engine YAMAHA WR 426F 2001 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: WR 426F, Model: YAMAHA WR 426F 2001Pages: 762, PDF Size: 62.36 MB

Page 687 of 762

–+ELECSISTEMA DE ENCENDIDO

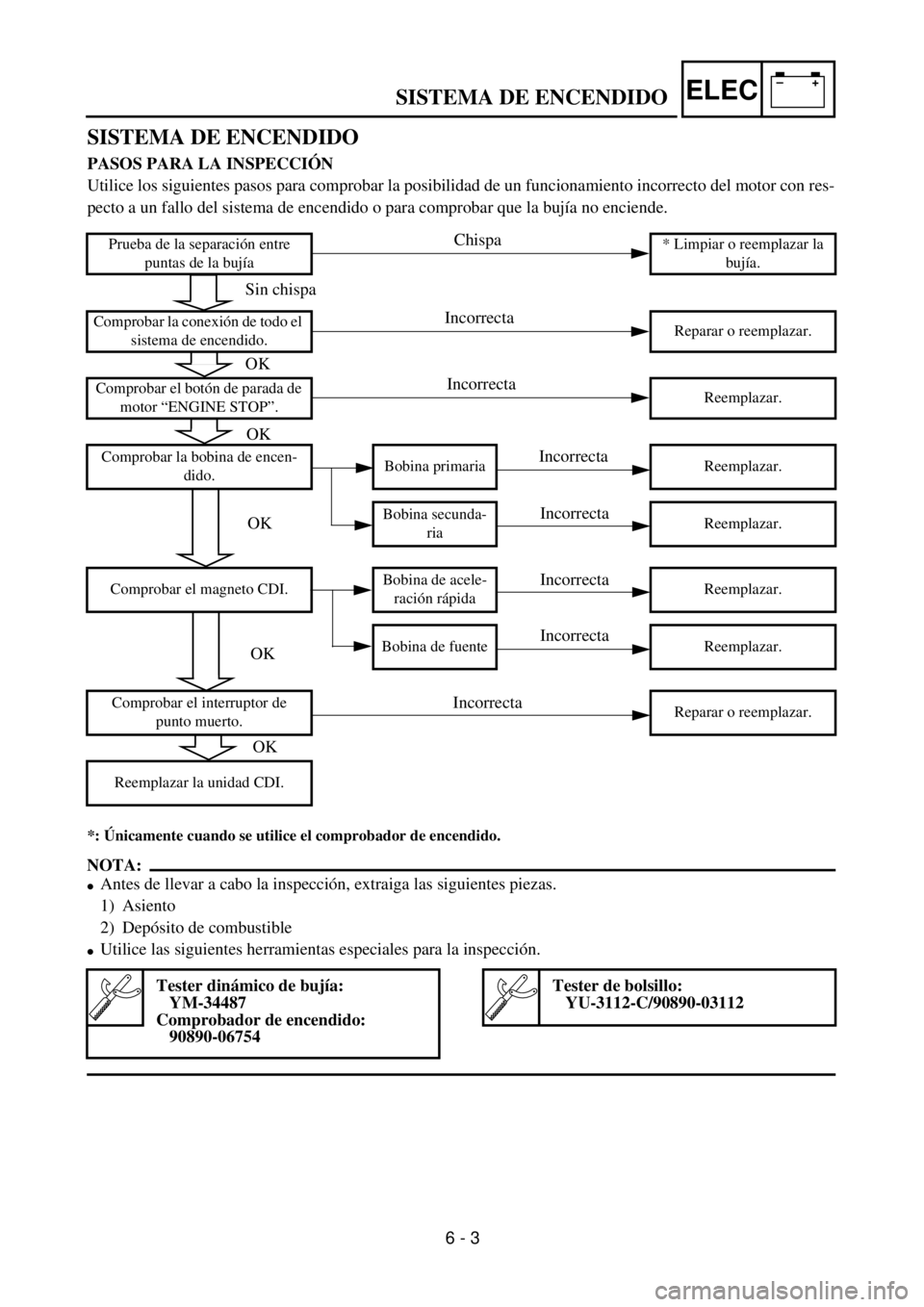

SISTEMA DE ENCENDIDO

PASOS PARA LA INSPECCIÓN

Utilice los siguientes pasos para comprobar la posibilidad de un funcionamiento incorrecto del motor con res-

pecto a un fallo del sistema de encendido o para comprobar que la bujía no enciende.

*: Únicamente cuando se utilice el comprobador de encendido.

