transmission oil YAMAHA WR 250F 2010 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2010, Model line: WR 250F, Model: YAMAHA WR 250F 2010Pages: 232, PDF Size: 13.94 MB

Page 10 of 232

CONTENTS

CHAPTER 1

GENERAL INFOR-

MATION

LOCATION OF

IMPORTANT LABELS ..... 1-1

DESCRIPTION ................. 1-5

CONSUMER

INFORMATION................. 1-6

INCLUDED PARTS .......... 1-6

IMPORTANT

INFORMATION................. 1-6

CHECKING OF

CONNECTION .................. 1-7

SPECIAL TOOLS ............. 1-8

CONTROL FUNCTIONS.. 1-12

MULTI-FUNCTION

DISPLAY ........................ 1-13

STARTING AND

BREAK-IN ...................... 1-18

TORQUE-CHECK

POINTS........................... 1-20

CLEANING AND

STORAGE ...................... 1-21

CHAPTER 2

SPECIFICATIONS

GENERAL

SPECIFICATIONS ............ 2-1

MAINTENANCE

SPECIFICATIONS ............ 2-3

TIGHTENING

TORQUES ...................... 2-12

LUBRICATION

DIAGRAMS .................... 2-19

CABLE ROUTING

DIAGRAM ....................... 2-21

CHAPTER 3

REGULAR INSPEC-

TION AND AD-JUSTMENTS

PERIODIC MAINTENANCE

CHART FOR THE EMISSION

CONTROL SYSTEM (For

Canada) ............................ 3-1

GENERAL MAINTENANCE

AND LUBRICATION CHART

(For Canada) .................... 3-2

MAINTENANCE INTER-

VALS FOR COMPETITION

USE ................................... 3-3

PRE-OPERATION

INSPECTION AND

MAINTENANCE................ 3-7

ENGINE ............................ 3-8

CHASSIS ........................ 3-19

ELECTRICAL ................. 3-29

CHAPTER 4 TUNING

ENGINE

(Except for Canada) ........ 4-1

CHASSIS .......................... 4-5

CHAPTER 5

ENGINE

RADIATOR ....................... 5-1

CARBURETOR................. 5-4

AIR INDICTOIN

SYSTEM ......................... 5-12

CAMSHAFTS.................. 5-14

CYLINDER HEAD........... 5-19

VALVES AND VALVE

SPRINGS ........................ 5-21

CYLINDER AND

PISTON ........................... 5-25

CLUTCH ......................... 5-29 OIL FILTER ELEMENT

AND WATER PUMP .......5-34

BALANCER ....................5-39

OIL PUMP .......................5-41

KICK SHAFT AND SHIFT

SHAFT ............................5-44

AC MAGNETO AND

STARTER CLUTCH........5-49

ENGINE REMOVAL........5-54

CRANKCASE AND

CRANKSHAFT ...............5-58

TRANSMISSION,

SHIFT CAM AND

SHIFT FORK ...................5-64

CHAPTER 6

CHASSIS

FRONT WHEEL AND

REAR WHEEL ..................6-1

FRONT BRAKE AND

REAR BRAKE ..................6-6

FRONT FORK .................6-16

HANDLEBAR..................6-23

STEERING ......................6-27

SWINGARM ....................6-31

REAR SHOCK

ABSORBER ....................6-36

CHAPTER 7

ELECTRICAL

ELECTRICAL COMPO-

NENTS AND WIRING

DIAGRAM .........................7-1

IGNITION SYSTEM...........7-3

ELECTRIC STARTING

SYSTEM............................7-5

CHARGING SYSTEM .....7-13

THROTTLE POSITION

SENSOR SYSTEM .........7-15

LIGHTING SYSTEM .......7-18

SIGNALING SYSTEM.....7-20

Page 28 of 232

1-18

STARTING AND BREAK-IN

STARTING AND BREAK-IN

FUEL

Always use the recommended fuel as

stated below. Also, be sure to use

new gasoline.

Use only unleaded gasoline. The

use of leaded gasoline will cause

severe damage to the engine inter-

nal parts such as valves, piston

rings, and exhaust system, etc.

If knocking or pinging occurs, use a

different brand of gasoline or higher

octane grade.

• For refueling, be sure to stop the

engine and use enough care not

to spill any fuel. Also be sure to

avoid refueling close to a fire.

• Refuel after the engine, exhaust pipe, etc. have cooled off.

Gasohol (For Canada)

There are two types of gasohol: gas-

ohol containing ethanol and that con-

taining methanol. Gasohol containing

ethanol can be used if the ethanol

content does not exceed 10%. Gaso-

hol containing methanol is not recom-

mended by Yamaha because it can

cause damage to the fuel system or

vehicle performance problems.

HANDLING NOTE

Never start or run the engine in a

closed area. The exhaust fumes

are poisonous; they can cause

loss of consciousness and death

in a very short time. Always oper-

ate the machine in a well-ventilated

area.

• The carburetor on this machine has a built-in accelerator pump.

Therefore, when starting the en-

gine, do not operate the throttle

or the spark plug will foul.

• Unlike a two-stroke engine, this engine cannot be kick started

when the throttl e is open be-

cause the kickstarter may kick

back. Also, if the throttle is open

the air/fuel mixture may be too

lean for the engine to start.

• Before starting the machine, per- form the checks in the pre-opera-

tion check list.

AIR FILTER MAINTENANCE

According to "CLEANING THE AIR

FILTER ELEMENT" section in the

CHAPTER 3, apply the foam-air-filter

oil or its equivalent to the element.

(Excess oil in the element may ad-

versely affect engine starting.)

STARTING A COLD ENGINE

This model is equipped with an igni-

tion circuit cut-off system. The engine

can be started under the following

conditions.

• When the transmission is in neutral.

• When the clutch is disengaged with

the transmission in any position.

However, it is recommended to shift

into neutral before starting the en-

gine.

