check engine YAMAHA WR 250F 2017 Service Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2017, Model line: WR 250F, Model: YAMAHA WR 250F 2017Pages: 432, PDF Size: 14.14 MB

Page 292 of 432

OIL PUMP AND BALANCER GEAR

6-63

3. Check:

• Oil pump operation

Rough movement Repeat steps (1) and

(2) or replace the defective part(s).

EAS2GBB303ASSEMBLING THE OIL PUMP

1. Install:

• Oil pump drive shaft “1”

• Inner rotor “2”

• Dowel pin “3”

TIP

• Apply the engine oil on the oil pump drive

shaft and inner rotor.

• Fit the dowel pin into the groove in the inner

rotor.

2. Install:

• Outer rotor “1”

TIP

Apply the engine oil on the outer rotor.

3. Install:

• Oil pump cover “1”

• Oil pump cover screw “2”

EAS2GBB304INSTALLING THE OIL PUMP AND BALANC-

ER GEAR

1. Install:

• Oil pump assembly “1”

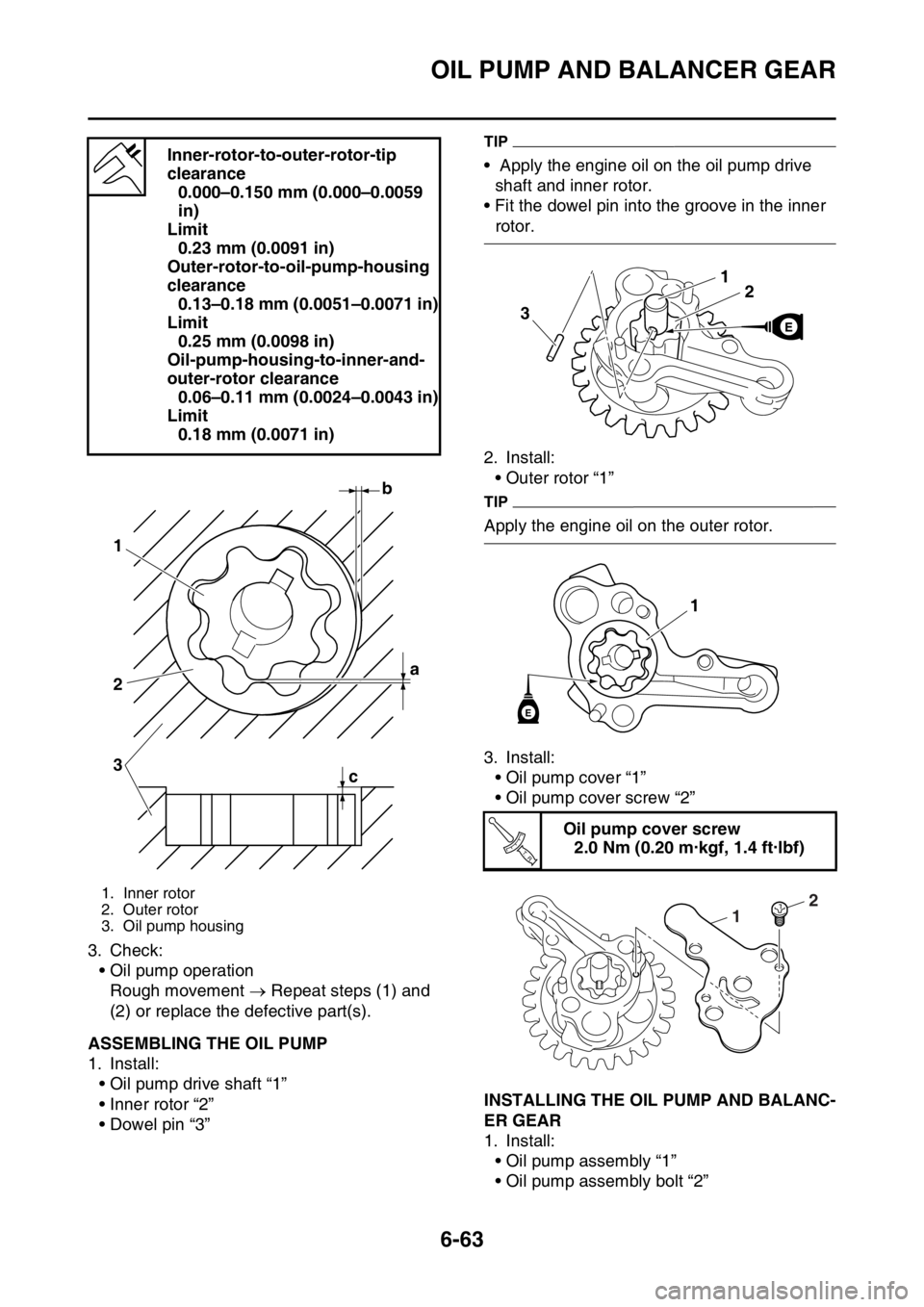

• Oil pump assembly bolt “2” Inner-rotor-to-outer-rotor-tip

clearance

0.000–0.150 mm (0.000–0.0059

in)

Limit

0.23 mm (0.0091 in)

Outer-rotor-to-oil-pump-housing

clearance

0.13–0.18 mm (0.0051–0.0071 in)

Limit

0.25 mm (0.0098 in)

Oil-pump-housing-to-inner-and-

outer-rotor clearance

0.06–0.11 mm (0.0024–0.0043 in)

Limit

0.18 mm (0.0071 in)

1. Inner rotor

2. Outer rotor

3. Oil pump housing

b

a 1

2

3

c

Oil pump cover screw

2.0 Nm (0.20 m·kgf, 1.4 ft·lbf)

21

3

1

E

T R..

