drain bolt YAMAHA WR 426F 2001 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: WR 426F, Model: YAMAHA WR 426F 2001Pages: 762, PDF Size: 62.36 MB

Page 26 of 762

1 - 1

GEN

INFO

DESCRIPTION

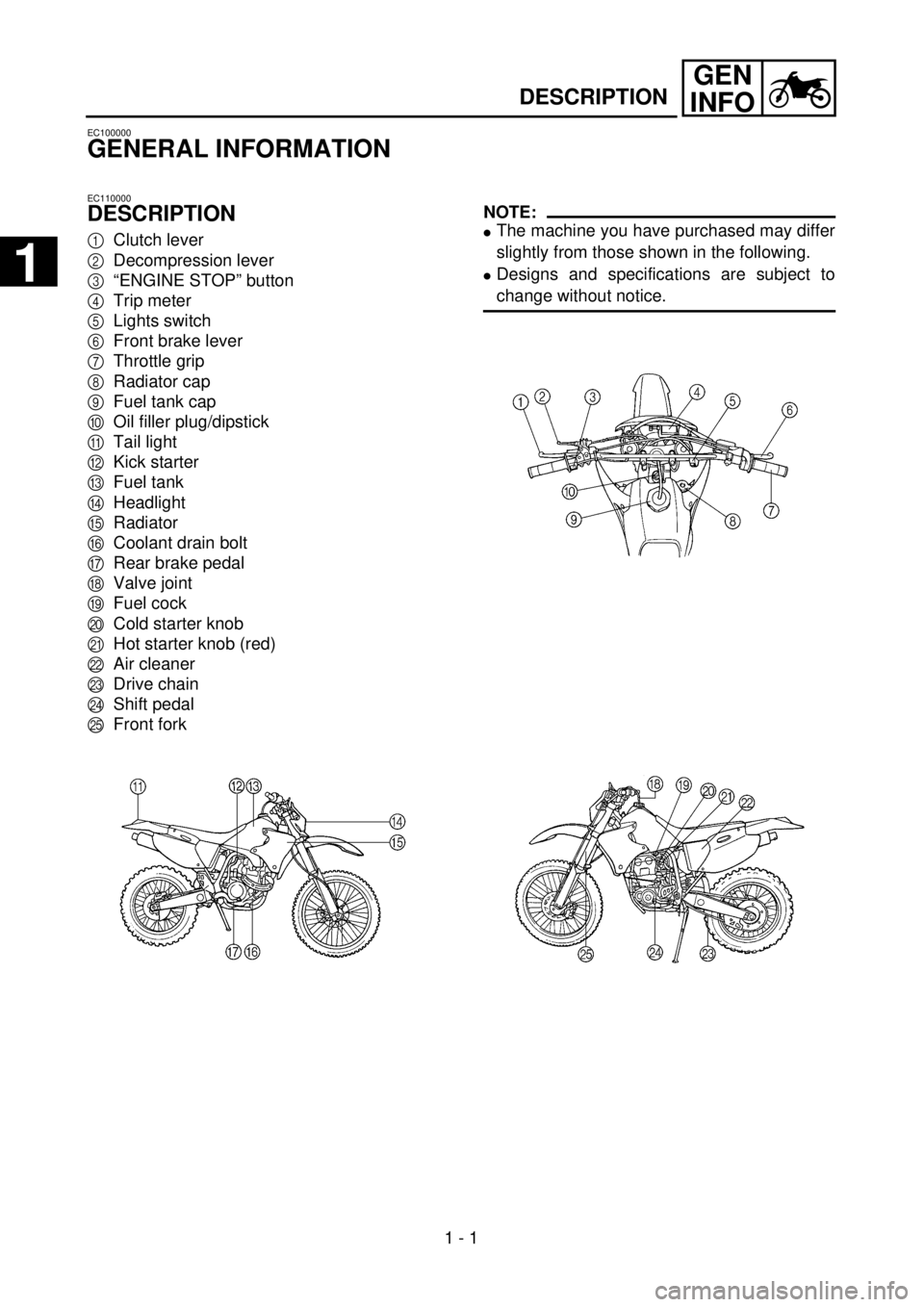

EC100000

GENERAL INFORMATION

EC110000

DESCRIPTION

1

Clutch lever

2

Decompression lever

3

“ENGINE STOP” button

4

Trip meter

5

Lights switch

6

Front brake lever

7

Throttle grip

8

Radiator cap

9

Fuel tank cap

0

Oil filler plug/dipstick

A

Tail light

B

Kick starter

C

Fuel tank

D

Headlight

E

Radiator

F

Coolant drain bolt

G

Rear brake pedal

H

Valve joint

I

Fuel cock

J

Cold starter knob

K

Hot starter knob (red)

L

Air cleaner

M

Drive chain

N

Shift pedal

O

Front fork

NOTE:

l

The machine you have purchased may differ

slightly from those shown in the following.

l

Designs and specifications are subject to

change without notice.