NOTA:

lAntes de llevar a cabo la inspección, extraiga las siguientes piezas.

1) Asiento

2) Depósito de combustible

lUtilice las siguientes herramientas especiales para la inspección.

Prueba de la separación entre

puntas de la bujía* Limpiar o reemplazar la

bujía.

Comprobar la conexión de todo el

sistema de encendido.Reparar o reemplazar.

Comprobar el botón de parada de

motor “ENGINE STOP”.Reemplazar.

Comprobar la bobina de encen-

dido.Bobina primaria Reemplazar.

Bobina secunda-

riaReemplazar.

Comprobar el magneto CDI.Bobina de acele-

ración rápidaReemplazar.

Bobina de fuente Reemplazar.

Comprobar el interruptor de

punto muerto.Reparar o reemplazar.

Reemplazar la unidad CDI.

Tester dinámico de bujía:

YM-34487

Comprobador de encendido:

90890-06754Tester de bolsillo:

YU-3112-C/90890-03112

Sin chispa

OK

Chispa

Incorrecta

Incorrecta

Incorrecta

Incorrecta

Incorrecta

Incorrecta

Incorrecta

OK

OK

OK

OK

6 - 3

Page 688 of 762

6 - 4

–+ELEC

IGNITION SYSTEM

EC622001

SPARK GAP TEST

1. Disconnect the spark plug cap from spark

plug.

2. Connect the dynamic spark tester

1

(ignition checker

2

) as shown.

l

Spark plug cap

3

l

Spark plug

4

For USA and CDN

õ

Except for USA and CDN

3. Kick the kick starter.

4. Check the ignition spark gap.

5. Start engine, and increase spark gap

until misfire occurs. (for USA and CDN

only)

Minimum spark gap:

6.0 mm (0.24 in)

õ

EC624000

COUPLERS AND LEADS CONNECTION

INSPECTION

1. Check:

l

Couplers and leads connection

Rust/dust/looseness/short-circuit

®

Repair or replace.

EC625001

“ENGINE STOP” BUTTON INSPECTION

1. Inspect:

l

“ENGINE STOP” button conduct

No continuity while being pushed

®

Replace.

Continuity while being freed

®

Replace.

Tester (+) lead

®

Black/White lead

1

Tester (–) lead

®

Black lead

2

B/W

1

B

2

Tester selec-

tor position

PUSH IN

W

´

1

FREE

Page 689 of 762

–+ELEC

SYSTEME D’ALLUMAGE

ZÜNDANLAGE

SISTEMA DE ENCENDIDO

ZÜNDFUNKENSTRECKE KON-

TROLLIEREN

1. Den Zündkerzenstecker von

der Zündkerze abziehen.

2. Den Zündfunkenstreckente-

ster 1 (bzw. 2) wie abgebil-

det anschließen.

lZündkerzenstecker 3

lZündkerze 4

Nur USA und CDN

õNicht USA und CDN

3.Den Motor mit dem Kick-

starter durchdrehen

.

4. Die Zündfunkenstrecke kon-

trollieren.

5. Den Motor anlassen und die

Zündfunkenstrecke vergrö-

ßern, bis es zu Fehlzündun-

gen kommt (nur USA und

CDN).

Min. Zündfunkenstrecke

6,0 mm

STECKVERBINDER- UND KABEL-

ANSCHLÜSSE KONTROLLIEREN

1. Kontrollieren:

lSteckverbinder- und Kabel-

anschlüsse

Rost/Staub/Lockerheit/Kurz-

schluß ® Instand setzen

oder erneuern.

MOTORSTOPPSCHALTER “ENGI-

NE STOP” KONTROLLIEREN

1. Kontrollieren:

lMotorstoppschalter

(auf Durchgang)

Kein Durchgang bei gedrücktem

Schalter ® Erneuern.

Durchgang bei freigelassenem

Schalter ® Erneuern. Meßkabel (+) ®

Schwarz/Weiß Kabel 1

Meßkabel (–) ®

Schwarz Kabel 2

B/W

1 B

2 Meßge-

rät-

Einstel-

GE-

DRÜCKT

W ´ 1

FREI

TEST DE L’INTERVALLE D’ETIN-

CELLEMENT D’ALLUMAGE

1. Déconnecter le capuchon de bou-

gie de la bougie.

