YAMAHA WR 450F 2010 Owners Manual

Manufacturer: YAMAHA, Model Year: 2010, Model line: WR 450F, Model: YAMAHA WR 450F 2010Pages: 230, PDF Size: 13.87 MB

Page 171 of 230

6-3

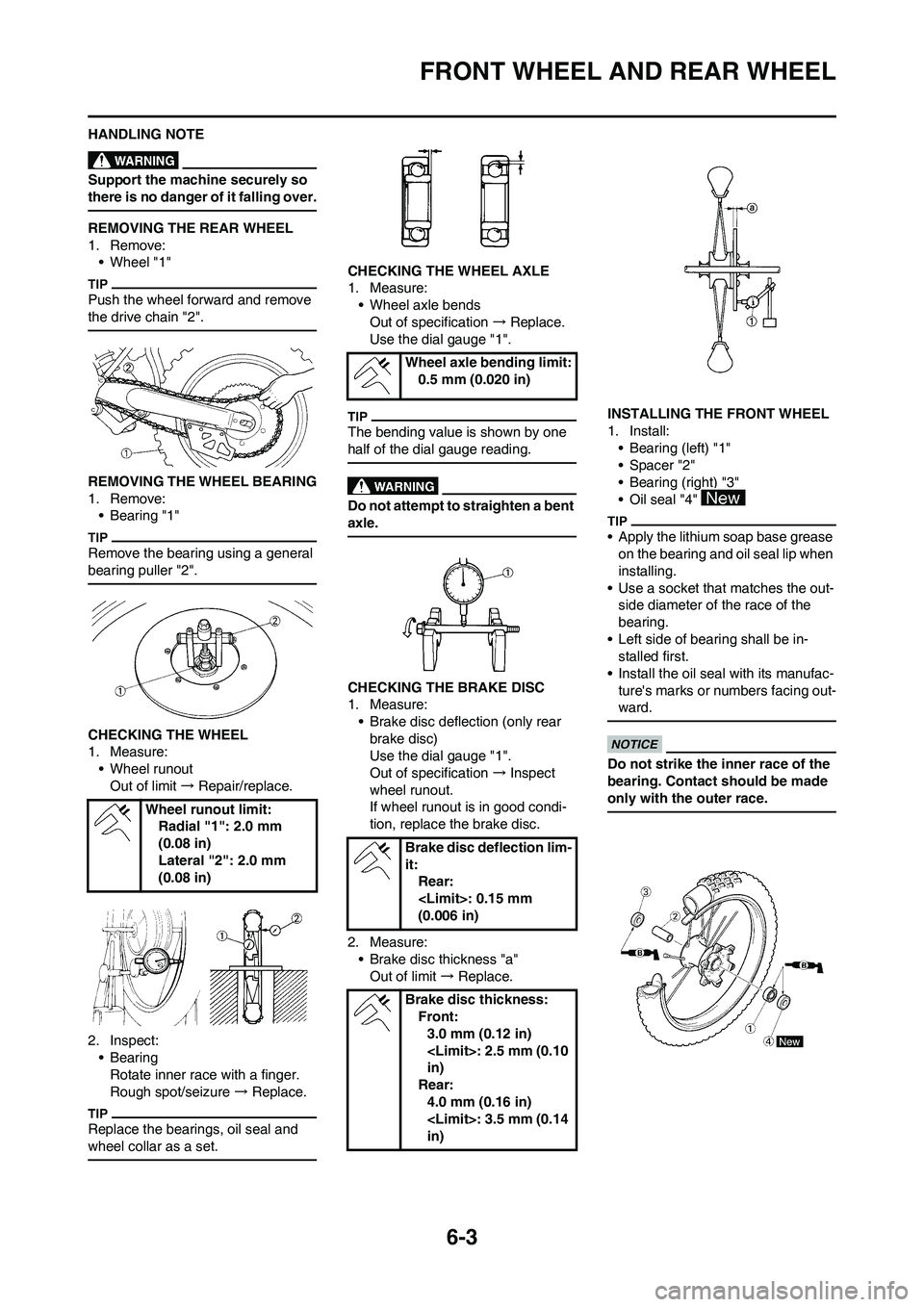

FRONT WHEEL AND REAR WHEEL

HANDLING NOTE

Support the machine securely so

there is no danger of it falling over.

REMOVING THE REAR WHEEL

1. Remove:

• Wheel "1"

Push the wheel forward and remove

the drive chain "2".

REMOVING THE WHEEL BEARING

1. Remove:

• Bearing "1"

Remove the bearing using a general

bearing puller "2".

CHECKING THE WHEEL

1. Measure:

• Wheel runout

Out of limit → Repair/replace.

2. Inspect:

• Bearing

Rotate inner race with a finger.

Rough spot/seizure → Replace.

Replace the bearings, oil seal and

wheel collar as a set.

CHECKING THE WHEEL AXLE

1. Measure:

• Wheel axle bends

Out of specification → Replace.

Use the dial gauge "1".

The bending value is shown by one

half of the dial gauge reading.

Do not attempt to straighten a bent

axle.

CHECKING THE BRAKE DISC

1. Measure:

• Brake disc deflection (only rear

brake disc)

Use the dial gauge "1".

Out of specification → Inspect

wheel runout.

If wheel runout is in good condi-

tion, replace the brake disc.

2. Measure:

• Brake disc thickness "a"

Out of limit → Replace.INSTALLING THE FRONT WHEEL

1. Install:

• Bearing (left) "1"

• Spacer "2"

• Bearing (right) "3"

• Oil seal "4"

• Apply the lithium soap base grease

on the bearing and oil seal lip when

installing.

• Use a socket that matches the out-

side diameter of the race of the

bearing.

• Left side of bearing shall be in-

stalled first.

• Install the oil seal with its manufac-

ture's marks or numbers facing out-

ward.