2

1

Page 304 of 432

CRANKCASE

6-75

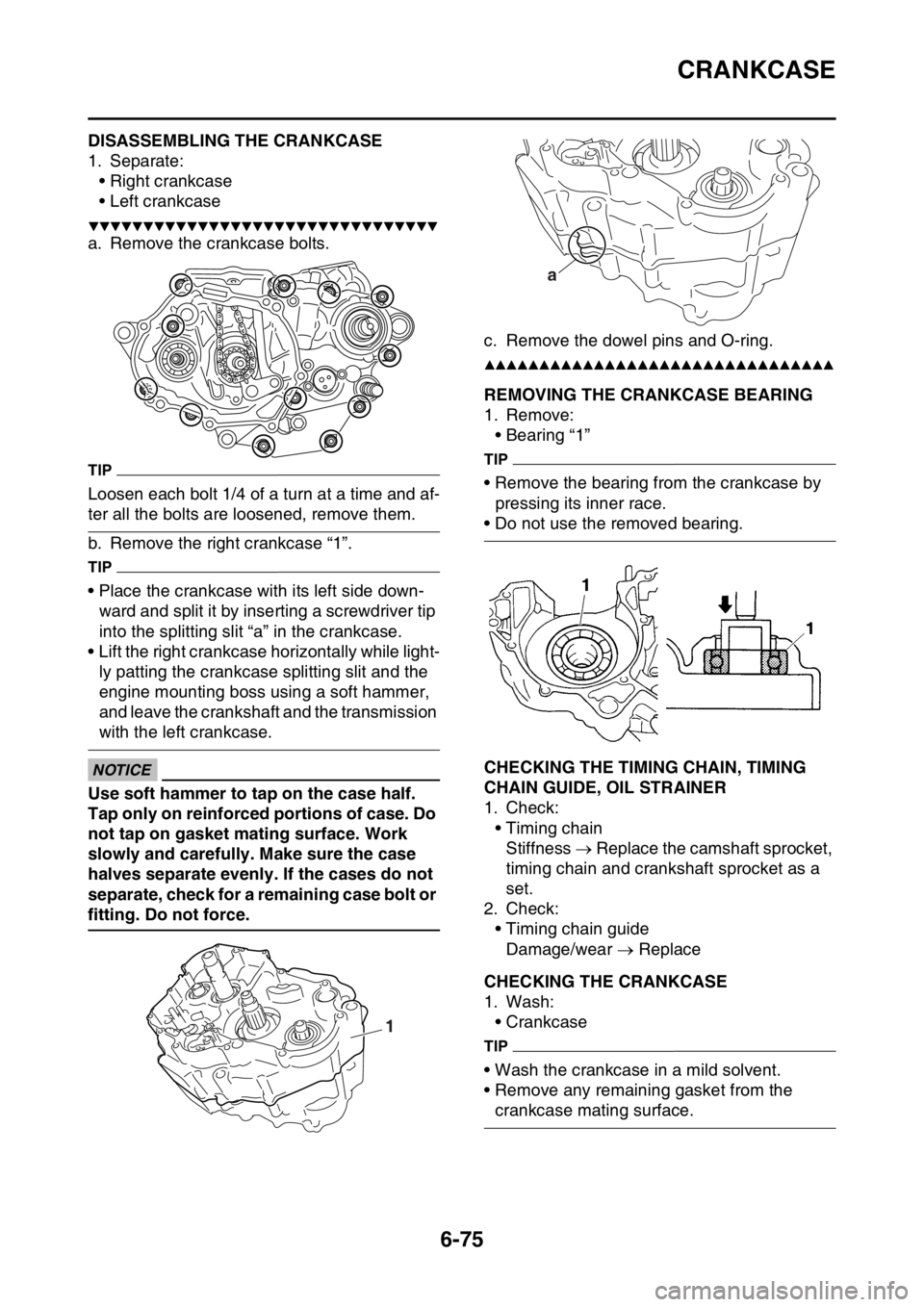

EAS2GBB311DISASSEMBLING THE CRANKCASE

1. Separate:

• Right crankcase

• Left crankcase

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the crankcase bolts.

TIP

Loosen each bolt 1/4 of a turn at a time and af-

ter all the bolts are loosened, remove them.

b. Remove the right crankcase “1”.

TIP

• Place the crankcase with its left side down-

ward and split it by inserting a screwdriver tip

into the splitting slit “a” in the crankcase.

• Lift the right crankcase horizontally while light-

ly patting the crankcase splitting slit and the

engine mounting boss using a soft hammer,

and leave the crankshaft and the transmission

with the left crankcase.

ECA

NOTICE

Use soft hammer to tap on the case half.

Tap only on reinforced portions of case. Do

not tap on gasket mating surface. Work

slowly and carefully. Make sure the case

halves separate evenly. If the cases do not

separate, check for a remaining case bolt or

fitting. Do not force.c. Remove the dowel pins and O-ring.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GBB312REMOVING THE CRANKCASE BEARING

1. Remove:

• Bearing “1”

TIP

• Remove the bearing from the crankcase by

pressing its inner race.

• Do not use the removed bearing.

EAS2GBB313CHECKING THE TIMING CHAIN, TIMING

CHAIN GUIDE, OIL STRAINER

1. Check:

• Timing chain

Stiffness Replace the camshaft sprocket,

timing chain and crankshaft sprocket as a

set.

2. Check:

• Timing chain guide

Damage/wear Replace

EAS2GBB314CHECKING THE CRANKCASE

1. Wash:

• Crankcase

TIP

• Wash the crankcase in a mild solvent.

• Remove any remaining gasket from the

crankcase mating surface.

