brake YAMAHA WR 400F 2000 Manuale duso (in Italian)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2000, Model line: WR 400F, Model: YAMAHA WR 400F 2000Pages: 654, PDF Dimensioni: 60.12 MB

Page 150 of 654

2 - 22

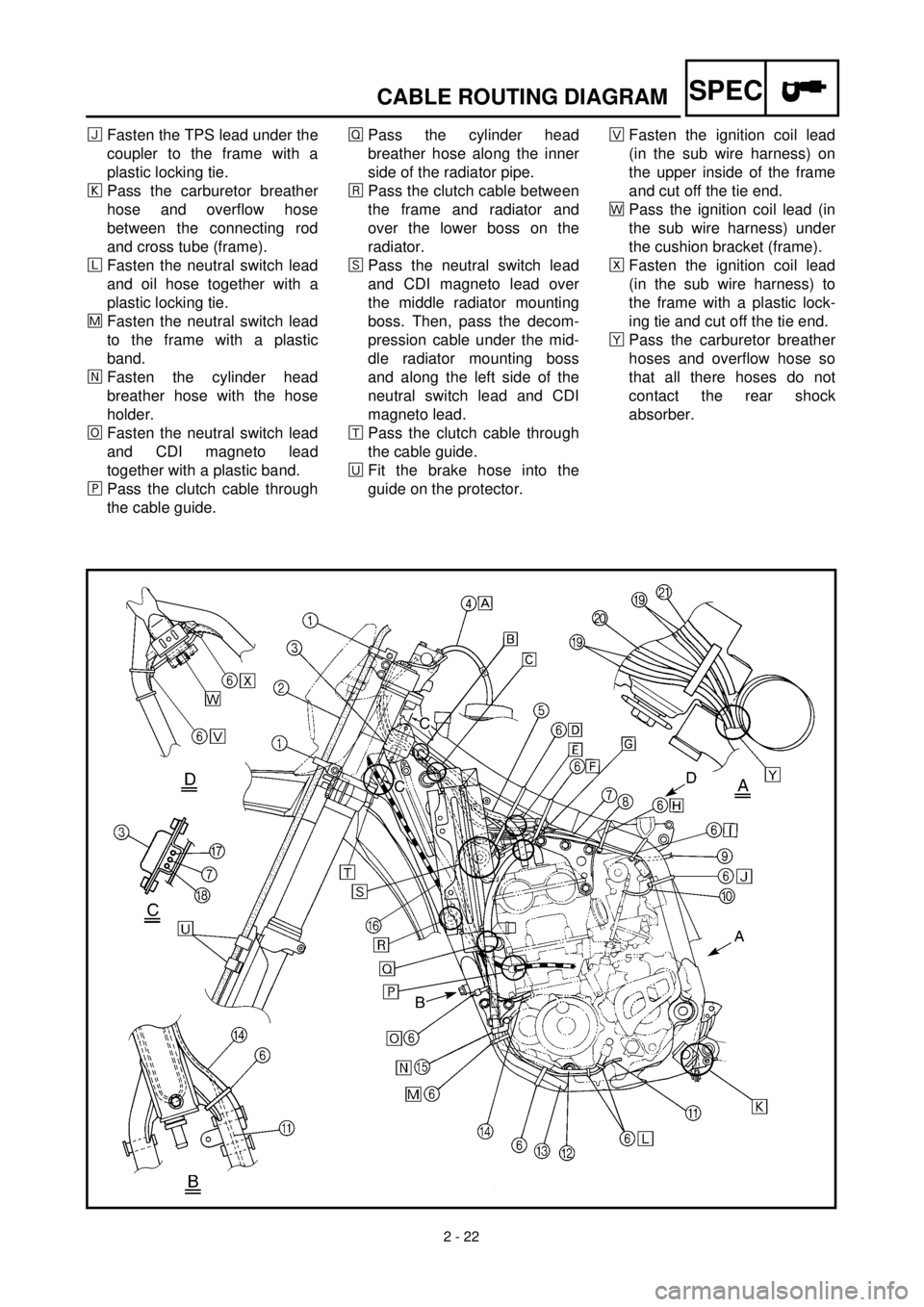

SPECCABLE ROUTING DIAGRAM

ïFasten the TPS lead under the

coupler to the frame with a

plastic locking tie.

ðPass the carburetor breather

hose and overflow hose

between the connecting rod

and cross tube (frame).

ñFasten the neutral switch lead

and oil hose together with a

plastic locking tie.

÷Fasten the neutral switch lead

to the frame with a plastic

band.

öFasten the cylinder head

breather hose with the hose

holder.

¯Fasten the neutral switch lead

and CDI magneto lead

together with a plastic band.

¸Pass the clutch cable through

the cable guide.ÎPass the cylinder head

breather hose along the inner

side of the radiator pipe.

åPass the clutch cable between

the frame and radiator and

over the lower boss on the

radiator.

êPass the neutral switch lead

and CDI magneto lead over

the middle radiator mounting

boss. Then, pass the decom-

pression cable under the mid-

dle radiator mounting boss

and along the left side of the

neutral switch lead and CDI

magneto lead.

æPass the clutch cable through

the cable guide.

èFit the brake hose into the

guide on the protector.×Fasten the ignition coil lead

(in the sub wire harness) on

the upper inside of the frame

and cut off the tie end.

ãPass the ignition coil lead (in

the sub wire harness) under

the cushion bracket (frame).

ÅFasten the ignition coil lead

(in the sub wire harness) to

the frame with a plastic lock-

ing tie and cut off the tie end.

çPass the carburetor breather

hoses and overflow hose so

that all there hoses do not

contact the rear shock

absorber.

