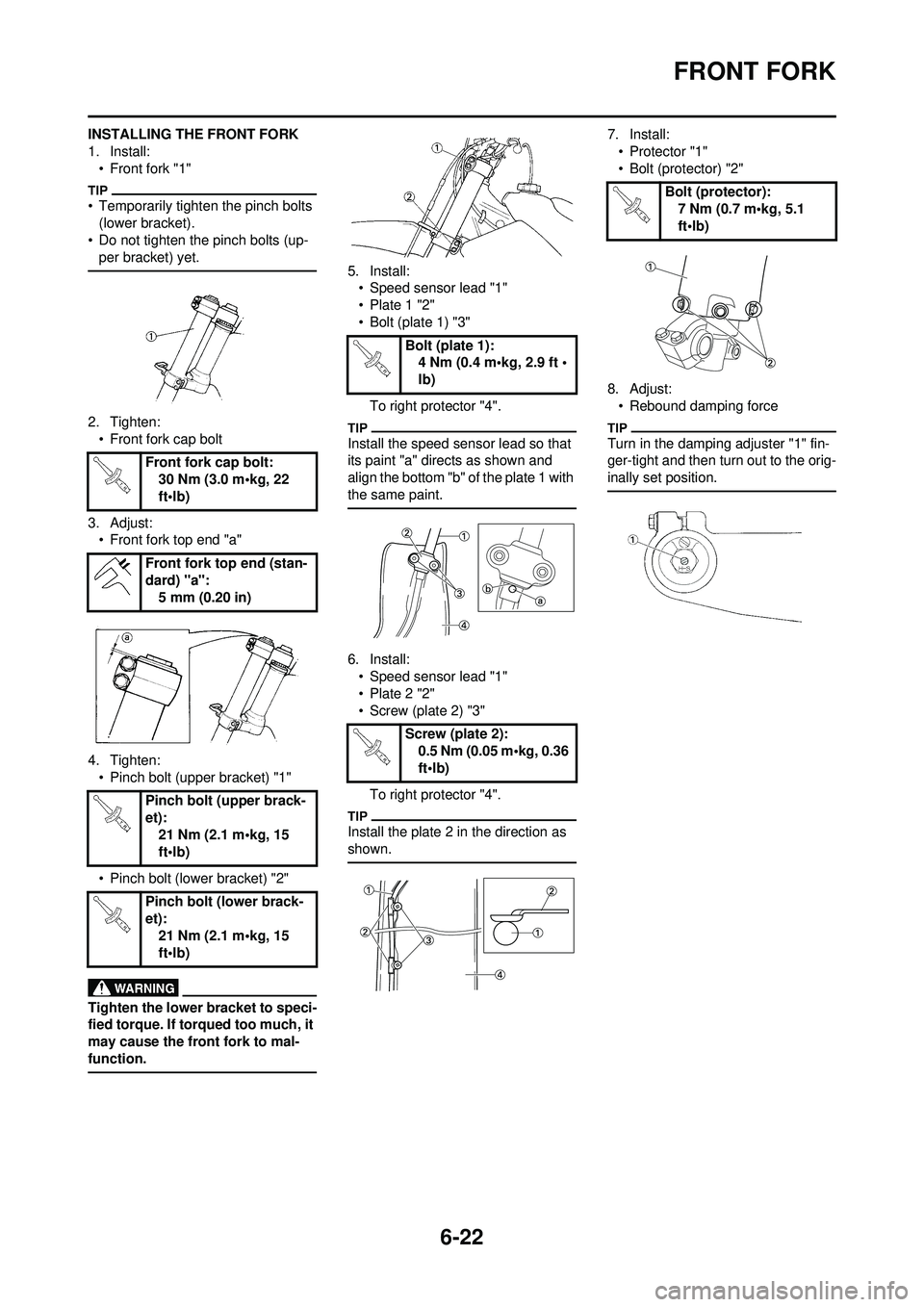

INSTALLING THE FRONT FORK

1. Install:• Front fork "1"

• Temporarily tighten the pinch bolts (lower bracket).

