steering YAMAHA WR 250F 2013 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2013, Model line: WR 250F, Model: YAMAHA WR 250F 2013Pages: 232, PDF Size: 13.36 MB

Page 10 of 232

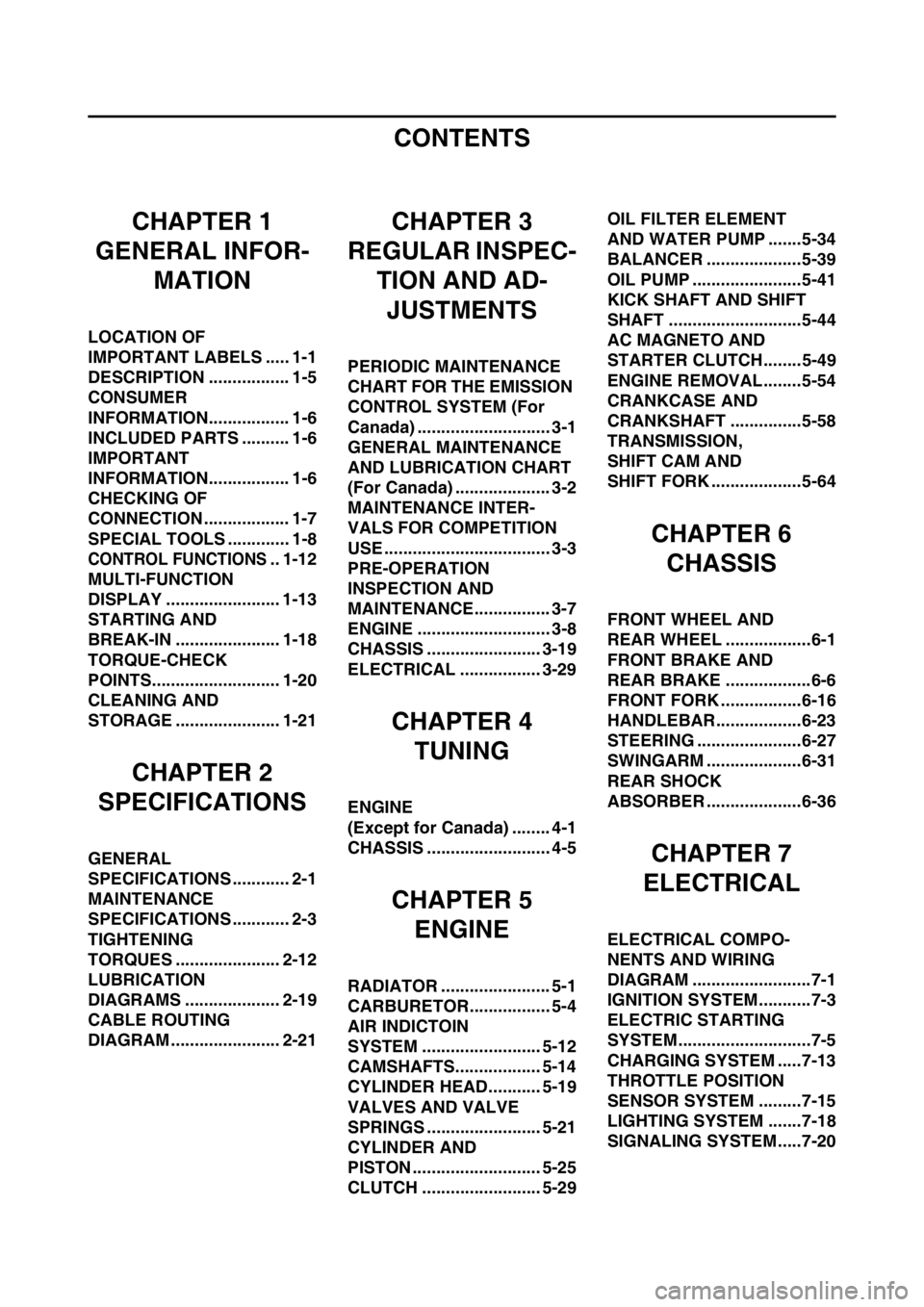

CONTENTS

CHAPTER 1

GENERAL INFOR-

MATION

LOCATION OF

IMPORTANT LABELS ..... 1-1

DESCRIPTION ................. 1-5

CONSUMER

INFORMATION................. 1-6

INCLUDED PARTS .......... 1-6

IMPORTANT

INFORMATION................. 1-6

CHECKING OF

CONNECTION .................. 1-7

SPECIAL TOOLS ............. 1-8

CONTROL FUNCTIONS.. 1-12

MULTI-FUNCTION

DISPLAY ........................ 1-13

STARTING AND

BREAK-IN ...................... 1-18

TORQUE-CHECK

POINTS........................... 1-20

CLEANING AND

STORAGE ...................... 1-21

CHAPTER 2

SPECIFICATIONS

GENERAL

SPECIFICATIONS ............ 2-1

MAINTENANCE

SPECIFICATIONS ............ 2-3

TIGHTENING

TORQUES ...................... 2-12

LUBRICATION

DIAGRAMS .................... 2-19

CABLE ROUTING

DIAGRAM ....................... 2-21

CHAPTER 3

REGULAR INSPEC-

TION AND AD-

JUSTMENTS

PERIODIC MAINTENANCE

CHART FOR THE EMISSION

CONTROL SYSTEM (For

Canada) ............................ 3-1

GENERAL MAINTENANCE

AND LUBRICATION CHART

(For Canada) .................... 3-2

MAINTENANCE INTER-

VALS FOR COMPETITION

USE ................................... 3-3

PRE-OPERATION

INSPECTION AND

MAINTENANCE................ 3-7

ENGINE ............................ 3-8

CHASSIS ........................ 3-19

ELECTRICAL ................. 3-29

CHAPTER 4

TUNING

ENGINE

(Except for Canada) ........ 4-1

CHASSIS .......................... 4-5

CHAPTER 5

ENGINE

RADIATOR ....................... 5-1

CARBURETOR................. 5-4

AIR INDICTOIN

SYSTEM ......................... 5-12

CAMSHAFTS.................. 5-14

CYLINDER HEAD........... 5-19

VALVES AND VALVE

SPRINGS ........................ 5-21

CYLINDER AND

PISTON ........................... 5-25

CLUTCH ......................... 5-29OIL FILTER ELEMENT

AND WATER PUMP .......5-34

BALANCER ....................5-39

OIL PUMP .......................5-41

