warning YAMAHA WR 250F 2016 Repair Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: WR 250F, Model: YAMAHA WR 250F 2016Pages: 428, PDF Size: 14.13 MB

Page 322 of 428

FUEL TANK

8-3

EAS2GB7340REMOVING THE FUEL TANK

1. Extract the fuel in the fuel tank through the

fuel tank cap with a pump.

2. Remove:

• Fuel hose coupler

EWA

WARNING

Cover the fuel hose connection with a cloth

when disconnecting it. This is because re-

sidual pressure in the fuel hose could cause

fuel to spurt out when the hose is removed.

ECA

NOTICE

Make sure that the fuel hose is disconnect-

ed by hand. Do not forcefully disconnect the

hose with tools.

TIP

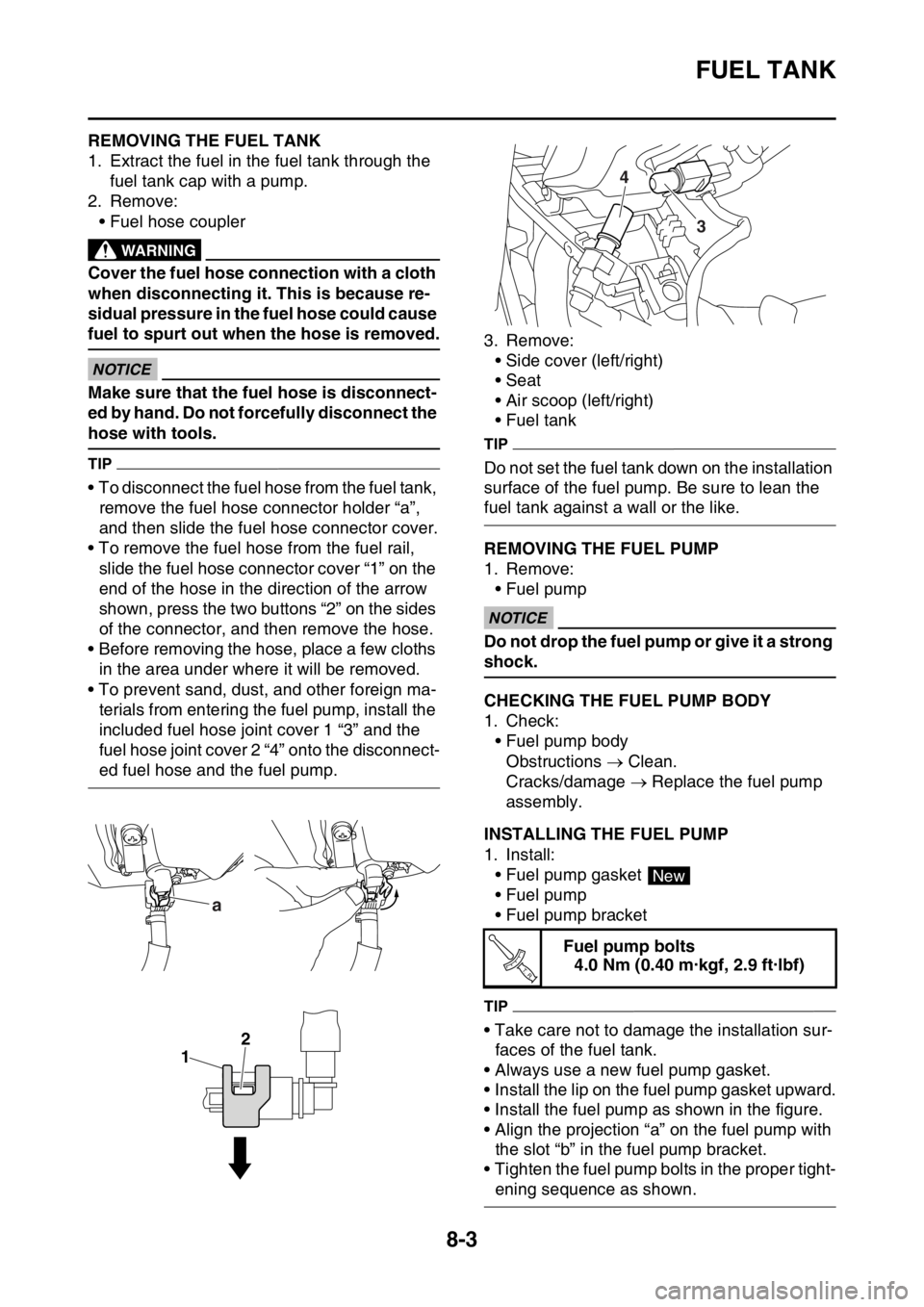

• To disconnect the fuel hose from the fuel tank,

remove the fuel hose connector holder “a”,

and then slide the fuel hose connector cover.

• To remove the fuel hose from the fuel rail,

slide the fuel hose connector cover “1” on the

end of the hose in the direction of the arrow

shown, press the two buttons “2” on the sides

of the connector, and then remove the hose.

