engine oil YAMAHA WR 250F 2010 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2010, Model line: WR 250F, Model: YAMAHA WR 250F 2010Pages: 232, PDF Size: 13.94 MB

Page 82 of 232

3-23

CHASSIS

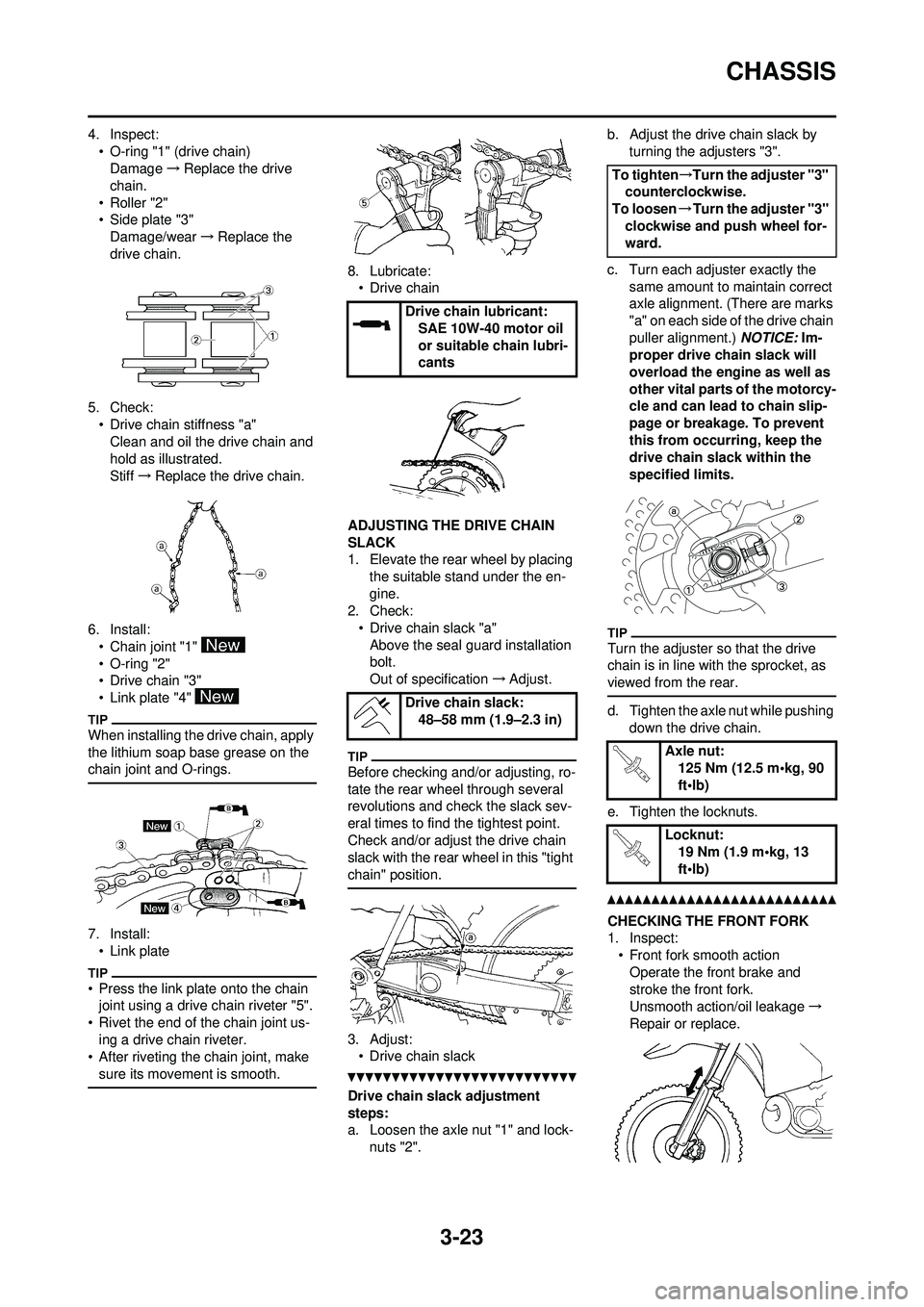

4. Inspect:• O-ring "1" (drive chain)Damage →Replace the drive

chain.

•Roller "2"

• Side plate "3" Damage/wear →Replace the

drive chain.

5. Check: • Drive chain stiffness "a"Clean and oil the drive chain and

hold as illustrated.

Stiff →Replace the drive chain.

6. Install: • Chain joint "1"

• O-ring "2"

• Drive chain "3"

• Link plate "4"

When installing the drive chain, apply

the lithium soap base grease on the

chain joint and O-rings.

7. Install:• Link plate

• Press the link plate onto the chain joint using a drive chain riveter "5".

• Rivet the end of the chain joint us- ing a drive chain riveter.

• After riveting the chain joint, make

sure its movement is smooth.

8. Lubricate:• Drive chain

ADJUSTING THE DRIVE CHAIN

SLACK

1. Elevate the rear wheel by placing the suitable stand under the en-

gine.

2. Check:

• Drive chain slack "a"Above the seal guard installation

bolt.

Out of specification →Adjust.

Before checking and/or adjusting, ro-

tate the rear wheel through several

revolutions and check the slack sev-

eral times to find the tightest point.

Check and/or adjust the drive chain

slack with the rear wheel in this "tight

chain" position.

3. Adjust:

• Drive chain slack

Drive chain slack adjustment

steps:

a. Loosen the axle nut "1" and lock-

nuts "2". b. Adjust the drive chain slack by

turning the adjusters "3".

c. Turn each adjuster exactly the same amount to maintain correct

axle alignment. (There are marks

"a" on each side of the drive chain

puller alignment.) NOTICE: Im-

proper drive chain slack will

overload the engine as well as

other vital parts of the motorcy-

cle and can lead to chain slip-

page or breakage. To prevent

this from occurring, keep the

drive chain slack within the

specified limits.

Turn the adjuster so that the drive

chain is in line with the sprocket, as

viewed from the rear.

d. Tighten the axle nut while pushing down the drive chain.

e. Tighten the locknuts.

CHECKING THE FRONT FORK

1. Inspect: • Front fork smooth action

Operate the front brake and

stroke the front fork.

Unsmooth action/oil leakage →

Repair or replace.

Drive chain lubricant: SAE 10W-40 motor oil

or suitable chain lubri-

cants

Drive chain slack: 48–58 mm (1.9–2.3 in)

To tighten →Turn the adjuster "3"

counterclockwise.

To loosen →Turn the adjuster "3"

clockwise and push wheel for-

ward.