2. Connecter le testeur dynamique

d’étincelle 1 (testeur d’allu-

mage 2) comme indiqué.

lCapuchon de bougie 3

lBougie 4

Pour les USA et le CDN

õExcepté pour les USA et le CDN

3. Actionner le démarreur au pied.

4. Contrôler la longueur d’étincelle

d’allumage.

5. Démarrer le moteur et augmenter

la longueur d’étincelle jusqu’à ce

qu’un raté se produise. (unique-

ment USA et CDN)

Longueur d’étincelle mini-

mum:

6,0 mm (0,24 in)

CONTROLE DES CONNEXIONS

DE COUPLEURS ET FILS

1. Contrôler:

lConnexion de coupleurs et fils

Rouille/poussière/jeu/court-cir-

cuit ® Réparer ou changer.

CONTROLE DU BOUTON

D’ARRET DU MOTEUR “ENGINE

STOP”

1. Vérifier:

lContinuité du bouton d’arrêt du

moteur “ENGINE STOP”

Pas de continuité lorsque enfoncé ®

Changer.

Continuité lorsque relâché ® Changer. Fil (+) de multimètre ®

Fil noir/blanc 1

Fil (–) de multimètre ® Fil noir 2

B/W

1B

2Position de

sélecteur

du multi-

mètre

EN-

FONCE

W ´ 1

RE-

LACHE

6 - 4

PRUEBA DE LA SEPARACIÓN

ENTRE PUNTAS DE LA BUJÍA

1. Desconecte la tapa de puntas de la

bujía de la bujía misma.

2. Conecte el tester dinámico de la

bujía 1 (comprobador de encen-

dido 2) tal y como se muestra.

lTapa de la bujía 3

lBujía 4

Para USA y CDN

õExcepto USA y CDN

3. Accione el arrancador del pedal.

4. Compruebe la separación entre

puntas de la bujía de encendido.

5. Arranque el motor e incremente

la separación entre puntas de la

bujía hasta que deje de saltar la

chispa (solamente para USA y

CDN).

Separación entre puntas

mínima de la bujía:

6,0 mm (0,24 in)

INSPECCIÓN DE ACOPLADORES

Y CONEXIÓN DE CABLES

1. Comprobar:

lConexión de acopladores y

cables

Oxido/polvo/flojedad/cortocir-

cuito ® Reparar o reemplazar.

INSPECCIÓN DEL BOTÓN DE

PARADA DE MOTOR “ENGINE

STOP”

1. Inspeccionar:

lConducto del botón de parada

de motor “ENGINE STOP”

Sin continuidad mientras se mantiene

pulsado ® Reemplazar.

Con continuidad mientras se suelta ®

Reemplazar.Cable del tester (+) ®

Cable negro/blanco 1

Cable del tester (–) ®

Cable negro 2

B/W

1B

2Posición

del selec-

tor del tes-

ter

PULSAR

(PUSH

IN)

W ´ 1

LIBRE

Page 694 of 762

6 - 7

–+ELECTPS (THROTTLE POSITION SENSOR) SYSTEM

EC69000

TPS (THROTTLE POSITION SENSOR) SYSTEM

INSPECTION STEPS

If the TPS will not operate, use the following inspection steps.

*marked: Refer to “IGNITION SYSTEM” section.

NOTE:

lRemove the following parts before inspection.

1) Seat

2) Fuel tank

lUse the following special tools in this inspection.

Check entire ignition

system for connection.Repair or replace.

Check TPS. TPS coil Replace.

*Check CDI magneto. Source coil Replace.

Check CDI unit.TPS input

voltageReplace.

Pocket tester:

YU-3112-C/90890-03112Inductive tachometer:

YU-08036-B

Engine tachometer:

90890-03113

No good

No good

No good

No good

OK

OK

OK

Page 702 of 762

6 - 10

–+ELECTPS (THROTTLE POSITION SENSOR) SYSTEM

6. Adjust:

lTPS coil resistance at idle speed

Adjustment steps:

Adjust the angle of the TPS 1 to obtain

the resistance calculated (example: 650 ~

750 W)

Tester (+) lead ® Yellow lead 2

Tester (–) lead ® Black lead 3

7. Tighten:

lScrew (TPS) 1

8. Install:

lTPS coupler

EC694000

TPS INPUT VOLTAGE INSPECTION

1. Disconnect the TPS coupler.

2. Start the engine.

3. Inspect:

lTPS input voltage

Out of specification ® Replace the CDI

unit.