Do not strike the inner race of the

bearing. Contact should be made

only with the outer race.

Wheel runout limit:

Radial "1": 2.0 mm

(0.08 in)

Lateral "2": 2.0 mm

(0.08 in)

Wheel axle bending limit:

0.5 mm (0.020 in)

Brake disc deflection lim-

it:

Rear:

(0.006 in)

Brake disc thickness:

Front:

3.0 mm (0.12 in)

in)

Rear:

4.0 mm (0.16 in)

in)

Page 172 of 230

6-4

FRONT WHEEL AND REAR WHEEL

2. Install:

• Brake disc "1"

• Bolt (brake disc) "2"

Tighten the bolts in stage, using a

crisscross pattern.

3. Install:

•Collar "1"

Apply the lithium soap base grease

on the oil seal lip.

4. Install:

• Speed sensor "1"

• Apply the lithium soap base grease

on the oil seal lip of the speed sen-

sor.

• Make sure the two projections "a" in

the wheel hub are meshed with the

two slots "b" in the speed sensor.

5. Install:

• Wheel

• Install the brake disc "1" between

the brake pads "2" correctly.

• Make sure that the projections "a" in

the speed sensor fits over the stop-

per "b" on the front fork inner tube.

6. Install:

• Wheel axle "1"

Apply the lithium soap base grease

on the wheel axle.

7. Install:

• Nut (wheel axle) "1"

8. Tighten:

• Bolt (axle holder) "1"

Before tightening the bolt, fit the

wheel axle to the axle holder by strok-

ing the front fork several times with

the front brake applied.

INSTALLING THE REAR WHEEL

1. Install:

• Bearing (right) "1"

• Circlip "2"

• Spacer "3"

• Bearing (left) "4"

• Oil seal "5"

• Apply the lithium soap base grease

on the bearing and oil seal lip when

installing.

• Install the bearing with seal facing

outward.

• Use a socket that matches the out-

side diameter of the race of the

bearing.

• Right side of bearing shall be in-

stalled first.

• Install the oil seal with its manufac-

ture's marks or numbers facing out-

ward.

Do not strike the inner race of the

bearing. Contact should be made

only with the outer race.

Bolt (brake disc):

12 Nm (1.2 m•kg, 8.7

ft•lb)

Nut (wheel axle):

90 Nm (9.0 m•kg, 65

ft•lb)

Bolt (axle holder):

21 Nm (2.1 m•kg, 15

ft•lb)

Page 173 of 230

6-5

FRONT WHEEL AND REAR WHEEL

2. Install:

• Brake disc "1"

• Bolt (brake disc) "2"

Tighten the bolts in stage, using a

crisscross pattern.

3. Install:

• Rear wheel sprocket "1"

• Bolt (rear wheel sprocket) "2"

• Washer (rear wheel sprocket) "3"

• Nut (rear wheel sprocket) "4"

Tighten the nuts in stage, using a

crisscross pattern.

4. Install:

•Collar "1"

Apply the lithium soap base grease

on the oil seal lip.

5. Install:

• Wheel

Install the brake disc "1" between the

brake pads "2" correctly.

6. Install:

• Drive chain "1"

Push the wheel "2" forward and install

the drive chain.

7. Install:

• Left drive chain puller "1"

• Wheel axle "2"

• Install the left drive chain puller, and

insert the wheel axle from left side.

• Apply the lithium soap base grease

on the wheel axle.

8. Install:

• Right drive chain puller "1"

• Washer "2"

• Nut (wheel axle) "3"

Temporarily tighten the nut (wheel

axle) at this point.

9. Adjust:

• Drive chain slack "a"

Refer to "ADJUSTING THE

DRIVE CHAIN SLACK" section in

the CHAPTER 3.

10. Tighten:

• Nut (wheel axle) "1"

• Locknut "2" Bolt (brake disc):

14 Nm (1.4 m•kg, 10

ft•lb)

Nut (rear wheel sprock-

et):

50 Nm (5.0 m•kg, 36

ft•lb)

Drive chain slack:

48–58 mm (1.9–2.3 in)

Nut (wheel axle):

125 Nm (12.5 m•kg, 90

ft•lb)

Locknut:

19 Nm (1.9 m•kg, 13

ft•lb)

