engine coolant YAMAHA WR 250F 2017 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2017, Model line: WR 250F, Model: YAMAHA WR 250F 2017Pages: 432, PDF Size: 14.14 MB

Page 111 of 432

ENGINE

3-11

5. Install:

• Copper washer

• Coolant drain bolt

6. Pour coolant.

EWA

WARNING

• If coolant splashes in your eyes, thorough-

ly wash them with water and consult a

doctor.

• If coolant splashes on your clothes, quick-

ly wash it away with water and then with

soap and water.

• If coolant is swallowed, induce vomiting

and get immediate medical attention.

ECA

NOTICE

• Adding water instead of coolant lowers the

antifreeze content of the coolant. If water

is used instead of coolant check, and if

necessary, correct the antifreeze concen-

tration of the coolant.

• Use only distilled water. However, if dis-

tilled water is not available, soft water may

be used.

• If coolant comes into contact with painted

surfaces, immediately wash them with wa-

ter.

• Do not mix different types of antifreeze.

7. Install:

• Radiator cap

8. Start the engine, warm this up for 3 minutes,

stop it, and then wait for it to cool down.

9. Check:

• Coolant level

Refer to “CHECKING THE COOLANT LEV-

EL” on page 3-10.

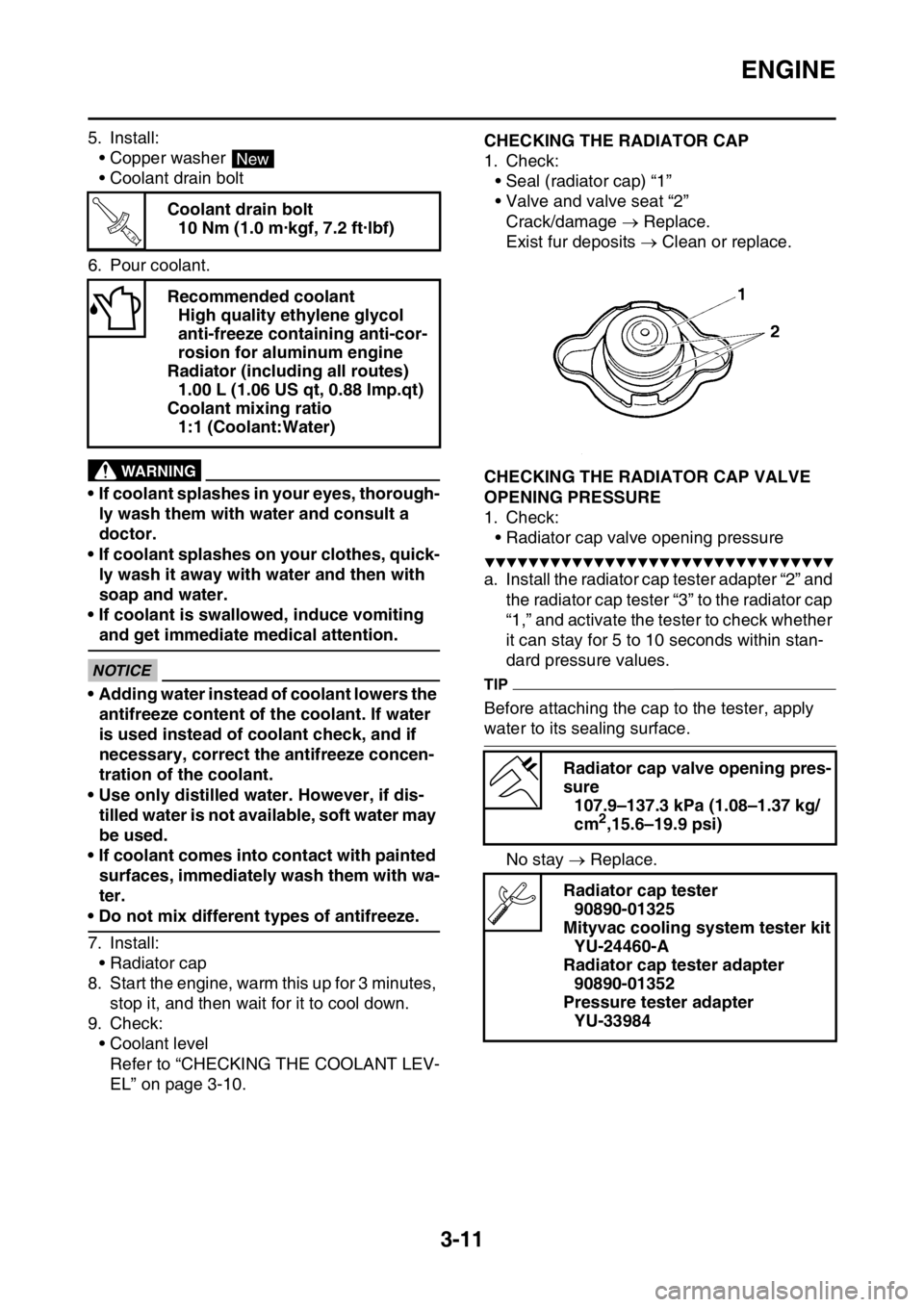

EAS2GBB085CHECKING THE RADIATOR CAP

1. Check:

• Seal (radiator cap) “1”

• Valve and valve seat “2”

Crack/damage Replace.

Exist fur deposits Clean or replace.