Tester (+) lead ® Blue lead 1

Tester (–) lead ® Black/Blue lead 2

TPS input

voltageTester selector

position

4 ~ 6 V DCV-20

Page 710 of 762

7 - 1

TUN

EC700000

TUNING

EC710000

ENGINE

Carburetor setting

l

The air/fuel mixture will vary depending on

atmospheric conditions. Therefore, it is nec-

essary to take into consideration the air pres-

sure, ambient temperature, humidity, etc.,

when adjusting the carburetor.

l

Perform a test run to check for proper engine

performance (e.g., throttle response) and

spark plug(-s) discoloration or fouling. Use

these readings to determine the best possi-

ble carburetor setting.

NOTE:

It is recommended to keep a record of all car-

buretor settings and external conditions (e.g.,

atmospheric conditions, track/surface condi-

tions, lap times) to make future carburetor set-

ting easier.

WARNING

l

The carburetor is a part of the fuel line.

Therefore, be sure to install it in a well-

ventilated area, away from flammable

objects and any sources of fire.

l

Never look into the carburetor intake.

Flames may shoot out from the pipe if the

engine backfires while it is being started.

Gasoline may be discharged from the

accelerator pump nozzle when the carbu-

retor has been removed.

SETTING

7

7

Page 712 of 762

7 - 2

TUN

CAUTION:

l

The carburetor is extremely sensitive to

foreign matter (dirt, sand, water, etc.).

During installation, do not allow foreign

matter to get into the carburetor.

l

Always handle the carburetor and its

components carefully. Even slight

scratches, bends or damage to carbure-

tor parts may prevent the carburetor from

functioning correctly. Carefully perform

all servicing with the appropriate tools

and without applying excessive force.

l

When the engine is stopped or when

riding at no load, do not open and close

the throttle unnecessarily. Otherwise, too

much fuel may be discharged, starting

may become difficult or the engine may

not run well.

l

After installing the carburetor, check that

the throttle operates correctly and opens

and closes smoothly.