• Before removing the hose, place a few cloths

in the area under where it will be removed.

• To prevent sand, dust, and other foreign ma-

terials from entering the fuel pump, install the

included fuel hose joint cover 1 “3” and the

fuel hose joint cover 2 “4” onto the disconnect-

ed fuel hose and the fuel pump.3. Remove:

• Side cover (left/right)

• Seat

• Air scoop (left/right)

• Fuel tank

TIP

Do not set the fuel tank down on the installation

surface of the fuel pump. Be sure to lean the

fuel tank against a wall or the like.

EAS2GB7341REMOVING THE FUEL PUMP

1. Remove:

• Fuel pump

ECA

NOTICE

Do not drop the fuel pump or give it a strong

shock.

EAS2GB7342CHECKING THE FUEL PUMP BODY

1. Check:

• Fuel pump body

Obstructions Clean.

Cracks/damage Replace the fuel pump

assembly.

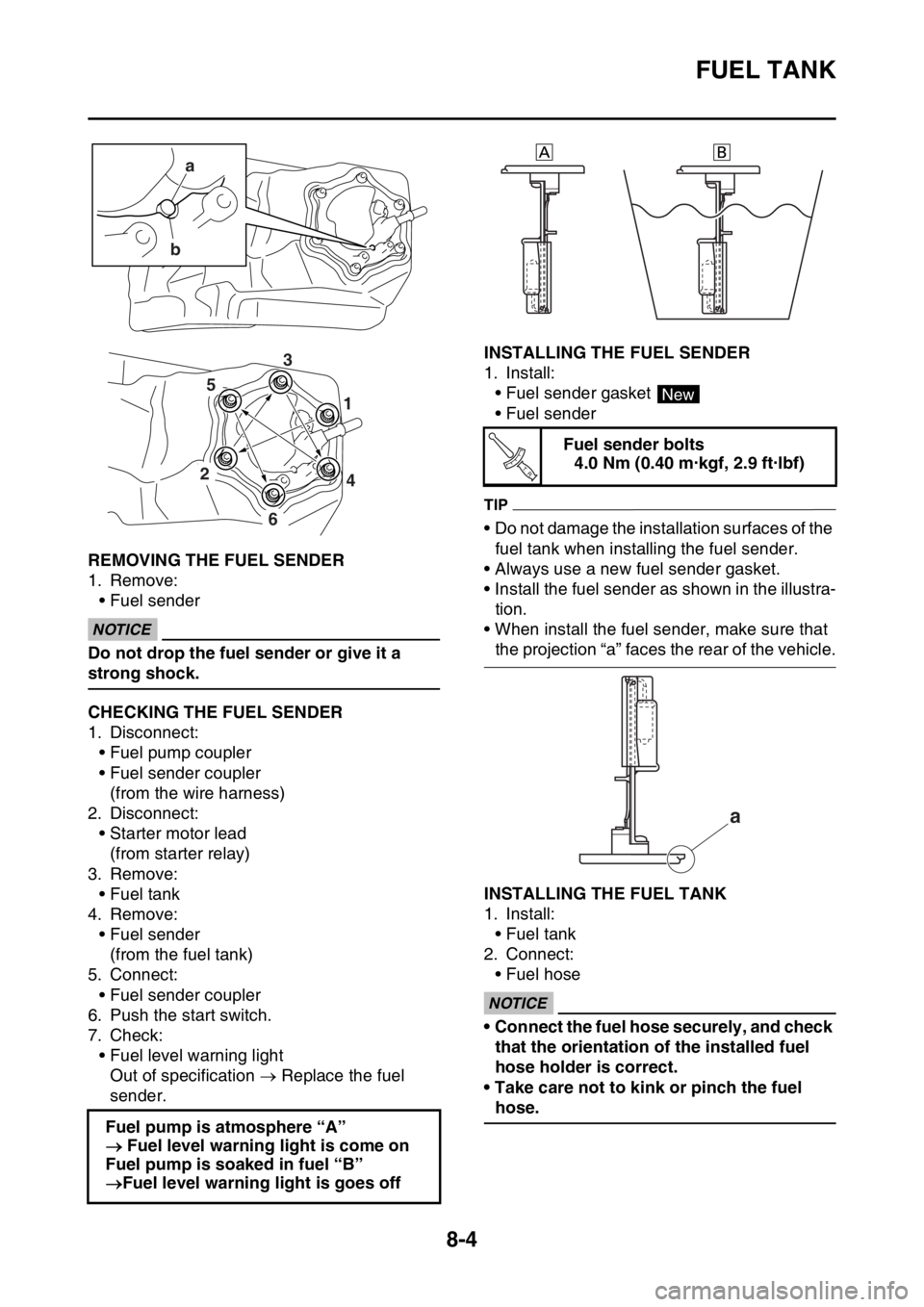

EAS2GB7343INSTALLING THE FUEL PUMP

1. Install:

• Fuel pump gasket

• Fuel pump

• Fuel pump bracket

TIP

• Take care not to damage the installation sur-

faces of the fuel tank.

