display YAMAHA WR 450F 2006 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: WR 450F, Model: YAMAHA WR 450F 2006Pages: 786, PDF Size: 22.49 MB

Page 67 of 786

GEN

INFO

2. Den Timer durch Drücken der

Taste “RST” starten.

3. Beim Stoppen des Timers müs-

sen die Tasten “SLCT1” und

“SLCT2” gleichzeitig gedrückt

werden.

HINWEIS:

Eine bei gestopptem Timer zurück-

gelegte Strecke wird nicht vom

Tageskilometerzähler A (TRIP A)

registriert.

4. Um die Messung wieder aufzu-

nehmen, die Tasten “SLCT1”

und “SLCT2” gleichzeitig drü-

cken.

Automatischer Start

1. Sicherstellen, dass das Display

sich in der RENNSPORT-

BETRIEBSART befindet. (Siehe

dazu “Von NORMAL- auf RENN-

SPORT-BETRIEBSART wech-

seln”.)

2. Die Maschine für ein Rennen

vorbereiten, indem die Taste

“SLCT1” mindestens 2 Sekun-

den lang gedrückt wird.

HINWEIS:

Wenn der Timer zu automatischem

Start bereit steht, blinken

und . Die Timer-Anzeige läuft von

links nach rechts ab.

3. Anfahren und den Timer starten.

4. Um den Timer zu stoppen, die

Tasten “SLCT1” und “SLCT2”

gleichzeitig drücken.

HINWEIS:

Eine bei gestopptem Timer zurück-

gelegte Strecke wird nicht vom

Tageskilometerzähler A (TRIP A)

registriert.

5. Um die Messung wieder aufzu-

nehmen, die Tasten “SLCT1”

und “SLCT2” gleichzeitig drü-

cken.

2. Lancer la mesure du chronomètre

en appuyant sur le bouton “RST”.

3. Pour arrêter la mesure du chrono-

mètre, appuyer sur les boutons

“SLCT1” et “SLCT2” en même

temps.

N.B.:

Si le véhicule continue à rouler lorsque

la mesure est désactivée, le chiffre du

totalisateur journalier A (TRIP A) n’est

pas modifié.

4. Pour reprendre la mesure, appuyer

de nouveau sur les boutons

“SLCT1” et “SLCT2” en même

temps.

Démarrage automatique

1. Vérifier que le passage en MODE

COURSE a bien été effectué. Se

reporter à la section “Passage du

MODE DE BASE en MODE

COURSE”.

2. Préparer le véhicule pour la course

en appuyant sur le bouton “SLCT1”

pendant 2 secondes minimum.

N.B.:

Lorsque le dispositif de mesure est prêt

pour la course avec démarrage automati-

que, et commencent à cligno-

ter. L’écran du chronomètre s’active et

défile de gauche à droite.

3. Démarrer le véhicule pour commen-

cer la mesure.

4. Pour arrêter la mesure du chrono-

mètre, appuyer sur les boutons

“SLCT1” et “SLCT2” en même

temps.

N.B.:

Si le véhicule continue à rouler lorsque

la mesure est désactivée, le chiffre du

totalisateur journalier A (TRIP A) n’est

pas modifié.

5. Pour reprendre la mesure, appuyer

de nouveau sur les boutons

“SLCT1” et “SLCT2” en même

temps.

2. Ponga en marcha el cronómetro pul-

sando el botón “RST”.

3. Para parar el cronómetro, pulse el

botón “SLCT1” y el botón

“SLCT2” al mismo tiempo.

NOTA:

Si la máquina avanza con el cronómetro

parado, las cifras del cuentakilómetros

parcial A (TRIP A) no cambian.

4. Para volver a poner en marcha el

cronómetro, pulse el botón

“SLCT1” y el botón “SLCT2” al

mismo tiempo.

Puesta en marcha automática

1. Compruebe que haya cambiado a

FUNCIÓN COMPETICIÓN. (Con-

sulte el apartado “Cambio de FUN-

CIÓN BÁSICA a FUNCIÓN

COMPETICIÓN”.)

2. Prepare el cronómetro para un reco-

rrido pulsando el botón “SLCT1”

durante 2 segundos o más.

NOTA:

Cuando el cronómetro está preparado

para un recorrido con puesta en marcha

automática, y comienzan a par-

padear. La indicación del cronómetro se

activa y se desplaza de izquierda a dere-

cha.