Axle nut:125 Nm (12.5 m•kg, 90

ft•lb)

Locknut: 19 Nm (1.9 m•kg, 13

ft•lb)

Page 83 of 232

3-24

CHASSIS

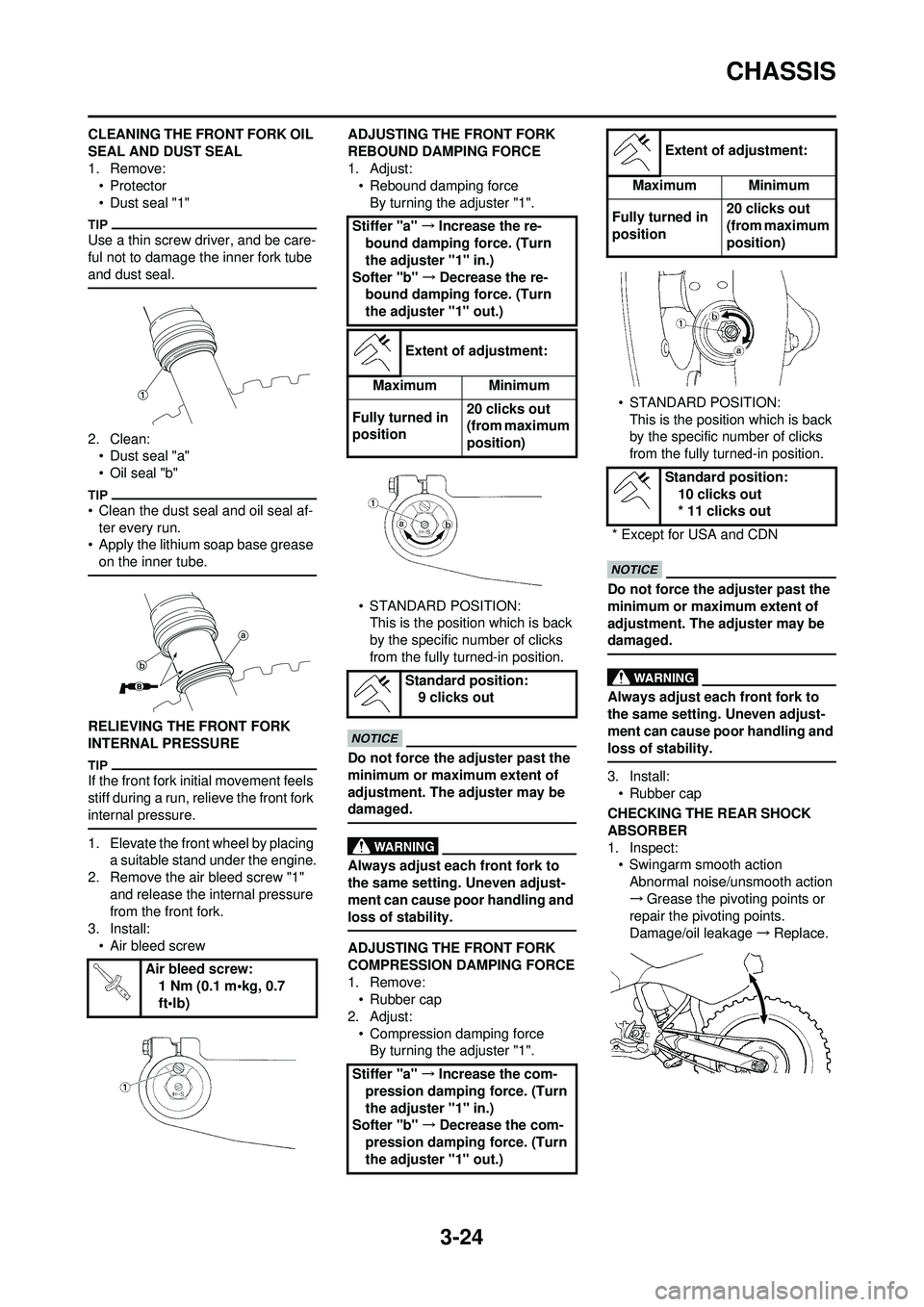

CLEANING THE FRONT FORK OIL

SEAL AND DUST SEAL

1. Remove:•Protector

• Dust seal "1"

Use a thin screw driver, and be care-

ful not to damage the inner fork tube

and dust seal.

2. Clean:• Dust seal "a"

• Oil seal "b"

• Clean the dust seal and oil seal af-

ter every run.

• Apply the lithium soap base grease on the inner tube.

RELIEVING THE FRONT FORK

INTERNAL PRESSURE

If the front fork initial movement feels

stiff during a run, relieve the front fork

internal pressure.

1. Elevate the front wheel by placing a suitable stand under the engine.

2. Remove the air bleed screw "1"

and release the internal pressure

from the front fork.

3. Install:

• Air bleed screw ADJUSTING THE FRONT FORK

REBOUND DAMPING FORCE

1. Adjust:

• Rebound damping force

By turning the adjuster "1".

• STANDARD POSITION: This is the position which is back

by the specific number of clicks

from the fully turned-in position.

Do not force the adjuster past the

minimum or maximum extent of

adjustment. The adjuster may be

damaged.

Always adjust each front fork to

the same setting. Uneven adjust-

ment can cause poor handling and

loss of stability.

ADJUSTING THE FRONT FORK

COMPRESSION DAMPING FORCE

1. Remove:• Rubber cap

2. Adjust:

• Compression damping forceBy turning the adjuster "1". • STANDARD POSITION:

This is the position which is back

by the specific number of clicks

from the fully turned-in position.

Do not force the adjuster past the

minimum or maximum extent of

adjustment. The adjuster may be

damaged.

Always adjust each front fork to

the same setting. Uneven adjust-

ment can cause poor handling and

loss of stability.

3. Install:• Rubber cap

CHECKING THE REAR SHOCK

ABSORBER

1. Inspect: • Swingarm smooth action

Abnormal noise/unsmooth action

→ Grease the pivoting points or

repair the pivoting points.

Damage/oil leakage →Replace.

Air bleed screw: 1 Nm (0.1 m•kg, 0.7

ft•lb)

Stiffer "a" →Increase the re-

bound damping force. (Turn

the adjuster "1" in.)

Softer "b" →Decrease the re-

bound damping force. (Turn

the adjuster "1" out.)

Extent of adjustment:

Maximum Minimum

Fully turned in

position 20 clicks out

(from maximum

position)

Standard position: 9 clicks out

Stiffer "a" →Increase the com-

pression damping force. (Turn

the adjuster "1" in.)

Softer "b" →Decrease the com-

pression damping force. (Turn

the adjuster "1" out.)

Extent of adjustment:

Maximum Minimum

Fully turned in

position 20 clicks out

(from maximum

position)