1. Inspect the coolant level.

2. Turn the fuel cock to "ON".

3. Push on the main switch to "ON".

4. Shift the transmission into neutral.

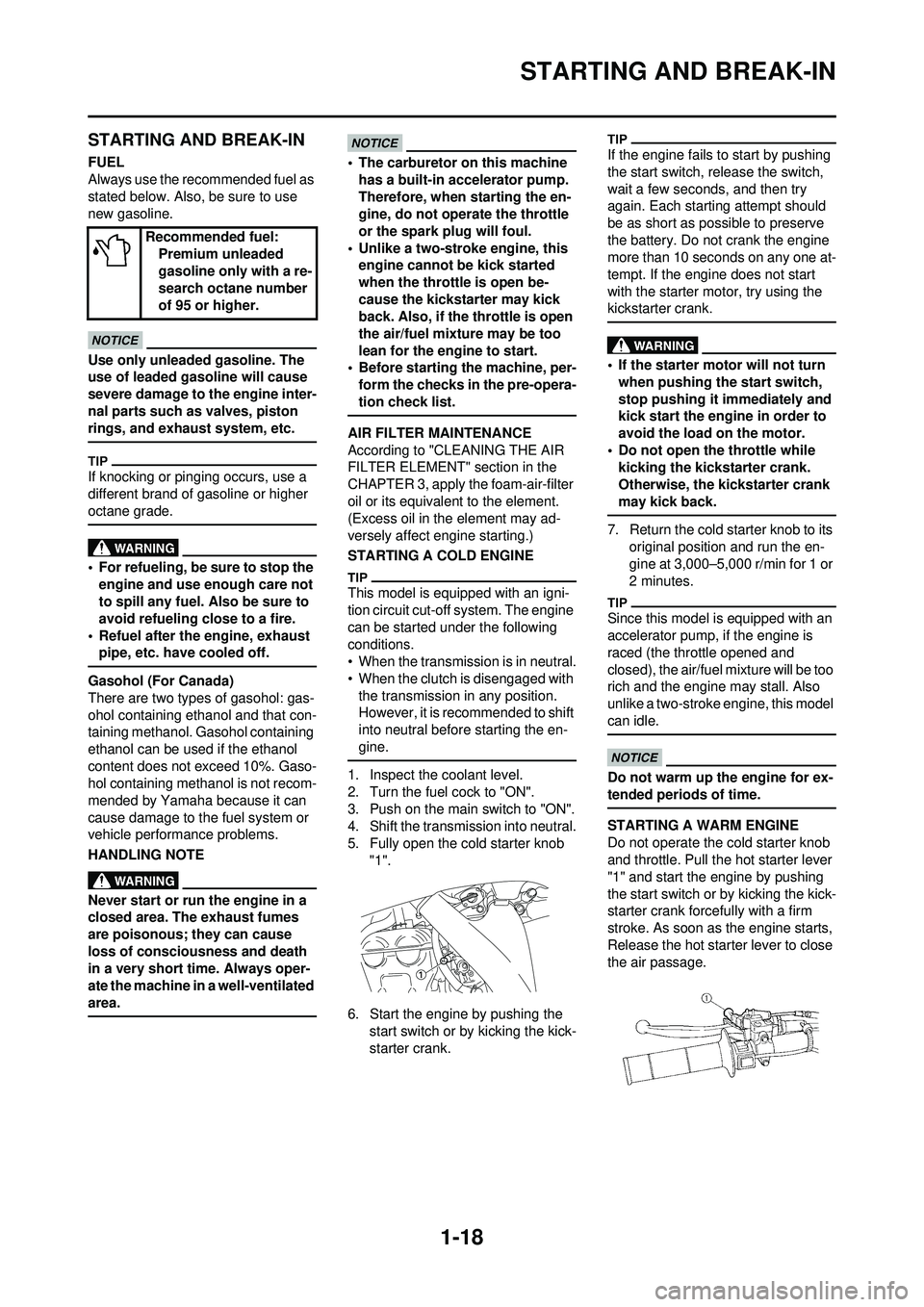

5. Fully open the cold starter knob "1".

6. Start the engine by pushing the start switch or by kicking the kick-

starter crank.

If the engine fails to start by pushing

the start switch, re lease the switch,

wait a few seconds, and then try

again. Each starting attempt should

be as short as possible to preserve

the battery. Do not crank the engine

more than 10 seconds on any one at-

tempt. If the engine does not start

with the starter motor, try using the

kickstarter crank.

• If the starter motor will no t turn

when pushing the start switch,

stop pushing it immediately and

kick start the engine in order to

avoid the load on the motor.

• Do not open the throttle while kicking the kickstarter crank.

Otherwise, the kickstarter crank

may kick back.

7. Return the cold starter knob to its original position and run the en-

gine at 3,000–5,000 r/min for 1 or

2 minutes.

Since this model is equipped with an

accelerator pump, if the engine is

raced (the throttle opened and

closed), the air/fuel mixture will be too

rich and the engine may stall. Also

unlike a two-stroke engine, this model

can idle.

Do not warm up th e engine for ex-

tended periods of time.

STARTING A WARM ENGINE

Do not operate the cold starter knob

and throttle. Pull the hot starter lever

"1" and start the engine by pushing

the start switch or by kicking the kick-

starter crank forcefully with a firm

stroke. As soon as the engine starts,

Release the hot starter lever to close

the air passage.

Recommended fuel:

Premium unleaded

gasoline only with a re-

search octane number

of 95 or higher.

Page 139 of 232

5-36

OIL FILTER ELEMENT AND WATER PUMP

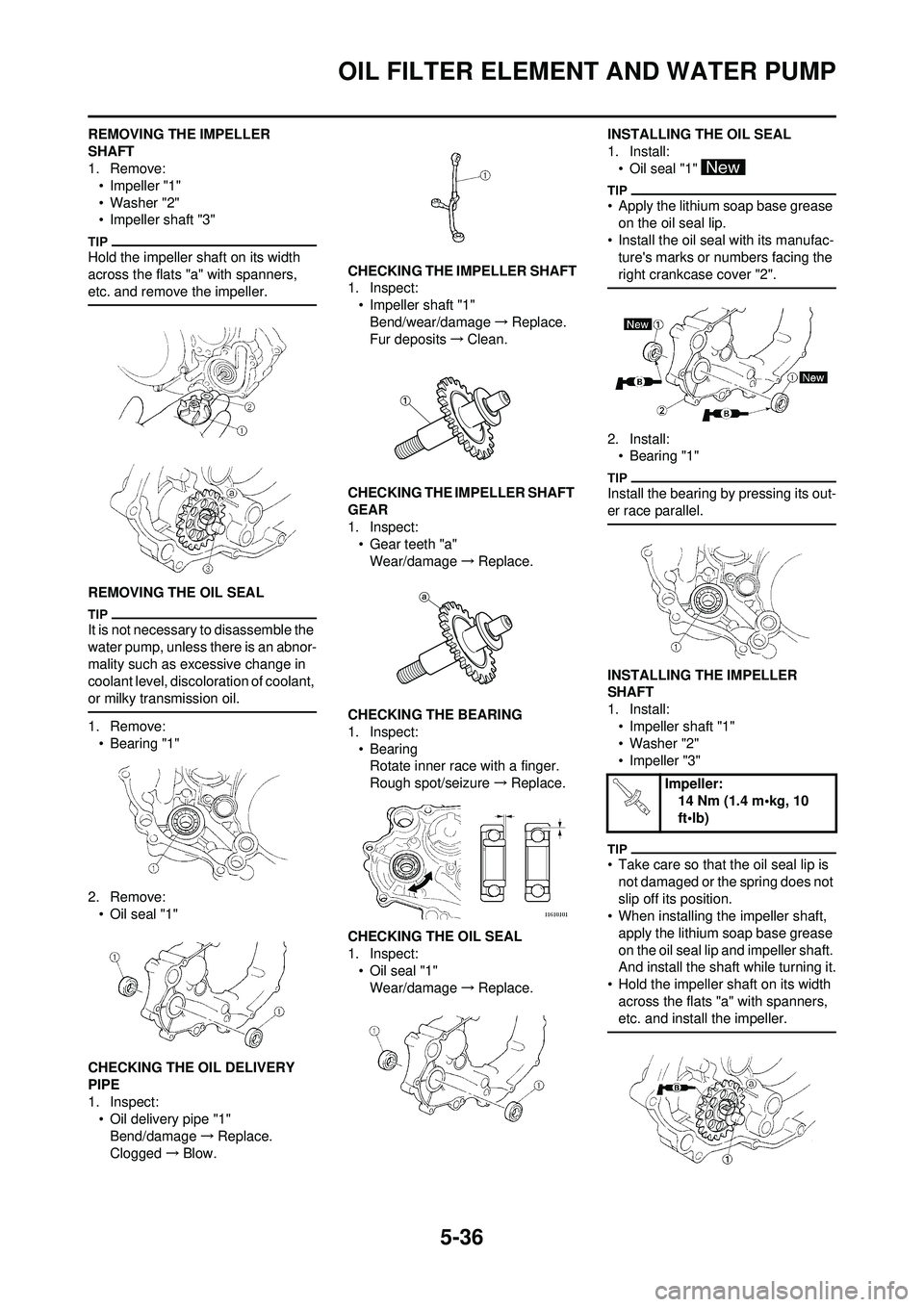

REMOVING THE IMPELLER

SHAFT

1. Remove:• Impeller "1"

• Washer "2"