Page 174 of 230

6-6

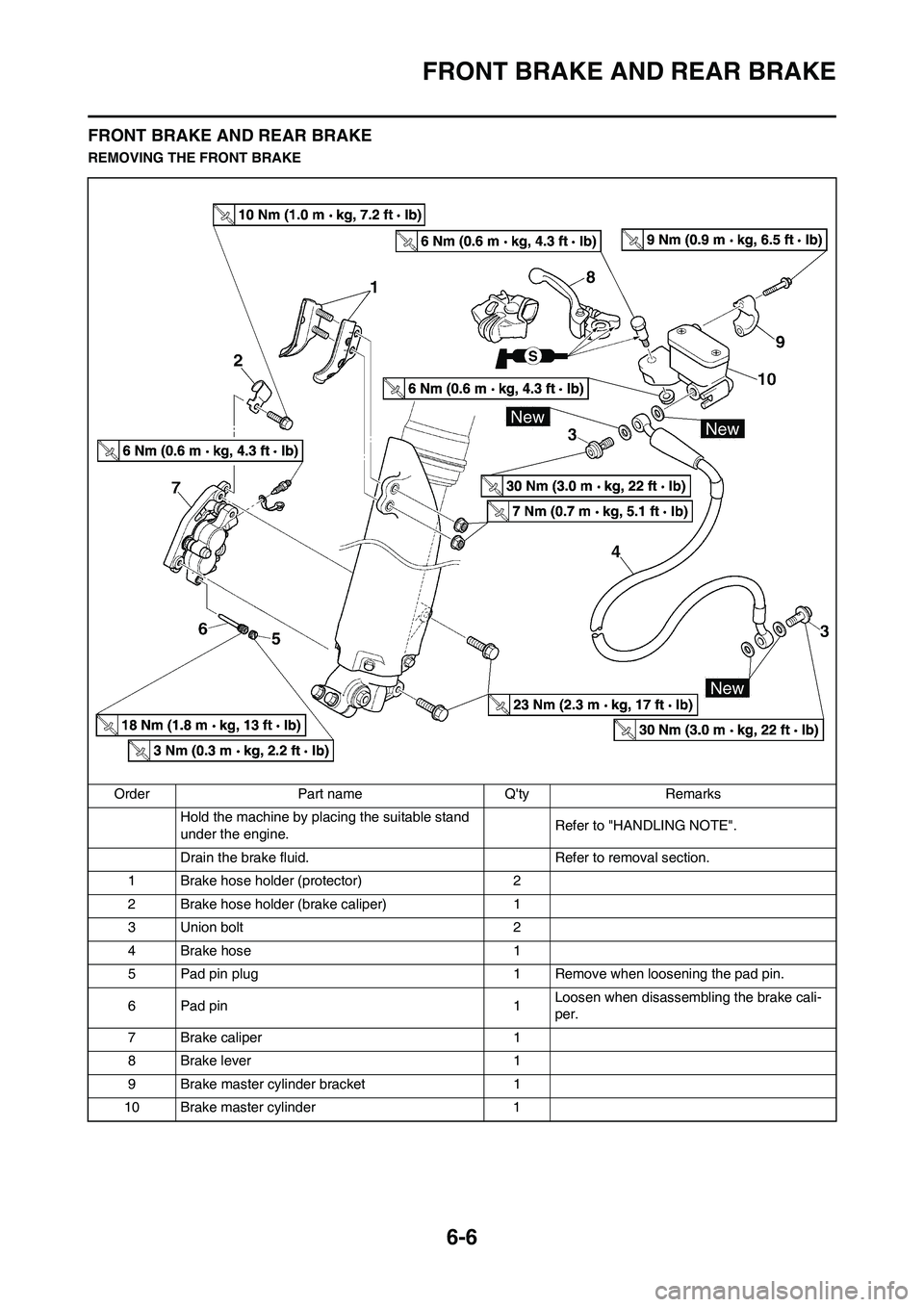

FRONT BRAKE AND REAR BRAKE

FRONT BRAKE AND REAR BRAKE

REMOVING THE FRONT BRAKE

Order Part name Q'ty Remarks

Hold the machine by placing the suitable stand

under the engine.Refer to "HANDLING NOTE".

Drain the brake fluid. Refer to removal section.

1 Brake hose holder (protector) 2

2 Brake hose holder (brake caliper) 1

3 Union bolt 2

4 Brake hose 1

5 Pad pin plug 1 Remove when loosening the pad pin.

6Pad pin 1Loosen when disassembling the brake cali-

per.

