wheel YAMAHA WR 450F 2006 Manuale de Empleo (in Spanish)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: WR 450F, Model: YAMAHA WR 450F 2006Pages: 786, tamaño PDF: 22.49 MB

Page 104 of 786

SPEC

2 - 15

NOTE:

1. First, tighten the ring nut approximately 38 Nm (3.8 m kg, 27 ft lb) by using the ring nut

wrench, then loosen the ring nut one turn.

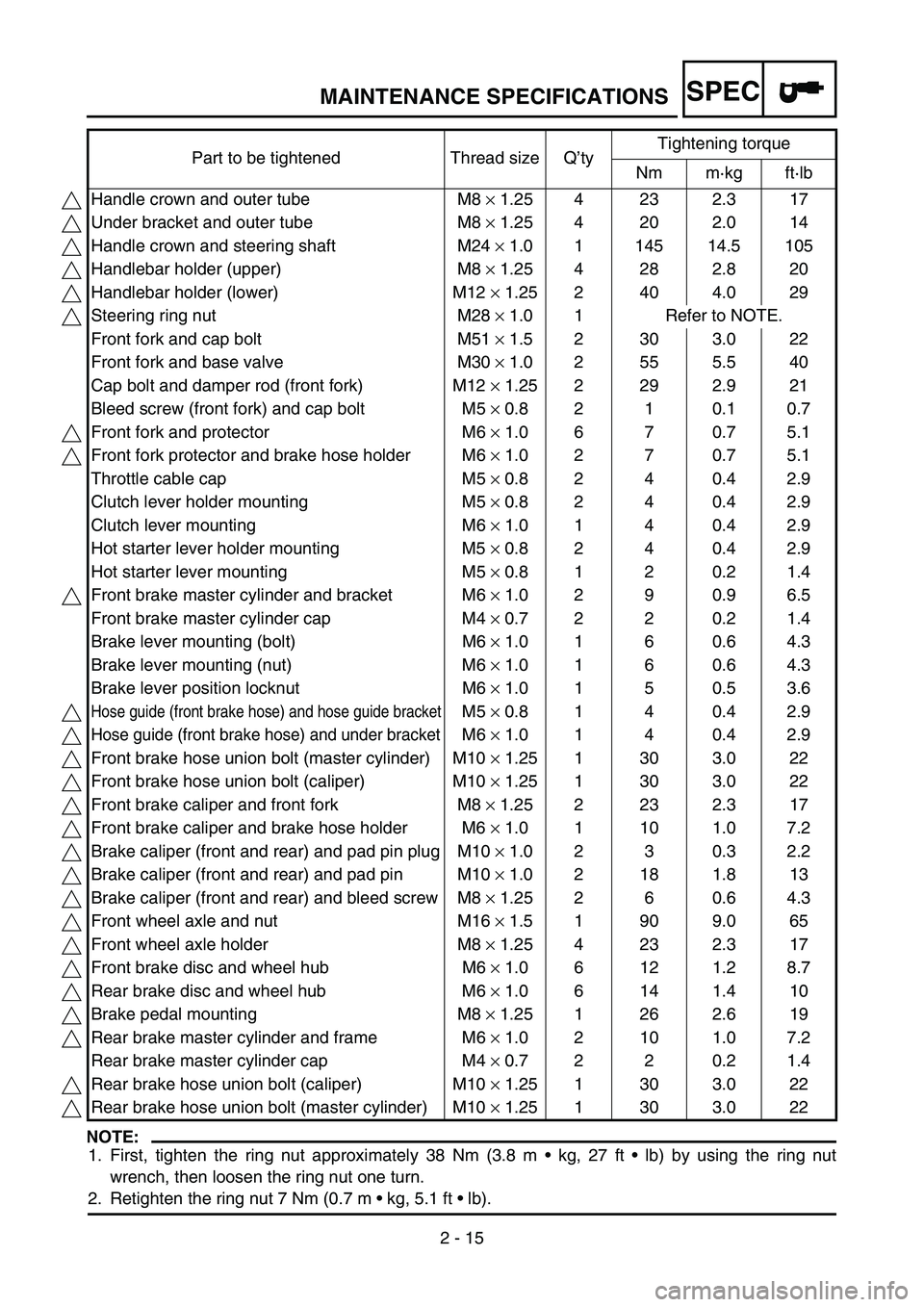

2. Retighten the ring nut 7 Nm (0.7 m kg, 5.1 ft lb). Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Handle crown and outer tube M8 × 1.25 4 23 2.3 17

Under bracket and outer tube M8 × 1.25 4 20 2.0 14

Handle crown and steering shaft M24 × 1.0 1 145 14.5 105

Handlebar holder (upper) M8 × 1.25 4 28 2.8 20

Handlebar holder (lower) M12 × 1.25 2 40 4.0 29

Steering ring nut M28 × 1.0 1 Refer to NOTE.