KICK SHAFT AND SHIFT

SHAFT ............................5-44

AC MAGNETO AND

STARTER CLUTCH........5-49

ENGINE REMOVAL........5-54

CRANKCASE AND

CRANKSHAFT ...............5-58

TRANSMISSION,

SHIFT CAM AND

SHIFT FORK ...................5-64

CHAPTER 6

CHASSIS

FRONT WHEEL AND

REAR WHEEL ..................6-1

FRONT BRAKE AND

REAR BRAKE ..................6-6

FRONT FORK .................6-16

HANDLEBAR..................6-23

STEERING ......................6-27

SWINGARM ....................6-31

REAR SHOCK

ABSORBER ....................6-36

CHAPTER 7

ELECTRICAL

ELECTRICAL COMPO-

NENTS AND WIRING

DIAGRAM .........................7-1

IGNITION SYSTEM...........7-3

ELECTRIC STARTING

SYSTEM............................7-5

CHARGING SYSTEM .....7-13

THROTTLE POSITION

SENSOR SYSTEM .........7-15

LIGHTING SYSTEM .......7-18

SIGNALING SYSTEM.....7-20

Page 16 of 232

1-6

CONSUMER INFORMATION

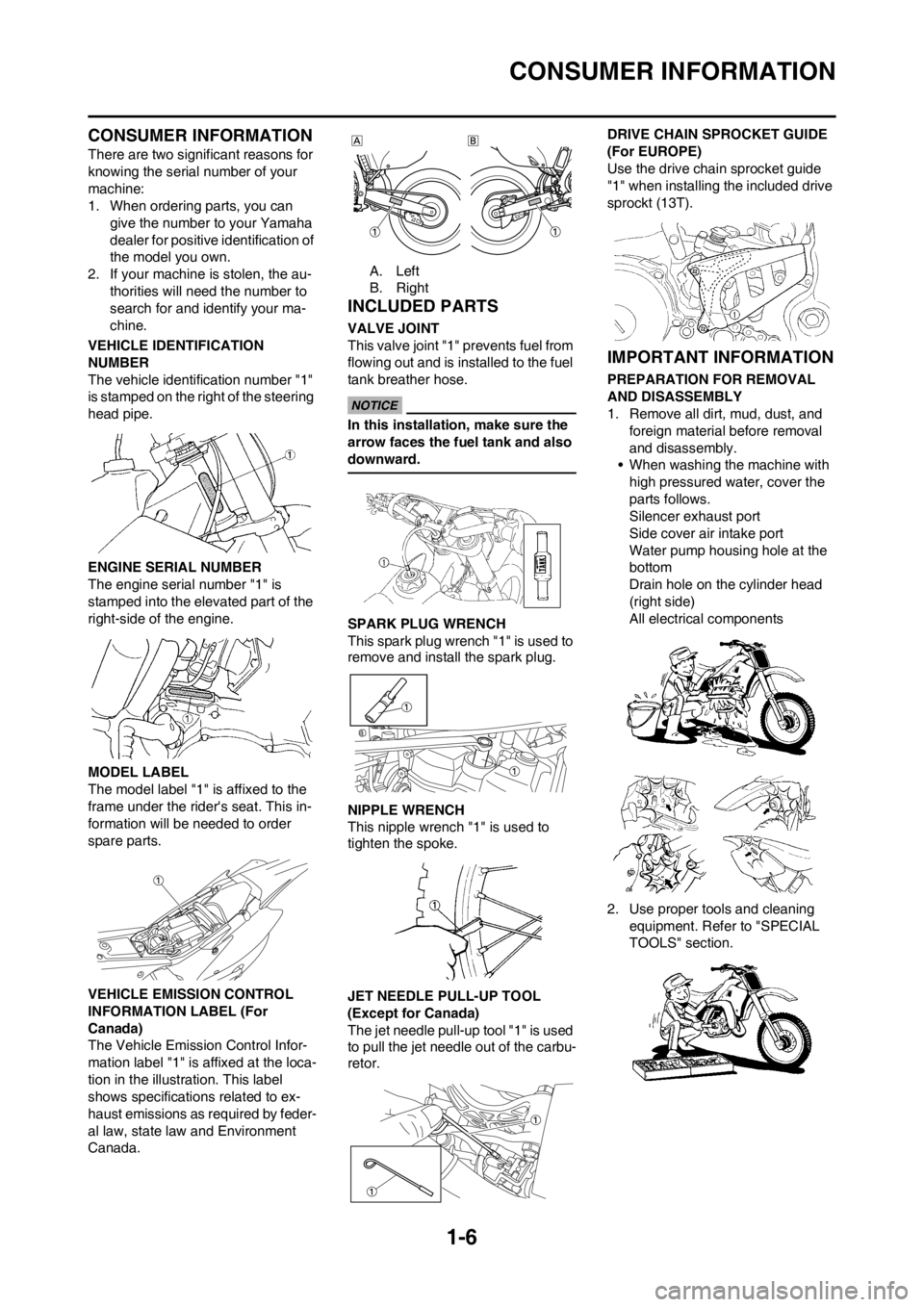

CONSUMER INFORMATION

There are two significant reasons for

knowing the serial number of your

machine:

1. When ordering parts, you can

give the number to your Yamaha

dealer for positive identification of

the model you own.

2. If your machine is stolen, the au-

thorities will need the number to

search for and identify your ma-

chine.

VEHICLE IDENTIFICATION

NUMBER

The vehicle identification number "1"

is stamped on the right of the steering

head pipe.

ENGINE SERIAL NUMBER

The engine serial number "1" is

stamped into the elevated part of the

right-side of the engine.

MODEL LABEL

The model label "1" is affixed to the

frame under the rider's seat. This in-

formation will be needed to order

spare parts.

VEHICLE EMISSION CONTROL

INFORMATION LABEL (For

Canada)

The Vehicle Emission Control Infor-

mation label "1" is affixed at the loca-

tion in the illustration. This label

shows specifications related to ex-

haust emissions as required by feder-

al law, state law and Environment

Canada.A. Left

B. Right

INCLUDED PARTS

VALVE JOINT

This valve joint "1" prevents fuel from

flowing out and is installed to the fuel

tank breather hose.