Page 154 of 654

2 - 24

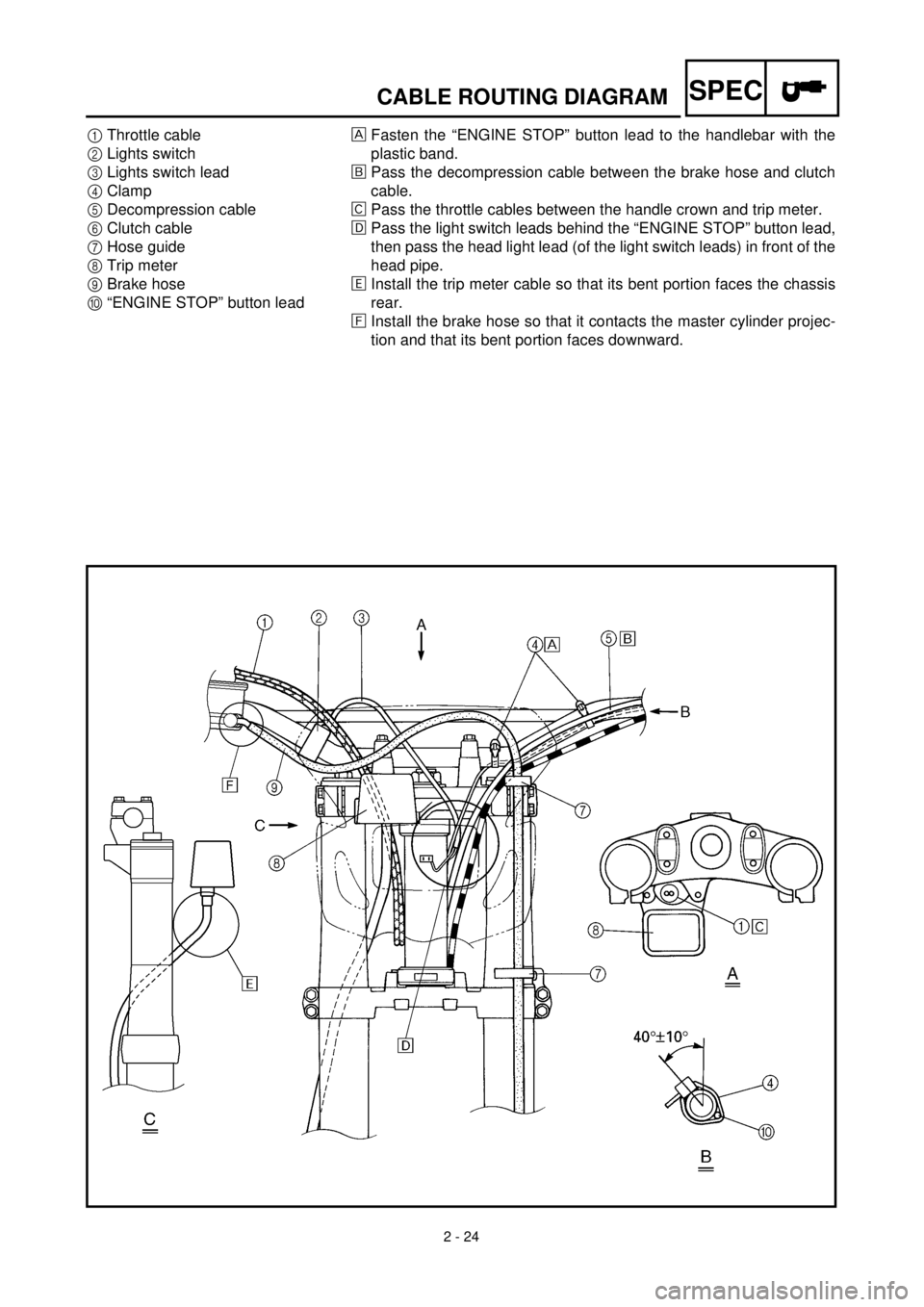

SPECCABLE ROUTING DIAGRAM

1Throttle cable

2Lights switch

3Lights switch lead

4Clamp

5Decompression cable

6Clutch cable

7Hose guide

8Trip meter

9Brake hose

0“ENGINE STOP” button leadFasten the “ENGINE STOP” button lead to the handlebar with the

plastic band.

õPass the decompression cable between the brake hose and clutch

cable.

‚Pass the throttle cables between the handle crown and trip meter.

ëPass the light switch leads behind the “ENGINE STOP” button lead,

then pass the head light lead (of the light switch leads) in front of the

head pipe.

äInstall the trip meter cable so that its bent portion faces the chassis

rear.

ìInstall the brake hose so that it contacts the master cylinder projec-

tion and that its bent portion faces downward.