Front fork and cap bolt M51 × 1.5 2 30 3.0 22

Front fork and base valve M30 × 1.0 2 55 5.5 40

Cap bolt and damper rod (front fork) M12 × 1.25 2 29 2.9 21

Bleed screw (front fork) and cap bolt M5 × 0.8 2 1 0.1 0.7

Front fork and protector M6 × 1.0 6 7 0.7 5.1

Front fork protector and brake hose holder M6 × 1.0 2 7 0.7 5.1

Throttle cable cap M5 × 0.8 2 4 0.4 2.9

Clutch lever holder mounting M5 × 0.8 2 4 0.4 2.9

Clutch lever mounting M6 × 1.0 1 4 0.4 2.9

Hot starter lever holder mounting M5 × 0.8 2 4 0.4 2.9

Hot starter lever mounting M5 × 0.8 1 2 0.2 1.4

Front brake master cylinder and bracket M6 × 1.0 2 9 0.9 6.5

Front brake master cylinder cap M4 × 0.7 2 2 0.2 1.4

Brake lever mounting (bolt) M6 × 1.0 1 6 0.6 4.3

Brake lever mounting (nut) M6 × 1.0 1 6 0.6 4.3

Brake lever position locknut M6 × 1.0 1 5 0.5 3.6

Hose guide (front brake hose) and hose guide bracketM5 × 0.8 1 4 0.4 2.9

Hose guide (front brake hose) and under bracketM6 × 1.0 1 4 0.4 2.9

Front brake hose union bolt (master cylinder) M10 × 1.25 1 30 3.0 22

Front brake hose union bolt (caliper) M10 × 1.25 1 30 3.0 22

Front brake caliper and front fork M8 × 1.25 2 23 2.3 17

Front brake caliper and brake hose holder M6 × 1.0 1 10 1.0 7.2

Brake caliper (front and rear) and pad pin plug M10 × 1.0 2 3 0.3 2.2

Brake caliper (front and rear) and pad pin M10 × 1.0 2 18 1.8 13

Brake caliper (front and rear) and bleed screw M8 × 1.25 2 6 0.6 4.3

Front wheel axle and nut M16 × 1.5 1 90 9.0 65

Front wheel axle holder M8 × 1.25 4 23 2.3 17

Front brake disc and wheel hub M6 × 1.0 6 12 1.2 8.7

Rear brake disc and wheel hub M6 × 1.0 6 14 1.4 10

Brake pedal mounting M8 × 1.25 1 26 2.6 19

Rear brake master cylinder and frame M6 × 1.0 2 10 1.0 7.2

Rear brake master cylinder cap M4 × 0.7 2 2 0.2 1.4

Rear brake hose union bolt (caliper) M10 × 1.25 1 30 3.0 22

Rear brake hose union bolt (master cylinder) M10 × 1.25 1 30 3.0 22

MAINTENANCE SPECIFICATIONS

Page 105 of 786

SPEC

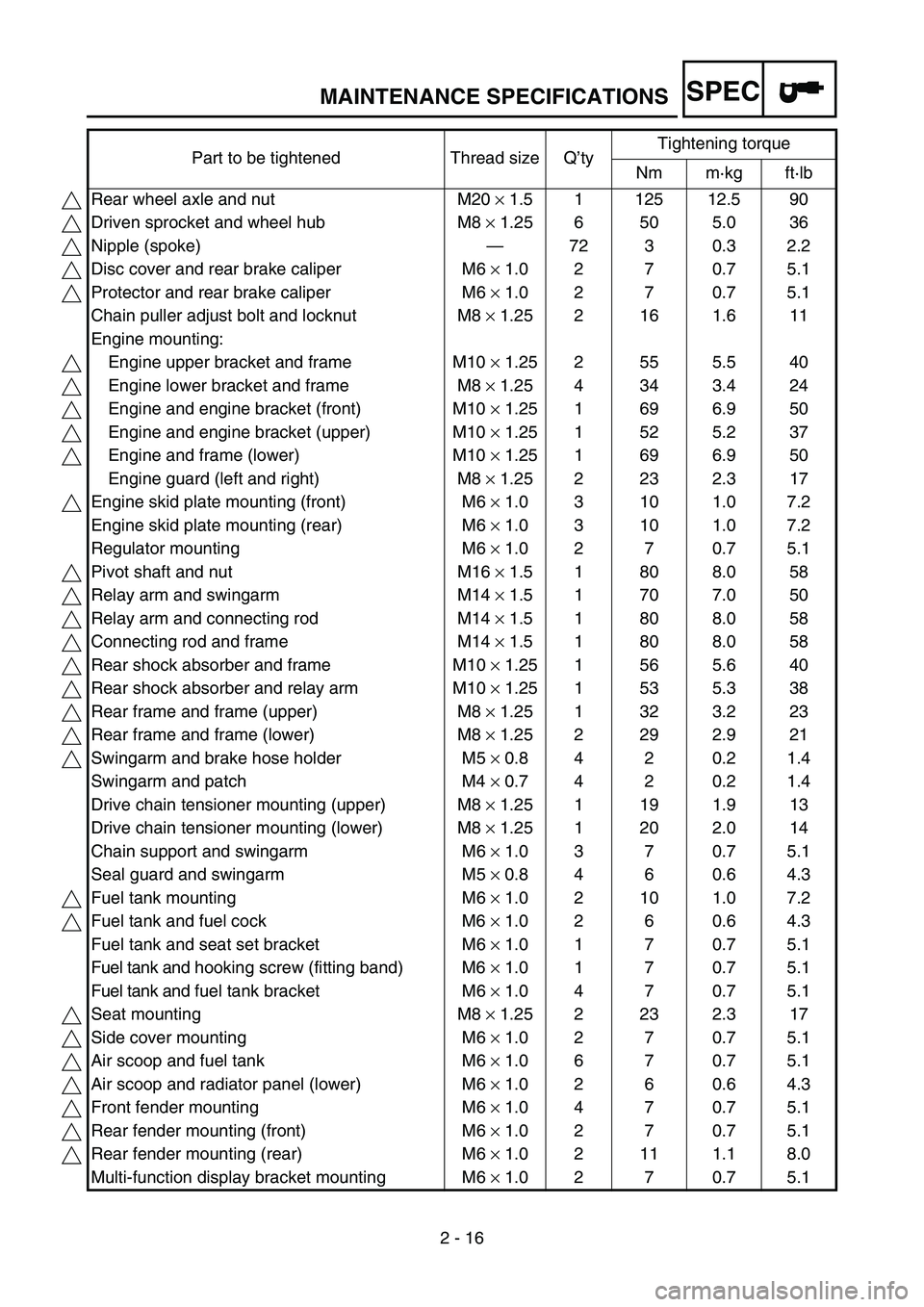

2 - 16 Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Rear wheel axle and nut M20 × 1.5 1 125 12.5 90

Driven sprocket and wheel hub M8 × 1.25 6 50 5.0 36

Nipple (spoke)—72 3 0.3 2.2

Disc cover and rear brake caliper M6 × 1.0 2 7 0.7 5.1

Protector and rear brake caliper M6 × 1.0 2 7 0.7 5.1

Chain puller adjust bolt and locknut M8 × 1.25 2 16 1.6 11

Engine mounting:

Engine upper bracket and frame M10 × 1.25 2 55 5.5 40

Engine lower bracket and frame M8 × 1.25 4 34 3.4 24

Engine and engine bracket (front) M10 × 1.25 1 69 6.9 50

Engine and engine bracket (upper) M10 × 1.25 1 52 5.2 37

Engine and frame (lower) M10 × 1.25 1 69 6.9 50

Engine guard (left and right) M8 × 1.25 2 23 2.3 17

Engine skid plate mounting (front) M6 × 1.0 3 10 1.0 7.2

Engine skid plate mounting (rear) M6 × 1.0 3 10 1.0 7.2

Regulator mounting M6 × 1.0 2 7 0.7 5.1

Pivot shaft and nut M16 × 1.5 1 80 8.0 58

Relay arm and swingarm M14 × 1.5 1 70 7.0 50

Relay arm and connecting rod M14 × 1.5 1 80 8.0 58

Connecting rod and frame M14 × 1.5 1 80 8.0 58

Rear shock absorber and frame M10 × 1.25 1 56 5.6 40

Rear shock absorber and relay arm M10 × 1.25 1 53 5.3 38

Rear frame and frame (upper) M8 × 1.25 1 32 3.2 23

Rear frame and frame (lower) M8 × 1.25 2 29 2.9 21

Swingarm and brake hose holder M5 × 0.8 4 2 0.2 1.4

Swingarm and patch M4 × 0.7 4 2 0.2 1.4

Drive chain tensioner mounting (upper) M8 × 1.25 1 19 1.9 13

Drive chain tensioner mounting (lower) M8 × 1.25 1 20 2.0 14

Chain support and swingarm M6 × 1.0 3 7 0.7 5.1

Seal guard and swingarm M5 × 0.8 4 6 0.6 4.3

Fuel tank mounting M6 × 1.0 2 10 1.0 7.2

Fuel tank and fuel cock M6 × 1.0 2 6 0.6 4.3

Fuel tank and seat set bracket M6 × 1.0 1 7 0.7 5.1

Fuel tank and hooking screw (fitting band) M6 × 1.0 1 7 0.7 5.1

Fuel tank and fuel tank bracket M6 × 1.0 4 7 0.7 5.1

Seat mounting M8 × 1.25 2 23 2.3 17

Side cover mounting M6 × 1.0 2 7 0.7 5.1

Air scoop and fuel tank M6 × 1.0 6 7 0.7 5.1

Air scoop and radiator panel (lower) M6 × 1.0 2 6 0.6 4.3

Front fender mounting M6 × 1.0 4 7 0.7 5.1

Rear fender mounting (front) M6 × 1.0 2 7 0.7 5.1

Rear fender mounting (rear) M6 × 1.0 2 11 1.1 8.0

Multi-function display bracket mounting M6 × 1.0 2 7 0.7 5.1

MAINTENANCE SPECIFICATIONS

Page 190 of 786

3 - 3

INSP

ADJ

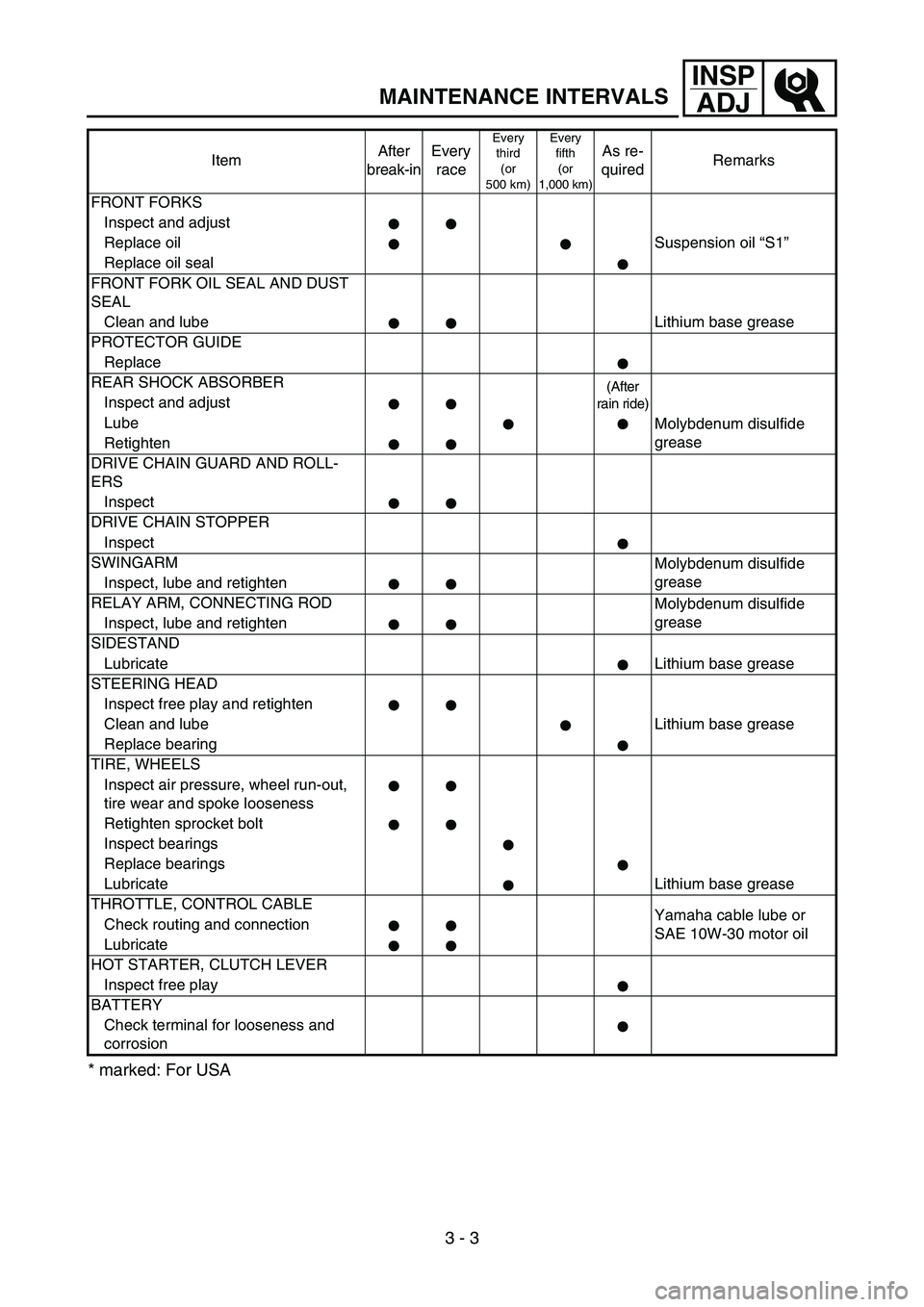

MAINTENANCE INTERVALS

* marked: For USA

FRONT FORKS

Inspect and adjust

Replace oil Suspension oil “S1”

Replace oil seal

FRONT FORK OIL SEAL AND DUST

SEAL

Clean and lube Lithium base grease

PROTECTOR GUIDE

Replace

REAR SHOCK ABSORBER

(After

rain ride)