• Impeller shaft "3"

Hold the impeller shaft on its width

across the flats "a" with spanners,

etc. and remove the impeller.

REMOVING THE OIL SEAL

It is not necessary to disassemble the

water pump, unless there is an abnor-

mality such as excessive change in

coolant level, discoloration of coolant,

or milky transmission oil.

1. Remove:• Bearing "1"

2. Remove: • Oil seal "1"

CHECKING THE OIL DELIVERY

PIPE

1. Inspect: • Oil delivery pipe "1"Bend/damage →Replace.

Clogged →Blow. CHECKING THE IMPELLER SHAFT

1. Inspect:

• Impeller shaft "1"Bend/wear/damage →Replace.

Fur deposits →Clean.

CHECKING THE IMPELLER SHAFT

GEAR

1. Inspect: • Gear teeth "a"Wear/damage →Replace.

CHECKING THE BEARING

1. Inspect: •BearingRotate inner race with a finger.

Rough spot/seizure →Replace.

CHECKING THE OIL SEAL

1. Inspect: • Oil seal "1"Wear/damage →Replace. INSTALLING THE OIL SEAL

1. Install:

• Oil seal "1"

• Apply the lithium soap base grease on the oil seal lip.

• Install the oil seal with its manufac- ture's marks or numbers facing the

right crankcase cover "2".

2. Install:• Bearing "1"

Install the bearing by pressing its out-

er race parallel.

INSTALLING THE IMPELLER

SHAFT

1. Install:• Impeller shaft "1"

• Washer "2"

• Impeller "3"

• Take care so that the oil seal lip is

not damaged or the spring does not

slip off its position.

• When installing the impeller shaft,

apply the lithium soap base grease

on the oil seal lip and impeller shaft.

And install the shaft while turning it.

• Hold the impeller shaft on its width across the flats "a" with spanners,

etc. and install the impeller.

Impeller: 14 Nm (1.4 m•kg, 10

ft•lb)

Page 163 of 232

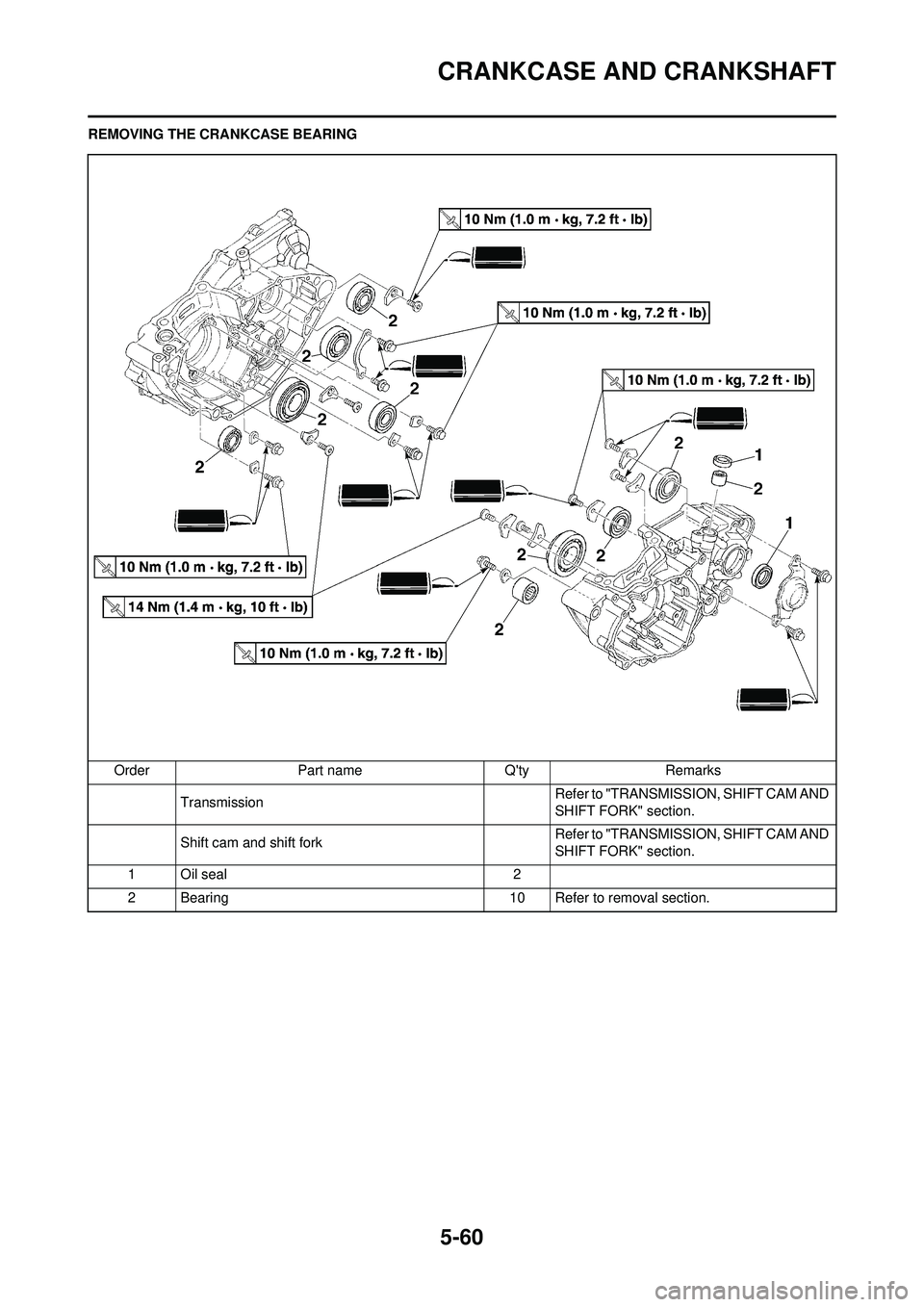

5-60

CRANKCASE AND CRANKSHAFT

REMOVING THE CRANKCASE BEARINGOrder Part name Q'ty Remarks Transmission Refer to "TRANSMISSION, SHIFT CAM AND

SHIFT FORK" section.

Shift cam and shift fork Refer to "TRANSMISSION, SHIFT CAM AND

SHIFT FORK" section.