• Always use a new fuel pump gasket.

• Install the lip on the fuel pump gasket upward.

• Install the fuel pump as shown in the figure.

• Align the projection “a” on the fuel pump with

the slot “b” in the fuel pump bracket.

• Tighten the fuel pump bolts in the proper tight-

ening sequence as shown.

a

1

2

Fuel pump bolts

4.0 Nm (0.40 m·kgf, 2.9 ft·lbf)

3 4

New

T R..

Page 323 of 428

FUEL TANK

8-4

EAS2GB7344REMOVING THE FUEL SENDER

1. Remove:

• Fuel sender

ECA

NOTICE

Do not drop the fuel sender or give it a

strong shock.

EAS2GB7345CHECKING THE FUEL SENDER

1. Disconnect:

• Fuel pump coupler

• Fuel sender coupler

(from the wire harness)

2. Disconnect:

• Starter motor lead

(from starter relay)

3. Remove:

• Fuel tank

4. Remove:

• Fuel sender

(from the fuel tank)

5. Connect:

• Fuel sender coupler

6. Push the start switch.

7. Check:

• Fuel level warning light

Out of specification Replace the fuel

sender.

EAS2GB7346INSTALLING THE FUEL SENDER

1. Install:

• Fuel sender gasket

• Fuel sender

TIP

• Do not damage the installation surfaces of the

fuel tank when installing the fuel sender.

• Always use a new fuel sender gasket.

• Install the fuel sender as shown in the illustra-

tion.

• When install the fuel sender, make sure that

the projection “a” faces the rear of the vehicle.

EAS2GB7347INSTALLING THE FUEL TANK

1. Install:

• Fuel tank

2. Connect:

• Fuel hose

ECA

NOTICE

• Connect the fuel hose securely, and check

that the orientation of the installed fuel

hose holder is correct.

• Take care not to kink or pinch the fuel

hose.

Fuel pump is atmosphere “A”

Fuel level warning light is come on

Fuel pump is soaked in fuel “B”

Fuel level warning light is goes off

a

b

4 1

2

6

53

Fuel sender bolts

4.0 Nm (0.40 m·kgf, 2.9 ft·lbf)

New

T R..