Standard position: 10 clicks out

* 11 clicks out

* Except for USA and CDN

Page 88 of 232

3-29

ELECTRICAL

ELECTRICAL

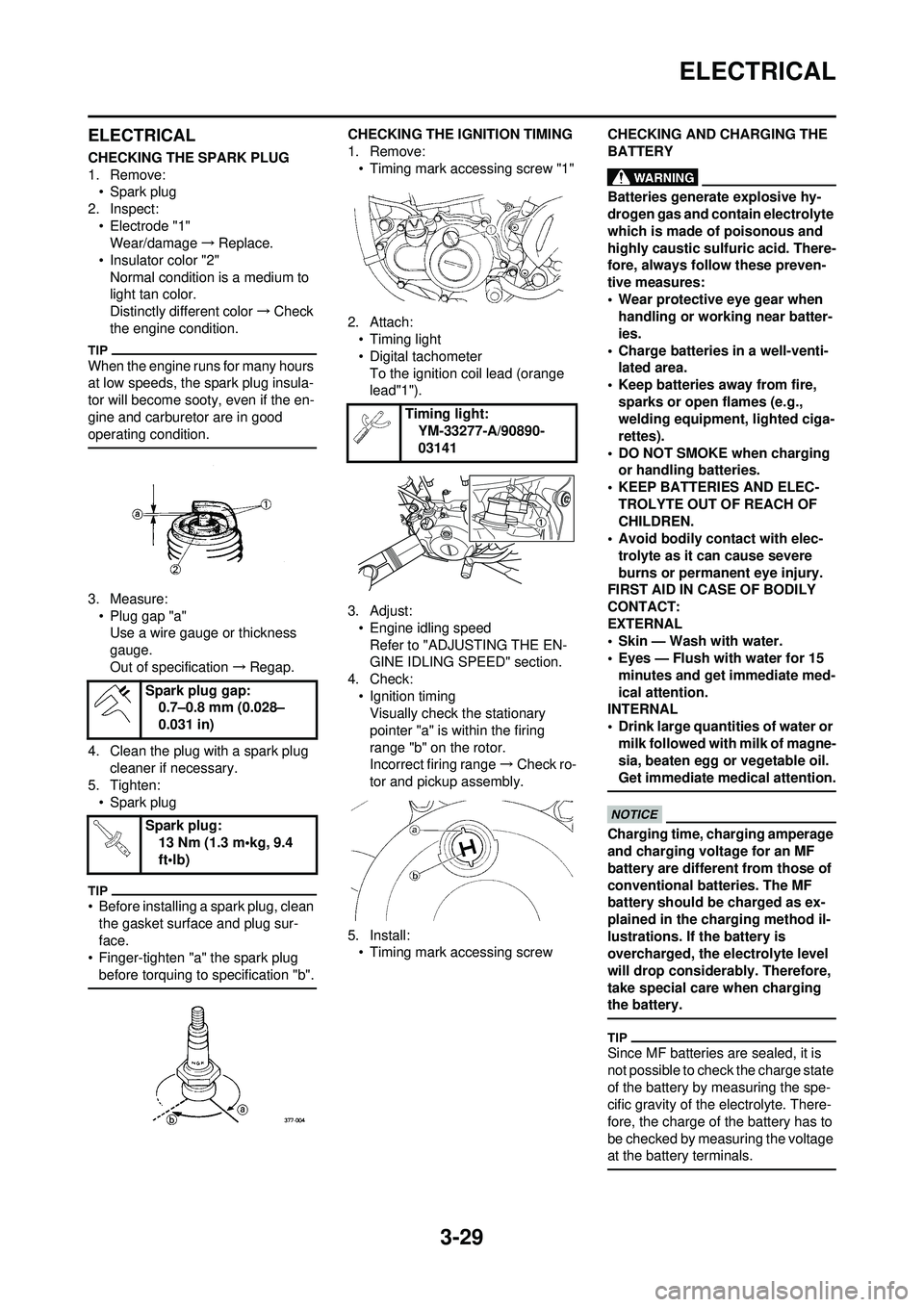

CHECKING THE SPARK PLUG

1. Remove:• Spark plug

2. Inspect:

• Electrode "1"Wear/damage →Replace.

• Insulator color "2"

Normal condition is a medium to

light tan color.

Distinctly different color →Check

the engine condition.

When the engine runs for many hours

at low speeds, the spark plug insula-

tor will become sooty, even if the en-

gine and carburetor are in good

operating condition.

3. Measure: • Plug gap "a"Use a wire gauge or thickness

gauge.

Out of specification →Regap.

4. Clean the plug with a spark plug cleaner if necessary.

5. Tighten: • Spark plug

• Before installing a spark plug, clean the gasket surface and plug sur-

face.

• Finger-tighten "a" the spark plug before torquing to specification "b".

CHECKING THE IGNITION TIMING

1. Remove:• Timing mark accessing screw "1"

2. Attach: • Timing light

• Digital tachometerTo the ignition coil lead (orange

lead"1").

3. Adjust: • Engine idling speedRefer to "ADJUSTING THE EN-

GINE IDLING SPEED" section.

4. Check: • Ignition timingVisually check the stationary

pointer "a" is within the firing

range "b" on the rotor.

Incorrect firing range →Check ro-

tor and pickup assembly.

5. Install: • Timing mark accessing screw CHECKING AND CHARGING THE

BATTERY

Batteries generate explosive hy-

drogen gas and contain electrolyte

which is made of poisonous and

highly caustic sulfuric acid. There-

fore, always follow these preven-

tive measures:

• Wear protective eye gear when

handling or working near batter-

ies.

• Charge batteries in a well-venti-

lated area.

• Keep batteries away from fire,

sparks or open flames (e.g.,

welding equipment, lighted ciga-

rettes).

• DO NOT SMOKE when charging or handling batteries.

• KEEP BATTERIES AND ELEC-

TROLYTE OUT OF REACH OF

CHILDREN.

• Avoid bodily contact with elec-

trolyte as it can cause severe

burns or permanent eye injury.

FIRST AID IN CASE OF BODILY

CONTACT:

EXTERNAL

• Skin — Wash with water.

• Eyes — Flush with water for 15 minutes and get immediate med-

ical attention.

INTERNAL

• Drink large quantities of water or

milk followed with milk of magne-

sia, beaten egg or vegetable oil.

Get immediate medical attention.

Charging time, charging amperage

and charging voltage for an MF

battery are different from those of

conventional batteries. The MF

battery should be charged as ex-

plained in the charging method il-

lustrations. If the battery is

overcharged, the electrolyte level

will drop considerably. Therefore,

take special care when charging

the battery.

Since MF batteries are sealed, it is

not possible to check the charge state

of the battery by measuring the spe-

cific gravity of the electrolyte. There-

fore, the charge of the battery has to

be checked by measuring the voltage

at the battery terminals.

Spark plug gap: 0.7–0.8 mm (0.028–

0.031 in)

Spark plug: 13 Nm (1.3 m•kg, 9.4

ft•lb)

Timing light:

YM-33277-A/90890-

03141

Page 98 of 232

4-5

CHASSIS

CHASSIS

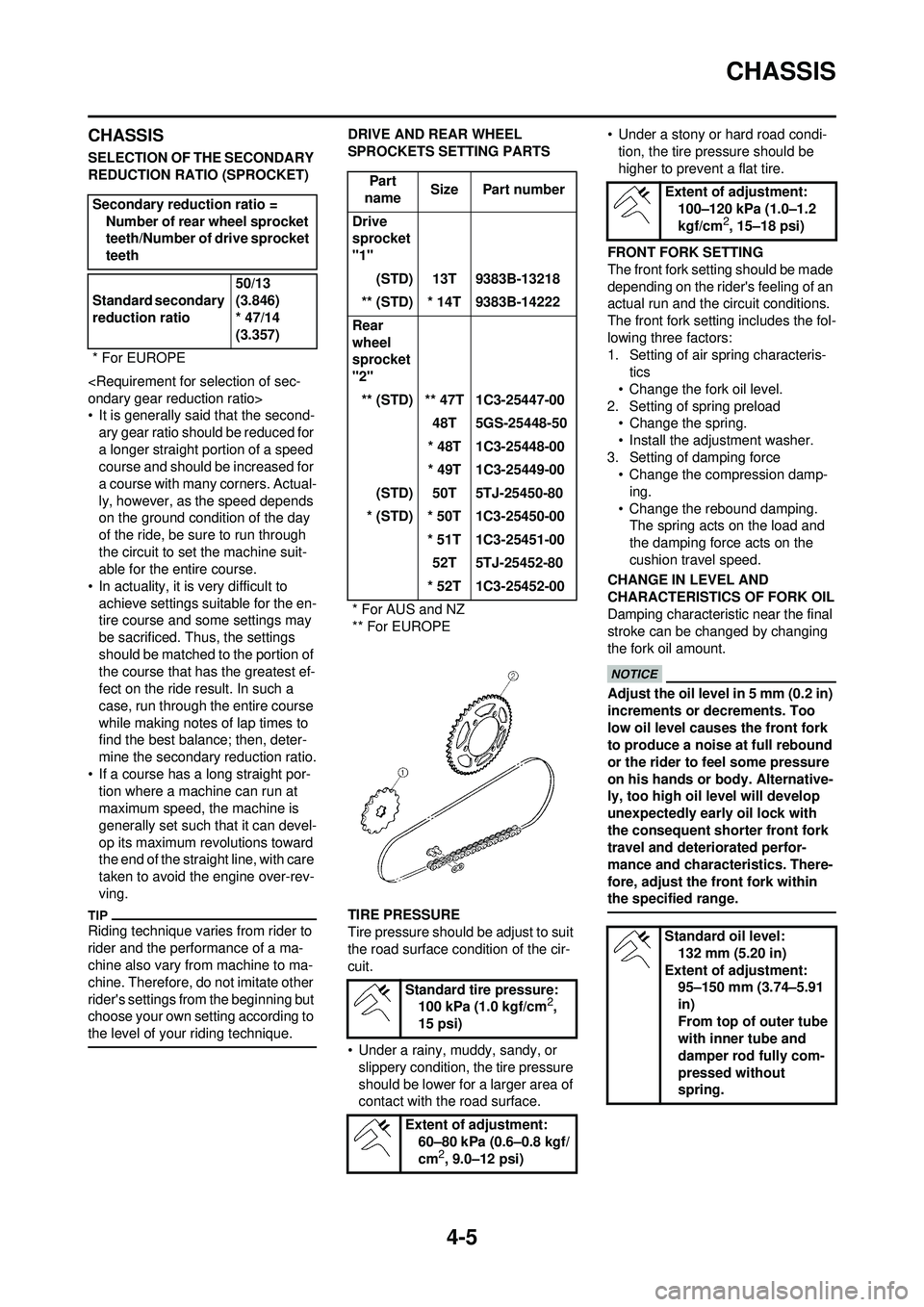

SELECTION OF THE SECONDARY

REDUCTION RATIO (SPROCKET)

• It is generally said that the second-ary gear ratio should be reduced for

a longer straight portion of a speed

course and should be increased for

a course with many corners. Actual-

ly, however, as the speed depends

on the ground condition of the day

of the ride, be su re to run through

the circuit to set the machine suit-

able for the entire course.

• In actuality, it is very difficult to

achieve settings suitable for the en-

tire course and some settings may

be sacrificed. Thus, the settings

should be matched to the portion of

the course that has the greatest ef-

fect on the ride result. In such a

case, run through the entire course

while making notes of lap times to

find the best balance; then, deter-

mine the secondary reduction ratio.

• If a course has a long straight por-

tion where a machine can run at

maximum speed, the machine is

generally set such that it can devel-

op its maximum revolutions toward

the end of the straight line, with care

taken to avoid the engine over-rev-

ving.

Riding technique varies from rider to

rider and the performance of a ma-

chine also vary fr om machine to ma-

chine. Therefore, do not imitate other

rider's settings from the beginning but

choose your own setting according to

the level of your riding technique.

DRIVE AND REAR WHEEL

SPROCKETS SETTING PARTS

TIRE PRESSURE

Tire pressure should be adjust to suit

the road surface condition of the cir-

cuit.

• Under a rainy, muddy, sandy, or slippery condition, the tire pressure

should be lower for a larger area of

contact with the road surface. • Under a stony or hard road condi-

tion, the tire pressure should be

higher to prevent a flat tire.

FRONT FORK SETTING

The front fork setting should be made

depending on the rider's feeling of an

actual run and the circuit conditions.

The front fork setting includes the fol-

lowing three factors:

1. Setting of air spring characteris- tics

• Change the fork oil level.

2. Setting of spring preload • Change the spring.

• Install the adjustment washer.

3. Setting of damping force • Change the compression damp-

ing.

• Change the rebound damping. The spring acts on the load and

the damping force acts on the

cushion travel speed.

CHANGE IN LEVEL AND

CHARACTERISTICS OF FORK OIL

Damping characteristic near the final

stroke can be changed by changing

the fork oil amount.

Adjust the oil level in 5 mm (0.2 in)

increments or decrements. Too

low oil level caus es the front fork

to produce a noise at full rebound

or the rider to feel some pressure

on his hands or body. Alternative-

ly, too high oil level will develop

unexpectedly early oil lock with

the consequent shorter front fork

travel and deteriorated perfor-

mance and characteristics. There-

fore, adjust the front fork within

the specified range.

Secondary reduction ratio =

Number of rear wheel sprocket

teeth/Number of drive sprocket

teeth

Standard secondary

reduction ratio 50/13

(3.846)

* 47/14

(3.357)

* For EUROPE

Part

name Size Part number

Drive

sprocket

"1" (STD) 13T 9383B-13218

** (STD) * 14T 9383B-14222

Rear

wheel

sprocket

"2" ** (STD) ** 47T 1C3-25447-00 48T 5GS-25448-50

* 48T 1C3-25448-00

* 49T 1C3-25449-00

(STD) 50T 5TJ-25450-80

* (STD) * 50T 1C3-25450-00 * 51T 1C3-25451-0052T 5TJ-25452-80

* 52T 1C3-25452-00

* For AUS and NZ

** For EUROPE

Standard tire pressure:100 kPa (1.0 kgf/cm

2,

15 psi)

Extent of adjustment: 60–80 kPa (0.6–0.8 kgf/

cm

2, 9.0–12 psi)

Extent of adjustment: 100–120 kPa (1.0–1.2

kgf/cm

2, 15–18 psi)

Standard oil level: 132 mm (5.20 in)

Extent of adjustment: 95–150 mm (3.74–5.91

in)

From top of outer tube

with inner tube and

damper rod fully com-

pressed without

spring.