1 Oil seal 2

2 Bearing 10 Refer to removal section.

Page 164 of 232

5-61

CRANKCASE AND CRANKSHAFT

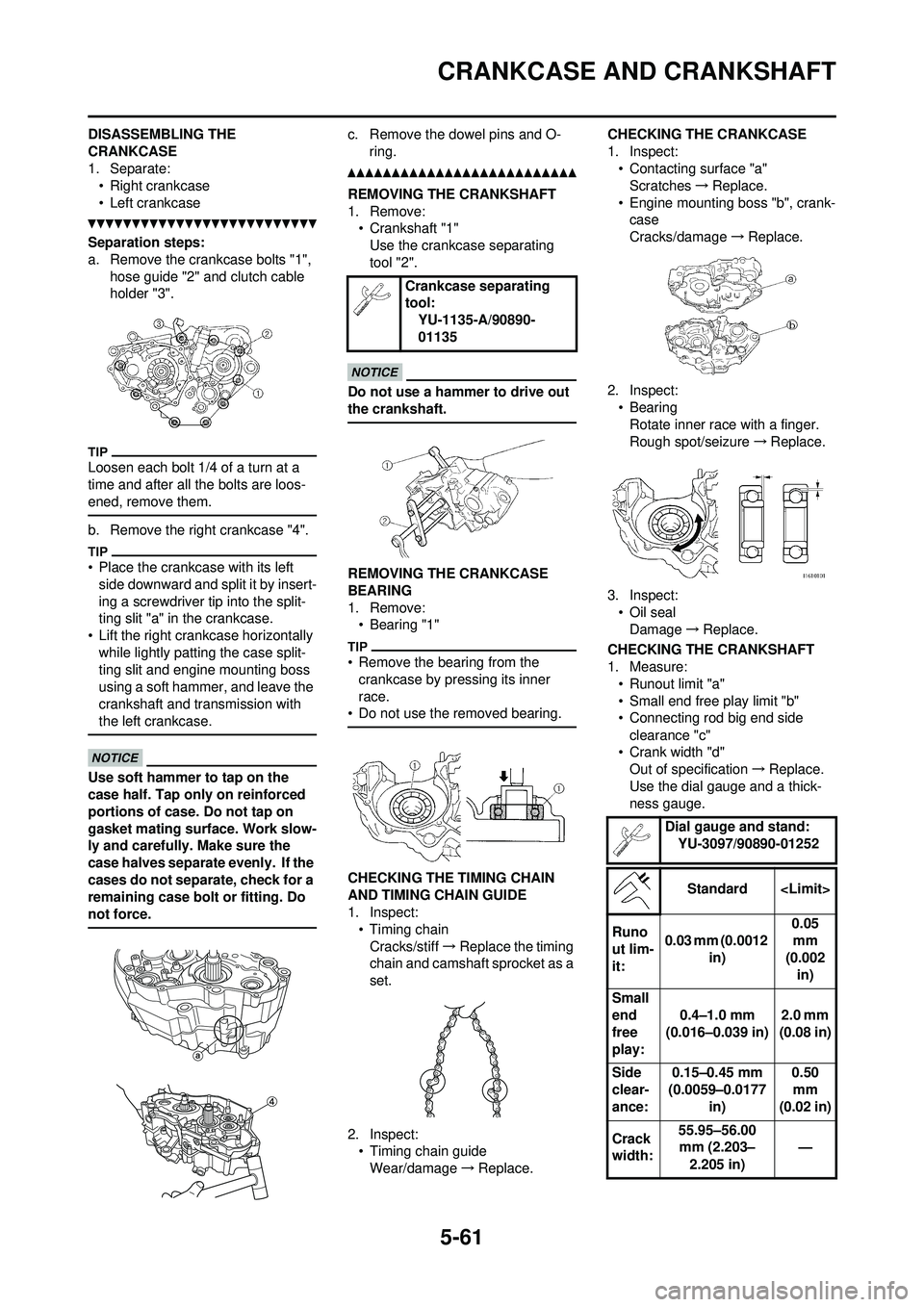

DISASSEMBLING THE

CRANKCASE

1. Separate:• Right crankcase

• Left crankcase

Separation steps:

a. Remove the crankcase bolts "1", hose guide "2" and clutch cable

holder "3".

Loosen each bolt 1/4 of a turn at a

time and after all the bolts are loos-

ened, remove them.

b. Remove the right crankcase "4".

• Place the crankcase with its left

side downward and split it by insert-

ing a screwdriver tip into the split-

ting slit "a" in the crankcase.

• Lift the right crankcase horizontally while lightly patting the case split-

ting slit and engine mounting boss

using a soft hammer, and leave the

crankshaft and transmission with

the left crankcase.

Use soft hammer to tap on the

case half. Tap only on reinforced

portions of case. Do not tap on

gasket mating surface. Work slow-

ly and carefully. Make sure the

case halves separate evenly. If the

cases do not separate, check for a

remaining case bolt or fitting. Do

not force.

c. Remove the dowel pins and O-

ring.

REMOVING THE CRANKSHAFT

1. Remove:• Crankshaft "1"

Use the crankcase separating

tool "2".

Do not use a hammer to drive out

the crankshaft.

REMOVING THE CRANKCASE

BEARING

1. Remove:•Bearing "1"

• Remove the bearing from the crankcase by pressing its inner

race.

• Do not use the removed bearing.

CHECKING THE TIMING CHAIN

AND TIMING CHAIN GUIDE

1. Inspect: • Timing chain

Cracks/stiff →Replace the timing

chain and camshaft sprocket as a

set.

2. Inspect: • Timing chain guideWear/damage →Replace. CHECKING THE CRANKCASE

1. Inspect:

• Contacting surface "a"Scratches →Replace.

• Engine mounting boss "b", crank- case

Cracks/damage →Replace.

2. Inspect: • BearingRotate inner race with a finger.

Rough spot/seizure →Replace.

3. Inspect: • Oil sealDamage →Replace.

CHECKING THE CRANKSHAFT

1. Measure: • Runout limit "a"

• Small end free play limit "b"

• Connecting rod big end side clearance "c"

• Crank width "d" Out of specification →Replace.

Use the dial gauge and a thick-

ness gauge.

