check engine light YAMAHA WR 450F 2008 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2008, Model line: WR 450F, Model: YAMAHA WR 450F 2008Pages: 224, PDF Size: 13.7 MB

Page 10 of 224

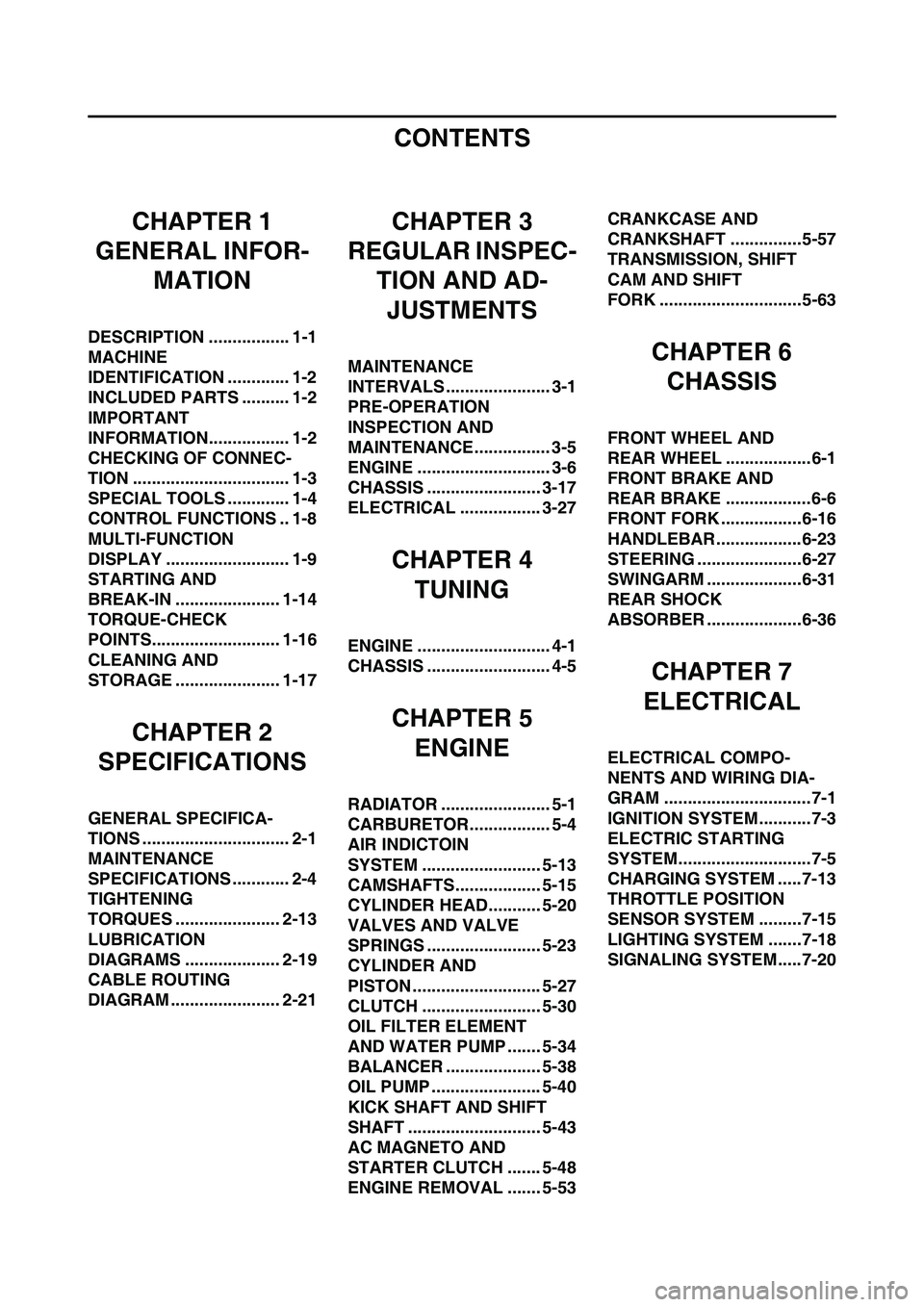

CONTENTS

CHAPTER 1

GENERAL INFOR-

MATION

DESCRIPTION ................. 1-1

MACHINE

IDENTIFICATION ............. 1-2

INCLUDED PARTS .......... 1-2

IMPORTANT

INFORMATION................. 1-2

CHECKING OF CONNEC-

TION ................................. 1-3

SPECIAL TOOLS ............. 1-4

CONTROL FUNCTIONS .. 1-8

MULTI-FUNCTION

DISPLAY .......................... 1-9

STARTING AND

BREAK-IN ...................... 1-14

TORQUE-CHECK

POINTS........................... 1-16

CLEANING AND

STORAGE ...................... 1-17

CHAPTER 2

SPECIFICATIONS

GENERAL SPECIFICA-

TIONS ............................... 2-1

MAINTENANCE

SPECIFICATIONS ............ 2-4

TIGHTENING

TORQUES ...................... 2-13

LUBRICATION

DIAGRAMS .................... 2-19

CABLE ROUTING

DIAGRAM ....................... 2-21

CHAPTER 3

REGULAR INSPEC-

TION AND AD-

JUSTMENTS

MAINTENANCE

INTERVALS ...................... 3-1

PRE-OPERATION

INSPECTION AND

MAINTENANCE................ 3-5

ENGINE ............................ 3-6

CHASSIS ........................ 3-17

ELECTRICAL ................. 3-27

CHAPTER 4

TUNING

ENGINE ............................ 4-1

CHASSIS .......................... 4-5

CHAPTER 5

ENGINE

RADIATOR ....................... 5-1

CARBURETOR................. 5-4

AIR INDICTOIN

SYSTEM ......................... 5-13

CAMSHAFTS.................. 5-15

CYLINDER HEAD........... 5-20

VALVES AND VALVE

SPRINGS ........................ 5-23

CYLINDER AND

PISTON ........................... 5-27

CLUTCH ......................... 5-30

OIL FILTER ELEMENT

AND WATER PUMP ....... 5-34