Inspect and adjust

Lube

Molybdenum disulfide

grease

Retighten

DRIVE CHAIN GUARD AND ROLL-

ERS

Inspect

DRIVE CHAIN STOPPER

Inspect

SWINGARM

Molybdenum disulfide

grease

Inspect, lube and retighten

RELAY ARM, CONNECTING ROD

Molybdenum disulfide

grease

Inspect, lube and retighten

SIDESTAND

Lubricate Lithium base grease

STEERING HEAD

Inspect free play and retighten

Clean and lube Lithium base grease

Replace bearing

TIRE, WHEELS

Inspect air pressure, wheel run-out,

tire wear and spoke looseness

Retighten sprocket bolt

Inspect bearings

Replace bearings

Lubricate Lithium base grease

THROTTLE, CONTROL CABLE

Yamaha cable lube or

SAE 10W-30 motor oil Check routing and connection

Lubricate

HOT STARTER, CLUTCH LEVER

Inspect free play

BATTERY

Check terminal for looseness and

corrosionItemAfter

break-inEvery

race

Every

third

(or

500 km)Every

fifth

(or

1,000 km)As re-

quiredRemarks

Page 200 of 786

3 - 4

INSP

ADJ

PRE-OPERATION INSPECTION AND MAINTENANCE

EC320000

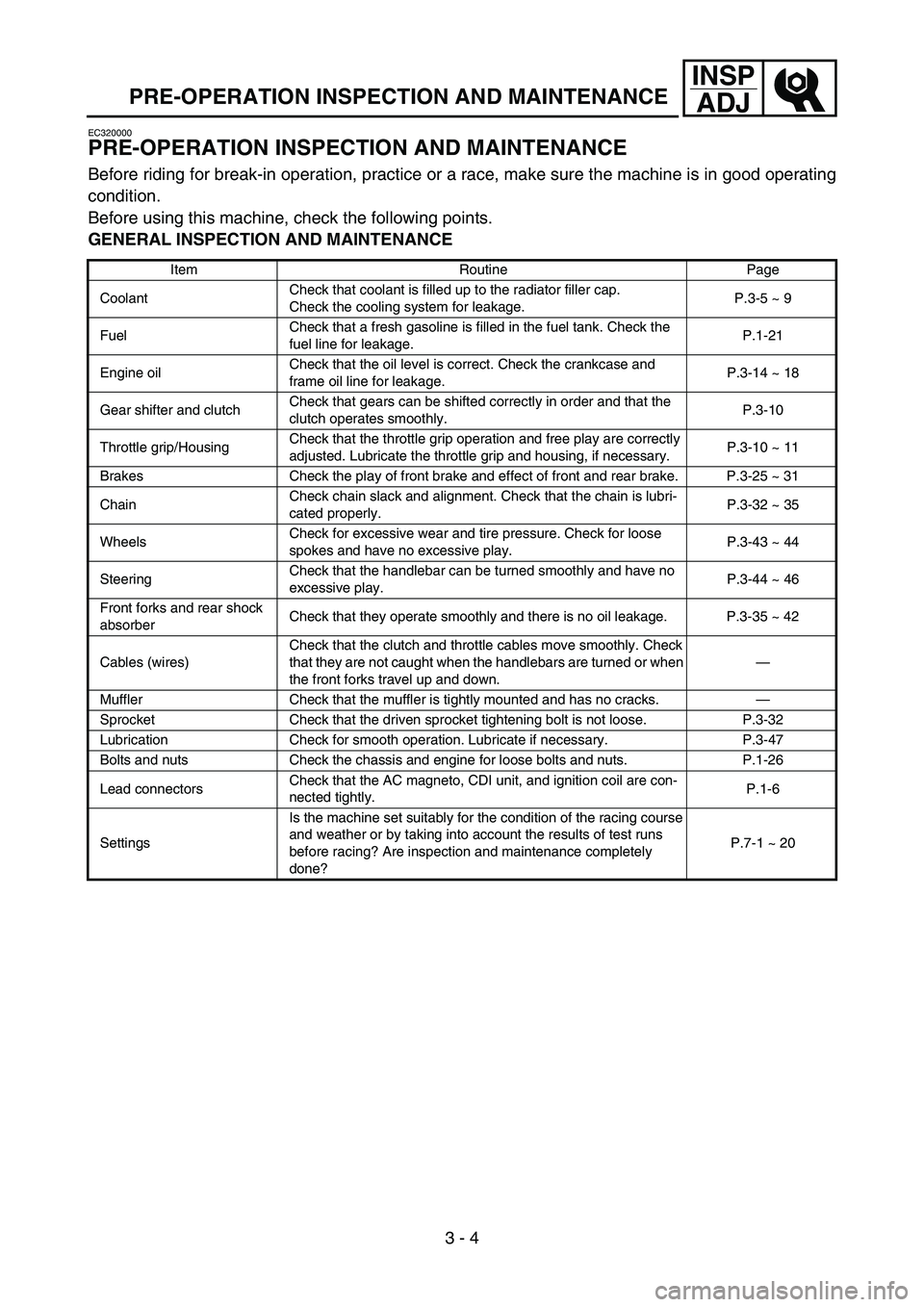

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating

condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCE

Item Routine Page

CoolantCheck that coolant is filled up to the radiator filler cap.

Check the cooling system for leakage.P.3-5 ~ 9

FuelCheck that a fresh gasoline is filled in the fuel tank. Check the

fuel line for leakage.P.1-21

Engine oilCheck that the oil level is correct. Check the crankcase and

frame oil line for leakage.P.3-14 ~ 18

Gear shifter and clutchCheck that gears can be shifted correctly in order and that the

clutch operates smoothly.P.3-10

Throttle grip/HousingCheck that the throttle grip operation and free play are correctly

adjusted. Lubricate the throttle grip and housing, if necessary.P.3-10 ~ 11

Brakes Check the play of front brake and effect of front and rear brake. P.3-25 ~ 31

ChainCheck chain slack and alignment. Check that the chain is lubri-

cated properly.P.3-32 ~ 35

WheelsCheck for excessive wear and tire pressure. Check for loose

spokes and have no excessive play.P.3-43 ~ 44

SteeringCheck that the handlebar can be turned smoothly and have no

excessive play.P.3-44 ~ 46

Front forks and rear shock

absorberCheck that they operate smoothly and there is no oil leakage. P.3-35 ~ 42

