engine YAMAHA WR 250F 2012 Repair Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2012, Model line: WR 250F, Model: YAMAHA WR 250F 2012Pages: 232, PDF Size: 13.32 MB

Page 140 of 232

5-37

OIL FILTER ELEMENT AND WATER PUMP

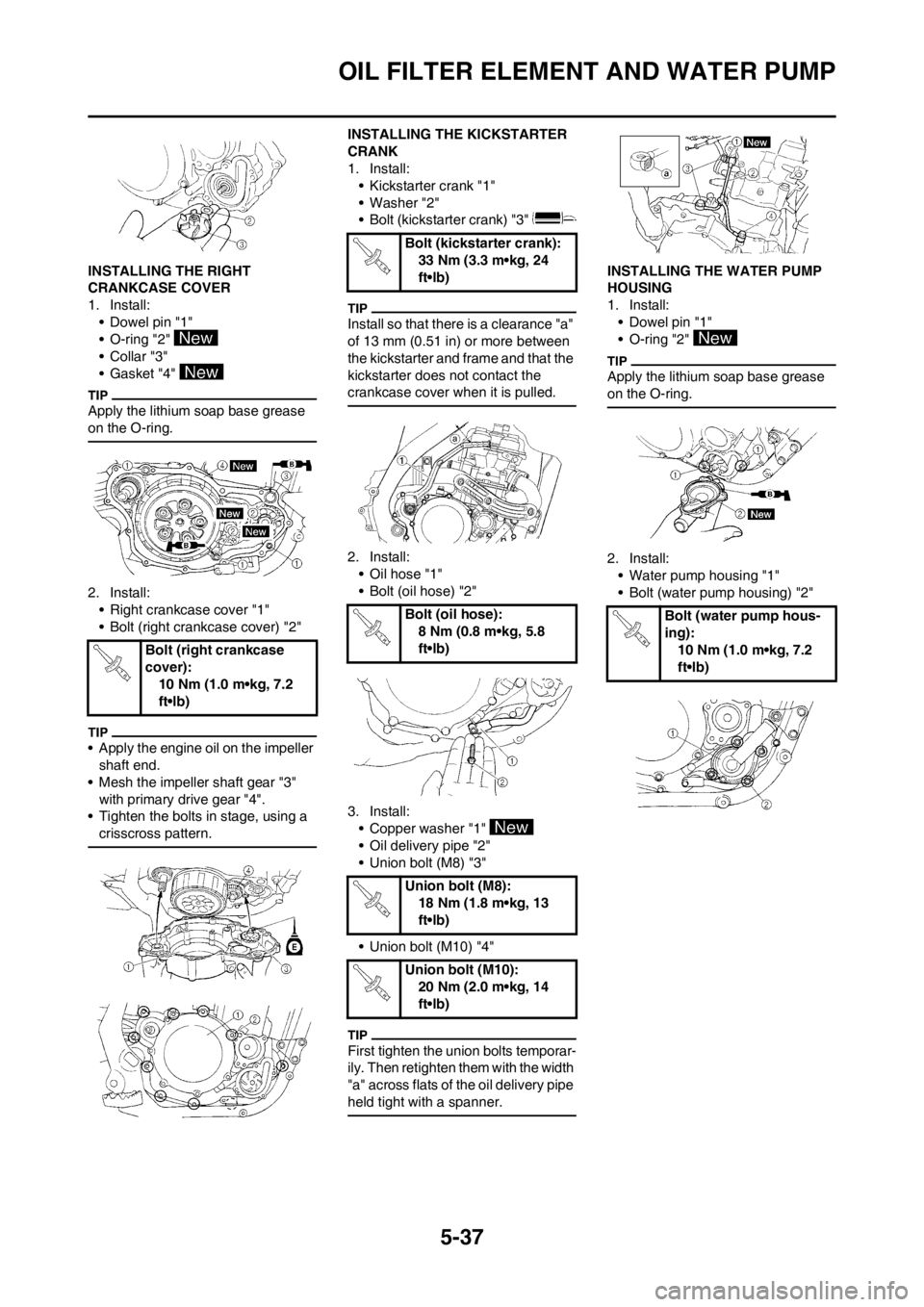

INSTALLING THE RIGHT

CRANKCASE COVER

1. Install:

• Dowel pin "1"

• O-ring "2"

•Collar "3"

• Gasket "4"

Apply the lithium soap base grease

on the O-ring.

2. Install:

• Right crankcase cover "1"

• Bolt (right crankcase cover) "2"

• Apply the engine oil on the impeller

shaft end.

• Mesh the impeller shaft gear "3"

with primary drive gear "4".

• Tighten the bolts in stage, using a

crisscross pattern.

INSTALLING THE KICKSTARTER

CRANK

1. Install:

• Kickstarter crank "1"

• Washer "2"

• Bolt (kickstarter crank) "3"

Install so that there is a clearance "a"

of 13 mm (0.51 in) or more between

the kickstarter and frame and that the

kickstarter does not contact the

crankcase cover when it is pulled.

2. Install:

• Oil hose "1"

• Bolt (oil hose) "2"

3. Install:

• Copper washer "1"

• Oil delivery pipe "2"

• Union bolt (M8) "3"

• Union bolt (M10) "4"

First tighten the union bolts temporar-

ily. Then retighten them with the width

"a" across flats of the oil delivery pipe

held tight with a spanner.

INSTALLING THE WATER PUMP

HOUSING

1. Install:

• Dowel pin "1"

• O-ring "2"

Apply the lithium soap base grease

on the O-ring.