3. El cronómetro se pone en marcha

cuando la máquina comienza a

moverse.

4. Para parar el cronómetro, pulse el

botón “SLCT1” y el botón

“SLCT2” al mismo tiempo.

NOTA:

Si la máquina avanza con el cronómetro

parado, las cifras del cuentakilómetros

parcial A (TRIP A) no cambian.

5. Para volver a poner en marcha el

cronómetro, pulse el botón

“SLCT1” y el botón “SLCT2” al

mismo tiempo.

ECRAN MULTIFONCTION

MULTIFUNKTIONSANZEIGE

VISOR MULTIFUNCIÓN

1 - 18

Page 68 of 786

1 - 19

GEN

INFO

MULTI-FUNCTION DISPLAY

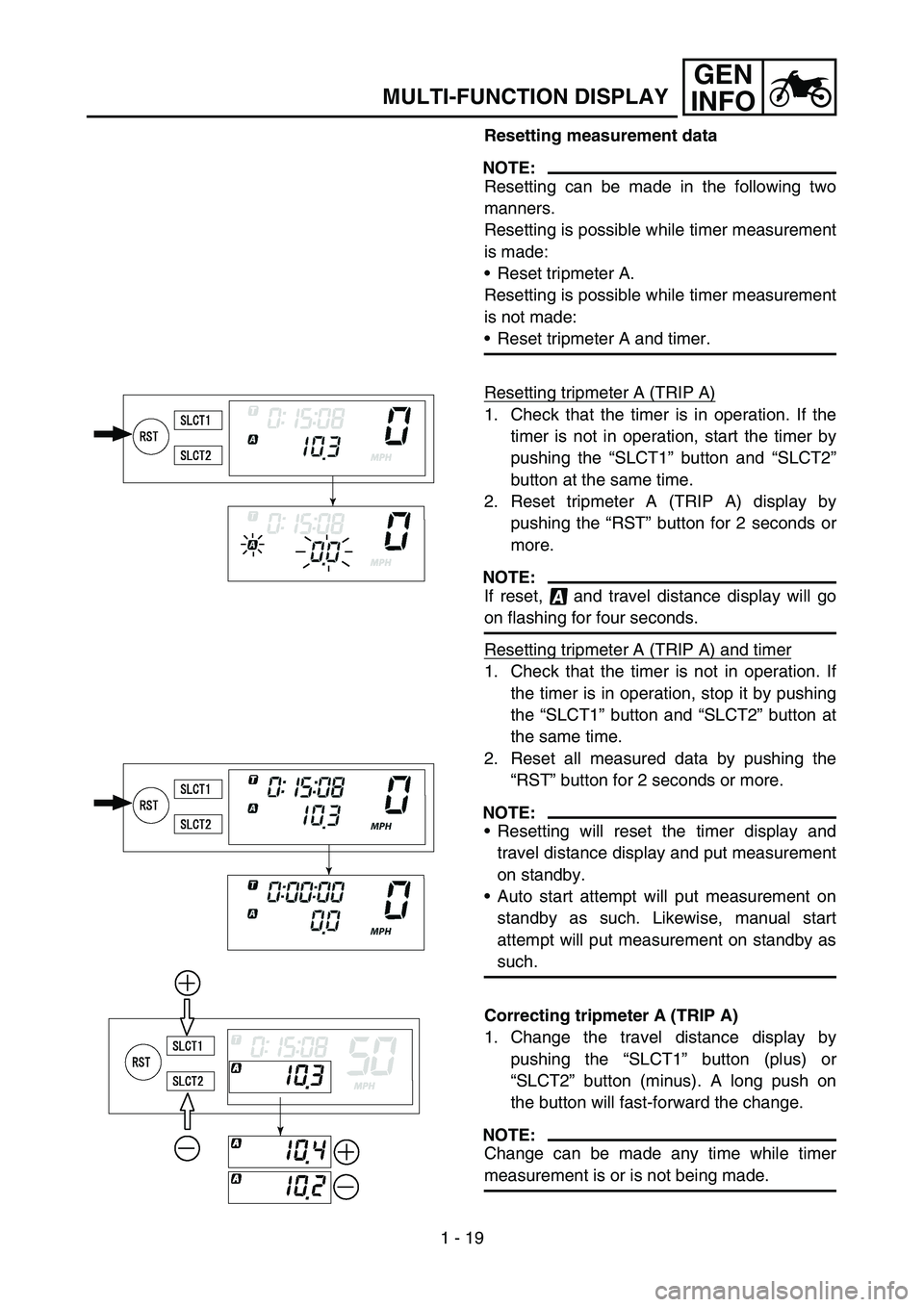

Resetting measurement data

NOTE:

Resetting can be made in the following two

manners.

