YAMAHA WR 450F 2010 User Guide

Manufacturer: YAMAHA, Model Year: 2010, Model line: WR 450F, Model: YAMAHA WR 450F 2010Pages: 230, PDF Size: 13.87 MB

Page 11 of 230

1-1

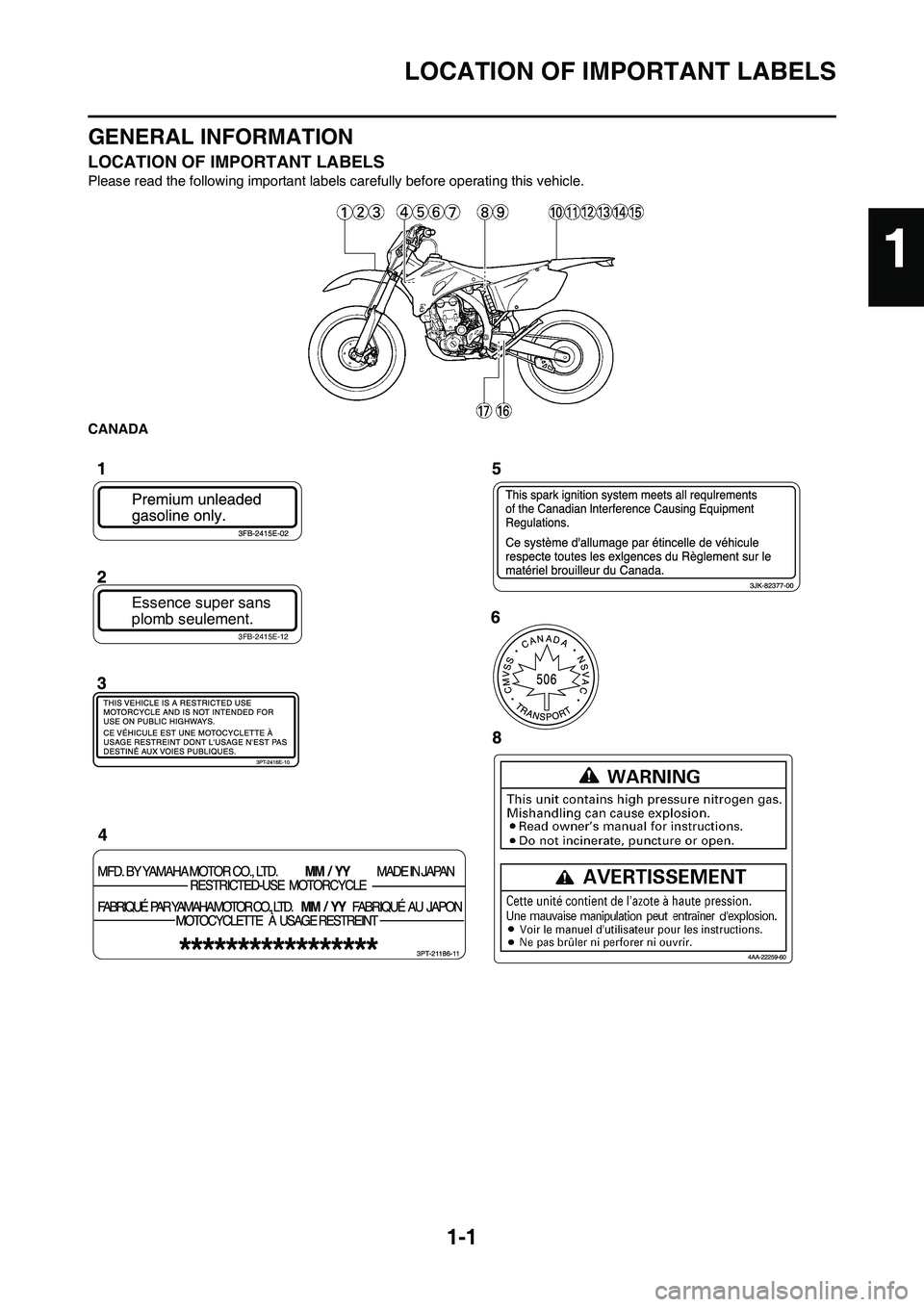

LOCATION OF IMPORTANT LABELS

GENERAL INFORMATION

LOCATION OF IMPORTANT LABELS

Please read the following important labels carefully before operating this vehicle.