a

Page 324 of 428

FUEL TANK

8-5

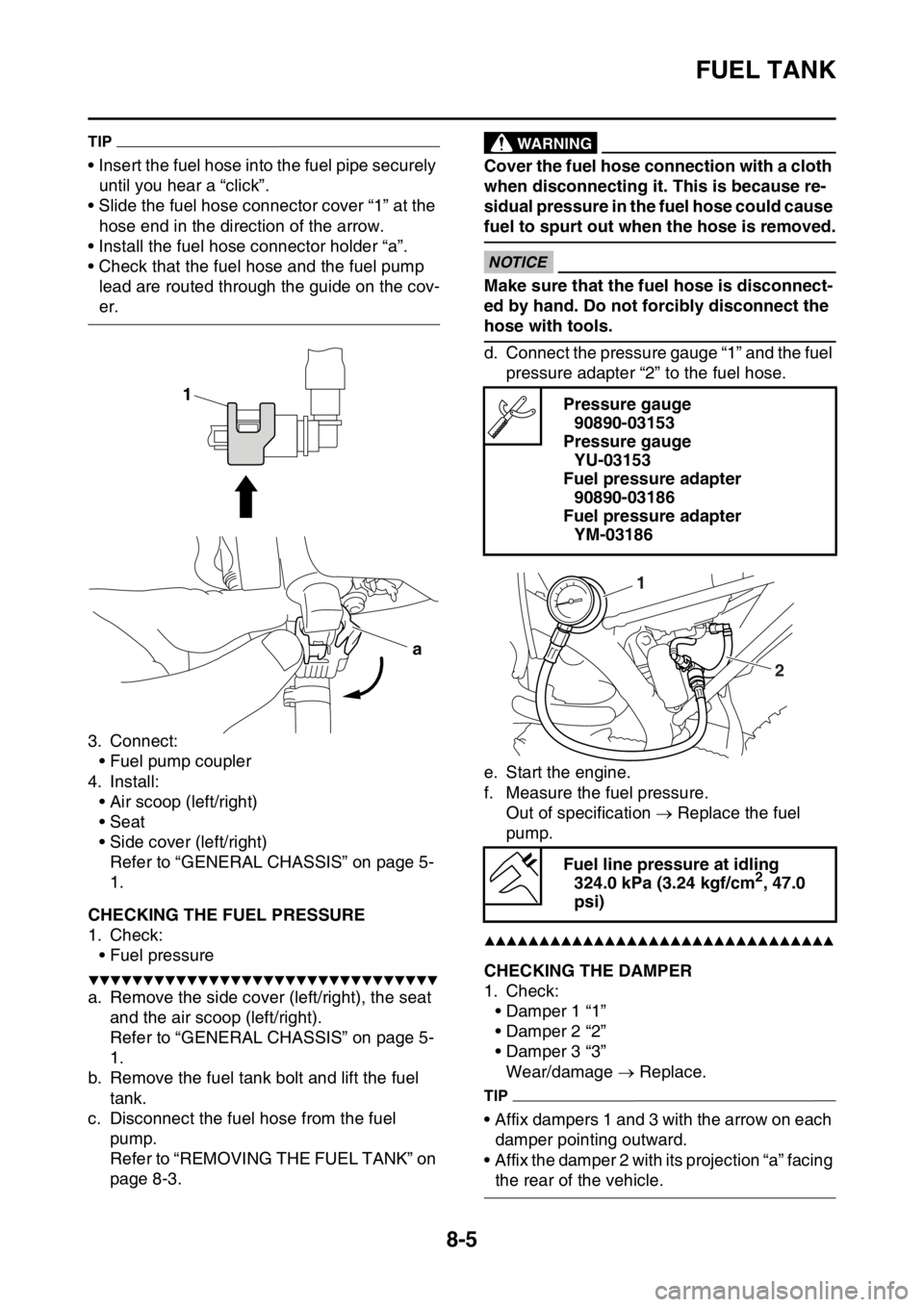

TIP

• Insert the fuel hose into the fuel pipe securely

until you hear a “click”.

• Slide the fuel hose connector cover “1” at the

hose end in the direction of the arrow.

• Install the fuel hose connector holder “a”.

• Check that the fuel hose and the fuel pump

lead are routed through the guide on the cov-

er.

3. Connect:

• Fuel pump coupler

4. Install:

• Air scoop (left/right)

• Seat

• Side cover (left/right)

Refer to “GENERAL CHASSIS” on page 5-

1.

EAS2GB7348CHECKING THE FUEL PRESSURE

1. Check:

• Fuel pressure

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the side cover (left/right), the seat

and the air scoop (left/right).

Refer to “GENERAL CHASSIS” on page 5-

1.

b. Remove the fuel tank bolt and lift the fuel

tank.

c. Disconnect the fuel hose from the fuel

pump.

Refer to “REMOVING THE FUEL TANK” on

page 8-3.

EWA

WARNING

Cover the fuel hose connection with a cloth

when disconnecting it. This is because re-

sidual pressure in the fuel hose could cause

fuel to spurt out when the hose is removed.

ECA

NOTICE

Make sure that the fuel hose is disconnect-

ed by hand. Do not forcibly disconnect the

hose with tools.

d. Connect the pressure gauge “1” and the fuel

pressure adapter “2” to the fuel hose.

e. Start the engine.

f. Measure the fuel pressure.

Out of specification Replace the fuel

pump.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GB7349CHECKING THE DAMPER

1. Check:

• Damper 1 “1”

• Damper 2 “2”

• Damper 3 “3”

Wear/damage Replace.

TIP

• Affix dampers 1 and 3 with the arrow on each

damper pointing outward.

• Affix the damper 2 with its projection “a” facing

the rear of the vehicle.

1

a

Pressure gauge

90890-03153

Pressure gauge

YU-03153

Fuel pressure adapter

90890-03186

Fuel pressure adapter

YM-03186

Fuel line pressure at idling

324.0 kPa (3.24 kgf/cm

2, 47.0

psi)