Page 120 of 232

5-17

CAMSHAFTS

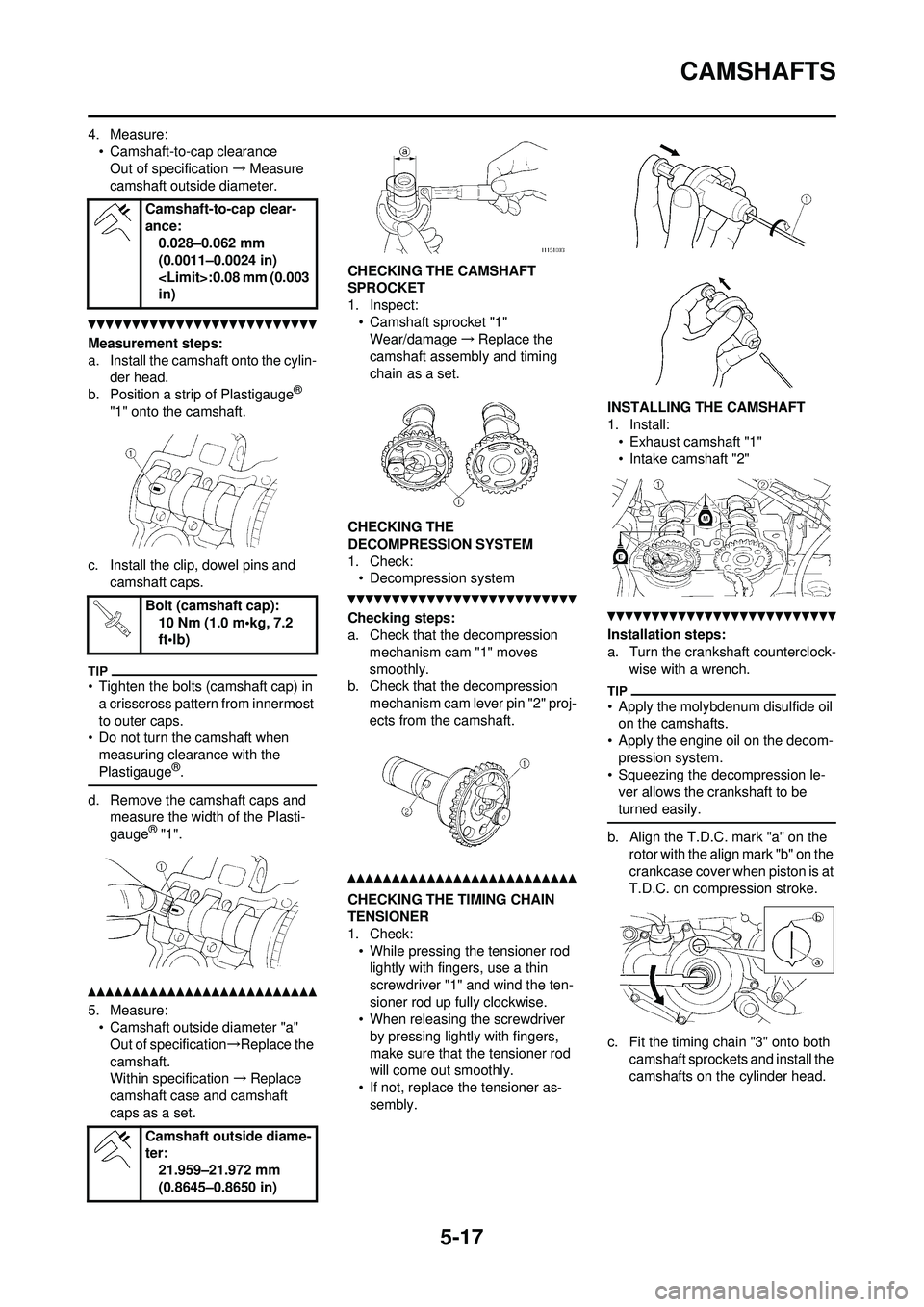

4. Measure:• Camshaft-to-cap clearanceOut of specification →Measure

camshaft outside diameter.

Measurement steps:

a. Install the camshaft onto the cylin- der head.

b. Position a strip of Plastigauge

®

"1" onto the camshaft.

c. Install the clip, dowel pins and camshaft caps.

• Tighten the bolts (camshaft cap) in a crisscross pattern from innermost

to outer caps.

• Do not turn the camshaft when

measuring clearance with the

Plastigauge

®.

d. Remove the camshaft caps and measure the width of the Plasti-

gauge

® "1".

5. Measure:• Camshaft outside diameter "a"

Out of specification →Replace the

camshaft.

Within specification →Replace

camshaft case and camshaft

caps as a set. CHECKING THE CAMSHAFT

SPROCKET

1. Inspect:

• Camshaft sprocket "1"Wear/damage →Replace the

camshaft assemb ly and timing

chain as a set.

CHECKING THE

DECOMPRESSION SYSTEM

1. Check: • Decompression system

Checking steps:

a. Check that the decompression

mechanism cam "1" moves

smoothly.

b. Check that the decompression

mechanism cam lever pin "2" proj-

ects from the camshaft.

CHECKING THE TIMING CHAIN

TENSIONER

1. Check:• While pressing the tensioner rod lightly with fingers, use a thin

screwdriver "1" and wind the ten-

sioner rod up fully clockwise.

• When releasing the screwdriver

by pressing lightly with fingers,

make sure that the tensioner rod

will come out smoothly.

• If not, replace the tensioner as- sembly. INSTALLING THE CAMSHAFT

1. Install:

• Exhaust camshaft "1"

• Intake camshaft "2"

Installation steps:

a. Turn the crankshaft counterclock- wise with a wrench.

• Apply the molybdenum disulfide oil on the camshafts.

• Apply the engine oil on the decom- pression system.

• Squeezing the decompression le-

ver allows the crankshaft to be

turned easily.

b. Align the T.D.C. mark "a" on the rotor with the align mark "b" on the

crankcase cover when piston is at

T.D.C. on compression stroke.

c. Fit the timing chain "3" onto both camshaft sprockets and install the

camshafts on the cylinder head.

Camshaft-to-cap clear-

ance:

0.028–0.062 mm

(0.0011–0.0024 in)

in)

Bolt (camshaft cap): 10 Nm (1.0 m•kg, 7.2

ft•lb)

Camshaft outside diame-

ter: 21.959–21.972 mm

(0.8645–0.8650 in)

Page 122 of 232

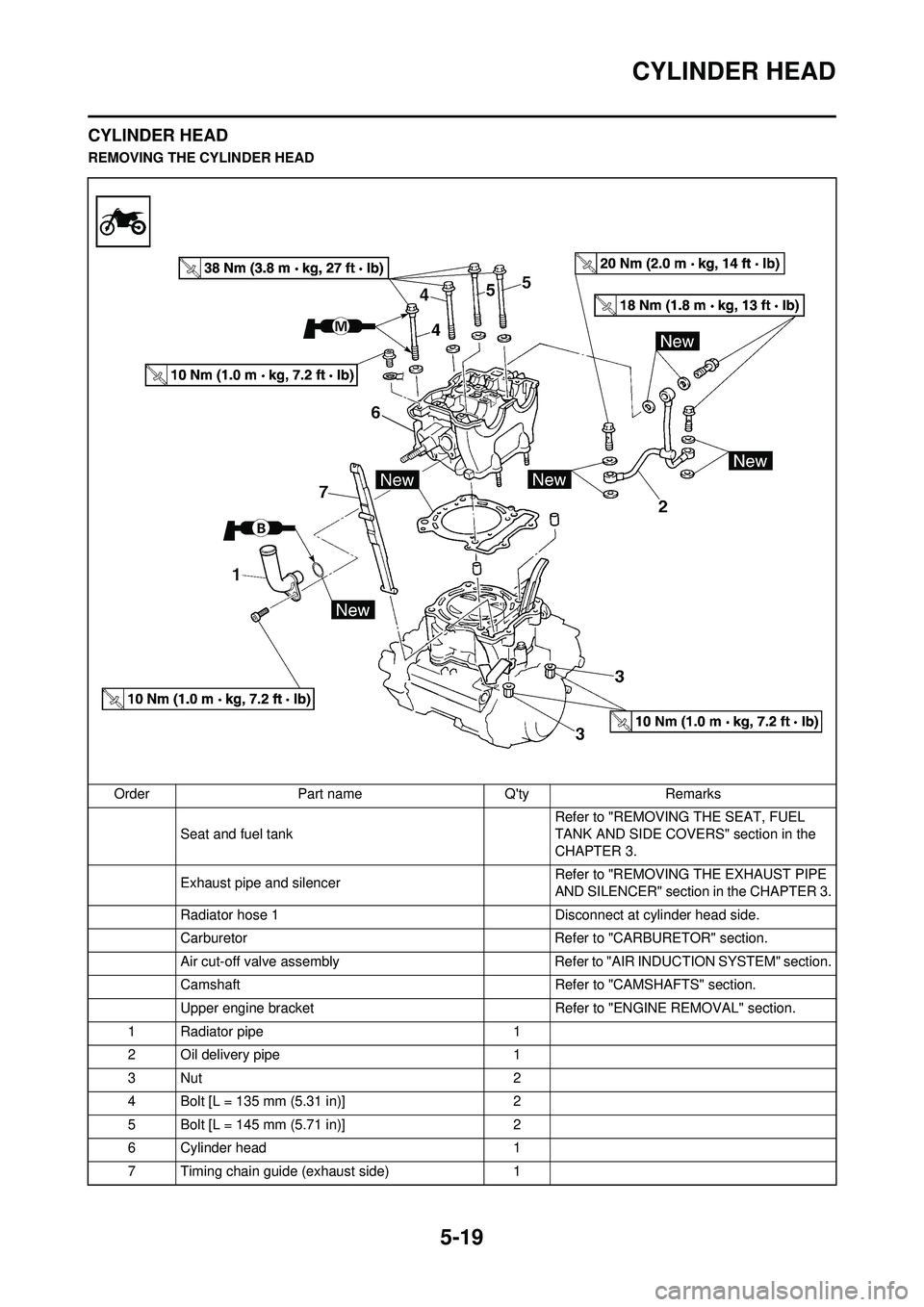

5-19

CYLINDER HEAD

CYLINDER HEAD

REMOVING THE CYLINDER HEADOrder Part name Q'ty Remarks Seat and fuel tank Refer to "REMOVING THE SEAT, FUEL

TANK AND SIDE COVERS" section in the

CHAPTER 3.

