battery YAMAHA WR 250F 2017 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2017, Model line: WR 250F, Model: YAMAHA WR 250F 2017Pages: 432, PDF Size: 14.14 MB

Page 103 of 432

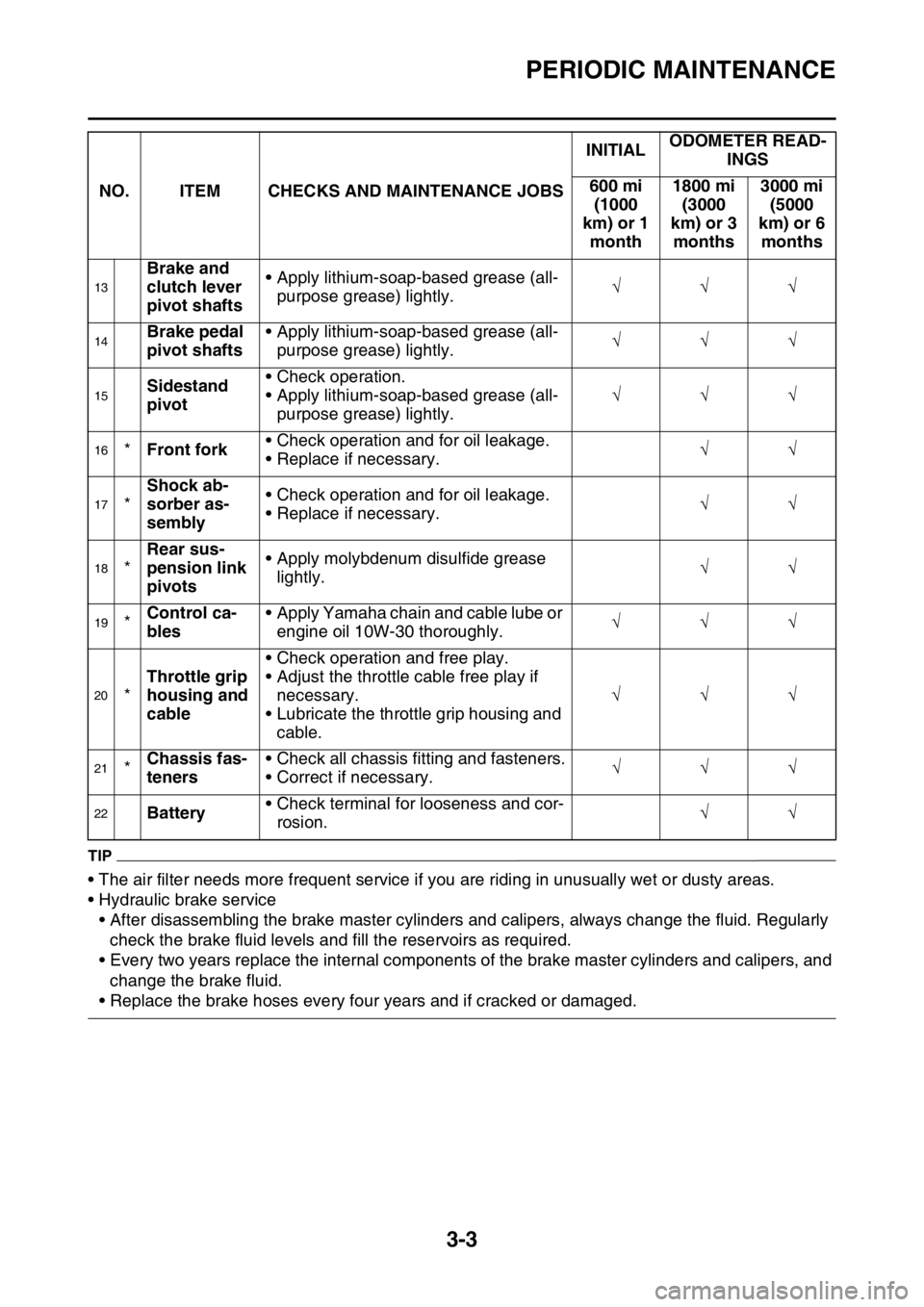

PERIODIC MAINTENANCE

3-3

TIP

• The air filter needs more frequent service if you are riding in unusually wet or dusty areas.