Resetting is possible while timer measurement

is made:

Reset tripmeter A.

Resetting is possible while timer measurement

is not made:

Reset tripmeter A and timer.

Resetting tripmeter A (TRIP A)

1. Check that the timer is in operation. If the

timer is not in operation, start the timer by

pushing the “SLCT1” button and “SLCT2”

button at the same time.

2. Reset tripmeter A (TRIP A) display by

pushing the “RST” button for 2 seconds or

more.

NOTE:

If reset, and travel distance display will go

on flashing for four seconds.

Resetting tripmeter A (TRIP A) and timer

1. Check that the timer is not in operation. If

the timer is in operation, stop it by pushing

the “SLCT1” button and “SLCT2” button at

the same time.

2. Reset all measured data by pushing the

“RST” button for 2 seconds or more.

NOTE:

Resetting will reset the timer display and

travel distance display and put measurement

on standby.

Auto start attempt will put measurement on

standby as such. Likewise, manual start

attempt will put measurement on standby as

such.

Correcting tripmeter A (TRIP A)

1. Change the travel distance display by

pushing the “SLCT1” button (plus) or

“SLCT2” button (minus). A long push on

the button will fast-forward the change.

NOTE:

Change can be made any time while timer

measurement is or is not being made.

Page 70 of 786

GEN

INFO

1 - 20

MULTI-FUNCTION DISPLAY

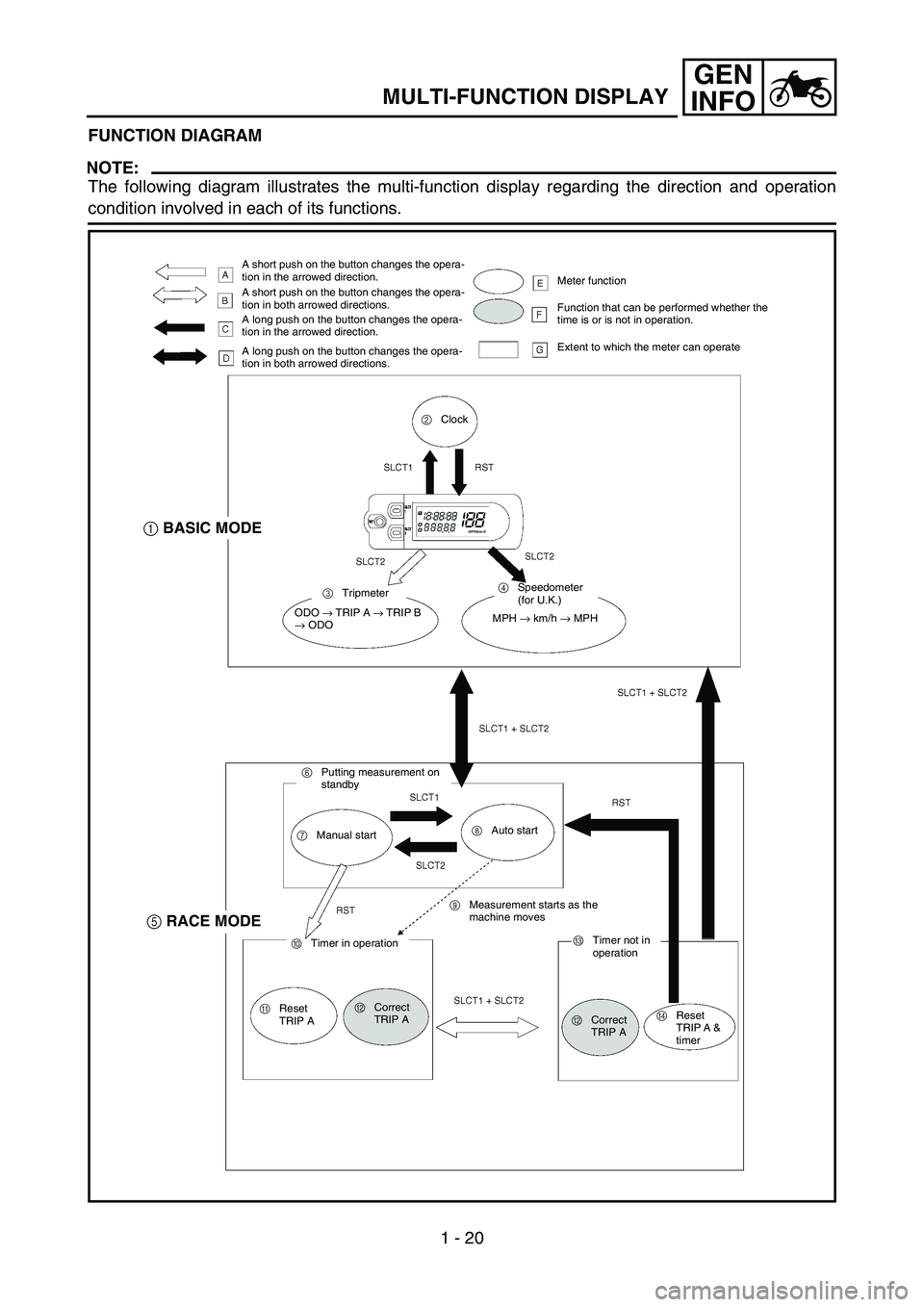

FUNCTION DIAGRAM

NOTE:

The following diagram illustrates the multi-function display regarding the direction and operation

condition involved in each of its functions.

A short push on the button changes the opera-

tion in the arrowed direction.

A short push on the button changes the opera-

tion in both arrowed directions.

A long push on the button changes the opera-

tion in the arrowed direction.

A long push on the button changes the opera-

tion in both arrowed directions.Meter function

Function that can be performed whether the

time is or is not in operation.

Extent to which the meter can operate

2Clock

3Tripmeter4Speedometer

(for U.K.)