In this installation, make sure the

arrow faces the fuel tank and also

downward.

SPARK PLUG WRENCH

This spark plug wrench "1" is used to

remove and install the spark plug.

NIPPLE WRENCH

This nipple wrench "1" is used to

tighten the spoke.

JET NEEDLE PULL-UP TOOL

(Except for Canada)

The jet needle pull-up tool "1" is used

to pull the jet needle out of the carbu-

retor.DRIVE CHAIN SPROCKET GUIDE

(For EUROPE)

Use the drive chain sprocket guide

"1" when installing the included drive

sprockt (13T).

IMPORTANT INFORMATION

PREPARATION FOR REMOVAL

AND DISASSEMBLY

1. Remove all dirt, mud, dust, and

foreign material before removal

and disassembly.

• When washing the machine with

high pressured water, cover the

parts follows.

Silencer exhaust port

Side cover air intake port

Water pump housing hole at the

bottom

Drain hole on the cylinder head

(right side)

All electrical components

2. Use proper tools and cleaning

equipment. Refer to "SPECIAL

TOOLS" section.

Page 19 of 232

1-9

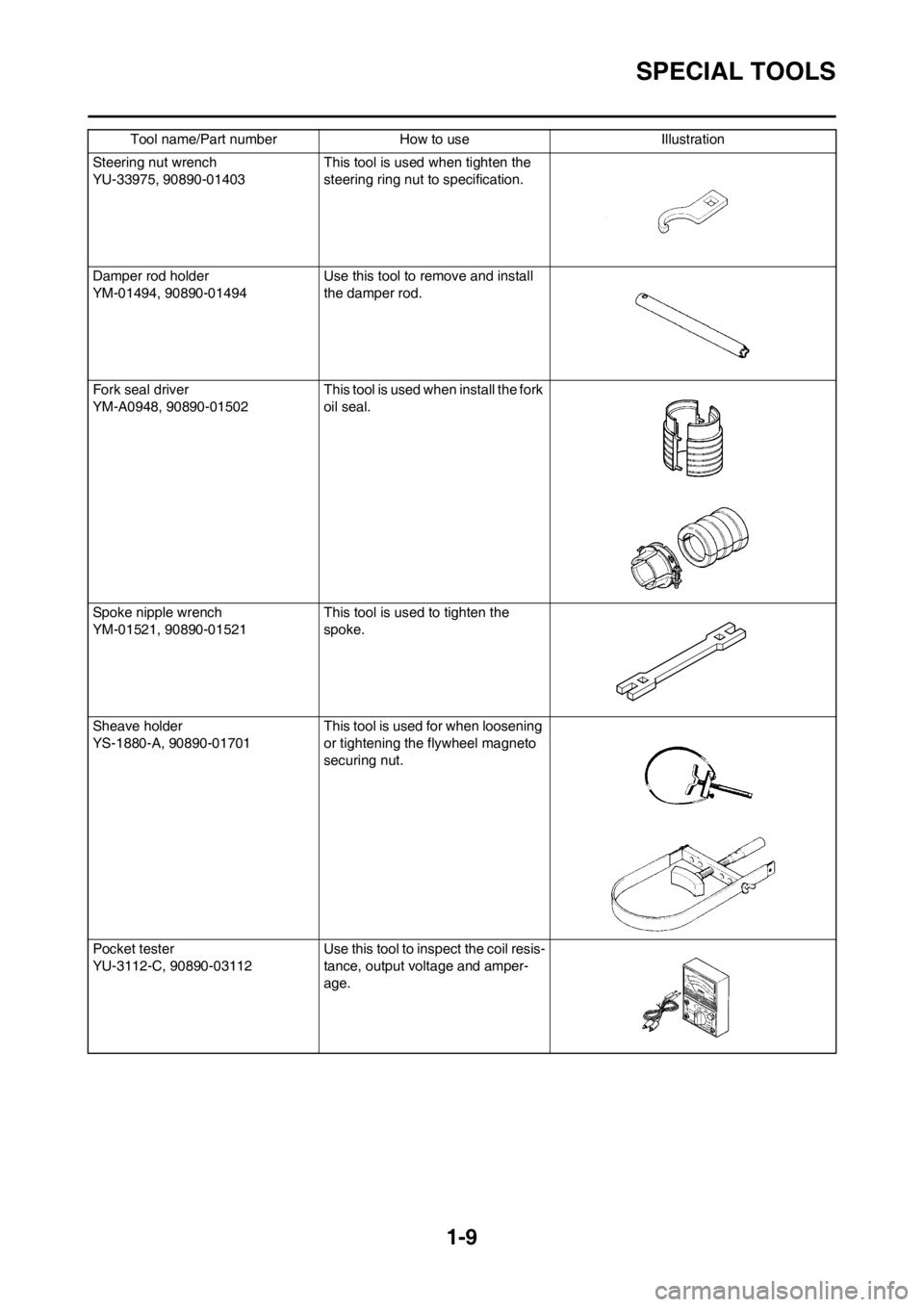

SPECIAL TOOLS

Steering nut wrench

YU-33975, 90890-01403 This tool is used when tighten the

steering ring nut to specification.

Damper rod holder

YM-01494, 90890-01494Use this tool to remove and install

the damper rod.

Fork seal driver

YM-A0948, 90890-01502 This tool is used when install the fork

oil seal.

Spoke nipple wrench

YM-01521, 90890-01521This tool is used to tighten the

spoke.

Sheave holder

YS-1880-A, 90890-01701This tool is used for when loosening

or tightening the flywheel magneto

securing nut.

