engine YAMAHA WR 250F 2012 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2012, Model line: WR 250F, Model: YAMAHA WR 250F 2012Pages: 232, PDF Size: 13.32 MB

Page 29 of 232

1-19

STARTING AND BREAK-IN

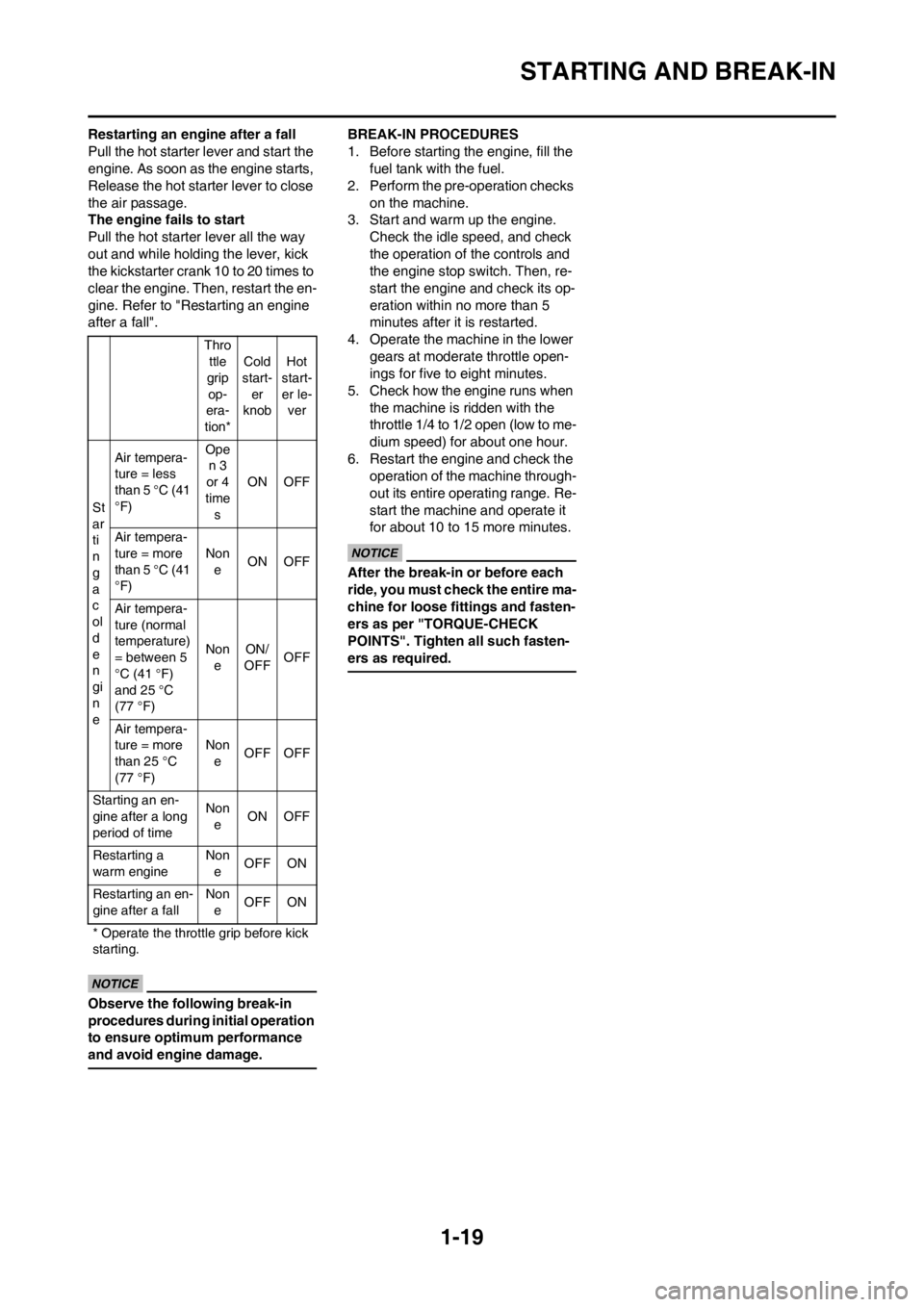

Restarting an engine after a fall

Pull the hot starter lever and start the

engine. As soon as the engine starts,

Release the hot starter lever to close

the air passage.

The engine fails to start

Pull the hot starter lever all the way

out and while holding the lever, kick

the kickstarter crank 10 to 20 times to

clear the engine. Then, restart the en-

gine. Refer to "Restarting an engine

after a fall".

Observe the following break-in

procedures during initial operation

to ensure optimum performance

and avoid engine damage.

BREAK-IN PROCEDURES

1. Before starting the engine, fill the

fuel tank with the fuel.

2. Perform the pre-operation checks

on the machine.

3. Start and warm up the engine.

Check the idle speed, and check

the operation of the controls and

the engine stop switch. Then, re-

start the engine and check its op-

eration within no more than 5

minutes after it is restarted.

4. Operate the machine in the lower

gears at moderate throttle open-

ings for five to eight minutes.

5. Check how the engine runs when

the machine is ridden with the

throttle 1/4 to 1/2 open (low to me-

dium speed) for about one hour.

6. Restart the engine and check the

operation of the machine through-

out its entire operating range. Re-

start the machine and operate it

for about 10 to 15 more minutes.

After the break-in or before each

ride, you must check the entire ma-

chine for loose fittings and fasten-

ers as per "TORQUE-CHECK

POINTS". Tighten all such fasten-

ers as required.

Thro

ttle

grip

op-

era-

tion*Cold

start-

er

knobHot

start-

er le-

ver

St

ar

ti

n

g

a

c

ol

d

e

n

gi

n

eAir tempera-

ture = less

than 5 °C (41

°F)Ope

n 3

or 4

time

sON OFF

Air tempera-

ture = more

than 5 °C (41

°F)Non

eON OFF

Air tempera-

ture (normal

temperature)

= between 5

°C (41 °F)

and 25 °C

(77 °F)Non

eON/

OFFOFF

Air tempera-

ture = more

than 25 °C

(77 °F)Non

eOFF OFF

Starting an en-

gine after a long

period of timeNon

eON OFF

Restarting a

warm engineNon

eOFF ON

Restarting an en-

gine after a fallNon

eOFF ON

* Operate the throttle grip before kick

starting.