1

2

Page 330 of 428

THROTTLE BODY

8-11

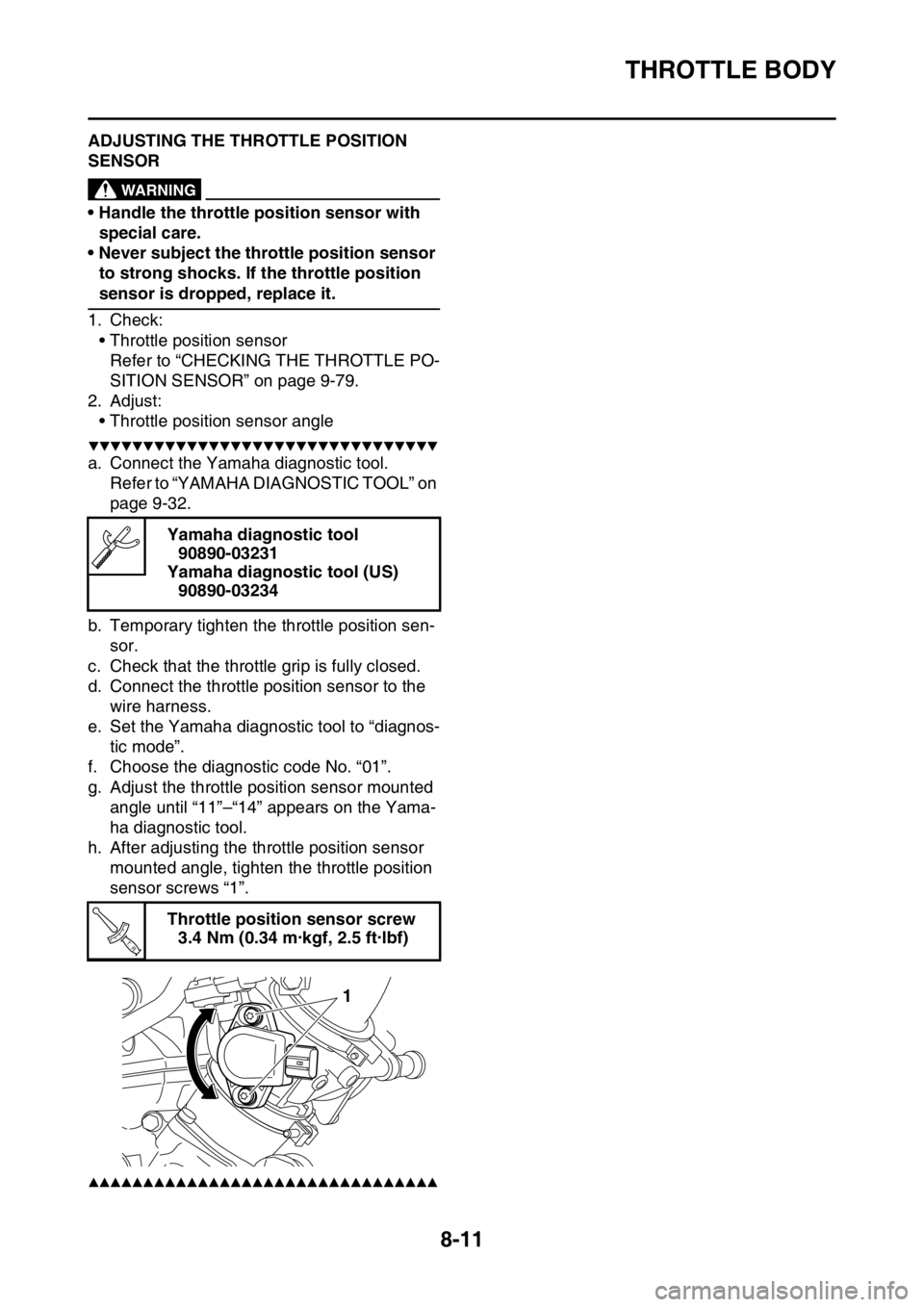

EAS2GB7355ADJUSTING THE THROTTLE POSITION

SENSOR

EWA

WARNING

• Handle the throttle position sensor with

special care.

• Never subject the throttle position sensor

to strong shocks. If the throttle position

sensor is dropped, replace it.

1. Check:

• Throttle position sensor

Refer to “CHECKING THE THROTTLE PO-

SITION SENSOR” on page 9-79.

2. Adjust:

• Throttle position sensor angle

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the Yamaha diagnostic tool.

Refer to “YAMAHA DIAGNOSTIC TOOL” on

page 9-32.

b. Temporary tighten the throttle position sen-

sor.

c. Check that the throttle grip is fully closed.

d. Connect the throttle position sensor to the

wire harness.

e. Set the Yamaha diagnostic tool to “diagnos-

tic mode”.

f. Choose the diagnostic code No. “01”.

g. Adjust the throttle position sensor mounted

angle until “11”–“14” appears on the Yama-

ha diagnostic tool.

h. After adjusting the throttle position sensor

mounted angle, tighten the throttle position

sensor screws “1”.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Yamaha diagnostic tool

90890-03231

Yamaha diagnostic tool (US)

90890-03234

Throttle position sensor screw

3.4 Nm (0.34 m·kgf, 2.5 ft·lbf)

T R..

1

Page 353 of 428

SIGNALING SYSTEM

9-21

1. Joint connector

2. Joint connector

3. Joint connector

7. Main relay

9. Battery

10.Frame ground

11.Starter relay

12.Main fuse

15.Indicator light

17.Fuel level warning light

18.Resistor

19.Fuel sender

22.ECU (engine control unit)

30.Joint connector

42.Joint connector

46.Speed sensor

47.Multi-function display

48.Frame ground

Page 355 of 428

SIGNALING SYSTEM

9-23

The fuel level warning light fails to come on.

1. Check the fuel sender.

Refer to “CHECKING THE FUEL

SENDER” on page 9-77.NG

Replace the fuel sender assembly.

OK

2. Check the resistor.

Refer to “CHECKING THE RESIST-

ER” on page 9-77.NG

Replace the resistor.

OK

3. Check the entire signaling system’s

wiring.

Refer to “CIRCUIT DIAGRAM” on

page 9-20.NG

Properly connect or repair the signaling

system’s wiring.