BALANCER .................... 5-38

OIL PUMP ....................... 5-40

KICK SHAFT AND SHIFT

SHAFT ............................ 5-43

AC MAGNETO AND

STARTER CLUTCH ....... 5-48

ENGINE REMOVAL ....... 5-53CRANKCASE AND

CRANKSHAFT ...............5-57

TRANSMISSION, SHIFT

CAM AND SHIFT

FORK ..............................5-63

CHAPTER 6

CHASSIS

FRONT WHEEL AND

REAR WHEEL ..................6-1

FRONT BRAKE AND

REAR BRAKE ..................6-6

FRONT FORK .................6-16

HANDLEBAR..................6-23

STEERING ......................6-27

SWINGARM ....................6-31

REAR SHOCK

ABSORBER ....................6-36

CHAPTER 7

ELECTRICAL

ELECTRICAL COMPO-

NENTS AND WIRING DIA-

GRAM ...............................7-1

IGNITION SYSTEM...........7-3

ELECTRIC STARTING

SYSTEM............................7-5

CHARGING SYSTEM .....7-13

THROTTLE POSITION

SENSOR SYSTEM .........7-15

LIGHTING SYSTEM .......7-18

SIGNALING SYSTEM.....7-20

Page 67 of 224

3-12

ENGINE

5. Inspect:

• Air filter element

Damage→Replace.

6. Apply:

• Foam-air-filter oil or equivalent oil

to the element

• Squeeze out the excess oil. Ele-

ment should be wet but not drip-

ping.

• Wipe off the oil left on the element

surface using a clean dry cloth. (Ex-

cess oil in the element may ad-

versely affect engine starting.)

7. Install:

• Air filter guide "1"

• Align the projection "a" on filter

guide with the hole "b" in air filter el-

ement.

• Apply the lithium soap base grease

on the matching surface "c" on air

filter element.

8. Install:

• Air filter element "1"

Align the projection "a" on filter guide

with the hole "b" in air filter case.

9. Hook:

•Binder "1"

Hook the binder "1" so that it contacts

the filter guide projections "a".

CHECKING THE ENGINE OIL

LEVEL

1. Stand the machine on a level sur-

face.