1

1

Page 84 of 762

2 - 11

SPEC

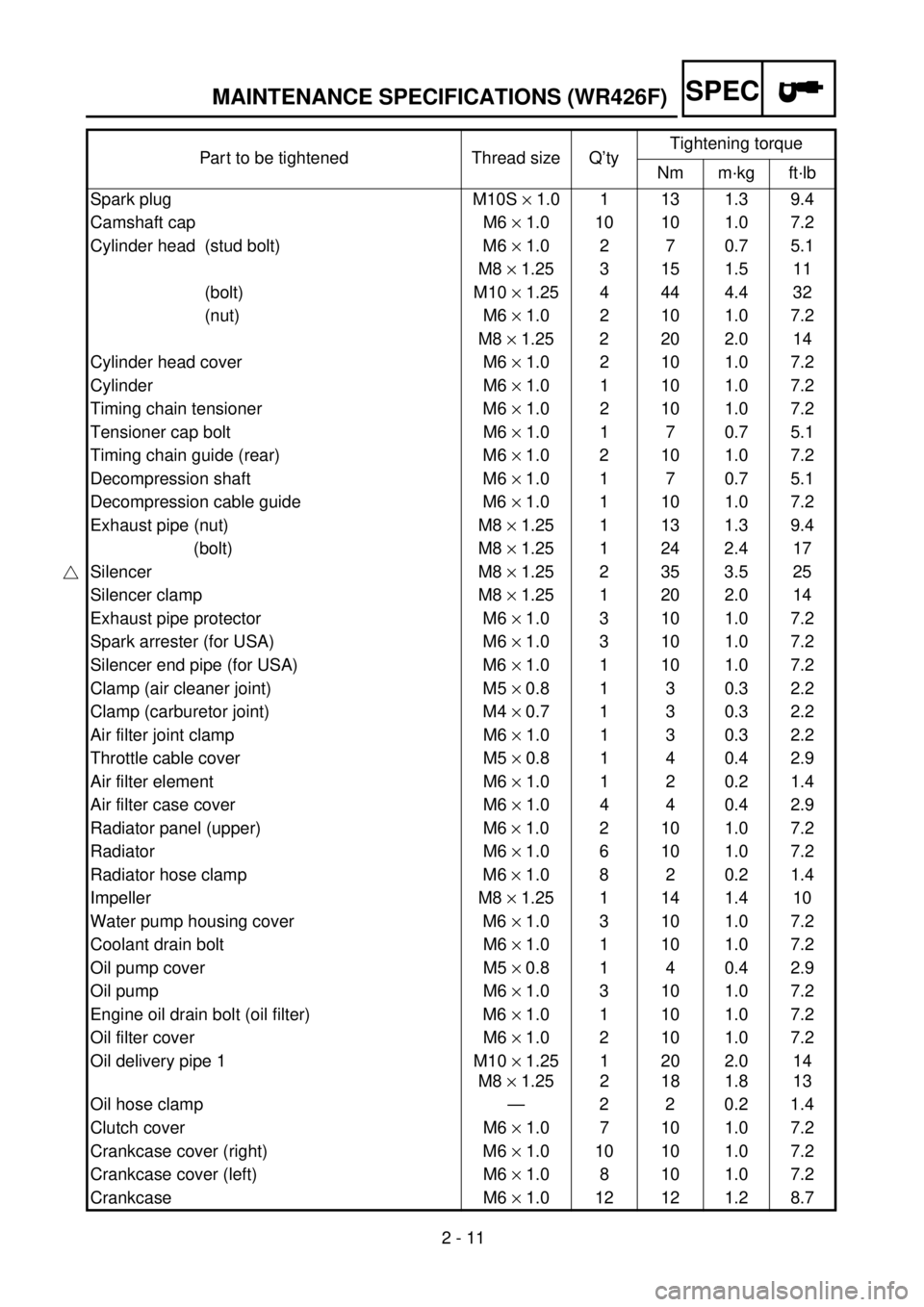

MAINTENANCE SPECIFICATIONS (WR426F)

Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Spark plug M10S

´

1.0 1 13 1.3 9.4

Camshaft cap M6

´

1.0 10 10 1.0 7.2

Cylinder head (stud bolt) M6

´

1.0 2 7 0.7 5.1

M8

´

1.25 3 15 1.5 11

(bolt) M10

´

1.25 4 44 4.4 32

(nut) M6

´

1.0 2 10 1.0 7.2

M8

´

1.25 2 20 2.0 14

Cylinder head cover M6

´

1.0 2 10 1.0 7.2

Cylinder M6

´

1.0 1 10 1.0 7.2

Timing chain tensioner M6

´

1.0 2 10 1.0 7.2

Tensioner cap bolt M6

´

1.0 1 7 0.7 5.1

Timing chain guide (rear) M6

´

1.0 2 10 1.0 7.2

Decompression shaft M6

´

1.0 1 7 0.7 5.1

Decompression cable guide M6

´

1.0 1 10 1.0 7.2

Exhaust pipe (nut) M8

´

1.25 1 13 1.3 9.4

(bolt) M8

´

1.25 1 24 2.4 17

Silencer M8

´

1.25 2 35 3.5 25

Silencer clamp M8

´

1.25 1 20 2.0 14

Exhaust pipe protector M6

´

1.0 3 10 1.0 7.2

Spark arrester (for USA) M6

´

1.0 3 10 1.0 7.2

Silencer end pipe (for USA) M6

´

1.0 1 10 1.0 7.2

Clamp (air cleaner joint) M5

´

0.8 1 3 0.3 2.2

Clamp (carburetor joint) M4

´

0.7 1 3 0.3 2.2

Air filter joint clamp M6

´

1.0 1 3 0.3 2.2

Throttle cable cover M5

´

0.8 1 4 0.4 2.9

Air filter element M6

´

1.0 1 2 0.2 1.4

Air filter case cover M6

´

1.0 4 4 0.4 2.9

Radiator panel (upper) M6

´

1.0 2 10 1.0 7.2

Radiator M6

´

1.0 6 10 1.0 7.2

Radiator hose clamp M6

´

1.0 8 2 0.2 1.4

Impeller M8

´

1.25 1 14 1.4 10

Water pump housing cover M6

´ 1.0 3 10 1.0 7.2

Coolant drain bolt M6 ´ 1.0 1 10 1.0 7.2

Oil pump cover M5 ´ 0.8 1 4 0.4 2.9

Oil pump M6 ´ 1.0 3 10 1.0 7.2

Engine oil drain bolt (oil filter) M6 ´ 1.0 1 10 1.0 7.2

Oil filter cover M6 ´ 1.0 2 10 1.0 7.2

Oil delivery pipe 1 M10 ´ 1.25

M8 ´ 1.251

220

182.0

1.814

13

Oil hose clamp — 2 2 0.2 1.4

Clutch cover M6 ´ 1.0 7 10 1.0 7.2

Crankcase cover (right) M6 ´ 1.0 10 10 1.0 7.2

Crankcase cover (left) M6 ´ 1.0 8 10 1.0 7.2

Crankcase M6 ´ 1.0 12 12 1.2 8.7

Page 85 of 762

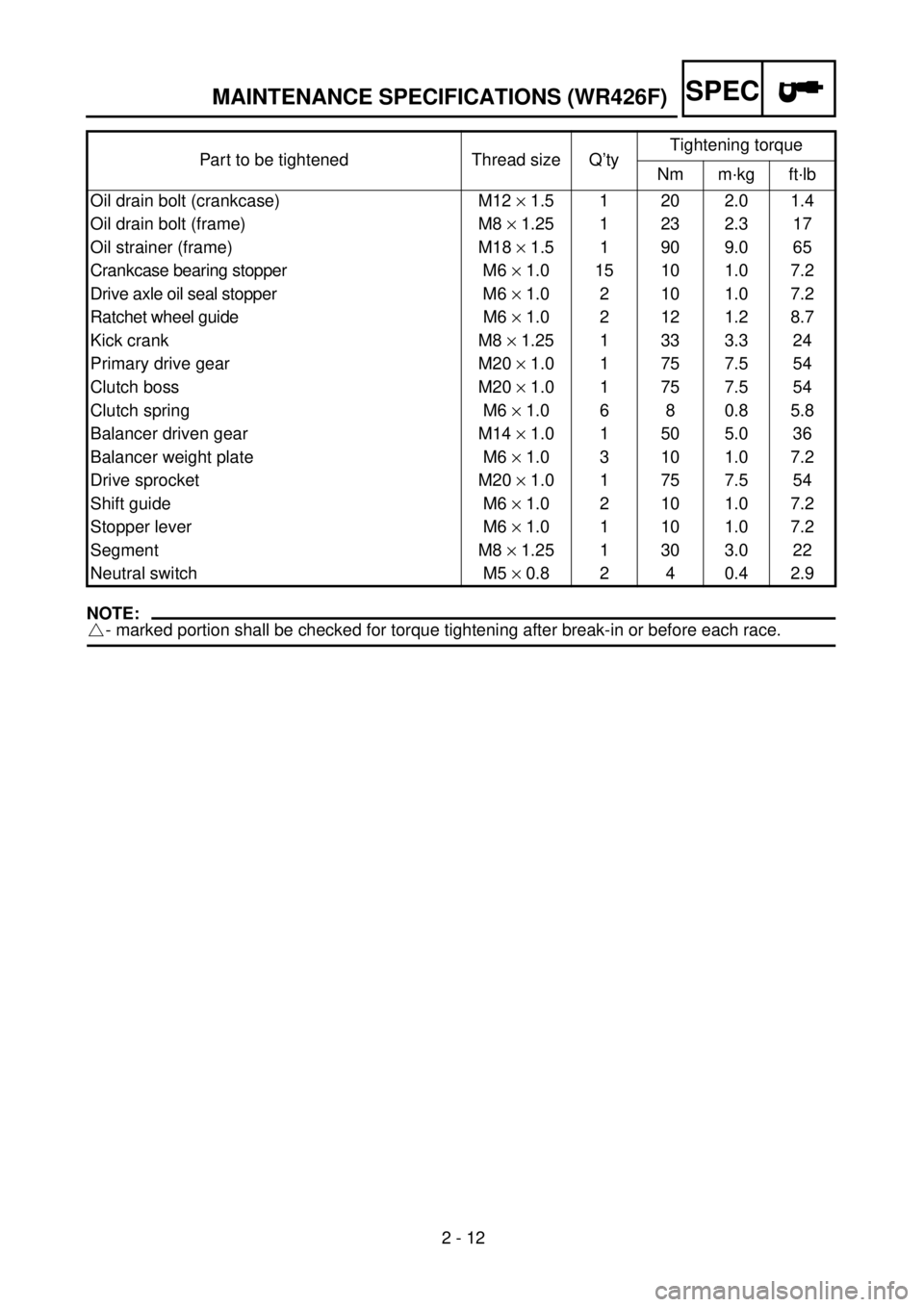

2 - 12

SPECMAINTENANCE SPECIFICATIONS (WR426F)

Oil drain bolt (crankcase) M12 ´ 1.5 1 20 2.0 1.4

Oil drain bolt (frame) M8 ´ 1.25 1 23 2.3 17

Oil strainer (frame) M18 ´ 1.5 1 90 9.0 65

Crankcase bearing stopper M6 ´ 1.0 15 10 1.0 7.2

Drive axle oil seal stopper M6 ´ 1.0 2 10 1.0 7.2

Ratchet wheel guide M6 ´ 1.0 2 12 1.2 8.7

Kick crank M8 ´ 1.25 1 33 3.3 24

Primary drive gear M20 ´ 1.0 1 75 7.5 54

Clutch boss M20 ´ 1.0 1 75 7.5 54

Clutch spring M6 ´ 1.0 6 8 0.8 5.8

Balancer driven gear M14 ´ 1.0 1 50 5.0 36

Balancer weight plate M6 ´ 1.0 3 10 1.0 7.2

Drive sprocket M20 ´ 1.0 1 75 7.5 54

Shift guide M6 ´ 1.0 2 10 1.0 7.2

Stopper lever M6 ´ 1.0 1 10 1.0 7.2

Segment M8 ´ 1.25 1 30 3.0 22

Neutral switch M5 ´ 0.8 2 4 0.4 2.9 Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

NOTE:

- marked portion shall be checked for torque tightening after break-in or before each race.