1

a

Page 314 of 432

TRANSMISSION

6-85

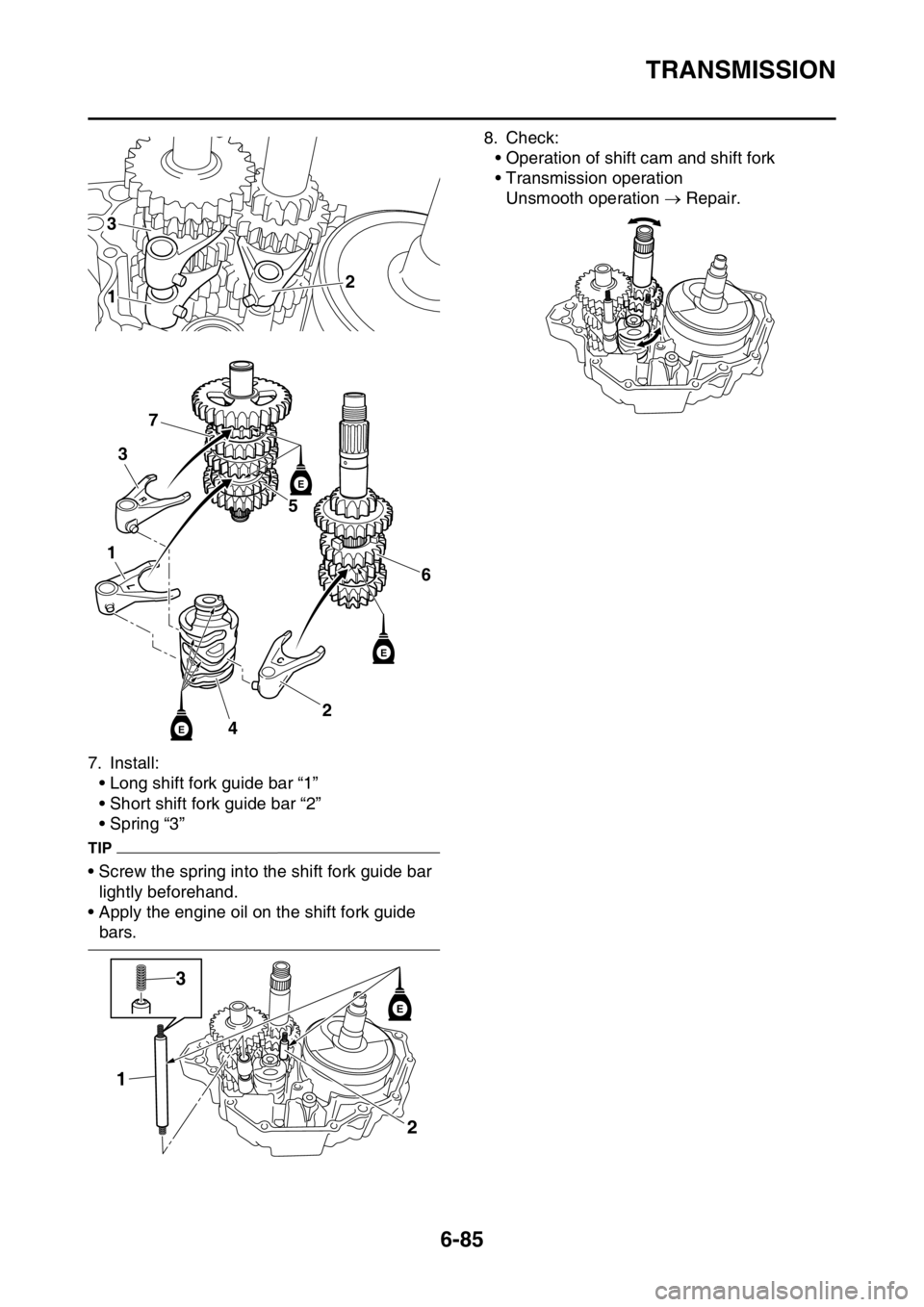

7. Install:

• Long shift fork guide bar “1”

• Short shift fork guide bar “2”

• Spring “3”

TIP

• Screw the spring into the shift fork guide bar

lightly beforehand.

• Apply the engine oil on the shift fork guide

bars.8. Check:

• Operation of shift cam and shift fork

• Transmission operation

Unsmooth operation Repair.

3

12

6

2

4

5

3

7

1

E

E

E

2 13

E

Page 321 of 432

WATER PUMP

7-6

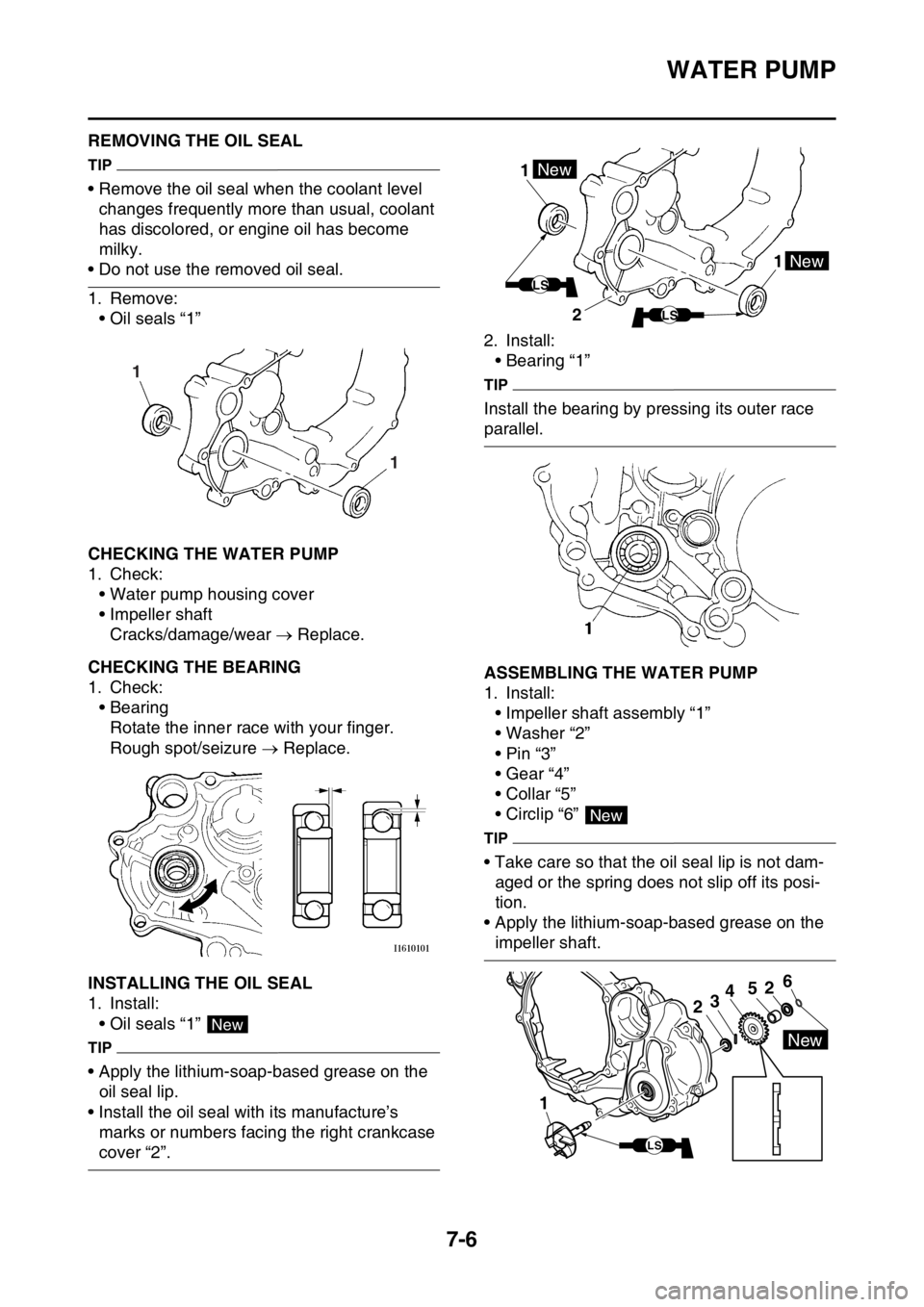

EAS2GBB333REMOVING THE OIL SEAL

TIP

• Remove the oil seal when the coolant level

changes frequently more than usual, coolant

has discolored, or engine oil has become

milky.