Page 157 of 654

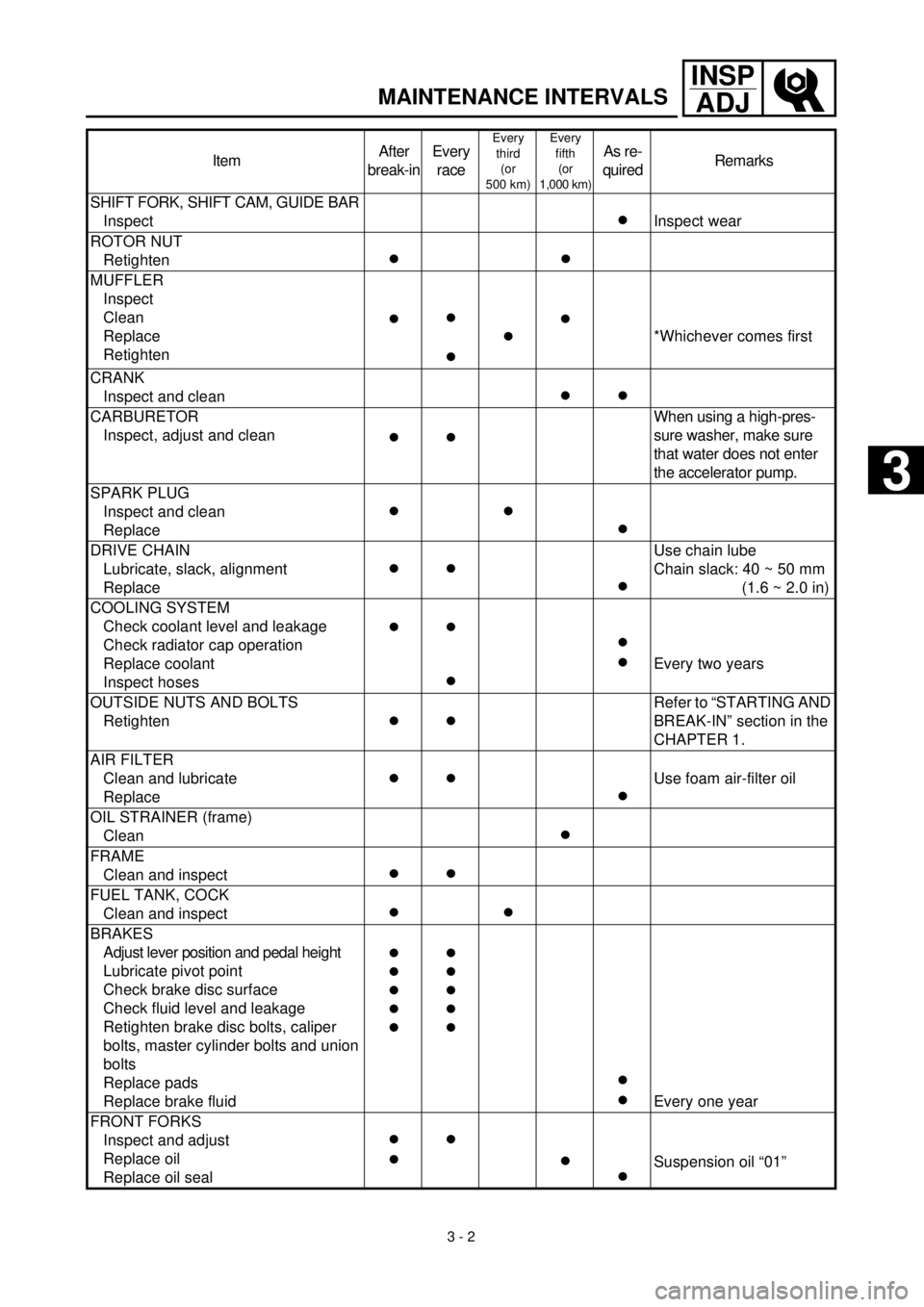

3 - 2

INSP

ADJ

MAINTENANCE INTERVALS

SHIFT FORK, SHIFT CAM, GUIDE BAR

Inspect

c

Inspect wear

ROTOR NUT

Retighten

cc

MUFFLER

Inspect

Clean

Replace

Retighten

cc

ccc

*Whichever comes first

CRANK

Inspect and clean

cc

CARBURETOR

Inspect, adjust and clean

cc

When using a high-pres-

sure washer, make sure

that water does not enter

the accelerator pump.

SPARK PLUG

Inspect and clean

Replace

cc

c

DRIVE CHAIN

Lubricate, slack, alignment

Replace

cc

c

Use chain lube

Chain slack: 40 ~ 50 mm

(1.6 ~ 2.0 in)

COOLING SYSTEM

Check coolant level and leakage

Check radiator cap operation

Replace coolant

Inspect hoses

cc

cc

c

Every two years

OUTSIDE NUTS AND BOLTS

Retighten

cc

Refer to “STARTING AND

BREAK-IN” section in the

CHAPTER 1.

AIR FILTER

Clean and lubricate

Replace

cc

c

Use foam air-filter oil

OIL STRAINER (frame)

Clean

c

FRAME

Clean and inspect

cc

FUEL TANK, COCK

Clean and inspect

cc

BRAKES

Adjust lever position and pedal height

Lubricate pivot point

Check brake disc surface

Check fluid level and leakage

Retighten brake disc bolts, caliper

bolts, master cylinder bolts and union

bolts

Replace pads

Replace brake fluid

c

c

c

c

cc

c

c

c

c

c

c

Every one year

FRONT FORKS

Inspect and adjust

Replace oil

Replace oil seal

c

cc

c

c

Suspension oil “01” ItemAfter

break-inEvery

race

Every

third

(or

500 km)Every

fifth

(or

1,000 km)

As re-

quiredRemarks

3

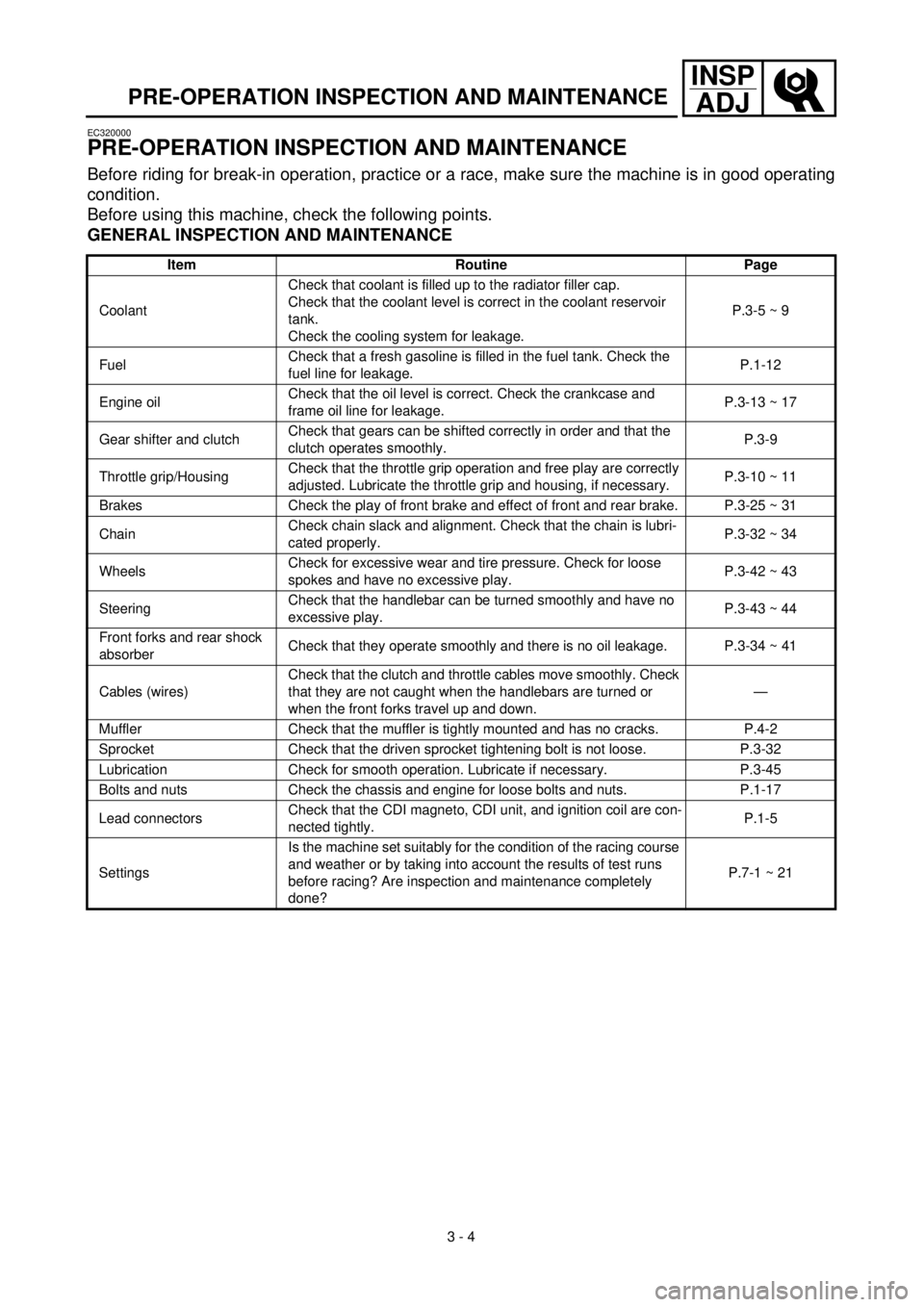

Page 168 of 654

3 - 4

INSP

ADJ

PRE-OPERATION INSPECTION AND MAINTENANCE

EC320000

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating

condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCE

Item Routine Page

CoolantCheck that coolant is filled up to the radiator filler cap.