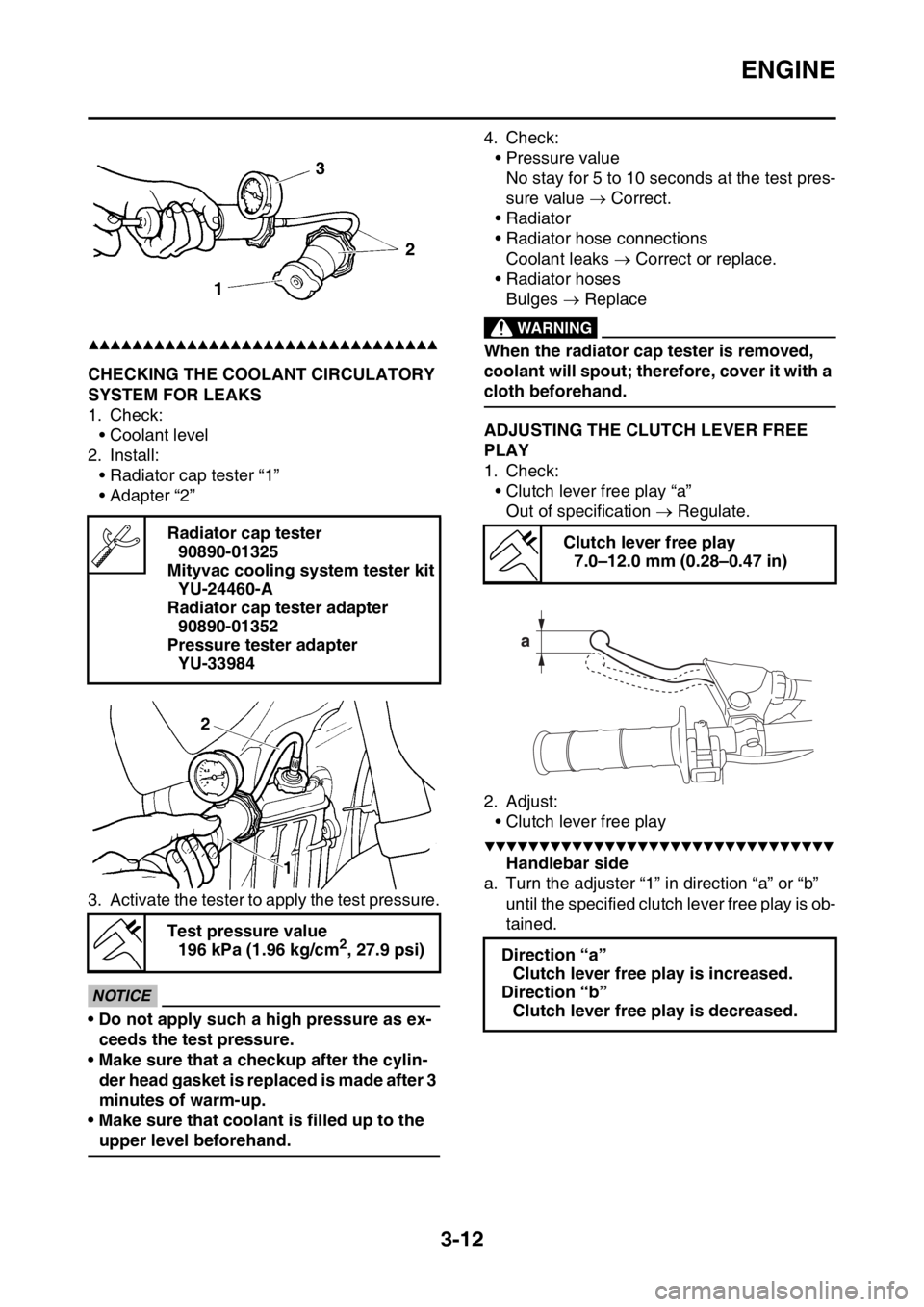

EAS2GBB086CHECKING THE RADIATOR CAP VALVE

OPENING PRESSURE

1. Check:

• Radiator cap valve opening pressure

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Install the radiator cap tester adapter “2” and

the radiator cap tester “3” to the radiator cap

“1,” and activate the tester to check whether

it can stay for 5 to 10 seconds within stan-

dard pressure values.

TIP

Before attaching the cap to the tester, apply

water to its sealing surface.

No stay Replace. Coolant drain bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Recommended coolant

High quality ethylene glycol

anti-freeze containing anti-cor-

rosion for aluminum engine

Radiator (including all routes)

1.00 L (1.06 US qt, 0.88 Imp.qt)

Coolant mixing ratio

1:1 (Coolant:Water)

New

T R..

Radiator cap valve opening pres-

sure

107.9–137.3 kPa (1.08–1.37 kg/

cm

2,15.6–19.9 psi)

Radiator cap tester

90890-01325

Mityvac cooling system tester kit

YU-24460-A

Radiator cap tester adapter

90890-01352

Pressure tester adapter

YU-33984

Page 112 of 432

ENGINE

3-12

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GBB087CHECKING THE COOLANT CIRCULATORY

SYSTEM FOR LEAKS

1. Check:

• Coolant level

2. Install:

• Radiator cap tester “1”

• Adapter “2”

3. Activate the tester to apply the test pressure.

ECA

NOTICE

• Do not apply such a high pressure as ex-

ceeds the test pressure.

• Make sure that a checkup after the cylin-

der head gasket is replaced is made after 3

minutes of warm-up.