Page 30 of 232

1-20

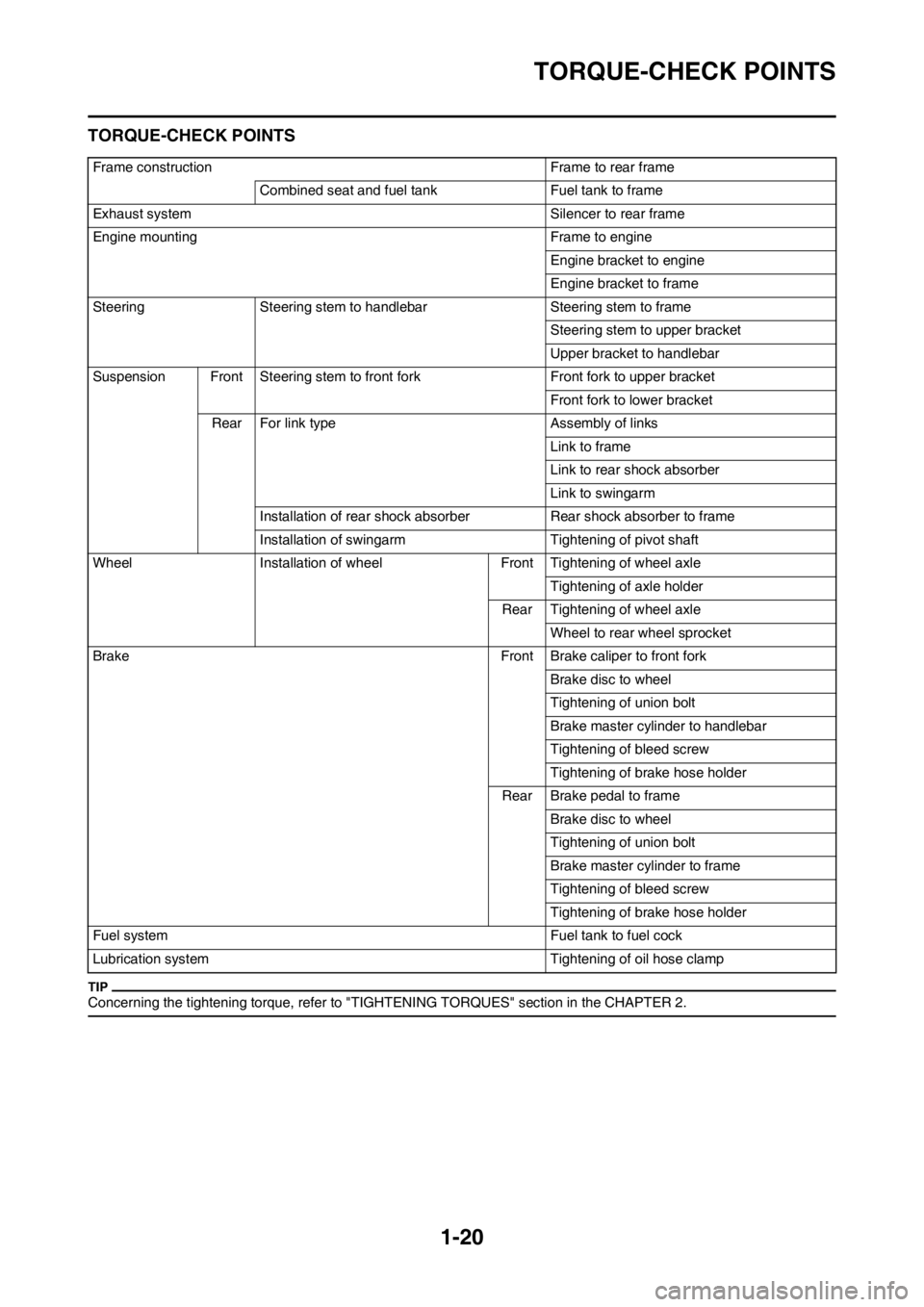

TORQUE-CHECK POINTS

TORQUE-CHECK POINTS

Concerning the tightening torque, refer to "TIGHTENING TORQUES" section in the CHAPTER 2.

Frame construction Frame to rear frame

Combined seat and fuel tank Fuel tank to frame

Exhaust system Silencer to rear frame

Engine mounting Frame to engine

Engine bracket to engine

Engine bracket to frame

Steering Steering stem to handlebar Steering stem to frame

Steering stem to upper bracket

Upper bracket to handlebar

Suspension Front Steering stem to front fork Front fork to upper bracket

Front fork to lower bracket

Rear For link type Assembly of links

Link to frame

Link to rear shock absorber

Link to swingarm

Installation of rear shock absorber Rear shock absorber to frame

Installation of swingarm Tightening of pivot shaft

Wheel Installation of wheel Front Tightening of wheel axle

Tightening of axle holder

Rear Tightening of wheel axle

Wheel to rear wheel sprocket

Brake Front Brake caliper to front fork

Brake disc to wheel

Tightening of union bolt

Brake master cylinder to handlebar

Tightening of bleed screw

Tightening of brake hose holder

Rear Brake pedal to frame

Brake disc to wheel

Tightening of union bolt

Brake master cylinder to frame

Tightening of bleed screw

Tightening of brake hose holder

Fuel system Fuel tank to fuel cock

Lubrication system Tightening of oil hose clamp

Page 31 of 232

1-21

CLEANING AND STORAGE

CLEANING AND STORAGE

CLEANING

Frequent cleaning of your machine

will enhance its appearance, maintain

good overall performance, and ex-

tend the life of many components.

1. Before washing the machine,

block off the end of the exhaust

pipe to prevent water from enter-

ing. A plastic bag secured with a

rubber band may be used for this

purpose.

2. If the engine is excessively

greasy, apply some degreaser to

it with a paint brush. Do not apply

degreaser to the chain, sprockets,

or wheel axles.

3. Rinse the dirt and degreaser off

with a garden hose; use only

enough pressure to do the job.

Do not use high-pressure washers

or steam-jet cleaners since they

cause water seepage and deterio-

ration seals.

4. After the majority of the dirt has

been hosed off, wash all surfaces

with warm water and a mild deter-

gent. Use an old toothbrush to

clean hard-to-reach places.

5. Rinse the machine off immediate-

ly with clean water, and dry all

surfaces with a soft towel or cloth.

6. Immediately after washing, re-

move excess water from the

chain with a paper towel and lubri-

cate the chain to prevent rust.

7. Clean the seat with a vinyl uphol-

stery cleaner to keep the cover

pliable and glossy.