Pocket tester

YU-3112-C, 90890-03112 Use this tool to inspect the coil resis-

tance, output voltage and amper-

age. Tool name/Part number How to use Illustration

Page 30 of 232

1-20

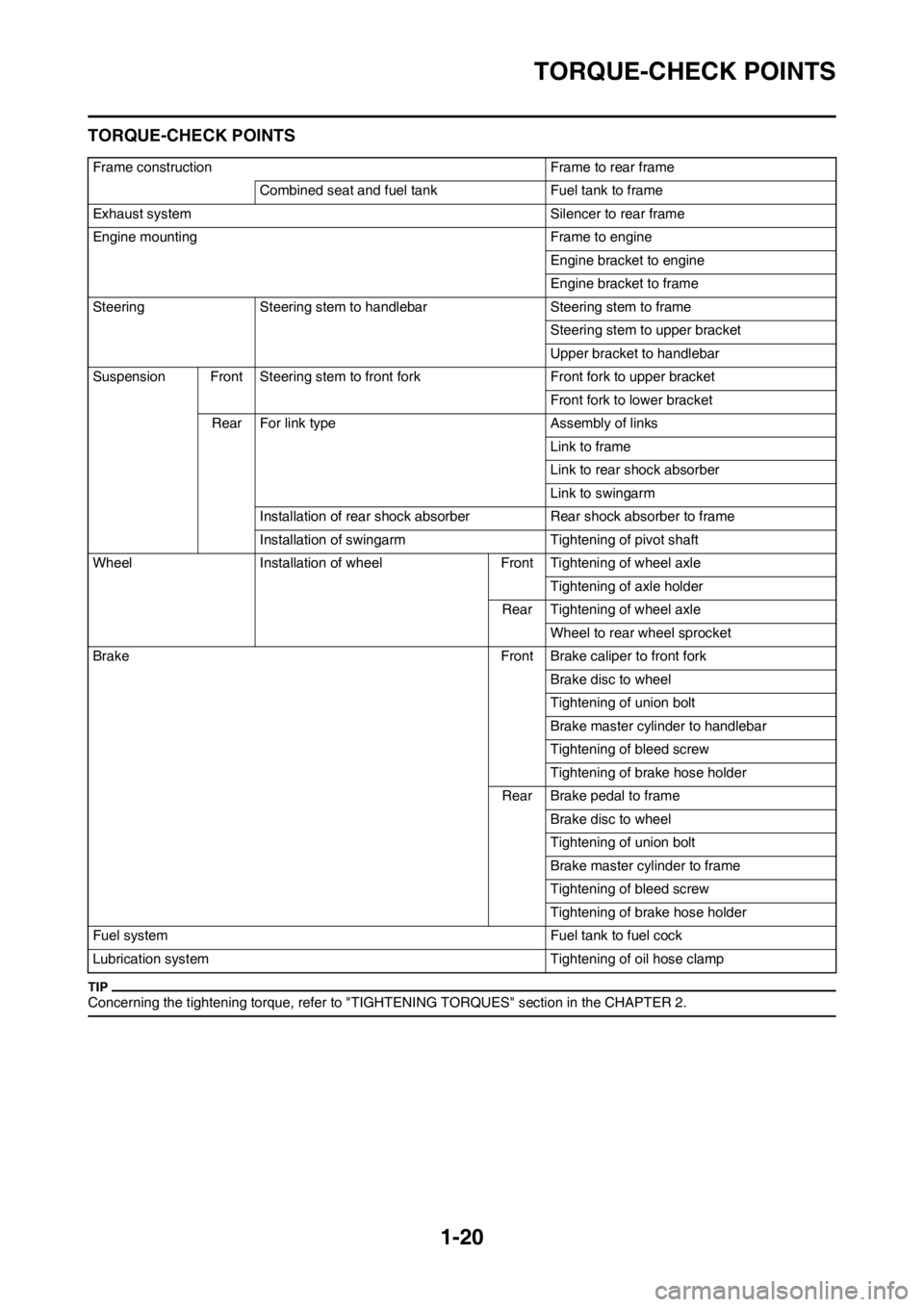

TORQUE-CHECK POINTS

TORQUE-CHECK POINTS

Concerning the tightening torque, refer to "TIGHTENING TORQUES" section in the CHAPTER 2.

