check engine YAMAHA WR 250F 2017 Manual PDF

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2017, Model line: WR 250F, Model: YAMAHA WR 250F 2017Pages: 432, PDF Size: 14.14 MB

Page 394 of 432

FUEL PUMP SYSTEM

9-58

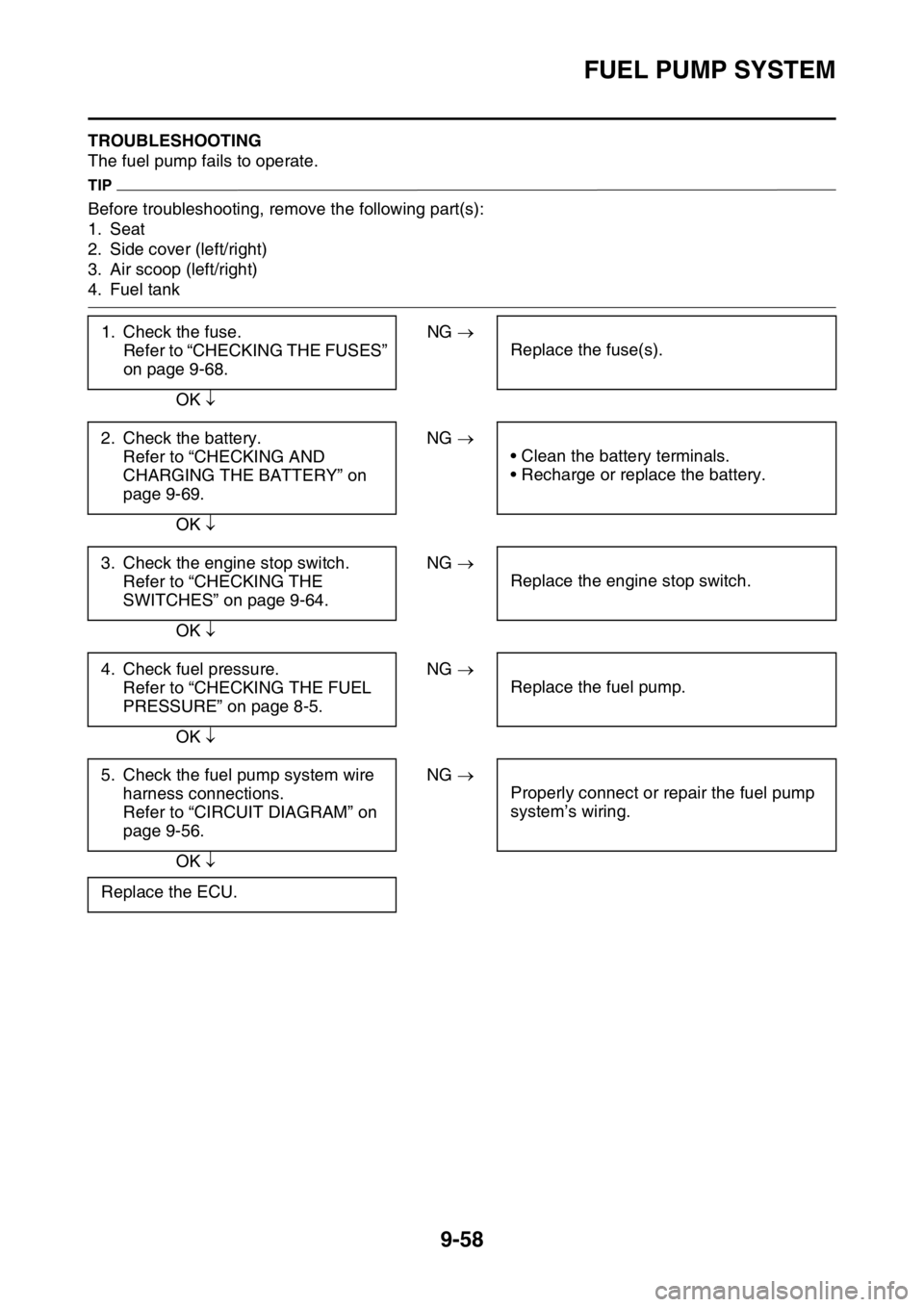

EAS2GBB380TROUBLESHOOTING

The fuel pump fails to operate.

TIP

Before troubleshooting, remove the following part(s):

1. Seat

2. Side cover (left/right)

3. Air scoop (left/right)

4. Fuel tank

1. Check the fuse.

Refer to “CHECKING THE FUSES”

on page 9-68.NG

Replace the fuse(s).

OK

2. Check the battery.

Refer to “CHECKING AND

CHARGING THE BATTERY” on

page 9-69.NG

• Clean the battery terminals.

• Recharge or replace the battery.