• Do not tighten the pinch bolts (up- per bracket) yet.

2. Tighten:

• Front fork cap bolt

3. Adjust: • Front fork top end "a"

4. Tighten: • Pinch bolt (upper bracket) "1"

• Pinch bolt (lower bracket) "2"

Tighten the lower bracket to speci-

fied torque. If to rqued too much, it

may cause the fron t fork to mal-

function.

5. Install: • Speed sensor lead "1"

•Plate 1 "2"

• Bolt (plate 1) "3"

To right protector "4".

Install the speed sensor lead so that

its paint "a" directs as shown and

align the bottom "b" of the plate 1 with

the same paint.

6. Install:• Speed sensor lead "1"

•Plate 2 "2"

• Screw (plate 2) "3"

To right protector "4".

Install the plate 2 in the direction as

shown.

7. Install:• Protector "1"

• Bolt (protector) "2"

8. Adjust: • Rebound damping force

Turn in the damping adjuster "1" fin-

ger-tight and then turn out to the orig-

inally set position.

Front fork cap bolt: 30 Nm (3.0 m•kg, 22

ft•lb)

Front fork top end (stan-

dard) "a": 5 mm (0.20 in)

Pinch bolt (upper brack-

et): 21 Nm (2.1 m•kg, 15

ft•lb)

Pinch bolt (lower brack-

et): 21 Nm (2.1 m•kg, 15

ft•lb)

Bolt (plate 1):4 Nm (0.4 m•kg, 2.9 ft •

lb)

Screw (plate 2): 0.5 Nm (0.05 m•kg, 0.36

ft•lb)

Bolt (protector): 7 Nm (0.7 m•kg, 5.1

ft•lb)