Frame construction Frame to rear frame

Combined seat and fuel tank Fuel tank to frame

Exhaust system Silencer to rear frame

Engine mounting Frame to engine

Engine bracket to engine

Engine bracket to frame

Steering Steering stem to handlebar Steering stem to frame

Steering stem to upper bracket

Upper bracket to handlebar

Suspension Front Steering stem to front fork Front fork to upper bracket

Front fork to lower bracket

Rear For link type Assembly of links

Link to frame

Link to rear shock absorber

Link to swingarm

Installation of rear shock absorber Rear shock absorber to frame

Installation of swingarm Tightening of pivot shaft

Wheel Installation of wheel Front Tightening of wheel axle

Tightening of axle holder

Rear Tightening of wheel axle

Wheel to rear wheel sprocket

Brake Front Brake caliper to front fork

Brake disc to wheel

Tightening of union bolt

Brake master cylinder to handlebar

Tightening of bleed screw

Tightening of brake hose holder

Rear Brake pedal to frame

Brake disc to wheel

Tightening of union bolt

Brake master cylinder to frame

Tightening of bleed screw

Tightening of brake hose holder

Fuel system Fuel tank to fuel cock

Lubrication system Tightening of oil hose clamp

Page 39 of 232

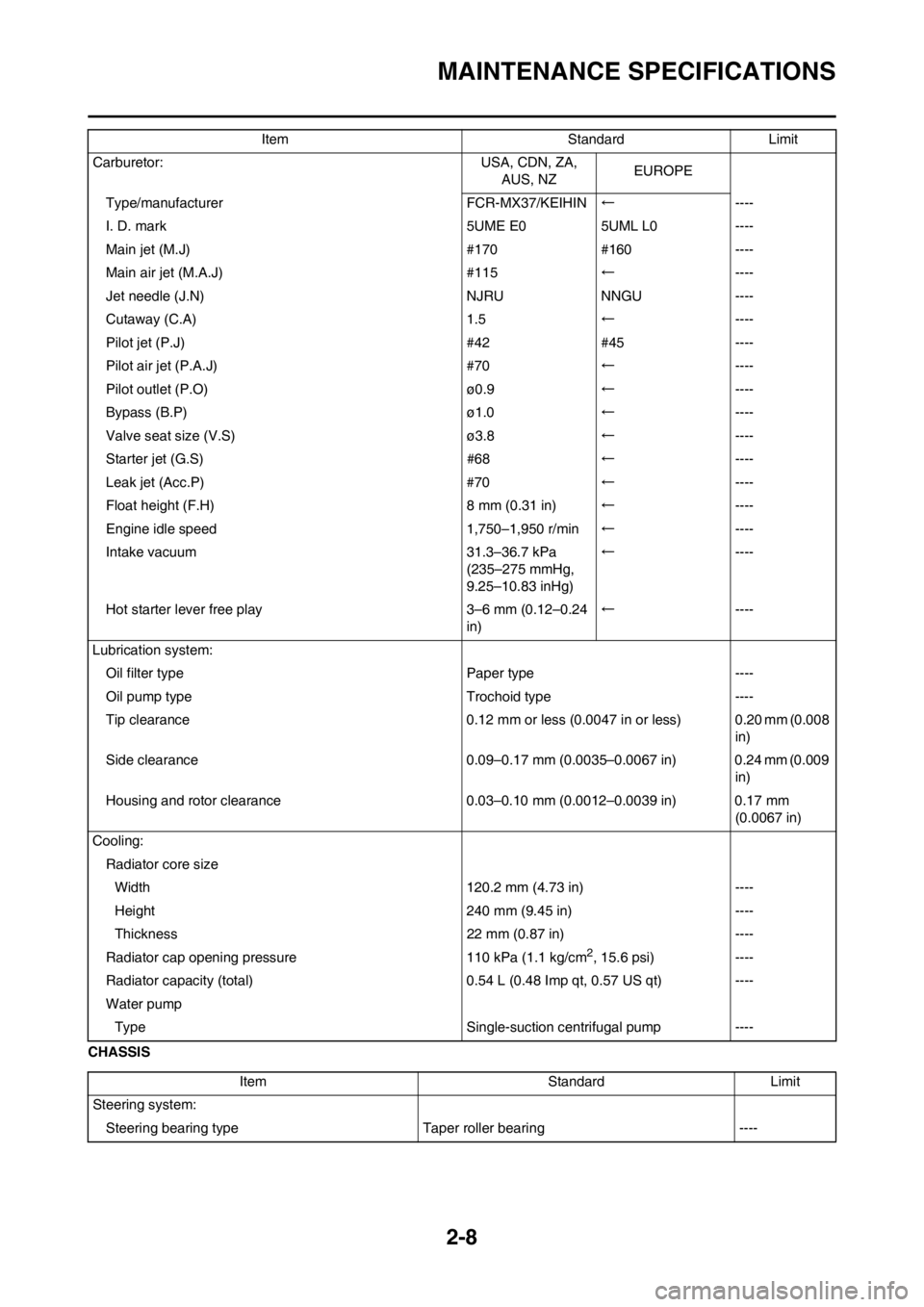

2-8

MAINTENANCE SPECIFICATIONS

CHASSISCarburetor: USA, CDN, ZA,

AUS, NZEUROPE

Type/manufacturer FCR-MX37/KEIHIN←----

I. D. mark 5UME E0 5UML L0 ----

Main jet (M.J) #170 #160 ----

Main air jet (M.A.J) #115←----

Jet needle (J.N) NJRU NNGU ----

Cutaway (C.A) 1.5←----

Pilot jet (P.J) #42 #45 ----

Pilot air jet (P.A.J) #70←----

Pilot outlet (P.O) ø0.9←----

Bypass (B.P) ø1.0←----

Valve seat size (V.S) ø3.8←----

Starter jet (G.S) #68←----

Leak jet (Acc.P) #70←----

Float height (F.H) 8 mm (0.31 in)←----

Engine idle speed 1,750–1,950 r/min←----

Intake vacuum 31.3–36.7 kPa

(235–275 mmHg,

9.25–10.83 inHg)←----

Hot starter lever free play 3–6 mm (0.12–0.24

in)←----

Lubrication system:

Oil filter type Paper type ----

Oil pump type Trochoid type ----

Tip clearance 0.12 mm or less (0.0047 in or less) 0.20 mm (0.008

in)

Side clearance 0.09–0.17 mm (0.0035–0.0067 in) 0.24 mm (0.009

in)

Housing and rotor clearance 0.03–0.10 mm (0.0012–0.0039 in) 0.17 mm

(0.0067 in)

Cooling:

Radiator core size

Width 120.2 mm (4.73 in) ----

Height 240 mm (9.45 in) ----

Thickness 22 mm (0.87 in) ----

Radiator cap opening pressure 110 kPa (1.1 kg/cm

2, 15.6 psi) ----

Radiator capacity (total) 0.54 L (0.48 Imp qt, 0.57 US qt) ----

Water pump

Type Single-suction centrifugal pump ----Item Standard Limit

Item Standard Limit

Steering system:

Steering bearing typeTaper roller bearing ----

Page 45 of 232

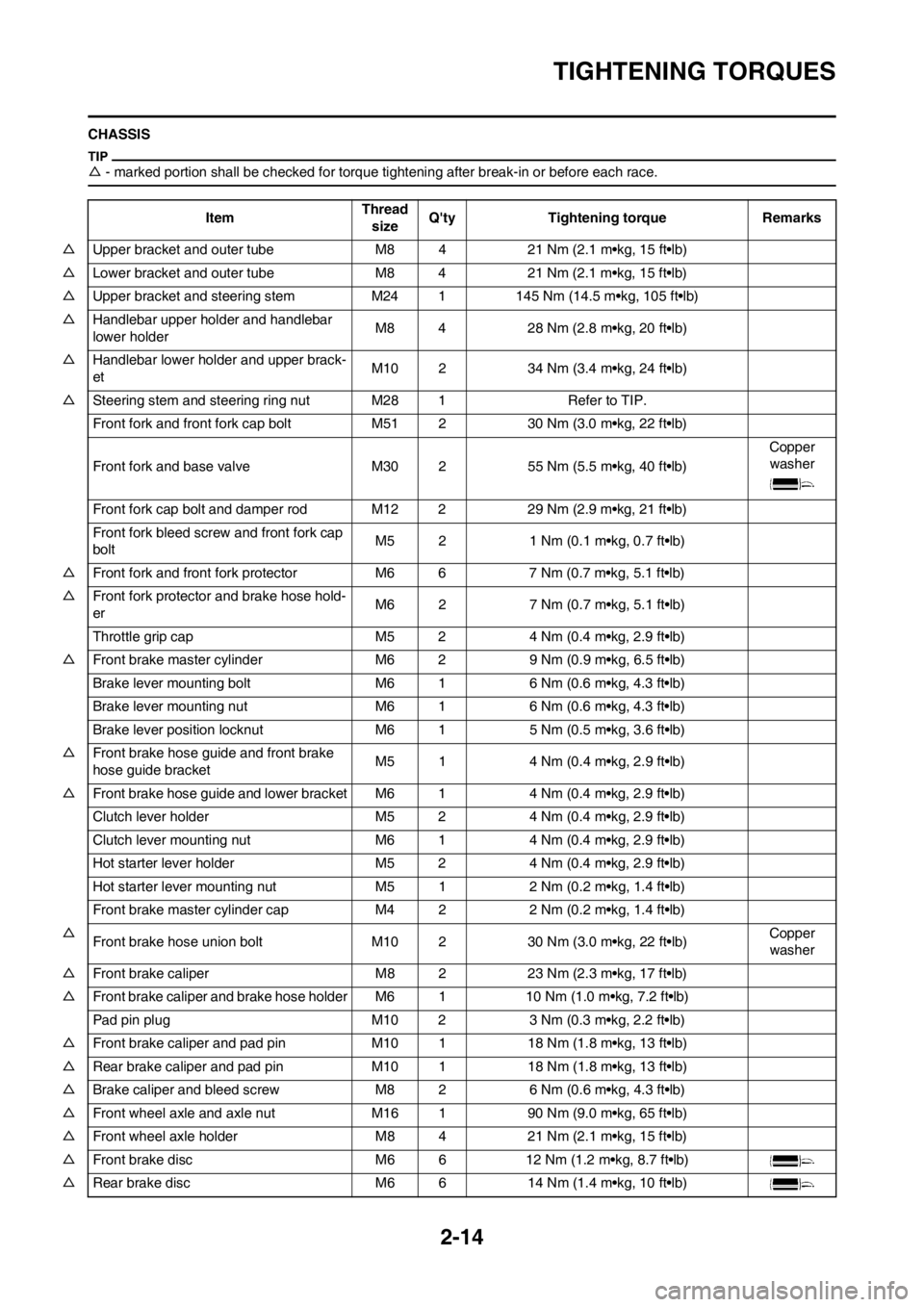

2-14

TIGHTENING TORQUES

CHASSIS

△- marked portion shall be checked for torque tightening after break-in or before each race.

ItemThread

sizeQ'ty Tightening torque Remarks

△Upper bracket and outer tube M84 21 Nm (2.1 m•kg, 15 ft•lb)

△Lower bracket and outer tube M8 4 21 Nm (2.1 m•kg, 15 ft•lb)

△Upper bracket and steering stem M24 1 145 Nm (14.5 m•kg, 105 ft•lb)

△Handlebar upper holder and handlebar

lower holderM8 4 28 Nm (2.8 m•kg, 20 ft•lb)

△Handlebar lower holder and upper brack-

etM10 2 34 Nm (3.4 m•kg, 24 ft•lb)

△Steering stem and steering ring nut M28 1 Refer to TIP.

Front fork and front fork cap bolt M51 2 30 Nm (3.0 m•kg, 22 ft•lb)

Front fork and base valve M30 2 55 Nm (5.5 m•kg, 40 ft•lb)Copper

washer

Front fork cap bolt and damper rod M12 2 29 Nm (2.9 m•kg, 21 ft•lb)

Front fork bleed screw and front fork cap

boltM5 2 1 Nm (0.1 m•kg, 0.7 ft•lb)

△Front fork and front fork protector M6 6 7 Nm (0.7 m•kg, 5.1 ft•lb)

△Front fork protector and brake hose hold-

erM6 2 7 Nm (0.7 m•kg, 5.1 ft•lb)

Throttle grip cap M5 2 4 Nm (0.4 m•kg, 2.9 ft•lb)

△Front brake master cylinder M6 29 Nm (0.9 m•kg, 6.5 ft•lb)

Brake lever mounting bolt M6 1 6 Nm (0.6 m•kg, 4.3 ft•lb)

Brake lever mounting nut M6 1 6 Nm (0.6 m•kg, 4.3 ft•lb)

Brake lever position locknut M6 1 5 Nm (0.5 m•kg, 3.6 ft•lb)

△Front brake hose guide and front brake

hose guide bracketM5 1 4 Nm (0.4 m•kg, 2.9 ft•lb)

△Front brake hose guide and lower bracket M6 1 4 Nm (0.4 m•kg, 2.9 ft•lb)

Clutch lever holder M5 2 4 Nm (0.4 m•kg, 2.9 ft•lb)

Clutch lever mounting nut M6 1 4 Nm (0.4 m•kg, 2.9 ft•lb)

Hot starter lever holder M5 2 4 Nm (0.4 m•kg, 2.9 ft•lb)

Hot starter lever mounting nut M5 1 2 Nm (0.2 m•kg, 1.4 ft•lb)

Front brake master cylinder cap M4 2 2 Nm (0.2 m•kg, 1.4 ft•lb)

△

Front brake hose union bolt M10 2 30 Nm (3.0 m•kg, 22 ft•lb)Copper

washer

△Front brake caliper M8 2 23 Nm (2.3 m•kg, 17 ft•lb)

△Front brake caliper and brake hose holder M6 1 10 Nm (1.0 m•kg, 7.2 ft•lb)

Pad pin plug M10 2 3 Nm (0.3 m•kg, 2.2 ft•lb)

△Front brake caliper and pad pin M10 1 18 Nm (1.8 m•kg, 13 ft•lb)

△Rear brake caliper and pad pin M10 1 18 Nm (1.8 m•kg, 13 ft•lb)

△Brake caliper and bleed screw M8 2 6 Nm (0.6 m•kg, 4.3 ft•lb)

△Front wheel axle and axle nut M16 1 90 Nm (9.0 m•kg, 65 ft•lb)

△Front wheel axle holder M8 4 21 Nm (2.1 m•kg, 15 ft•lb)

△Front brake disc M6 6 12 Nm (1.2 m•kg, 8.7 ft•lb)

△Rear brake disc M6 6 14 Nm (1.4 m•kg, 10 ft•lb)

Page 47 of 232

2-16

TIGHTENING TORQUES

1. First, tighten the steering ring nut approximately 38 Nm (3.8 m•kg, 27 ft•lb) by using the steering nut wrench, then loosen

the steering ring nut one turn.

2. Retighten the steering ring nut 7 Nm (0.7 m•kg, 5.1 ft•lb).

ELECTRICAL

Tighten the rotor nut to 65 Nm (6.5 m•kg, 47 ft•lb), loosen and retighten the rotor nut to 65 Nm (6.5 m •kg, 47 ft•lb).

