oil pressure YAMAHA WR 250F 2010 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2010, Model line: WR 250F, Model: YAMAHA WR 250F 2010Pages: 232, PDF Size: 13.94 MB

Page 31 of 232

1-21

CLEANING AND STORAGE

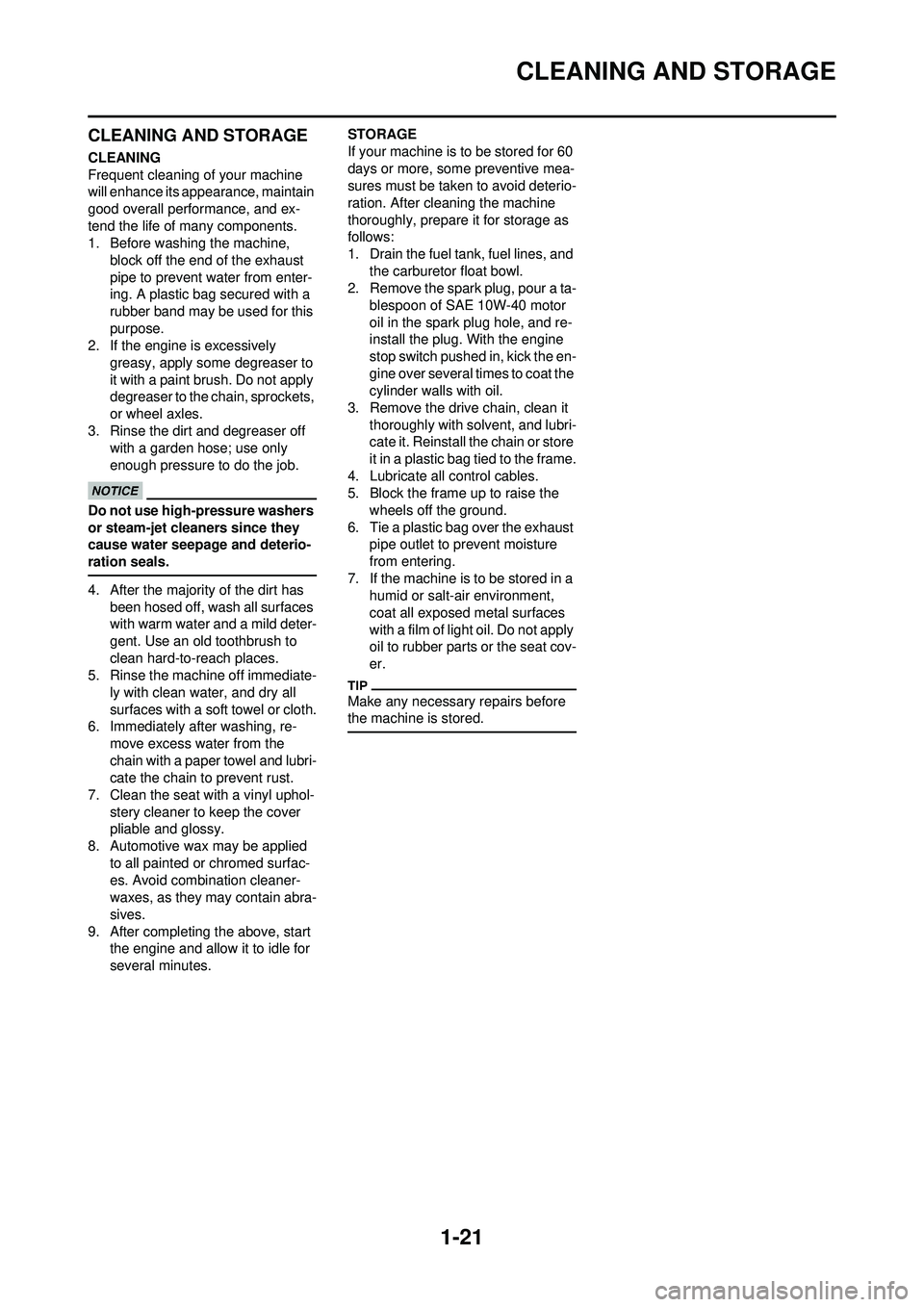

CLEANING AND STORAGE

CLEANING

Frequent cleaning of your machine

will enhance its appearance, maintain

good overall performance, and ex-

tend the life of many components.

1. Before washing the machine, block off the end of the exhaust

pipe to prevent water from enter-

ing. A plastic bag secured with a

rubber band may be used for this

purpose.

2. If the engine is excessively greasy, apply some degreaser to

it with a paint brush. Do not apply

degreaser to the chain, sprockets,

or wheel axles.

3. Rinse the dirt and degreaser off with a garden hose; use only

enough pressure to do the job.

Do not use high-pressure washers

or steam-jet cleaners since they

cause water seepage and deterio-

ration seals.

4. After the majority of the dirt has

been hosed off, wash all surfaces

with warm water and a mild deter-

gent. Use an old toothbrush to

clean hard-to-reach places.

5. Rinse the machine off immediate- ly with clean water, and dry all

surfaces with a soft towel or cloth.

6. Immediately after washing, re- move excess water from the

chain with a paper towel and lubri-

cate the chain to prevent rust.

7. Clean the seat with a vinyl uphol-

stery cleaner to keep the cover

pliable and glossy.

8. Automotive wax may be applied

to all painted or chromed surfac-

es. Avoid combination cleaner-

waxes, as they may contain abra-

sives.

9. After completing the above, start the engine and allow it to idle for

several minutes. STORAGE

If your machine is to be stored for 60

days or more, some preventive mea-

sures must be taken to avoid deterio-

ration. After cleaning the machine

thoroughly, prepare it for storage as

follows:

1. Drain the fuel tank, fuel lines, and

the carburetor float bowl.

2. Remove the spark plug, pour a ta-

blespoon of SAE 10W-40 motor

oil in the spark plug hole, and re-

install the plug. With the engine

stop switch pushed in, kick the en-

gine over several times to coat the

cylinder walls with oil.

3. Remove the drive chain, clean it thoroughly with solvent, and lubri-

cate it. Reinstall the chain or store

it in a plastic bag tied to the frame.

4. Lubricate all control cables.

5. Block the frame up to raise the

wheels off the ground.

6. Tie a plastic bag over the exhaust pipe outlet to prevent moisture

from entering.

7. If the machine is to be stored in a humid or salt-air environment,

coat all exposed metal surfaces

with a film of light oil. Do not apply

oil to rubber parts or the seat cov-

er.

Make any necessary repairs before

the machine is stored.