Page 101 of 762

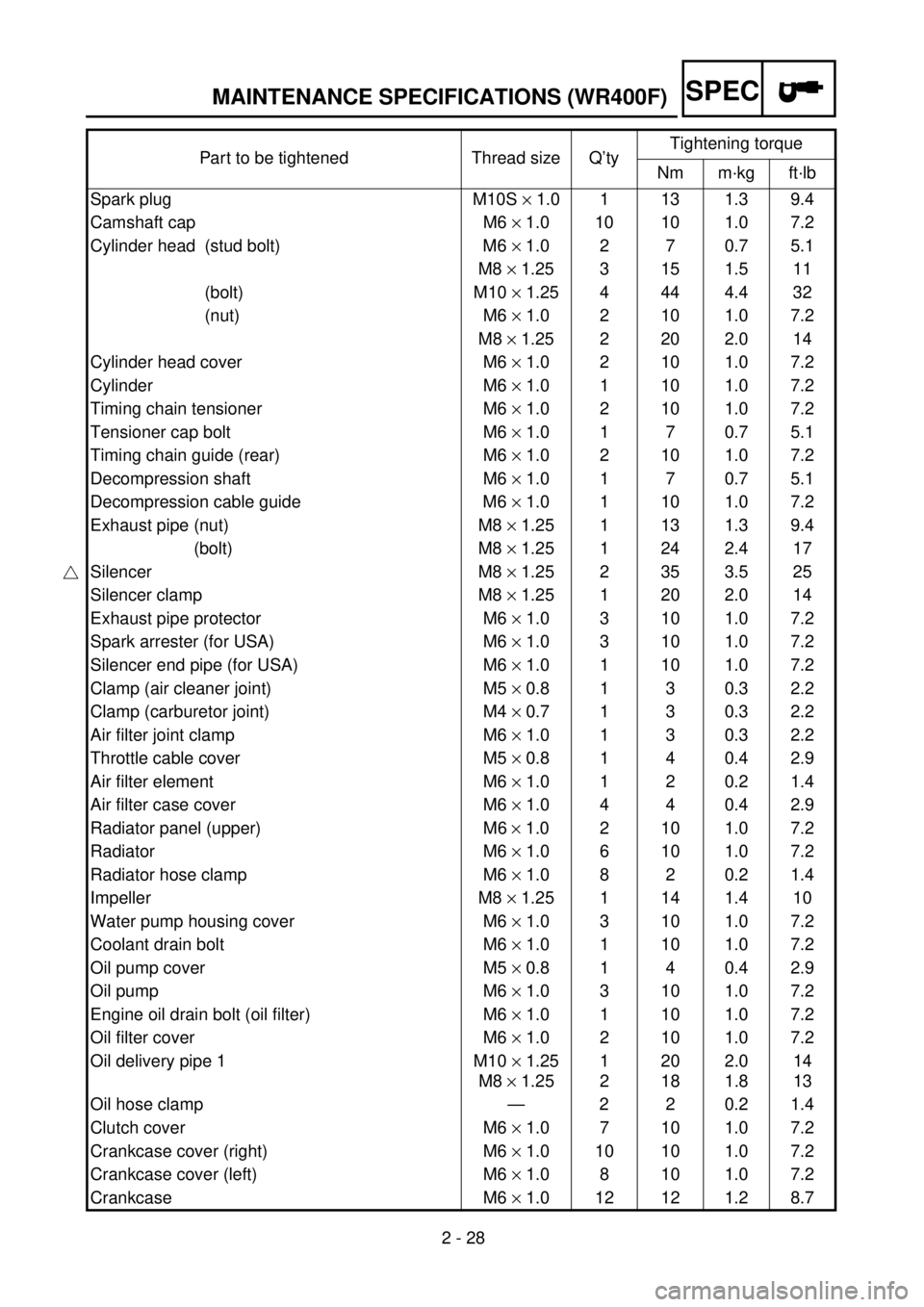

2 - 28

SPECMAINTENANCE SPECIFICATIONS (WR400F)

Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Spark plug M10S ´ 1.0 1 13 1.3 9.4