ODO

→ TRIP A

→ TRIP B

→ ODOMPH

→ km/h

→ MPH

6Putting measurement on

standby

7Manual start8Auto start

9Measurement starts as the

machine moves

0Timer in operation

AReset

TRIP ABCorrect

TRIP ACTimer not in

operation

BCorrect

TRIP ADReset

TRIP A &

timer

1BASIC MODE

5RACE MODE

Page 105 of 786

SPEC

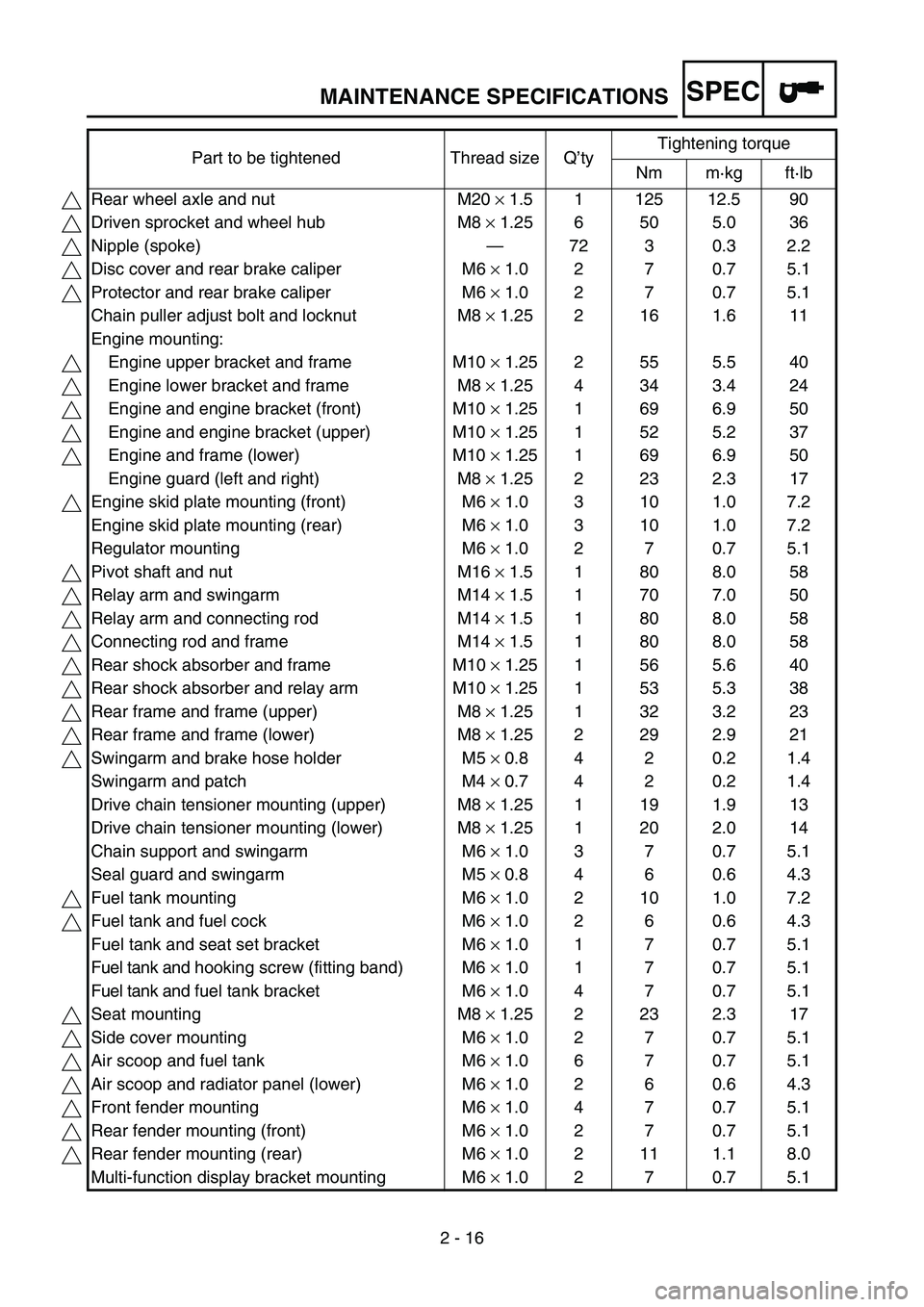

2 - 16 Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Rear wheel axle and nut M20 × 1.5 1 125 12.5 90

Driven sprocket and wheel hub M8 × 1.25 6 50 5.0 36

Nipple (spoke)—72 3 0.3 2.2

Disc cover and rear brake caliper M6 × 1.0 2 7 0.7 5.1

Protector and rear brake caliper M6 × 1.0 2 7 0.7 5.1

Chain puller adjust bolt and locknut M8 × 1.25 2 16 1.6 11

Engine mounting:

Engine upper bracket and frame M10 × 1.25 2 55 5.5 40

Engine lower bracket and frame M8 × 1.25 4 34 3.4 24

Engine and engine bracket (front) M10 × 1.25 1 69 6.9 50

Engine and engine bracket (upper) M10 × 1.25 1 52 5.2 37

Engine and frame (lower) M10 × 1.25 1 69 6.9 50

Engine guard (left and right) M8 × 1.25 2 23 2.3 17

Engine skid plate mounting (front) M6 × 1.0 3 10 1.0 7.2

Engine skid plate mounting (rear) M6 × 1.0 3 10 1.0 7.2

Regulator mounting M6 × 1.0 2 7 0.7 5.1

Pivot shaft and nut M16 × 1.5 1 80 8.0 58

Relay arm and swingarm M14 × 1.5 1 70 7.0 50

Relay arm and connecting rod M14 × 1.5 1 80 8.0 58

Connecting rod and frame M14 × 1.5 1 80 8.0 58

Rear shock absorber and frame M10 × 1.25 1 56 5.6 40

Rear shock absorber and relay arm M10 × 1.25 1 53 5.3 38

Rear frame and frame (upper) M8 × 1.25 1 32 3.2 23

Rear frame and frame (lower) M8 × 1.25 2 29 2.9 21

Swingarm and brake hose holder M5 × 0.8 4 2 0.2 1.4

Swingarm and patch M4 × 0.7 4 2 0.2 1.4

Drive chain tensioner mounting (upper) M8 × 1.25 1 19 1.9 13

Drive chain tensioner mounting (lower) M8 × 1.25 1 20 2.0 14

Chain support and swingarm M6 × 1.0 3 7 0.7 5.1

Seal guard and swingarm M5 × 0.8 4 6 0.6 4.3

Fuel tank mounting M6 × 1.0 2 10 1.0 7.2

Fuel tank and fuel cock M6 × 1.0 2 6 0.6 4.3

Fuel tank and seat set bracket M6 × 1.0 1 7 0.7 5.1

Fuel tank and hooking screw (fitting band) M6 × 1.0 1 7 0.7 5.1

Fuel tank and fuel tank bracket M6 × 1.0 4 7 0.7 5.1

Seat mounting M8 × 1.25 2 23 2.3 17

Side cover mounting M6 × 1.0 2 7 0.7 5.1

Air scoop and fuel tank M6 × 1.0 6 7 0.7 5.1

Air scoop and radiator panel (lower) M6 × 1.0 2 6 0.6 4.3

Front fender mounting M6 × 1.0 4 7 0.7 5.1

Rear fender mounting (front) M6 × 1.0 2 7 0.7 5.1

Rear fender mounting (rear) M6 × 1.0 2 11 1.1 8.0

Multi-function display bracket mounting M6 × 1.0 2 7 0.7 5.1

MAINTENANCE SPECIFICATIONS

Page 106 of 786

SPEC

2 - 17

NOTE:

- marked portion shall be checked for torque tightening after break-in or before each race. Multi-function display mounting M5 × 0.8 2 4 0.4 2.9

Plate 1 and protector M5 × 0.8 2 4 0.4 2.9

Plate 2 and protector—2 0.5 0.05 0.36

Speed sensor lead holder and headlight stay

(lower)M6 × 1.0 1 7 0.7 5.1

Headlight stay (lower) and under bracket M8 × 1.25 2 15 1.5 11

Headlight body and headlight unit M6 × 1.0 2 7 0.7 5.1

Headlight mounting (left and right) M6 × 1.0 2 7 0.7 5.1

Headlight mounting (lower) M6 × 1.0 1 7 0.7 5.1

Taillight mounting M6 × 1.0 3 4 0.4 2.9

Taillight lead clamp and rear fender—2 0.5 0.05 0.36

Coolant reservoir tank mounting M6 × 1.0 2 7 0.7 5.1

Sidestand bracket mounting M10 × 1.25 2 66 6.6 48

Drive chain stopper and sidestand bracket M6 × 1.0 1 7 0.7 5.1

Sidestand mounting M8 × 1.25 1 20 2.0 14 Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