2. Install:

• Water pump housing "1"

• Bolt (water pump housing) "2"

Bolt (right crankcase

cover):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (kickstarter crank):

33 Nm (3.3 m•kg, 24

ft•lb)

Bolt (oil hose):

8 Nm (0.8 m•kg, 5.8

ft•lb)

Union bolt (M8):

18 Nm (1.8 m•kg, 13

ft•lb)

Union bolt (M10):

20 Nm (2.0 m•kg, 14

ft•lb)

Bolt (water pump hous-

ing):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 143 of 232

5-40

BALANCER

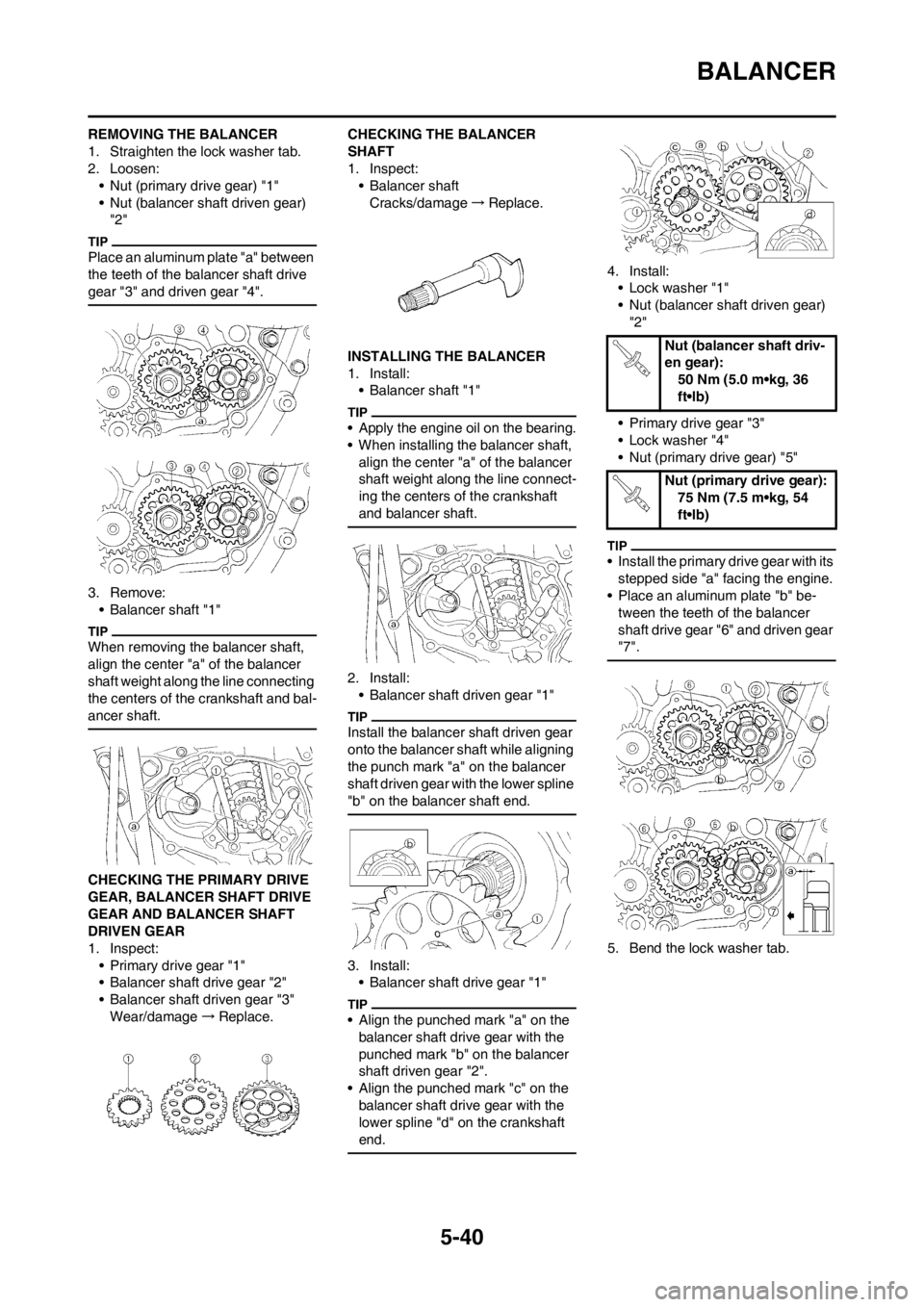

REMOVING THE BALANCER

1. Straighten the lock washer tab.

2. Loosen:

• Nut (primary drive gear) "1"

• Nut (balancer shaft driven gear)

"2"

Place an aluminum plate "a" between

the teeth of the balancer shaft drive

gear "3" and driven gear "4".

3. Remove:

• Balancer shaft "1"

When removing the balancer shaft,

align the center "a" of the balancer

shaft weight along the line connecting

the centers of the crankshaft and bal-

ancer shaft.

CHECKING THE PRIMARY DRIVE

GEAR, BALANCER SHAFT DRIVE

GEAR AND BALANCER SHAFT

DRIVEN GEAR

1. Inspect:

• Primary drive gear "1"

• Balancer shaft drive gear "2"

• Balancer shaft driven gear "3"

Wear/damage→Replace.CHECKING THE BALANCER

SHAFT

1. Inspect:

• Balancer shaft

Cracks/damage→Replace.

INSTALLING THE BALANCER

1. Install:

• Balancer shaft "1"

• Apply the engine oil on the bearing.

• When installing the balancer shaft,

align the center "a" of the balancer

shaft weight along the line connect-

ing the centers of the crankshaft

and balancer shaft.

2. Install:

• Balancer shaft driven gear "1"

Install the balancer shaft driven gear

onto the balancer shaft while aligning

the punch mark "a" on the balancer

shaft driven gear with the lower spline

"b" on the balancer shaft end.

3. Install:

• Balancer shaft drive gear "1"

• Align the punched mark "a" on the

balancer shaft drive gear with the

punched mark "b" on the balancer

shaft driven gear "2".

• Align the punched mark "c" on the

balancer shaft drive gear with the

lower spline "d" on the crankshaft

end.

4. Install:

• Lock washer "1"

• Nut (balancer shaft driven gear)

"2"

• Primary drive gear "3"

• Lock washer "4"

• Nut (primary drive gear) "5"

• Install the primary drive gear with its

stepped side "a" facing the engine.

• Place an aluminum plate "b" be-

tween the teeth of the balancer

shaft drive gear "6" and driven gear

"7".