7 Brake caliper 1

8Brake lever 1

9 Brake master cylinder bracket 1

10 Brake master cylinder 1

Page 175 of 230

6-7

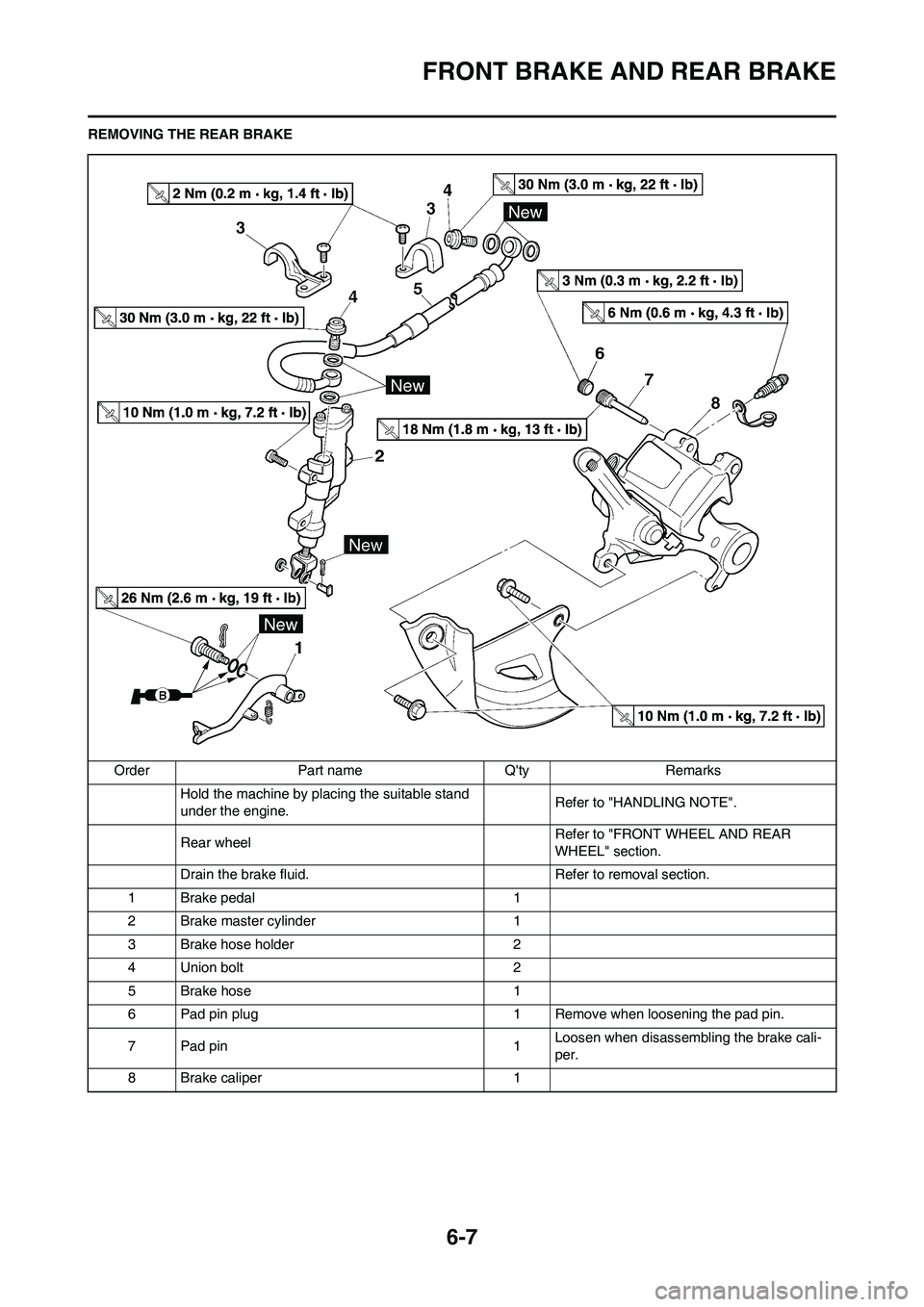

FRONT BRAKE AND REAR BRAKE

REMOVING THE REAR BRAKE

Order Part name Q'ty Remarks

Hold the machine by placing the suitable stand

under the engine.Refer to "HANDLING NOTE".

Rear wheel Refer to "FRONT WHEEL AND REAR

WHEEL" section.

Drain the brake fluid. Refer to removal section.

1 Brake pedal 1

2 Brake master cylinder 1

3 Brake hose holder 2

4 Union bolt 2

5 Brake hose 1

6 Pad pin plug 1 Remove when loosening the pad pin.

7Pad pin 1Loosen when disassembling the brake cali-

per.