Multi-function display bracket and upper

bracketM6 2 7 Nm (0.7 m•kg, 5.1 ft•lb)

Multi-function display M5 2 4 Nm (0.4 m•kg, 2.9 ft•lb)

Plate 1 and front fork protector M5 2 4 Nm (0.4 m•kg, 2.9 ft•lb)

Plate 2 and front fork protector — 2 0.5 Nm (0.05 m•kg, 0.36 ft•lb)

Speed sensor lead holder and lower

bracketM6 1 13 Nm (1.3 m•kg, 9.4 ft•lb)

Speed sensor lead holder and clamp M6 1 7 Nm (0.7 m•kg, 5.1 ft•lb)

Headlight body and headlight unit — 2 1 Nm (0.1 m•kg, 0.7 ft•lb)

△Headlight M6 2 7 Nm (0.7 m•kg, 5.1 ft•lb)

Taillight — 3 1 Nm (0.1 m•kg, 0.7 ft•lb)

Taillight lead clamp and rear fender— 3 0.5 Nm (0.05 m•kg, 0.36 ft•lb)

△Catch tank (upper) M6 1 16 Nm (1.6 m•kg, 11 ft•lb)

△Catch tank (lower) M6 1 7 Nm (0.7 m•kg, 5.1 ft•lb)

Footrest bracket and frame M10 4 55 Nm (5.5 m•kg, 40 ft•lb)TORX

Sidestand M10 1 25 Nm (2.5 m•kg, 18 ft•lb)

Front reflector (For CDN) M6 2 4 Nm (0.4 m•kg, 2.9 ft•lb)

Rear reflector (For CDN) M5 3 2 Nm (0.2 m•kg, 1.4 ft•lb) ItemThread

sizeQ'ty Tightening torque Remarks

ItemThread

sizeQ'ty Tightening torque Remarks

Stator M5 2 7 Nm (0.7 m•kg, 5.1 ft•lb)

Holder (AC magneto lead) M5 27 Nm (0.7 m•kg, 5.1 ft•lb)

Rotor M12 1 Refer to TIP.

Neutral switch M5 2 4 Nm (0.4 m•kg, 2.9 ft•lb)

Starter motor M6 2 10 Nm (1.0 m•kg, 7.2 ft•lb)

Starter relay terminal M6 2 4 Nm (0.4 m•kg, 2.9 ft•lb)

Negative lead and cylinder head M6 1 10 Nm (1.0 m•kg, 7.2 ft•lb)

Pickup coil M6 2 10 Nm (1.0 m•kg, 7.2 ft•lb)

Page 53 of 232

2-22

CABLE ROUTING DIAGRAM

A. Insert the end of the fuel tank

breather hose into the hole in

the steering stem.

B. Fasten the throttle cable, hot

starter cable and rectifier/regula-

tor lead onto the frame. Locate

the clamp under the throttle ca-

ble on the right side of the frame,

and face its ends, as well as the

tie ends, downward.

C. Fasten the diode (at the mark-

ing), throttle cable and hot start-

er cable onto the frame. Locate

the clamp end facing toward the

lower right of the frame and with

the tie end facing downward.

D. Fasten the wire harness, throttle

position sensor lead, starter mo-

tor lead and negative battery

lead onto the frame. Pass the

clamp through the hole in the

stay (air cut-off valve). Locate

the clamp end facing toward the

lower side of the frame and cut

off the tie end.

E. Pass the carburetor breather

hoses, carburetor overflow hose

and catch tank breather hose

between the connecting rod and

cross tube (frame).

F. Fasten the neutral switch lead

and oil hose together with the

plastic locking ties and cut off

the tie ends.

G. Fasten the neutral switch lead

and AC magneto lead onto the

frame. Locate the clamp end

facing toward the outside of the

frame and tie end facing toward

the rear of the frame.

H. Pass the clutch cable through

the cable guide.

I. Fasten the starter motor lead,

AC magneto lead and neutral

switch lead onto the frame. Lo-

cate the clamp end facing to-

ward the rear of the frame and

cut off the tie end.

J. Fasten the clutch cable, starter

motor lead, negative battery

lead, AC magneto lead and neu-

tral switch lead onto the frame.

Locate the clamp end facing to-

ward the rear of the frame and

cut off the tie end.

K. Pass the neutral switch lead and

AC magneto lead on the inside

of the wire harness.

L. Fasten the clutch cable, AC

magneto lead and neutral switch

lead onto the frame. Locate the

clamp end near the clutch cable

and cut off the tie end.M. Pass the clutch cable and wire

harness through the cable

guide.

N. Locate the couplers in the frame

recess.

O. Pass the carburetor breather

hoses, carburetor overflow hose

and catch tank breather hose so

that the hoses do not contact the

rear shock absorber.

P. Secure the coupler by pushing it

into the hole in the headlight

unit.

Q. Fasten the throttle position sen-

sor lead and the hot starter ca-

ble.

R. Locate the clamp between the

hot starter cable protector and

rubber cap.