5. Bend the lock washer tab.

Nut (balancer shaft driv-

en gear):

50 Nm (5.0 m•kg, 36

ft•lb)

Nut (primary drive gear):

75 Nm (7.5 m•kg, 54

ft•lb)

Page 145 of 232

5-42

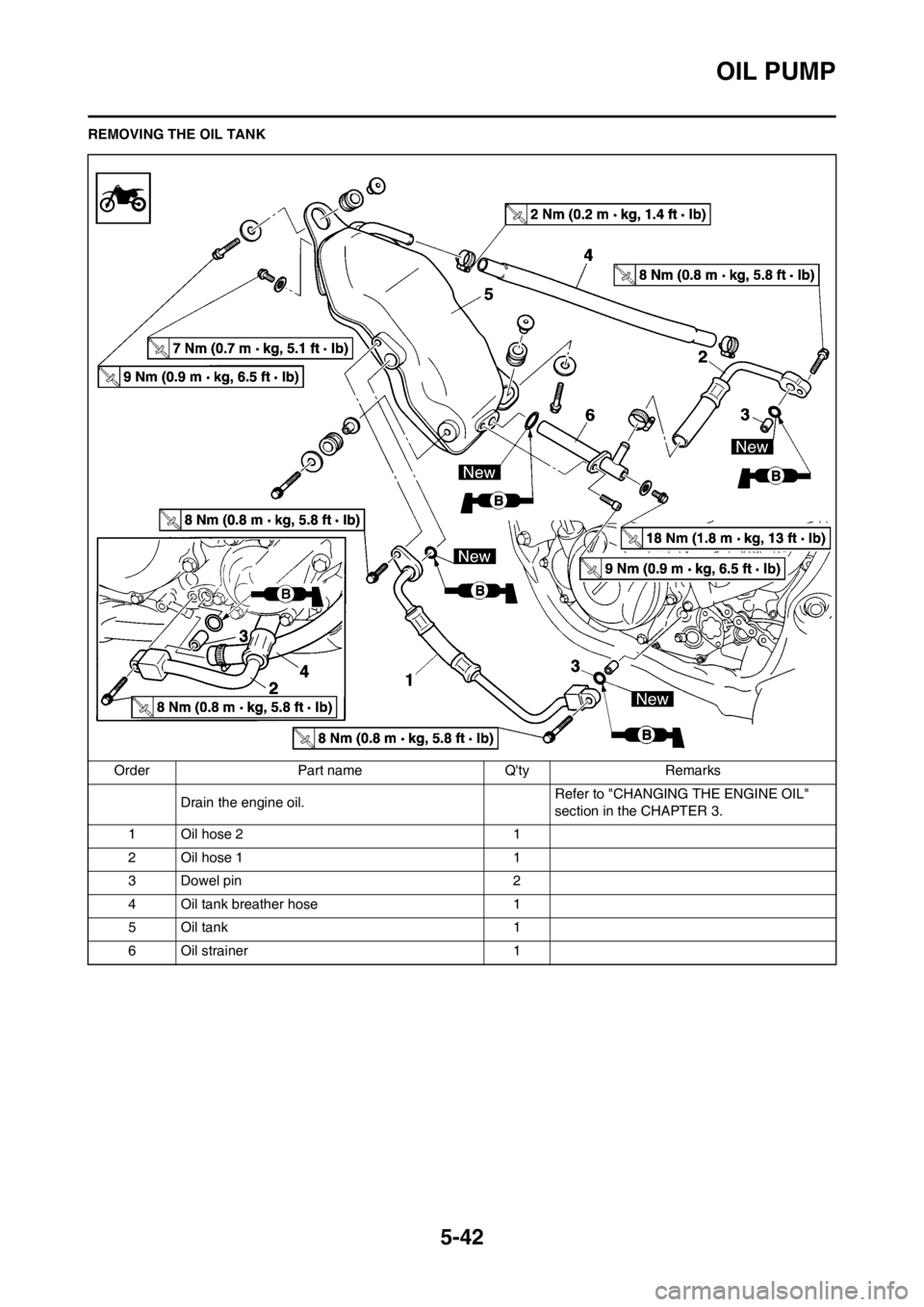

OIL PUMP

REMOVING THE OIL TANK

Order Part name Q'ty Remarks

Drain the engine oil.Refer to "CHANGING THE ENGINE OIL"

section in the CHAPTER 3.