• Make sure that coolant is filled up to the

upper level beforehand.4. Check:

• Pressure value

No stay for 5 to 10 seconds at the test pres-

sure value Correct.

• Radiator

• Radiator hose connections

Coolant leaks Correct or replace.

• Radiator hoses

Bulges Replace

EWA

WARNING

When the radiator cap tester is removed,

coolant will spout; therefore, cover it with a

cloth beforehand.

EAS2GBB088ADJUSTING THE CLUTCH LEVER FREE

PLAY

1. Check:

• Clutch lever free play “a”

Out of specification Regulate.

2. Adjust:

• Clutch lever free play

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

Handlebar side

a. Turn the adjuster “1” in direction “a” or “b”

until the specified clutch lever free play is ob-

tained. Radiator cap tester

90890-01325

Mityvac cooling system tester kit

YU-24460-A

Radiator cap tester adapter

90890-01352

Pressure tester adapter

YU-33984

Test pressure value

196 kPa (1.96 kg/cm

2, 27.9 psi)

Clutch lever free play

7.0–12.0 mm (0.28–0.47 in)

Direction “a”

Clutch lever free play is increased.

Direction “b”

Clutch lever free play is decreased.

Page 232 of 432

ENGINE REMOVAL

6-3

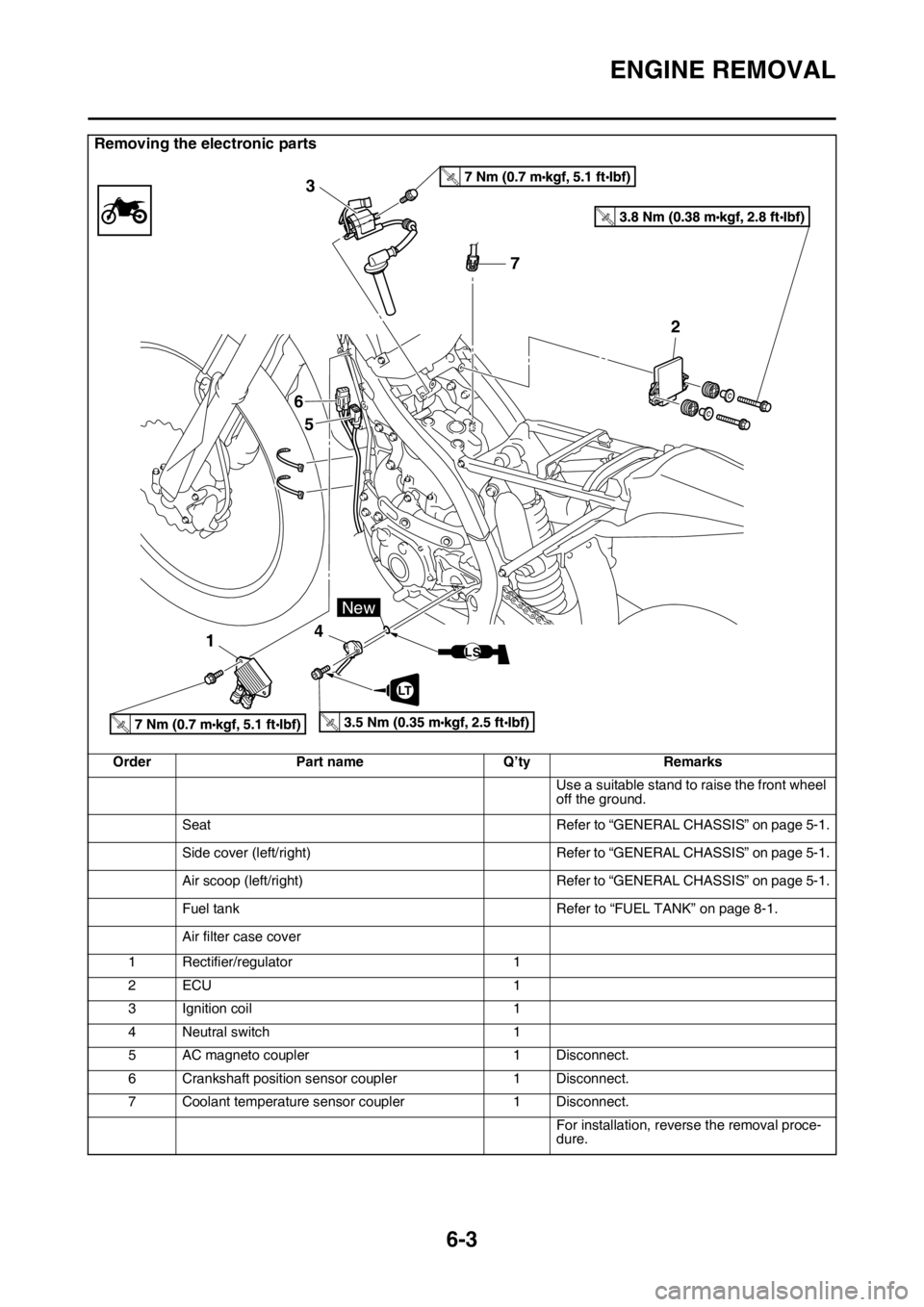

Removing the electronic parts

Order Part name Q’ty Remarks

Use a suitable stand to raise the front wheel

off the ground.

Seat Refer to “GENERAL CHASSIS” on page 5-1.

Side cover (left/right) Refer to “GENERAL CHASSIS” on page 5-1.