Cables (wires)Check that the clutch and throttle cables move smoothly. Check

that they are not caught when the handlebars are turned or when

the front forks travel up and down.—

Muffler Check that the muffler is tightly mounted and has no cracks.—

Sprocket Check that the driven sprocket tightening bolt is not loose. P.3-32

Lubrication Check for smooth operation. Lubricate if necessary. P.3-47

Bolts and nuts Check the chassis and engine for loose bolts and nuts. P.1-26

Lead connectorsCheck that the AC magneto, CDI unit, and ignition coil are con-

nected tightly.P.1-6

SettingsIs the machine set suitably for the condition of the racing course

and weather or by taking into account the results of test runs

before racing? Are inspection and maintenance completely

done?P.7-1 ~ 20

Page 254 of 786

3 - 29

INSP

ADJ

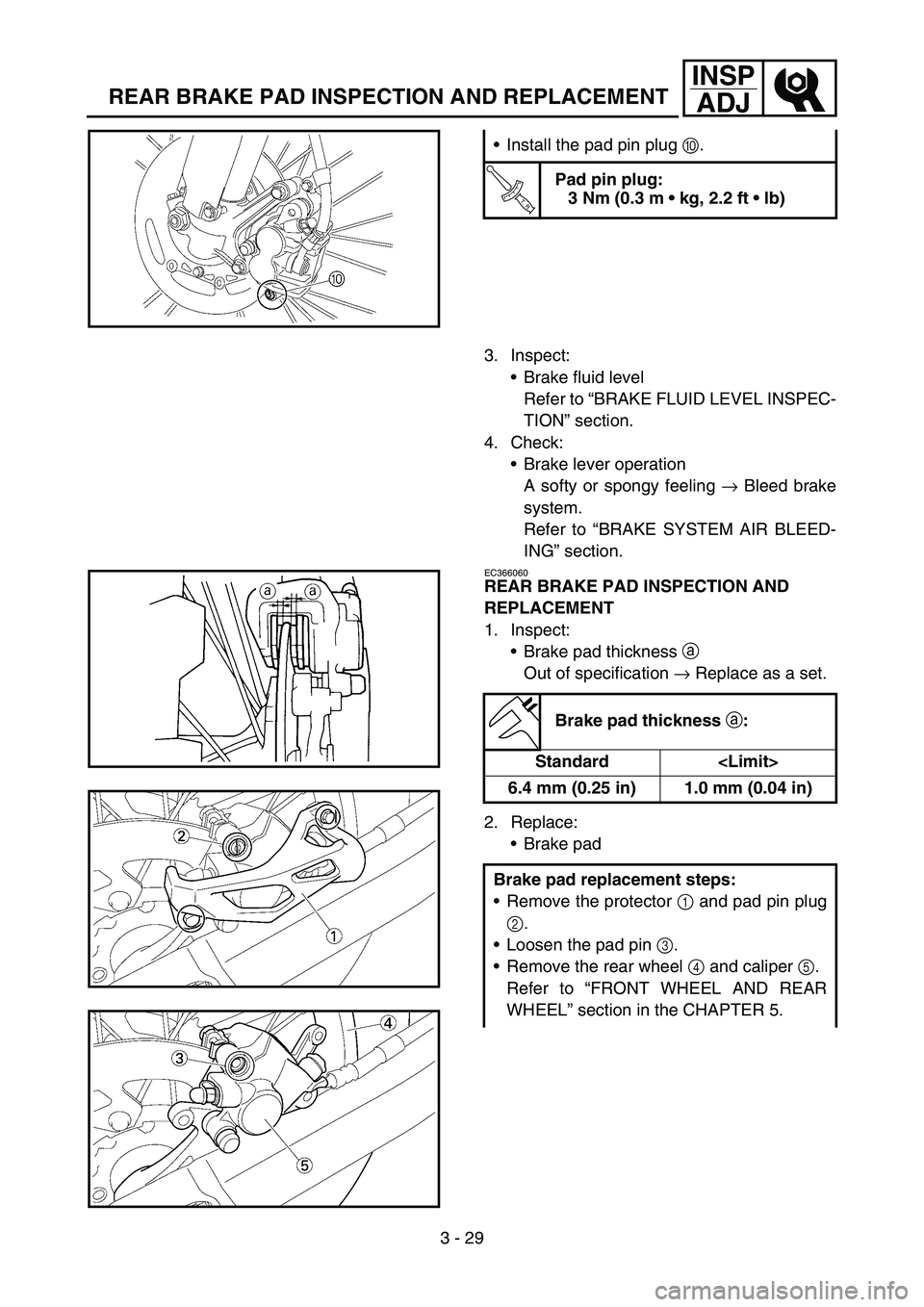

REAR BRAKE PAD INSPECTION AND REPLACEMENT

Install the pad pin plug 0.

T R..

Pad pin plug:

3 Nm (0.3 m kg, 2.2 ft lb)

3. Inspect:

Brake fluid level

Refer to “BRAKE FLUID LEVEL INSPEC-

TION” section.

4. Check:

Brake lever operation

A softy or spongy feeling → Bleed brake

system.

Refer to “BRAKE SYSTEM AIR BLEED-

ING” section.

EC366060

REAR BRAKE PAD INSPECTION AND

REPLACEMENT

1. Inspect:

Brake pad thickness a

Out of specification → Replace as a set.

2. Replace:

Brake pad

Brake pad thickness

a:

Standard

6.4 mm (0.25 in) 1.0 mm (0.04 in)

Brake pad replacement steps:

Remove the protector 1 and pad pin plug

2.

Loosen the pad pin 3.

Remove the rear wheel 4 and caliper 5.

Refer to “FRONT WHEEL AND REAR

WHEEL” section in the CHAPTER 5.