MAINTENANCE SPECIFICATIONS

Page 184 of 786

2 - 28

SPECCABLE ROUTING DIAGRAM

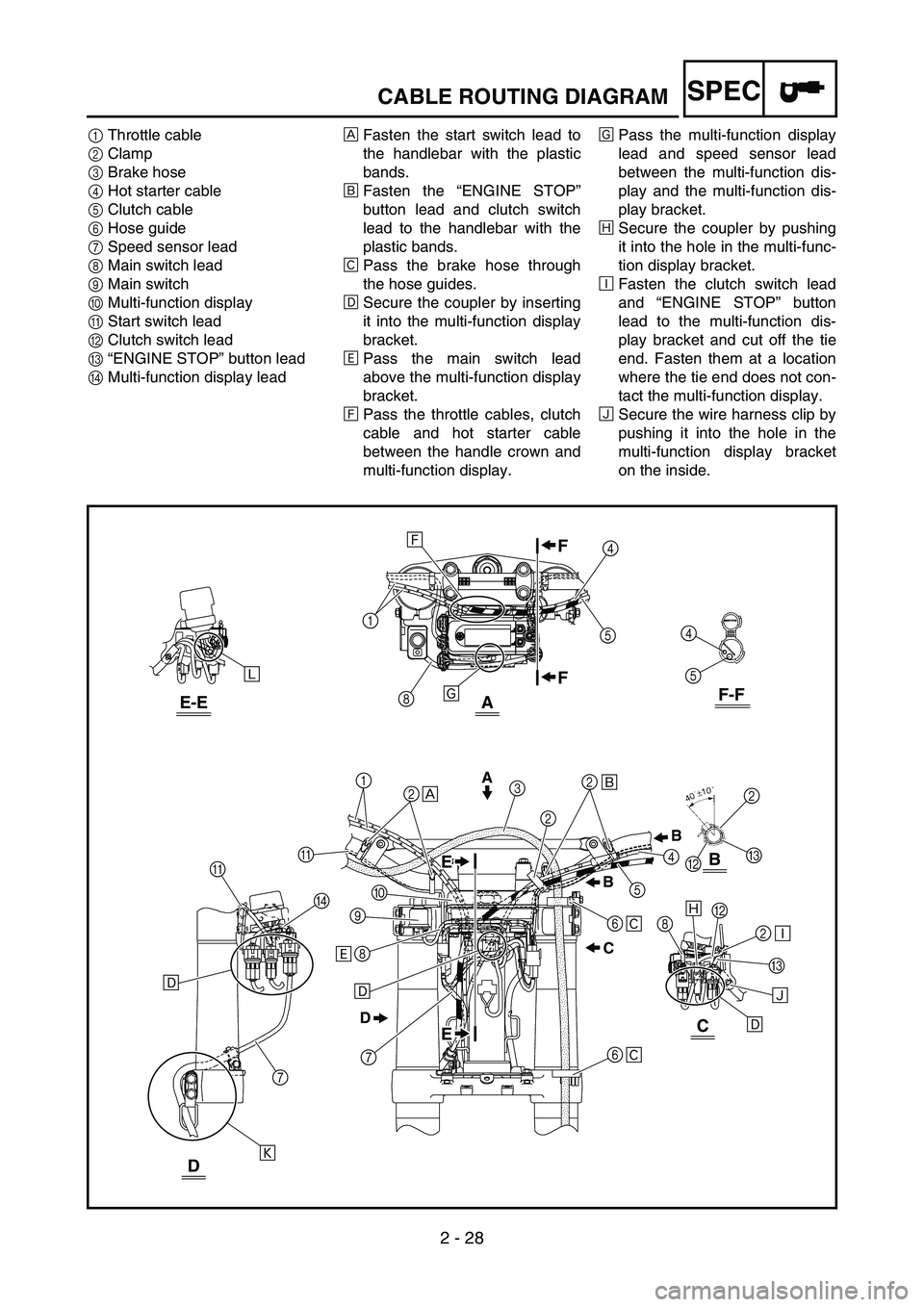

1Throttle cable

2Clamp

3Brake hose

4Hot starter cable

5Clutch cable

6Hose guide

7Speed sensor lead

8Main switch lead

9Main switch

0Multi-function display

AStart switch lead

BClutch switch lead

C“ENGINE STOP” button lead

DMulti-function display leadÈFasten the start switch lead to

the handlebar with the plastic

bands.

ÉFasten the “ENGINE STOP”

button lead and clutch switch

lead to the handlebar with the

plastic bands.

ÊPass the brake hose through

the hose guides.

ËSecure the coupler by inserting

it into the multi-function display

bracket.

ÌPass the main switch lead

above the multi-function display

bracket.

ÍPass the throttle cables, clutch

cable and hot starter cable

between the handle crown and

multi-function display.ÎPass the multi-function display

lead and speed sensor lead

between the multi-function dis-

play and the multi-function dis-

play bracket.

ÏSecure the coupler by pushing

it into the hole in the multi-func-

tion display bracket.

ÐFasten the clutch switch lead

and “ENGINE STOP” button

lead to the multi-function dis-

play bracket and cut off the tie