Air scoop (left/right) Refer to “GENERAL CHASSIS” on page 5-1.

Fuel tank Refer to “FUEL TANK” on page 8-1.

Air filter case cover

1 Rectifier/regulator 1

2ECU 1

3 Ignition coil 1

4 Neutral switch 1

5 AC magneto coupler 1 Disconnect.

6 Crankshaft position sensor coupler 1 Disconnect.

7 Coolant temperature sensor coupler 1 Disconnect.

For installation, reverse the removal proce-

dure.

T.R.

T.R.

T.R.T.R.

7 3

6

5

142

LT

New

LS

Page 249 of 432

CYLINDER HEAD

6-20

EAS2GBB244

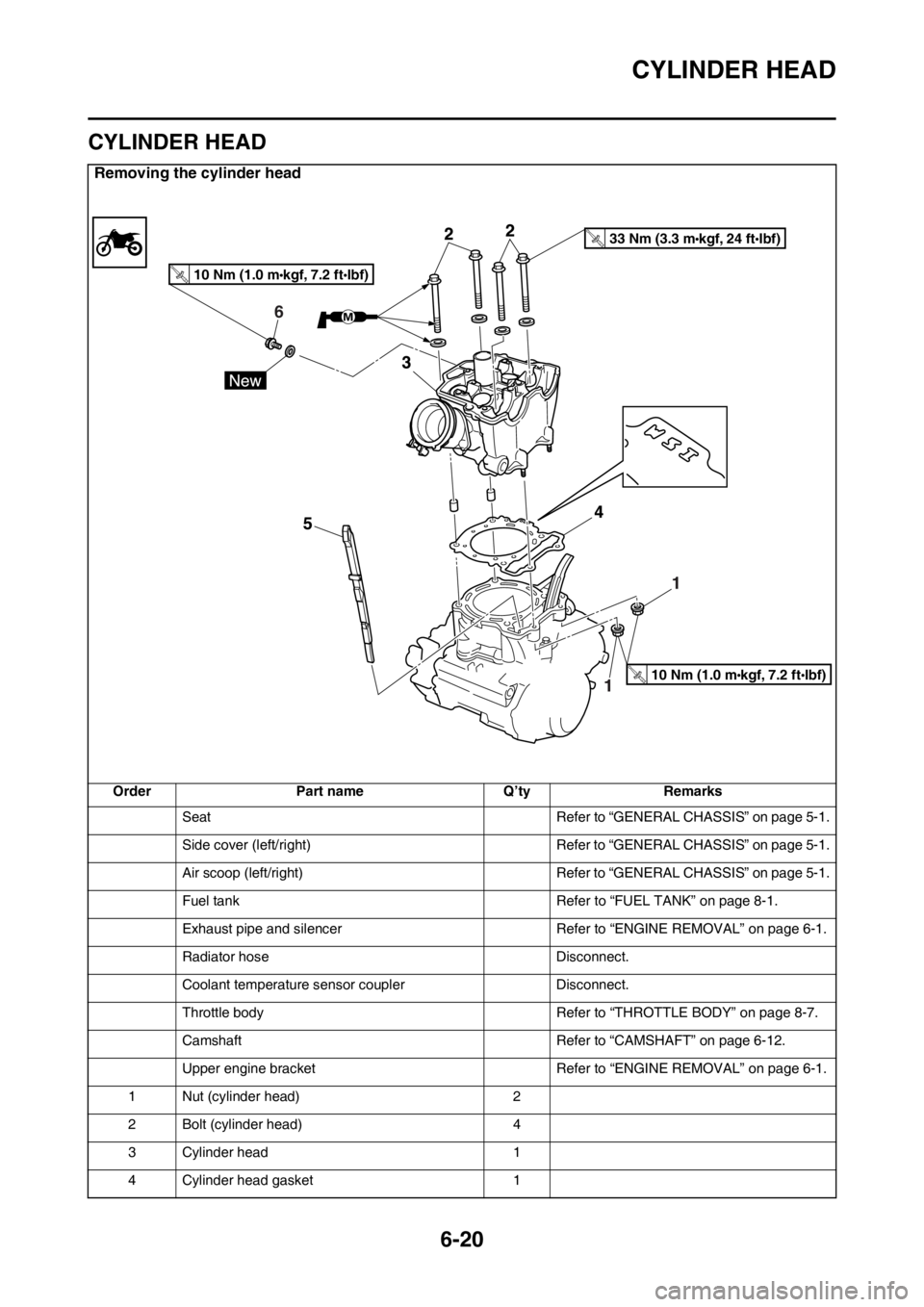

CYLINDER HEAD

Removing the cylinder head

Order Part name Q’ty Remarks

Seat Refer to “GENERAL CHASSIS” on page 5-1.

Side cover (left/right) Refer to “GENERAL CHASSIS” on page 5-1.

Air scoop (left/right) Refer to “GENERAL CHASSIS” on page 5-1.

Fuel tank Refer to “FUEL TANK” on page 8-1.

Exhaust pipe and silencer Refer to “ENGINE REMOVAL” on page 6-1.

Radiator hose Disconnect.

Coolant temperature sensor coupler Disconnect.

Throttle body Refer to “THROTTLE BODY” on page 8-7.

Camshaft Refer to “CAMSHAFT” on page 6-12.

Upper engine bracket Refer to “ENGINE REMOVAL” on page 6-1.