8 Brake caliper 1

Page 176 of 230

6-8

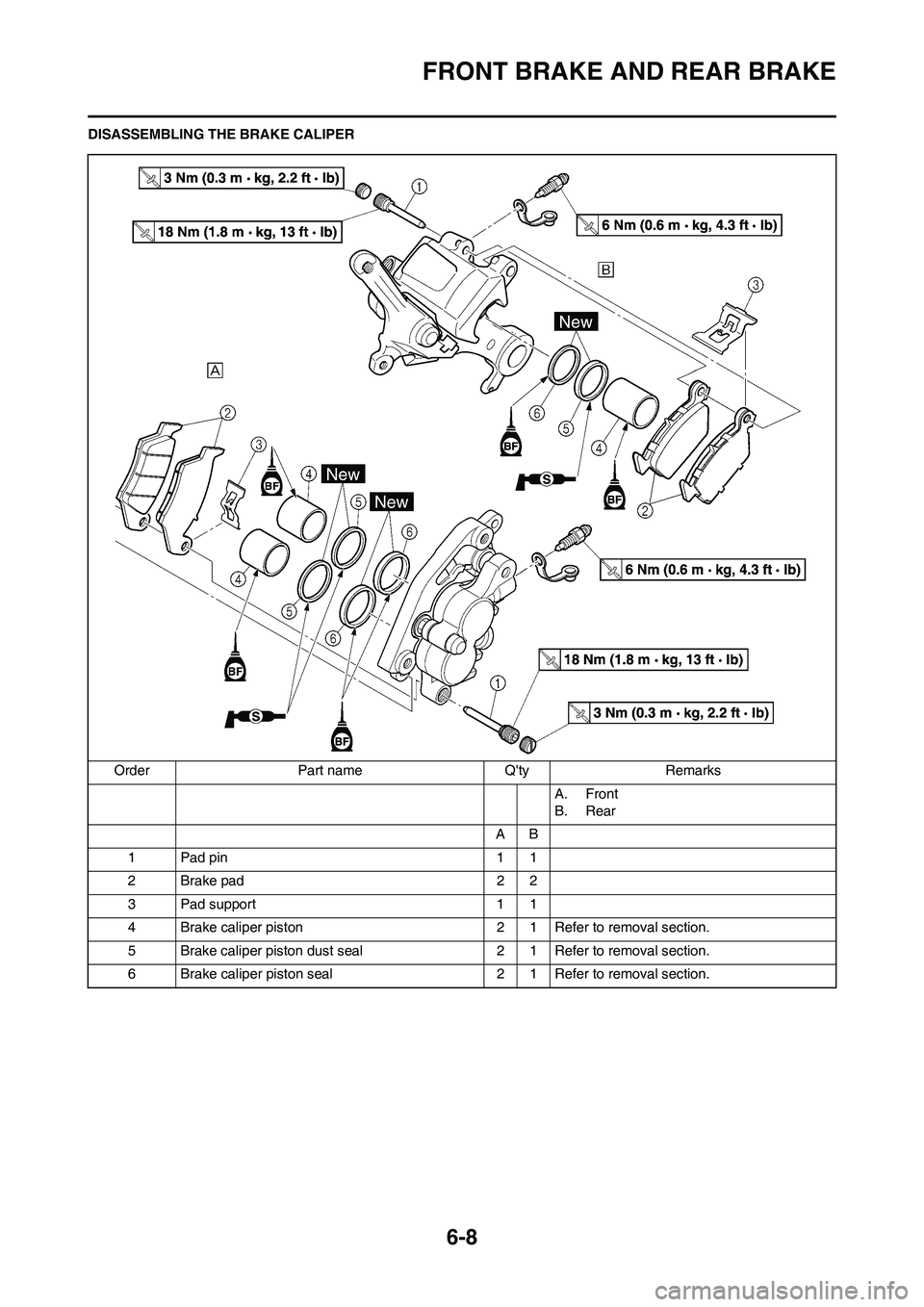

FRONT BRAKE AND REAR BRAKE

DISASSEMBLING THE BRAKE CALIPER

Order Part name Q'ty Remarks

A. Front

B. Rear

AB

1Pad pin 11

2 Brake pad 2 2

3 Pad support 1 1

4 Brake caliper piston 2 1 Refer to removal section.

5 Brake caliper piston dust seal 2 1 Refer to removal section.

6 Brake caliper piston seal2 1 Refer to removal section.

Page 177 of 230

6-9

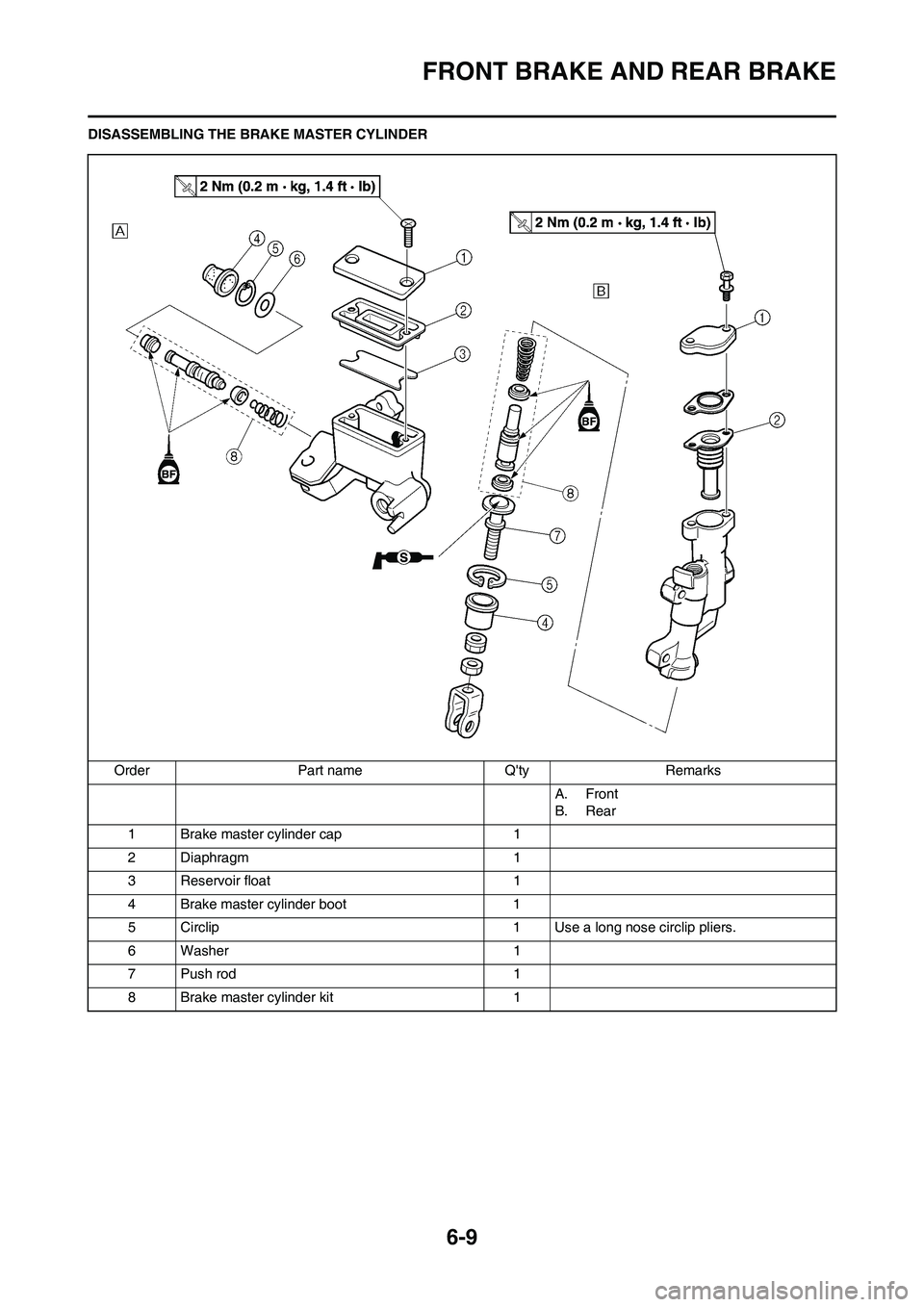

FRONT BRAKE AND REAR BRAKE

DISASSEMBLING THE BRAKE MASTER CYLINDER

Order Part name Q'ty Remarks

A. Front

B. Rear

1 Brake master cylinder cap 1

2 Diaphragm 1

3 Reservoir float 1

4 Brake master cylinder boot 1

5 Circlip 1 Use a long nose circlip pliers.

6 Washer 1

7 Push rod 1

8 Brake master cylinder kit 1

Page 178 of 230

6-10

FRONT BRAKE AND REAR BRAKE

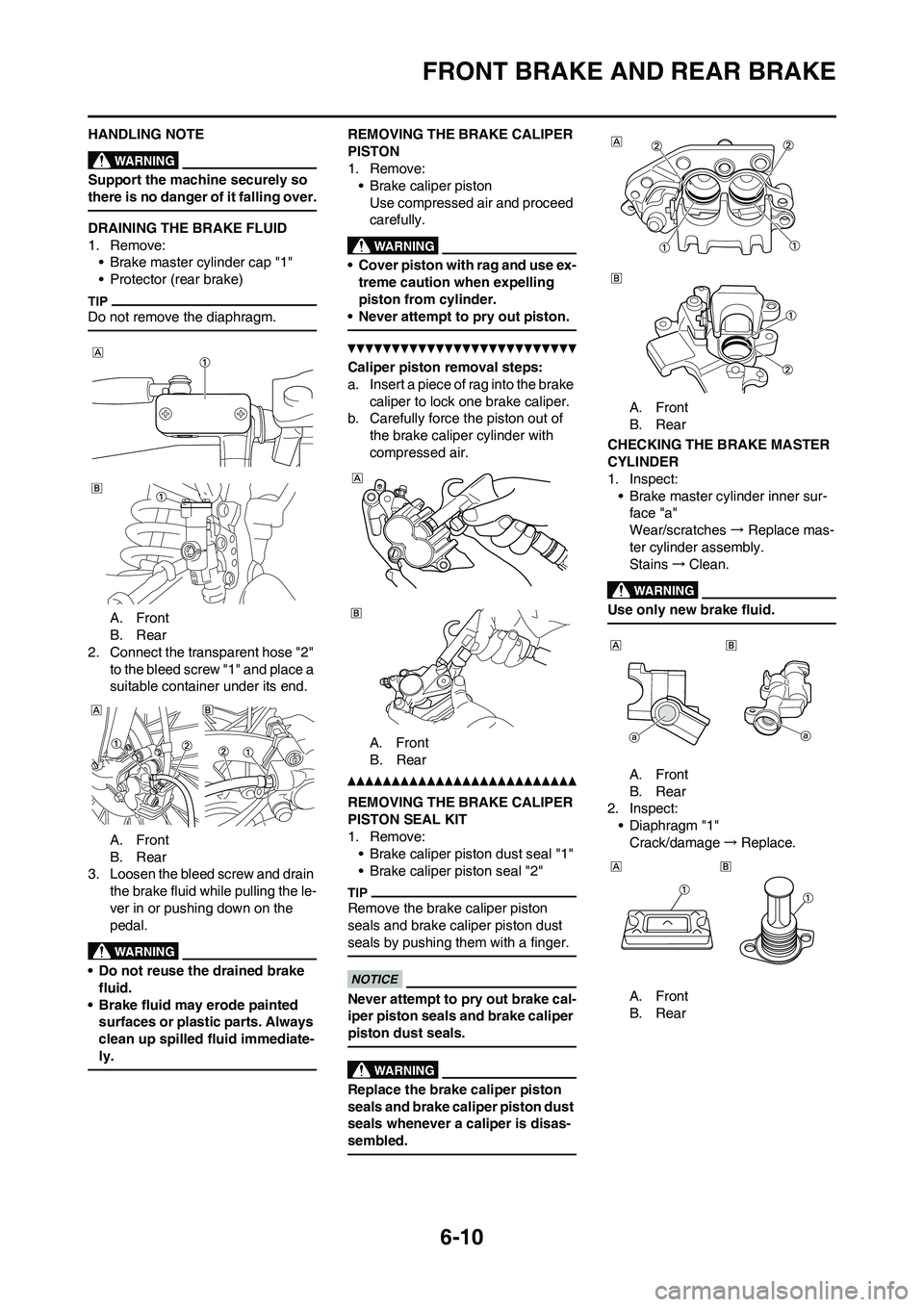

HANDLING NOTE

Support the machine securely so

there is no danger of it falling over.

DRAINING THE BRAKE FLUID

1. Remove:

• Brake master cylinder cap "1"

• Protector (rear brake)

Do not remove the diaphragm.

A. Front

B. Rear

2. Connect the transparent hose "2"

to the bleed screw "1" and place a

suitable container under its end.

A. Front

B. Rear

3. Loosen the bleed screw and drain

the brake fluid while pulling the le-

ver in or pushing down on the