Page 256 of 786

3 - 30

INSP

ADJ

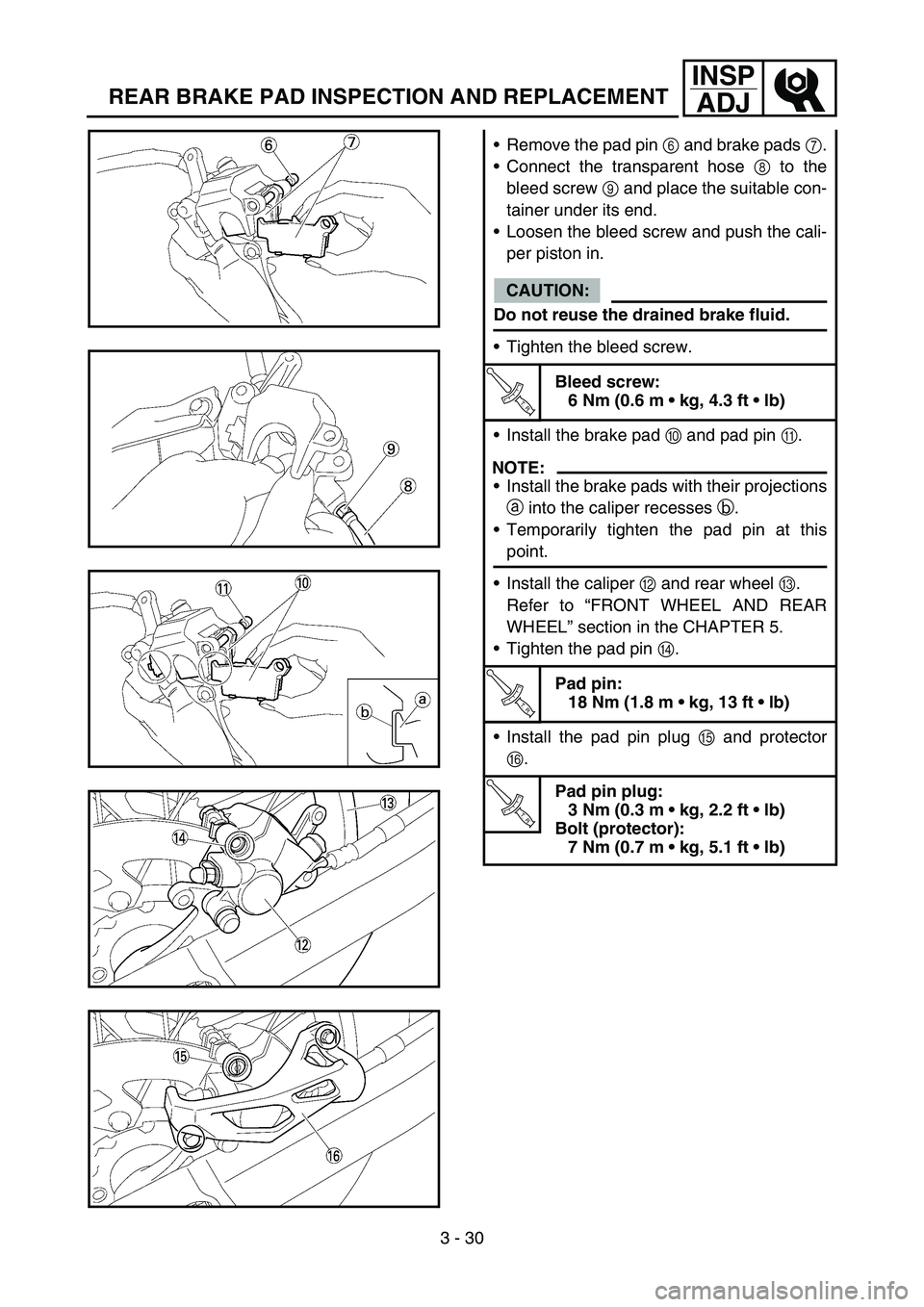

REAR BRAKE PAD INSPECTION AND REPLACEMENT

Remove the pad pin 6 and brake pads 7.

Connect the transparent hose 8 to the

bleed screw 9 and place the suitable con-

tainer under its end.

Loosen the bleed screw and push the cali-

per piston in.

CAUTION:

Do not reuse the drained brake fluid.

Tighten the bleed screw.

T R..

Bleed screw:

6 Nm (0.6 m kg, 4.3 ft lb)

Install the brake pad 0 and pad pin A.

NOTE:

Install the brake pads with their projections

a into the caliper recesses b.

Temporarily tighten the pad pin at this

point.

Install the caliper B and rear wheel C.

Refer to “FRONT WHEEL AND REAR

WHEEL” section in the CHAPTER 5.

Tighten the pad pin D.

T R..

Pad pin:

18 Nm (1.8 m kg, 13 ft lb)

Install the pad pin plug E and protector

F.

T R..

Pad pin plug:

3 Nm (0.3 m kg, 2.2 ft lb)

Bolt (protector):

7 Nm (0.7 m kg, 5.1 ft lb)

Page 264 of 786

3 - 34

INSP

ADJ

DRIVE CHAIN SLACK ADJUSTMENT

DRIVE CHAIN SLACK ADJUSTMENT

1. Elevate the rear wheel by placing the suit-

able stand under the engine.

2. Check:

Drive chain slack a

Above the seal guard installation bolt.

Out of specification → Adjust.

NOTE:

Before checking and/or adjusting, rotate the

rear wheel through several revolutions and

check the slack several times to find the tight-

est point. Check and/or adjust the chain slack

with the rear wheel in this “tight chain” position.

Drive chain slack:

48 ~ 58 mm (1.9 ~ 2.3 in)

3. Adjust:

Drive chain slack

Drive chain slack adjustment steps:

Loosen the axle nut 1 and locknuts 2.

Adjust the chain slack by turning the

adjusters 3.

To tighten

→Turn the adjuster

3 coun-

terclockwise.

To loosen

→Turn the adjuster

3 clock-

wise and push wheel for-

ward.

Turn each adjuster exactly the same

amount to maintain correct axle alignment.

(There are marks a on each side of the

chain puller alignment.)

NOTE:

Turn the adjuster so that the chain is in line

with the sprocket, as viewed from the rear.

CAUTION:

Too small chain slack will overload the

engine and other vital parts; keep the

slack within the specified limits.