Camshaft cap M6 ´ 1.0 10 10 1.0 7.2

Cylinder head (stud bolt) M6 ´ 1.0 2 7 0.7 5.1

M8 ´ 1.25 3 15 1.5 11

(bolt) M10 ´ 1.25 4 44 4.4 32

(nut) M6 ´ 1.0 2 10 1.0 7.2

M8 ´ 1.25 2 20 2.0 14

Cylinder head cover M6 ´ 1.0 2 10 1.0 7.2

Cylinder M6 ´ 1.0 1 10 1.0 7.2

Timing chain tensioner M6 ´ 1.0 2 10 1.0 7.2

Tensioner cap bolt M6 ´ 1.0 1 7 0.7 5.1

Timing chain guide (rear) M6 ´ 1.0 2 10 1.0 7.2

Decompression shaft M6 ´ 1.0 1 7 0.7 5.1

Decompression cable guide M6 ´ 1.0 1 10 1.0 7.2

Exhaust pipe (nut) M8 ´ 1.25 1 13 1.3 9.4

(bolt) M8 ´ 1.25 1 24 2.4 17

Silencer M8 ´ 1.25 2 35 3.5 25

Silencer clamp M8 ´ 1.25 1 20 2.0 14

Exhaust pipe protector M6 ´ 1.0 3 10 1.0 7.2

Spark arrester (for USA) M6 ´ 1.0 3 10 1.0 7.2

Silencer end pipe (for USA) M6 ´ 1.0 1 10 1.0 7.2

Clamp (air cleaner joint) M5 ´ 0.8 1 3 0.3 2.2

Clamp (carburetor joint) M4 ´ 0.7 1 3 0.3 2.2

Air filter joint clamp M6 ´ 1.0 1 3 0.3 2.2

Throttle cable cover M5 ´ 0.8 1 4 0.4 2.9

Air filter element M6 ´ 1.0 1 2 0.2 1.4

Air filter case cover M6 ´ 1.0 4 4 0.4 2.9

Radiator panel (upper) M6 ´ 1.0 2 10 1.0 7.2

Radiator M6 ´ 1.0 6 10 1.0 7.2

Radiator hose clamp M6 ´ 1.0 8 2 0.2 1.4

Impeller M8 ´ 1.25 1 14 1.4 10

Water pump housing cover M6 ´ 1.0 3 10 1.0 7.2

Coolant drain bolt M6 ´ 1.0 1 10 1.0 7.2

Oil pump cover M5 ´ 0.8 1 4 0.4 2.9

Oil pump M6 ´ 1.0 3 10 1.0 7.2

Engine oil drain bolt (oil filter) M6 ´ 1.0 1 10 1.0 7.2

Oil filter cover M6 ´ 1.0 2 10 1.0 7.2

Oil delivery pipe 1 M10 ´ 1.25

M8 ´ 1.251

220

182.0

1.814

13

Oil hose clamp — 2 2 0.2 1.4

Clutch cover M6 ´ 1.0 7 10 1.0 7.2

Crankcase cover (right) M6 ´ 1.0 10 10 1.0 7.2

Crankcase cover (left) M6 ´ 1.0 8 10 1.0 7.2

Crankcase M6 ´ 1.0 12 12 1.2 8.7

Page 102 of 762

2 - 29

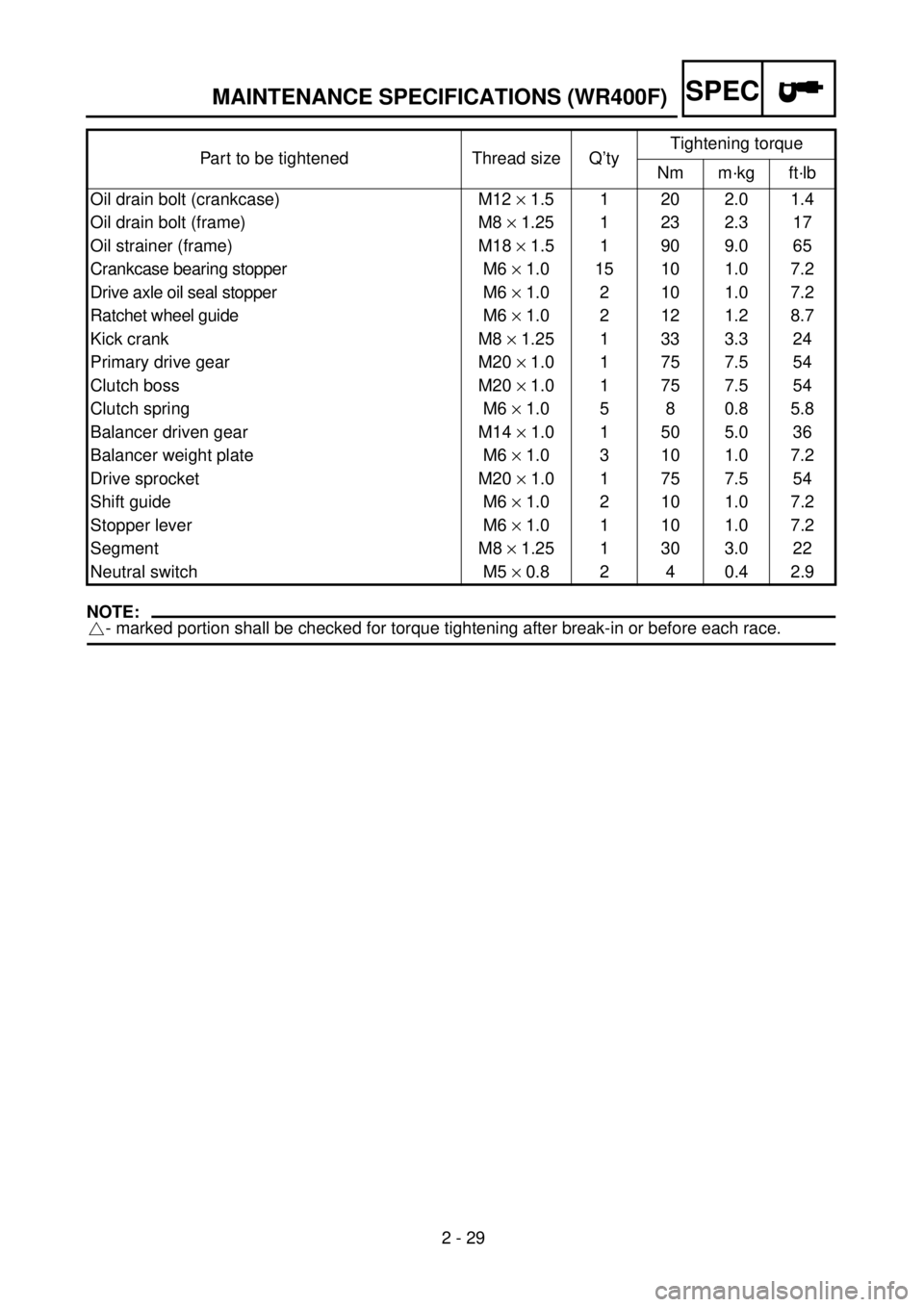

SPECMAINTENANCE SPECIFICATIONS (WR400F)

NOTE:

- marked portion shall be checked for torque tightening after break-in or before each race. Oil drain bolt (crankcase) M12 ´ 1.5 1 20 2.0 1.4

Oil drain bolt (frame) M8 ´ 1.25 1 23 2.3 17

Oil strainer (frame) M18 ´ 1.5 1 90 9.0 65

Crankcase bearing stopper M6 ´ 1.0 15 10 1.0 7.2

Drive axle oil seal stopper M6 ´ 1.0 2 10 1.0 7.2

Ratchet wheel guide M6 ´ 1.0 2 12 1.2 8.7

Kick crank M8 ´ 1.25 1 33 3.3 24

Primary drive gear M20 ´ 1.0 1 75 7.5 54

Clutch boss M20 ´ 1.0 1 75 7.5 54

Clutch spring M6 ´ 1.0 5 8 0.8 5.8

Balancer driven gear M14 ´ 1.0 1 50 5.0 36

Balancer weight plate M6 ´ 1.0 3 10 1.0 7.2

Drive sprocket M20 ´ 1.0 1 75 7.5 54

Shift guide M6 ´ 1.0 2 10 1.0 7.2

Stopper lever M6 ´ 1.0 1 10 1.0 7.2

Segment M8 ´ 1.25 1 30 3.0 22

Neutral switch M5 ´ 0.8 2 4 0.4 2.9 Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Page 242 of 762