Crankcase separating

tool: YU-1135-A/90890-

01135

Dial gauge and stand: YU-3097/90890-01252

Standard

Runo

ut lim-

it: 0.03 mm (0.0012

in) 0.05

mm

(0.002 in)

Small

end

free

play: 0.4–1.0 mm

(0.016–0.039 in) 2.0 mm

(0.08 in)

Side

clear-

ance: 0.15–0.45 mm

(0.0059–0.0177 in) 0.50

mm

(0.02 in)

Crack

width: 55.95–56.00

mm (2.203–

2.205 in) —

Page 165 of 232

5-62

CRANKCASE AND CRANKSHAFT

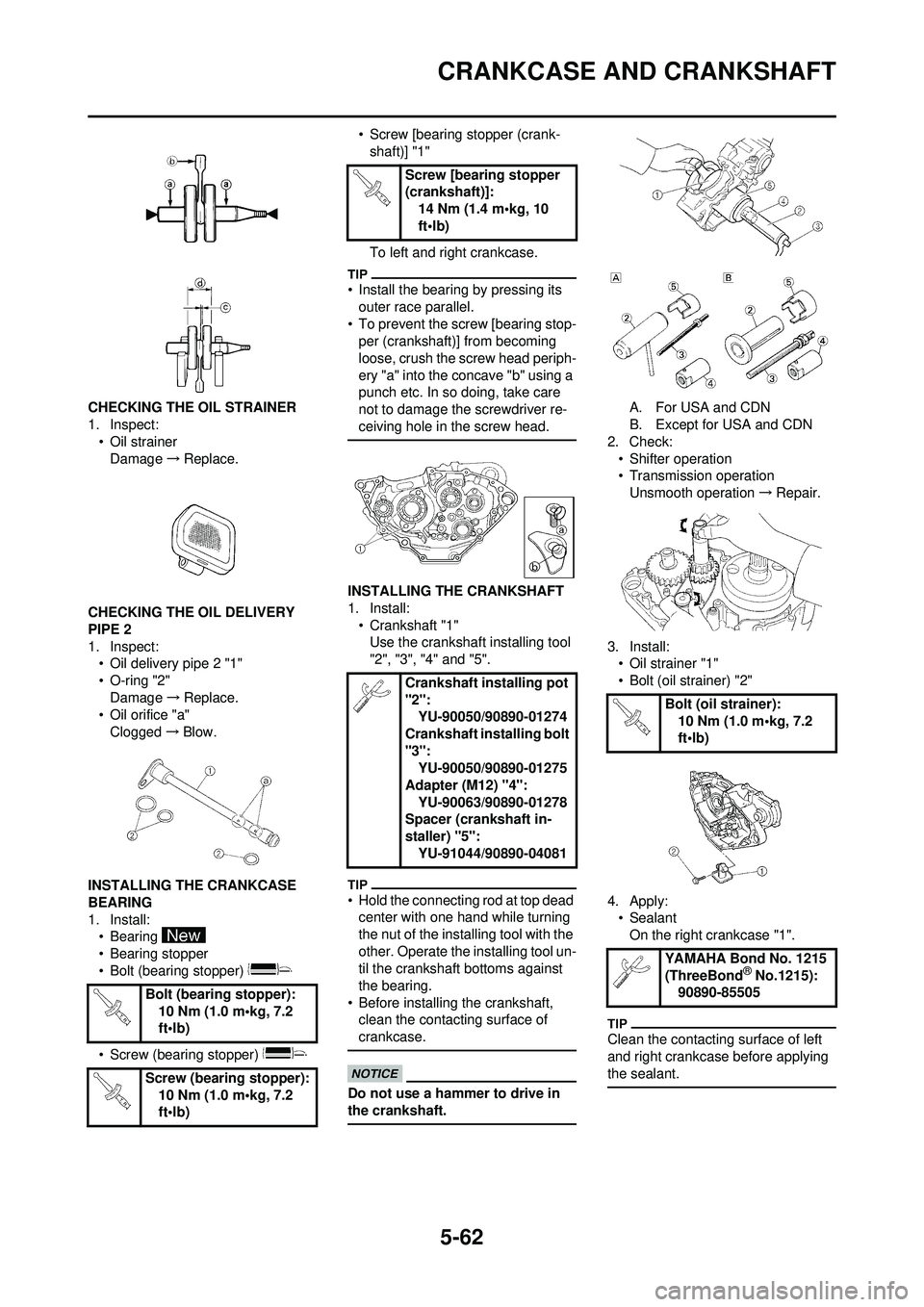

CHECKING THE OIL STRAINER

1. Inspect:• Oil strainer

Damage →Replace.

CHECKING THE OIL DELIVERY

PIPE 2

1. Inspect: • Oil delivery pipe 2 "1"

• O-ring "2"

Damage →Replace.

• Oil orifice "a" Clogged →Blow.

INSTALLING THE CRANKCASE

BEARING

1. Install: • Bearing

• Bearing stopper

• Bolt (bearing stopper)

• Screw (bearing stopper) • Screw [bearing stopper (crank-

shaft)] "1"

To left and right crankcase.

• Install the bearing by pressing its outer race parallel.

• To prevent the screw [bearing stop- per (crankshaft)] from becoming

loose, crush the screw head periph-

ery "a" into the concave "b" using a

punch etc. In so doing, take care

not to damage the screwdriver re-

ceiving hole in the screw head.

INSTALLING THE CRANKSHAFT

1. Install:

• Crankshaft "1"Use the crankshaft installing tool

"2", "3", "4" and "5".

• Hold the connecting rod at top dead center with one hand while turning

the nut of the installing tool with the

other. Operate the installing tool un-

til the crankshaft bottoms against

the bearing.

• Before installing the crankshaft, clean the contacting surface of

crankcase.

Do not use a hammer to drive in

the crankshaft.

A. For USA and CDN

B. Except for USA and CDN

2. Check:

• Shifter operation

• Transmission operationUnsmooth operation →Repair.

3. Install: • Oil strainer "1"

• Bolt (oil strainer) "2"

4. Apply: • Sealant

On the right crankcase "1".

Clean the contacting surface of left

and right crankcase before applying

the sealant.

Bolt (bearing stopper): 10 Nm (1.0 m•kg, 7.2

ft•lb)

Screw (bearing stopper): 10 Nm (1.0 m•kg, 7.2

ft•lb)

Screw [bearing stopper

(crankshaft)]:14 Nm (1.4 m•kg, 10

ft•lb)

Crankshaft installing pot

"2": YU-90050/90890-01274

Crankshaft installing bolt

"3": YU-90050/90890-01275

Adapter (M12) "4": YU-90063/90890-01278

Spacer (crankshaft in-

staller) "5": YU-91044/90890-04081

Bolt (oil strainer):

10 Nm (1.0 m•kg, 7.2

ft•lb)

YAMAHA Bond No. 1215

(ThreeBond

® No.1215):