• When checking the oil level make

sure that the machine is upright.

• Place the machine on a suitable

stand.

Never remove the oil tank cap just

after high speed operation. The

heated oil could spurt out. causing

danger. Wait until the oil cools

down to approximately 70°C

(158°F).

2. Idle the engine more than 3 min-

utes while keeping the machine

upright. Then stop the engine and

inspect the oil level.

3. Remove:

• Oil tank cap 1

4. Inspect:

• Oil level

Check that the engine oil is above

the level mark "a" and that the oil

does not come out when the

check bolt "1" is removed.

Below the level mark "a"→Add oil

through the filler cap hole until it is

above the level mark "a".

Oil comes out at the check bolt→

Drain the oil until it stops coming

out.

When inspecting the oil level, do not

screw the oil level gauge into the oil

tank. Insert the gauge lightly.

(For CDN)

• Do not add any chemical addi-

tives. Engine oil also lubricates

the clutch and additives could

cause clutch slippage.

• Do not allow foreign material to

enter the crankcase.

(Except for CDN)

Recommended oil:

Yamalube 4,

SAE10W30 or

SAE20W40

Yamalube 4-R,

SAE10W50

API service SG type or

higher, JASO standard

MA

Recommended oil:

SAE10W30,

SAE10W40,

SAE15W40, SAE20W40

or SAE20W50

API service SG type or

higher, JASO standard

MA

Page 68 of 224

3-13

ENGINE

• Do not add any chemical addi-

tives or use oils with a grade of

CD "a" or higher.

• Do not use oils labeled "ENERGY

CONSERVING II" "b" or higher.

Engine oil also lubricates the

clutch and additives could cause

clutch slippage.

• Do not allow foreign material to

enter the crankcase.

5. Start the engine and let it warm up

for several minutes.

When the oil tank is empty, never

start the engine.

6. Idle the engine more than 10 sec-

onds while keeping the machine

upright. Then stop the engine and

add the oil to the maximum level.

7. Install:

• Oil tank cap

CHANGING THE ENGINE OIL

1. Start the engine and let it warm up

for several minutes.

2. Stop the engine and place an oil

pan under the drain bolt.

3. Remove:

• Engine guard "1"

• Oil tank plug "2"

• Oil filler cap "3"

• Drain bolt (with gasket) "4"

• Oil filter drain bolt (O-ring) "5"

• Drain bolt (with gasket) "6"

Drain the crankcase and oil tank

of its oil.4. If the oil filter is to be replaced dur-

ing this oil change, remove the fol-

lowing parts and reinstall them.

Replacement steps:

a. Remove the oil filter element cov-

er "1" and oil filter element "2".

b. Check the O-rings "3", if cracked

or damaged, replace them with a

new one.

c. Install the oil filter element and oil

filter element cover.

5. Install:

• Gaskets

• Oil filter drain bolt

• Drain bolt (right crankcase)

• Drain bolt (left crankcase)

6. Fill:

• Engine oil7. Install:

• Oil filler cap "1"

8. Inspect:

• Engine (for oil leaks)

• Oil level

Refer to "CHECKING THE EN-

GINE OIL LEVEL".

CHECKING THE OIL PRESSURE

1. Check:

• Oil pressure

Checking steps:

a. Slightly loosen the oil pressure

check bolt "1".

b. Start the engine and keep it idling

until oil starts to seep from the oil

pressure check bolt. If no oil

comes out after one minute, turn

the engine off so it will not seize.

c. Check oil passages and oil pump

for damage or leakage.

d. Start the engine after solving the

problem(s) and recheck the oil

pressure.

e. Tighten the oil pressure check

bolt.