• Hydraulic brake service

• After disassembling the brake master cylinders and calipers, always change the fluid. Regularly

check the brake fluid levels and fill the reservoirs as required.

• Every two years replace the internal components of the brake master cylinders and calipers, and

change the brake fluid.

• Replace the brake hoses every four years and if cracked or damaged.

13

Brake and

clutch lever

pivot shafts• Apply lithium-soap-based grease (all-

purpose grease) lightly.

14Brake pedal

pivot shafts• Apply lithium-soap-based grease (all-

purpose grease) lightly.

15Sidestand

pivot• Check operation.

• Apply lithium-soap-based grease (all-

purpose grease) lightly.

16*Front fork• Check operation and for oil leakage.

• Replace if necessary.

17*Shock ab-

sorber as-

sembly• Check operation and for oil leakage.

• Replace if necessary.

18*Rear sus-

pension link

pivots• Apply molybdenum disulfide grease

lightly.

19*Control ca-

bles• Apply Yamaha chain and cable lube or

engine oil 10W-30 thoroughly.

20*Throttle grip

housing and

cable• Check operation and free play.

• Adjust the throttle cable free play if

necessary.

• Lubricate the throttle grip housing and

cable.

21*Chassis fas-

teners• Check all chassis fitting and fasteners.

• Correct if necessary.

22Battery• Check terminal for looseness and cor-

rosion. NO. ITEM CHECKS AND MAINTENANCE JOBSINITIALODOMETER READ-

INGS

600 mi

(1000

km) or 1

month1800 mi

(3000

km) or 3

months3000 mi

(5000

km) or 6

months

Page 141 of 432

ELECTRICAL SYSTEM

3-41

3. Adjust:

• Engine idling speed

Refer to “ADJUSTING THE ENGINE

IDLING SPEED” on page 3-18.

4. Check:

• Ignition timing

Check whether the alignment mark “a” on

the left crankcase cover is within the firing

range “b” on the rotor.

Incorrect firing range Check rotor and

Crankshaft position sensor.

5. Install:

• Timing mark accessing screw

EAS2GBB133CHECKING AND CHARGING THE BATTERY

Refer to “CHECKING AND CHARGING THE

BATTERY” on page 9-69.