90890-85505

Page 166 of 232

5-63

CRANKCASE AND CRANKSHAFT

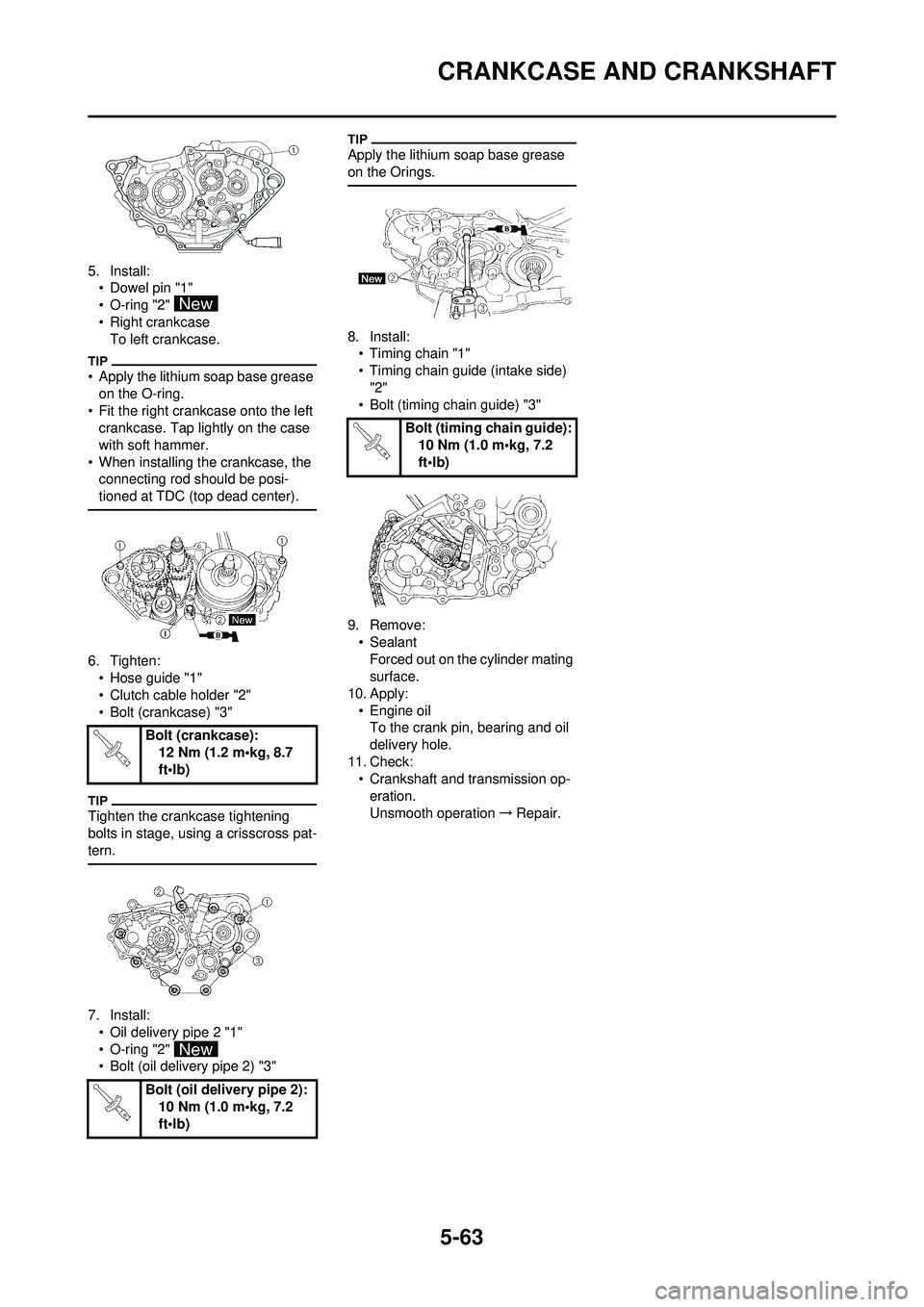

5. Install:• Dowel pin "1"

• O-ring "2"

• Right crankcaseTo left crankcase.

• Apply the lithium soap base grease

on the O-ring.

• Fit the right crankcase onto the left crankcase. Tap lightly on the case

with soft hammer.

• When installing the crankcase, the connecting rod should be posi-

tioned at TDC (top dead center).

6. Tighten:

• Hose guide "1"

• Clutch cable holder "2"

• Bolt (crankcase) "3"

Tighten the crankcase tightening

bolts in stage, using a crisscross pat-

tern.

7. Install:• Oil delivery pipe 2 "1"

• O-ring "2"

• Bolt (oil delivery pipe 2) "3"

Apply the lithium soap base grease

on the Orings.

8. Install:• Timing chain "1"

• Timing chain guide (intake side)

"2"

• Bolt (timing chain guide) "3"

9. Remove: • Sealant

Forced out on the cylinder mating

surface.

10. Apply:

• Engine oilTo the crank pin, bearing and oil

delivery hole.

11. Check: • Crankshaft and transmission op-eration.

Unsmooth operation →Repair.

Bolt (crankcase):

12 Nm (1.2 m•kg, 8.7

ft•lb)

Bolt (oil delivery pipe 2): 10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (timing chain guide):10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 168 of 232

5-65

TRANSMISSION, SHIFT CAM AND SHIFT FORK

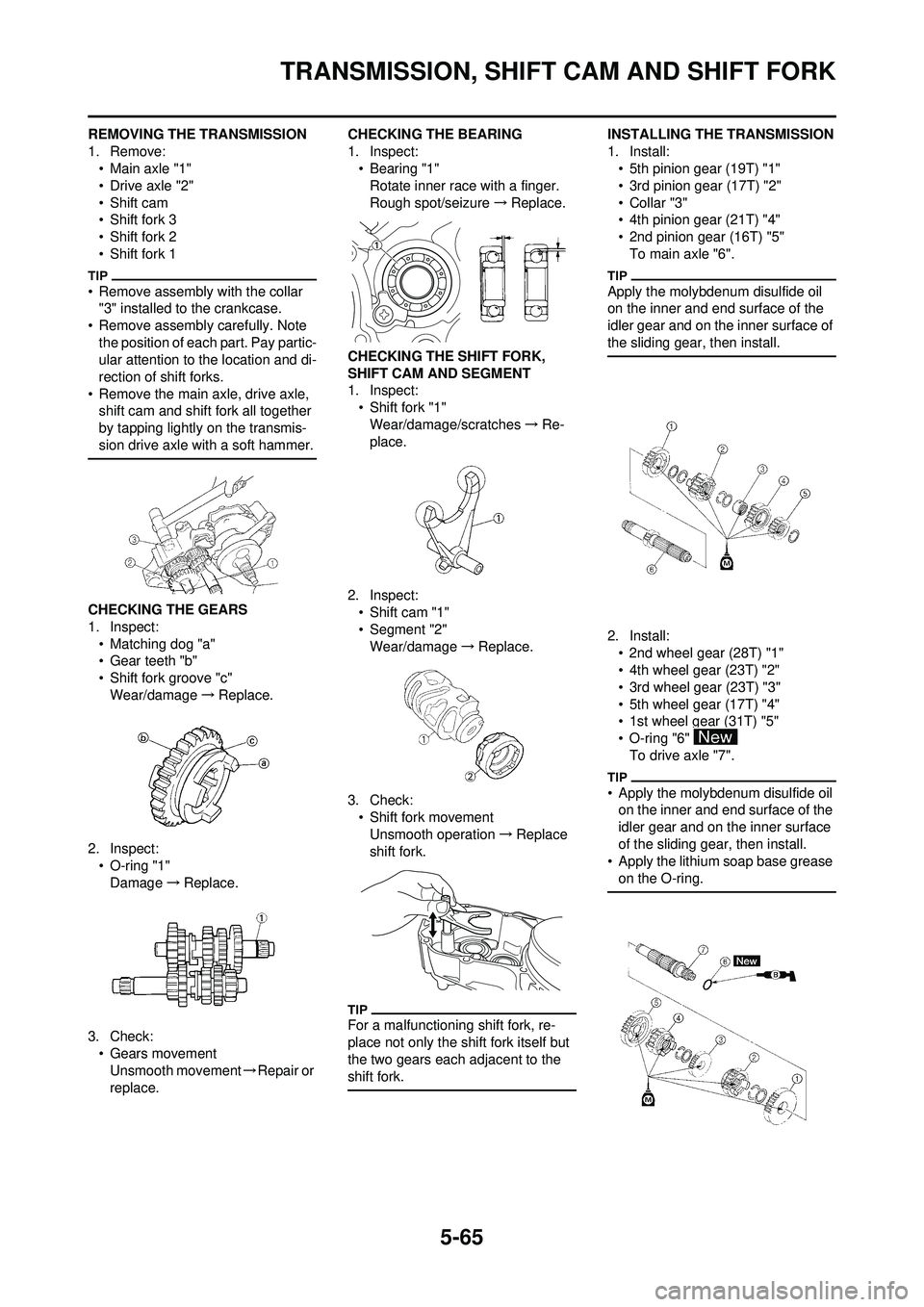

REMOVING THE TRANSMISSION

1. Remove:• Main axle "1"

• Drive axle "2"

• Shift cam

• Shift fork 3

• Shift fork 2

• Shift fork 1

• Remove assembly with the collar "3" installed to the crankcase.