1 Nut (cylinder head) 2

2 Bolt (cylinder head) 4

3 Cylinder head 1

4 Cylinder head gasket 1

6

10 Nm (1.0 m kgf, 7.2 ft Ibf)T.R.

33 Nm (3.3 m kgf, 24 ft Ibf)T.R.

10 Nm (1.0 m kgf, 7.2 ft Ibf)T.R.

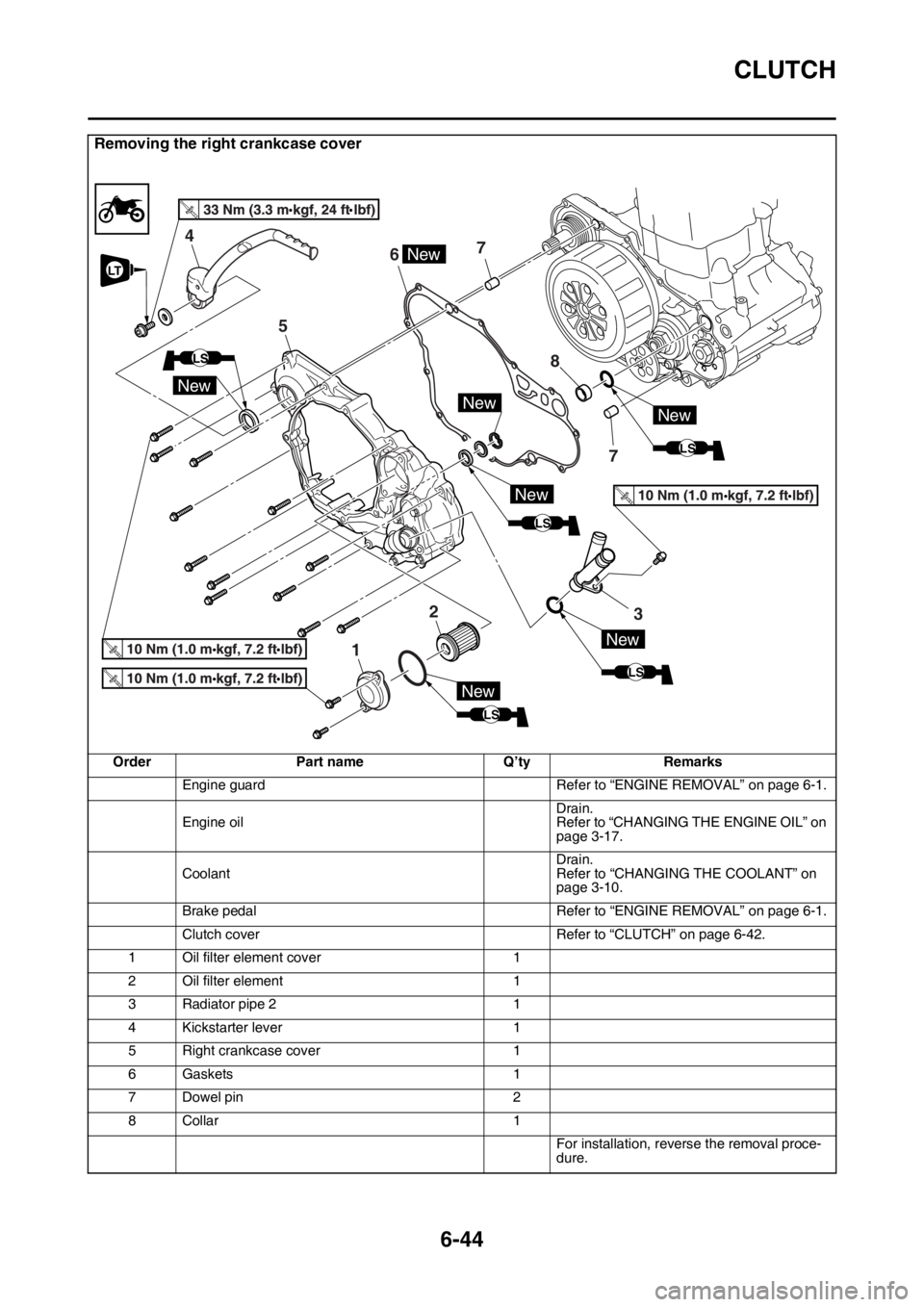

Page 273 of 432

CLUTCH

6-44

Removing the right crankcase cover

Order Part name Q’ty Remarks

Engine guard Refer to “ENGINE REMOVAL” on page 6-1.

Engine oilDrain.

Refer to “CHANGING THE ENGINE OIL” on

page 3-17.

CoolantDrain.

Refer to “CHANGING THE COOLANT” on

page 3-10.

Brake pedal Refer to “ENGINE REMOVAL” on page 6-1.

Clutch cover Refer to “CLUTCH” on page 6-42.

1 Oil filter element cover 1

2 Oil filter element 1

3 Radiator pipe 2 1

4 Kickstarter lever 1

5 Right crankcase cover 1

6 Gaskets 1

7 Dowel pin 2

8Collar 1

For installation, reverse the removal proce-

dure.

T.R.