OK

3. Check the engine stop switch.

Refer to “CHECKING THE

SWITCHES” on page 9-64.NG

Replace the engine stop switch.

OK

4. Check fuel pressure.

Refer to “CHECKING THE FUEL

PRESSURE” on page 8-5.NG

Replace the fuel pump.

OK

5. Check the fuel pump system wire

harness connections.

Refer to “CIRCUIT DIAGRAM” on

page 9-56.NG

Properly connect or repair the fuel pump

system’s wiring.

OK

Replace the ECU.

Page 407 of 432

ELECTRICAL COMPONENTS

9-71

TIP

Voltage should be measured 30 minutes after

the engine is stopped.

b. Connect a charger and ammeter to the bat-

tery and start charging.

TIP

Set the charging voltage to 16–17 V. If the set-

ting is lower, charging will be insufficient. If too

high, the battery will be over-charged.

c. Make sure that the current is higher than the

standard charging current written on the bat-

tery.

TIP

If the current is lower than the standard charg-

ing current written on the battery, set the charg-

ing voltage adjust dial at 20–24 V and monitor

the amperage for 3–5 minutes to check the bat-

tery.

d. Adjust the voltage so that the current is at

the standard charging level.

e. Set the time according to the charging time

suitable for the open-circuit voltage.

f. If charging requires more than 5 hours, it is

advisable to check the charging current after

a lapse of 5 hours. If there is any change in

the amperage, readjust the voltage to obtain

the standard charging current.

g. Measure the battery open-circuit voltage af-

ter leaving the battery unused for more than

30 minutes.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

Charging method using a constant volt-

age charger

a. Measure the open-circuit voltage prior to

charging.

TIP

Voltage should be measured 30 minutes after

the engine is stopped.

b. Connect a charger and ammeter to the bat-

tery and start charging.c. Make sure that the current is higher than the

standard charging current written on the bat-

tery.

TIP

If the current is lower than the standard charg-

ing current written on the battery, this type of

battery charger cannot charge the VRLA (Valve

Regulated Lead Acid) battery. A variable volt-

age charger is recommended.

d. Charge the battery until the battery’s charg-

ing voltage is 15 V.

TIP

Set the charging time at 20 hours (maximum).