• Remove assembly carefully. Note

the position of each part. Pay partic-

ular attention to the location and di-

rection of shift forks.

• Remove the main axle, drive axle, shift cam and shift fork all together

by tapping lightly on the transmis-

sion drive axle with a soft hammer.

CHECKING THE GEARS

1. Inspect:

• Matching dog "a"

• Gear teeth "b"

• Shift fork groove "c"Wear/damage →Replace.

2. Inspect: • O-ring "1"

Damage →Replace.

3. Check: • Gears movementUnsmooth movement →Repair or

replace. CHECKING THE BEARING

1. Inspect:

•Bearing "1"Rotate inner race with a finger.

Rough spot/seizure →Replace.

CHECKING THE SHIFT FORK,

SHIFT CAM AND SEGMENT

1. Inspect: • Shift fork "1"Wear/damage/scratches →Re-

place.

2. Inspect: • Shift cam "1"

• Segment "2"

Wear/damage →Replace.

3. Check: • Shift fork movementUnsmooth operation →Replace

shift fork.

For a malfunctioning shift fork, re-

place not only the shift fork itself but

the two gears each adjacent to the

shift fork.

INSTALLING THE TRANSMISSION

1. Install: • 5th pinion gear (19T) "1"

• 3rd pinion gear (17T) "2"

•Collar "3"

• 4th pinion gear (21T) "4"

• 2nd pinion gear (16T) "5"

To main axle "6".

Apply the molybdenum disulfide oil

on the inner and end surface of the

idler gear and on the inner surface of

the sliding gear, then install.

2. Install:• 2nd wheel gear (28T) "1"

• 4th wheel gear (23T) "2"

• 3rd wheel gear (23T) "3"

• 5th wheel gear (17T) "4"

• 1st wheel gear (31T) "5"

• O-ring "6" To drive axle "7".

• Apply the molybdenum disulfide oil on the inner and end surface of the

idler gear and on the inner surface

of the sliding gear, then install.

• Apply the lithium soap base grease on the O-ring.

Page 169 of 232

5-66

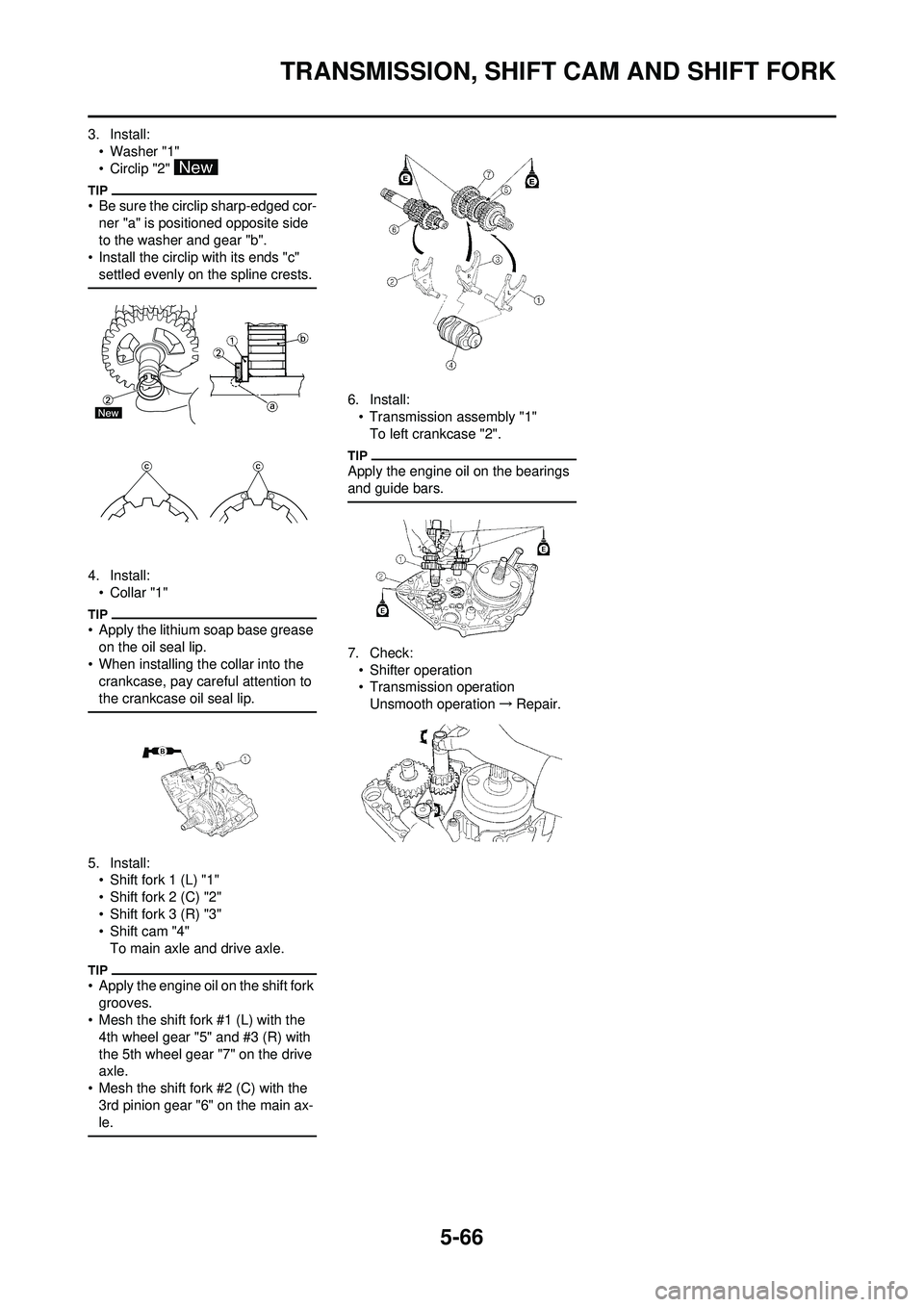

TRANSMISSION, SHIFT CAM AND SHIFT FORK

3. Install:• Washer "1"

• Circlip "2"

• Be sure the circlip sharp-edged cor-ner "a" is positioned opposite side

to the washer and gear "b".

• Install the circlip with its ends "c" settled evenly on the spline crests.