Oil filter element cover:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Oil filter drain bolt:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Drain bolt (right crank-

case):

20 Nm (2.0 m•kg, 14

ft•lb)

Drain bolt (left crank-

case):

20 Nm (2.0 m•kg, 14

ft•lb)

Oil quantity:

Periodic oil change:

0.95 L (0.84 Imp qt,

1.00 US qt)

With oil filter replace-

ment:

1.0 L (0.88 Imp qt, 1.06

US qt)

Total amount:

1.2 L (1.06 Imp qt, 1.27

US qt)

Oil pressure check bolt:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 69 of 224

3-14

ENGINE

ADJUSTING THE PILOT SCREW

1. Adjust:

• Pilot screw "1"

Adjustment steps:

To optimize the fuel flow at a smaller

throttle opening, each machine's pilot

screw has been individually set at the

factory. Before adjusting the pilot

screw, turn it in fully and count the

number of turns. Record this number

as the factory-set number of turns

out.

a. Turn in the pilot screw until it is

lightly seated.

b. Turn out the pilot screw by the

factory-set number of turns.

ADJUSTING THE ENGINE IDLING

SPEED

1. Start the engine and thoroughly

warm it up.

2. Adjust:

• Engine idling speed

Adjustment steps:

a. Turn the throttle stop screw "1"

until the specified engine idling

speed.

Using a digital engine tachometer for

idle speed adjustment, detect the en-

gine idling speed by bringing the

sensing element "c" of the engine ta-

chometer close to the ignition coil "2".

ADJUSTING THE VALVE

CLEARANCE

• The valve clearance should be ad-

justed when the engine is cool to

the touch.

• The piston must be at Top Dead

Center (T.D.C.) on compression

stroke to check or adjust the valve

clearance.

1. Remove:

•Seat

•Fuel tank

Refer to "REMOVING THE SEAT,

FUEL TANK AND SIDE COV-

ERS" section.

2. Remove:

• Air cut-off valve assembly

Refer to "AIR INDUCTION SYS-

TEM" section in the CHAPTER 5.

• Spark plug

• Engine upper bracket

• Cylinder head cover

Refer to "CAMSHAFTS" section

in the CHAPTER 5.

3. Remove:

• Timing mark accessing screw "1"

• Crankshaft end accessing screw

"2"

• O-ring4. Check:

• Valve clearance

Out of specification→Adjust.

Checking steps:

a. Turn the crankshaft counterclock-

wise with a wrench.

b. Align the T.D.C. mark "a" on the

rotor with the align mark "b" on the

crankcase cover when piston is at

T.D.C. on compression stroke.

In order to be sure that the piston is at

Top Dead Center, the punch mark "c"

on the exhaust camshaft and the

punch mark "d" on the intake cam-

shaft must align with the cylinder

head surface, as shown in the illustra-

tion.

c. Measure the valve clearance "e"

using a feeler gauge "1".

Record the measured reading if the

clearance is incorrect.

Pilot screw (example):

2 turns out

(For EUROPE)

To increase idle speed→Turn the

throttle stop screw "1" in "a".

To decrease idle speed→Turn the

throttle stop screw "1" out "b".

Engine idling speed:

1,750–1,950 r/min

Valve clearance (cold):

Intake valve:

0.10–0.15 mm

(0.0039–0.0059 in)

Exhaust valve:

0.20–0.25 mm

(0.0079–0.0098 in)

Page 72 of 224

3-17

CHASSIS

CLEANING THE SPARK

ARRESTER (For USA)

• Be sure the exhaust pipe and si-

lencer are cool before cleaning

the spark arrester.

• Do not start the engine when

cleaning the exhaust system.

1. Remove:

• Screw (silencer cap) "1"

2. Remove:

• Bolt (spark arrester) "1"

3. Remove:

• Tail pipe "1"

• Gasket (tail pipe) "2"

• Spark arrester "3"

Pull the spark arrester out of the

silencer.

• Gasket (spark arrester) "4"

4. Clean:

• Spark arrester

Tap the spark arrester lightly,

then use a wire brush to remove

any carbon deposits.

5. Install:

• Gasket (spark arrester)

• Spark arrester

Insert the spark arrester into the

silencer and align the bolt holes.

• Gasket (tail pipe)

• Bolt (spark arrester)6. Install:

• Silencer cap

First tighten the two screws "a" locat-

ed horizontally apart, and then tighten

the others.

CHASSIS

BLEEDING THE HYDRAULIC

BRAKE SYSTEM

Bleed the brake system if:

• The system has been disassem-

bled.

• A brake hose has been loosened

or removed.

• The brake fluid is very low.