1 Oil hose 2 1

2 Oil hose 1 1

3 Dowel pin 2

4 Oil tank breather hose 1

5 Oil tank 1

6 Oil strainer 1

Page 146 of 232

5-43

OIL PUMP

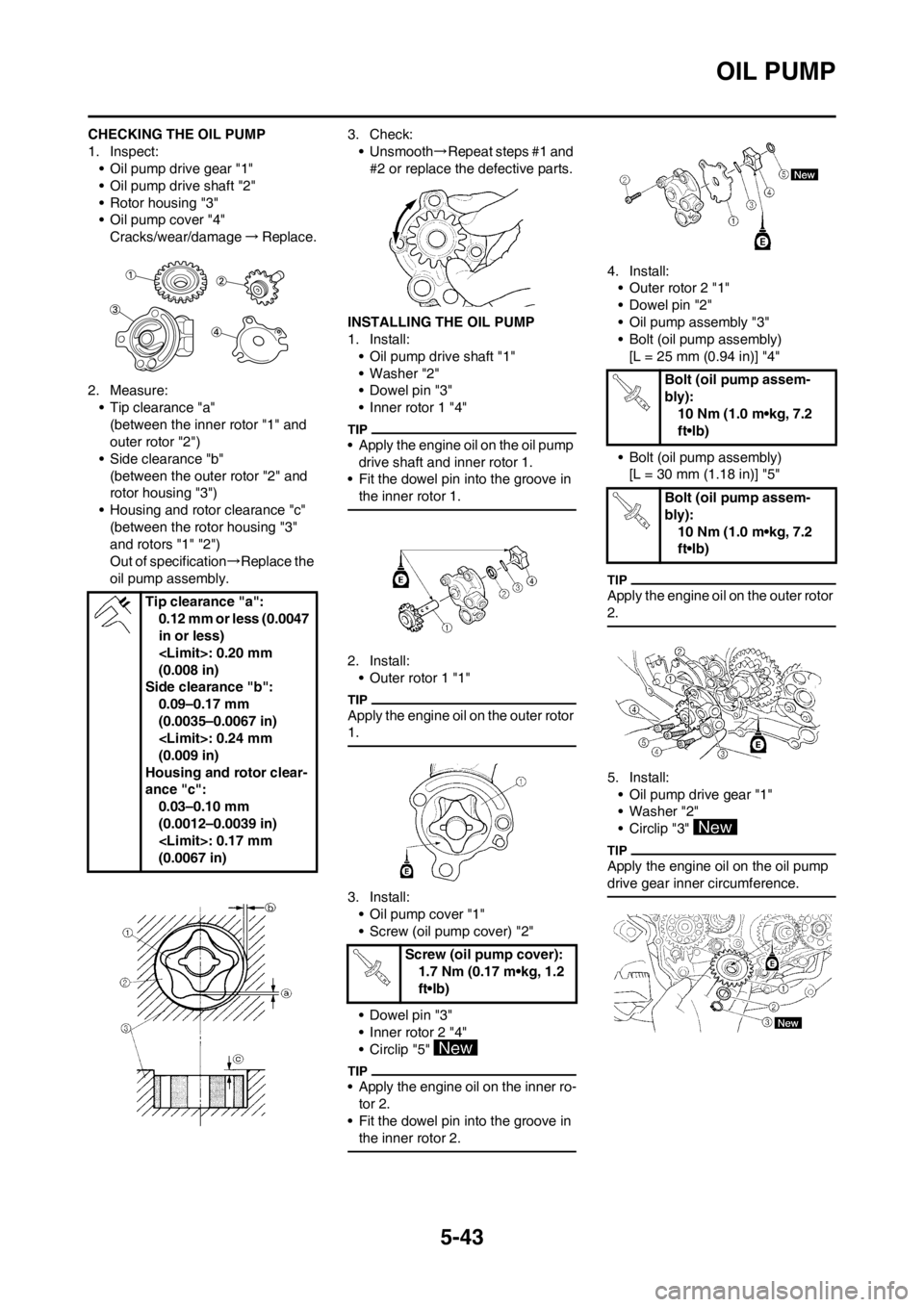

CHECKING THE OIL PUMP

1. Inspect:

• Oil pump drive gear "1"

• Oil pump drive shaft "2"

• Rotor housing "3"

• Oil pump cover "4"

Cracks/wear/damage→Replace.

2. Measure:

• Tip clearance "a"

(between the inner rotor "1" and

outer rotor "2")

• Side clearance "b"

(between the outer rotor "2" and

rotor housing "3")

• Housing and rotor clearance "c"

(between the rotor housing "3"

and rotors "1" "2")

Out of specification→Replace the

oil pump assembly.3. Check:

• Unsmooth→Repeat steps #1 and

#2 or replace the defective parts.

INSTALLING THE OIL PUMP

1. Install:

• Oil pump drive shaft "1"

• Washer "2"

• Dowel pin "3"

• Inner rotor 1 "4"

• Apply the engine oil on the oil pump

drive shaft and inner rotor 1.

• Fit the dowel pin into the groove in

the inner rotor 1.

2. Install:

• Outer rotor 1 "1"

Apply the engine oil on the outer rotor

1.

3. Install:

• Oil pump cover "1"

• Screw (oil pump cover) "2"

• Dowel pin "3"

• Inner rotor 2 "4"

• Circlip "5"

• Apply the engine oil on the inner ro-

tor 2.

• Fit the dowel pin into the groove in

the inner rotor 2.

4. Install:

• Outer rotor 2 "1"

• Dowel pin "2"

• Oil pump assembly "3"

• Bolt (oil pump assembly)

[L = 25 mm (0.94 in)] "4"

• Bolt (oil pump assembly)

[L = 30 mm (1.18 in)] "5"

Apply the engine oil on the outer rotor

2.

5. Install:

• Oil pump drive gear "1"

• Washer "2"

• Circlip "3"

Apply the engine oil on the oil pump

drive gear inner circumference.

Tip clearance "a":

0.12 mm or less (0.0047

in or less)

(0.008 in)

Side clearance "b":

0.09–0.17 mm

(0.0035–0.0067 in)

(0.009 in)

Housing and rotor clear-

ance "c":

0.03–0.10 mm

(0.0012–0.0039 in)

(0.0067 in)

Screw (oil pump cover):

1.7 Nm (0.17 m•kg, 1.2

ft•lb)