OK

Replace the indicator light assembly.

Page 361 of 428

FUEL INJECTION SYSTEM

9-29

1. Joint connector

2. Joint connector

3. Joint connector

4. AC magneto

7. Main relay

9. Battery

10.Frame ground

11.Starter relay

12.Main fuse

15.Indicator light

16.Engine trouble warning light

22.ECU (engine control unit)

25.Injector

30.Joint connector

31.Intake air temperature sensor

32.Coolant temperature sensor

33.Throttle position sensor

34.Intake air pressure sensor

35.Lean angle sensor

36.Engine stop switch

37.Neutral switch

38.Diode

39.Starting circuit cut-off relay

40.Clutch switch

42.Joint connector

48.Frame ground

Page 362 of 428

FUEL INJECTION SYSTEM

9-30

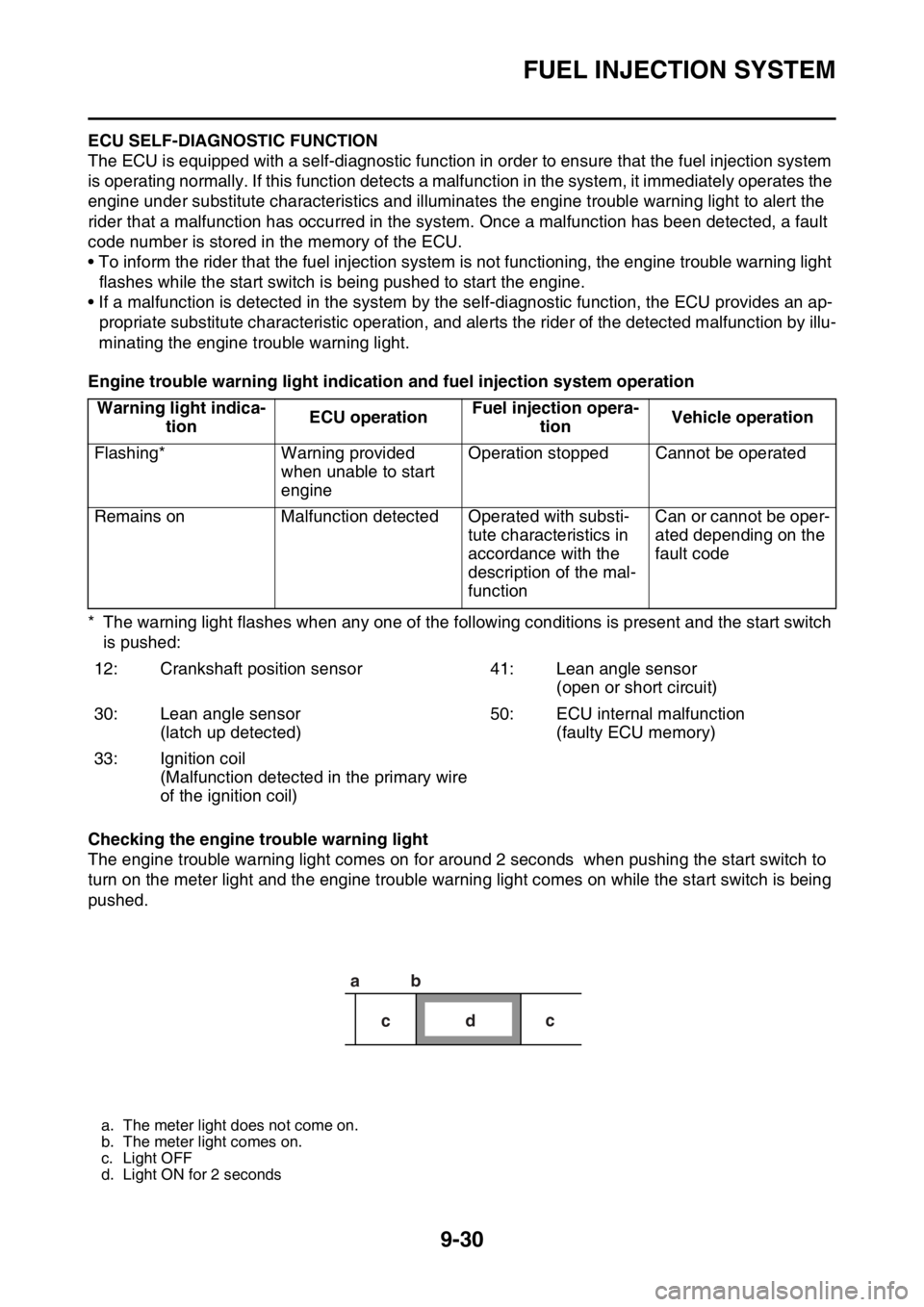

EAS2GB7374ECU SELF-DIAGNOSTIC FUNCTION

The ECU is equipped with a self-diagnostic function in order to ensure that the fuel injection system

is operating normally. If this function detects a malfunction in the system, it immediately operates the

engine under substitute characteristics and illuminates the engine trouble warning light to alert the

rider that a malfunction has occurred in the system. Once a malfunction has been detected, a fault

code number is stored in the memory of the ECU.