Check that the coolant level is correct in the coolant reservoir

tank.

Check the cooling system for leakage.P.3-5 ~ 9

FuelCheck that a fresh gasoline is filled in the fuel tank. Check the

fuel line for leakage.P.1-12

Engine oilCheck that the oil level is correct. Check the crankcase and

frame oil line for leakage.P.3-13 ~ 17

Gear shifter and clutchCheck that gears can be shifted correctly in order and that the

clutch operates smoothly.P.3-9

Throttle grip/HousingCheck that the throttle grip operation and free play are correctly

adjusted. Lubricate the throttle grip and housing, if necessary.P.3-10 ~ 11

Brakes Check the play of front brake and effect of front and rear brake. P.3-25 ~ 31

ChainCheck chain slack and alignment. Check that the chain is lubri-

cated properly.P.3-32 ~ 34

WheelsCheck for excessive wear and tire pressure. Check for loose

spokes and have no excessive play.P.3-42 ~ 43

SteeringCheck that the handlebar can be turned smoothly and have no

excessive play.P.3-43 ~ 44

Front forks and rear shock

absorberCheck that they operate smoothly and there is no oil leakage. P.3-34 ~ 41

Cables (wires)Check that the clutch and throttle cables move smoothly. Check

that they are not caught when the handlebars are turned or

when the front forks travel up and down.—

Muffler Check that the muffler is tightly mounted and has no cracks. P.4-2

Sprocket Check that the driven sprocket tightening bolt is not loose. P.3-32

Lubrication Check for smooth operation. Lubricate if necessary. P.3-45

Bolts and nuts Check the chassis and engine for loose bolts and nuts. P.1-17

Lead connectorsCheck that the CDI magneto, CDI unit, and ignition coil are con-

nected tightly.P.1-5

SettingsIs the machine set suitably for the condition of the racing course

and weather or by taking into account the results of test runs

before racing? Are inspection and maintenance completely

done?P.7-1 ~ 21

Page 214 of 654

3 - 25

INSP

ADJ

CHASSIS/BRAKE SYSTEM AIR BLEEDING

EC360000

CHASSIS

EC361012

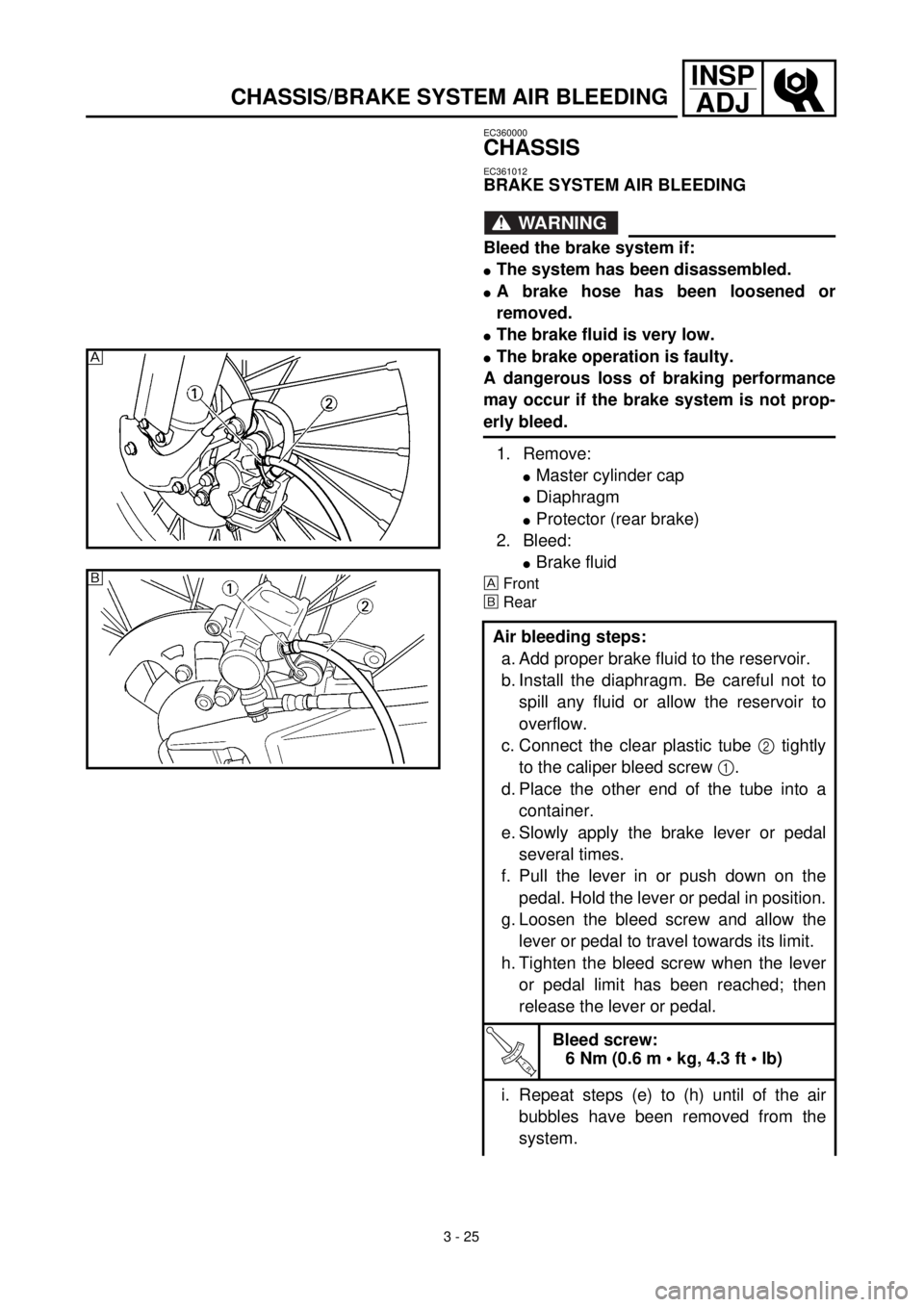

BRAKE SYSTEM AIR BLEEDING

WARNING

Bleed the brake system if:

lThe system has been disassembled.

lA brake hose has been loosened or

removed.

lThe brake fluid is very low.

lThe brake operation is faulty.