• Do not use the removed oil seal.

1. Remove:

• Oil seals “1”

EAS2GBB334CHECKING THE WATER PUMP

1. Check:

• Water pump housing cover

• Impeller shaft

Cracks/damage/wear Replace.

EAS2GBB335CHECKING THE BEARING

1. Check:

• Bearing

Rotate the inner race with your finger.

Rough spot/seizure Replace.

EAS2GBB336INSTALLING THE OIL SEAL

1. Install:

• Oil seals “1”

TIP

• Apply the lithium-soap-based grease on the

oil seal lip.

• Install the oil seal with its manufacture’s

marks or numbers facing the right crankcase

cover “2”.2. Install:

• Bearing “1”

TIP

Install the bearing by pressing its outer race

parallel.

EAS2GBB337ASSEMBLING THE WATER PUMP

1. Install:

• Impeller shaft assembly “1”

• Washer “2”

•Pin “3”

• Gear “4”

• Collar “5”

• Circlip “6”

TIP

• Take care so that the oil seal lip is not dam-

aged or the spring does not slip off its posi-

tion.

• Apply the lithium-soap-based grease on the

impeller shaft.

1 1

New

1 1New

New

LS

LS2

New

1

2

52346

New

LS

Page 328 of 432

FUEL TANK

8-5

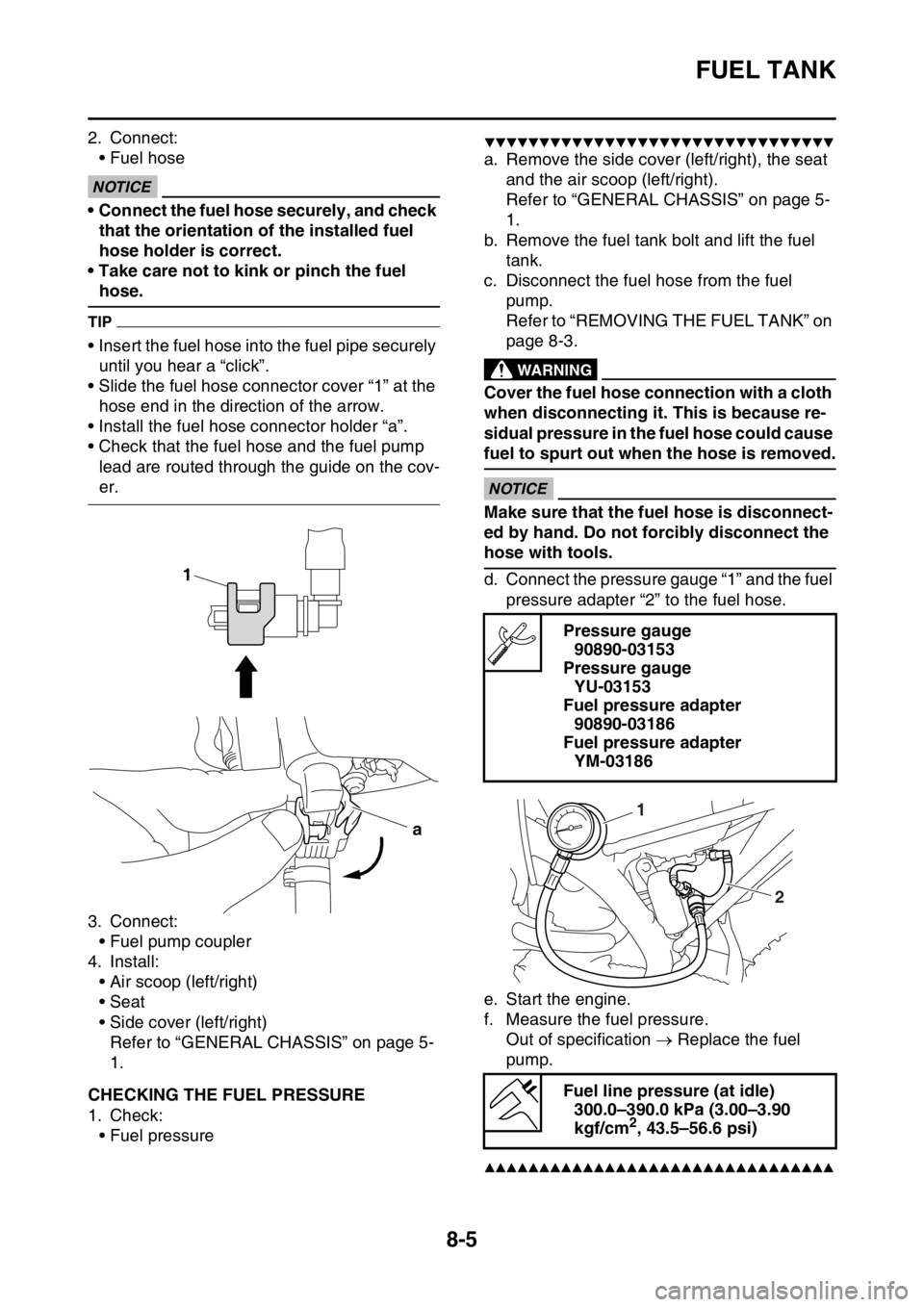

2. Connect:

• Fuel hose

ECA

NOTICE

• Connect the fuel hose securely, and check

that the orientation of the installed fuel

hose holder is correct.

• Take care not to kink or pinch the fuel

hose.

TIP

• Insert the fuel hose into the fuel pipe securely

until you hear a “click”.

• Slide the fuel hose connector cover “1” at the

hose end in the direction of the arrow.

• Install the fuel hose connector holder “a”.