Exhaust pipe and silencer Refer to "REMOVING THE EXHAUST PIPE

AND SILENCER" section in the CHAPTER 3.

Radiator hose 1 Disconnect at cylinder head side.

Carburetor Refer to "CARBURETOR" section.

Air cut-off valve assembly Refer to "AIR INDUCTION SYSTEM" section.

Camshaft Refer to "CAMSHAFTS" section.

Upper engine bracket Refer to "ENGINE REMOVAL" section.

1 Radiator pipe 1

2 Oil delivery pipe 1

3Nut 2

4 Bolt [L = 135 mm (5.31 in)] 2

5 Bolt [L = 145 mm (5.71 in)] 2

6 Cylinder head 1

7 Timing chain guide (exhaust side) 1

Page 127 of 232

5-24

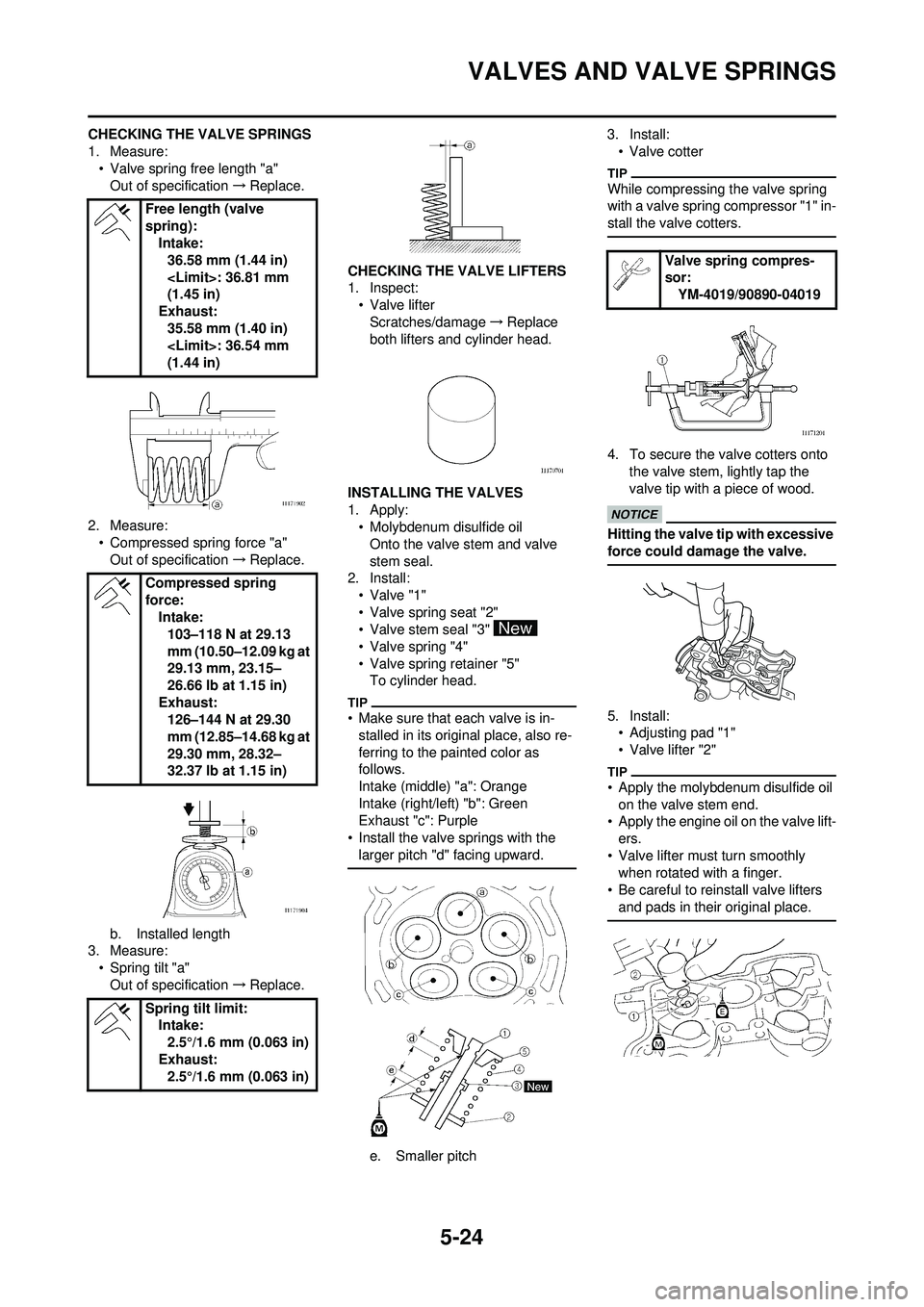

VALVES AND VALVE SPRINGS

CHECKING THE VALVE SPRINGS

1. Measure:• Valve spring free length "a"Out of specification →Replace.

2. Measure: • Compressed spring force "a"Out of specification →Replace.

b. Installed length

3. Measure:

• Spring tilt "a"Out of specification →Replace. CHECKING THE

VALVE LIFTERS

1. Inspect:

• Valve lifterScratches/damage →Replace

both lifters and cylinder head.

INSTALLING THE VALVES

1. Apply: • Molybdenum disulfide oil

Onto the valve stem and valve

stem seal.

2. Install:

• Valve "1"

• Valve spring seat "2"

• Valve stem seal "3"

• Valve spring "4"

• Valve spring retainer "5"To cylinder head.

• Make sure that each valve is in-

stalled in its original place, also re-

ferring to the painted color as

follows.

Intake (middle) "a": Orange

Intake (right/left) "b": Green

Exhaust "c": Purple

• Install the valve springs with the larger pitch "d" facing upward.

e. Smaller pitch 3. Install:

• Valve cotter

While compressing the valve spring

with a valve spring compressor "1" in-

stall the valve cotters.

4. To secure the valve cotters onto the valve stem, lightly tap the

valve tip with a piece of wood.

Hitting the valve tip with excessive

force could damage the valve.

5. Install:• Adjusting pad "1"

• Valve lifter "2"

• Apply the molybdenum disulfide oil on the valve stem end.

• Apply the engine oil on the valve lift-

ers.

• Valve lifter must turn smoothly when rotated with a finger.

• Be careful to reinstall valve lifters and pads in their original place.