A dangerous loss of braking performance

may occur if the brake system is not prop-

erly bleed.

1. Remove:

lMaster cylinder cap

lDiaphragm

lProtector (rear brake)

2. Bleed:

lBrake fluid

Front

õRear

Air bleeding steps:

a. Add proper brake fluid to the reservoir.

b. Install the diaphragm. Be careful not to

spill any fluid or allow the reservoir to

overflow.

c. Connect the clear plastic tube 2 tightly

to the caliper bleed screw 1.

d. Place the other end of the tube into a

container.

e. Slowly apply the brake lever or pedal

several times.

f. Pull the lever in or push down on the

pedal. Hold the lever or pedal in position.

g. Loosen the bleed screw and allow the

lever or pedal to travel towards its limit.

h. Tighten the bleed screw when the lever

or pedal limit has been reached; then

release the lever or pedal.

T R..

Bleed screw:

6 Nm (0.6 m • kg, 4.3 ft • lb)

i. Repeat steps (e) to (h) until of the air

bubbles have been removed from the

system.

õ

Page 216 of 654

3 - 26

INSP

ADJ

FRONT BRAKE ADJUSTMENT

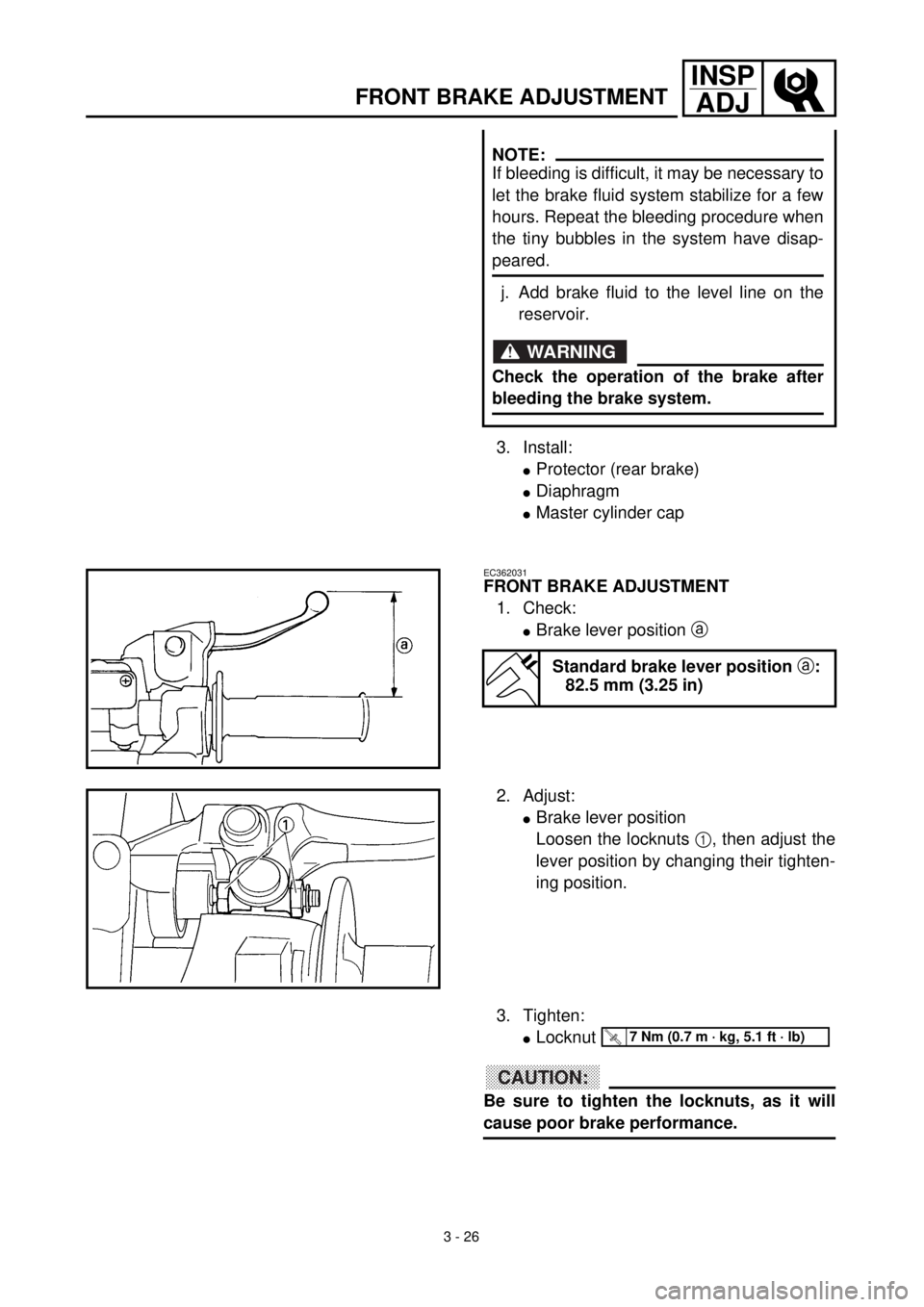

3. Install:

lProtector (rear brake)

lDiaphragm

lMaster cylinder cap

NOTE:

If bleeding is difficult, it may be necessary to

let the brake fluid system stabilize for a few

hours. Repeat the bleeding procedure when

the tiny bubbles in the system have disap-

peared.

j. Add brake fluid to the level line on the

reservoir.

WARNING

Check the operation of the brake after

bleeding the brake system.

EC362031

FRONT BRAKE ADJUSTMENT

1. Check:

lBrake lever position a

Standard brake lever position a:

82.5 mm (3.25 in)

2. Adjust:

lBrake lever position

Loosen the locknuts 1, then adjust the

lever position by changing their tighten-

ing position.

3. Tighten:

lLocknut

CAUTION:

Be sure to tighten the locknuts, as it will

cause poor brake performance.