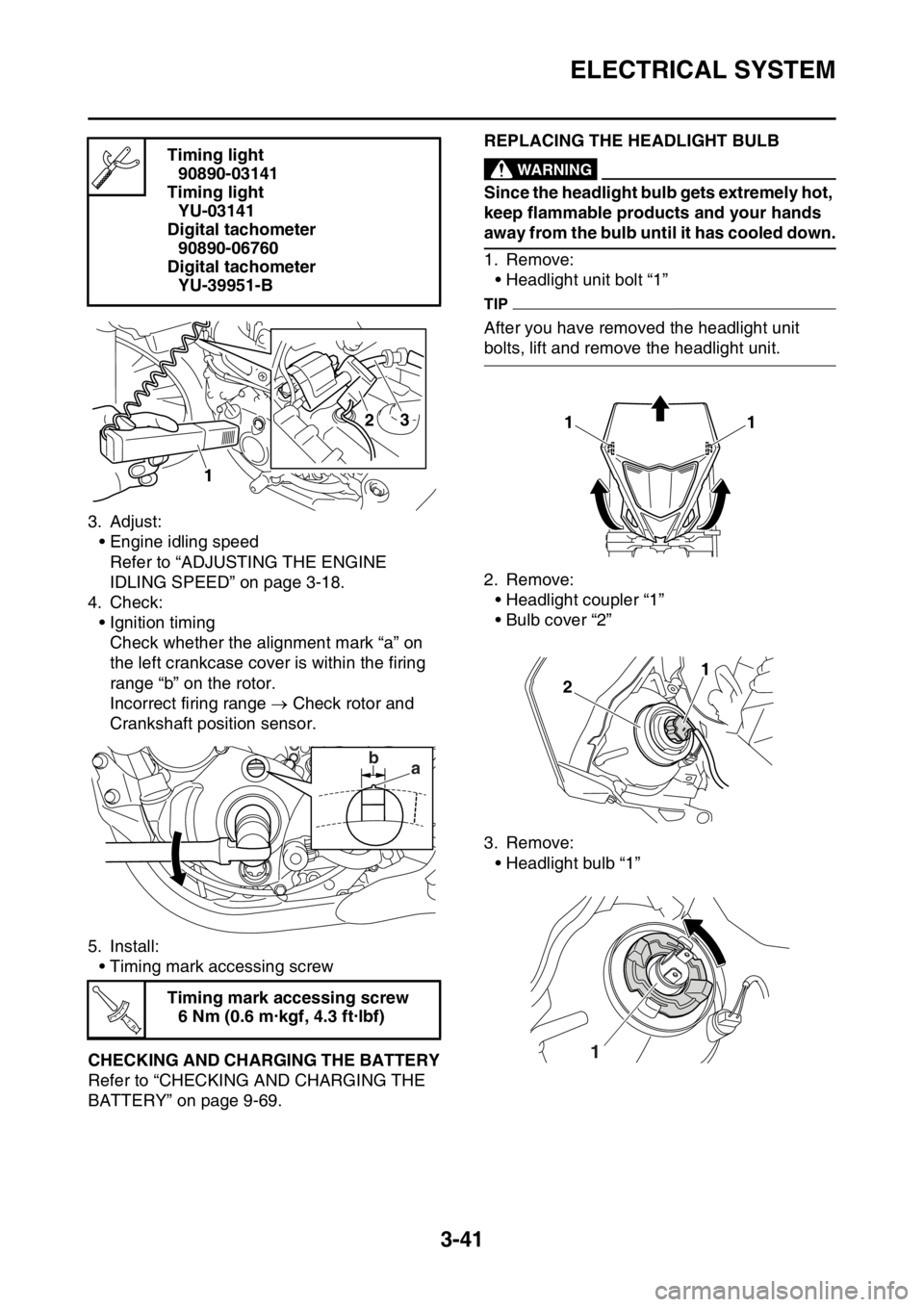

EAS2GBB134REPLACING THE HEADLIGHT BULBEWA

WARNING

Since the headlight bulb gets extremely hot,

keep flammable products and your hands

away from the bulb until it has cooled down.

1. Remove:

• Headlight unit bolt “1”

TIP

After you have removed the headlight unit

bolts, lift and remove the headlight unit.

2. Remove:

• Headlight coupler “1”

• Bulb cover “2”

3. Remove:

• Headlight bulb “1” Timing light

90890-03141

Timing light

YU-03141

Digital tachometer

90890-06760

Digital tachometer

YU-39951-B

Timing mark accessing screw

6 Nm (0.6 m·kgf, 4.3 ft·lbf)

2

1

3

ba

T R..