Page 39 of 232

2-8

MAINTENANCE SPECIFICATIONS

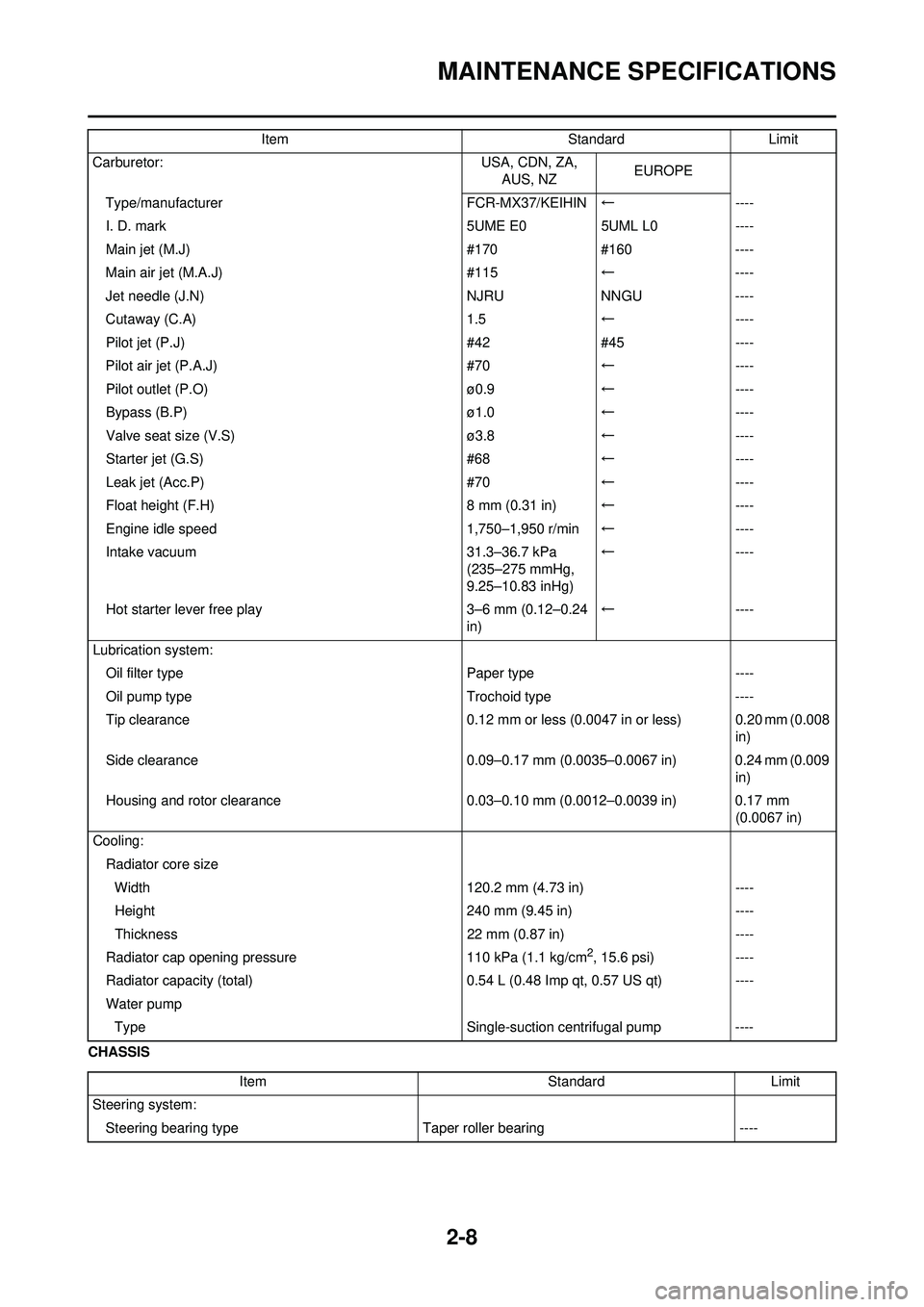

CHASSISCarburetor:

USA, CDN, ZA,

AUS, NZ EUROPE

Type/manufacturer FCR-MX37/KEIHIN← ----

I. D. mark 5UME E05UML L0----

Main jet (M.J) #170#160----

Main air jet (M.A.J) #115← ----

Jet needle (J.N) NJRUNNGU----

Cutaway (C.A) 1.5←----

Pilot jet (P.J) #42#45 ----

Pilot air jet (P.A.J) #70← ----

Pilot outlet (P.O) ø0.9←----

Bypass (B.P) ø1.0←----

Valve seat size (V.S) ø3.8←----

Starter jet (G.S) #68← ----

Leak jet (Acc.P) #70← ----

Float height (F.H) 8 mm (0.31 in)← ----

Engine idle speed 1,750–1,950 r/min← ----

Intake vacuum 31.3–36.7 kPa

(235–275 mmHg,

9.25–10.83 inHg) ←

----

Hot starter lever free play 3–6 mm (0.12–0.24

in) ←

----

Lubrication system: Oil filter type Paper type----

Oil pump type Trochoid type----

Tip clearance 0.12 mm or less (0.0047 in or less) 0.20 mm (0.008

in)

Side clearance 0.09–0.17 mm (0.0035–0.0067 in) 0.24 mm (0.009

in)

Housing and rotor clearance 0.03–0.10 mm (0.0012–0.0039 in) 0.17 mm

(0.0067 in)

Cooling: Radiator core sizeWidth 120.2 mm (4.73 in)----

Height 240 mm (9.45 in)----

Thickness 22 mm (0.87 in)----

Radiator cap opening pressure 110 kPa (1.1 kg/cm

2, 15.6 psi)----

Radiator capacity (total) 0.54 L (0.48 Imp qt, 0.57 US qt)----

Water pump Type Single-suction centrifugal pump----

Item

StandardLimit

Item StandardLimit

Steering system: Steering bearing type Taper roller bearing----

Page 40 of 232

2-9

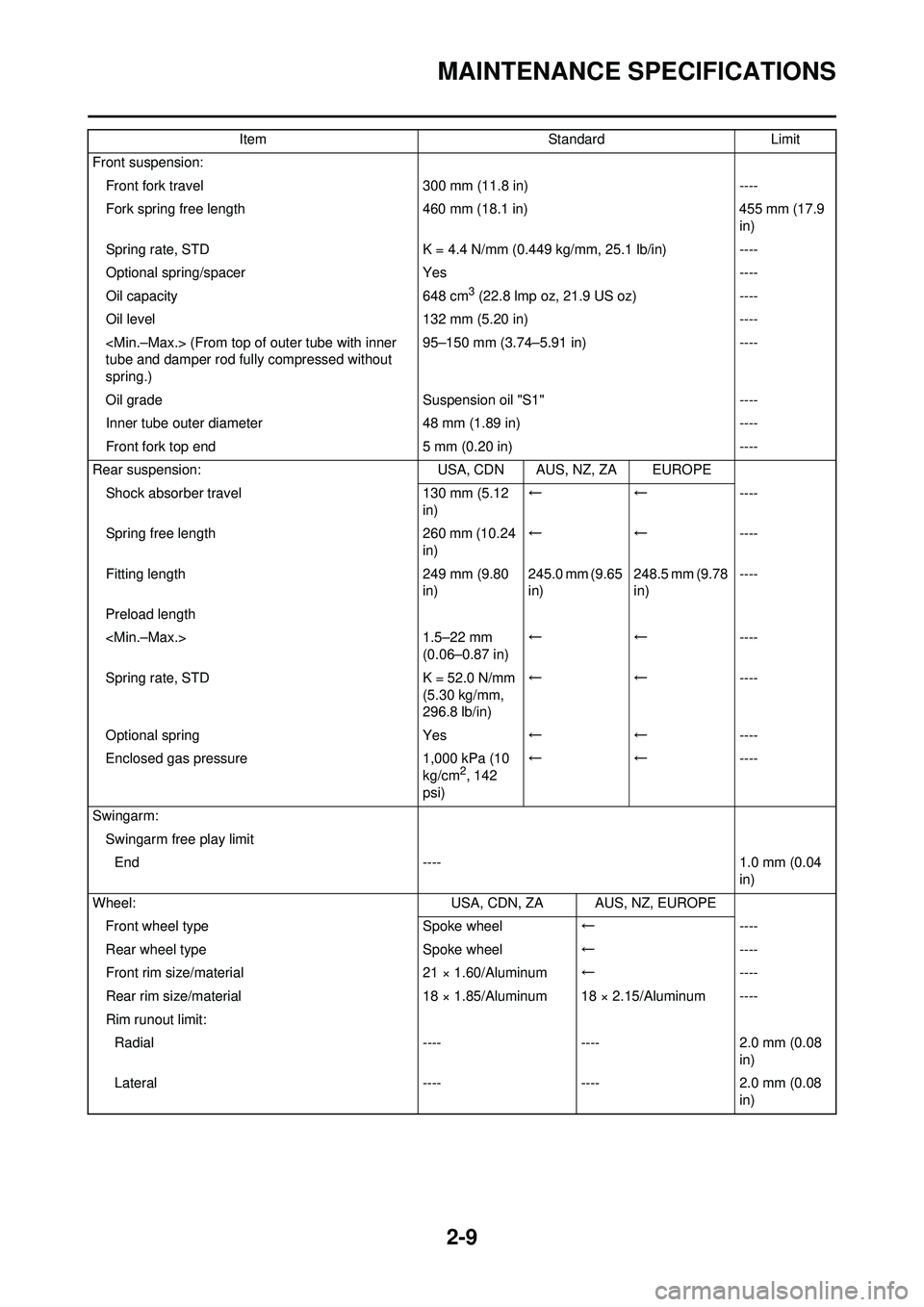

MAINTENANCE SPECIFICATIONS

Front suspension:Front fork travel 300 mm (11.8 in)----

Fork spring free length 460 mm (18.1 in)455 mm (17.9

in)