T R..7 Nm (0.7 m · kg, 5.1 ft · lb)

Page 218 of 654

3 - 27

INSP

ADJREAR BRAKE ADJUSTMENT/

FRONT BRAKE PAD INSPECTION AND REPLACEMENT

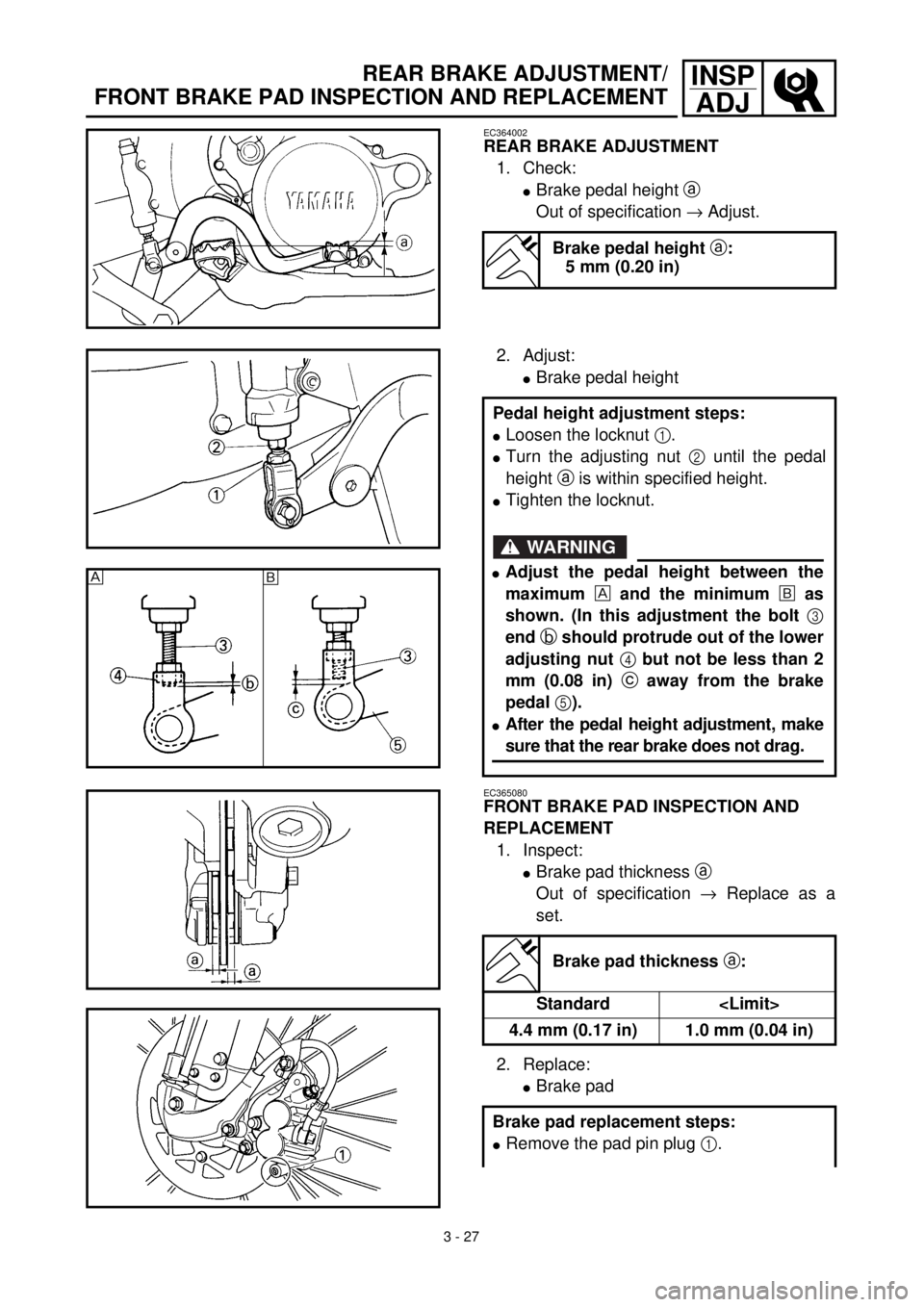

EC364002

REAR BRAKE ADJUSTMENT

1. Check:

lBrake pedal height a

Out of specification ® Adjust.

Brake pedal height a:

5 mm (0.20 in)

2. Adjust:

lBrake pedal height

EC365080

FRONT BRAKE PAD INSPECTION AND

REPLACEMENT

1. Inspect:

lBrake pad thickness a

Out of specification ® Replace as a

set.

2. Replace:

lBrake pad Pedal height adjustment steps:

lLoosen the locknut 1.

lTurn the adjusting nut 2 until the pedal

height a is within specified height.

lTighten the locknut.

Brake pad thickness a:

Standard

4.4 mm (0.17 in) 1.0 mm (0.04 in)

Brake pad replacement steps:

lRemove the pad pin plug 1.

õ

WARNING

lAdjust the pedal height between the

maximum and the minimum õ as

shown. (In this adjustment the bolt 3

end b should protrude out of the lower

adjusting nut 4 but not be less than 2

mm (0.08 in) c away from the brake

pedal 5).

lAfter the pedal height adjustment, make

sure that the rear brake does not drag.