11

1

2

1

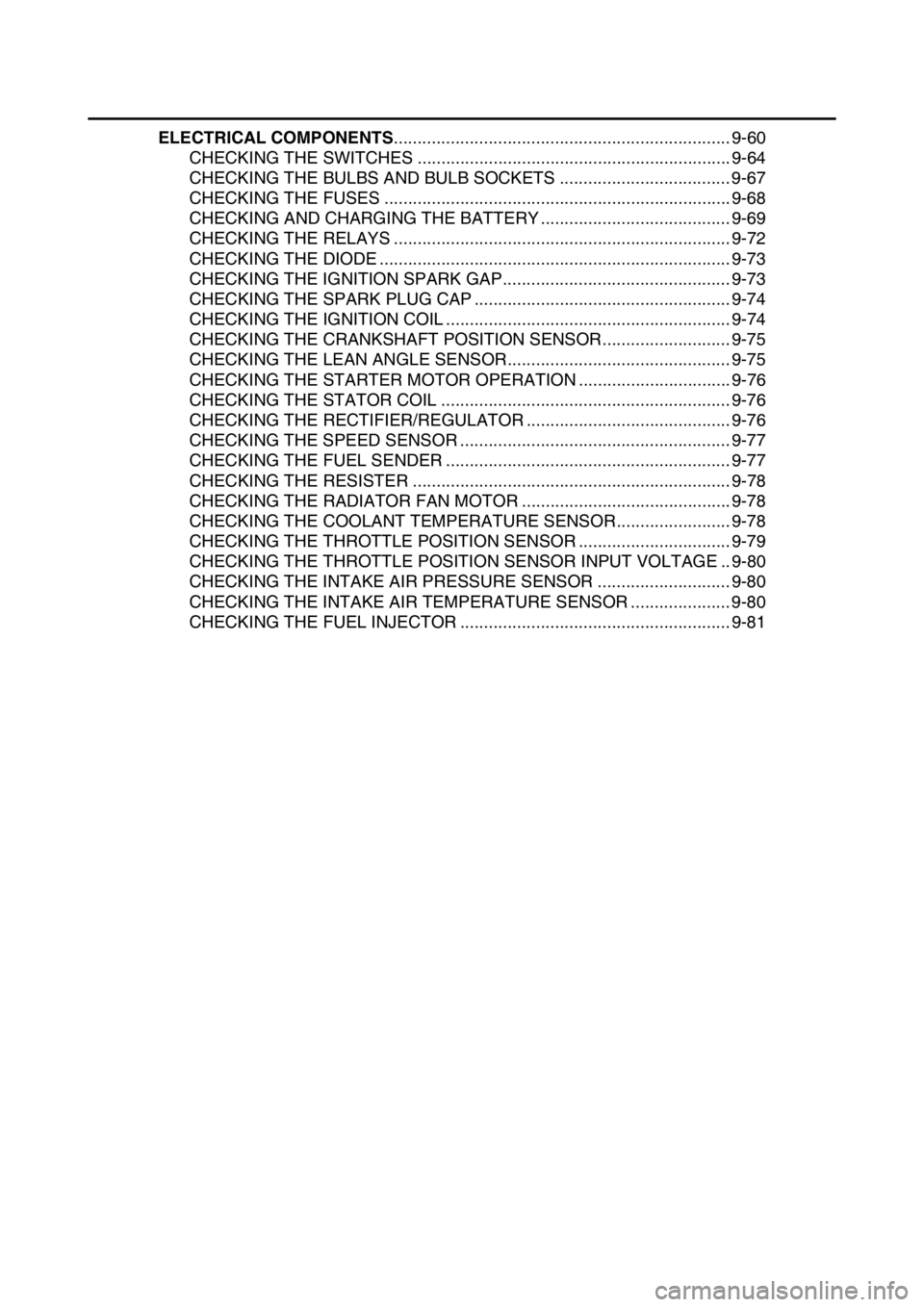

Page 336 of 432

ELECTRICAL COMPONENTS....................................................................... 9-60

CHECKING THE SWITCHES .................................................................. 9-64

CHECKING THE BULBS AND BULB SOCKETS .................................... 9-67

CHECKING THE FUSES ......................................................................... 9-68

CHECKING AND CHARGING THE BATTERY ........................................ 9-69

CHECKING THE RELAYS ....................................................................... 9-72

CHECKING THE DIODE .......................................................................... 9-73

CHECKING THE IGNITION SPARK GAP................................................ 9-73

CHECKING THE SPARK PLUG CAP ...................................................... 9-74

CHECKING THE IGNITION COIL ............................................................ 9-74

CHECKING THE CRANKSHAFT POSITION SENSOR........................... 9-75

CHECKING THE LEAN ANGLE SENSOR............................................... 9-75

CHECKING THE STARTER MOTOR OPERATION ................................ 9-76

CHECKING THE STATOR COIL ............................................................. 9-76

CHECKING THE RECTIFIER/REGULATOR ........................................... 9-76

CHECKING THE SPEED SENSOR ......................................................... 9-77

CHECKING THE FUEL SENDER ............................................................ 9-77

CHECKING THE RESISTER ................................................................... 9-78

CHECKING THE RADIATOR FAN MOTOR ............................................ 9-78

CHECKING THE COOLANT TEMPERATURE SENSOR........................ 9-78

CHECKING THE THROTTLE POSITION SENSOR ................................ 9-79

CHECKING THE THROTTLE POSITION SENSOR INPUT VOLTAGE .. 9-80

CHECKING THE INTAKE AIR PRESSURE SENSOR ............................ 9-80

CHECKING THE INTAKE AIR TEMPERATURE SENSOR ..................... 9-80

CHECKING THE FUEL INJECTOR ......................................................... 9-81

Page 339 of 432

IGNITION SYSTEM

9-3

1. Joint connector

2. Joint connector

4. AC magneto

9. Battery

10.Frame ground

11.Starter relay

12.Main fuse

22.ECU (engine control unit)