Bolt (oil pump assem-

bly):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (oil pump assem-

bly):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 150 of 232

5-47

KICK SHAFT AND SHIFT SHAFT

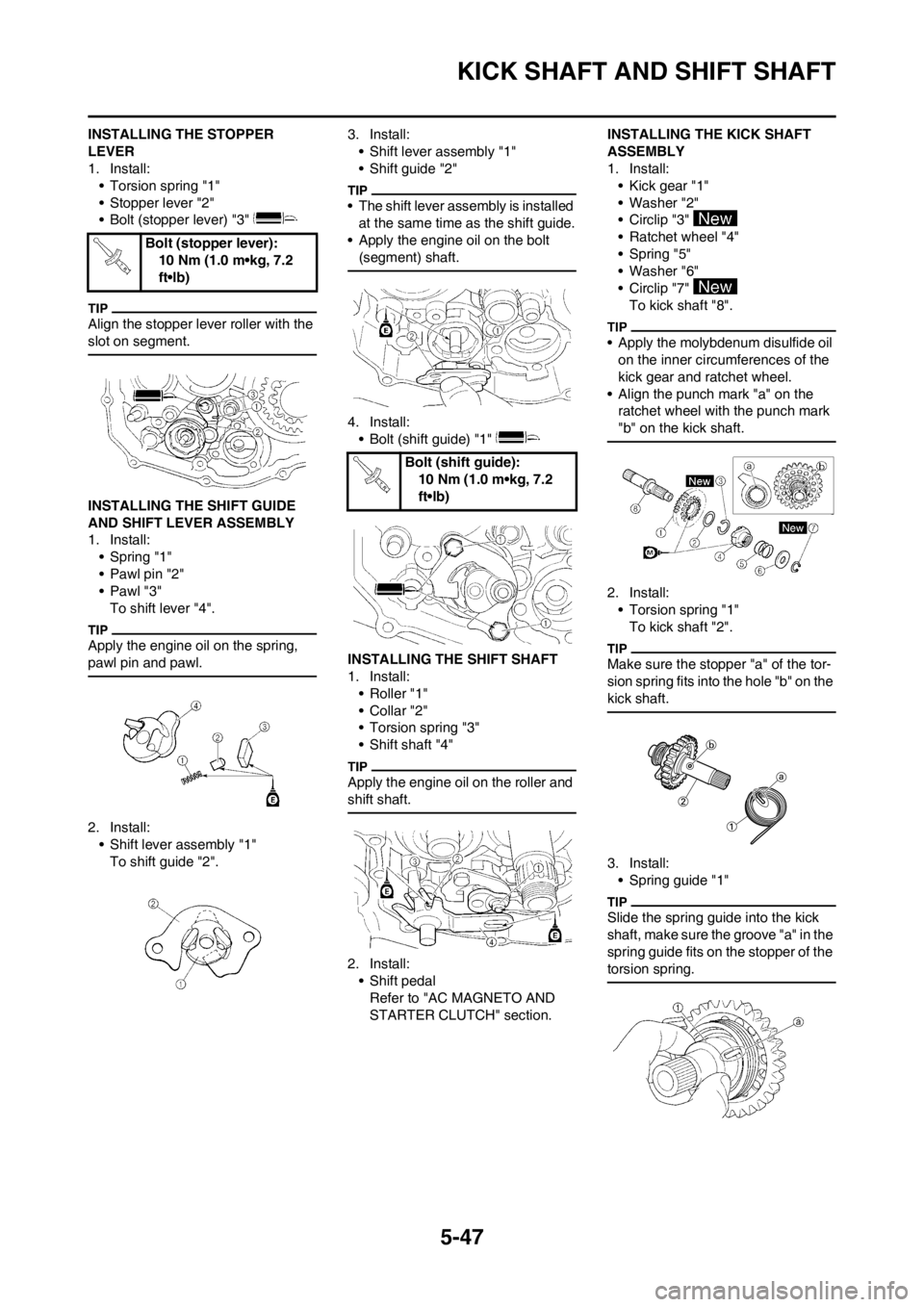

INSTALLING THE STOPPER

LEVER

1. Install:

• Torsion spring "1"

• Stopper lever "2"

• Bolt (stopper lever) "3"

Align the stopper lever roller with the

slot on segment.

INSTALLING THE SHIFT GUIDE

AND SHIFT LEVER ASSEMBLY

1. Install:

• Spring "1"

• Pawl pin "2"

•Pawl "3"

To shift lever "4".

Apply the engine oil on the spring,

pawl pin and pawl.

2. Install:

• Shift lever assembly "1"

To shift guide "2".3. Install:

• Shift lever assembly "1"

• Shift guide "2"

• The shift lever assembly is installed

at the same time as the shift guide.

• Apply the engine oil on the bolt

(segment) shaft.

4. Install:

• Bolt (shift guide) "1"

INSTALLING THE SHIFT SHAFT

1. Install:

• Roller "1"

• Collar "2"

• Torsion spring "3"

• Shift shaft "4"

Apply the engine oil on the roller and

shift shaft.

2. Install:

• Shift pedal

Refer to "AC MAGNETO AND

STARTER CLUTCH" section.INSTALLING THE KICK SHAFT

ASSEMBLY

1. Install:

• Kick gear "1"

• Washer "2"

• Circlip "3"

• Ratchet wheel "4"

• Spring "5"

• Washer "6"

• Circlip "7"

To kick shaft "8".

• Apply the molybdenum disulfide oil

on the inner circumferences of the

kick gear and ratchet wheel.

• Align the punch mark "a" on the

ratchet wheel with the punch mark

"b" on the kick shaft.

2. Install:

• Torsion spring "1"

To kick shaft "2".

Make sure the stopper "a" of the tor-

sion spring fits into the hole "b" on the

kick shaft.

3. Install:

• Spring guide "1"

Slide the spring guide into the kick

shaft, make sure the groove "a" in the

spring guide fits on the stopper of the

torsion spring.

Bolt (stopper lever):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (shift guide):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 151 of 232

5-48

KICK SHAFT AND SHIFT SHAFT

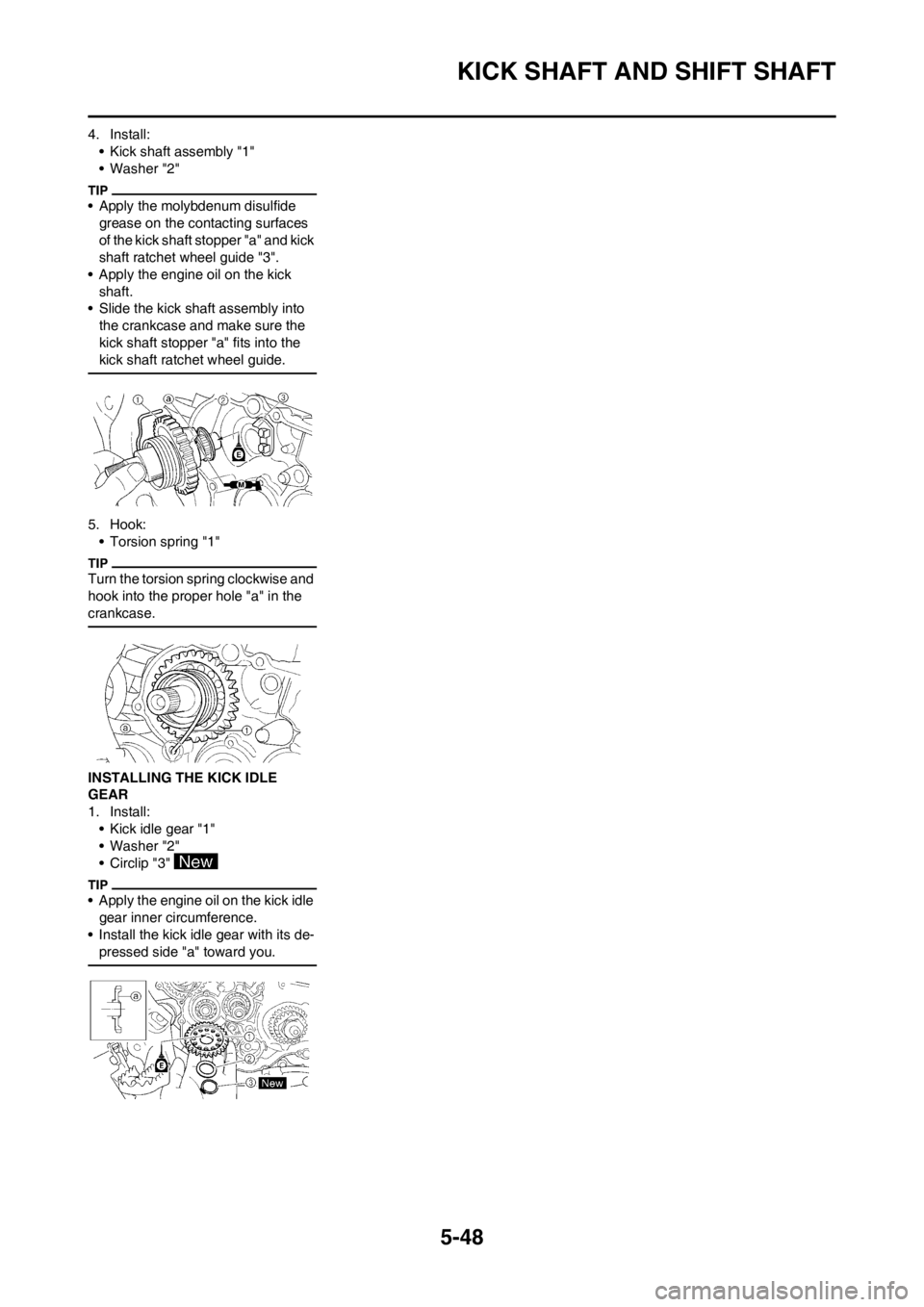

4. Install:

• Kick shaft assembly "1"

• Washer "2"

• Apply the molybdenum disulfide

grease on the contacting surfaces

of the kick shaft stopper "a" and kick

shaft ratchet wheel guide "3".