LS

New

New

67

2

5

4

1

7 8

New

3

LS

New

New

LS

NewNew

LT

LS

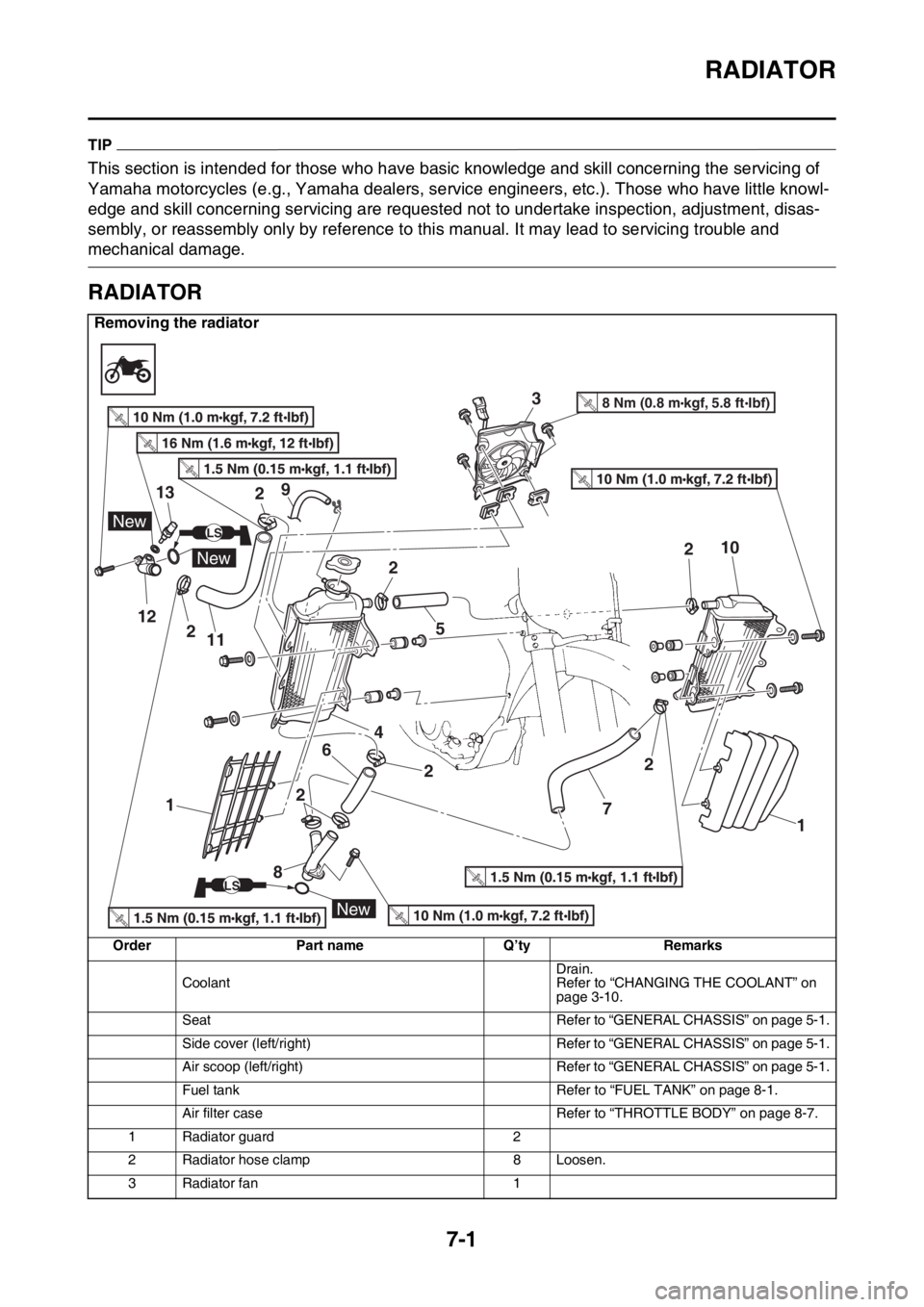

Page 316 of 432

RADIATOR

7-1

EAS2GBB328

TIP

This section is intended for those who have basic knowledge and skill concerning the servicing of

Yamaha motorcycles (e.g., Yamaha dealers, service engineers, etc.). Those who have little knowl-

edge and skill concerning servicing are requested not to undertake inspection, adjustment, disas-

sembly, or reassembly only by reference to this manual. It may lead to servicing trouble and

mechanical damage.

EAS2GBB329

RADIATOR

Removing the radiator

Order Part name Q’ty Remarks

CoolantDrain.

Refer to “CHANGING THE COOLANT” on

page 3-10.

Seat Refer to “GENERAL CHASSIS” on page 5-1.

Side cover (left/right) Refer to “GENERAL CHASSIS” on page 5-1.

Air scoop (left/right) Refer to “GENERAL CHASSIS” on page 5-1.

Fuel tank Refer to “FUEL TANK” on page 8-1.

Air filter case Refer to “THROTTLE BODY” on page 8-7.