Free length (valve

spring): Intake:36.58 mm (1.44 in)

(1.45 in)

Exhaust:

35.58 mm (1.40 in)

(1.44 in)

Compressed spring

force: Intake:103–118 N at 29.13

mm (10.50–12.09 kg at

29.13 mm, 23.15–

26.66 lb at 1.15 in)

Exhaust: 126–144 N at 29.30

mm (12.85–14.68 kg at

29.30 mm, 28.32–

32.37 lb at 1.15 in)

Spring tilt limit: Intake:

2.5°/1.6 mm (0.063 in)

Exhaust: 2.5°/1.6 mm (0.063 in)

Valve spring compres-

sor:

YM-4019/90890-04019

Page 130 of 232

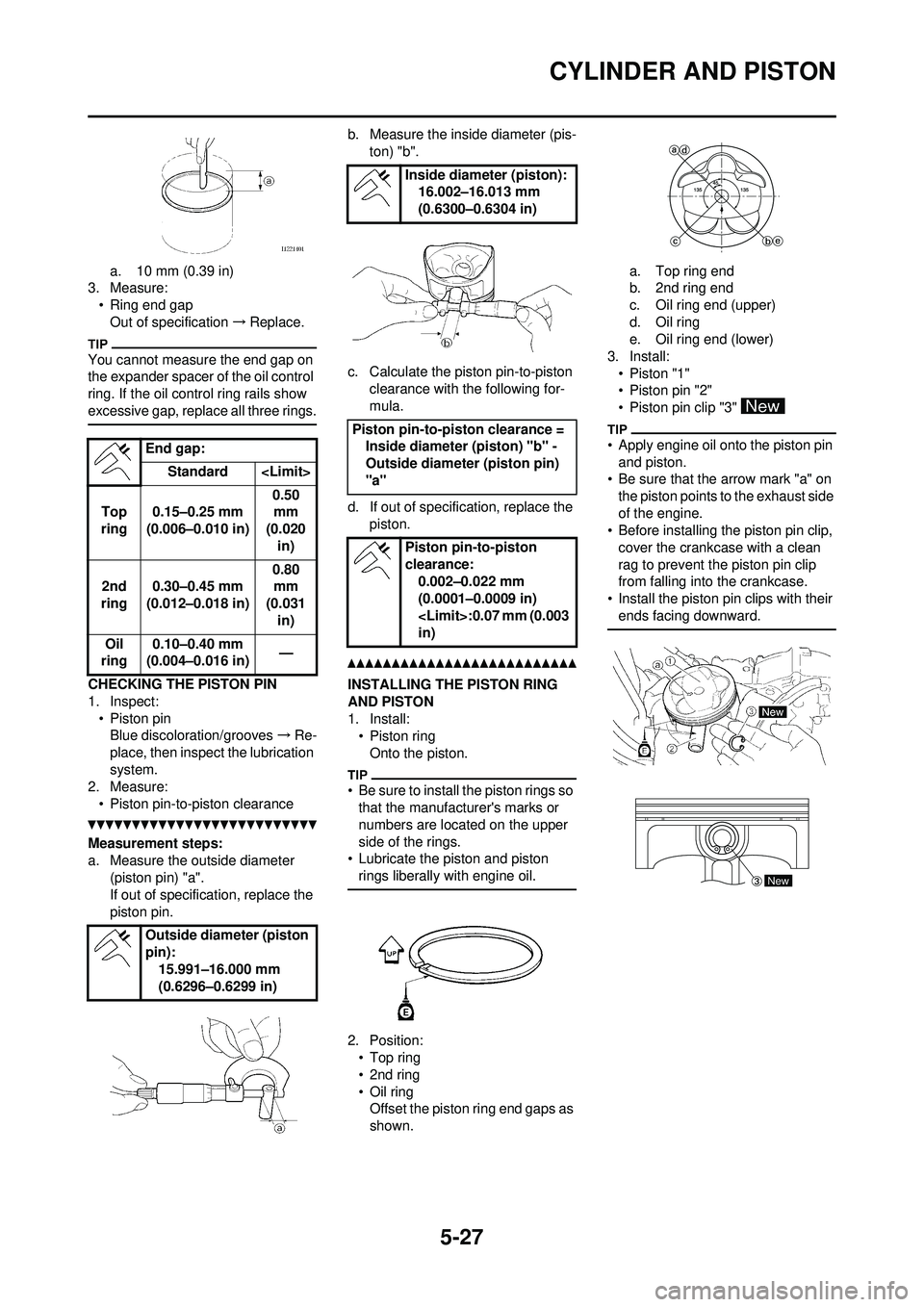

5-27

CYLINDER AND PISTON

a. 10 mm (0.39 in)

3. Measure:

• Ring end gapOut of specification →Replace.

You cannot measure the end gap on

the expander spacer of the oil control

ring. If the oil control ring rails show

excessive gap, replace all three rings.

CHECKING THE PISTON PIN

1. Inspect:

• Piston pinBlue discoloration/grooves →Re-

place, then inspect the lubrication

system.

2. Measure:

• Piston pin-to-piston clearance

Measurement steps:

a. Measure the outside diameter (piston pin) "a".

If out of specification, replace the

piston pin. b. Measure the inside diameter (pis-

ton) "b".

c. Calculate the piston pin-to-piston clearance with the following for-

mula.

d. If out of specific ation, replace the

piston.

INSTALLING THE PISTON RING

AND PISTON

1. Install: •Piston ringOnto the piston.

• Be sure to install the piston rings so that the manufacturer's marks or

numbers are located on the upper

side of the rings.

• Lubricate the piston and piston

rings liberally with engine oil.

2. Position:•Top ring

• 2nd ring

• Oil ringOffset the piston ring end gaps as

shown. a. Top ring end

b. 2nd ring end

c. Oil ring end (upper)

d. Oil ring

e. Oil ring end (lower)

3. Install: • Piston "1"

• Piston pin "2"

• Piston pin clip "3"

• Apply engine oil onto the piston pin and piston.

• Be sure that the arrow mark "a" on

the piston points to the exhaust side

of the engine.

• Before installing the piston pin clip,

cover the crankcase with a clean

rag to prevent the piston pin clip

from falling into the crankcase.

• Install the piston pin clips with their ends facing downward.End gap:

Standard

Top

ring 0.15–0.25 mm

(0.006–0.010 in) 0.50

mm

(0.020

in)

2nd

ring 0.30–0.45 mm

(0.012–0.018 in) 0.80

mm

(0.031

in)

Oil

ring 0.10–0.40 mm

(0.004–0.016 in) —

Outside diameter (piston

pin): 15.991–16.000 mm

(0.6296–0.6299 in)

Inside diameter (piston):16.002–16.013 mm

(0.6300–0.6304 in)

Piston pin-to-pis ton clearance =

Inside diameter (piston) "b" -

Outside diameter (piston pin)

"a"

Piston pin-to-piston

clearance:0.002–0.022 mm

(0.0001–0.0009 in)

in)