Spring rate, STD K = 4.4 N/mm (0.449 kg/mm, 25.1 lb/in)----

Optional spring/spacer Yes----

Oil capacity 648 cm

3 (22.8 lmp oz, 21.9 US oz)----

Oil level 132 mm (5.20 in)----

tube and damper rod fully compressed without

spring.) 95–150 mm (3.74–5.91 in)

----

Oil grade Suspension oil "S1"----

Inner tube outer diamet er 48 mm (1.89 in) ----

Front fork top end 5 mm (0.20 in)----

Rear suspension: USA, CDN AUS, NZ, ZA EUROPE

Shock absorber travel 130 mm (5.12

in) ←←----

Spring free length 260 mm (10.24

in) ←←----

Fitting length 249 mm (9.80

in) 245.0 mm (9.65

in)248.5 mm (9.78

in)----

Preload length

(0.06–0.87 in) ←←----

Spring rate, STD K = 52.0 N/mm

(5.30 kg/mm,

296.8 lb/in) ←←----

Optional spring Yes←←----

Enclosed gas pressure 1,000 kPa (10

kg/cm

2, 142

psi) ←←----

Swingarm: Swingarm free play limitEnd ---- 1.0 mm (0.04 in)

Wheel: USA, CDN, ZA AUS, NZ, EUROPE

Front wheel type Spoke wheel←----

Rear wheel type Spoke wheel←----

Front rim size/material 21 × 1.60/Aluminum←----

Rear rim size/mater ial 18 × 1.85/Aluminum 18 × 2.15/Aluminum ----

Rim runout limit: Radial --------2.0 mm (0.08

in)

Lateral --------2.0 mm (0.08

in)

Item

StandardLimit

Page 43 of 232

2-12

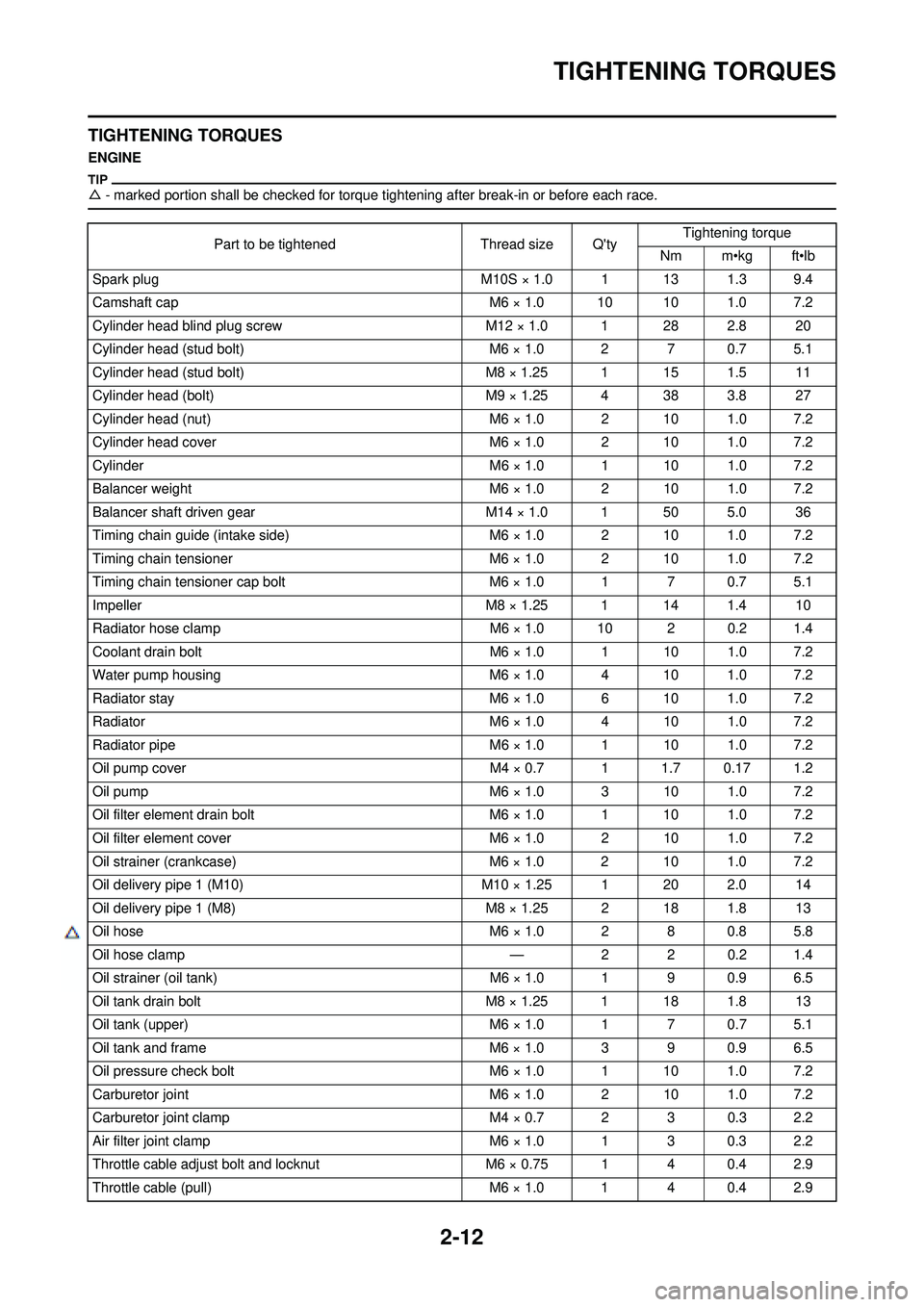

TIGHTENING TORQUES

TIGHTENING TORQUES

ENGINE

△- marked portion shall be checked for torque ti ghtening after break-in or before each race.