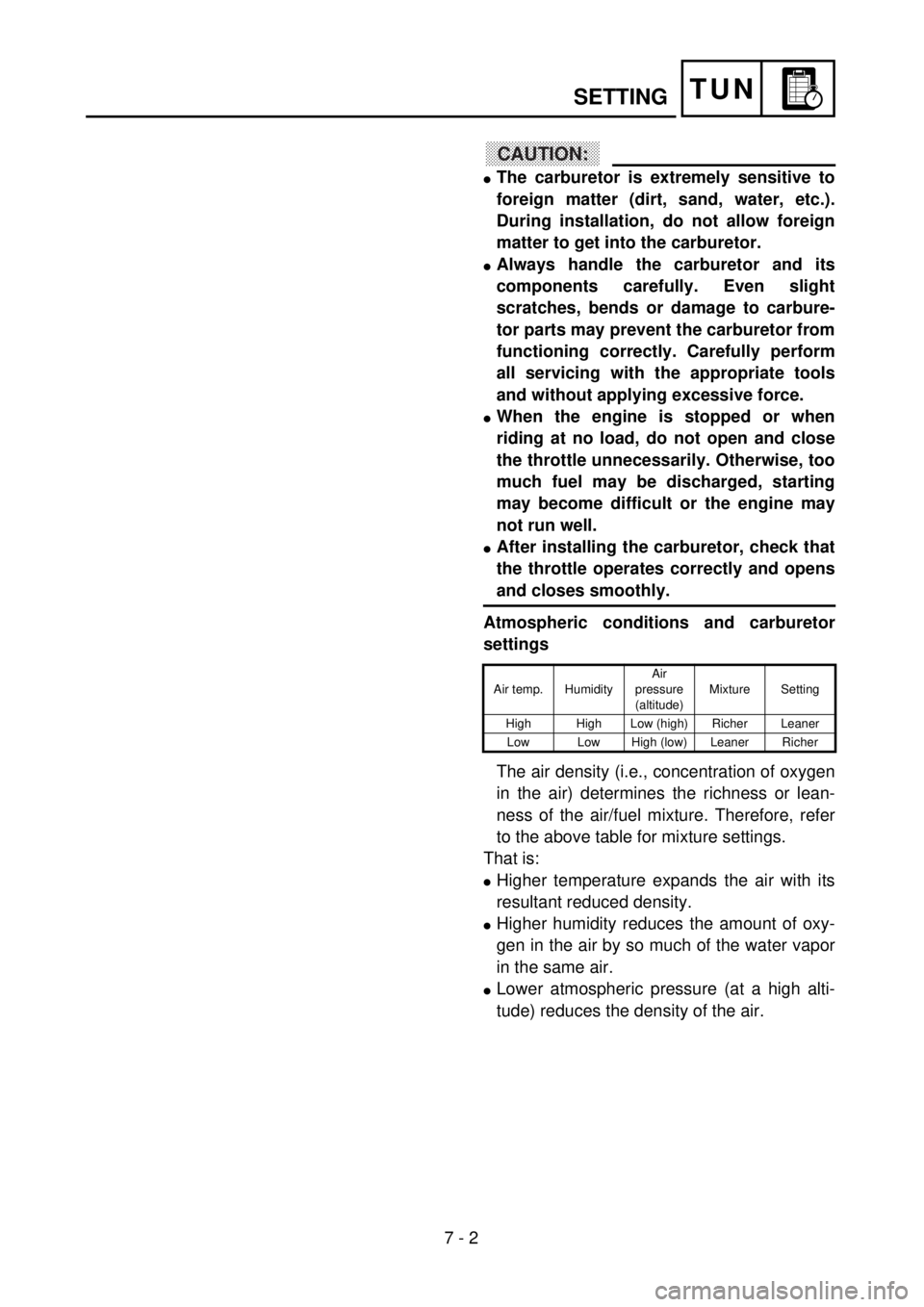

Atmospheric conditions and carburetor

settings

The air density (i.e., concentration of oxygen

in the air) determines the richness or lean-

ness of the air/fuel mixture. Therefore, refer

to the above table for mixture settings.

That is:

l

Higher temperature expands the air with its

resultant reduced density.

l

Higher humidity reduces the amount of oxy-

gen in the air by so much of the water vapor

in the same air.

l

Lower atmospheric pressure (at a high alti-

tude) reduces the density of the air.