• The brake operation is faulty.

A dangerous loss of braking per-

formance may occur if the brake

system is not properly bled.

1. Remove:

• Brake master cylinder cap

• Diaphragm

• Reservoir float (front brake)

• Protector (rear brake)

2. Bleed:

•Brake fluid

Air bleeding steps:

a. Add proper brake fluid to the res-

ervoir.

b. Install the diaphragm. Be careful

not to spill any fluid or allow the

reservoir to overflow.

c. Connect the clear plastic tube "2"

tightly to the caliper bleed screw

"1".A. Front

B. Rear

d. Place the other end of the tube

into a container.

e. Slowly apply the brake lever or

pedal several times.

f. Pull the lever in or push down on

the pedal. Hold the lever or pedal

in position.

g. Loosen the bleed screw and allow

the lever or pedal to travel to-

wards its limit.

h. Tighten the bleed screw when the

lever or pedal limit has been

reached; then release the lever or

pedal.

i. Repeat steps (e) to (h) until of the

air bubbles have been removed

from the system.

If bleeding is difficult, it may be nec-

essary to let the brake fluid system

stabilize for a few hours. Repeat the

bleeding procedure when the tiny

bubbles in the system have disap-

peared.

j. Add brake fluid to the level line on

the reservoir.

Check the operation of the brake

after bleeding the brake system.

3. Install:

• Protector (rear brake)

• Reservoir float (front brake)

• Diaphragm

• Brake master cylinder cap

ADJUSTING THE FRONT BRAKE

1. Check:

• Brake lever position "a"

Bolt (spark arrester):

7 Nm (0.7 m•kg, 5.1

ft•lb)

Silencer cap:

5 Nm (0.5 m•kg, 3.6

ft•lb)

Bleed screw:

6 Nm (0.6 m•kg, 4.3

ft•lb)

Brake lever position "a":

Standard posi-

tionExtent of ad-

justment

95 mm (3.74 in)76–97 mm

(2.99–3.82 in)

Page 79 of 224

3-24

CHASSIS

CHECKING THE TIRE PRESSURE

1. Measure:

• Tire pressure

Out of specification→Adjust.

• Check the tire while it is cold.

• Loose bead stoppers allow the tire

to slip off its position on the rim

when the tire pressure is low.

• A tilted tire valve stem indicates that

the tire slips off its position on the

rim.

• If the tire valve stem is found tilted,

the tire is considered to be slipping

off its position. Correct the tire posi-

tion.

CHECKING AND TIGHTENING THE

SPOKES

1. Inspect:

• Spokes "1"

Bend/damage→Replace.

Loose spoke→Retighten.

2. Tighten:

• Spokes

Be sure to retighten these spokes be-

fore and after break-in. After a prac-

tice or a race check spokes for

looseness.

CHECKING THE WHEELS

1. Inspect:

• Wheel runout

Elevate the wheel and turn it.

Abnormal runout→ Replace.

2. Inspect:

• Bearing free play

Exist play→Replace.

CHECKING AND ADJUSTING THE

STEERING HEAD

1. Elevate the front wheel by placing

a suitable stand under the engine.

2. Check:

• Steering stem

Grasp the bottom of the forks and

gently rock the fork assembly

back and forth.

Free play→Adjust steering head.

3. Check:

• Steering smooth action

Turn the handlebar lock to lock.

Unsmooth action→Adjust steer-

ing ring nut.

4. Adjust:

• Steering ring nut

Steering ring nut adjustment

steps:

a. Remove the headlight.

b. Remove the handlebar and upper

bracket.c. Loosen the steering ring nut "1"

using the steering nut wrench "2".

d. Tighten the steering ring nut "3"

using steering nut wrench "4".

• Apply the lithium soap base grease

on the thread of the steering stem.

• Set the torque wrench to the steer-

ing nut wrench so that they form a

right angle.

e. Loosen the steering ring nut one

turn.

f. Retighten the steering ring nut us-

ing the steering nut wrench.