• To inform the rider that the fuel injection system is not functioning, the engine trouble warning light

flashes while the start switch is being pushed to start the engine.

• If a malfunction is detected in the system by the self-diagnostic function, the ECU provides an ap-

propriate substitute characteristic operation, and alerts the rider of the detected malfunction by illu-

minating the engine trouble warning light.

Engine trouble warning light indication and fuel injection system operation

* The warning light flashes when any one of the following conditions is present and the start switch

is pushed:

Checking the engine trouble warning light

The engine trouble warning light comes on for around 2 seconds when pushing the start switch to

turn on the meter light and the engine trouble warning light comes on while the start switch is being

pushed.Warning light indica-

tionECU operationFuel injection opera-

tionVehicle operation

Flashing* Warning provided

when unable to start

engineOperation stopped Cannot be operated

Remains on Malfunction detected Operated with substi-

tute characteristics in

accordance with the

description of the mal-

functionCan or cannot be oper-

ated depending on the

fault code

12: Crankshaft position sensor 41: Lean angle sensor

(open or short circuit)

30: Lean angle sensor

(latch up detected)50: ECU internal malfunction

(faulty ECU memory)

33: Ignition coil

(Malfunction detected in the primary wire

of the ignition coil)

a. The meter light does not come on.

b. The meter light comes on.

c. Light OFF

d. Light ON for 2 seconds

ab

cdc

Page 363 of 428

FUEL INJECTION SYSTEM

9-31

ECU detects an abnormal signal from a sensor

If the ECU detects an abnormal signal from a sensor while the vehicle is being driven, the ECU illu-

minates the engine trouble warning light and provides the engine with alternate operating instructions

that are appropriate for the type of malfunction.

When an abnormal signal is received from a sensor, the ECU processes the specified values that are

programmed for each sensor in order to provide the engine with alternate operating instructions that

enable the engine to continue operating or stop operating, depending on the conditions.

EAS2GB7375TROUBLESHOOTING METHOD

The engine operation is not normal and the engine trouble warning light comes on.

1. Check:

• Fault code number

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the Yamaha diagnostic tool. Refer to “YAMAHA DIAGNOSTIC TOOL” on page 9-32.

b. Check the fault code number displayed on the Yamaha diagnostic tool.

c. Identify the faulty system with the fault code number.

d. Identify the probable cause of the malfunction.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

2. Check and repair the probable cause of the malfunction.

3. Perform the reinstatement action for the fuel injection system. Refer to “Confirmation of service

completion” in the appropriate table in “TROUBLESHOOTING DETAILS” on page 9-35.

4. After pushing the engine stop switch, push the start switch to check whether the fault code no. is

displayed.

TIP

If another fault code number is displayed, repeat steps (1) to (4) until no fault code number is dis-

played.

5. Erase the malfunction history in the diagnostic mode. Refer to “SENSOR OPERATION TABLE”

(Diagnostic code No.62).

TIP

Turning off the meter light will not erase the malfunction history.

The engine operation is not normal, but the engine trouble warning light does not come on.

1. Check the operation of the following sensors and actuators in the diagnostic mode. Refer to

“TROUBLESHOOTING DETAILS” on page 9-35.

If a malfunction is detected in the sensors or actuators, repair or replace all faulty parts.

If no malfunction is detected in the sensors and actuators, check and repair the inner parts of the

engine.Fault code No. No fault code No.

Check and repair. Refer to “TROUBLESHOOT-

ING DETAILS” on page 9-35.

Monitor the operation of the sensors and actua-

tors in the diagnostic mode. Refer to “TROU-

BLESHOOTING DETAILS” on page 9-35 and

“LIST OF SELF-DIAGNOSTIC AND FAIL-SAFE

ACTIONS” on page 10-5.Check and repair.

01: Throttle position sensor signal (throttle angle)