• Apply the engine oil on the kick

shaft.

• Slide the kick shaft assembly into

the crankcase and make sure the

kick shaft stopper "a" fits into the

kick shaft ratchet wheel guide.

5. Hook:

• Torsion spring "1"

Turn the torsion spring clockwise and

hook into the proper hole "a" in the

crankcase.

INSTALLING THE KICK IDLE

GEAR

1. Install:

• Kick idle gear "1"

• Washer "2"

• Circlip "3"

• Apply the engine oil on the kick idle

gear inner circumference.

• Install the kick idle gear with its de-

pressed side "a" toward you.

Page 152 of 232

5-49

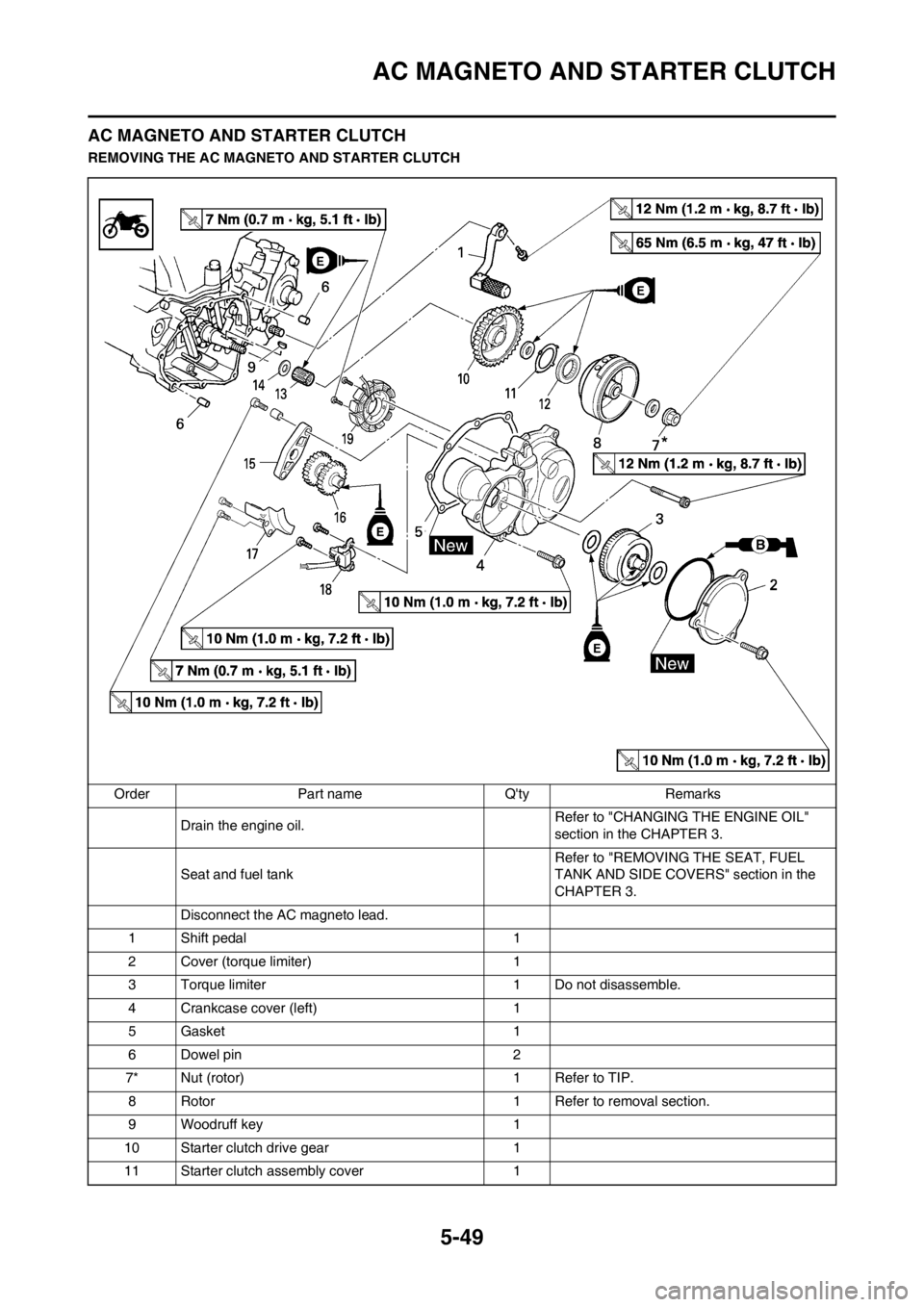

AC MAGNETO AND STARTER CLUTCH

AC MAGNETO AND STARTER CLUTCH

REMOVING THE AC MAGNETO AND STARTER CLUTCH

Order Part name Q'ty Remarks

Drain the engine oil.Refer to "CHANGING THE ENGINE OIL"

section in the CHAPTER 3.

Seat and fuel tankRefer to "REMOVING THE SEAT, FUEL

TANK AND SIDE COVERS" section in the

CHAPTER 3.

Disconnect the AC magneto lead.

1 Shift pedal 1

2 Cover (torque limiter) 1

3 Torque limiter 1 Do not disassemble.

4 Crankcase cover (left) 1

5 Gasket 1

6 Dowel pin 2

7* Nut (rotor) 1 Refer to TIP.