e. Measure the battery open-circuit voltage af-

ter leaving the battery unused for more than

30 minutes.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

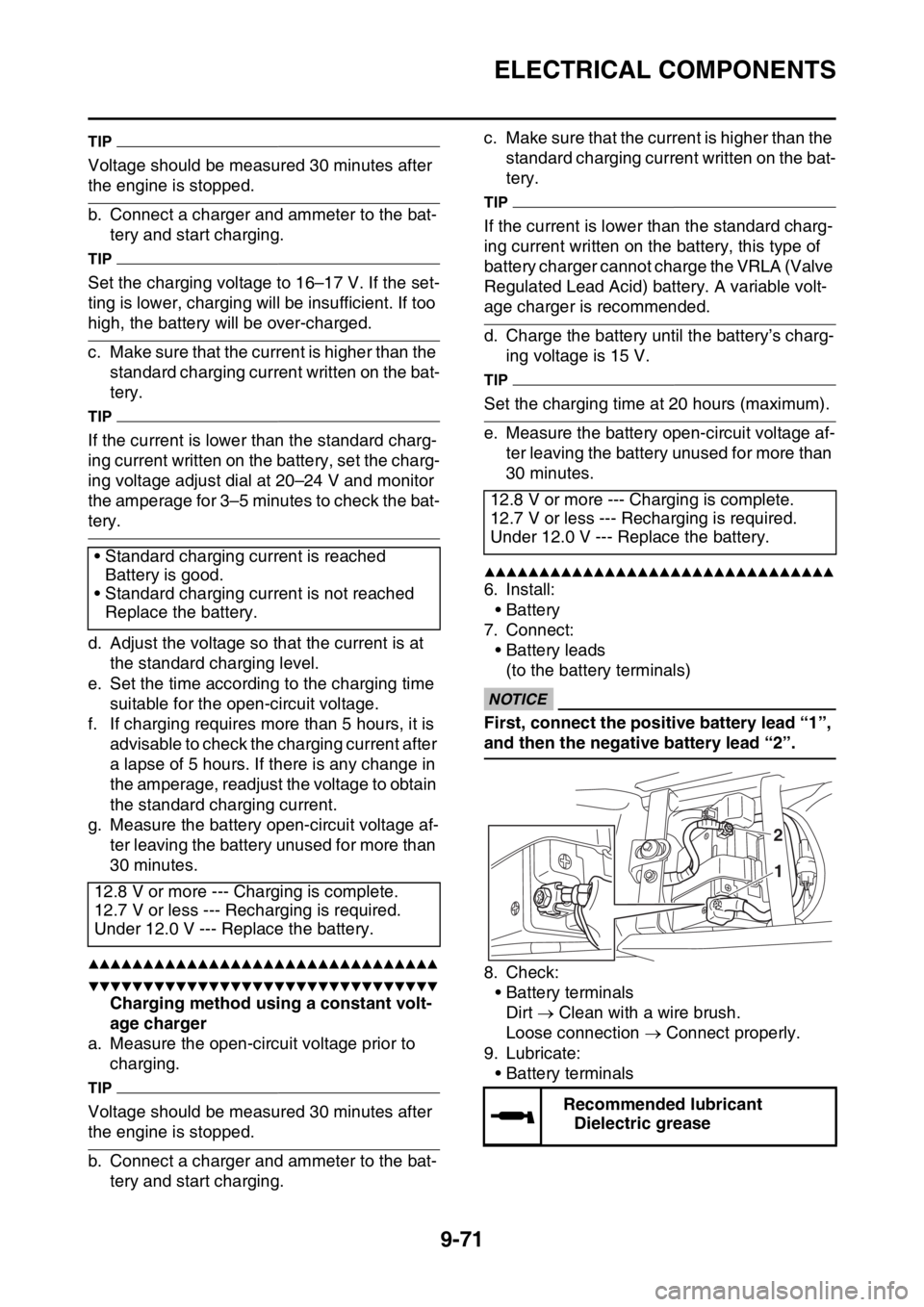

6. Install:

• Battery

7. Connect:

• Battery leads

(to the battery terminals)

ECA

NOTICE

First, connect the positive battery lead “1”,

and then the negative battery lead “2”.

8. Check:

• Battery terminals

Dirt Clean with a wire brush.

Loose connection Connect properly.

9. Lubricate:

• Battery terminals • Standard charging current is reached

Battery is good.

• Standard charging current is not reached

Replace the battery.

12.8 V or more --- Charging is complete.

12.7 V or less --- Recharging is required.

Under 12.0 V --- Replace the battery.

12.8 V or more --- Charging is complete.

12.7 V or less --- Recharging is required.

Under 12.0 V --- Replace the battery.

Recommended lubricant

Dielectric grease

2

1

Page 409 of 432

ELECTRICAL COMPONENTS

9-73

Radiator fan motor relay

EAS2GBB387CHECKING THE DIODE

1. Check:

•Diode

Out of specification Replace.

TIP

The pocket tester and the analog pocket tester

readings are shown in the following table.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Disconnect the diode from the wire harness.b. Connect the pocket tester ( 1) to the di-

ode coupler as shown.

c. Check the diode for continuity.

d. Check the diode for no continuity.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GBB388CHECKING THE IGNITION SPARK GAP

1. Check:

• Ignition spark gap

Out of specification Perform the ignition

system troubleshooting, starting with step 4.

Refer to “TROUBLESHOOTING” on page 9-

4.

TIP

If the ignition spark gap is within specification,

the ignition system circuit is operating normally.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the spark plug cap from the spark

plug.

b. Connect the ignition checker “1” as shown.

c. Push the engine stop switch.

d. Measure the ignition spark gap “a”.

1. Positive battery terminal

2. Negative battery terminal

3. Positive tester probe

4. Negative tester probe

Result

Continuity

(between “3” to “4”)

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

No continuity

Tester positive lead Sky blue

“1”

Tester negative lead Green/

Black “2”

Continuity

Tester positive lead Green/

Black “2”

Tester negative lead Sky blue

“1”

No continuity

Tester positive lead Red “3”

Tester negative lead Red/Blue

“4”

Continuity

Tester positive lead Red/Blue

“4”

Tester negative lead Red “3”

1 23

4

P/L

R/L

R/W

Br,R/W

Minimum ignition spark gap

6.0 mm (0.24 in)