• Check that the fuel hose and the fuel pump

lead are routed through the guide on the cov-

er.

3. Connect:

• Fuel pump coupler

4. Install:

• Air scoop (left/right)

• Seat

• Side cover (left/right)

Refer to “GENERAL CHASSIS” on page 5-

1.

EAS2GBB348CHECKING THE FUEL PRESSURE

1. Check:

• Fuel pressure

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the side cover (left/right), the seat

and the air scoop (left/right).

Refer to “GENERAL CHASSIS” on page 5-

1.

b. Remove the fuel tank bolt and lift the fuel

tank.

c. Disconnect the fuel hose from the fuel

pump.

Refer to “REMOVING THE FUEL TANK” on

page 8-3.

EWA

WARNING

Cover the fuel hose connection with a cloth

when disconnecting it. This is because re-

sidual pressure in the fuel hose could cause

fuel to spurt out when the hose is removed.

ECA

NOTICE

Make sure that the fuel hose is disconnect-

ed by hand. Do not forcibly disconnect the

hose with tools.

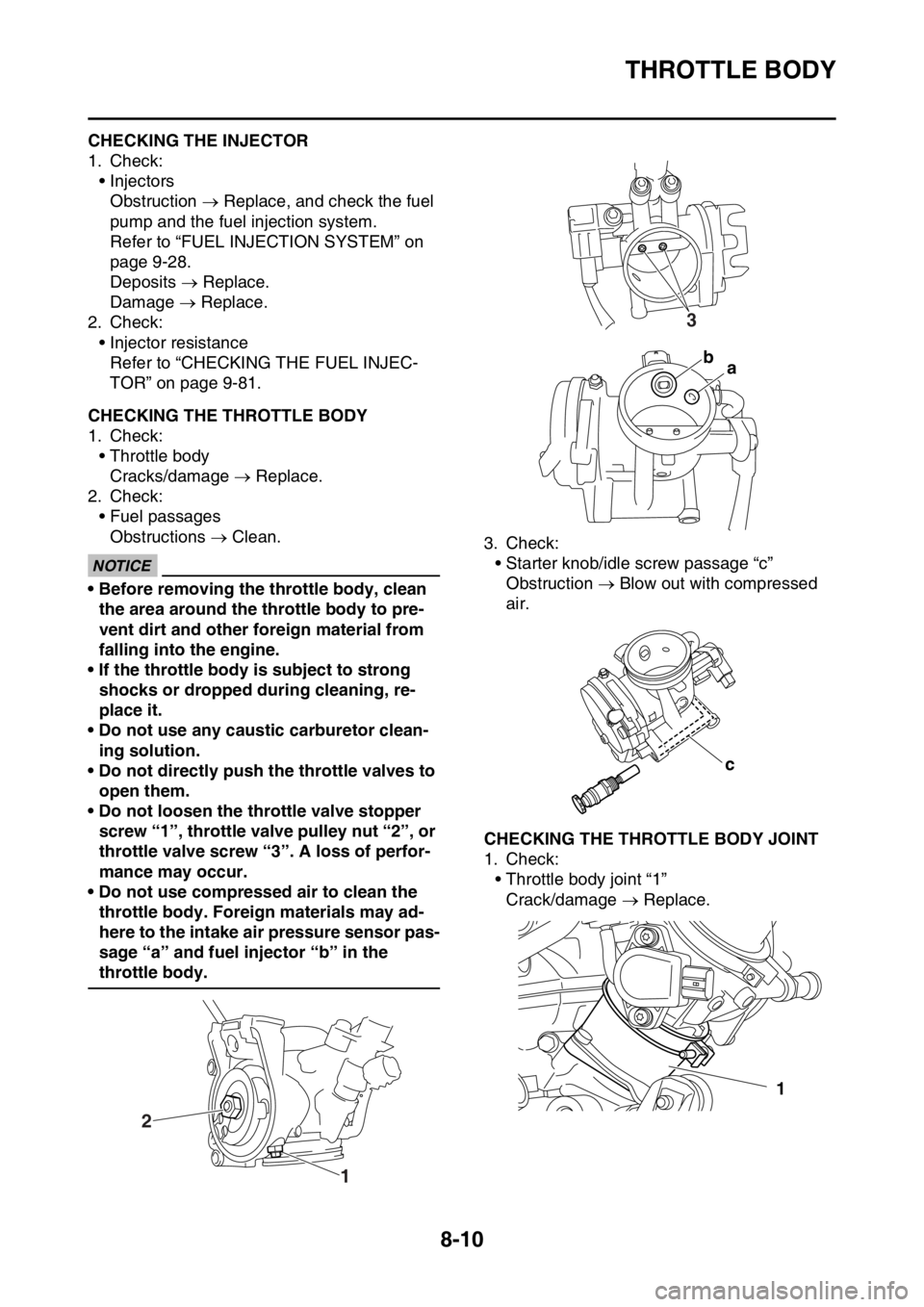

d. Connect the pressure gauge “1” and the fuel

pressure adapter “2” to the fuel hose.

e. Start the engine.

f. Measure the fuel pressure.

Out of specification Replace the fuel

pump.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

1

a

Pressure gauge

90890-03153

Pressure gauge

YU-03153

Fuel pressure adapter

90890-03186

Fuel pressure adapter

YM-03186

Fuel line pressure (at idle)

300.0–390.0 kPa (3.00–3.90

kgf/cm

2, 43.5–56.6 psi)

1

2

Page 333 of 432

THROTTLE BODY

8-10

EAS2GBB352CHECKING THE INJECTOR

1. Check:

• Injectors

Obstruction Replace, and check the fuel

pump and the fuel injection system.

Refer to “FUEL INJECTION SYSTEM” on

page 9-28.

Deposits Replace.

Damage Replace.

2. Check:

• Injector resistance

Refer to “CHECKING THE FUEL INJEC-

TOR” on page 9-81.