Page 268 of 786

3 - 36

INSP

ADJFRONT FORK INTERNAL PRESSURE RELIEVING/

FRONT FORK REBOUND DAMPING FORCE ADJUSTMENT

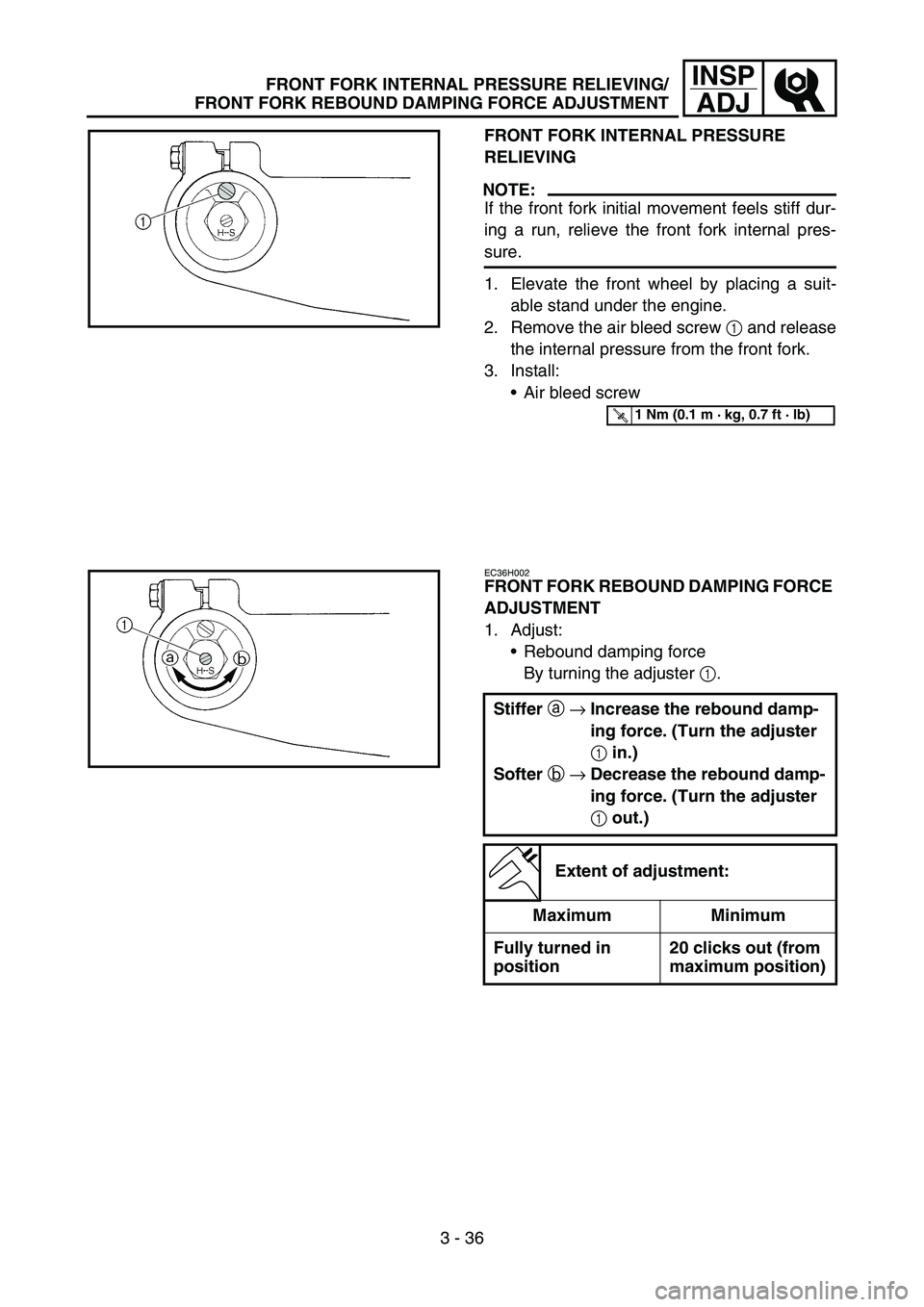

FRONT FORK INTERNAL PRESSURE

RELIEVING

NOTE:

If the front fork initial movement feels stiff dur-

ing a run, relieve the front fork internal pres-

sure.

1. Elevate the front wheel by placing a suit-

able stand under the engine.

2. Remove the air bleed screw 1 and release

the internal pressure from the front fork.

3. Install:

Air bleed screw

T R..1 Nm (0.1 m · kg, 0.7 ft · lb)

EC36H002

FRONT FORK REBOUND DAMPING FORCE

ADJUSTMENT

1. Adjust:

Rebound damping force

By turning the adjuster 1.

Stiffer a →Increase the rebound damp-

ing force. (Turn the adjuster

1 in.)

Softer b →Decrease the rebound damp-

ing force. (Turn the adjuster

1 out.)

Extent of adjustment:

Maximum Minimum

Fully turned in

position20 clicks out (from

maximum position)

Page 274 of 786

3 - 39

INSP

ADJREAR SHOCK ABSORBER SPRING PRELOAD

ADJUSTMENT

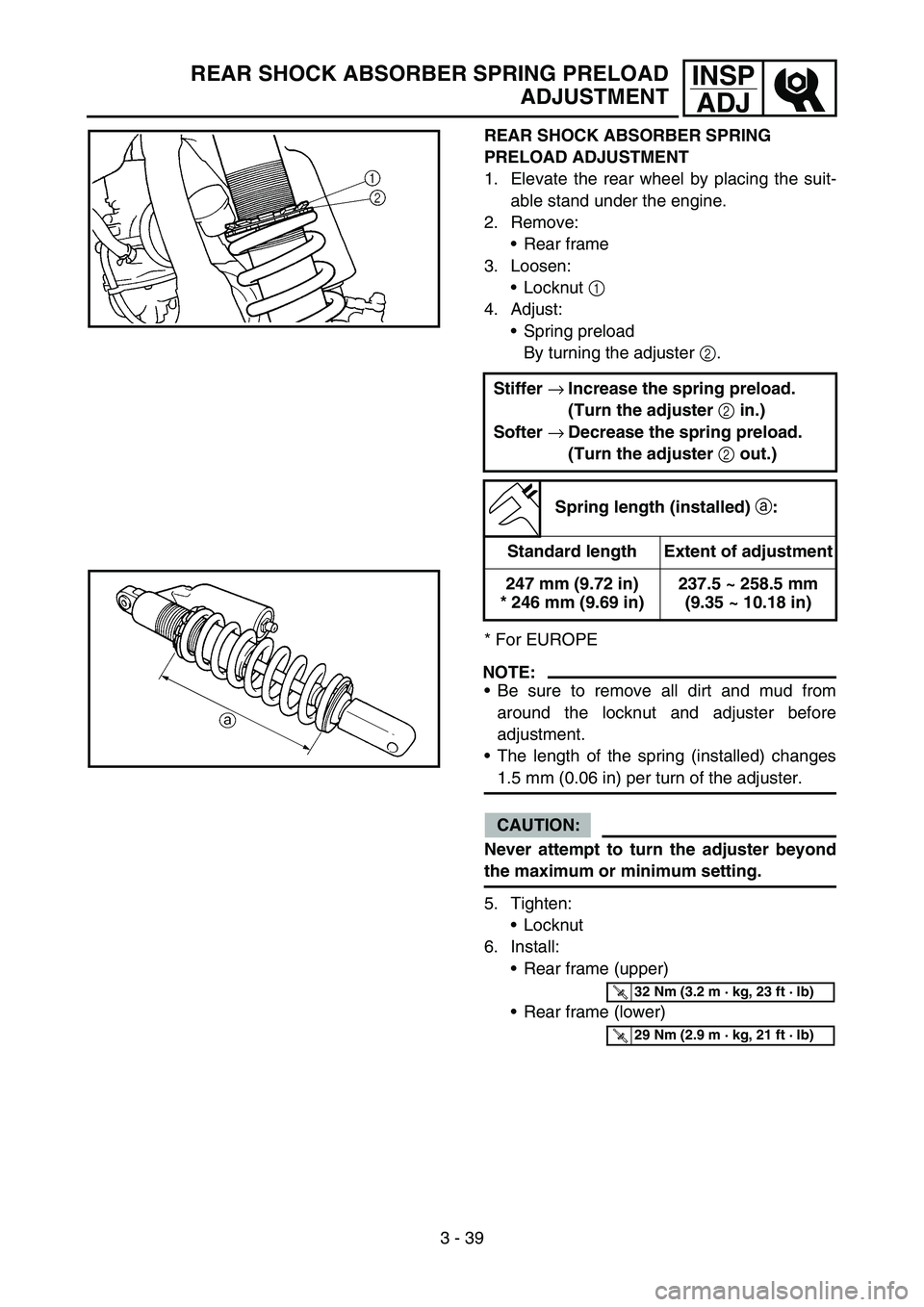

REAR SHOCK ABSORBER SPRING

PRELOAD ADJUSTMENT

1. Elevate the rear wheel by placing the suit-

able stand under the engine.