Ignition checker

90890-06754

Oppama pet–4000 spark checker

YM-34487

2. Spark plug cap

2

1

4

3

R Sb

G/B R/L

Page 410 of 432

ELECTRICAL COMPONENTS

9-74

e. Crank the engine by pushing the start switch

and gradually increase the spark gap until a

misfire occurs.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

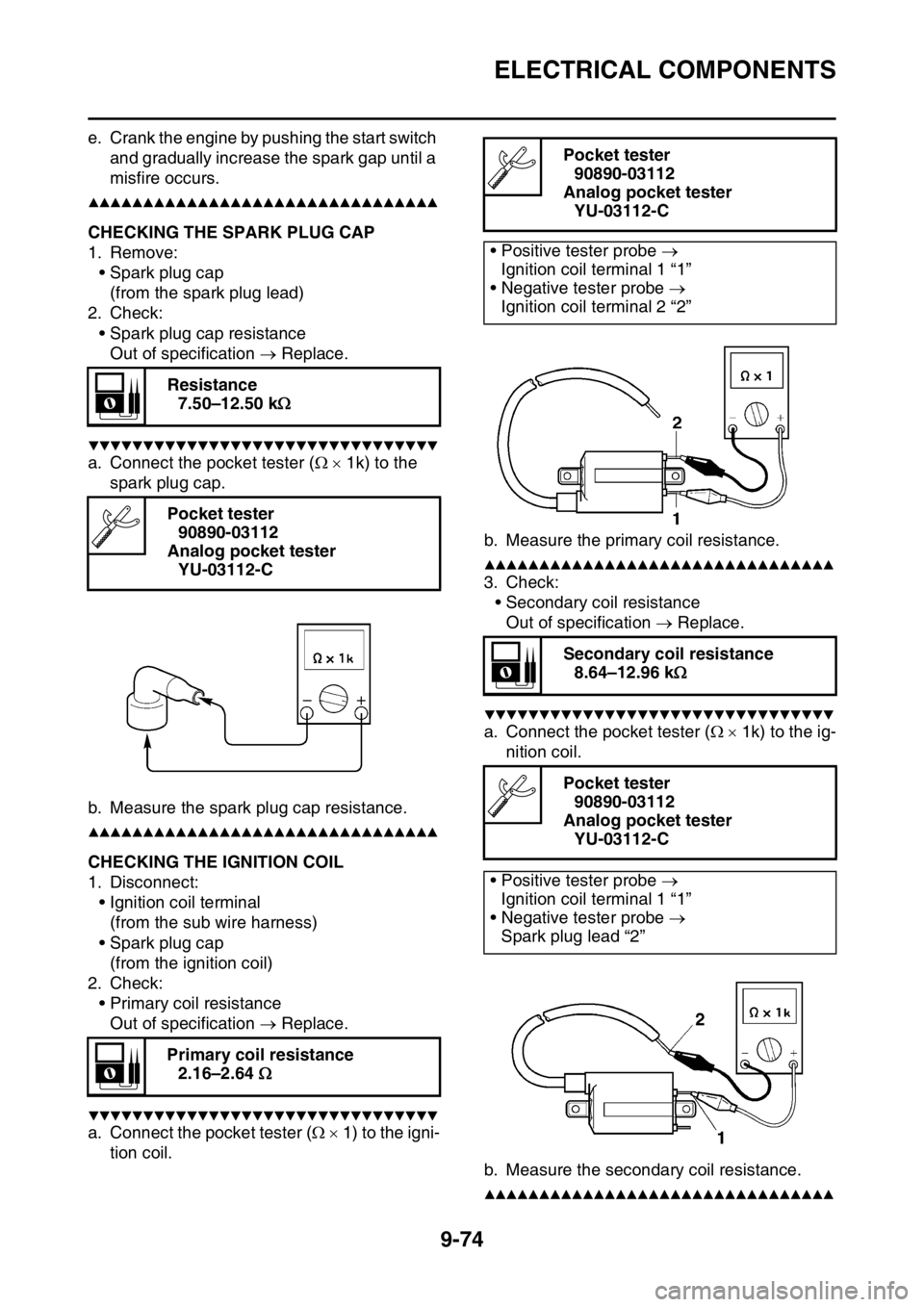

EAS2GBB389CHECKING THE SPARK PLUG CAP

1. Remove:

• Spark plug cap

(from the spark plug lead)

2. Check:

• Spark plug cap resistance

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester ( 1k) to the

spark plug cap.

b. Measure the spark plug cap resistance.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GBB390CHECKING THE IGNITION COIL

1. Disconnect:

• Ignition coil terminal

(from the sub wire harness)

• Spark plug cap

(from the ignition coil)

2. Check:

• Primary coil resistance

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester ( 1) to the igni-

tion coil.b. Measure the primary coil resistance.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

3. Check:

• Secondary coil resistance

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester ( 1k) to the ig-

nition coil.

b. Measure the secondary coil resistance.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Resistance

7.50–12.50 k

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

Primary coil resistance

2.16–2.64

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

Ignition coil terminal 1 “1”

• Negative tester probe

Ignition coil terminal 2 “2”

Secondary coil resistance

8.64–12.96 k

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

Ignition coil terminal 1 “1”

• Negative tester probe

Spark plug lead “2”

Page 413 of 432

ELECTRICAL COMPONENTS

9-77

c. Start the engine and let it run at approxi-

mately 5000 r/min.

d. Measure the charging voltage.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