Part to be tightenedThread size Q'tyTightening torque

Nm m•kg ft•lb

Spark plug M10S × 1.0 1 13 1.3 9.4

Camshaft cap M6 × 1.0 10 10 1.0 7.2

Cylinder head blind plug screw M12 × 1.0 1 28 2.8 20

Cylinder head (stud bolt) M6 × 1.0 2 7 0.7 5.1

Cylinder head (stud bolt) M8 × 1.25 1 15 1.5 11

Cylinder head (bolt) M9 × 1.25 4 38 3.8 27

Cylinder head (nut) M6 × 1.0 2 10 1.0 7.2

Cylinder head cover M6 × 1.0 2 10 1.0 7.2

Cylinder M6 × 1.0 1 10 1.0 7.2

Balancer weight M6 × 1.0 2 10 1.0 7.2

Balancer shaft driven gear M14 × 1.0 1 50 5.0 36

Timing chain guide (intake side) M6 × 1.0 2 10 1.0 7.2

Timing chain tensioner M6 × 1.0 2 10 1.0 7.2

Timing chain tensioner cap bolt M6 × 1.0 1 7 0.7 5.1

Impeller M8 × 1.25 1 14 1.4 10

Radiator hose clamp M6 × 1.0 10 2 0.2 1.4

Coolant drain bolt M6 × 1.0 1 10 1.0 7.2

Water pump housing M6 × 1.0 4 10 1.0 7.2

Radiator stay M6 × 1.0 6 10 1.0 7.2

Radiator M6 × 1.0 4 10 1.0 7.2

Radiator pipe M6 × 1.0 1 10 1.0 7.2

Oil pump cover M4 × 0.7 1 1.7 0.17 1.2

Oil pump M6 × 1.0 3 10 1.0 7.2

Oil filter element drain bolt M6 × 1.0 1 10 1.0 7.2

Oil filter element cover M6 × 1.0 2 10 1.0 7.2

Oil strainer (crankcase) M6 × 1.0 2 10 1.0 7.2

Oil delivery pipe 1 (M10) M10 × 1.25 1 20 2.0 14

Oil delivery pipe 1 (M8) M8 × 1.25 2 18 1.8 13

Oil hose M6 × 1.0 2 8 0.8 5.8

△ Oil hose clamp —2 2 0.2 1.4

Oil strainer (oil tank) M6 × 1.0 1 9 0.9 6.5

Oil tank drain bolt M8 × 1.25 1 18 1.8 13

Oil tank (upper) M6 × 1.0 1 7 0.7 5.1

Oil tank and frame M6 × 1.0 3 9 0.9 6.5

Oil pressure check bolt M6 × 1.0 1 10 1.0 7.2

Carburetor joint M6 × 1.0 2 10 1.0 7.2

Carburetor joint clamp M4 × 0.7 2 3 0.3 2.2

Air filter joint clamp M6 × 1.0 1 3 0.3 2.2

Throttle cable adjust bolt and locknut M6 × 0.75 1 4 0.4 2.9

Throttle cable (pull) M6 × 1.0 1 4 0.4 2.9

Page 65 of 232

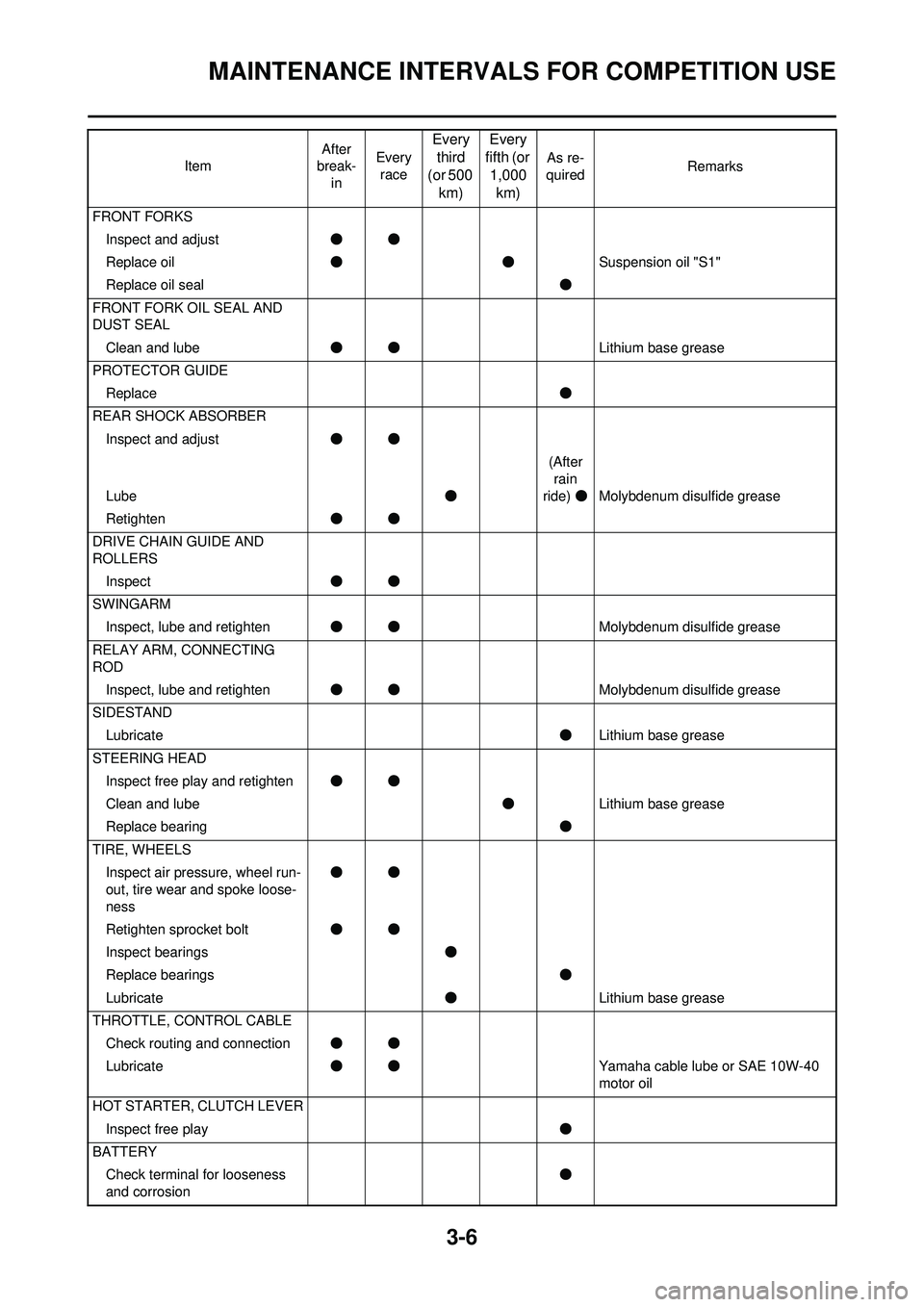

3-6

MAINTENANCE INTERVALS FOR COMPETITION USE

FRONT FORKSInspect and adjust ●●

Replace oil ●● Suspension oil "S1"

Replace oil seal ●

FRONT FORK OIL SEAL AND

DUST SEAL Clean and lube ●● Lithium base grease

PROTECTOR GUIDE Replace ●

REAR SHOCK ABSORBER Inspect and adjust ●●

Lube ●(After

rain

ride) ●Molybdenum disulfide grease

Retighten ●●

DRIVE CHAIN GUIDE AND

ROLLERS Inspect ●●

SWINGARM Inspect, lube and retighten ●● Molybdenum disulfide grease

RELAY ARM, CONNECTING

ROD Inspect, lube and retighten ●● Molybdenum disulfide grease

SIDESTAND Lubricate ●Lithium base grease

STEERING HEAD Inspect free play and retighten ●●

Clean and lube ●Lithium base grease

Replace bearing ●

TIRE, WHEELS Inspect air pressure, wheel run-

out, tire wear and spoke loose-

ness ●●

Retighten sprocket bolt ●●

Inspect bearings ●

Replace bearings ●

Lubricate ●Lithium base grease

THROTTLE, CONTROL CABLE Check routing and connection ●●

Lubricate ●● Yamaha cable lube or SAE 10W-40

motor oil

HOT STARTER, CLUTCH LEVER Inspect free play ●

BATTERY Check terminal for looseness

and corrosion ●

Item

After

break- in Every

race

Every third

(or 500 km) Every

fifth (or

1,000 km)