2. Remove:

Rear frame

3. Loosen:

Locknut 1

4. Adjust:

Spring preload

By turning the adjuster 2.

* For EUROPE

NOTE:

Be sure to remove all dirt and mud from

around the locknut and adjuster before

adjustment.

The length of the spring (installed) changes

1.5 mm (0.06 in) per turn of the adjuster.

CAUTION:

Never attempt to turn the adjuster beyond

the maximum or minimum setting.

5. Tighten:

Locknut

6. Install:

Rear frame (upper)

Rear frame (lower) Stiffer

→Increase the spring preload.

(Turn the adjuster

2 in.)

Softer

→Decrease the spring preload.

(Turn the adjuster

2 out.)

Spring length (installed)

a:

Standard length Extent of adjustment

247 mm (9.72 in)

* 246 mm (9.69 in)237.5 ~ 258.5 mm

(9.35 ~ 10.18 in)

T R..32 Nm (3.2 m · kg, 23 ft · lb)

T R..29 Nm (2.9 m · kg, 21 ft · lb)

Page 282 of 786

3 - 43

INSP

ADJTIRE PRESSURE CHECK/SPOKES INSPECTION AND

TIGHTENING/WHEEL INSPECTION

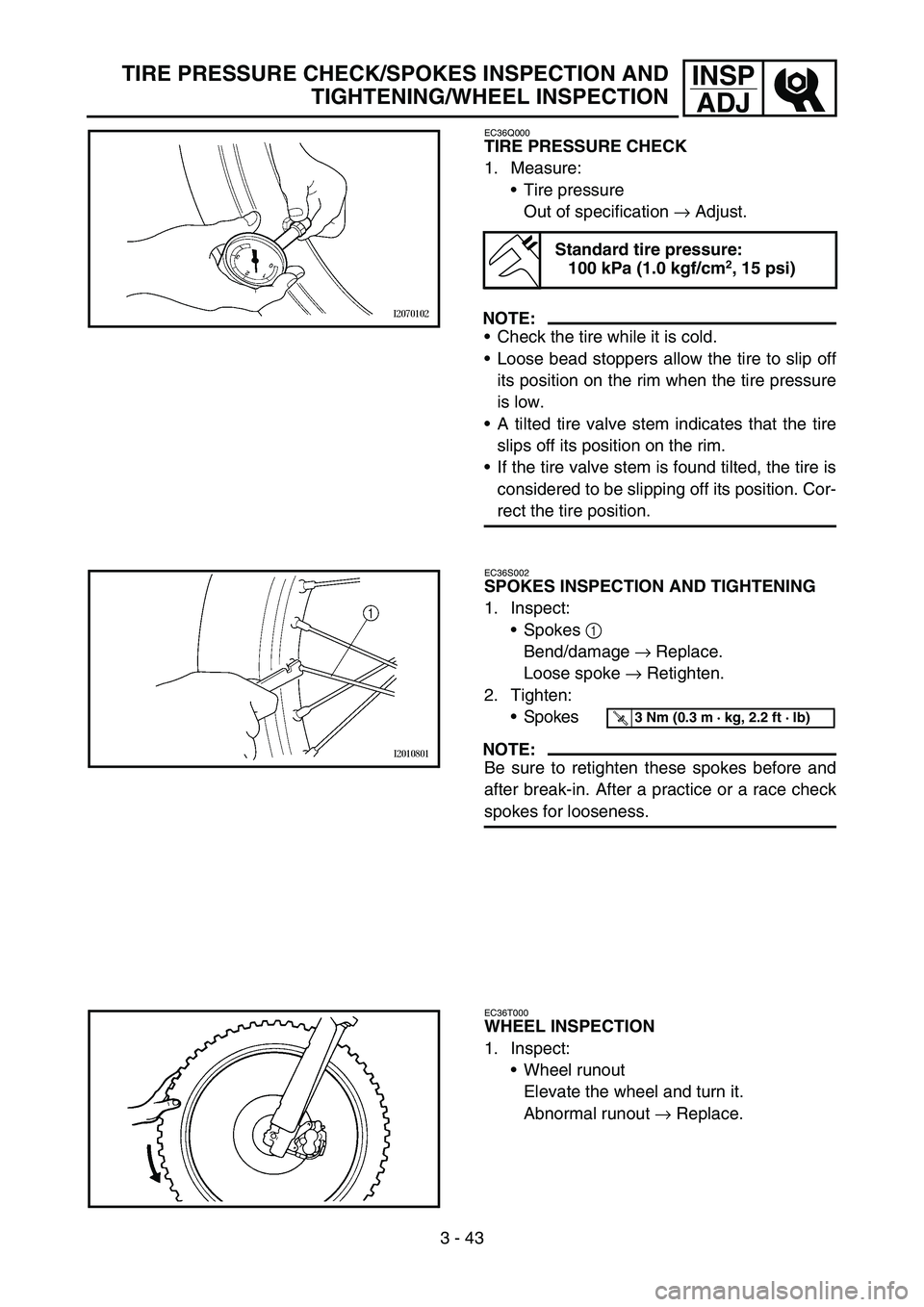

EC36Q000

TIRE PRESSURE CHECK

1. Measure:

Tire pressure

Out of specification → Adjust.

NOTE:

Check the tire while it is cold.

Loose bead stoppers allow the tire to slip off

its position on the rim when the tire pressure

is low.

A tilted tire valve stem indicates that the tire

slips off its position on the rim.

If the tire valve stem is found tilted, the tire is

considered to be slipping off its position. Cor-

rect the tire position.

Standard tire pressure:

100 kPa (1.0 kgf/cm2, 15 psi)

EC36S002

SPOKES INSPECTION AND TIGHTENING

1. Inspect:

Spokes 1

Bend/damage → Replace.

Loose spoke → Retighten.

2. Tighten:

Spokes

NOTE:

Be sure to retighten these spokes before and

after break-in. After a practice or a race check

spokes for looseness.

T R..3 Nm (0.3 m · kg, 2.2 ft · lb)

EC36T000

WHEEL INSPECTION

1. Inspect:

Wheel runout

Elevate the wheel and turn it.

Abnormal runout → Replace.