pedal.

• Do not reuse the drained brake

fluid.

• Brake fluid may erode painted

surfaces or plastic parts. Always

clean up spilled fluid immediate-

ly.

REMOVING THE BRAKE CALIPER

PISTON

1. Remove:

• Brake caliper piston

Use compressed air and proceed

carefully.

• Cover piston with rag and use ex-

treme caution when expelling

piston from cylinder.

• Never attempt to pry out piston.

Caliper piston removal steps:

a. Insert a piece of rag into the brake

caliper to lock one brake caliper.

b. Carefully force the piston out of

the brake caliper cylinder with

compressed air.

A. Front

B. Rear

REMOVING THE BRAKE CALIPER

PISTON SEAL KIT

1. Remove:

• Brake caliper piston dust seal "1"

• Brake caliper piston seal "2"

Remove the brake caliper piston

seals and brake caliper piston dust

seals by pushing them with a finger.

Never attempt to pry out brake cal-

iper piston seals and brake caliper

piston dust seals.

Replace the brake caliper piston

seals and brake caliper piston dust

seals whenever a caliper is disas-

sembled.

A. Front

B. Rear

CHECKING THE BRAKE MASTER

CYLINDER

1. Inspect:

• Brake master cylinder inner sur-

face "a"

Wear/scratches → Replace mas-

ter cylinder assembly.

Stains→Clean.

Use only new brake fluid.

A. Front

B. Rear

2. Inspect:

• Diaphragm "1"

Crack/damage→Replace.

