display YAMAHA WR 450F 2008 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2008, Model line: WR 450F, Model: YAMAHA WR 450F 2008Pages: 224, PDF Size: 13.7 MB

Page 188 of 224

6-27

STEERING

STEERING

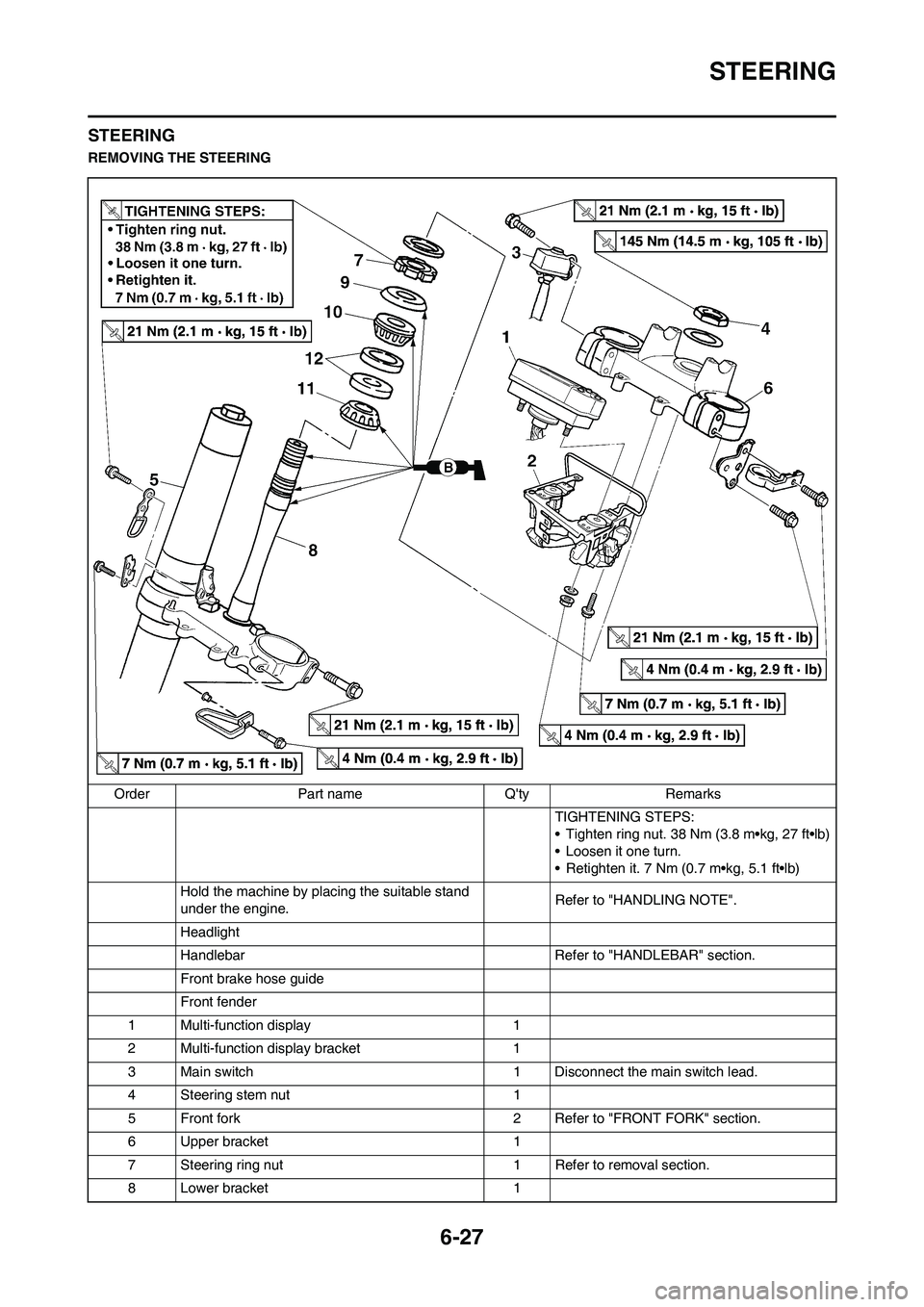

REMOVING THE STEERING

Order Part name Q'ty Remarks

TIGHTENING STEPS:

• Tighten ring nut. 38 Nm (3.8 m•kg, 27 ft•lb)

• Loosen it one turn.