Page 61 of 232

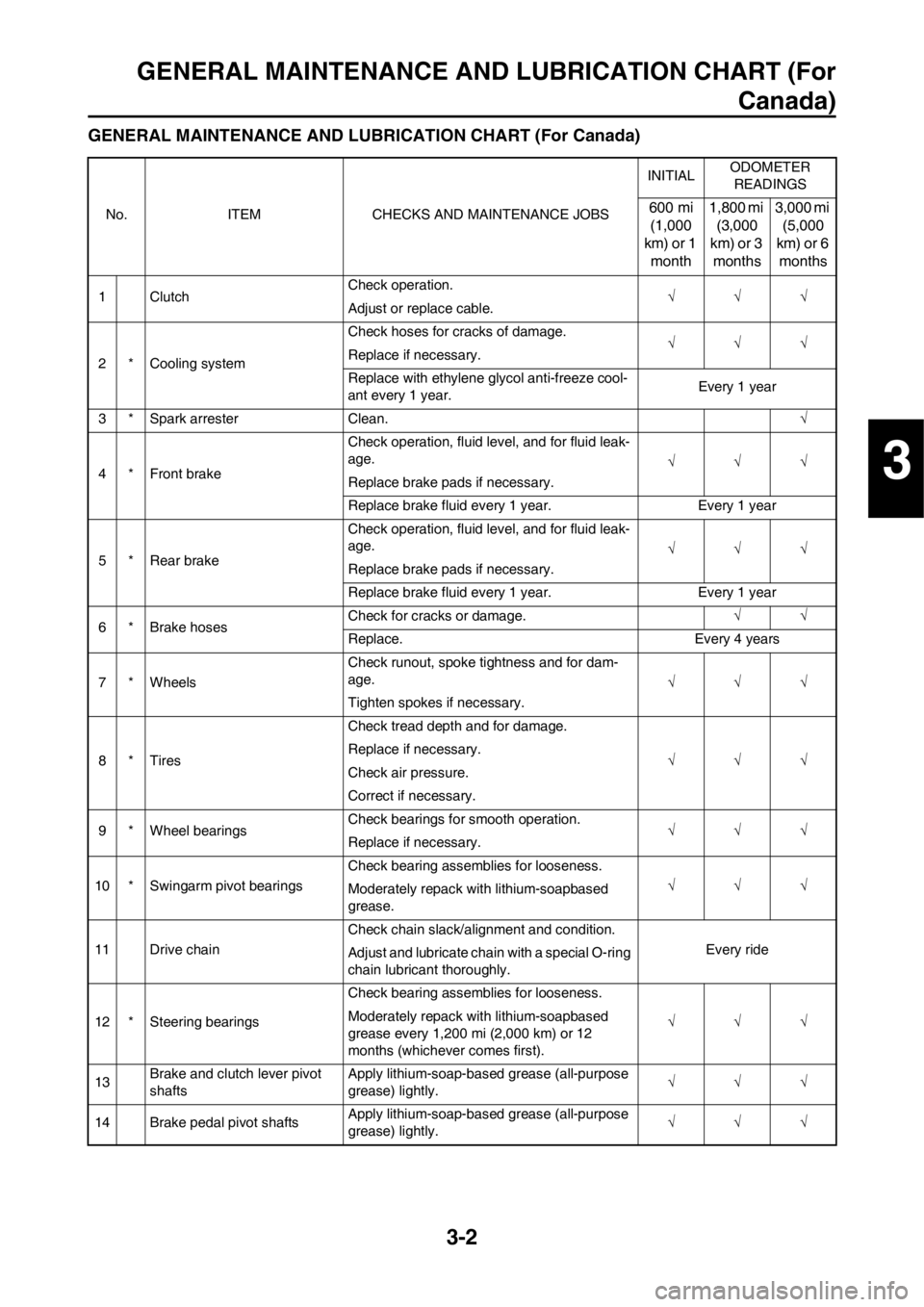

3-2

GENERAL MAINTENANCE AND LUBRICATION CHART (For

Canada)

GENERAL MAINTENANCE AND LUBRICATION CHART (For Canada)

No. ITEM CHECKS AND MAINTENANCE JOBSINITIALODOMETER

READINGS600 mi

(1,000

km) or 1

month1,800 mi

(3,000

km) or 3

months3,000 mi

(5,000

km) or 6

months

1 ClutchCheck operation.

Adjust or replace cable.

2 * Cooling systemCheck hoses for cracks of damage.

Replace if necessary.

Replace with ethylene glycol anti-freeze cool-

ant every 1 year.Every 1 year

3 * Spark arrester Clean.

4 * Front brakeCheck operation, fluid level, and for fluid leak-

age.

Replace brake pads if necessary.

Replace brake fluid every 1 year. Every 1 year

5 * Rear brakeCheck operation, fluid level, and for fluid leak-

age.

Replace brake pads if necessary.

Replace brake fluid every 1 year. Every 1 year

6 * Brake hosesCheck for cracks or damage.

Replace. Every 4 years

7 * WheelsCheck runout, spoke tightness and for dam-

age.

Tighten spokes if necessary.

8*TiresCheck tread depth and for damage.

Replace if necessary.

Check air pressure.

Correct if necessary.

9 * Wheel bearingsCheck bearings for smooth operation.

Replace if necessary.

10 * Swingarm pivot bearingsCheck bearing assemblies for looseness.

Moderately repack with lithium-soapbased

grease.

11 Drive chainCheck chain slack/alignment and condition.

Every ride

Adjust and lubricate chain with a special O-ring

chain lubricant thoroughly.

12 * Steering bearingsCheck bearing assemblies for looseness.

Moderately repack with lithium-soapbased

grease every 1,200 mi (2,000 km) or 12

months (whichever comes first).

13Brake and clutch lever pivot

shaftsApply lithium-soap-based grease (all-purpose

grease) lightly.

14 Brake pedal pivot shaftsApply lithium-soap-based grease (all-purpose

grease) lightly.

3

Page 65 of 232

3-6

MAINTENANCE INTERVALS FOR COMPETITION USE

FRONT FORKS

Inspect and adjust●●

Replace oil●●Suspension oil "S1"

Replace oil seal●

FRONT FORK OIL SEAL AND

DUST SEAL

Clean and lube●●Lithium base grease

PROTECTOR GUIDE

Replace●

REAR SHOCK ABSORBER

Inspect and adjust●●

Lube●(After

rain

ride)●Molybdenum disulfide grease

Retighten●●

DRIVE CHAIN GUIDE AND

ROLLERS

Inspect●●

SWINGARM

Inspect, lube and retighten●●Molybdenum disulfide grease

RELAY ARM, CONNECTING

ROD

Inspect, lube and retighten●●Molybdenum disulfide grease

SIDESTAND

Lubricate●Lithium base grease

STEERING HEAD

Inspect free play and retighten●●

Clean and lube●Lithium base grease

Replace bearing●

TIRE, WHEELS

Inspect air pressure, wheel run-

out, tire wear and spoke loose-

ness●●

Retighten sprocket bolt●●

Inspect bearings●

Replace bearings●

Lubricate●Lithium base grease

THROTTLE, CONTROL CABLE

Check routing and connection●●

Lubricate●●Yamaha cable lube or SAE 10W-40

motor oil

HOT STARTER, CLUTCH LEVER

Inspect free play●

BATTERY

Check terminal for looseness

and corrosion● ItemAfter

break-

inEvery

race

Every

third

(or 500

km)Every

fifth (or

1,000

km)

As re-

quiredRemarks