As re-

quired Remarks

Page 66 of 232

3-7

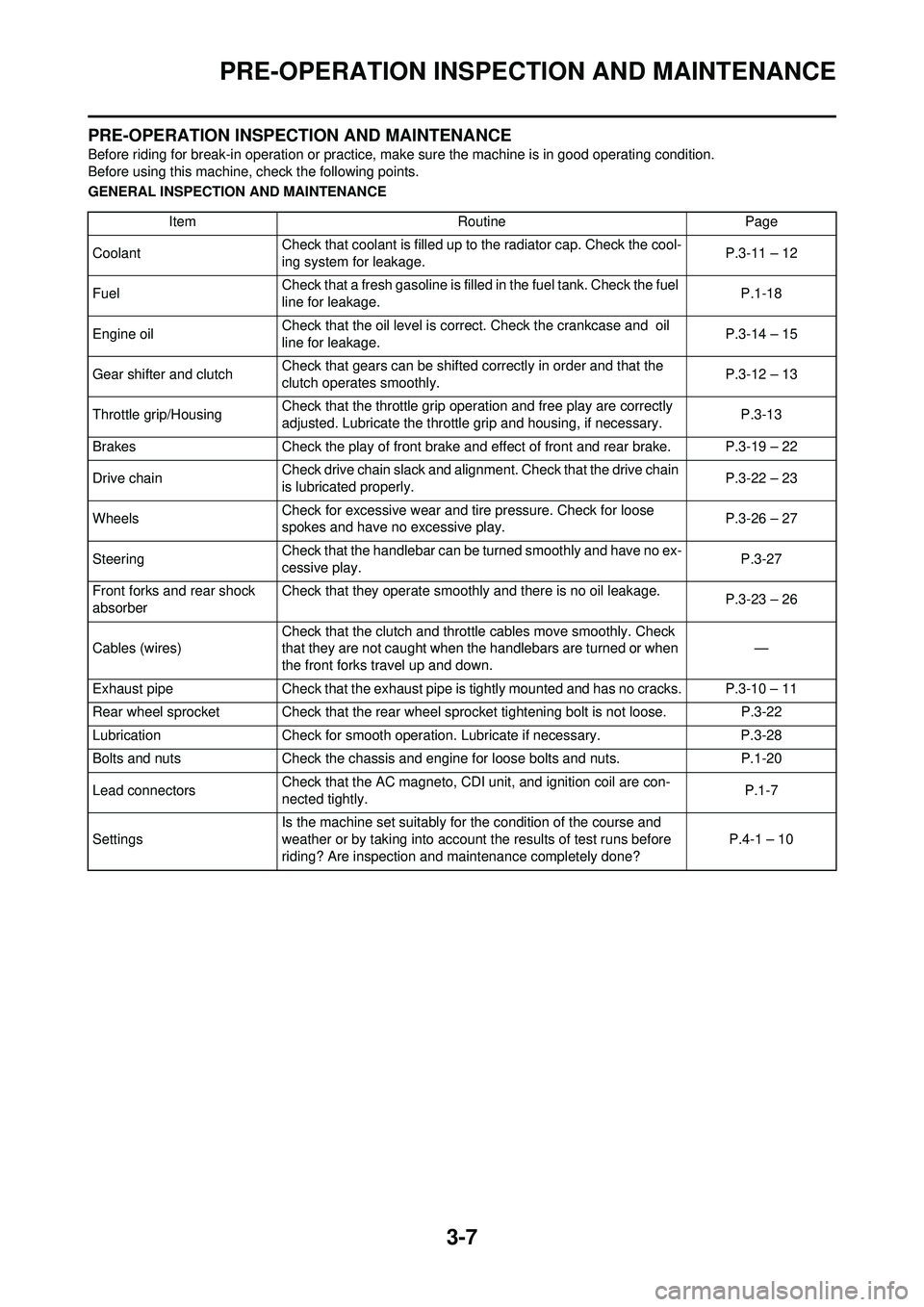

PRE-OPERATION INSPECTION AND MAINTENANCE

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation or practice, make sure the machine is in good operating condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCEItem RoutinePage

Coolant Check that coolant is filled up to the radiator cap. Check the cool-

ing system for leakage. P.3-11 – 12

Fuel Check that a fresh gasoline is filled in the fuel tank. Check the fuel

line for leakage.

P.1-18

Engine oil Check that the oil level is corre

ct. Check the crankcase and oil

line for leakage. P.3-14 – 15

Gear shifter and clutch Check that gears can be shifted correctly in order and that the

clutch operates smoothly. P.3-12 – 13

Throttle grip/Housing Check that the throttle grip operation and free play are correctly

adjusted. Lubricate the throttle grip and housing, if necessary.

P.3-13

Brakes Check the play of front brake and ef fect of front and rear brake. P.3-19 – 22

Drive chain Check drive chain slack and alignment. Check that the drive chain

is lubricated properly. P.3-22 – 23

Wheels Check for excessive wear and ti

re pressure. Check for loose

spokes and have no excessive play. P.3-26 – 27

Steering Check that the handlebar can be turned smoothly and have no ex-

cessive play.

P.3-27

Front forks and rear shock

absorber Check that they operate smoothly and there is no oil leakage.

P.3-23 – 26

Cables (wires) Check that the clutch and throttle cables move smoothly. Check

that they are not caught when the handlebars are turned or when

the front forks travel up and down. —

Exhaust pipe Check that the exhaust pipe is tightly mount ed and has no cracks. P.3-10 – 11

Rear wheel sprocket Check that the rear wheel sprocket tightening bolt is not loose. P.3-22

Lubrication Check for smooth operation. Lubricate if necessary. P.3-28

Bolts and nuts Check the chassis and engine for loose bolts and nuts. P.1-20

Lead connectors Check that the AC magneto, CDI unit, and ignition coil are con-

nected tightly. P.1-7

Settings Is the machine set suitably for the condition of the course and

weather or by taking into account the results of test runs before

riding? Are inspection and maintenance completely done? P.4-1 – 10

Page 71 of 232

3-12

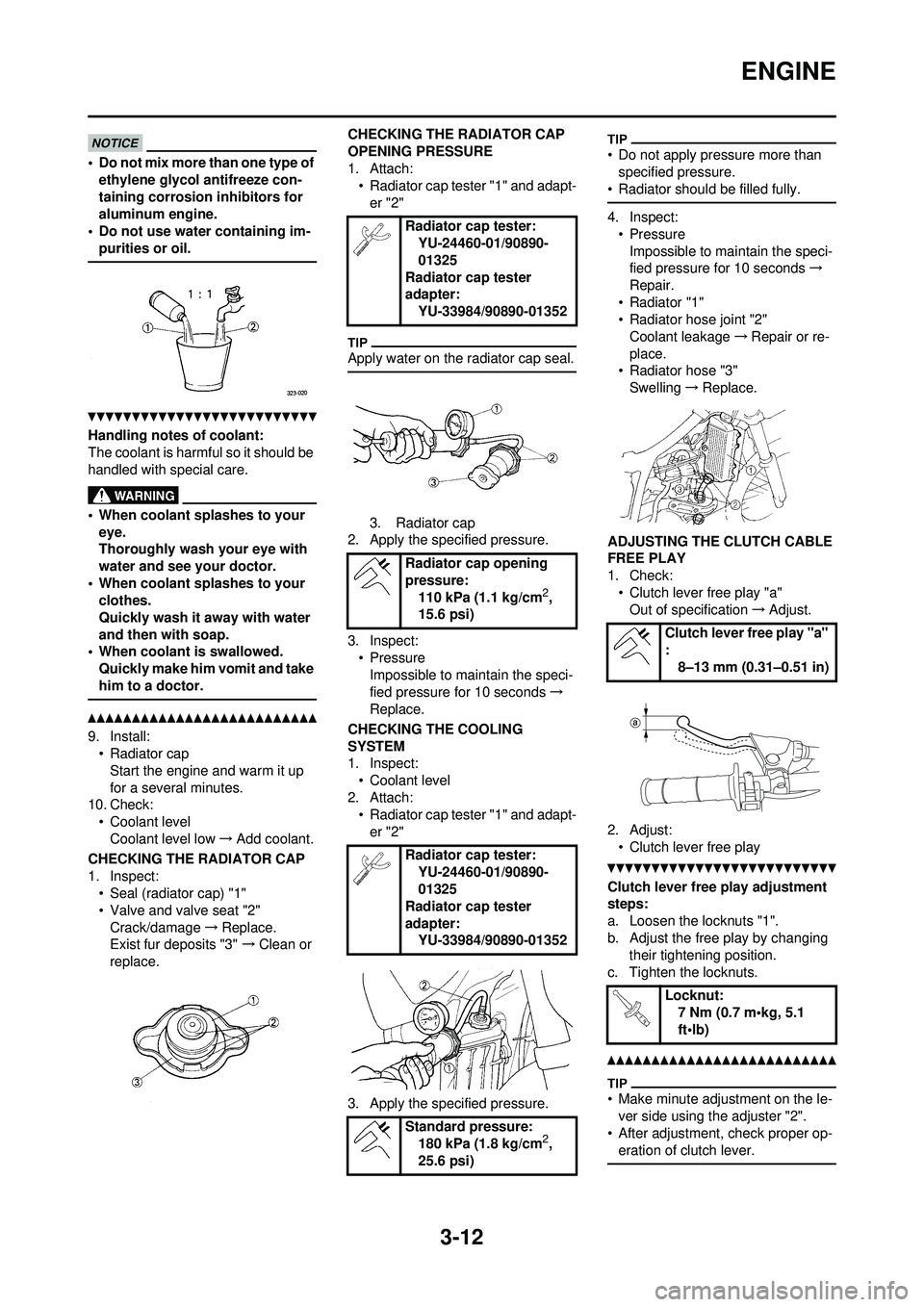

ENGINE

• Do not mix more than one type of ethylene glycol antifreeze con-

taining corrosion inhibitors for

aluminum engine.