23.Ignition coil

24.Spark plug

30.Joint connector

35.Lean angle sensor

36.Engine stop switch

48.Frame ground

49.Ignition coil sub-lead

Page 340 of 432

IGNITION SYSTEM

9-4

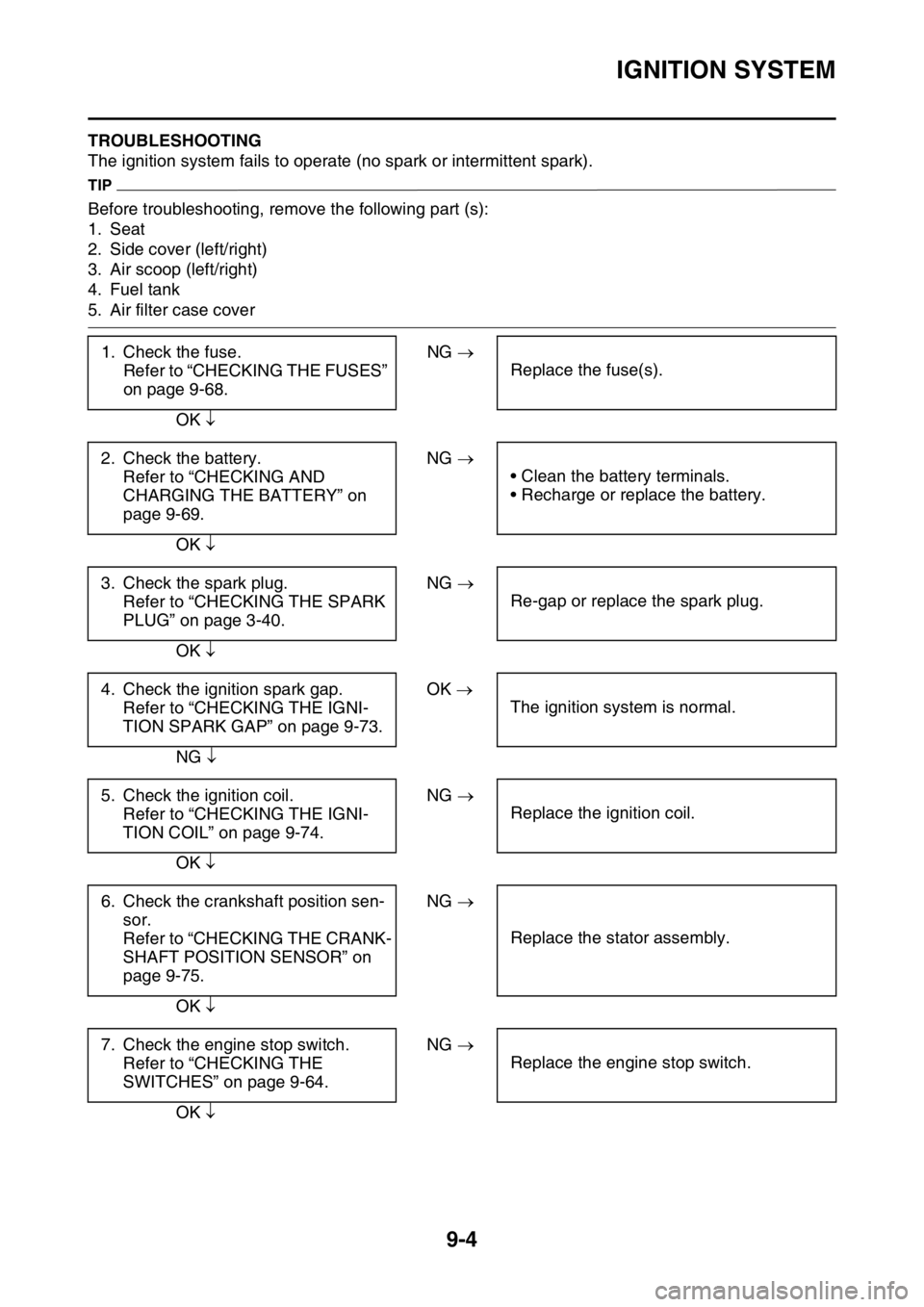

EAS2GBB359TROUBLESHOOTING

The ignition system fails to operate (no spark or intermittent spark).