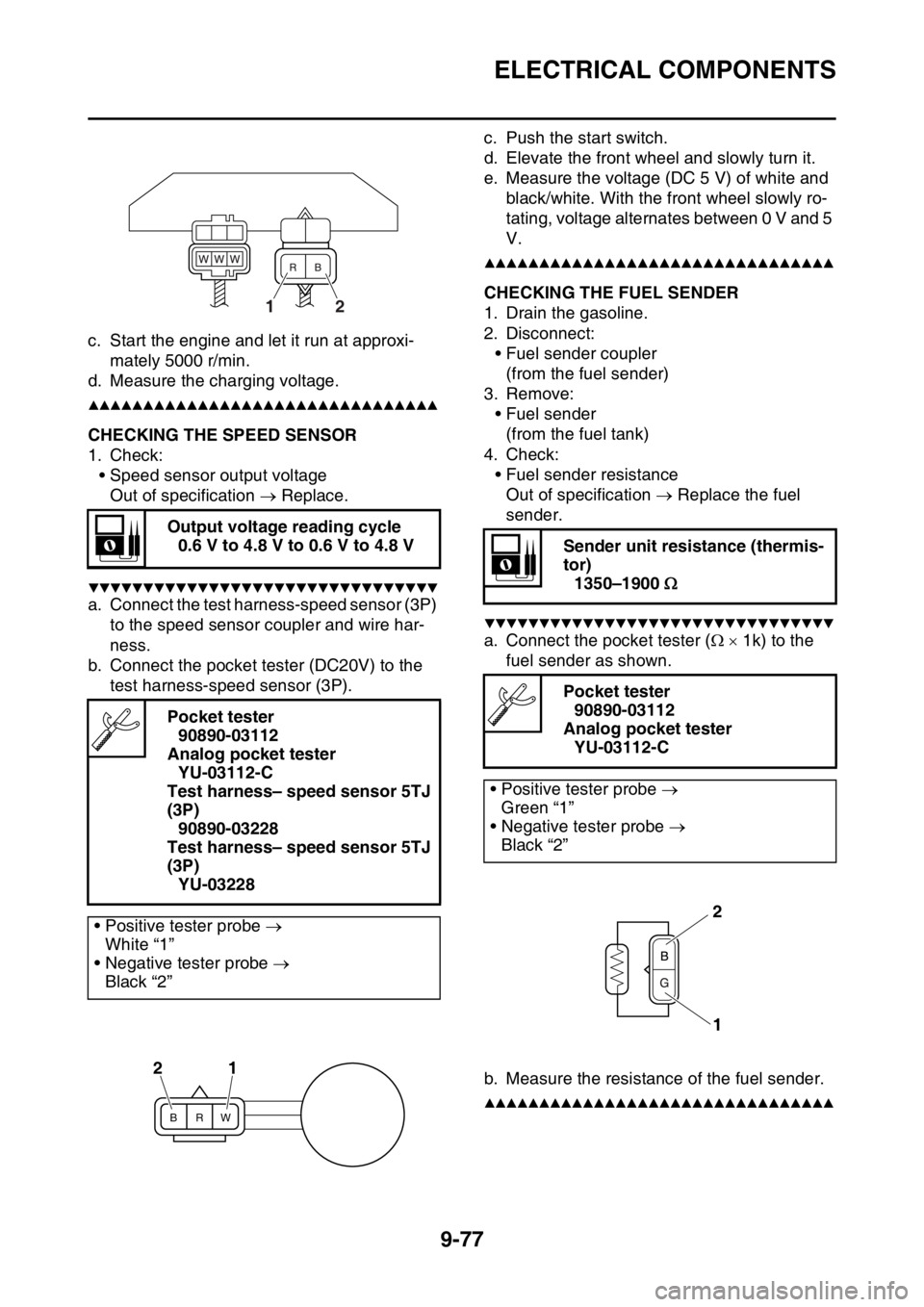

EAS2GBB395CHECKING THE SPEED SENSOR

1. Check:

• Speed sensor output voltage

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the test harness-speed sensor (3P)

to the speed sensor coupler and wire har-

ness.

b. Connect the pocket tester (DC20V) to the

test harness-speed sensor (3P).c. Push the start switch.

d. Elevate the front wheel and slowly turn it.

e. Measure the voltage (DC 5 V) of white and

black/white. With the front wheel slowly ro-

tating, voltage alternates between 0 V and 5

V.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GBB396CHECKING THE FUEL SENDER

1. Drain the gasoline.

2. Disconnect:

• Fuel sender coupler

(from the fuel sender)

3. Remove:

• Fuel sender

(from the fuel tank)

4. Check:

• Fuel sender resistance

Out of specification Replace the fuel

sender.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester ( 1k) to the

fuel sender as shown.

b. Measure the resistance of the fuel sender.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Output voltage reading cycle

0.6 V to 4.8 V to 0.6 V to 4.8 V

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

Test harness– speed sensor 5TJ

(3P)

90890-03228

Test harness– speed sensor 5TJ

(3P)

YU-03228

• Positive tester probe

White “1”

• Negative tester probe

Black “2”