Air temp. HumidityAir

pressure

(altitude)Mixture Setting

High High Low (high) Richer Leaner

Low Low High (low) Leaner Richer

SETTING

Page 716 of 762

7 - 4

TUN

SETTING

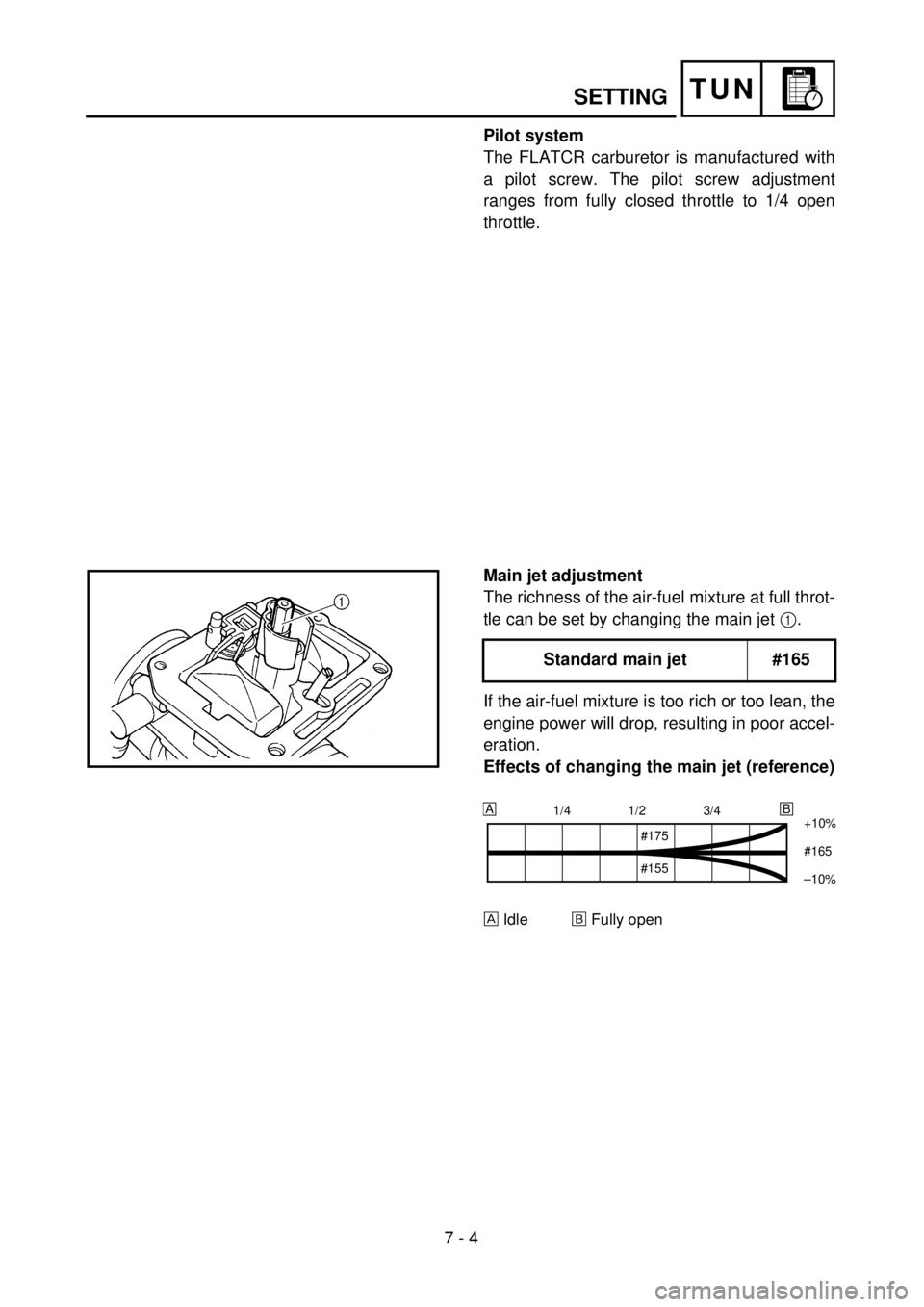

Pilot system

The FLATCR carburetor is manufactured with

a pilot screw. The pilot screw adjustment

ranges from fully closed throttle to 1/4 open

throttle.

Main jet adjustment

The richness of the air-fuel mixture at full throt-

tle can be set by changing the main jet

1

.

If the air-fuel mixture is too rich or too lean, the

engine power will drop, resulting in poor accel-

eration.

Effects of changing the main jet (reference)