4. Install:•Collar "1"

• Apply the lithium soap base grease on the oil seal lip.

• When installing the collar into the crankcase, pay careful attention to

the crankcase oil seal lip.

5. Install:• Shift fork 1 (L) "1"

• Shift fork 2 (C) "2"

• Shift fork 3 (R) "3"

• Shift cam "4"To main axle and drive axle.

• Apply the engine oil on the shift fork

grooves.

• Mesh the shift fork #1 (L) with the 4th wheel gear "5" and #3 (R) with

the 5th wheel gear "7" on the drive

axle.

• Mesh the shift fork #2 (C) with the

3rd pinion gear "6" on the main ax-

le.

6. Install:• Transmission assembly "1"To left crankcase "2".

Apply the engine oil on the bearings

and guide bars.

7. Check:• Shifter operation

• Transmission operation

Unsmooth operation →Repair.

Page 214 of 232

7-5

ELECTRIC STARTING SYSTEM

3. Inspect:• Secondary coil resistanceOut of specification →Replace.

4. Inspect: • Sealed portion of ignition coil "a"

• Spark plug terminal pin "b"

• Threaded portion of spark plug "c"Wear →Replace.

CHECKING THE AC MAGNETO

1. Inspect: • Pickup coil resistance

Out of specification →Replace. CHECKING THE NEUTRAL

SWITCH

1. Inspect:

• Neutral switch conduction

Not conductive while it is in neutral →

Replace.

Conductive while it is engaged →Re-

place.

Set the tester selection position to " Ω

× 1".

CHECKING THE CDI UNIT

Check all electrical components. If no

fault is found, replace the CDI unit.

Then check the electrical compo-

nents again.

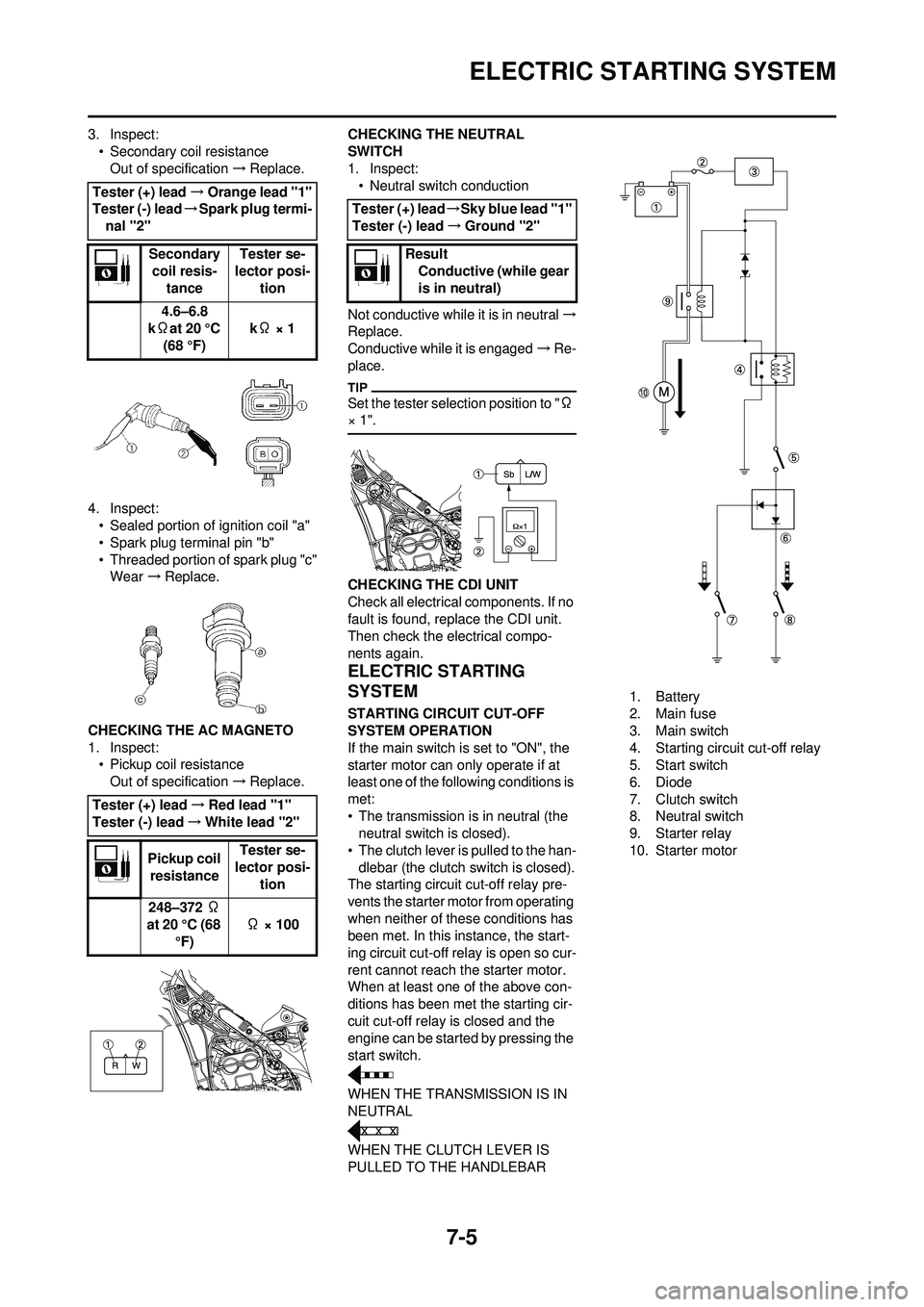

ELECTRIC STARTING

SYSTEM

STARTING CIRCUIT CUT-OFF

SYSTEM OPERATION

If the main switch is set to "ON", the

starter motor can only operate if at

least one of the following conditions is

met:

• The transmission is in neutral (the neutral switch is closed).

• The clutch lever is pulled to the han- dlebar (the clutch switch is closed).

The starting circuit cut-off relay pre-

vents the starter motor from operating

when neither of these conditions has

been met. In this instance, the start-

ing circuit cut-off relay is open so cur-

rent cannot reach the starter motor.

When at least one of the above con-

ditions has been met the starting cir-

cuit cut-off relay is closed and the

engine can be started by pressing the

start switch.

WHEN THE TRANSMISSION IS IN

NEUTRAL

WHEN THE CLUTCH LEVER IS

PULLED TO THE HANDLEBAR 1. Battery

2. Main fuse

3. Main switch

4. Starting circuit cut-off relay

5. Start switch

6. Diode

7. Clutch switch

8. Neutral switch

9. Starter relay

10. Starter motor

Tester (+) lead

→Orange lead "1"

Tester (-) lead →Spark plug termi-

nal "2"

Secondary coil resis- tance Tester se-

lector posi- tion

4.6–6.8

k Ωat 20 °C

(68 °F) k

Ω × 1

Tester (+) lead →Red lead "1"

Tester (-) lead →White lead "2"

Pickup coil resistance Tester se-

lector posi-

tion

248–372 Ω

at 20 °C (68 °F) Ω × 100

Tester (+) lead

→Sky blue lead "1"

Tester (-) lead →Ground "2"

Result Conductive (while gear

is in neutral)