8. Automotive wax may be applied

to all painted or chromed surfac-

es. Avoid combination cleaner-

waxes, as they may contain abra-

sives.

9. After completing the above, start

the engine and allow it to idle for

several minutes.STORAGE

If your machine is to be stored for 60

days or more, some preventive mea-

sures must be taken to avoid deterio-

ration. After cleaning the machine

thoroughly, prepare it for storage as

follows:

1. Drain the fuel tank, fuel lines, and

the carburetor float bowl.

2. Remove the spark plug, pour a ta-

blespoon of SAE 10W-40 motor

oil in the spark plug hole, and re-

install the plug. With the engine

stop switch pushed in, kick the en-

gine over several times to coat the

cylinder walls with oil.

3. Remove the drive chain, clean it

thoroughly with solvent, and lubri-

cate it. Reinstall the chain or store

it in a plastic bag tied to the frame.

4. Lubricate all control cables.

5. Block the frame up to raise the

wheels off the ground.

6. Tie a plastic bag over the exhaust

pipe outlet to prevent moisture

from entering.

7. If the machine is to be stored in a

humid or salt-air environment,

coat all exposed metal surfaces

with a film of light oil. Do not apply

oil to rubber parts or the seat cov-

er.

Make any necessary repairs before

the machine is stored.

Page 32 of 232

2-1

GENERAL SPECIFICATIONS

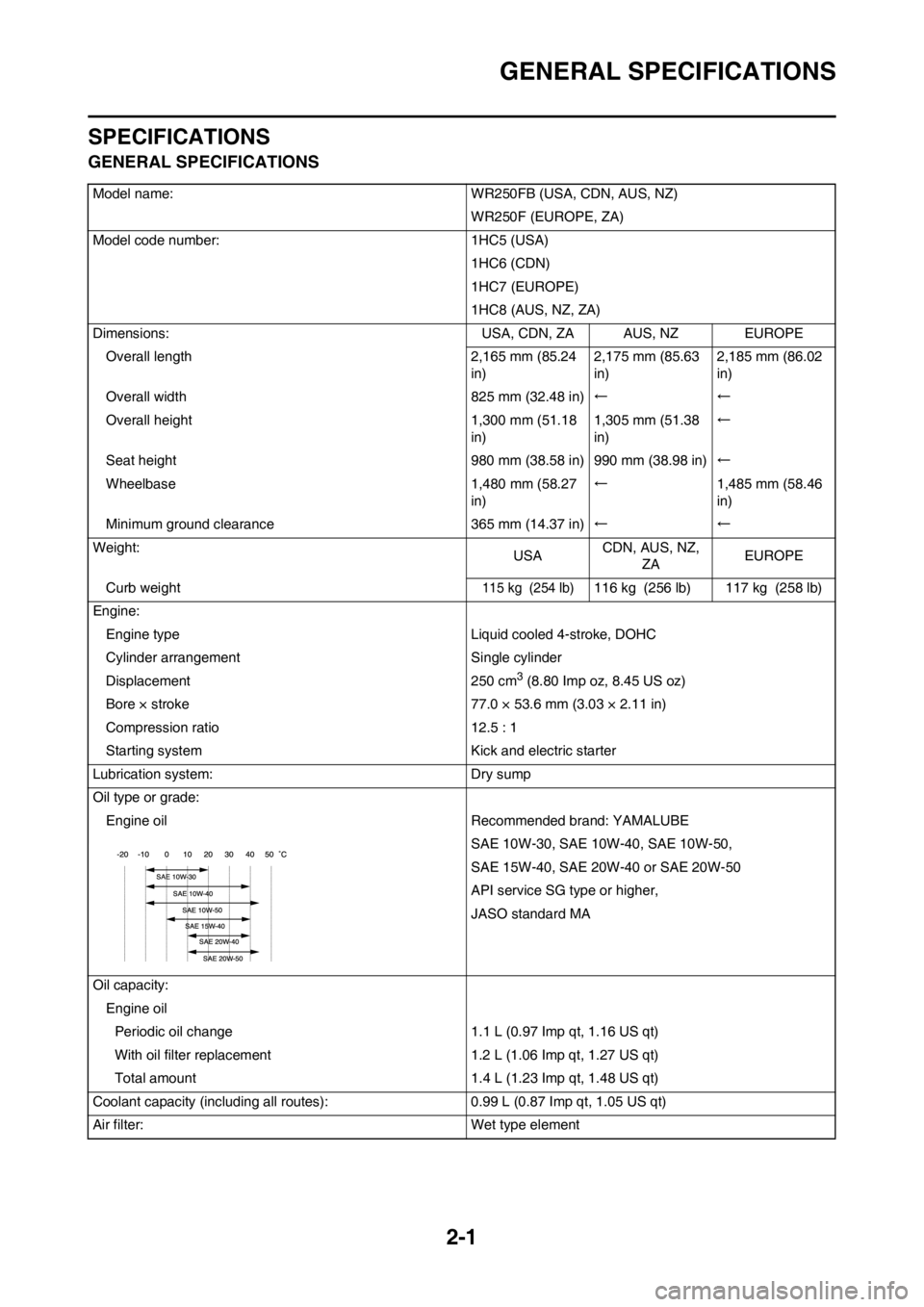

SPECIFICATIONS

GENERAL SPECIFICATIONS

Model name: WR250FB (USA, CDN, AUS, NZ)

WR250F (EUROPE, ZA)

Model code number: 1HC5 (USA)

1HC6 (CDN)

1HC7 (EUROPE)

1HC8 (AUS, NZ, ZA)

Dimensions: USA, CDN, ZA AUS, NZ EUROPE

Overall length 2,165 mm (85.24

in)2,175 mm (85.63

in)2,185 mm (86.02

in)

Overall width 825 mm (32.48 in)←←

Overall height 1,300 mm (51.18

in)1,305 mm (51.38

in)←

Seat height 980 mm (38.58 in) 990 mm (38.98 in)←

Wheelbase 1,480 mm (58.27

in)←1,485 mm (58.46

in)

Minimum ground clearance 365 mm (14.37 in)←←

Weight:

USA CDN, AUS, NZ,

ZAEUROPE

Curb weight

115 kg (254 lb)116 kg (256 lb) 117 kg (258 lb)

Engine:

Engine type Liquid cooled 4-stroke, DOHC

Cylinder arrangement Single cylinder

Displacement 250 cm

3 (8.80 Imp oz, 8.45 US oz)