• Do not use water containing im-

purities or oil.

Handling notes of coolant:

The coolant is harmful so it should be

handled with special care.

• When coolant splashes to your eye.

Thoroughly wash your eye with

water and see your doctor.

• When coolant splashes to your clothes.

Quickly wash it away with water

and then with soap.

• When coolant is swallowed. Quickly make him vomit and take

him to a doctor.

9. Install:• Radiator cap

Start the engine and warm it up

for a several minutes.

10. Check:

• Coolant levelCoolant level low →Add coolant.

CHECKING THE RADIATOR CAP

1. Inspect: • Seal (radiator cap) "1"

• Valve and valve seat "2"Crack/damage →Replace.

Exist fur deposits "3" →Clean or

replace. CHECKING THE RADIATOR CAP

OPENING PRESSURE

1. Attach:

• Radiator cap tester "1" and adapt-

er "2"

Apply water on the radiator cap seal.

3. Radiator cap

2. Apply the specified pressure.

3. Inspect:

•PressureImpossible to maintain the speci-

fied pressure for 10 seconds →

Replace.

CHECKING THE COOLING

SYSTEM

1. Inspect: • Coolant level

2. Attach: • Radiator cap tester "1" and adapt-

er "2"

3. Apply the specified pressure.

• Do not apply pressure more than specified pressure.

• Radiator should be filled fully.

4. Inspect: • PressureImpossible to maintain the speci-

fied pressure for 10 seconds →

Repair.

•Radiator "1"

• Radiator hose joint "2"

Coolant leakage →Repair or re-

place.

• Radiator hose "3"

Swelling →Replace.

ADJUSTING THE CLUTCH CABLE

FREE PLAY

1. Check: • Clutch lever free play "a"Out of specification →Adjust.

2. Adjust: • Clutch lever free play

Clutch lever free play adjustment

steps:

a. Loosen the locknuts "1".

b. Adjust the free play by changing their tightening position.

c. Tighten the locknuts.

• Make minute adjustment on the le- ver side using the adjuster "2".

• After adjustment, check proper op- eration of clutch lever.

Radiator cap tester: YU-24460-01/90890-

01325

Radiator cap tester

adapter: YU-33984/90890-01352

Radiator cap opening

pressure: 110 kPa (1.1 kg/cm

2,

15.6 psi)

Radiator cap tester: YU-24460-01/90890-

01325

Radiator cap tester

adapter: YU-33984/90890-01352

Standard pressure: 180 kPa (1.8 kg/cm

2,

25.6 psi)

Clutch lever free play "a"

: 8–13 mm (0.31–0.51 in)

Locknut: 7 Nm (0.7 m•kg, 5.1

ft•lb)

Page 74 of 232

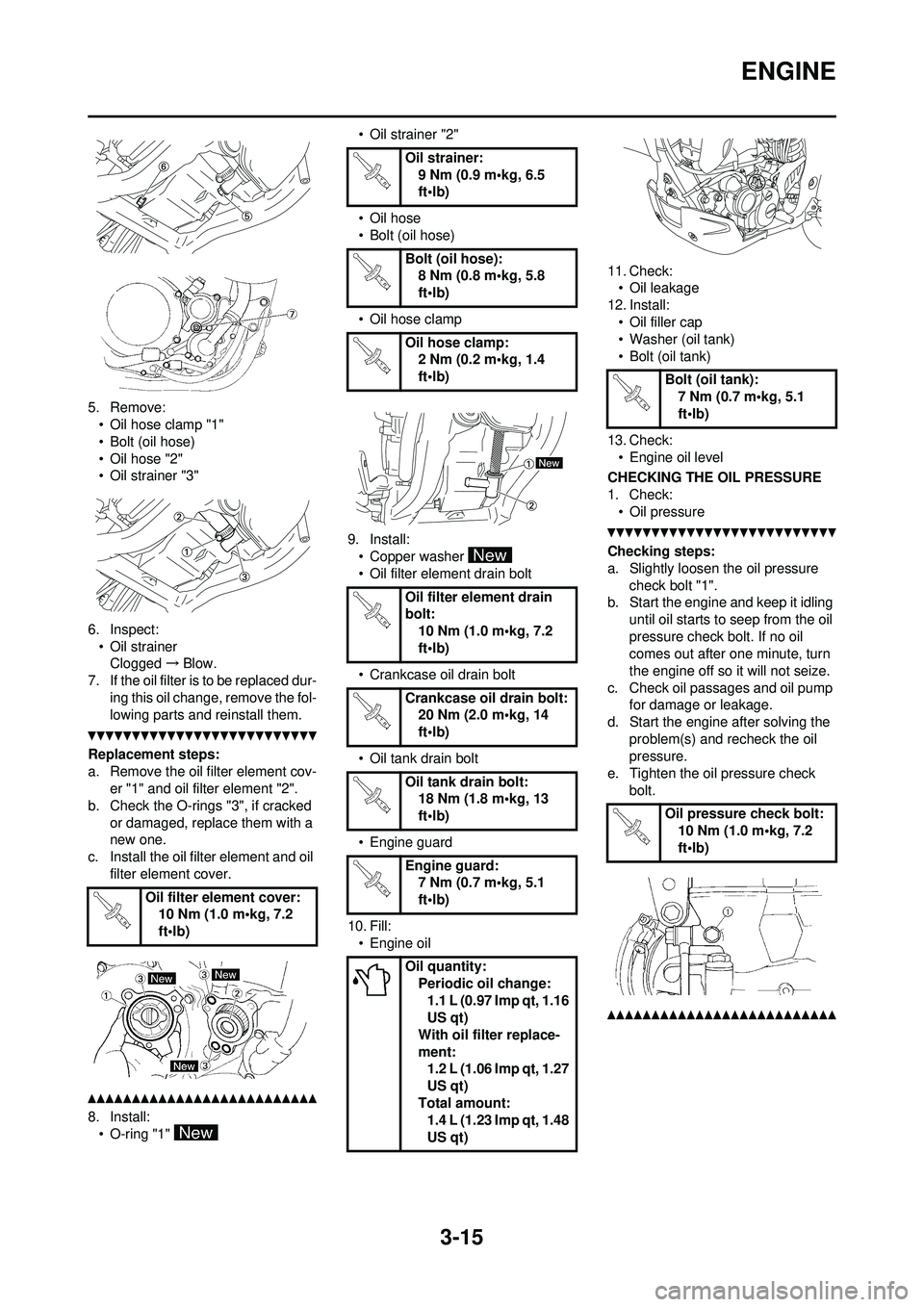

3-15

ENGINE

5. Remove:• Oil hose clamp "1"

• Bolt (oil hose)

• Oil hose "2"

• Oil strainer "3"

6. Inspect: • Oil strainerClogged →Blow.

7. If the oil filter is to be replaced dur-

ing this oil change, remove the fol-

lowing parts and reinstall them.

Replacement steps:

a. Remove the oil filter element cov-er "1" and oil filter element "2".

b. Check the O-rings "3", if cracked or damaged, replace them with a

new one.

c. Install the oil filter element and oil filter element cover.