Page 220 of 654

3 - 28

INSP

ADJ

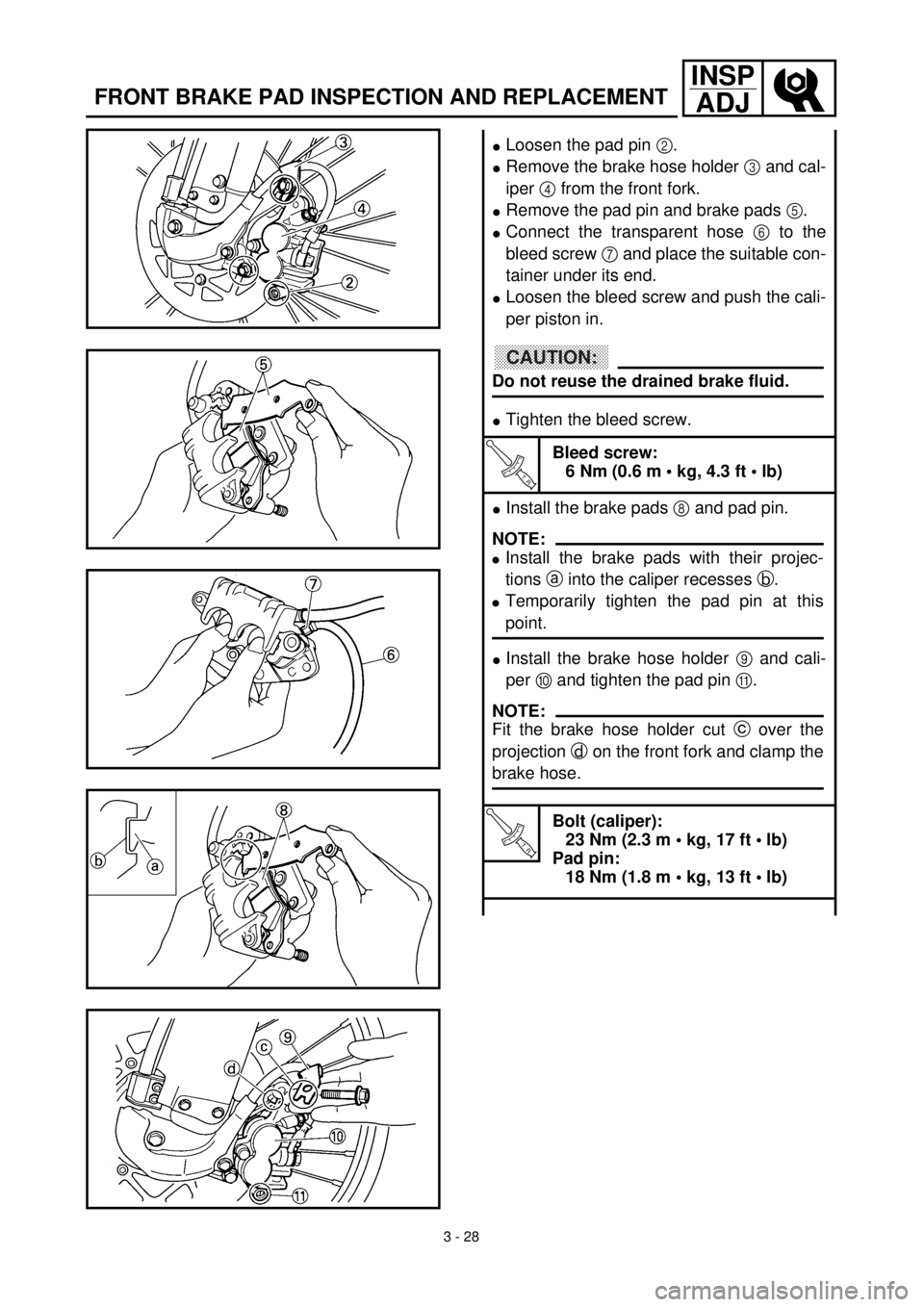

FRONT BRAKE PAD INSPECTION AND REPLACEMENT

lLoosen the pad pin 2.

lRemove the brake hose holder 3 and cal-

iper 4 from the front fork.

lRemove the pad pin and brake pads 5.

lConnect the transparent hose 6 to the

bleed screw 7 and place the suitable con-

tainer under its end.

lLoosen the bleed screw and push the cali-

per piston in.

lTighten the bleed screw.

T R..

Bleed screw:

6 Nm (0.6 m • kg, 4.3 ft • lb)

lInstall the brake pads 8 and pad pin.

lInstall the brake hose holder 9 and cali-

per 0 and tighten the pad pin A.

T R..

Bolt (caliper):

23 Nm (2.3 m • kg, 17 ft • lb)

Pad pin:

18 Nm (1.8 m • kg, 13 ft • lb)

CAUTION:

Do not reuse the drained brake fluid.

NOTE:

lInstall the brake pads with their projec-

tions a into the caliper recesses b.

lTemporarily tighten the pad pin at this

point.

NOTE:

Fit the brake hose holder cut c over the

projection d on the front fork and clamp the

brake hose.

Page 222 of 654

3 - 29

INSP

ADJ

REAR BRAKE PAD INSPECTION AND REPLACEMENT

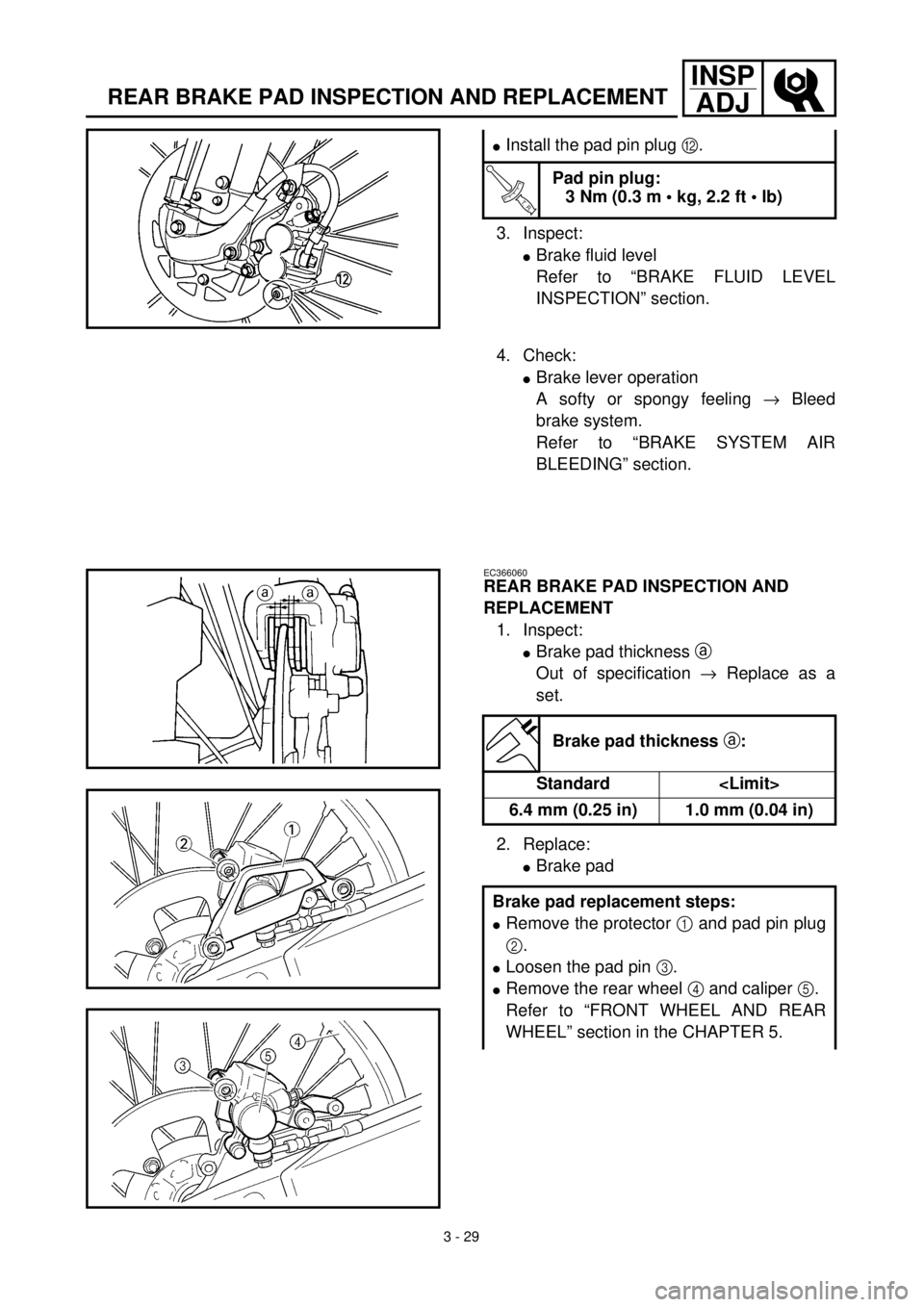

3. Inspect:

lBrake fluid level

Refer to “BRAKE FLUID LEVEL

INSPECTION” section.

lInstall the pad pin plug B.