Avoid over-tightening.

g. Check the steering stem by turn-

ing it lock to lock. If there is any

binding, remove the steering stem

assembly and inspect the steer-

ing bearings.

h. Install the washer "5", upper

bracket "6", washer "7", steering

stem nut "8", handlebar "9", han-

dlebar upper holder "10" and

headlight "11". Standard tire pressure:

100 kPa (1.0 kgf/cm

2,

15 psi)

Spokes:

3 Nm (0.3 m•kg, 2.2

ft•lb)

Steering nut wrench:

YU-33975/90890-01403

Steering nut wrench:

YU-33975/90890-01403

Steering ring nut (initial

tightening):

38 Nm (3.8 m•kg, 27

ft•lb)

Steering ring nut (final

tightening):

7 Nm (0.7 m•kg, 5.1

ft•lb)

Page 82 of 224

3-27

ELECTRICAL

ELECTRICAL

CHECKING THE SPARK PLUG

1. Remove:

• Spark plug

2. Inspect:

• Electrode "1"

Wear/damage→Replace.

• Insulator color "2"

Normal condition is a medium to

light tan color.

Distinctly different color→Check

the engine condition.

When the engine runs for many hours

at low speeds, the spark plug insula-

tor will become sooty, even if the en-

gine and carburetor are in good

operating condition.

3. Measure:

• Plug gap "a"

Use a wire gauge or thickness

gauge.

Out of specification→Regap.

4. Clean the plug with a spark plug

cleaner if necessary.

5. Tighten:

• Spark plug

• Before installing a spark plug, clean

the gasket surface and plug sur-

face.

• Finger-tighten "a" the spark plug

before torquing to specification "b".

CHECKING THE IGNITION TIMING

1. Remove:

• Timing mark accessing screw "1"

2. Attach:

• Timing light

• Inductive tachometer

To the ignition coil lead (orange

lead"1").

3. Adjust:

• Engine idling speed

Refer to "ADJUSTING THE EN-

GINE IDLING SPEED" section.

4. Check:

• Ignition timing

Visually check the stationary

pointer "a" is within the firing

range "b" on the rotor.

Incorrect firing range→Check ro-

tor and pickup assembly.

5. Install:

• Timing mark accessing screw

CHECKING AND CHARGING THE

BATTERY

Batteries generate explosive hy-

drogen gas and contain electrolyte

which is made of poisonous and

highly caustic sulfuric acid. There-

fore, always follow these preven-

tive measures:

• Wear protective eye gear when

handling or working near batter-

ies.• Charge batteries in a well-venti-

lated area.

• Keep batteries away from fire,

sparks or open flames (e.g.,

welding equipment, lighted ciga-

rettes).

• DO NOT SMOKE when charging

or handling batteries.

• KEEP BATTERIES AND ELEC-

TROLYTE OUT OF REACH OF

CHILDREN.

• Avoid bodily contact with elec-

trolyte as it can cause severe

burns or permanent eye injury.

FIRST AID IN CASE OF BODILY

CONTACT:

EXTERNAL

• Skin — Wash with water.

• Eyes — Flush with water for 15

minutes and get immediate med-

ical attention.

INTERNAL

• Drink large quantities of water or

milk followed with milk of magne-

sia, beaten egg or vegetable oil.

Get immediate medical attention.

Charging time, charging amperage

and charging voltage for an MF

battery are different from those of

conventional batteries. The MF

battery should be charged as ex-

plained in the charging method il-

lustrations. If the battery is

overcharged, the electrolyte level

will drop considerably. Therefore,

take special care when charging

the battery.

Since MF batteries are sealed, it is

not possible to check the charge state

of the battery by measuring the spe-

cific gravity of the electrolyte. There-

fore, the charge of the battery has to

be checked by measuring the voltage

at the battery terminals.

1. Remove:

• Seat

2. Disconnect:

• Battery leads

(from the battery terminals)

First, disconnect the negative bat-

tery lead "1", and then the positive

battery lead "2".

Spark plug gap:

0.7–0.8 mm (0.028–

0.031 in)

Spark plug:

13 Nm (1.3 m•kg, 9.4

ft•lb)

Timing light:

YM-33277-A/90890-

03141

Page 88 of 224

4-1

ENGINE

TUNING

ENGINE

CARBURETOR SETTING

• The air/fuel mixture will vary de-

pending on atmospheric conditions.