Idle

õ

Fully open

Standard main jet #165

1/4 1/2 3/4

+10%

#165

–10

%

AB

#175

#155

Page 720 of 762

7 - 6

TUN

SETTING

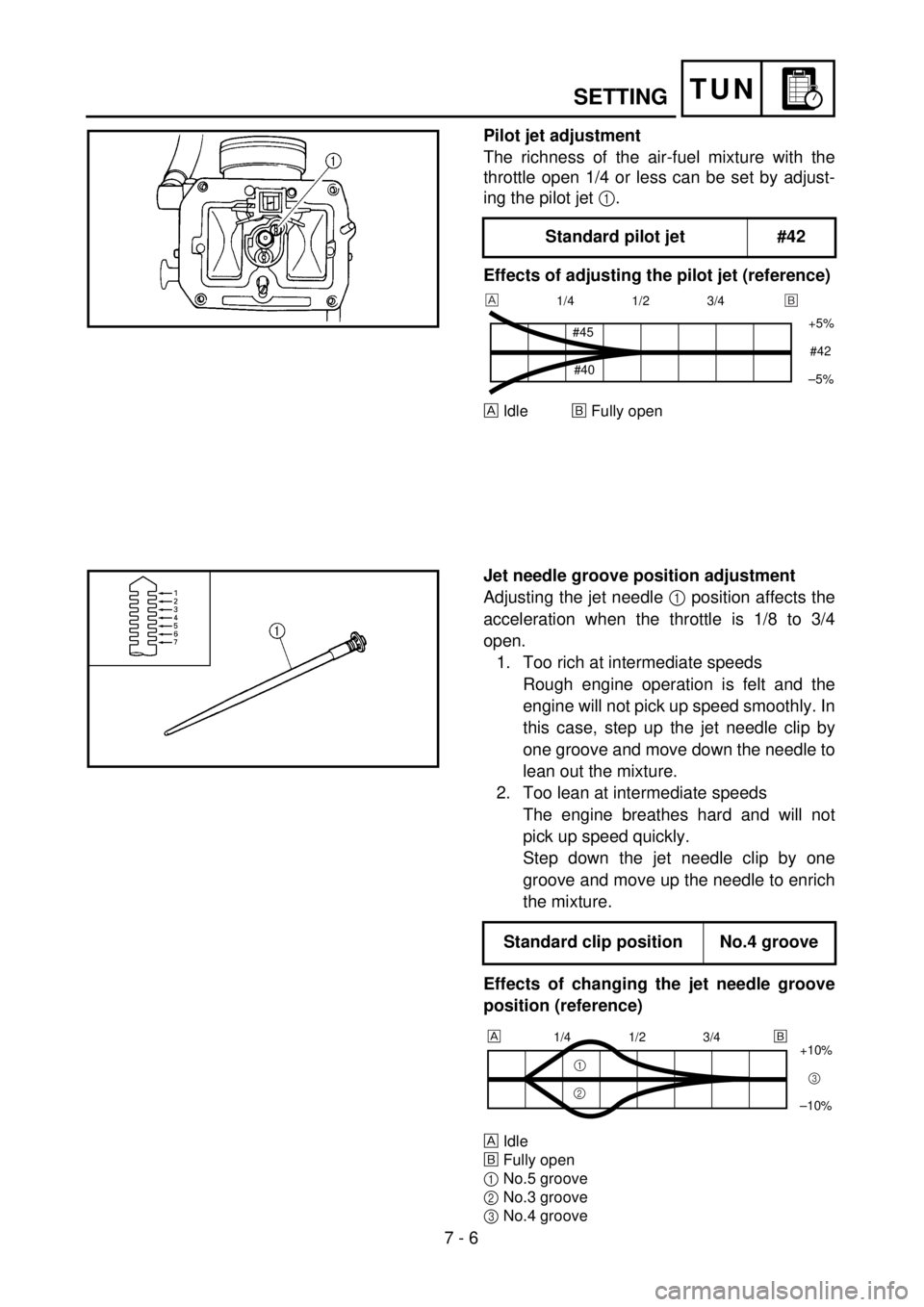

Pilot jet adjustment

The richness of the air-fuel mixture with the

throttle open 1/4 or less can be set by adjust-

ing the pilot jet

1

.

Effects of adjusting the pilot jet (reference)

Idle

õ

Fully open

Standard pilot jet #42

1/4 1/2 3/4

+5%

–5%

#45

#40#42

õ

Jet needle groove position adjustment

Adjusting the jet needle

1 position affects the

acceleration when the throttle is 1/8 to 3/4

open.

1. Too rich at intermediate speeds

Rough engine operation is felt and the

engine will not pick up speed smoothly. In

this case, step up the jet needle clip by

one groove and move down the needle to

lean out the mixture.

2. Too lean at intermediate speeds

The engine breathes hard and will not

pick up speed quickly.

Step down the jet needle clip by one

groove and move up the needle to enrich

the mixture.

Effects of changing the jet needle groove

position (reference)