3 - 5

INSP

ADJ

EC350000

ENGINE

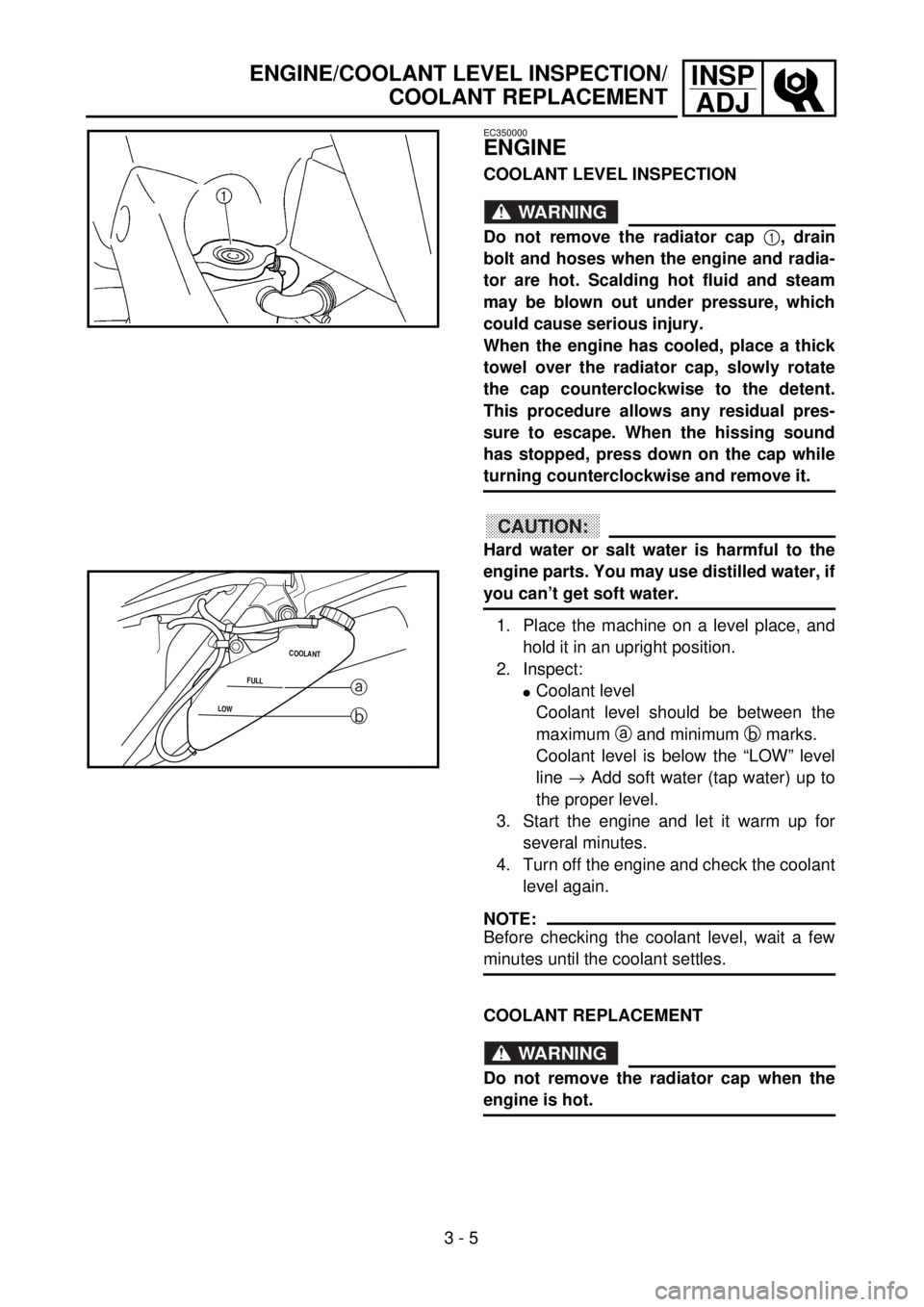

COOLANT LEVEL INSPECTION

WARNING

Do not remove the radiator cap

1

, drain

bolt and hoses when the engine and radia-

tor are hot. Scalding hot fluid and steam

may be blown out under pressure, which

could cause serious injury.

When the engine has cooled, place a thick

towel over the radiator cap, slowly rotate

the cap counterclockwise to the detent.

This procedure allows any residual pres-

sure to escape. When the hissing sound

has stopped, press down on the cap while

turning counterclockwise and remove it.

CAUTION:

Hard water or salt water is harmful to the

engine parts. You may use distilled water, if

you can’t get soft water.

1. Place the machine on a level place, and

hold it in an upright position.

2. Inspect:

l

Coolant level

Coolant level should be between the

maximum

a

and minimum

b

marks.

Coolant level is below the “LOW” level

line

®

Add soft water (tap water) up to

the proper level.

3. Start the engine and let it warm up for

several minutes.

4. Turn off the engine and check the coolant

level again.

NOTE:

Before checking the coolant level, wait a few

minutes until the coolant settles.

LOWFULLCOOLANT

a

b

COOLANT REPLACEMENT

WARNING

Do not remove the radiator cap when the

engine is hot.

ENGINE/COOLANT LEVEL INSPECTION/

COOLANT REPLACEMENT

Page 244 of 762

3 - 6

INSP

ADJ

COOLANT REPLACEMENT

CAUTION:

Take care so that coolant does not splash

on painted surfaces. If it splashes, wash it

away with water.

1. Place a container under the engine.

2. Remove:

l

Seat

Refer to ”SEAT FUEL TANK AND SIDE

COVERS” section in the CHAPTER 4.

3. Disconnect:

l

Coolant reservoir hose

1

Drain the coolant completely.

4. Connect:

l

Coolant reservoir hose

LOWFULLCOOLANT1

5. Remove:

l

Engine guard

1

l

Coolant drain bolt

2

6. Remove:

l

Radiator cap

Drain the coolant completely.

7. Clean:

l

Cooling system

Thoroughly flush the cooling system

with clean tap water.

8. Install:

l

Copper washer

l

Coolant drain bolt

l

Engine guard

l

Bolt [engine guard (front)]

l

Bolt [engine guard (rear)]

New

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

T R..34 Nm (3.4 m · kg, 24 ft · lb)

T R..23 Nm (2.3 m · kg, 17 ft · lb)

Page 264 of 762

3 - 16

INSP

ADJ

ENGINE OIL REPLACEMENT

5. Start the engine and let it warm up for

several minutes.

CAUTION:

When the oil tank is empty, never start the

engine.

6. Idle the engine more than 10 seconds

while keeping the motorcycle upright.

Then stop the engine and add the oil to

the maximum level.