Therefore, it is necessary to take

into consideration the air pressure,

ambient temperature, humidity,

etc., when adjusting the carburetor.

• Perform a test run to check for prop-

er engine performance (e.g., throt-

tle response) and spark plug(-s)

discoloration or fouling. Use these

readings to determine the best pos-

sible carburetor setting.

It is recommended to keep a record of

all carburetor settings and external

conditions (e.g., atmospheric condi-

tions, track/surface conditions, lap

times) to make future carburetor set-

ting easier.

• The carburetor is a part of the

fuel line. Therefore, be sure to in-

stall it in a wellventilated area,

away from flammable objects

and any sources of fire.

• Never look into the carburetor in-

take. Flames may shoot out from

the pipe if the engine backfires

while it is being started. Gasoline

may be discharged from the ac-

celerator pump nozzle when the

carburetor has been removed.

• The carburetor is extremely sen-

sitive to foreign matter (dirt,

sand, water, etc.). During instal-

lation, do not allow foreign mat-

ter to get into the carburetor.

• Always handle the carburetor

and its components carefully.

Even slight scratches, bends or

damage to carburetor parts may

prevent the carburetor from

functioning correctly. Carefully

perform all servicing with the ap-

propriate tools and without ap-

plying excessive force.

• When the engine is stopped or

when riding at no load, do not

open and close the throttle un-

necessarily. Otherwise, too

much fuel may be discharged,

starting may become difficult or

the engine may not run well.• After installing the carburetor,

check that the throttle operates

correctly and opens and closes

smoothly.

ATMOSPHERIC CONDITIONS AND

CARBURETOR SETTINGS

The air density (i.e., concentration of

oxygen in the air) determines the rich-

ness or leanness of the air/fuel mix-

ture.

• Higher temperature expands the air

with its resultant reduced density.

• Higher humidity reduces the

amount of oxygen in the air by so

much of the water vapor in the

same air.

• Lower atmospheric pressure (at a

high altitude) reduces the density of

the air.

EFFECT OF SETTING PARTS IN

RELATION TO THROTTLE VALVE

OPENING

A. Closed

B. Fully open

1. Pilot jet

2. Throttle valve cutaway

3. Jet needle

4. Main jetCONSTRUCTION OF

CARBURETOR AND SETTING

PARTS

The FLATCR carburetor has a prima-

ry main jet. This type of main jet is

perfect for racing machines since it

supplies an even flow of fuel, even at

full load. Use the main jet and the jet

needle to set the carburetor.

1. Jet needle

2. Pilot air jet

3. Needle jet

4. Main jet

5. Pilot jet

ADJUSTING THE MAIN JET

The richness of the air-fuel mixture at

full throttle can be set by changing the

main jet "1".

If the air-fuel mixture is too rich or too

lean, the engine power will drop, re-

sulting in poor acceleration.

Effects of changing the main jet

(reference)

A. Idle

B. Fully open

1. #165

2. #160

3. #162 Air

tem

p.Hu-

midi-

tyAir

pres-

sure

(alti-

tude)Mix-

tureSet-

ting

High HighLow

(high)Rich-

erLean-

er

Low LowHigh

(low)Lean-

erRich-

er

Standard main jet#162

* #160

* For EUROPE

Page 114 of 224

5-18

CAMSHAFTS

Measurement steps:

a. Install the camshaft onto the cylin-

der head.

b. Position a strip of Plastigauge

®

"1" onto the camshaft.

c. Install the clip, dowel pins and

camshaft caps.

• Tighten the bolts (camshaft cap) in

a crisscross pattern from innermost

to outer caps.

• Do not turn the camshaft when

measuring clearance with the Plas-

tigauge

®.

d. Remove the camshaft caps and

measure the width of the Plasti-

gauge

® "1".

5. Measure:

• Camshaft outside diameter "a"

Out of specification→Replace the

camshaft.

Within specification→Replace

camshaft case and camshaft

caps as a set.CHECKING THE CAMSHAFT

SPROCKET

1. Inspect:

• Camshaft sprocket "1"

Wear/damage→Replace the

camshaft assembly and timing

chain as a set.