Page 199 of 232

6-30

STEERING

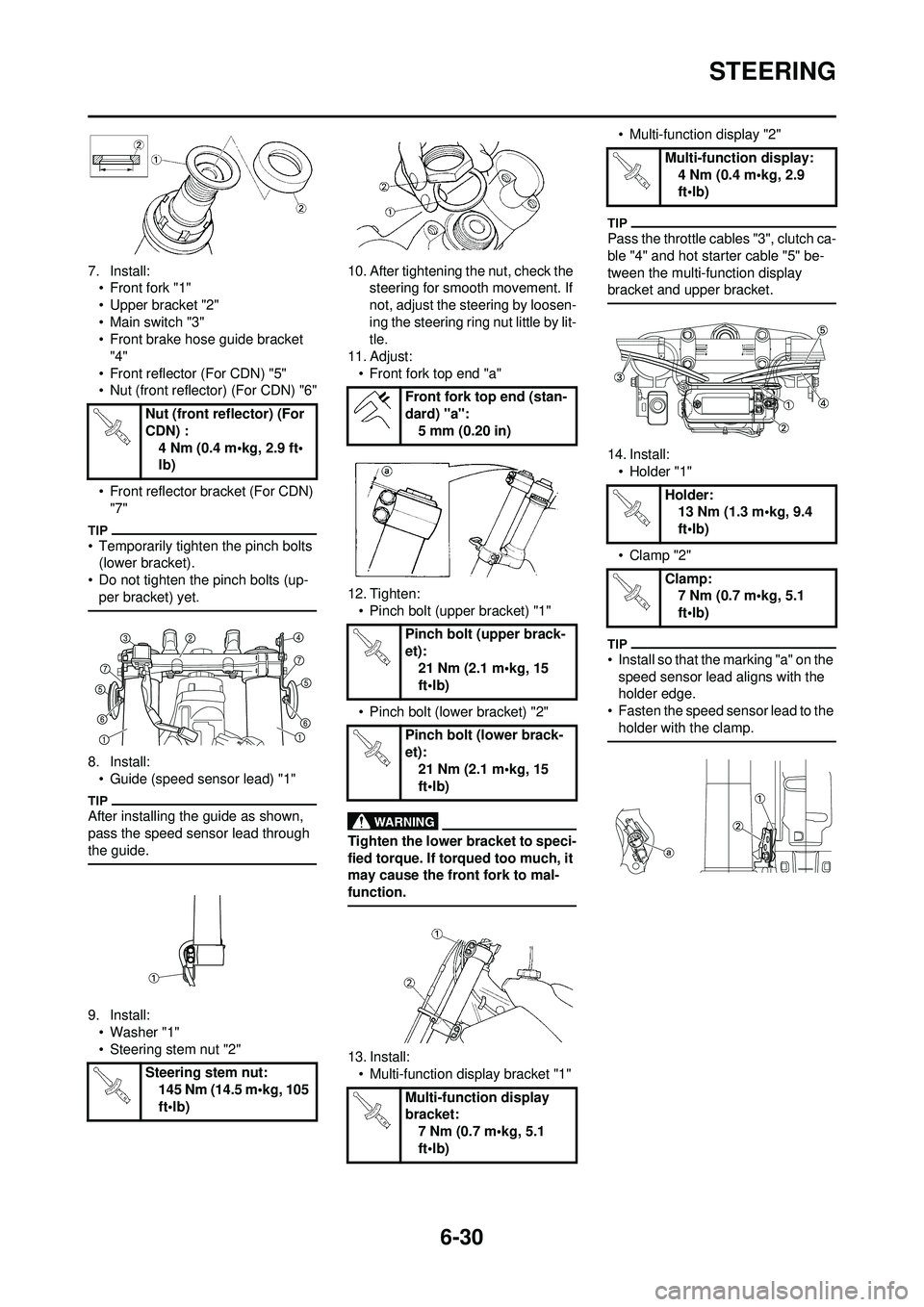

7. Install:• Front fork "1"

• Upper bracket "2"

• Main switch "3"

• Front brake hose guide bracket

"4"

• Front reflector (For CDN) "5"

• Nut (front reflector) (For CDN) "6"

• Front reflector bracket (For CDN) "7"

• Temporarily tighten the pinch bolts (lower bracket).

• Do not tighten the pinch bolts (up- per bracket) yet.

8. Install:• Guide (speed sensor lead) "1"

After installing the guide as shown,

pass the speed sensor lead through

the guide.

9. Install:• Washer "1"

• Steering stem nut "2" 10. After tightening the nut, check the

steering for smooth movement. If

not, adjust the steering by loosen-

ing the steering ring nut little by lit-

tle.

11. Adjust: • Front fork top end "a"

12. Tighten: • Pinch bolt (upper bracket) "1"

• Pinch bolt (lower bracket) "2"

Tighten the lower bracket to speci-

fied torque. If to rqued too much, it

may cause the front fork to mal-

function.

13. Install:

• Multi-function display bracket "1" • Multi-function display "2"

Pass the throttle cabl

es "3", clutch ca-

ble "4" and hot starter cable "5" be-

tween the multi-function display

bracket and upper bracket.

14. Install:

• Holder "1"

• Clamp "2"

• Install so that the marking "a" on the speed sensor lead aligns with the

holder edge.

• Fasten the speed sensor lead to the

holder with the clamp.

Nut (front reflector) (For

CDN) : 4 Nm (0.4 m•kg, 2.9 ft•

lb)

Steering stem nut: 145 Nm (14.5 m•kg, 105

ft•lb)

Front fork top end (stan-

dard) "a":

5 mm (0.20 in)

Pinch bolt (upper brack-

et): 21 Nm (2.1 m•kg, 15

ft•lb)

Pinch bolt (lower brack-

et): 21 Nm (2.1 m•kg, 15

ft•lb)

Multi-function display

bracket: 7 Nm (0.7 m•kg, 5.1

ft•lb)

Multi-function display:

4 Nm (0.4 m•kg, 2.9

ft•lb)

Holder: 13 Nm (1.3 m•kg, 9.4

ft•lb)

Clamp: 7 Nm (0.7 m•kg, 5.1

ft•lb)