Bore × stroke 77.0 × 53.6 mm (3.03 × 2.11 in)

Compression ratio 12.5 : 1

Starting system Kick and electric starter

Lubrication system: Dry sump

Oil type or grade:

Engine oil Recommended brand: YAMALUBE

SAE 10W-30, SAE 10W-40, SAE 10W-50,

SAE 15W-40, SAE 20W-40 or SAE 20W-50

API service SG type or higher,

JASO standard MA

Oil capacity:

Engine oil

Periodic oil change 1.1 L (0.97 Imp qt, 1.16 US qt)

With oil filter replacement 1.2 L (1.06 Imp qt, 1.27 US qt)

Total amount 1.4 L (1.23 Imp qt, 1.48 US qt)

Coolant capacity (including all routes): 0.99 L (0.87 Imp qt, 1.05 US qt)

Air filter: Wet type element

Page 34 of 232

2-3

MAINTENANCE SPECIFICATIONS

MAINTENANCE SPECIFICATIONS

ENGINEShock absorber:

Front shock absorber Coil spring/oil damper

Rear shock absorber Coil spring/gas, oil damper

Wheel travel:

Front wheel travel 300 mm (11.8 in)

Rear wheel travel 310 mm (12.2 in)

Electrical:

Ignition system CDI

Generator system AC magneto

Battery type YTZ7S (F)

Battery voltage/capacity 12V/6 AH

Specific gravity 1.310

Headlight type: Quartz bulb (halogen)

Bulb wattage × quantity:

Headlight 12 V 35/36.5 W × 1

Taillight 12 V 1.6/0.3 W × 1

Item Standard Limit

Cylinder head:

Warp limit ---- 0.05 mm (0.002

in)

Cylinder:

Bore size 77.00–77.01 mm (3.0315–3.0319 in) ----

Out of round limit ---- 0.05 mm (0.002

in)

Camshaft:

Drive method Chain drive (Left) ----

Camshaft cap inside diameter 22.000–22.021 mm (0.8661–0.8670 in) ----

Camshaft outside diameter 21.959–21.972 mm (0.8645–0.8650 in) ----

Shaft-to-cap clearance 0.028–0.062 mm (0.0011–0.0024 in) 0.08 mm (0.003

in)

Cam dimensions

Page 39 of 232

2-8

MAINTENANCE SPECIFICATIONS

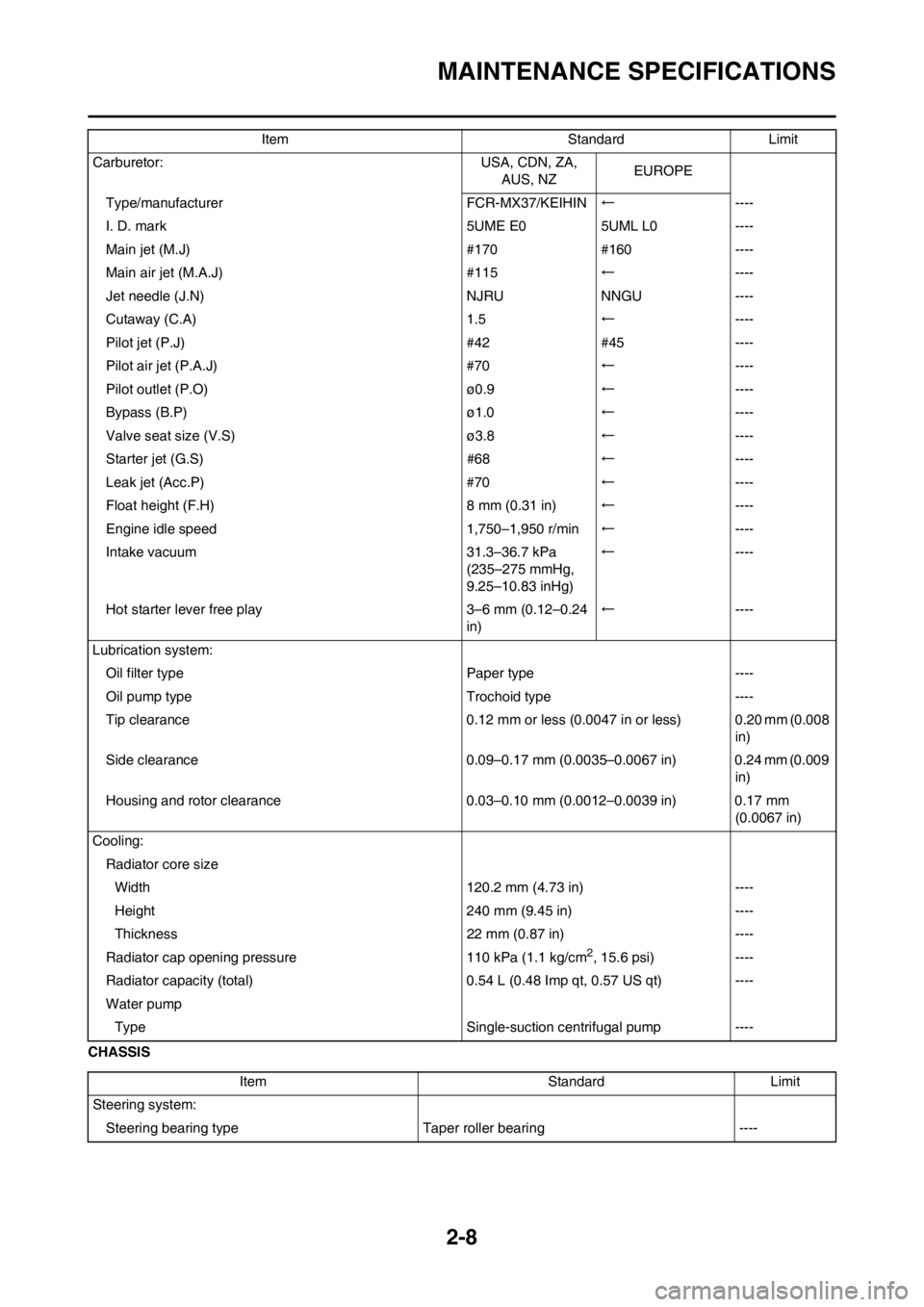

CHASSISCarburetor: USA, CDN, ZA,

AUS, NZEUROPE

Type/manufacturer FCR-MX37/KEIHIN←----

I. D. mark 5UME E0 5UML L0 ----

Main jet (M.J) #170 #160 ----

Main air jet (M.A.J) #115←----

Jet needle (J.N) NJRU NNGU ----

Cutaway (C.A) 1.5←----

Pilot jet (P.J) #42 #45 ----

Pilot air jet (P.A.J) #70←----

Pilot outlet (P.O) ø0.9←----

Bypass (B.P) ø1.0←----

Valve seat size (V.S) ø3.8←----

Starter jet (G.S) #68←----

Leak jet (Acc.P) #70←----

Float height (F.H) 8 mm (0.31 in)←----

Engine idle speed 1,750–1,950 r/min←----

Intake vacuum 31.3–36.7 kPa

(235–275 mmHg,

9.25–10.83 inHg)←----

Hot starter lever free play 3–6 mm (0.12–0.24

in)←----

Lubrication system:

Oil filter type Paper type ----

Oil pump type Trochoid type ----

Tip clearance 0.12 mm or less (0.0047 in or less) 0.20 mm (0.008

in)

Side clearance 0.09–0.17 mm (0.0035–0.0067 in) 0.24 mm (0.009

in)

Housing and rotor clearance 0.03–0.10 mm (0.0012–0.0039 in) 0.17 mm

(0.0067 in)

Cooling:

Radiator core size

Width 120.2 mm (4.73 in) ----

Height 240 mm (9.45 in) ----

Thickness 22 mm (0.87 in) ----

Radiator cap opening pressure 110 kPa (1.1 kg/cm

2, 15.6 psi) ----

Radiator capacity (total) 0.54 L (0.48 Imp qt, 0.57 US qt) ----

Water pump

Type Single-suction centrifugal pump ----Item Standard Limit

Item Standard Limit

Steering system:

Steering bearing typeTaper roller bearing ----

Page 43 of 232

2-12

TIGHTENING TORQUES

TIGHTENING TORQUES

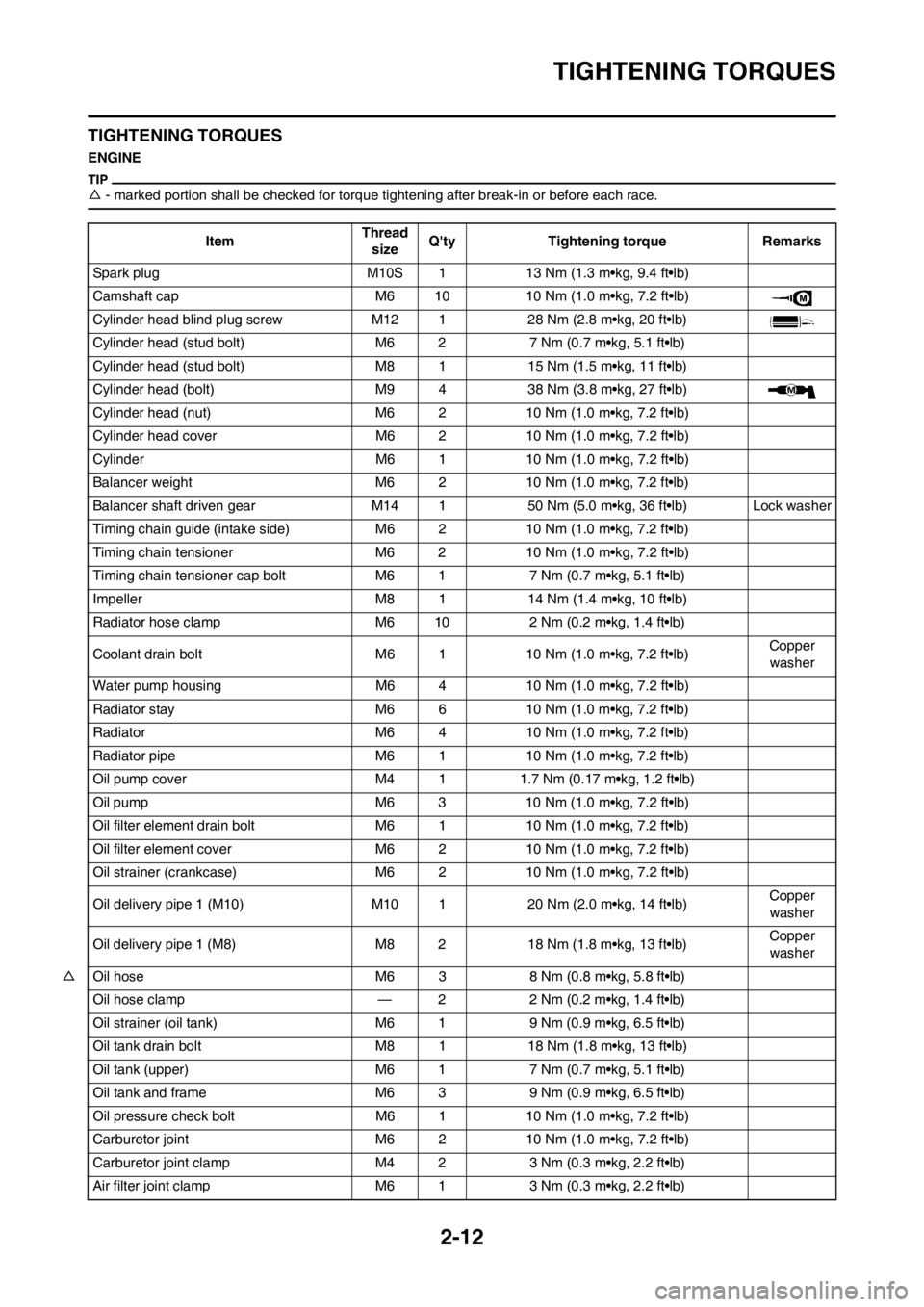

ENGINE

△- marked portion shall be checked for torque tightening after break-in or before each race.