12

BRW

21

Sender unit resistance (thermis-

tor)

1350–1900

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

Green “1”

• Negative tester probe

Black “2”

1

2

Page 416 of 432

ELECTRICAL COMPONENTS

9-80

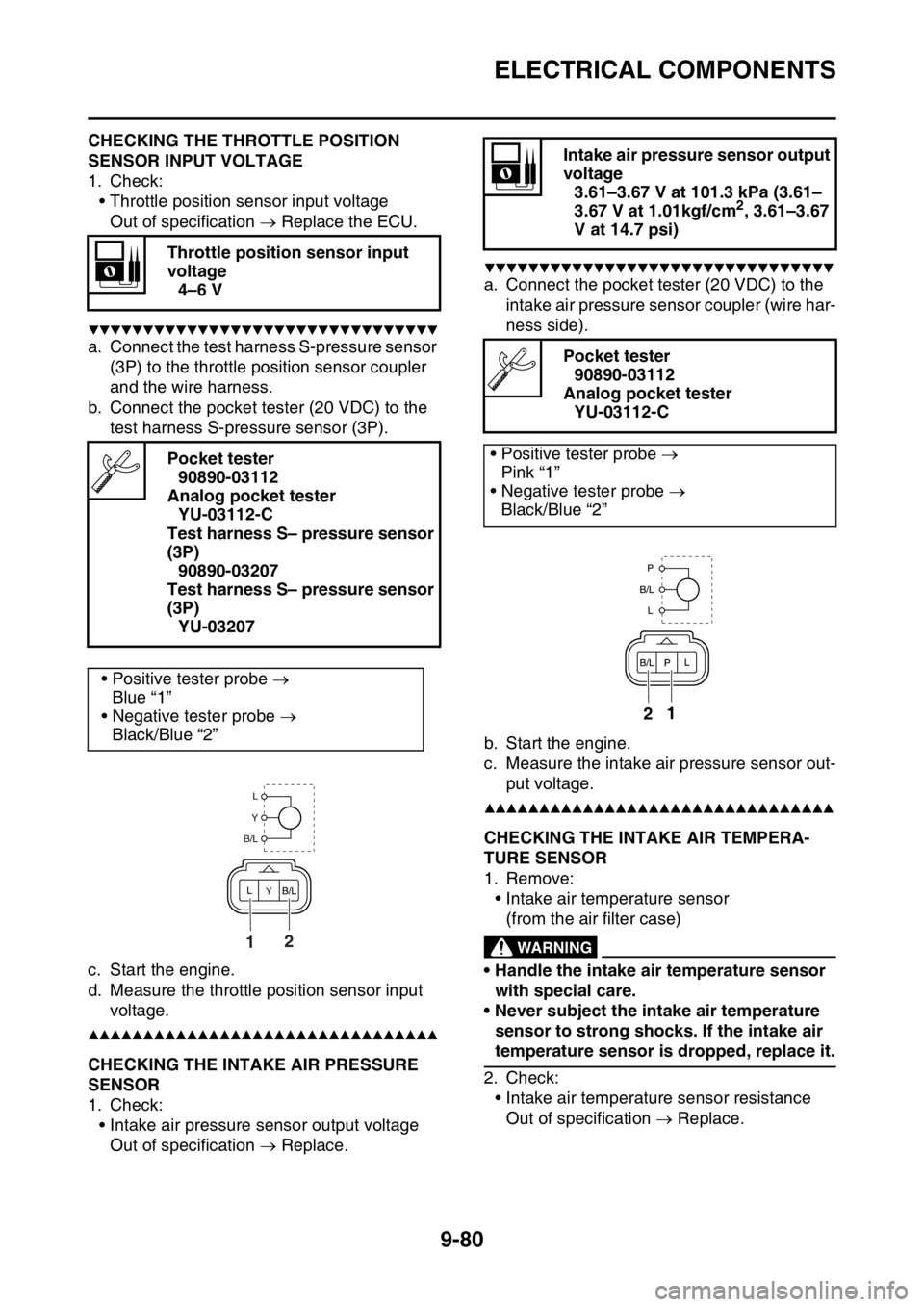

EAS2GBB401CHECKING THE THROTTLE POSITION

SENSOR INPUT VOLTAGE

1. Check:

• Throttle position sensor input voltage

Out of specification Replace the ECU.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the test harness S-pressure sensor

(3P) to the throttle position sensor coupler

and the wire harness.

b. Connect the pocket tester (20 VDC) to the

test harness S-pressure sensor (3P).

c. Start the engine.

d. Measure the throttle position sensor input

voltage.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GBB402CHECKING THE INTAKE AIR PRESSURE

SENSOR

1. Check:

• Intake air pressure sensor output voltage

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester (20 VDC) to the

intake air pressure sensor coupler (wire har-

ness side).

b. Start the engine.

c. Measure the intake air pressure sensor out-

put voltage.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GBB403CHECKING THE INTAKE AIR TEMPERA-

TURE SENSOR

1. Remove:

• Intake air temperature sensor

(from the air filter case)

EWA

WARNING

• Handle the intake air temperature sensor

with special care.