TIP

Before troubleshooting, remove the following part (s):

1. Seat

2. Side cover (left/right)

3. Air scoop (left/right)

4. Fuel tank

5. Air filter case cover

1. Check the fuse.

Refer to “CHECKING THE FUSES”

on page 9-68.NG

Replace the fuse(s).

OK

2. Check the battery.

Refer to “CHECKING AND

CHARGING THE BATTERY” on

page 9-69.NG

• Clean the battery terminals.

• Recharge or replace the battery.

OK

3. Check the spark plug.

Refer to “CHECKING THE SPARK

PLUG” on page 3-40.NG

Re-gap or replace the spark plug.

OK

4. Check the ignition spark gap.

Refer to “CHECKING THE IGNI-

TION SPARK GAP” on page 9-73.OK

The ignition system is normal.

NG

5. Check the ignition coil.

Refer to “CHECKING THE IGNI-

TION COIL” on page 9-74.NG

Replace the ignition coil.

OK

6. Check the crankshaft position sen-

sor.

Refer to “CHECKING THE CRANK-

SHAFT POSITION SENSOR” on

page 9-75.NG

Replace the stator assembly.

OK

7. Check the engine stop switch.

Refer to “CHECKING THE

SWITCHES” on page 9-64.NG

Replace the engine stop switch.

OK

Page 343 of 432

ELECTRIC STARTING SYSTEM

9-7

1. Joint connector

2. Joint connector

3. Joint connector

7. Main relay

9. Battery

10.Frame ground

11.Starter relay

12.Main fuse

13.Starter motor

14.Starter relay diode

22.ECU (engine control unit)