30: Ignition coil

36: Injector

Page 377 of 428

FUEL INJECTION SYSTEM

9-45

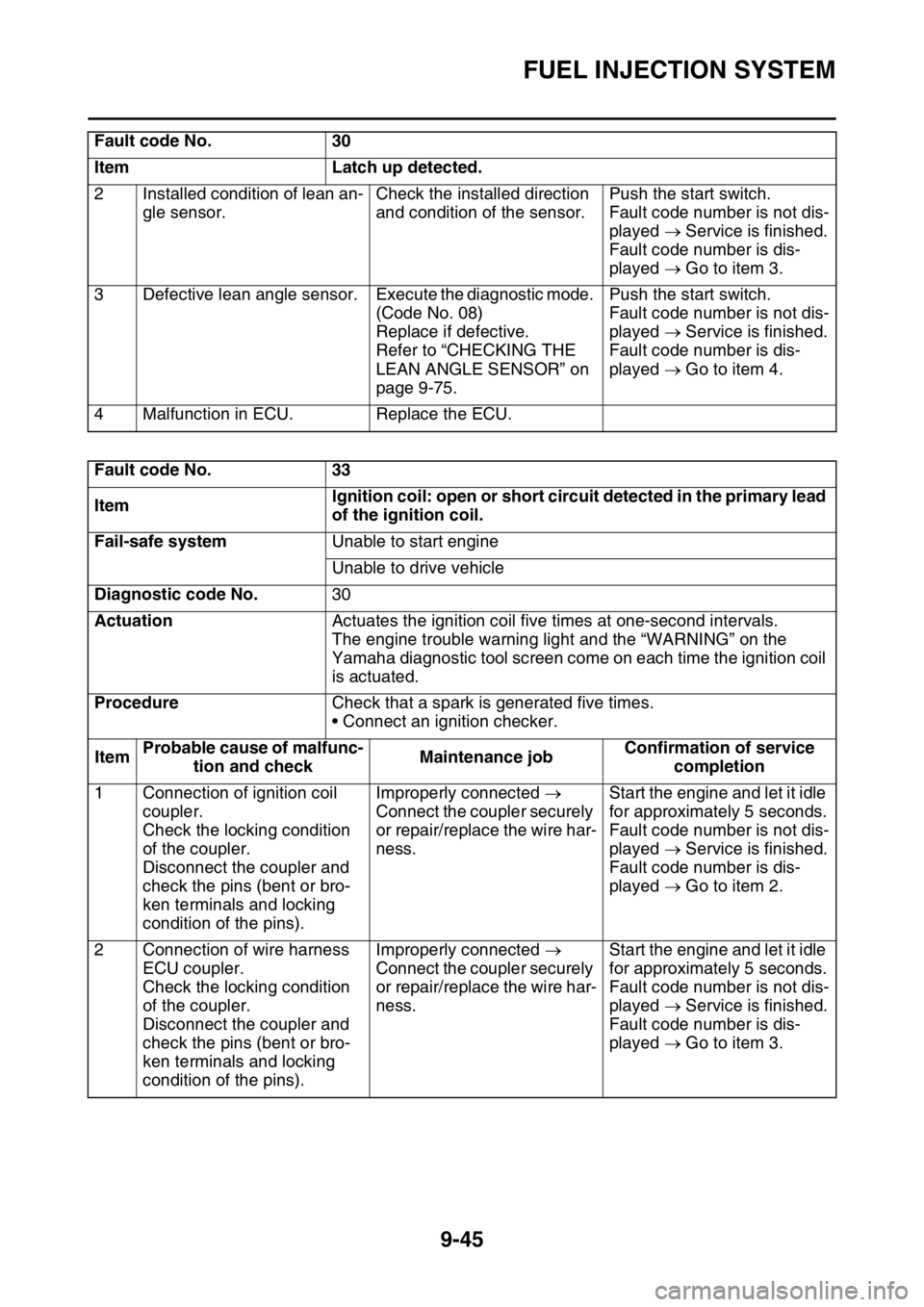

2 Installed condition of lean an-

gle sensor.Check the installed direction

and condition of the sensor.Push the start switch.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 3.

3 Defective lean angle sensor. Execute the diagnostic mode.

(Code No. 08)

Replace if defective.

Refer to “CHECKING THE

LEAN ANGLE SENSOR” on

page 9-75.Push the start switch.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 4.

4 Malfunction in ECU. Replace the ECU.

Fault code No. 33

ItemIgnition coil: open or short circuit detected in the primary lead

of the ignition coil.

Fail-safe systemUnable to start engine

Unable to drive vehicle

Diagnostic code No.30

ActuationActuates the ignition coil five times at one-second intervals.

The engine trouble warning light and the “WARNING” on the

Yamaha diagnostic tool screen come on each time the ignition coil

is actuated.

ProcedureCheck that a spark is generated five times.

• Connect an ignition checker.

ItemProbable cause of malfunc-

tion and checkMaintenance jobConfirmation of service

completion

1 Connection of ignition coil

coupler.

Check the locking condition

of the coupler.

Disconnect the coupler and

check the pins (bent or bro-

ken terminals and locking

condition of the pins).Improperly connected

Connect the coupler securely

or repair/replace the wire har-

ness.Start the engine and let it idle

for approximately 5 seconds.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 2.

2 Connection of wire harness

ECU coupler.

Check the locking condition

of the coupler.

Disconnect the coupler and

check the pins (bent or bro-

ken terminals and locking

condition of the pins).Improperly connected

Connect the coupler securely

or repair/replace the wire har-

ness.Start the engine and let it idle

for approximately 5 seconds.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 3. Fault code No. 30

Item Latch up detected.