Idle

õFully open

1No.5 groove

2No.3 groove

3No.4 groove

Standard clip position No.4 groove

1/4 1/2 3/4

+10%

–10%

1

23

õ

Page 728 of 762

7 - 10

TUNSETTING

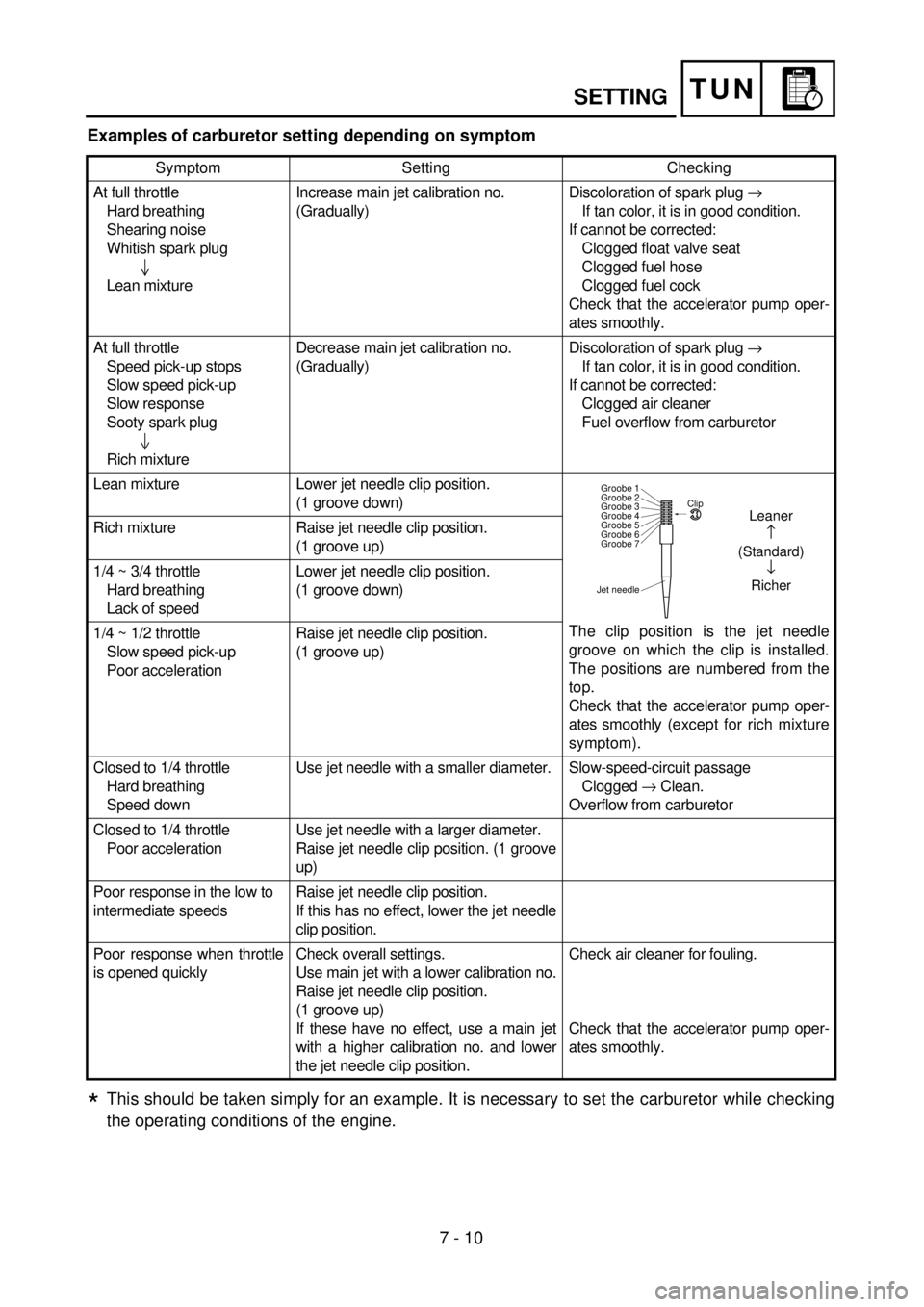

Examples of carburetor setting depending on symptom

This should be taken simply for an example. It is necessary to set the carburetor while checking

the operating conditions of the engine.

Symptom Setting Checking

At full throttle

Hard breathing

Shearing noise

Whitish spark plug

Lean mixtureIncrease main jet calibration no.

(Gradually)Discoloration of spark plug ®

If tan color, it is in good condition.

If cannot be corrected:

Clogged float valve seat

Clogged fuel hose

Clogged fuel cock

Check that the accelerator pump oper-

ates smoothly.

At full throttle

Speed pick-up stops

Slow speed pick-up

Slow response

Sooty spark plug

Rich mixtureDecrease main jet calibration no.

(Gradually)Discoloration of spark plug ®

If tan color, it is in good condition.

If cannot be corrected:

Clogged air cleaner

Fuel overflow from carburetor

Lean mixture Lower jet needle clip position.

(1 groove down)

The clip position is the jet needle

groove on which the clip is installed.

The positions are numbered from the

top.

Check that the accelerator pump oper-

ates smoothly (except for rich mixture

symptom). Rich mixture Raise jet needle clip position.

(1 groove up)

1/4 ~ 3/4 throttle

Hard breathing

Lack of speedLower jet needle clip position.

(1 groove down)

1/4 ~ 1/2 throttle

Slow speed pick-up

Poor accelerationRaise jet needle clip position.

(1 groove up)

Closed to 1/4 throttle

Hard breathing

Speed downUse jet needle with a smaller diameter. Slow-speed-circuit passage

Clogged ® Clean.

Overflow from carburetor

Closed to 1/4 throttle

Poor accelerationUse jet needle with a larger diameter.

Raise jet needle clip position. (1 groove

up)

Poor response in the low to

intermediate speedsRaise jet needle clip position.

If this has no effect, lower the jet needle

clip position.

Poor response when throttle

is opened quicklyCheck overall settings.

Use main jet with a lower calibration no.

Raise jet needle clip position.

(1 groove up)

If these have no effect, use a main jet

with a higher calibration no. and lower

the jet needle clip position.Check air cleaner for fouling.

Check that the accelerator pump oper-

ates smoothly.

Jet needleClip

Groobe 7 Groobe 6

Groobe 5

Groobe 4

Groobe 3

Groobe 2

Groobe 1

Leaner

(Standard)

¯

Richer

*