• Never subject the intake air temperature

sensor to strong shocks. If the intake air

temperature sensor is dropped, replace it.

2. Check:

• Intake air temperature sensor resistance

Out of specification Replace. Throttle position sensor input

voltage

4–6 V

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

Test harness S– pressure sensor

(3P)

90890-03207

Test harness S– pressure sensor

(3P)

YU-03207

• Positive tester probe

Blue “1”

• Negative tester probe

Black/Blue “2”

21

Intake air pressure sensor output

voltage

3.61–3.67 V at 101.3 kPa (3.61–

3.67 V at 1.01kgf/cm

2, 3.61–3.67

V at 14.7 psi)

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

Pink “1”

• Negative tester probe

Black/Blue “2”

12

Page 420 of 432

TROUBLESHOOTING

10-1

EAS2GBB405

TROUBLESHOOTING

EAS2GBB406GENERAL INFORMATION

TIP

The following guide for troubleshooting does

not cover all the possible causes of trouble. It

should be helpful, however, as a guide to basic

troubleshooting. Refer to the relative procedure

in this manual for checks, adjustments, and re-

placement of parts.

EAS2GBB407STARTING FAILURES

Engine

1. Cylinder and cylinder head

• Loose spark plug

• Loose cylinder head or cylinder

• Damaged cylinder head gasket

• Damaged cylinder gasket

• Worn or damaged cylinder

• Incorrect valve clearance

• Improperly sealed valve

• Incorrect valve-to-valve-seat contact

• Incorrect valve timing

• Faulty valve spring

• Seized valve

2. Piston and piston ring(s)

• Improperly installed piston ring

• Damaged, worn or fatigued piston ring

• Seized piston ring

• Seized or damaged piston

3. Air filter

• Improperly installed air filter

• Clogged air filter element

4. Crankcase and crankshaft

• Improperly assembled crankcase

• Seized crankshaft

Fuel system

1. Fuel tank

• Empty fuel tank

• Clogged fuel tank breather hose

• Deteriorated or contaminated fuel

• Clogged or damaged fuel hose

2. Fuel pump

• Faulty fuel pump

3. Throttle body

• Deteriorated or contaminated fuel

• Sucked-in airElectrical system

1. Battery

• Discharged battery

• Faulty battery

2. Fuse

• Blown, damaged or incorrect fuse

• Improperly installed fuse

3. Spark plug

• Incorrect spark plug gap

• Incorrect spark plug heat range

• Fouled spark plug

• Worn or damaged electrode

• Worn or damaged insulator

4. Ignition coil

• Cracked or broken ignition coil body

• Broken or shorted primary or secondary

coils

5. Ignition system

• Faulty ECU

• Faulty crankshaft position sensor