CANADA

Essence super sans

plomb seulement.

3FB-2415E-12

1

Page 12 of 230

1-2

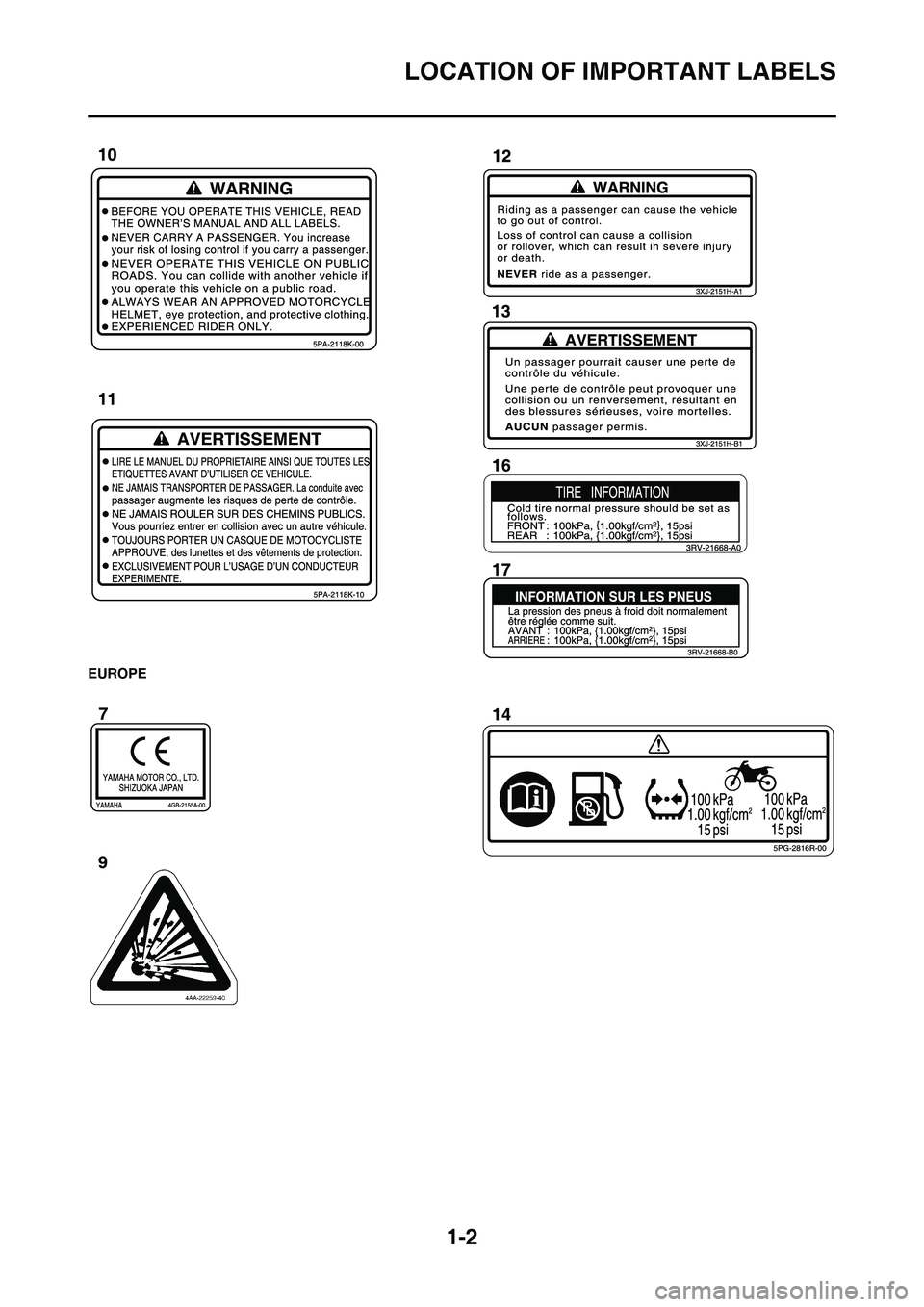

LOCATION OF IMPORTANT LABELS