7. Install:

lOil tank cap

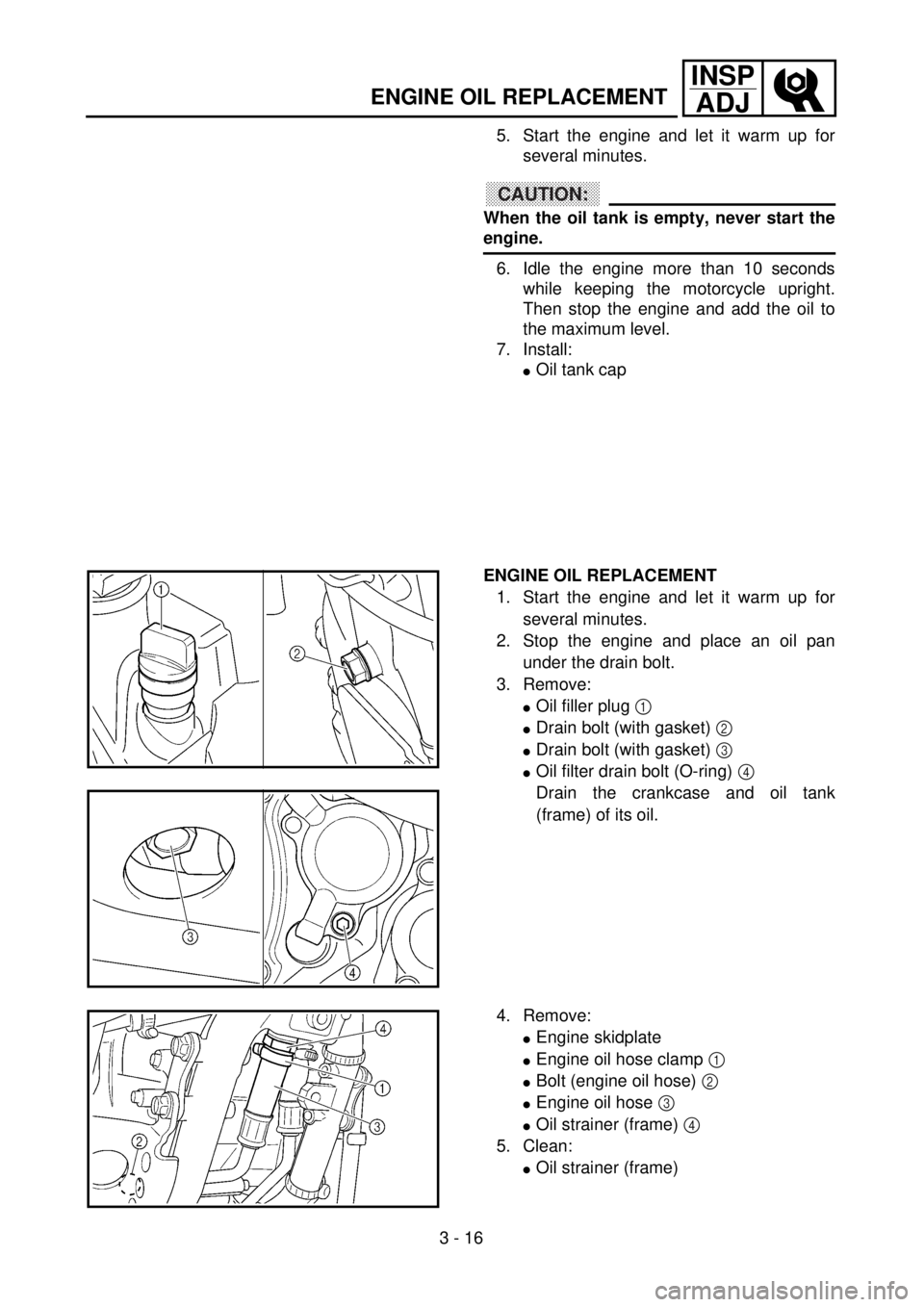

ENGINE OIL REPLACEMENT

1. Start the engine and let it warm up for

several minutes.

2. Stop the engine and place an oil pan

under the drain bolt.

3. Remove:

lOil filler plug 1

lDrain bolt (with gasket) 2

lDrain bolt (with gasket) 3

lOil filter drain bolt (O-ring) 4

Drain the crankcase and oil tank

(frame) of its oil.

4. Remove:

lEngine skidplate

lEngine oil hose clamp 1

lBolt (engine oil hose) 2

lEngine oil hose 3

lOil strainer (frame) 4

5. Clean:

lOil strainer (frame)

Page 266 of 762

3 - 17

INSP

ADJ

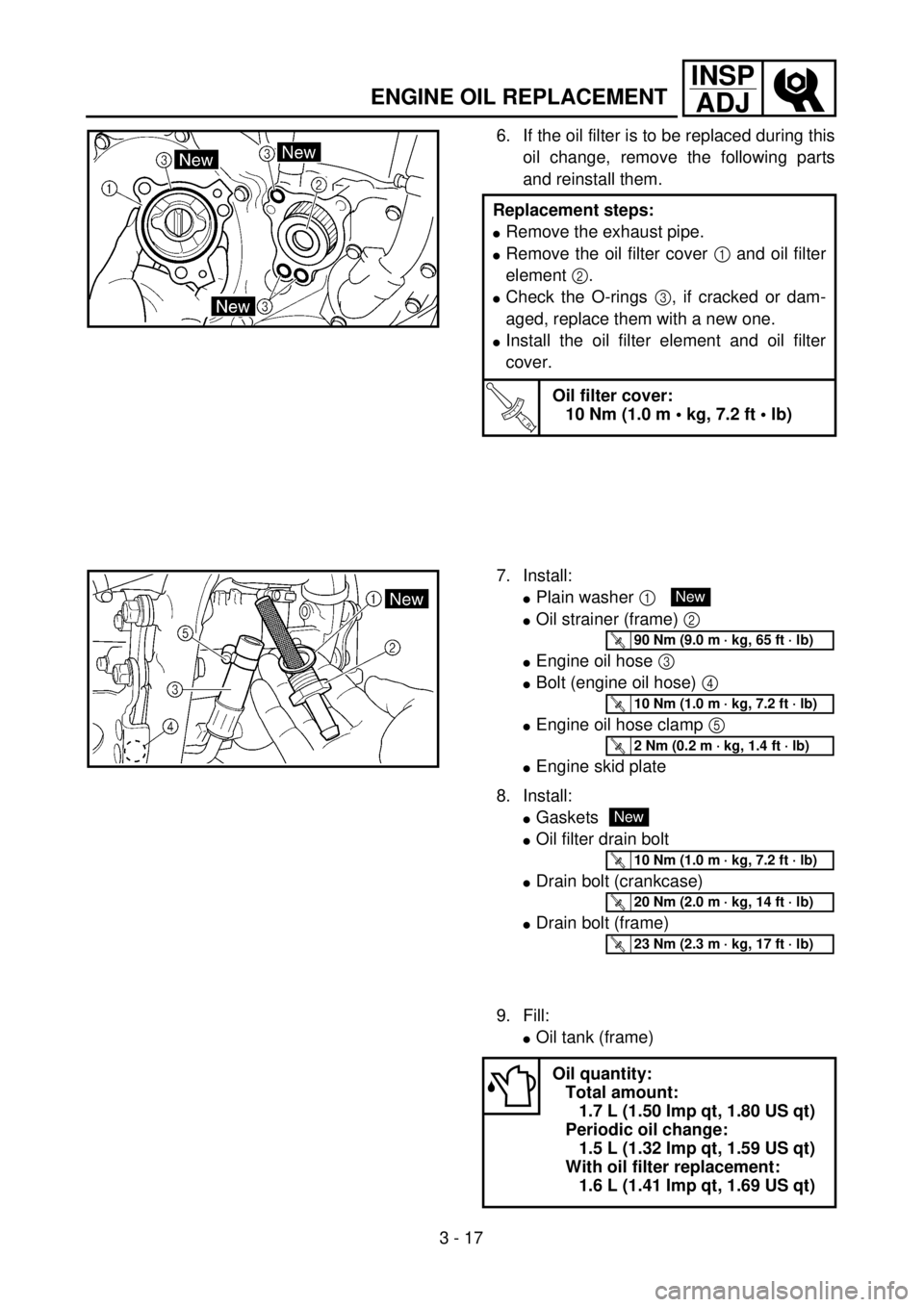

ENGINE OIL REPLACEMENT

6. If the oil filter is to be replaced during this

oil change, remove the following parts

and reinstall them.