• Broken generator rotor woodruff key

6. Switches and wiring

• Faulty ECU

• Faulty engine stop switch

• Broken or shorted wiring

• Faulty neutral switch

• Improperly grounded circuit

• Loose connections

7. Starting system

• Faulty starter motor

• Faulty starter relay

• Faulty starting circuit cut-off relay

• Faulty starter clutch

EAS2GBB408INCORRECT ENGINE IDLING SPEED

Engine

1. Cylinder and cylinder head

• Incorrect valve clearance

• Damaged valve train components

2. Air filter

• Clogged air filter element

Fuel system

1. Throttle body

• Damaged or loose throttle body joint

• Improperly synchronized throttle bodies

• Improper throttle cable free play

• Flooded throttle body

Page 425 of 432

LIST OF SELF-DIAGNOSTIC AND FAIL-SAFE ACTIONS

10-6

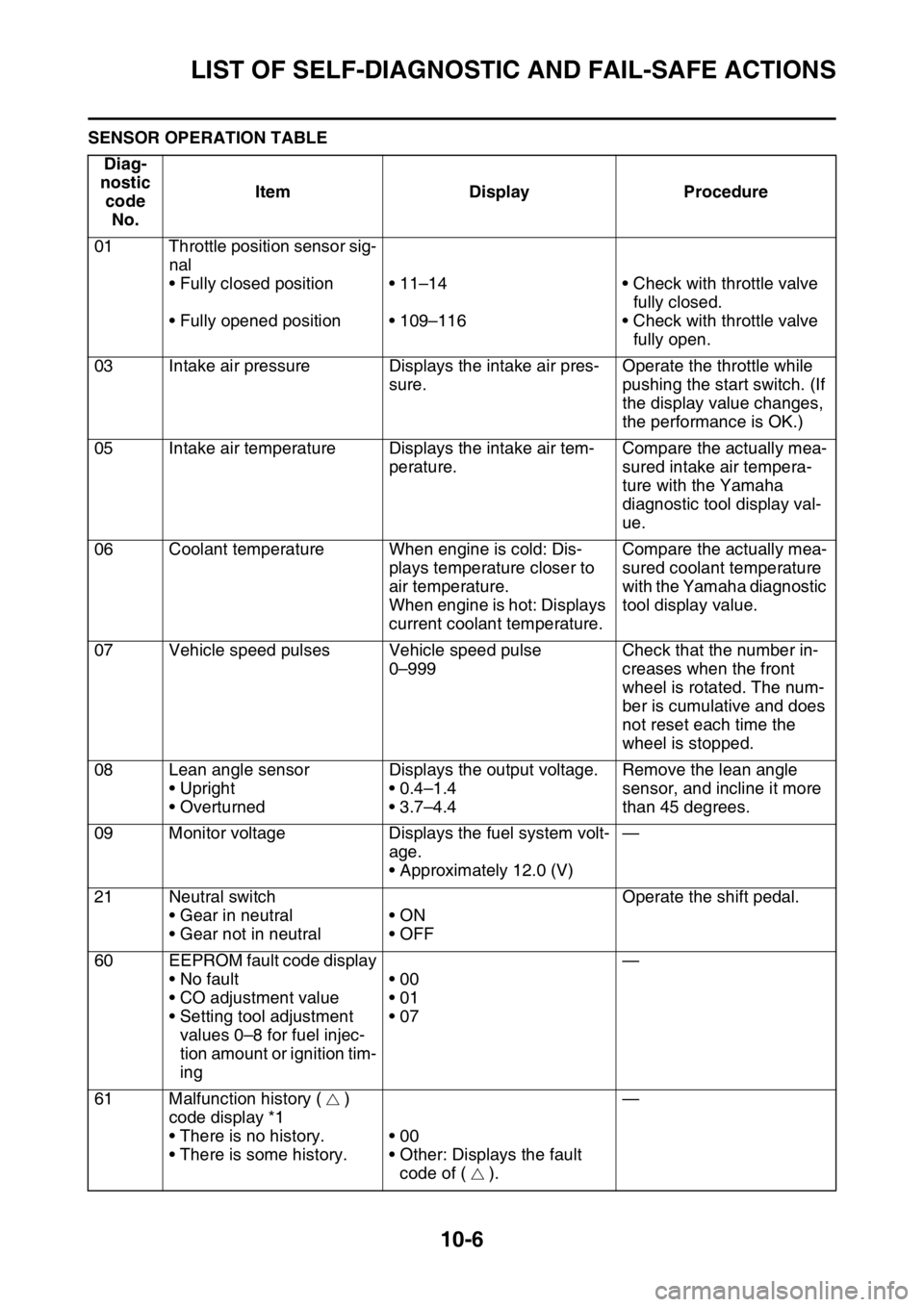

SENSOR OPERATION TABLE

Diag-

nostic

code

No.Item Display Procedure

01 Throttle position sensor sig-

nal

• Fully closed position

• Fully opened position• 11–14

• 109–116• Check with throttle valve

fully closed.

• Check with throttle valve

fully open.

03 Intake air pressure Displays the intake air pres-

sure.Operate the throttle while

pushing the start switch. (If

the display value changes,

the performance is OK.)

05 Intake air temperature Displays the intake air tem-

perature.Compare the actually mea-

sured intake air tempera-

ture with the Yamaha

diagnostic tool display val-

ue.

06 Coolant temperature When engine is cold: Dis-

plays temperature closer to

air temperature.

When engine is hot: Displays

current coolant temperature.Compare the actually mea-

sured coolant temperature

with the Yamaha diagnostic

tool display value.

07 Vehicle speed pulses Vehicle speed pulse

0–999Check that the number in-

creases when the front

wheel is rotated. The num-

ber is cumulative and does

not reset each time the

wheel is stopped.

08 Lean angle sensor

• Upright

• OverturnedDisplays the output voltage.

• 0.4–1.4

• 3.7–4.4Remove the lean angle

sensor, and incline it more

than 45 degrees.

09 Monitor voltage Displays the fuel system volt-

age.

• Approximately 12.0 (V)—

21 Neutral switch

• Gear in neutral

• Gear not in neutral•ON

•OFFOperate the shift pedal.

60 EEPROM fault code display

• No fault

• CO adjustment value

• Setting tool adjustment

values 0–8 for fuel injec-

tion amount or ignition tim-

ing•00

•01

•07—

61 Malfunction history ( )

code display *1

• There is no history.

• There is some history.•00

• Other: Displays the fault

code of ( ).—