8 Rotor 1 Refer to removal section.

9 Woodruff key 1

10 Starter clutch drive gear 1

11 Starter clutch assembly cover 1

Page 155 of 232

5-52

AC MAGNETO AND STARTER CLUTCH

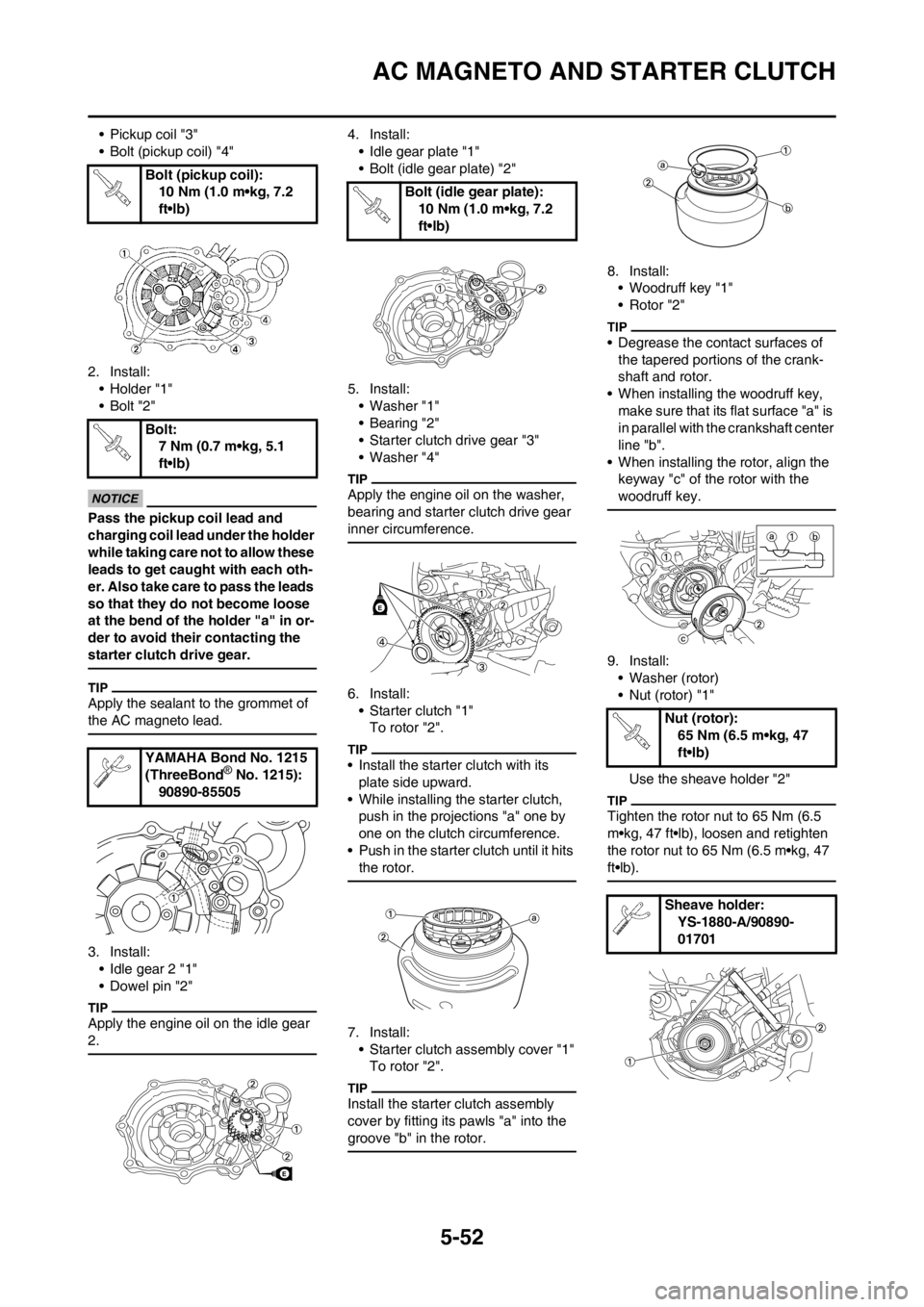

• Pickup coil "3"

• Bolt (pickup coil) "4"

2. Install:

• Holder "1"

•Bolt "2"

Pass the pickup coil lead and

charging coil lead under the holder

while taking care not to allow these

leads to get caught with each oth-

er. Also take care to pass the leads

so that they do not become loose

at the bend of the holder "a" in or-

der to avoid their contacting the

starter clutch drive gear.

Apply the sealant to the grommet of

the AC magneto lead.

3. Install:

• Idle gear 2 "1"

• Dowel pin "2"

Apply the engine oil on the idle gear

2.

4. Install:

• Idle gear plate "1"

• Bolt (idle gear plate) "2"

5. Install:

• Washer "1"

•Bearing "2"

• Starter clutch drive gear "3"

• Washer "4"

Apply the engine oil on the washer,

bearing and starter clutch drive gear

inner circumference.

6. Install:

• Starter clutch "1"

To rotor "2".

• Install the starter clutch with its

plate side upward.

• While installing the starter clutch,

push in the projections "a" one by

one on the clutch circumference.

• Push in the starter clutch until it hits

the rotor.

7. Install:

• Starter clutch assembly cover "1"

To rotor "2".

Install the starter clutch assembly

cover by fitting its pawls "a" into the

groove "b" in the rotor.

8. Install:

• Woodruff key "1"

• Rotor "2"

• Degrease the contact surfaces of

the tapered portions of the crank-

shaft and rotor.

• When installing the woodruff key,

make sure that its flat surface "a" is

in parallel with the crankshaft center

line "b".

• When installing the rotor, align the

keyway "c" of the rotor with the

woodruff key.

9. Install:

• Washer (rotor)

• Nut (rotor) "1"

Use the sheave holder "2"

Tighten the rotor nut to 65 Nm (6.5

m•kg, 47 ft•lb), loosen and retighten

the rotor nut to 65 Nm (6.5 m•kg, 47

ft•lb).

Bolt (pickup coil):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt:

7 Nm (0.7 m•kg, 5.1

ft•lb)

YAMAHA Bond No. 1215

(ThreeBond

® No. 1215):

90890-85505

E

Bolt (idle gear plate):

10 Nm (1.0 m•kg, 7.2

ft•lb)

E

Nut (rotor):

65 Nm (6.5 m•kg, 47

ft•lb)

Sheave holder:

YS-1880-A/90890-

01701

Page 156 of 232

![YAMAHA WR 250F 2012 Repair Manual 5-53

AC MAGNETO AND STARTER CLUTCH

10. Install:

• Dowel pin

• Gasket [crankcase cover (left)]

• Crankcase cover (left) "1"

• Bolt [crankcase cover (left)] "2"

• Bolt [crankcase cover (left) YAMAHA WR 250F 2012 Repair Manual 5-53

AC MAGNETO AND STARTER CLUTCH

10. Install:

• Dowel pin

• Gasket [crankcase cover (left)]

• Crankcase cover (left) "1"

• Bolt [crankcase cover (left)] "2"

• Bolt [crankcase cover (left)](/img/51/52308/w960_52308-155.png)

5-53

AC MAGNETO AND STARTER CLUTCH

10. Install:

• Dowel pin

• Gasket [crankcase cover (left)]

• Crankcase cover (left) "1"

• Bolt [crankcase cover (left)] "2"

• Bolt [crankcase cover (left)] "3"

Tighten the bolts in stage, using a

crisscross pattern.