• Retighten it. 7 Nm (0.7 m•kg, 5.1 ft•lb)

Hold the machine by placing the suitable stand

under the engine.Refer to "HANDLING NOTE".

Headlight

Handlebar Refer to "HANDLEBAR" section.

Front brake hose guide

Front fender

1 Multi-function display 1

2 Multi-function display bracket 1

3 Main switch 1 Disconnect the main switch lead.

4 Steering stem nut 1

5 Front fork 2 Refer to "FRONT FORK" section.

6 Upper bracket 1

7 Steering ring nut 1 Refer to removal section.

8 Lower bracket 1

Page 191 of 224

6-30

STEERING

6. Install:

• Washer "1"

7. Install:

• Front fork "1"

• Upper bracket "2"

• Main switch "3"

• Front brake hose guide bracket

"4"

• Temporarily tighten the pinch bolts

(lower bracket).

• Do not tighten the pinch bolts (up-

per bracket) yet.

8. Install:

• Guide (speed sensor lead) "1"

After installing the guide as shown,

pass the speed sensor lead through

the guide.

9. Install:

• Washer "1"

• Steering stem nut "2"10. After tightening the nut, check the

steering for smooth movement. If

not, adjust the steering by loosen-

ing the steering ring nut little by lit-

tle.

11. Adjust:

• Front fork top end "a"

12. Tighten:

• Pinch bolt (upper bracket) "1"

• Pinch bolt (lower bracket) "2"

Tighten the lower bracket to speci-

fied torque. If torqued too much, it

may cause the front fork to mal-

function.

13. Install:

• Multi-function display bracket "1"

• Multi-function display "2"

Pass the throttle cables "3", clutch ca-

ble "4" and hot starter cable "5" be-

tween the multi-function display

bracket and upper bracket.

14. Install:

• Holder "1"

• Clamp "2"

• Install so that the marking "a" on the

speed sensor lead aligns with the

holder edge.

• Fasten the speed sensor lead to the

holder with the clamp.

Steering stem nut:

145 Nm (14.5 m•kg, 105

ft•lb)

Front fork top end (stan-

dard) "a":

Zero mm (Zero in)

Pinch bolt (upper brack-

et):

21 Nm (2.1 m•kg, 15

ft•lb)

Pinch bolt (lower brack-

et):

21 Nm (2.1 m•kg, 15

ft•lb)

Multi-function display

bracket:

7 Nm (0.7 m•kg, 5.1

ft•lb)

Multi-function display:

4 Nm (0.4 m•kg, 2.9

ft•lb)

Holder:

13 Nm (1.3 m•kg, 9.4

ft•lb)

Clamp:

7 Nm (0.7 m•kg, 5.1

ft•lb)