A. Front

B. Rear

Page 179 of 230

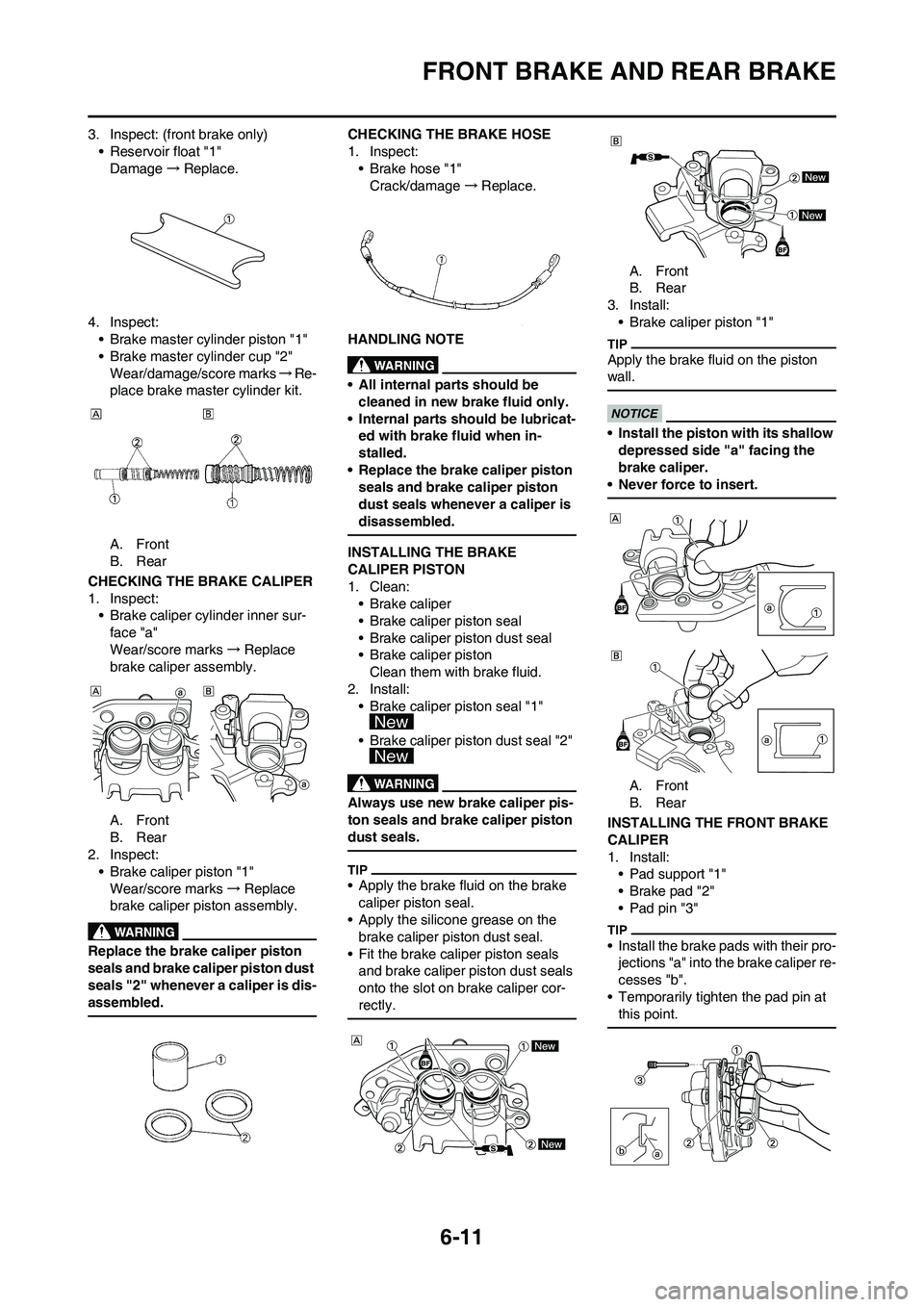

6-11

FRONT BRAKE AND REAR BRAKE

3. Inspect: (front brake only)

• Reservoir float "1"

Damage→Replace.

4. Inspect:

• Brake master cylinder piston "1"

• Brake master cylinder cup "2"

Wear/damage/score marks→Re-

place brake master cylinder kit.

A. Front

B. Rear

CHECKING THE BRAKE CALIPER

1. Inspect:

• Brake caliper cylinder inner sur-

face "a"

Wear/score marks→Replace

brake caliper assembly.

A. Front

B. Rear

2. Inspect:

• Brake caliper piston "1"

Wear/score marks→Replace

brake caliper piston assembly.

Replace the brake caliper piston

seals and brake caliper piston dust

seals "2" whenever a caliper is dis-

assembled.

CHECKING THE BRAKE HOSE

1. Inspect:

• Brake hose "1"

Crack/damage→Replace.

HANDLING NOTE

• All internal parts should be

cleaned in new brake fluid only.

• Internal parts should be lubricat-

ed with brake fluid when in-

stalled.

• Replace the brake caliper piston

seals and brake caliper piston

dust seals whenever a caliper is

disassembled.

INSTALLING THE BRAKE

CALIPER PISTON

1. Clean:

• Brake caliper

• Brake caliper piston seal

• Brake caliper piston dust seal

• Brake caliper piston

Clean them with brake fluid.

2. Install:

• Brake caliper piston seal "1"

• Brake caliper piston dust seal "2"

Always use new brake caliper pis-

ton seals and brake caliper piston

dust seals.

• Apply the brake fluid on the brake

caliper piston seal.

• Apply the silicone grease on the

brake caliper piston dust seal.

• Fit the brake caliper piston seals

and brake caliper piston dust seals

onto the slot on brake caliper cor-

rectly.

A. Front

B. Rear

3. Install:

• Brake caliper piston "1"

Apply the brake fluid on the piston

wall.

• Install the piston with its shallow

depressed side "a" facing the

brake caliper.

• Never force to insert.

A. Front

B. Rear

INSTALLING THE FRONT BRAKE

CALIPER

1. Install:

• Pad support "1"

• Brake pad "2"

• Pad pin "3"

• Install the brake pads with their pro-

jections "a" into the brake caliper re-

cesses "b".

• Temporarily tighten the pad pin at

this point.