30.Joint connector

36.Engine stop switch

37.Neutral switch

38.Diode

39.Starting circuit cut-off relay

40.Clutch switch

41.Start switch

48.Frame ground

Page 345 of 432

ELECTRIC STARTING SYSTEM

9-9

a. WHEN THE TRANSMISSION IS IN NEU-

TRAL

b. WHEN THE CLUTCH LEVER IS PULLED

TO THE HANDLEBAR

1. Battery

2. Main fuse

3. Main relay

4. Starting circuit cut-off relay

5. Start switch

6. Diode

7. Clutch switch

8. Neutral switch

9. Starter relay

10.Starter motor

Page 346 of 432

ELECTRIC STARTING SYSTEM

9-10

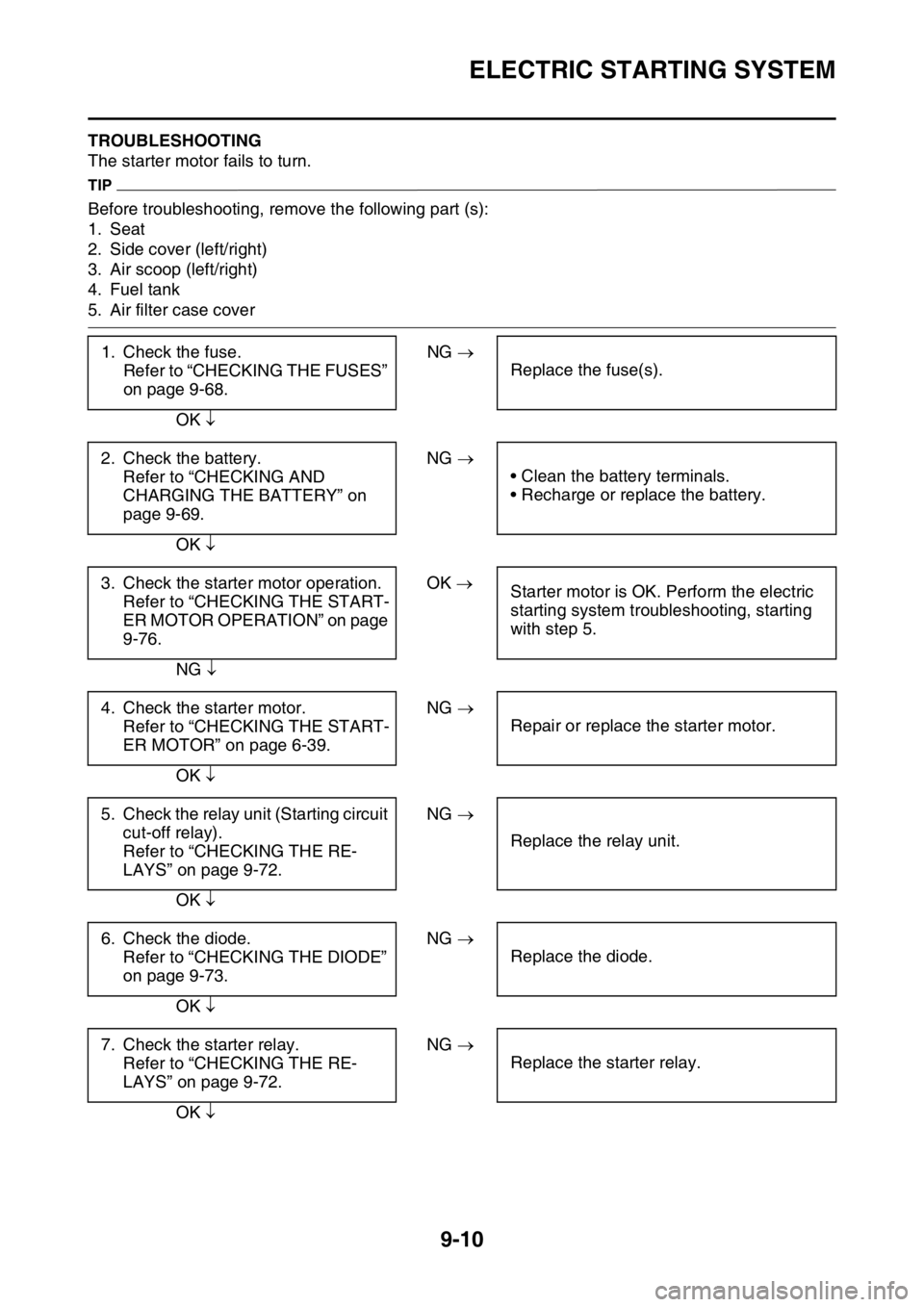

EAS2GBB362TROUBLESHOOTING

The starter motor fails to turn.

TIP

Before troubleshooting, remove the following part (s):

1. Seat

2. Side cover (left/right)

3. Air scoop (left/right)

4. Fuel tank

5. Air filter case cover

1. Check the fuse.

Refer to “CHECKING THE FUSES”

on page 9-68.NG

Replace the fuse(s).

OK

2. Check the battery.

Refer to “CHECKING AND

CHARGING THE BATTERY” on

page 9-69.NG

• Clean the battery terminals.

• Recharge or replace the battery.

OK

3. Check the starter motor operation.

Refer to “CHECKING THE START-

ER MOTOR OPERATION” on page

9-76.OK

Starter motor is OK. Perform the electric

starting system troubleshooting, starting

with step 5.

NG

4. Check the starter motor.

Refer to “CHECKING THE START-

ER MOTOR” on page 6-39.NG

Repair or replace the starter motor.

OK

5. Check the relay unit (Starting circuit

cut-off relay).

Refer to “CHECKING THE RE-

LAYS” on page 9-72.NG

Replace the relay unit.

OK

6. Check the diode.

Refer to “CHECKING THE DIODE”

on page 9-73.NG

Replace the diode.

OK

7. Check the starter relay.

Refer to “CHECKING THE RE-

LAYS” on page 9-72.NG

Replace the starter relay.