New

Page 131 of 232

5-28

CYLINDER AND PISTON

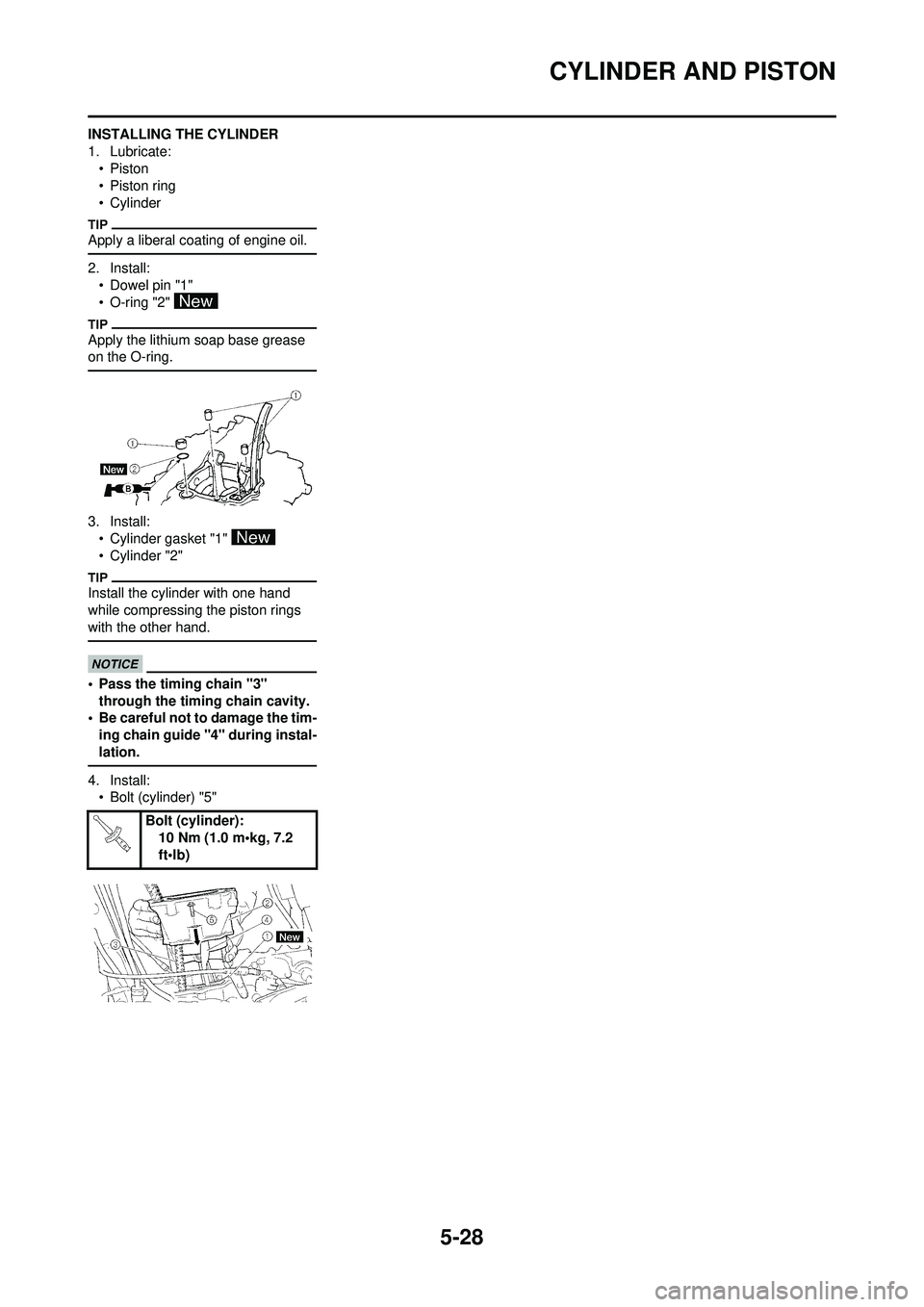

INSTALLING THE CYLINDER

1. Lubricate:•Piston

• Piston ring

• Cylinder

Apply a liberal coating of engine oil.

2. Install:

• Dowel pin "1"

• O-ring "2"

Apply the lithium soap base grease

on the O-ring.

3. Install:• Cylinder gasket "1"

• Cylinder "2"

Install the cylinder with one hand

while compressing the piston rings

with the other hand.

• Pass the timing chain "3" through the timing chain cavity.

• Be careful not to damage the tim-

ing chain guide "4" during instal-

lation.

4. Install:• Bolt (cylinder) "5"

Bolt (cylinder):10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 132 of 232

5-29

CLUTCH

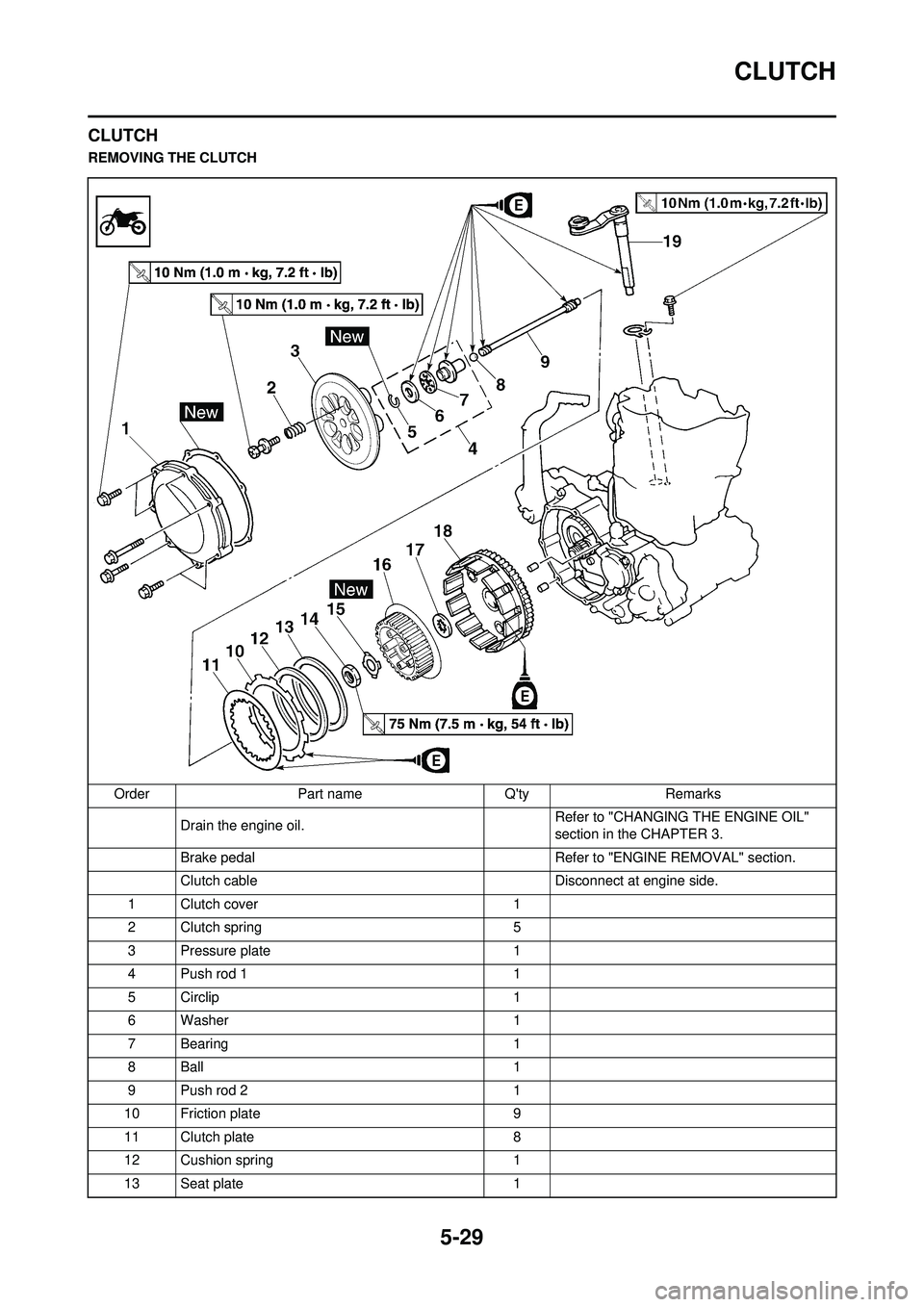

CLUTCH

REMOVING THE CLUTCHOrder Part name Q'ty Remarks Drain the engine oil. Refer to "CHANGING THE ENGINE OIL"

section in the CHAPTER 3.

Brake pedal Refer to "ENGINE REMOVAL" section.

Clutch cable Disconnect at engine side.

1 Clutch cover 1

2 Clutch spring 5

3 Pressure plate 1

4 Push rod 1 1

5 Circlip 1

6 Washer 1

7 Bearing 1

8Ball 1

9 Push rod 2 1

10 Friction plate 9

11 Clutch plate 8

12 Cushion spring 1

13 Seat plate 1