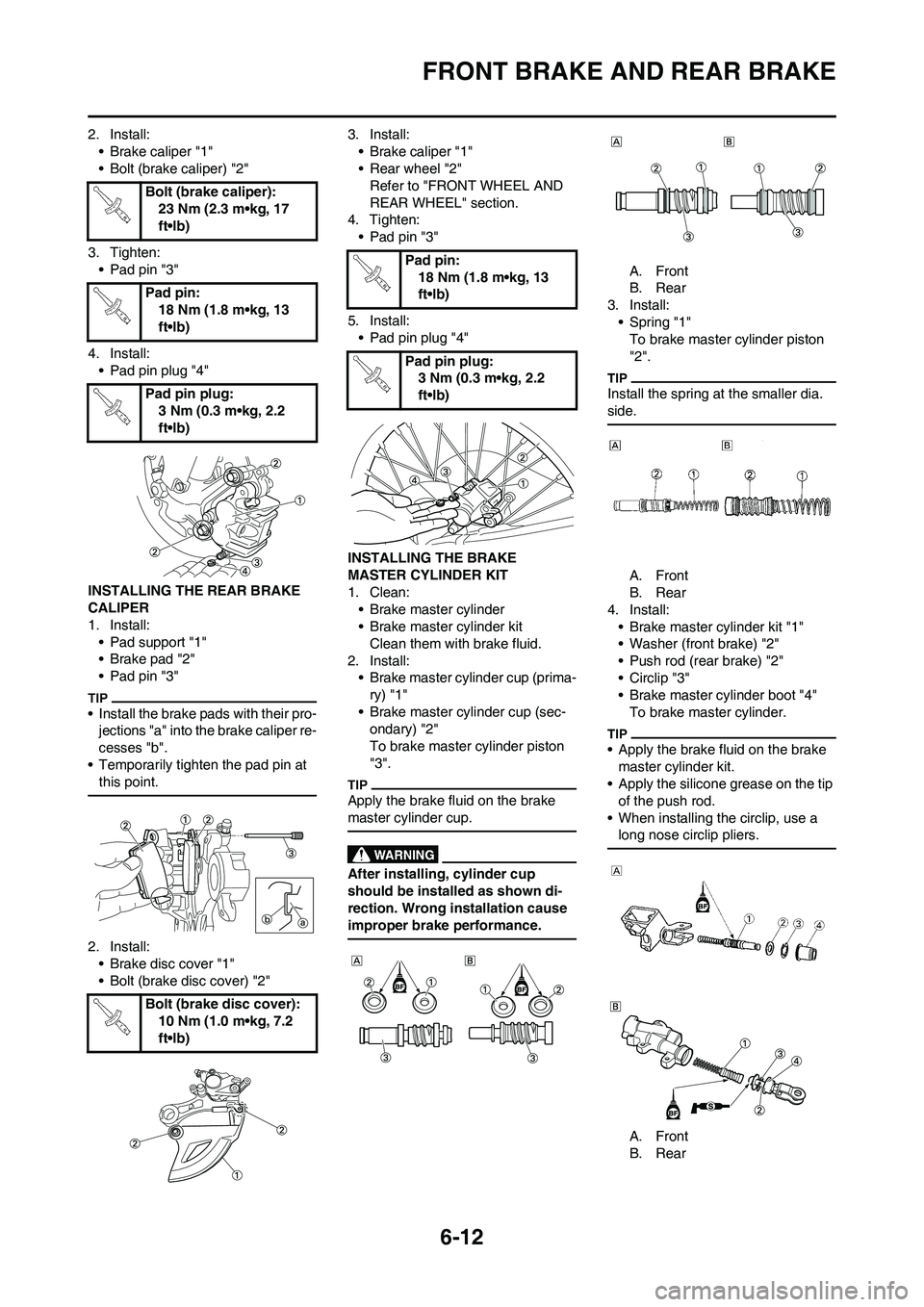

Page 180 of 230

6-12

FRONT BRAKE AND REAR BRAKE

2. Install:

• Brake caliper "1"

• Bolt (brake caliper) "2"

3. Tighten:

• Pad pin "3"

4. Install:

• Pad pin plug "4"

INSTALLING THE REAR BRAKE

CALIPER

1. Install:

• Pad support "1"

• Brake pad "2"

• Pad pin "3"

• Install the brake pads with their pro-

jections "a" into the brake caliper re-

cesses "b".

• Temporarily tighten the pad pin at

this point.

2. Install:

• Brake disc cover "1"

• Bolt (brake disc cover) "2"3. Install:

• Brake caliper "1"

• Rear wheel "2"

Refer to "FRONT WHEEL AND

REAR WHEEL" section.

4. Tighten:

• Pad pin "3"

5. Install:

• Pad pin plug "4"

INSTALLING THE BRAKE

MASTER CYLINDER KIT

1. Clean:

• Brake master cylinder

• Brake master cylinder kit

Clean them with brake fluid.

2. Install:

• Brake master cylinder cup (prima-

ry) "1"

• Brake master cylinder cup (sec-

ondary) "2"

To brake master cylinder piston

"3".

Apply the brake fluid on the brake

master cylinder cup.

After installing, cylinder cup

should be installed as shown di-

rection. Wrong installation cause

improper brake performance.

A. Front

B. Rear

3. Install:

• Spring "1"

To brake master cylinder piston

"2".

Install the spring at the smaller dia.

side.

A. Front

B. Rear

4. Install:

• Brake master cylinder kit "1"

• Washer (front brake) "2"

• Push rod (rear brake) "2"

• Circlip "3"

• Brake master cylinder boot "4"

To brake master cylinder.

• Apply the brake fluid on the brake

master cylinder kit.

• Apply the silicone grease on the tip

of the push rod.

• When installing the circlip, use a

long nose circlip pliers.

A. Front

B. Rear Bolt (brake caliper):

23 Nm (2.3 m•kg, 17

ft•lb)

Pad pin:

18 Nm (1.8 m•kg, 13

ft•lb)

Pad pin plug:

3 Nm (0.3 m•kg, 2.2

ft•lb)

Bolt (brake disc cover):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Pad pin:

18 Nm (1.8 m•kg, 13

ft•lb)

Pad pin plug:

3 Nm (0.3 m•kg, 2.2

ft•lb)