OK

Page 349 of 432

CHARGING SYSTEM

9-13

4. AC magneto

5. Rectifier/regulator

9. Battery

10.Frame ground

11.Starter relay

12.Main fuse

50.Negative battery lead

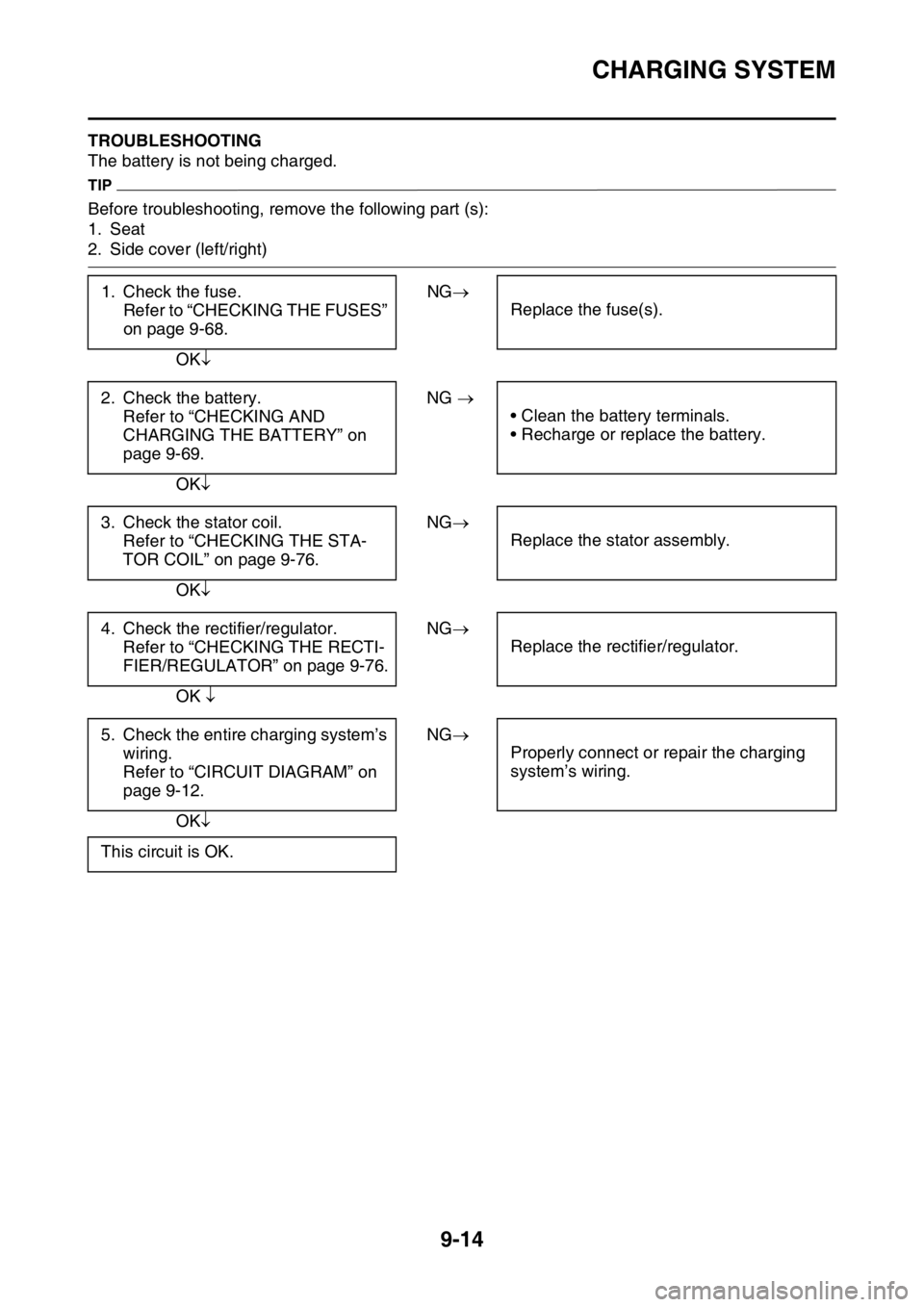

Page 350 of 432

CHARGING SYSTEM

9-14

EAS2GBB364TROUBLESHOOTING

The battery is not being charged.

TIP

Before troubleshooting, remove the following part (s):

1. Seat

2. Side cover (left/right)

1. Check the fuse.

Refer to “CHECKING THE FUSES”

on page 9-68.NG

Replace the fuse(s).

OK

2. Check the battery.

Refer to “CHECKING AND

CHARGING THE BATTERY” on

page 9-69.NG

• Clean the battery terminals.

• Recharge or replace the battery.

OK

3. Check the stator coil.

Refer to “CHECKING THE STA-

TOR COIL” on page 9-76.NG

Replace the stator assembly.

OK

4. Check the rectifier/regulator.

Refer to “CHECKING THE RECTI-

FIER/REGULATOR” on page 9-76.NG

Replace the rectifier/regulator.

OK

5. Check the entire charging system’s

wiring.

Refer to “CIRCUIT DIAGRAM” on

page 9-12.NG

Properly connect or repair the charging

system’s wiring.

OK

This circuit is OK.