end. Fasten them at a location

where the tie end does not con-

tact the multi-function display.

ÑSecure the wire harness clip by

pushing it into the hole in the

multi-function display bracket

on the inside.

4

5

Î

Ê Ó

A

B

F-FE-E

C

D

A

D

7

7

Ò ËA

12

È32

É

6

Ê

6

8

Ì0

9

ËÑ C

BÏ

2

Ð 8

8

1Í

4

5

4

5B2

C

DC BB A

F F

EE

EE

Ë

2

Page 186 of 786

2 - 29

SPECCABLE ROUTING DIAGRAM

ÒPass the speed sensor lead

through the guide on the out-

side of the front fork.

ÓPass the start switch lead and

multi-function display lead (on

the wire harness side) above

the multi-function display lead

(on the side of the multi-func-

tion display lead) and speed

sensor lead, and then to the

right of the chassis.

4

5

Î

Ê Ó

A

B

F-FE-E

C

D

A

D

7

7

Ò ËA

12

È32

É

6

Ê

6

8

Ì0

9

ËÑ C

BÏ

2

Ð 8

8

1Í

4

5

4

5B2

C

DC BB A

F F

EE

EE

Ë

2

Page 666 of 786

6 - 1

–+ELECELECTRICAL COMPONENTS AND WIRING DIAGRAM

EC600000

ELECTRICAL

EC610000

ELECTRICAL COMPONENTS AND WIRING DIAGRAM

EC611000

ELECTRICAL COMPONENTS

1Headlight

2Multi-function display

3“ENGINE STOP” but-

ton

4Clutch switch

5Diode

6Starter relay diode

7TPS (throttle posi-

tion sensor)