8. Install:

• O-ring "1" • Oil strainer "2"

• Oil hose

• Bolt (oil hose)

• Oil hose clamp

9. Install: • Copper washer

• Oil filter element drain bolt

• Crankcase oil drain bolt

• Oil tank drain bolt

• Engine guard

10. Fill: • Engine oil 11. Check:

• Oil leakage

12. Install: • Oil filler cap

• Washer (oil tank)

• Bolt (oil tank)

13. Check: • Engine oil level

CHECKING THE OIL PRESSURE

1. Check: • Oil pressure

Checking steps:

a. Slightly loosen the oil pressure check bolt "1".

b. Start the engine and keep it idling

until oil starts to seep from the oil

pressure check bolt. If no oil

comes out after one minute, turn

the engine off so it will not seize.

c. Check oil passages and oil pump for damage or leakage.

d. Start the engine after solving the problem(s) and recheck the oil

pressure.

e. Tighten the oil pressure check bolt.

Oil filter element cover:10 Nm (1.0 m•kg, 7.2

ft•lb)

Oil strainer:

9 Nm (0.9 m•kg, 6.5

ft•lb)

Bolt (oil hose): 8 Nm (0.8 m•kg, 5.8

ft•lb)

Oil hose clamp: 2 Nm (0.2 m•kg, 1.4

ft•lb)

Oil filter element drain

bolt: 10 Nm (1.0 m•kg, 7.2

ft•lb)

Crankcase oil drain bolt: 20 Nm (2.0 m•kg, 14

ft•lb)

Oil tank drain bolt: 18 Nm (1.8 m•kg, 13

ft•lb)

Engine guard: 7 Nm (0.7 m•kg, 5.1

ft•lb)

Oil quantity: Periodic oil change:

1.1 L (0.97 Imp qt, 1.16

US qt)

With oil filter replace-

ment: 1.2 L (1.06 Imp qt, 1.27

US qt)

Total amount: 1.4 L (1.23 Imp qt, 1.48

US qt)

Bolt (oil tank): 7 Nm (0.7 m•kg, 5.1

ft•lb)

Oil pressure check bolt: 10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 83 of 232

3-24

CHASSIS

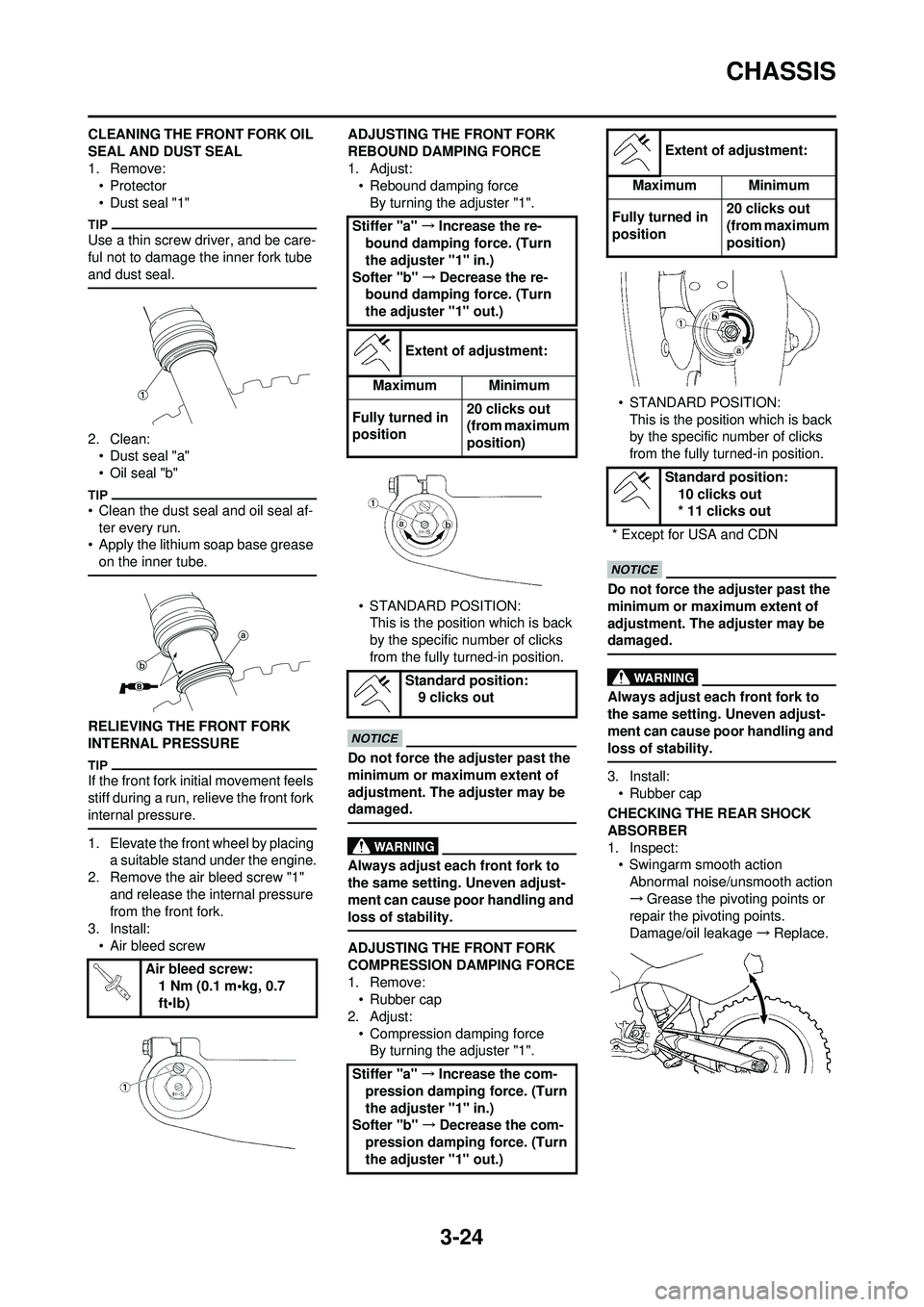

CLEANING THE FRONT FORK OIL

SEAL AND DUST SEAL

1. Remove:•Protector

• Dust seal "1"

Use a thin screw driver, and be care-

ful not to damage the inner fork tube

and dust seal.

2. Clean:• Dust seal "a"

• Oil seal "b"

• Clean the dust seal and oil seal af-

ter every run.

• Apply the lithium soap base grease on the inner tube.

RELIEVING THE FRONT FORK

INTERNAL PRESSURE

If the front fork initial movement feels

stiff during a run, relieve the front fork

internal pressure.

1. Elevate the front wheel by placing a suitable stand under the engine.

2. Remove the air bleed screw "1"

and release the internal pressure

from the front fork.

3. Install:

• Air bleed screw ADJUSTING THE FRONT FORK

REBOUND DAMPING FORCE

1. Adjust:

• Rebound damping force

By turning the adjuster "1".

• STANDARD POSITION: This is the position which is back

by the specific number of clicks

from the fully turned-in position.

Do not force the adjuster past the

minimum or maximum extent of

adjustment. The adjuster may be

damaged.

Always adjust each front fork to

the same setting. Uneven adjust-

ment can cause poor handling and

loss of stability.

ADJUSTING THE FRONT FORK

COMPRESSION DAMPING FORCE

1. Remove:• Rubber cap

2. Adjust:

• Compression damping forceBy turning the adjuster "1". • STANDARD POSITION:

This is the position which is back

by the specific number of clicks

from the fully turned-in position.

Do not force the adjuster past the

minimum or maximum extent of

adjustment. The adjuster may be

damaged.

Always adjust each front fork to

the same setting. Uneven adjust-

ment can cause poor handling and

loss of stability.

3. Install:• Rubber cap

CHECKING THE REAR SHOCK

ABSORBER

1. Inspect: • Swingarm smooth action

Abnormal noise/unsmooth action

→ Grease the pivoting points or

repair the pivoting points.

Damage/oil leakage →Replace.

Air bleed screw: 1 Nm (0.1 m•kg, 0.7

ft•lb)

Stiffer "a" →Increase the re-

bound damping force. (Turn

the adjuster "1" in.)

Softer "b" →Decrease the re-

bound damping force. (Turn

the adjuster "1" out.)

Extent of adjustment:

Maximum Minimum

Fully turned in

position 20 clicks out

(from maximum

position)

Standard position: 9 clicks out

Stiffer "a" →Increase the com-

pression damping force. (Turn

the adjuster "1" in.)