ItemThread

sizeQ'ty Tightening torque Remarks

Spark plug M10S 1 13 Nm (1.3 m•kg, 9.4 ft•lb)

Camshaft cap M6 10 10 Nm (1.0 m•kg, 7.2 ft•lb)

Cylinder head blind plug screw M12 1 28 Nm (2.8 m•kg, 20 ft•lb)

Cylinder head (stud bolt) M6 2 7 Nm (0.7 m•kg, 5.1 ft•lb)

Cylinder head (stud bolt) M8 1 15 Nm (1.5 m•kg, 11 ft•lb)

Cylinder head (bolt) M9 4 38 Nm (3.8 m•kg, 27 ft•lb)

Cylinder head (nut) M6 2 10 Nm (1.0 m•kg, 7.2 ft•lb)

Cylinder head cover M6 2 10 Nm (1.0 m•kg, 7.2 ft•lb)

Cylinder M6 1 10 Nm (1.0 m•kg, 7.2 ft•lb)

Balancer weight M6 2 10 Nm (1.0 m•kg, 7.2 ft•lb)

Balancer shaft driven gear M14 1 50 Nm (5.0 m•kg, 36 ft•lb) Lock washer

Timing chain guide (intake side) M6 2 10 Nm (1.0 m•kg, 7.2 ft•lb)

Timing chain tensioner M6 2 10 Nm (1.0 m•kg, 7.2 ft•lb)

Timing chain tensioner cap bolt M6 1 7 Nm (0.7 m•kg, 5.1 ft•lb)

Impeller M8 1 14 Nm (1.4 m•kg, 10 ft•lb)

Radiator hose clamp M6 10 2 Nm (0.2 m•kg, 1.4 ft•lb)

Coolant drain bolt M6 1 10 Nm (1.0 m•kg, 7.2 ft•lb)Copper

washer

Water pump housing M6 4 10 Nm (1.0 m•kg, 7.2 ft•lb)

Radiator stay M6 6 10 Nm (1.0 m•kg, 7.2 ft•lb)

Radiator M6 4 10 Nm (1.0 m•kg, 7.2 ft•lb)

Radiator pipe M6 1 10 Nm (1.0 m•kg, 7.2 ft•lb)

Oil pump cover M4 1 1.7 Nm (0.17 m•kg, 1.2 ft•lb)

Oil pump M6 3 10 Nm (1.0 m•kg, 7.2 ft•lb)

Oil filter element drain bolt M6 1 10 Nm (1.0 m•kg, 7.2 ft•lb)

Oil filter element cover M6 2 10 Nm (1.0 m•kg, 7.2 ft•lb)

Oil strainer (crankcase) M6 2 10 Nm (1.0 m•kg, 7.2 ft•lb)

Oil delivery pipe 1 (M10) M10 1 20 Nm (2.0 m•kg, 14 ft•lb)Copper

washer

Oil delivery pipe 1 (M8) M8 2 18 Nm (1.8 m•kg, 13 ft•lb)Copper

washer

△Oil hose M6 3 8 Nm (0.8 m•kg, 5.8 ft•lb)

Oil hose clamp — 2 2 Nm (0.2 m•kg, 1.4 ft•lb)

Oil strainer (oil tank) M6 1 9 Nm (0.9 m•kg, 6.5 ft•lb)

Oil tank drain bolt M8 1 18 Nm (1.8 m•kg, 13 ft•lb)

Oil tank (upper) M6 1 7 Nm (0.7 m•kg, 5.1 ft•lb)

Oil tank and frame M6 3 9 Nm (0.9 m•kg, 6.5 ft•lb)

Oil pressure check bolt M6 1 10 Nm (1.0 m•kg, 7.2 ft•lb)

Carburetor joint M6 2 10 Nm (1.0 m•kg, 7.2 ft•lb)

Carburetor joint clamp M4 2 3 Nm (0.3 m•kg, 2.2 ft•lb)

Air filter joint clamp M6 1 3 Nm (0.3 m•kg, 2.2 ft•lb)