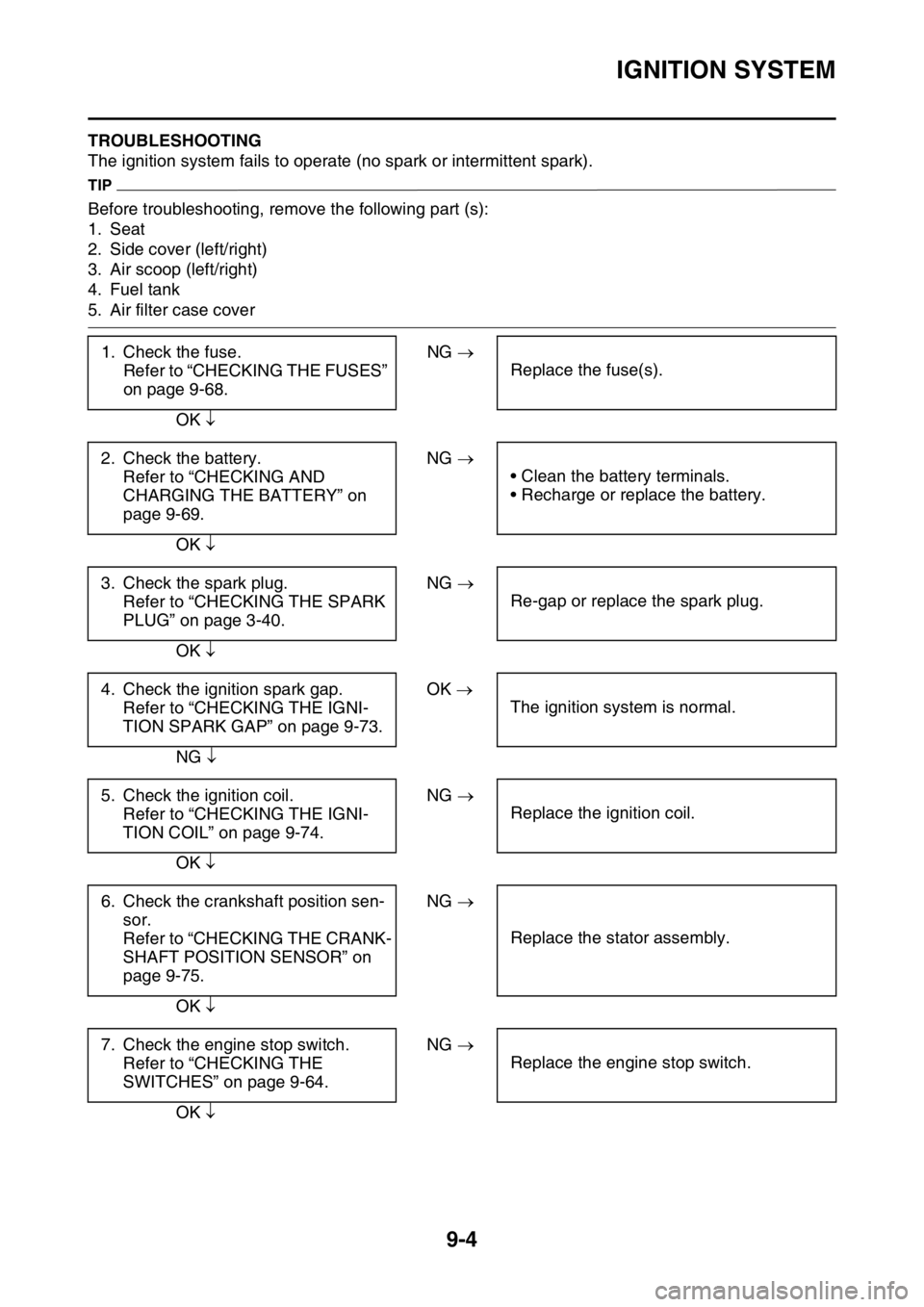

EAS2GBB353CHECKING THE THROTTLE BODY

1. Check:

• Throttle body

Cracks/damage Replace.

2. Check:

• Fuel passages

Obstructions Clean.

ECA

NOTICE

• Before removing the throttle body, clean

the area around the throttle body to pre-

vent dirt and other foreign material from

falling into the engine.

• If the throttle body is subject to strong

shocks or dropped during cleaning, re-

place it.

• Do not use any caustic carburetor clean-

ing solution.

• Do not directly push the throttle valves to

open them.

• Do not loosen the throttle valve stopper

screw “1”, throttle valve pulley nut “2”, or

throttle valve screw “3”. A loss of perfor-

mance may occur.

• Do not use compressed air to clean the

throttle body. Foreign materials may ad-

here to the intake air pressure sensor pas-

sage “a” and fuel injector “b” in the

throttle body.3. Check:

• Starter knob/idle screw passage “c”

Obstruction Blow out with compressed

air.

EAS2GBB354CHECKING THE THROTTLE BODY JOINT

1. Check:

• Throttle body joint “1”

Crack/damage Replace.