11. Install:

• Washer "1"

• Torque limiter "2"

• Washer "3"

Apply the engine oil to the shaft and

washers.

12. Install:

• O-ring

• Cover (idle gear 1) "1"

•Bolt "2"

• Apply the lithium soap base grease

on the O-ring.

• Install the cover (idle gear 1) with its

mark "a" facing upward.

13. Connect:

• AC magneto lead

Refer to "CABLE ROUTING DIA-

GRAM" section in the CHAPTER

2.

14. Install:

• Shift pedal "1"

• Bolt (shift pedal) "2"

When installing the shift pedal onto

the shift shaft, be sure that the center

of the shift pedal is about 1.4 mm

(0.06 in) "a" above the top of the foot-

rest.

Bolt [crankcase cover

(left)]:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt [crankcase cover

(left)]:

12 Nm (1.2 m•kg, 8.7

ft•lb)

Bolt:

10 Nm (1.0 m•kg, 7.2

ft•lb)

E

Bolt (shift pedal):

12 Nm (1.2 m•kg, 8.7

ft•lb)

Page 157 of 232

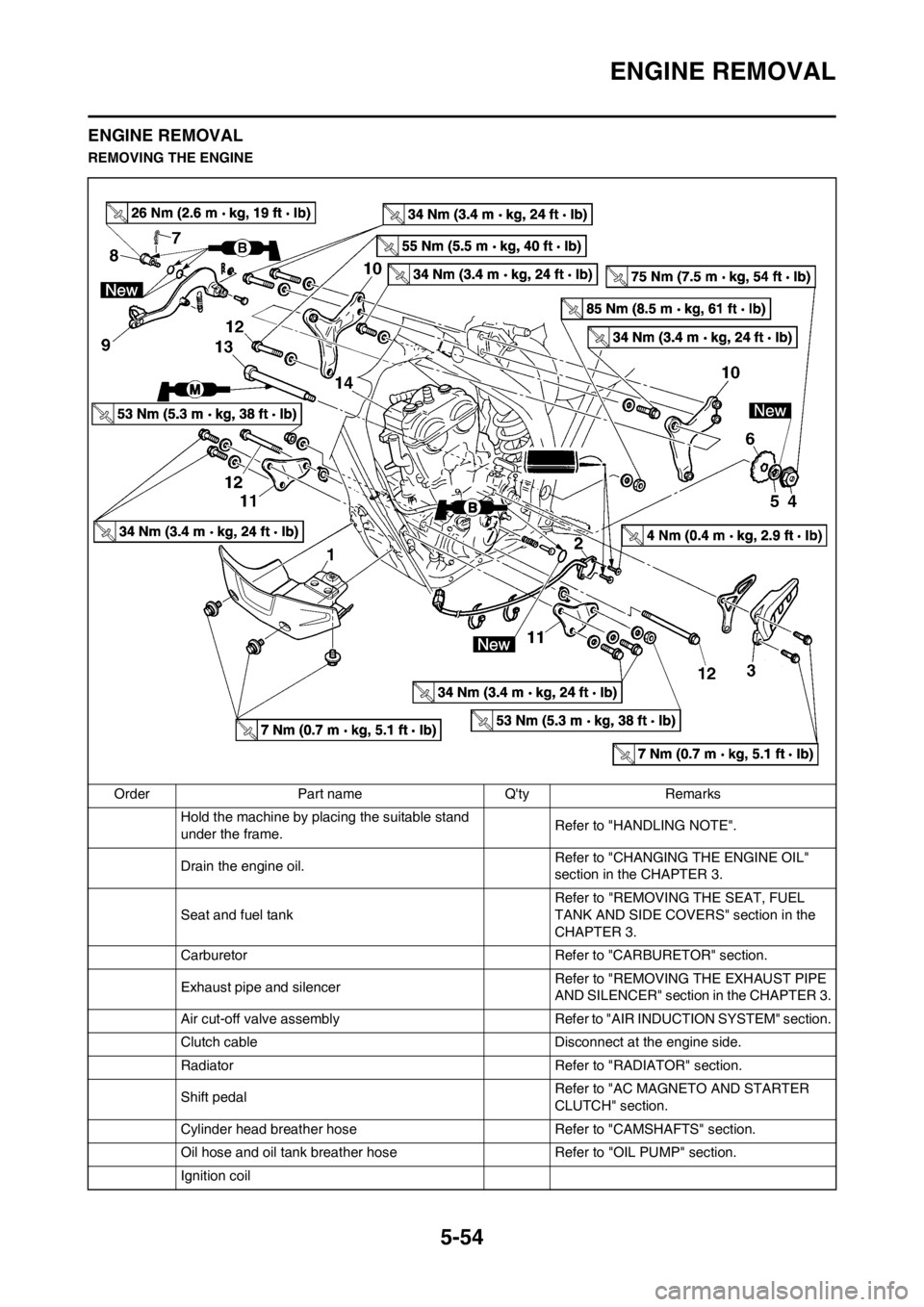

5-54

ENGINE REMOVAL

ENGINE REMOVAL

REMOVING THE ENGINE

Order Part name Q'ty Remarks

Hold the machine by placing the suitable stand

under the frame.Refer to "HANDLING NOTE".

Drain the engine oil.Refer to "CHANGING THE ENGINE OIL"

section in the CHAPTER 3.

Seat and fuel tank Refer to "REMOVING THE SEAT, FUEL

TANK AND SIDE COVERS" section in the

CHAPTER 3.

Carburetor Refer to "CARBURETOR" section.

Exhaust pipe and silencer Refer to "REMOVING THE EXHAUST PIPE

AND SILENCER" section in the CHAPTER 3.

Air cut-off valve assembly Refer to "AIR INDUCTION SYSTEM" section.

Clutch cable Disconnect at the engine side.

Radiator Refer to "RADIATOR" section.

Shift pedalRefer to "AC MAGNETO AND STARTER

CLUTCH" section.

Cylinder head breather hose Refer to "CAMSHAFTS" section.

Oil hose and oil tank breather hose Refer to "OIL PUMP" section.

Ignition coil