Page 46 of 232

2-15

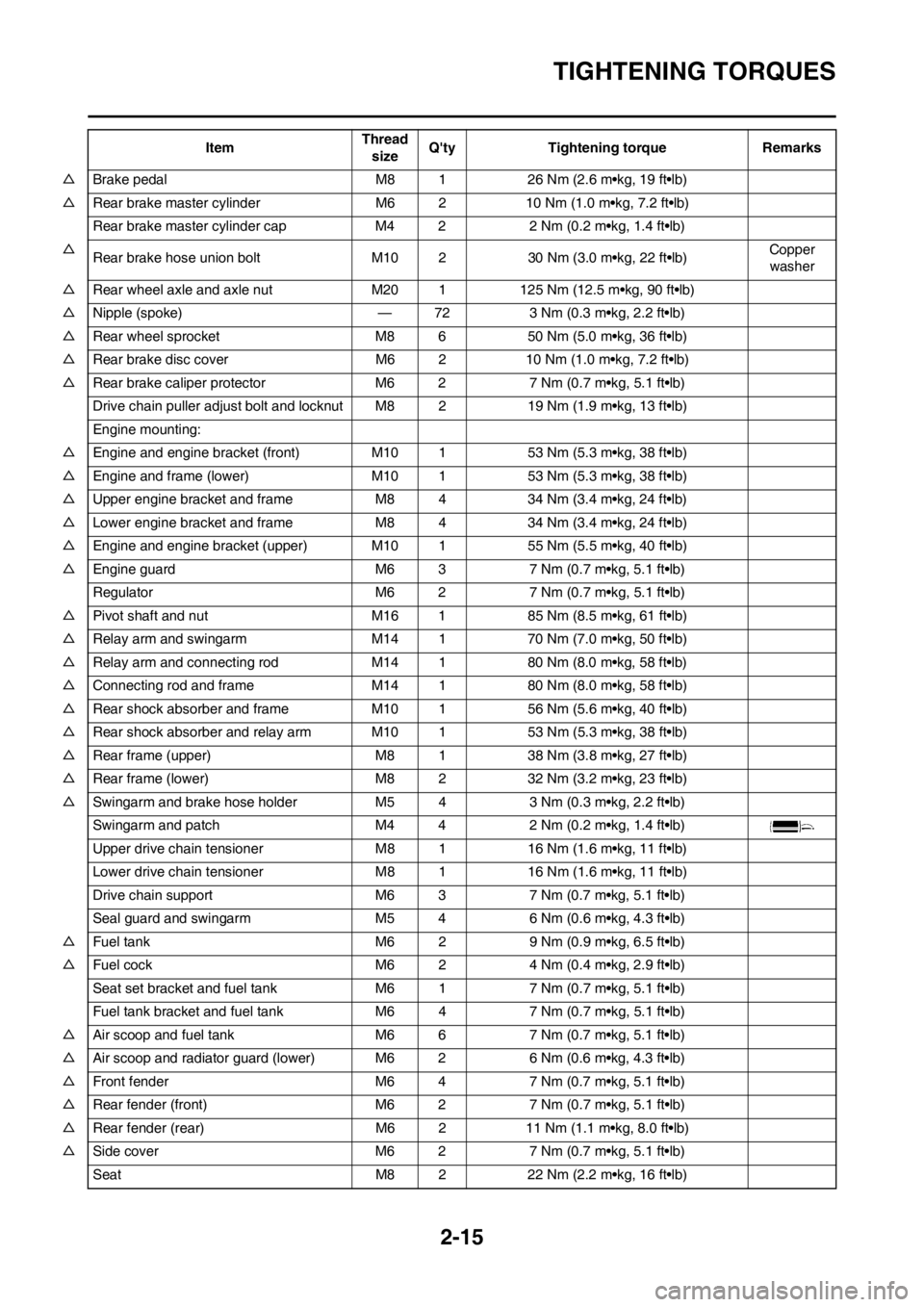

TIGHTENING TORQUES

△Brake pedal M8 1 26 Nm (2.6 m•kg, 19 ft•lb)

△Rear brake master cylinder M6 2 10 Nm (1.0 m•kg, 7.2 ft•lb)

Rear brake master cylinder cap M4 2 2 Nm (0.2 m•kg, 1.4 ft•lb)

△

Rear brake hose union bolt M10 2 30 Nm (3.0 m•kg, 22 ft•lb)Copper

washer

△Rear wheel axle and axle nut M20 1 125 Nm (12.5 m•kg, 90 ft•lb)

△Nipple (spoke) — 72 3 Nm (0.3 m•kg, 2.2 ft•lb)

△Rear wheel sprocket M8 6 50 Nm (5.0 m•kg, 36 ft•lb)

△Rear brake disc cover M6 2 10 Nm (1.0 m•kg, 7.2 ft•lb)

△Rear brake caliper protector M6 2 7 Nm (0.7 m•kg, 5.1 ft•lb)

Drive chain puller adjust bolt and locknut M8 2 19 Nm (1.9 m•kg, 13 ft•lb)

Engine mounting:

△Engine and engine bracket (front) M10 1 53 Nm (5.3 m•kg, 38 ft•lb)

△Engine and frame (lower) M10 1 53 Nm (5.3 m•kg, 38 ft•lb)

△Upper engine bracket and frame M8 4 34 Nm (3.4 m•kg, 24 ft•lb)

△Lower engine bracket and frame M8 4 34 Nm (3.4 m•kg, 24 ft•lb)

△Engine and engine bracket (upper) M10 1 55 Nm (5.5 m•kg, 40 ft•lb)

△Engine guard M6 3 7 Nm (0.7 m•kg, 5.1 ft•lb)

Regulator M6 2 7 Nm (0.7 m•kg, 5.1 ft•lb)

△Pivot shaft and nut M16 1 85 Nm (8.5 m•kg, 61 ft•lb)

△Relay arm and swingarm M14 1 70 Nm (7.0 m•kg, 50 ft•lb)

△Relay arm and connecting rod M14 1 80 Nm (8.0 m•kg, 58 ft•lb)

△Connecting rod and frame M14 1 80 Nm (8.0 m•kg, 58 ft•lb)

△Rear shock absorber and frame M10 1 56 Nm (5.6 m•kg, 40 ft•lb)

△Rear shock absorber and relay arm M10 1 53 Nm (5.3 m•kg, 38 ft•lb)

△Rear frame (upper) M8 1 38 Nm (3.8 m•kg, 27 ft•lb)

△Rear frame (lower) M8 2 32 Nm (3.2 m•kg, 23 ft•lb)

△Swingarm and brake hose holder M54 3 Nm (0.3 m•kg, 2.2 ft•lb)

Swingarm and patch M4 4 2 Nm (0.2 m•kg, 1.4 ft•lb)

Upper drive chain tensioner M8 1 16 Nm (1.6 m•kg, 11 ft•lb)

Lower drive chain tensioner M8 1 16 Nm (1.6 m•kg, 11 ft•lb)

Drive chain support M6 3 7 Nm (0.7 m•kg, 5.1 ft•lb)

Seal guard and swingarm M5 4 6 Nm (0.6 m•kg, 4.3 ft•lb)

△Fuel tank M6 2 9 Nm (0.9 m•kg, 6.5 ft•lb)

△Fuel cock M6 2 4 Nm (0.4 m•kg, 2.9 ft•lb)

Seat set bracket and fuel tankM6 1 7 Nm (0.7 m•kg, 5.1 ft•lb)

Fuel tank bracket and fuel tank M6 4 7 Nm (0.7 m•kg, 5.1 ft•lb)

△Air scoop and fuel tank M6 6 7 Nm (0.7 m•kg, 5.1 ft•lb)

△Air scoop and radiator guard (lower) M6 2 6 Nm (0.6 m•kg, 4.3 ft•lb)

△Front fender M6 4 7 Nm (0.7 m•kg, 5.1 ft•lb)

△Rear fender (front) M6 2 7 Nm (0.7 m•kg, 5.1 ft•lb)

△Rear fender (rear) M6 2 11 Nm (1.1 m•kg, 8.0 ft•lb)

△Side cover M6 2 7 Nm (0.7 m•kg, 5.1 ft•lb)