8Starter relay

9Fuse

0Starting circuit cut-off

relayATaillight

BNeutral switch

CStarter motor

DAC magneto

ERectifier/regulator

FIgnition coil

GSpark plug

HStart switch

IMain switch

JCDI unit

KSpeed sensor

LBatteryCOLOR CODE

B ...................... Black

Br ..................... Brown

Ch .................... Chocolate

Dg .................... Dark green

Gy .................... Gray

L....................... Blue

O ...................... Orange

R ...................... Red

Sb .................... Sky blue

W ..................... White

EC612000

WIRING DIAGRAM

FGH

I

J

K

L

1 234

56

789

0A

B C

D E

B/L

W

W

R

BR/BBr

R

BR/BBr

R

Y

Y

L/R/BBB

SbL/W

L/YBBB

WY

RY

R

LY

B

YLB/L

B

B

ON

OFF

10A

BB

OFF

START

R-BrL/W

B

BrL/W

BrL/W

L/B

-Y

Y

B

LY

B

L/WSb

B/WBBB

W/R/W

R/

BGyBrL/W

ON

STOP

O

LSbB/L

W RBrB/W

L

/

BGyWR

/B

B O

L/YSbL/R

R W

Y W

Y W

Y

L B

B

B

RRR/B

B Br B

B B B B

L/W

R

R

R R B

R

BrBr

L/W L/

W

Br B

L/B

L/B

L/R

Br

R/B

L/B L

/W

B/W

WW

/RW

RO

L

Y

ELO

B

L

Y

B/LSb*1

Sb

*2B/W

B

B

L/R L/Y L/Y

B

SbSbL/W

B

Gy

SbBB/LYO

L

*2

O B

L YL/W

B/L

*1

D

E

CI

6

H4 5

B3J

K

2FG

7

8L9

1A

*2

*1

W

B

R/W

Ch

Dg

Y

B BrRW

WRB/W

SIGNAL

+

Backup

SLCT1

SLCT2

RST

GND

BrR/WB

B

R/WBr

WRB/W

R B

W

ChDgYB

B/WWRB/WWR

0

R

W

W W

L/WB/L

Y B

RB

B

L

L

*1: For USA

*2: Except for USA

Y ...................... Yellow

B/L ................... Black/Blue

B/W .................. Black/White

L/B ................... Blue/Black

L/R ................... Blue/Red

L/Y ................... Blue/Yellow

L/W .................. Blue/White

R/B................... Red/Black

R/W.................. Red/White

Page 728 of 786

–+ELEC

6 - 26

SIGNALING SYSTEM

SIGNALING SYSTEM

INSPECTION STEPS

If the speedometer will not operate, use the following inspection steps.

*1 marked: Refer to “BATTERY INSPECTION AND CHARGING” section in the CHAPTER 3.

NOTE:

•Remove the following parts before inspection.

1) Headlight

•Use the following special tools in this inspection.

Pocket tester:

YU-3112-C/90890-03112

*1 Check battery. Recharge or replace.

Check each coupler and

wire connection.Repair or replace.

Check multi-function dis-

play.Input voltage Replace wire harness.

Output voltageReplace multi-func-

tion display.

Check speed sensor. Replace.

OK

OK

OK

No good

No good

No good No good

No good

Page 732 of 786

6 - 27

–+ELECSIGNALING SYSTEM

COUPLERS AND LEADS CONNECTION

INSPECTION

1. Check:

•Couplers and leads connection

Rust/dust/looseness/short-circuit →

Repair or replace.

MULTI-FUNCTION DISPLAY INPUT

VOLTAGE INSPECTION

1. Disconnect the multi-function display cou-

pler.

2. Set the main switch to “ON”.

3. Measure:

•Multi-function display input voltage

Out of specification → Replace wire har-

ness.

CAUTION:

Make sure that a short-circuit does not

develop between the terminals because it

may cause damage to electrical compo-

nents.Tester (+) lead

→ Brown lead

1

Tester (–) lead

→ Black lead

2

Multi-function dis-

play input voltageTester selec-

tor position

10 V or more DCV-20

MULTI-FUNCTION DISPLAY OUTPUT

VOLTAGE INSPECTION

1. Disconnect the multi-function display cou-

pler.

2. Set the main switch to “ON”.