T R..

Pad pin plug:

3 Nm (0.3 m • kg, 2.2 ft • lb)

4. Check:

lBrake lever operation

A softy or spongy feeling ® Bleed

brake system.

Refer to “BRAKE SYSTEM AIR

BLEEDING” section.

EC366060

REAR BRAKE PAD INSPECTION AND

REPLACEMENT

1. Inspect:

lBrake pad thickness a

Out of specification ® Replace as a

set.

2. Replace:

lBrake pad

Brake pad thickness a:

Standard

6.4 mm (0.25 in) 1.0 mm (0.04 in)

Brake pad replacement steps:

lRemove the protector 1 and pad pin plug

2.

lLoosen the pad pin 3.

lRemove the rear wheel 4 and caliper 5.

Refer to “FRONT WHEEL AND REAR

WHEEL” section in the CHAPTER 5.

Page 224 of 654

3 - 30

INSP

ADJ

REAR BRAKE PAD INSPECTION AND REPLACEMENT

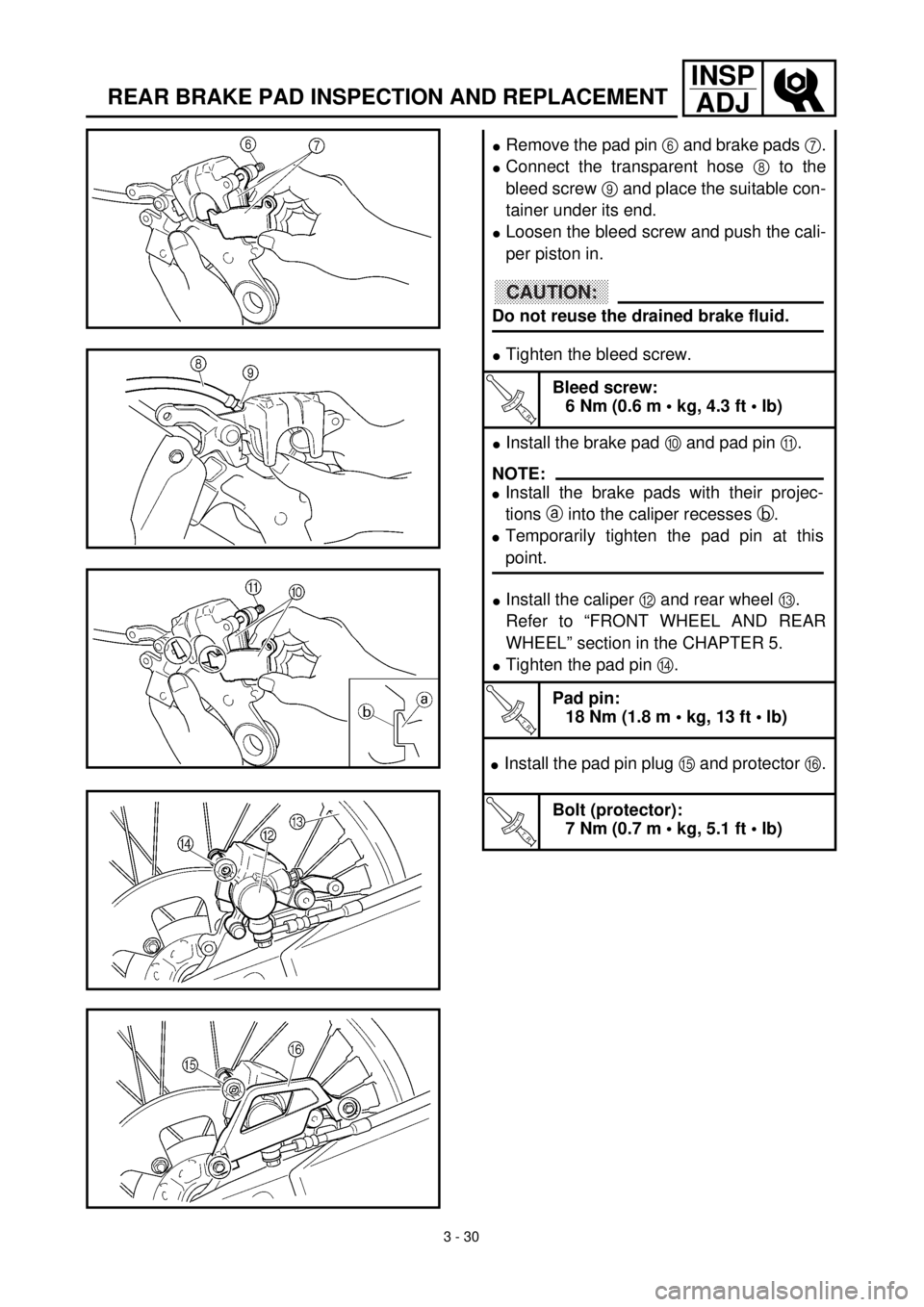

lRemove the pad pin 6 and brake pads 7.

lConnect the transparent hose 8 to the

bleed screw 9 and place the suitable con-

tainer under its end.

lLoosen the bleed screw and push the cali-

per piston in.

lTighten the bleed screw.

T R..

Bleed screw:

6 Nm (0.6 m • kg, 4.3 ft • lb)

lInstall the brake pad 0 and pad pin A.

lInstall the caliper B and rear wheel C.

Refer to “FRONT WHEEL AND REAR

WHEEL” section in the CHAPTER 5.

lTighten the pad pin D.

T R..

Pad pin:

18 Nm (1.8 m • kg, 13 ft • lb)

lInstall the pad pin plug E and protector F.

T R..

Bolt (protector):

7 Nm (0.7 m • kg, 5.1 ft • lb)

CAUTION:

Do not reuse the drained brake fluid.

NOTE:

lInstall the brake pads with their projec-

tions a into the caliper recesses b.

lTemporarily tighten the pad pin at this

point.