Seat M8 2 22 Nm (2.2 m•kg, 16 ft•lb)ItemThread

sizeQ'ty Tightening torque Remarks

Page 48 of 232

2-17

TIGHTENING TORQUES

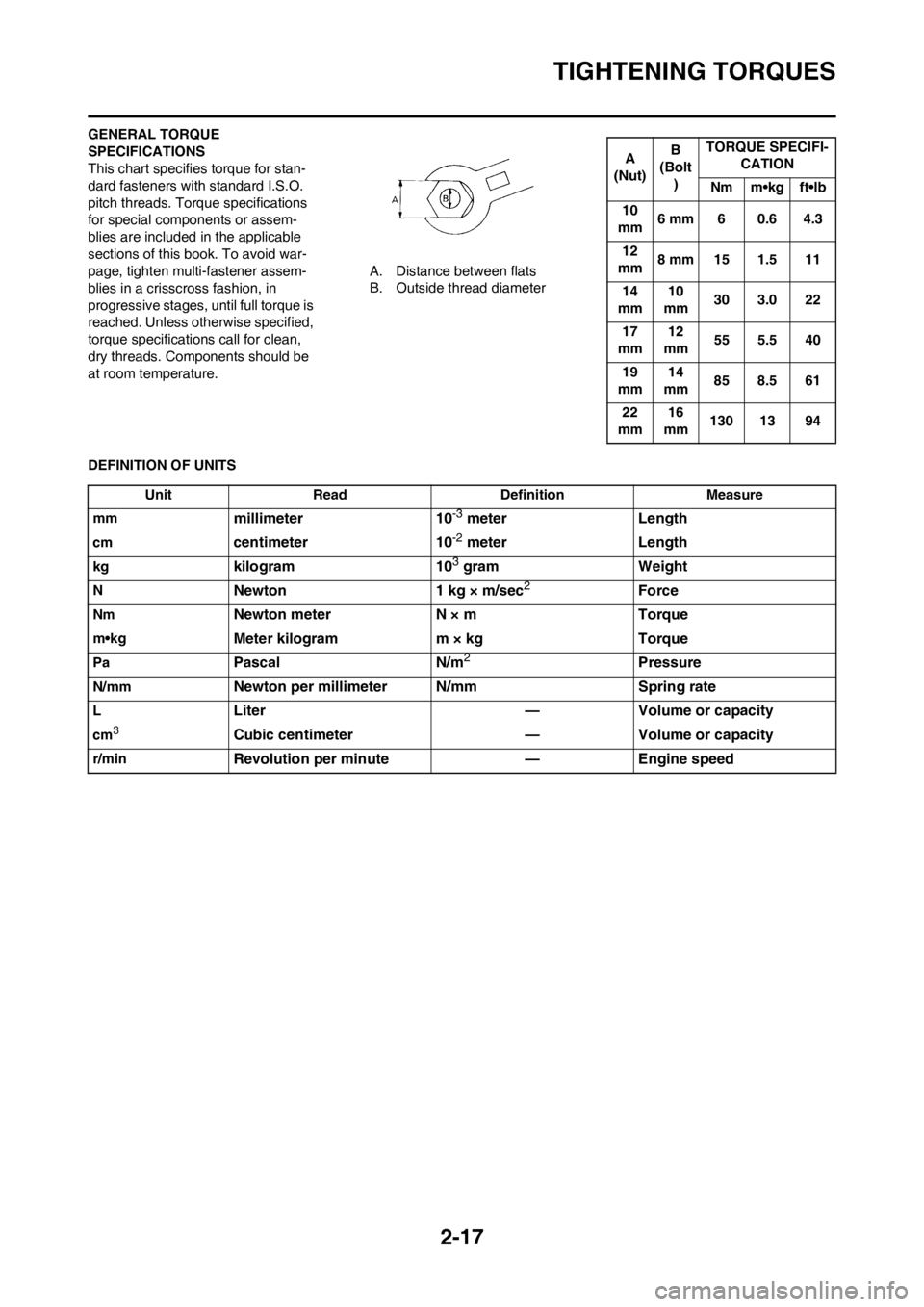

GENERAL TORQUE

SPECIFICATIONS

This chart specifies torque for stan-

dard fasteners with standard I.S.O.

pitch threads. Torque specifications

for special components or assem-

blies are included in the applicable

sections of this book. To avoid war-

page, tighten multi-fastener assem-

blies in a crisscross fashion, in

progressive stages, until full torque is

reached. Unless otherwise specified,

torque specifications call for clean,

dry threads. Components should be

at room temperature.A. Distance between flats

B. Outside thread diameter

DEFINITION OF UNITS

A

(Nut)B

(Bolt

)TORQUE SPECIFI-

CATION

Nm m•kg ft•lb

10

mm6 mm 6 0.6 4.3

12

mm8 mm 15 1.5 11

14

mm10

mm30 3.0 22

17

mm12

mm55 5.5 40

19

mm14

mm85 8.5 61

22

mm16

mm130 13 94

Unit Read Definition Measure

mm

millimeter 10-3 meter Length

cmcentimeter 10-2 meter Length

kgkilogram 103 gram Weight

NNewton 1 kg × m/sec2Force

NmNewton meter N × m Torque

m•kgMeter kilogram m × kg Torque

PaPascal N/m2Pressure

N/mmNewton per millimeter N/mm Spring rate

LLiter — Volume or capacity

cm3Cubic centimeter — Volume or capacity

r/minRevolution per minute — Engine speed

Page 57 of 232

2-26

CABLE ROUTING DIAGRAM

A. Fasten the wire harness, nega-

tive battery lead and starter mo-

tor lead to the upper engine

bracket (left side). Locate the

clamp end facing toward the up-

per side of the frame with the tie

end cut off on the inside of the

frame.

B. Fasten the wire harness, nega-

tive battery lead and starter mo-

tor lead to the upper engine

bracket (left side). Locate the

clamp end facing toward the up-

per side of the frame with the tie

end cut off on the inside of the

frame. Clamp the wire harness

and negative lead at the mark-

ing.

C. Pass the starter motor lead

through the hole in the relay

holder.

D. Fit the cover securely.

E. Connect the wire harness to the

starter relay.

F. Fasten the catch tank breather

hose and catch tank hose to the

rear frame. Clamp them close to

where they are joined to the

frame. Fasten the pipe tightly

enough not to crush it. Locate

the clamp end facing toward the

rear of the frame with the tie end

facing downward.

G. Fasten the (three) CDI unit leads

and taillight lead to the rear

frame. Locate the clamp end

facing toward the upper side of

the frame and cut off the tie end.

H. Connect the negative battery

lead to the battery negative ter-

minal.

I. Connect the negative battery

lead to the wire harness.

J. Fasten the wire harness to the

rear frame. Locate the clamp

end facing toward the upper side

of the frame and the tie end to-

ward the inside of the frame.

Clamp the wire harness at the

marking.

K. Pass the wire harness, starter

relay lead, starting circuit cut-off

relay lead and negative battery

lead through the hole in the relay

holder.

L. Fasten the (three) CDI unit leads

and taillight lead to the rear

frame. Locate the clamp end

facing toward the lower side of

the frame and cut off the tie end.M. Fasten the taillight lead to the

rear frame. Locate the clamp

end facing toward the upper side

of the frame and cut off the tie

end.

N. Do not allow the taillight lead to

slacken.

O. Locate the CDI unit lead be-

tween the CDI unit and rear

fender.

P. Locate the CDI unit coupler in

the clearance between the up-

per side of the CDI unit and low-

er side of the catch tank stay.

Q. Locate the CDI unit lead be-

tween the CDI unit and rear

frame.