CHECKING THE

DECOMPRESSION SYSTEM

1. Check:

• Decompression system

Checking steps:

a. Check that the decompression

mechanism cam "1" moves

smoothly.

b. Check that the decompression

mechanism cam lever pin "2"

projects from the camshaft.

CHECKING THE TIMING CHAIN

TENSIONER

1. Check:

• While pressing the tensioner rod

lightly with fingers, use a thin

screwdriver "1" and wind the ten-

sioner rod up fully clockwise.

• When releasing the screwdriver

by pressing lightly with fingers,

make sure that the tensioner rod

will come out smoothly.

• If not, replace the tensioner as-

sembly.INSTALLING THE CAMSHAFT

1. Install:

• Exhaust camshaft "1"

• Intake camshaft "2"

Installation steps:

a. Turn the crankshaft counterclock-

wise with a wrench.

• Apply the molybdenum disulfide oil

on the camshafts.

• Apply the engine oil on the decom-

pression system.

b. Align the T.D.C. mark "a" on the

rotor with the align mark "b" on the

crankcase cover when piston is at

T.D.C. on compression stroke.

c. Fit the timing chain "3" onto both

camshaft sprockets and install the

camshafts on the cylinder head.

The camshafts should be installed

onto the cylinder head so that the

punch mark "c" on the exhaust cam-

shaft and the punch mark "d" on the

intake camshaft must align with the

cylinder head surface, as shown in

the illustration.

Camshaft-to-cap clear-

ance:

0.028–0.062 mm

(0.0011–0.0024 in)

in)

Bolt (camshaft cap):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Camshaft outside diame-

ter:

21.959–21.972 mm

(0.8645–0.8650 in)

Page 122 of 224

5-26

VALVES AND VALVE SPRINGS

CHECKING THE VALVE SPRINGS

1. Measure:

• Valve spring free length "a"

Out of specification→Replace.

2. Measure:

• Compressed spring force "a"

Out of specification→Replace.

b. Installed length

3. Measure:

• Spring tilt "a"

Out of specification→Replace.CHECKING THE VALVE LIFTERS

1. Inspect:

• Valve lifter

Scratches/damage→Replace

both lifters and cylinder head.

INSTALLING THE VALVES

1. Apply:

• Molybdenum disulfide oil

Onto the valve stem and valve

stem seal.

2. Install:

• Valves "1"

• Valve spring seats "2"

• Valve stem seals "3"

• Valve springs "4"

• Valve spring retainers "5"

• Make sure that each valve is in-

stalled in its original place, also re-

ferring to the painted color as

follows.

Intake (middle) "a": blue

Intake (right/left) "b": gray

Exhaust "c": brown

• Install the valve springs with the

larger pitch "d" facing upward.

e. Smaller pitch3. Install:

• Valve cotters

While compressing the valve spring

with a valve spring compressor "1" in-

stall the valve cotters.

4. To secure the valve cotters onto

the valve stem, lightly tap the

valve tip with a piece of wood.

Hitting the valve tip with excessive

force could damage the valve.

5. Install:

• Adjusting pad "1"

• Valve lifter "2"

• Apply the molybdenum disulfide oil

on the valve stem end.

• Apply the engine oil on the valve lift-

ers.

• Valve lifter must turn smoothly

when rotated with a finger.

• Be careful to reinstall valve lifters

and pads in their original place.

Free length (valve

spring):

Intake:

39.46 mm (1.55 in)

(1.51 in)

Exhaust:

37.61 mm (1.48 in)

(1.44 in)

Compressed spring

force:

Intake:

130.2–149.8 N at 27.87

mm (13.28–15.28 kg at

27.87 mm, 29.27–

33.68 lb at 1.10 in)

Exhaust:

123.1–141.7 N at 28.38

mm (12.55–14.45 kg at

28.38 mm, 27.67–

31.85 lb at 1.12 in)

Spring tilt limit:

Intake:

2.5°/1.7 mm (0.067 in)

Exhaust:

2.5°/1.6 mm (0.063 in)

Valve spring compres-

sor:

YM-4019/90890-04019