Softer "b" →Decrease the com-

pression damping force. (Turn

the adjuster "1" out.)

Extent of adjustment:

Maximum Minimum

Fully turned in

position 20 clicks out

(from maximum

position)

Standard position: 10 clicks out

* 11 clicks out

* Except for USA and CDN

Page 98 of 232

4-5

CHASSIS

CHASSIS

SELECTION OF THE SECONDARY

REDUCTION RATIO (SPROCKET)

• It is generally said that the second-ary gear ratio should be reduced for

a longer straight portion of a speed

course and should be increased for

a course with many corners. Actual-

ly, however, as the speed depends

on the ground condition of the day

of the ride, be su re to run through

the circuit to set the machine suit-

able for the entire course.

• In actuality, it is very difficult to

achieve settings suitable for the en-

tire course and some settings may

be sacrificed. Thus, the settings

should be matched to the portion of

the course that has the greatest ef-

fect on the ride result. In such a

case, run through the entire course

while making notes of lap times to

find the best balance; then, deter-

mine the secondary reduction ratio.

• If a course has a long straight por-

tion where a machine can run at

maximum speed, the machine is

generally set such that it can devel-

op its maximum revolutions toward

the end of the straight line, with care

taken to avoid the engine over-rev-

ving.

Riding technique varies from rider to

rider and the performance of a ma-

chine also vary fr om machine to ma-

chine. Therefore, do not imitate other

rider's settings from the beginning but

choose your own setting according to

the level of your riding technique.

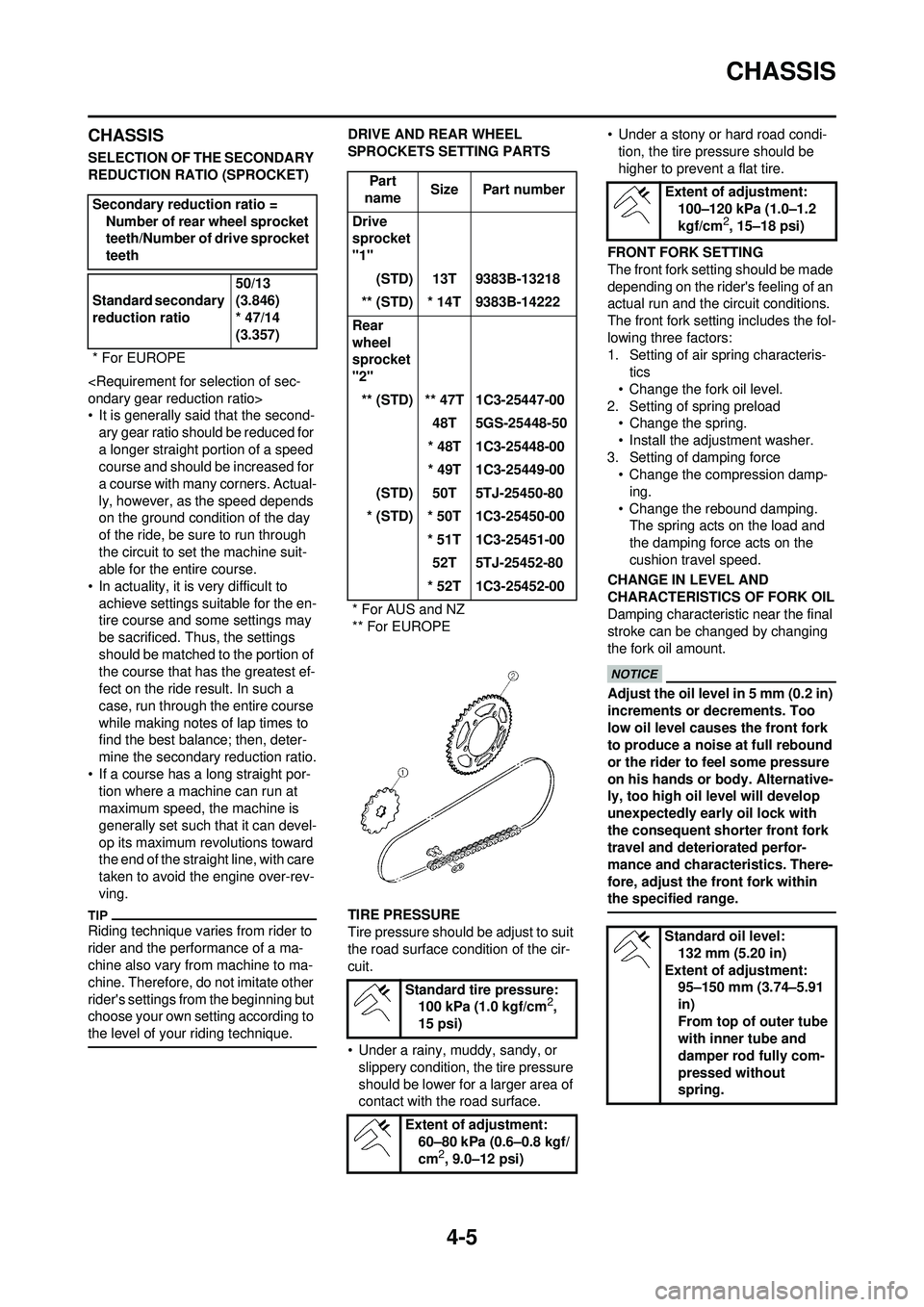

DRIVE AND REAR WHEEL

SPROCKETS SETTING PARTS

TIRE PRESSURE

Tire pressure should be adjust to suit

the road surface condition of the cir-

cuit.

• Under a rainy, muddy, sandy, or slippery condition, the tire pressure

should be lower for a larger area of

contact with the road surface. • Under a stony or hard road condi-

tion, the tire pressure should be

higher to prevent a flat tire.

FRONT FORK SETTING

The front fork setting should be made

depending on the rider's feeling of an

actual run and the circuit conditions.

The front fork setting includes the fol-

lowing three factors:

1. Setting of air spring characteris- tics

• Change the fork oil level.

2. Setting of spring preload • Change the spring.

• Install the adjustment washer.

3. Setting of damping force • Change the compression damp-

ing.

• Change the rebound damping. The spring acts on the load and

the damping force acts on the

cushion travel speed.

CHANGE IN LEVEL AND

CHARACTERISTICS OF FORK OIL

Damping characteristic near the final

stroke can be changed by changing

the fork oil amount.

Adjust the oil level in 5 mm (0.2 in)

increments or decrements. Too

low oil level caus es the front fork

to produce a noise at full rebound

or the rider to feel some pressure

on his hands or body. Alternative-

ly, too high oil level will develop

unexpectedly early oil lock with

the consequent shorter front fork

travel and deteriorated perfor-

mance and characteristics. There-

fore, adjust the front fork within

the specified range.

Secondary reduction ratio =

Number of rear wheel sprocket

teeth/Number of drive sprocket

teeth

Standard secondary

reduction ratio 50/13

(3.846)

* 47/14

(3.357)

* For EUROPE

Part

name Size Part number

Drive

sprocket

"1" (STD) 13T 9383B-13218

** (STD) * 14T 9383B-14222

Rear

wheel

sprocket

"2" ** (STD) ** 47T 1C3-25447-00 48T 5GS-25448-50

* 48T 1C3-25448-00

* 49T 1C3-25449-00

(STD) 50T 5TJ-25450-80

* (STD) * 50T 1C3-25450-00 * 51T 1C3-25451-0052T 5TJ-25452-80

* 52T 1C3-25452-00

* For AUS and NZ

** For EUROPE

Standard tire pressure:100 kPa (1.0 kgf/cm

2,

15 psi)

Extent of adjustment: 60–80 kPa (0.6–0.8 kgf/

cm

2, 9.0–12 psi)

Extent of adjustment: 100–120 kPa (1.0–1.2

kgf/cm

2, 15–18 psi)

Standard oil level: 132 mm (5.20 in)

Extent of adjustment: 95–150 mm (3.74–5.91

in)

From top of outer tube

with inner tube and

damper rod fully com-

pressed without

spring.