Page 202 of 224

7-1

ELECTRICAL COMPONENTS AND WIRING DIAGRAM

ELECTRICAL

ELECTRICAL

COMPONENTS AND

WIRING DIAGRAM

ELECTRICAL COMPONENTS

1. Headlight

2. Multi-function display

3. Engine stop switch

4. Clutch switch

5. Diode

6. Starter relay diode

7. Throttle position sensor

8. Starter relay9. Fuse

10. Starting circuit cut-off relay

11. CDI unit

12. Taillight

13. Neutral switch

14. Starter motor

15. AC magneto

16. Rectifier/regulator17. Ignition coil

18. Spark plug

19. Start switch

20. Main switch

21. Speed sensor

22. Battery

Page 203 of 224

7-2

ELECTRICAL COMPONENTS AND WIRING DIAGRAM

WIRING DIAGRAM

1. Headlight

2. Multi-function display

3. Engine stop switch

4. Clutch switch

5. Diode

6. Starter relay diode

7. Throttle position sensor

8. Starter relay

9. Fuse

10. Starting circuit cut-off relay

11. CDI unit

12. Taillight

13. Neutral switch

14. Starter motor

15. AC magneto

16. Rectifier/regulator

17. Ignition coil

18. Spark plug

19. Start switch

20. Main switch

21. Speed sensor

22. Battery

*1: For USA

*2: Except for USACOLOR CODE

BBlack

Br Brown

Ch Chocolate

Dg Dark green

GGreen

Gy Gray

LBlue

O Orange

RRed

Sb Sky blue

WWhite

YYellow

B/L Black/Blue

B/W Black/White

L/B Blue/Black

L/R Blue/Red

L/Y Blue/Yellow

L/W Blue/White

R/B Red/Black

R/W Red/White

7

Page 221 of 224

7-20

SIGNALING SYSTEM

SIGNALING SYSTEM

INSPECTION STEPS

If the speedometer will not operate, use the following inspection steps.

*1 marked: Refer to "CHECKING AND CHARGING THE BATTERY" section in the CHAPTER 3.

• Remove the following parts before inspection.

1. Headlight

• Use the following special tools in this inspection.

*1 Check battery. No good→Recharge or replace.

OK↓

Check each coupler and wire connection. No good→Repair or replace.

OK↓

Check multi-function display. (Input voltage) No good→Replace wire harness.

OK↓

Check multi-function display. (Output voltage) No good→Replace multi-function display.

OK↓

Check speed sensor. No good→Replace.

Pocket tester:

YU-3112-C/90890-03112

Page 222 of 224

7-21

SIGNALING SYSTEM

CHECKING THE COUPLERS AND

LEADS CONNECTION

1. Check:

• Couplers and leads connection

Rust/dust/looseness/short-circuit

→Repair or replace.

CHECKING THE MULTI-FUNCTION

DISPLAY INPUT VOLTAGE

1. Disconnect the multi-function dis-

play coupler.

2. Set the main switch to "ON".

3. Measure:

• Multi-function display input volt-

age

Out of specification→Replace

wire harness.

Make sure that a short-circuit does

not develop between the terminals

because it may cause damage to

electrical components.

CHECKING THE MULTI-FUNCTION

DISPLAY OUTPUT VOLTAGE

1. Disconnect the multi-function dis-

play coupler.

2. Set the main switch to "ON".

3. Measure:

• Multi-function display output volt-

age

Out of specification→Replace

multi-function display.

Make sure that a short-circuit does

not develop between the terminals

because it may cause damage to

electrical components.

CHECKING THE SPEED SENSOR

OUTPUT VOLTAGE

1. Insert the thin electric conductors

"1" (lead) into the speed sensor

coupler "2", as shown, and con-

nect the tester to them.

• Do not insert the electric conduc-

tors more than required because

it may reduce the waterproof

function of the coupler.

• Make sure that a short-circuit

does not develop between the

terminals because it may cause

damage to electrical compo-

nents.

2. Set the main switch to "ON".

3. Measure:

• Speed sensor output voltage

Output voltage not correct→Re-

place the speed sensor.

Measurement steps:

a. Elevate the front wheel and slowly

rotate it.

b. Measure the voltage (DCV) of

white lead and black lead. With

each full rotation of the front

wheel, the voltage reading should

cycle from 0.6 V to 4.8 V to 0.6 V

to 4.8 V.

Tester (+) lead→Brown lead "1"

Tester (-) lead→Black lead "2"

Multi-func-

tion dis-

play input

voltageTester se-

lector posi-

tion

10 V or

moreDCV-20

Tester (+) lead→Red lead "1"

Tester (-) lead→Black/White lead

"2"

Multi-func-

tion dis-

play output

voltageTester se-

lector posi-

tion

4.5 V or

moreDCV-20

Tester (+) lead→White lead "3"

Tester (-) lead→Black lead "4"