1 Radiator guard 2

2 Radiator hose clamp 8 Loosen.

3 Radiator fan 1

12

13

New

New

New

LS

LS

3

458 Nm (0.8 m kgf, 5.8 ft Ibf)T.R.

6

7

89

10

112

2

2

2 22 2

1 1

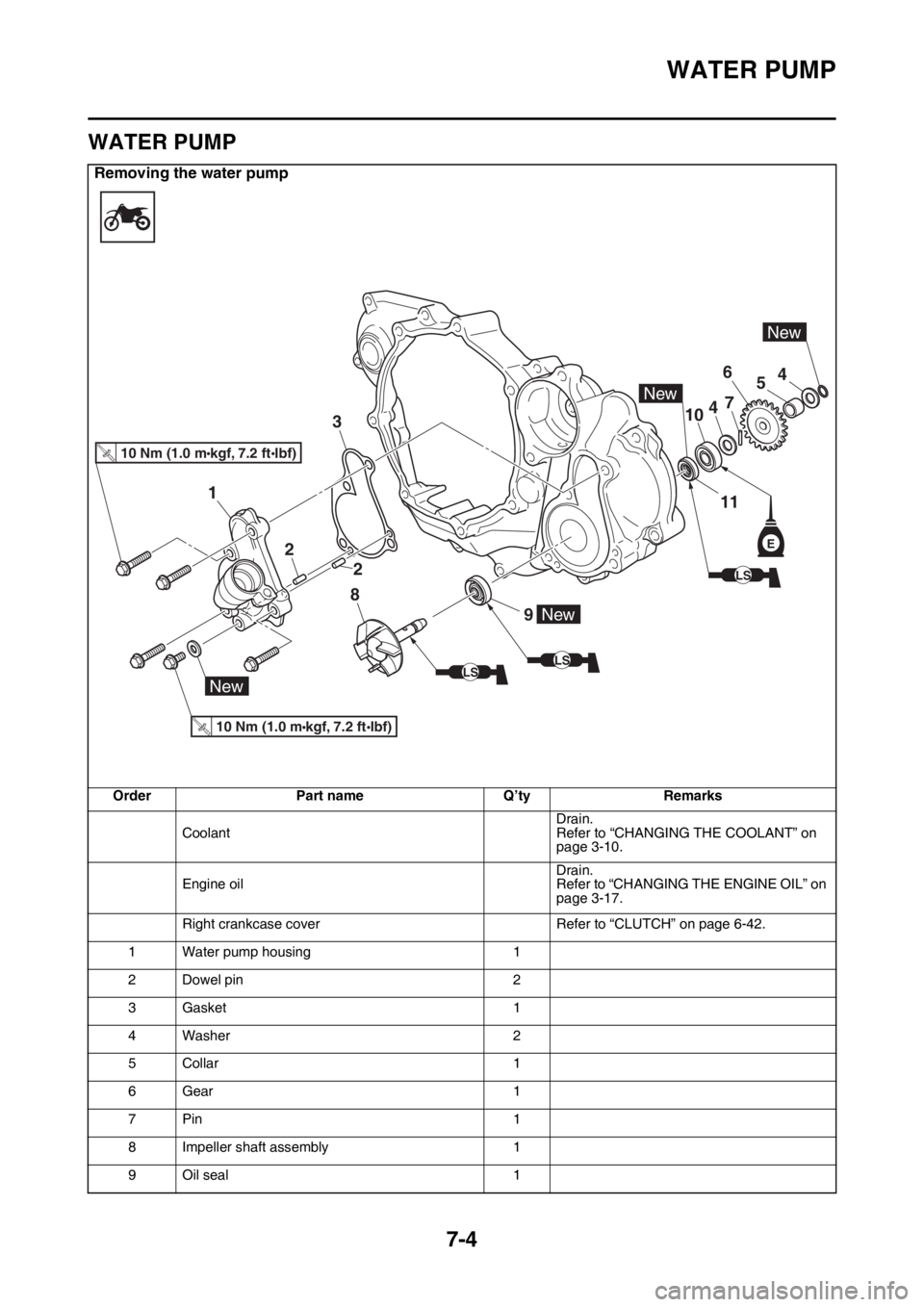

Page 319 of 432

WATER PUMP

7-4

EAS2GBB332

WATER PUMP

Removing the water pump

Order Part name Q’ty Remarks

CoolantDrain.

Refer to “CHANGING THE COOLANT” on

page 3-10.

Engine oilDrain.

Refer to “CHANGING THE ENGINE OIL” on

page 3-17.

Right crankcase cover Refer to “CLUTCH” on page 6-42.