1 2

3

ba

c

1

Page 340 of 432

IGNITION SYSTEM

9-4

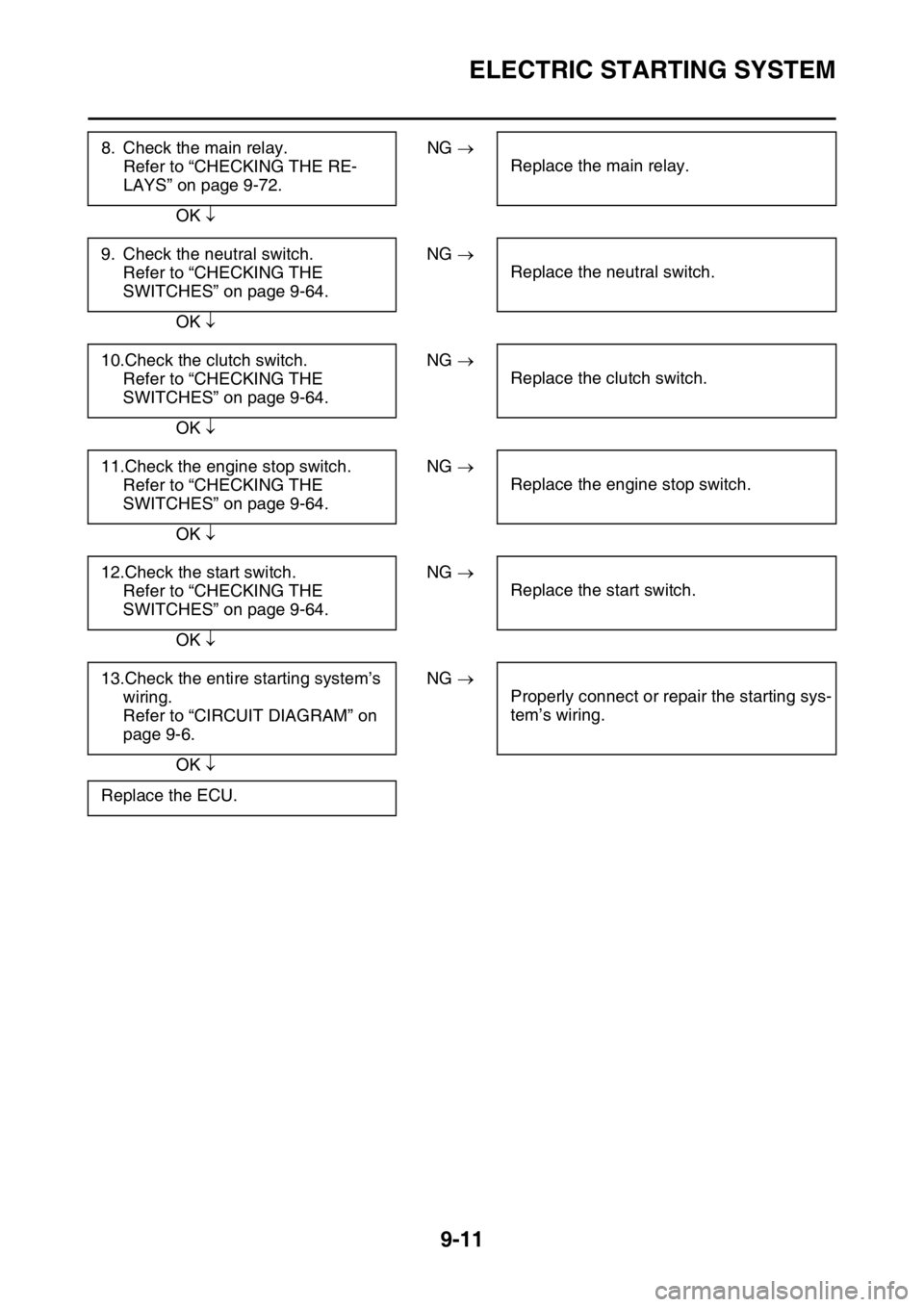

EAS2GBB359TROUBLESHOOTING

The ignition system fails to operate (no spark or intermittent spark).

TIP

Before troubleshooting, remove the following part (s):

1. Seat

2. Side cover (left/right)

3. Air scoop (left/right)

4. Fuel tank

5. Air filter case cover

1. Check the fuse.

Refer to “CHECKING THE FUSES”

on page 9-68.NG

Replace the fuse(s).

OK

2. Check the battery.

Refer to “CHECKING AND

CHARGING THE BATTERY” on

page 9-69.NG

• Clean the battery terminals.

• Recharge or replace the battery.

OK

3. Check the spark plug.

Refer to “CHECKING THE SPARK

PLUG” on page 3-40.NG

Re-gap or replace the spark plug.

OK

4. Check the ignition spark gap.

Refer to “CHECKING THE IGNI-

TION SPARK GAP” on page 9-73.OK

The ignition system is normal.

NG

5. Check the ignition coil.

Refer to “CHECKING THE IGNI-

TION COIL” on page 9-74.NG

Replace the ignition coil.

OK

6. Check the crankshaft position sen-

sor.

Refer to “CHECKING THE CRANK-

SHAFT POSITION SENSOR” on

page 9-75.NG

Replace the stator assembly.

OK

7. Check the engine stop switch.

Refer to “CHECKING THE

SWITCHES” on page 9-64.NG

Replace the engine stop switch.

OK

Page 347 of 432

ELECTRIC STARTING SYSTEM

9-11

8. Check the main relay.

Refer to “CHECKING THE RE-

LAYS” on page 9-72.NG

Replace the main relay.

OK

9. Check the neutral switch.

Refer to “CHECKING THE

SWITCHES” on page 9-64.NG

Replace the neutral switch.

OK

10.Check the clutch switch.

Refer to “CHECKING THE

SWITCHES” on page 9-64.NG

Replace the clutch switch.

OK

11.Check the engine stop switch.

Refer to “CHECKING THE

SWITCHES” on page 9-64.NG

Replace the engine stop switch.

OK

12.Check the start switch.

Refer to “CHECKING THE

SWITCHES” on page 9-64.NG

Replace the start switch.

OK

13.Check the entire starting system’s

wiring.

Refer to “CIRCUIT DIAGRAM” on

page 9-6.NG

Properly connect or repair the starting sys-

tem’s wiring.

OK

Replace the ECU.

Page 366 of 432

FUEL INJECTION SYSTEM

9-30

EAS2GBB374ECU SELF-DIAGNOSTIC FUNCTION

The ECU is equipped with a self-diagnostic function in order to ensure that the fuel injection system

is operating normally. If this function detects a malfunction in the system, it immediately operates the

engine under substitute characteristics and illuminates the engine trouble warning light to alert the

rider that a malfunction has occurred in the system. Once a malfunction has been detected, a fault

code number is stored in the memory of the ECU.

• To inform the rider that the fuel injection system is not functioning, the engine trouble warning light

flashes while the start switch is being pushed to start the engine.

• If a malfunction is detected in the system by the self-diagnostic function, the ECU provides an ap-

propriate substitute characteristic operation, and alerts the rider of the detected malfunction by illu-

minating the engine trouble warning light.

Engine trouble warning light indication and fuel injection system operation

* The warning light flashes when any one of the following conditions is present and the start switch

is pushed:

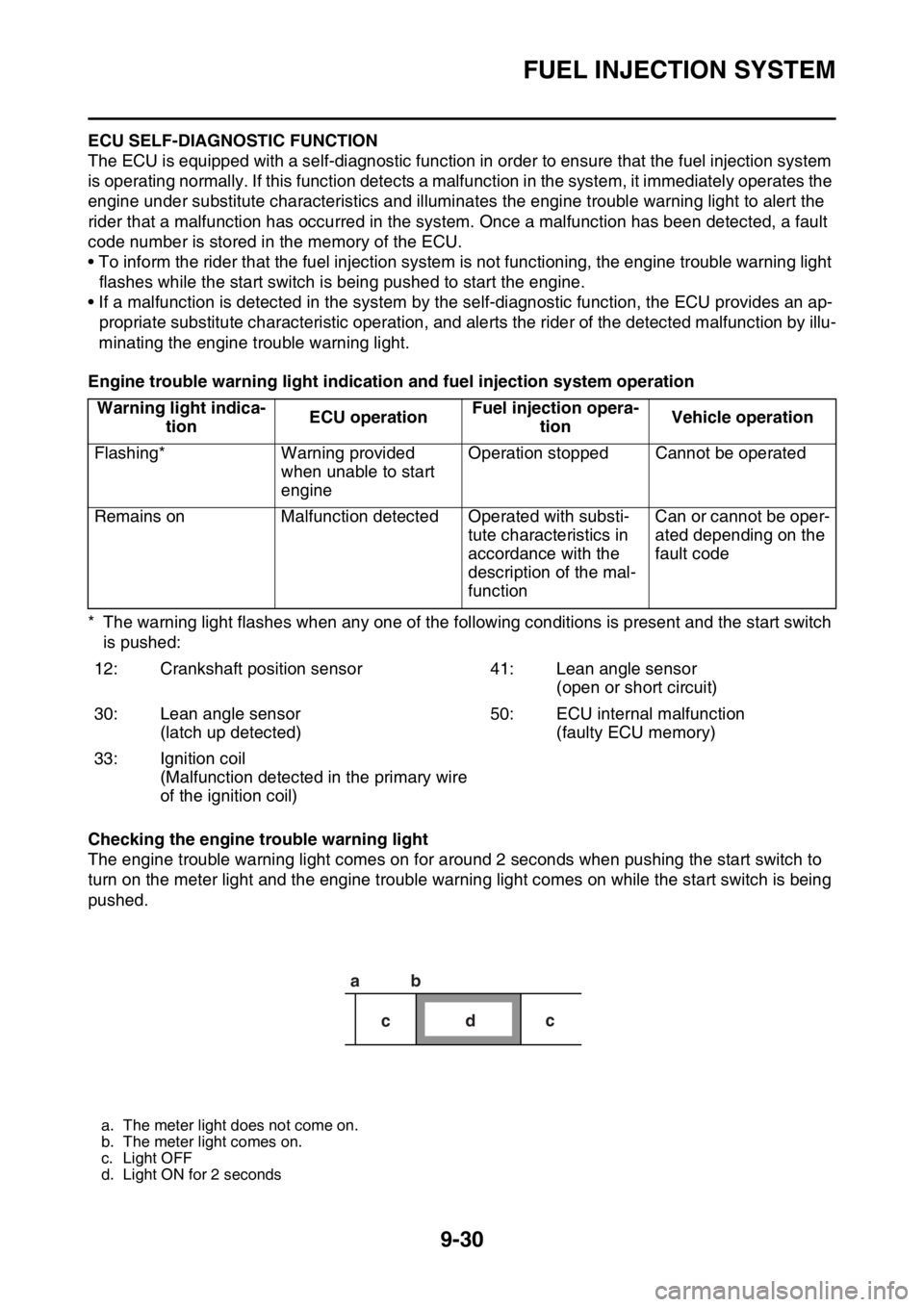

Checking the engine trouble warning light

The engine trouble warning light comes on for around 2 seconds when pushing the start switch to

turn on the meter light and the engine trouble warning light comes on while the start switch is being

pushed.Warning light indica-

tionECU operationFuel injection opera-

tionVehicle operation

Flashing* Warning provided

when unable to start

engineOperation stopped Cannot be operated

Remains on Malfunction detected Operated with substi-

tute characteristics in

accordance with the

description of the mal-

functionCan or cannot be oper-

ated depending on the

fault code

12: Crankshaft position sensor 41: Lean angle sensor

(open or short circuit)

30: Lean angle sensor

(latch up detected)50: ECU internal malfunction

(faulty ECU memory)

33: Ignition coil

(Malfunction detected in the primary wire

of the ignition coil)

a. The meter light does not come on.

b. The meter light comes on.

c. Light OFF

d. Light ON for 2 seconds

ab

cdc

Page 367 of 432

FUEL INJECTION SYSTEM

9-31

ECU detects an abnormal signal from a sensor

If the ECU detects an abnormal signal from a sensor while the vehicle is being driven, the ECU illu-

minates the engine trouble warning light and provides the engine with alternate operating instructions

that are appropriate for the type of malfunction.

When an abnormal signal is received from a sensor, the ECU processes the specified values that are

programmed for each sensor in order to provide the engine with alternate operating instructions that

enable the engine to continue operating or stop operating, depending on the conditions.

EAS2GBB375TROUBLESHOOTING METHOD

The engine operation is not normal and the engine trouble warning light comes on.

1. Check:

• Fault code number

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the Yamaha diagnostic tool. Refer to “YAMAHA DIAGNOSTIC TOOL” on page 9-32.

b. Check the fault code number displayed on the Yamaha diagnostic tool.

c. Identify the faulty system with the fault code number.

d. Identify the probable cause of the malfunction.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

2. Check and repair the probable cause of the malfunction.

3. Perform the reinstatement action for the fuel injection system. Refer to “Confirmation of service

completion” in the appropriate table in “TROUBLESHOOTING DETAILS” on page 9-35.

4. After pushing the engine stop switch, push the start switch to check whether the fault code number

is displayed.

TIP

If another fault code number is displayed, repeat steps (1) to (4) until no fault code number is dis-

played.

5. Erase the malfunction history in the diagnostic mode. Refer to “SENSOR OPERATION TABLE”

(Diagnostic code No.62).

TIP

Turning off the meter light will not erase the malfunction history.

The engine operation is not normal, but the engine trouble warning light does not come on.

1. Check the operation of the following sensors and actuators in the diagnostic mode. Refer to

“TROUBLESHOOTING DETAILS” on page 9-35.

If a malfunction is detected in the sensors or actuators, repair or replace all faulty parts.

If no malfunction is detected in the sensors and actuators, check and repair the inner parts of the

engine.Fault code No. No fault code No.

Check and repair. Refer to “TROUBLESHOOT-

ING DETAILS” on page 9-35.

Monitor the operation of the sensors and actua-

tors in the diagnostic mode. Refer to “TROU-

BLESHOOTING DETAILS” on page 9-35 and

“LIST OF SELF-DIAGNOSTIC AND FAIL-SAFE

ACTIONS” on page 10-5.Check and repair.

01: Throttle position sensor signal (throttle angle)

30: Ignition coil

36: Injector