Replacement steps:

lRemove the exhaust pipe.

lRemove the oil filter cover 1 and oil filter

element 2.

lCheck the O-rings 3, if cracked or dam-

aged, replace them with a new one.

lInstall the oil filter element and oil filter

cover.

T R..

Oil filter cover:

10 Nm (1.0 m • kg, 7.2 ft • lb)

7. Install:

lPlain washer 1

lOil strainer (frame) 2

lEngine oil hose 3

lBolt (engine oil hose) 4

lEngine oil hose clamp 5

lEngine skid plate

New

T R..90 Nm (9.0 m · kg, 65 ft · lb)

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

T R..2 Nm (0.2 m · kg, 1.4 ft · lb)

8. Install:

lGaskets

lOil filter drain bolt

lDrain bolt (crankcase)

lDrain bolt (frame)

New

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

T R..20 Nm (2.0 m · kg, 14 ft · lb)

T R..23 Nm (2.3 m · kg, 17 ft · lb)

9. Fill:

lOil tank (frame)

Oil quantity:

Total amount:

1.7 L (1.50 Imp qt, 1.80 US qt)

Periodic oil change:

1.5 L (1.32 Imp qt, 1.59 US qt)

With oil filter replacement:

1.6 L (1.41 Imp qt, 1.69 US qt)

Page 292 of 762

3 - 29

INSP

ADJ

FRONT BRAKE PAD INSPECTION AND REPLACEMENT

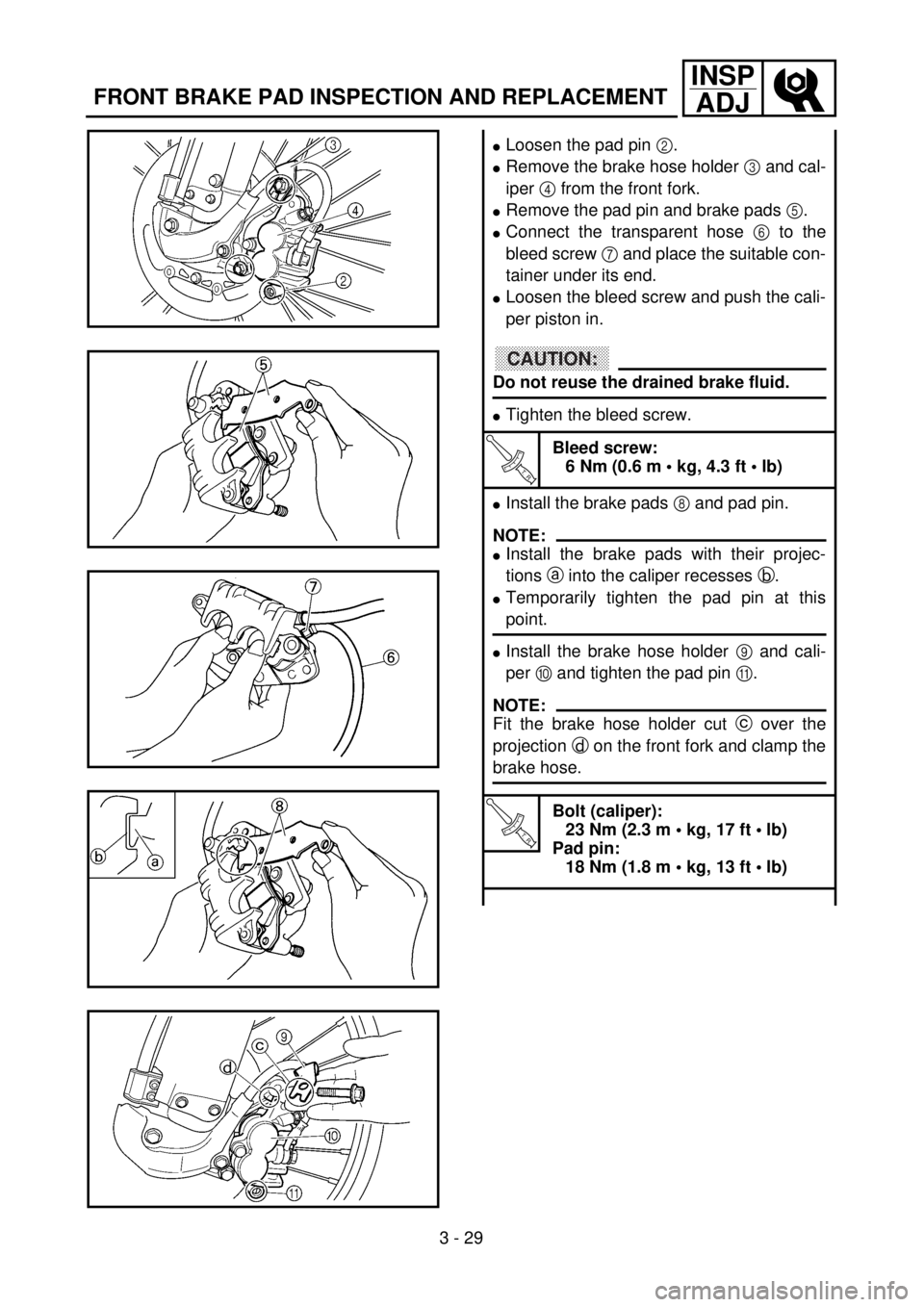

lLoosen the pad pin 2.

lRemove the brake hose holder 3 and cal-

iper 4 from the front fork.

lRemove the pad pin and brake pads 5.

lConnect the transparent hose 6 to the

bleed screw 7 and place the suitable con-

tainer under its end.

lLoosen the bleed screw and push the cali-

per piston in.

CAUTION:

Do not reuse the drained brake fluid.

lTighten the bleed screw.

T R..

Bleed screw:

6 Nm (0.6 m • kg, 4.3 ft • lb)

lInstall the brake pads 8 and pad pin.

NOTE:

lInstall the brake pads with their projec-

tions a into the caliper recesses b.

lTemporarily tighten the pad pin at this

point.

lInstall the brake hose holder 9 and cali-

per 0 and tighten the pad pin A.

NOTE:

Fit the brake hose holder cut c over the

projection d on the front fork and clamp the

brake hose.

T R..

Bolt (caliper):

23 Nm (2.3 m • kg, 17 ft • lb)

Pad pin:

18 Nm (1.8 m • kg, 13 ft • lb)