1 Water pump housing 1

2 Dowel pin 2

3Gasket 1

4Washer 2

5Collar 1

6Gear 1

7Pin 1

8 Impeller shaft assembly 1

9 Oil seal 1

9

8

2

2

3

1

10

6

7

5

4

4

10 Nm (1.0 mkgf, 7.2 ftIbf)T.R.

10 Nm (1.0 mkgf, 7.2 ftIbf)T.R.

New

New

New

11

New

E

LS

LS

LS

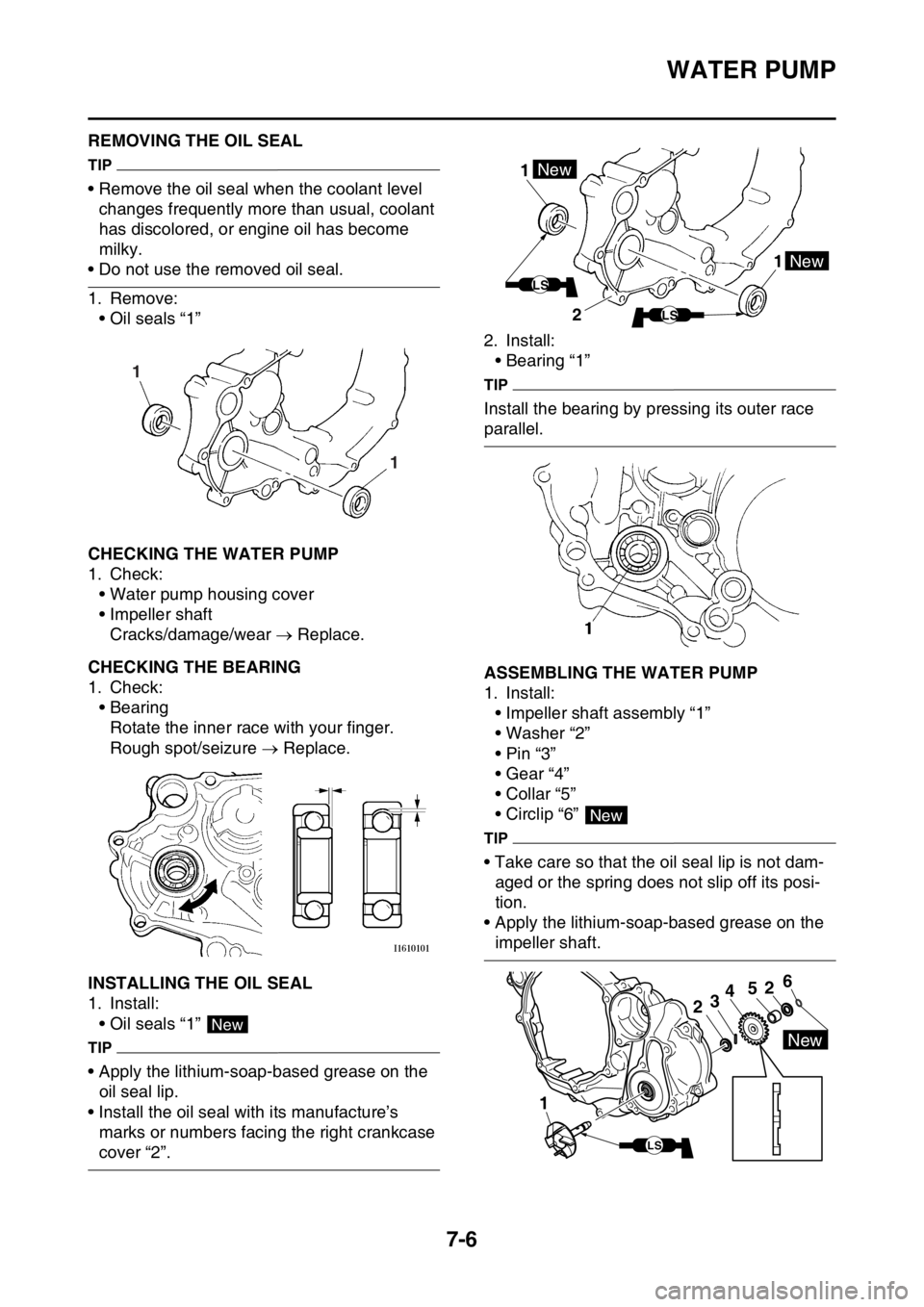

Page 321 of 432

WATER PUMP

7-6

EAS2GBB333REMOVING THE OIL SEAL

TIP

• Remove the oil seal when the coolant level

changes frequently more than usual, coolant

has discolored, or engine oil has become

milky.

• Do not use the removed oil seal.

1. Remove:

• Oil seals “1”

EAS2GBB334CHECKING THE WATER PUMP

1. Check:

• Water pump housing cover

• Impeller shaft

Cracks/damage/wear Replace.

EAS2GBB335CHECKING THE BEARING

1. Check:

• Bearing

Rotate the inner race with your finger.

Rough spot/seizure Replace.

EAS2GBB336INSTALLING THE OIL SEAL

1. Install:

• Oil seals “1”

TIP

• Apply the lithium-soap-based grease on the

oil seal lip.

• Install the oil seal with its manufacture’s

marks or numbers facing the right crankcase

cover “2”.2. Install:

• Bearing “1”

TIP

Install the bearing by pressing its outer race

parallel.

EAS2GBB337ASSEMBLING THE WATER PUMP

1. Install:

• Impeller shaft assembly “1”

• Washer “2”

•Pin “3”

• Gear “4”

• Collar “5”

• Circlip “6”

TIP

• Take care so that the oil seal lip is not dam-

aged or the spring does not slip off its posi-

tion.

• Apply the lithium-soap-based grease on the

impeller shaft.

1 1

New

1 1New

New

LS

LS2

New

1

2

52346

New

LS

Page 361 of 432

COOLING SYSTEM

9-25

1. Joint connector

2. Joint connector

3. Joint connector

7. Main relay

9. Battery

10.Frame ground

11.Starter relay

12.Main fuse

22.ECU (engine control unit)

27.Radiator fan motor relay

28.Radiator fan motor fuse

29.Radiator fan motor

30.Joint connector

32.Coolant temperature sensor

48.Frame ground

Page 365 of 432

FUEL INJECTION SYSTEM

9-29

1. Joint connector

2. Joint connector

3. Joint connector

4. AC magneto

7. Main relay

9. Battery

10.Frame ground

11.Starter relay

12.Main fuse

15.Indicator light

16.Engine trouble warning light

22.ECU (engine control unit)

25.Injector

30.Joint connector

31.Intake air temperature sensor

32.Coolant temperature sensor

33.Throttle position sensor

34.Intake air pressure sensor

35.Lean angle sensor

36.Engine stop switch

37.Neutral switch

38.Diode

39.Starting circuit cut-off relay

40.Clutch switch

42.Joint connector

48.Frame ground