EUROPE

Page 13 of 230

1-3

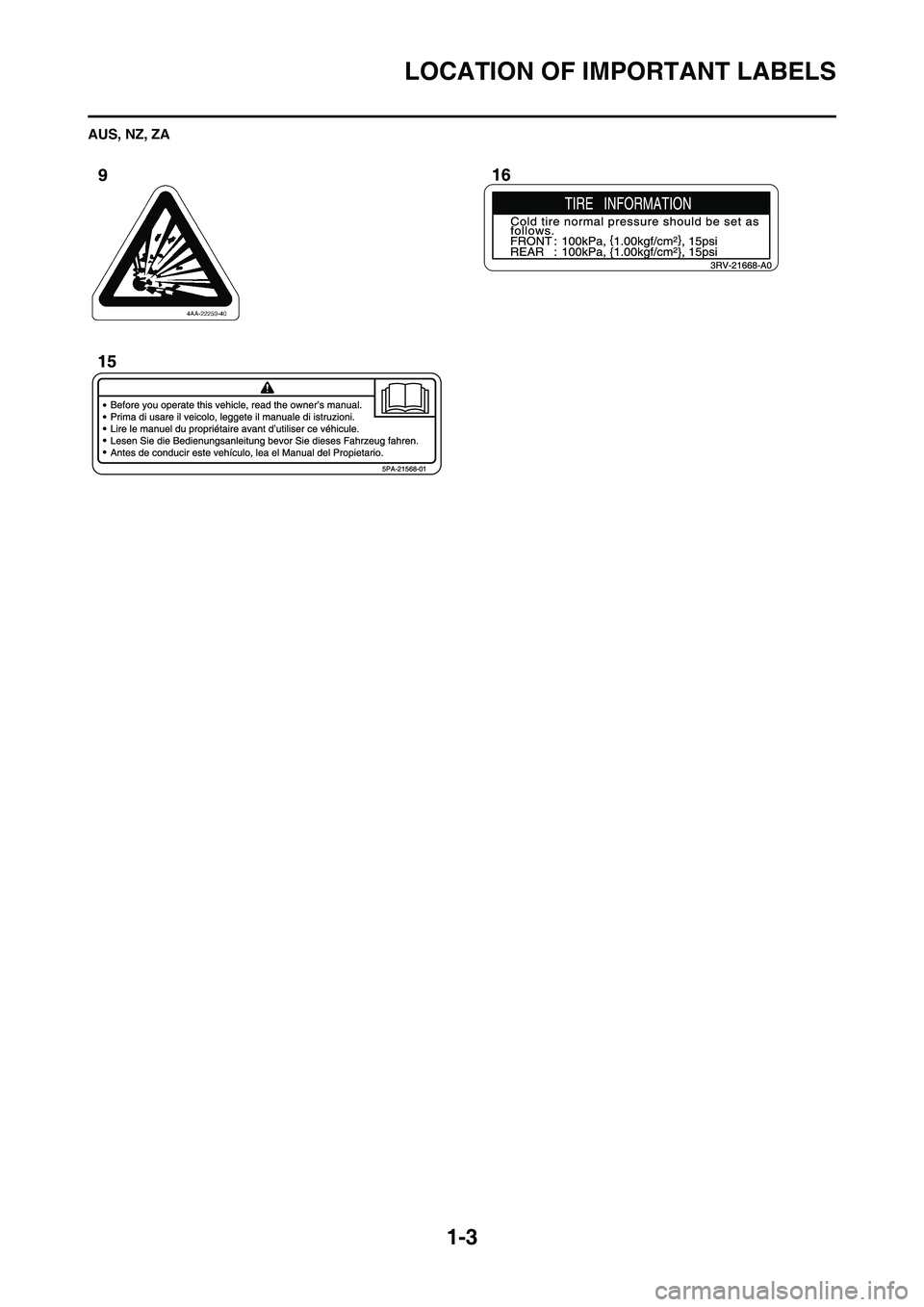

LOCATION OF IMPORTANT LABELS

AUS, NZ, ZA

Page 14 of 230

1-4

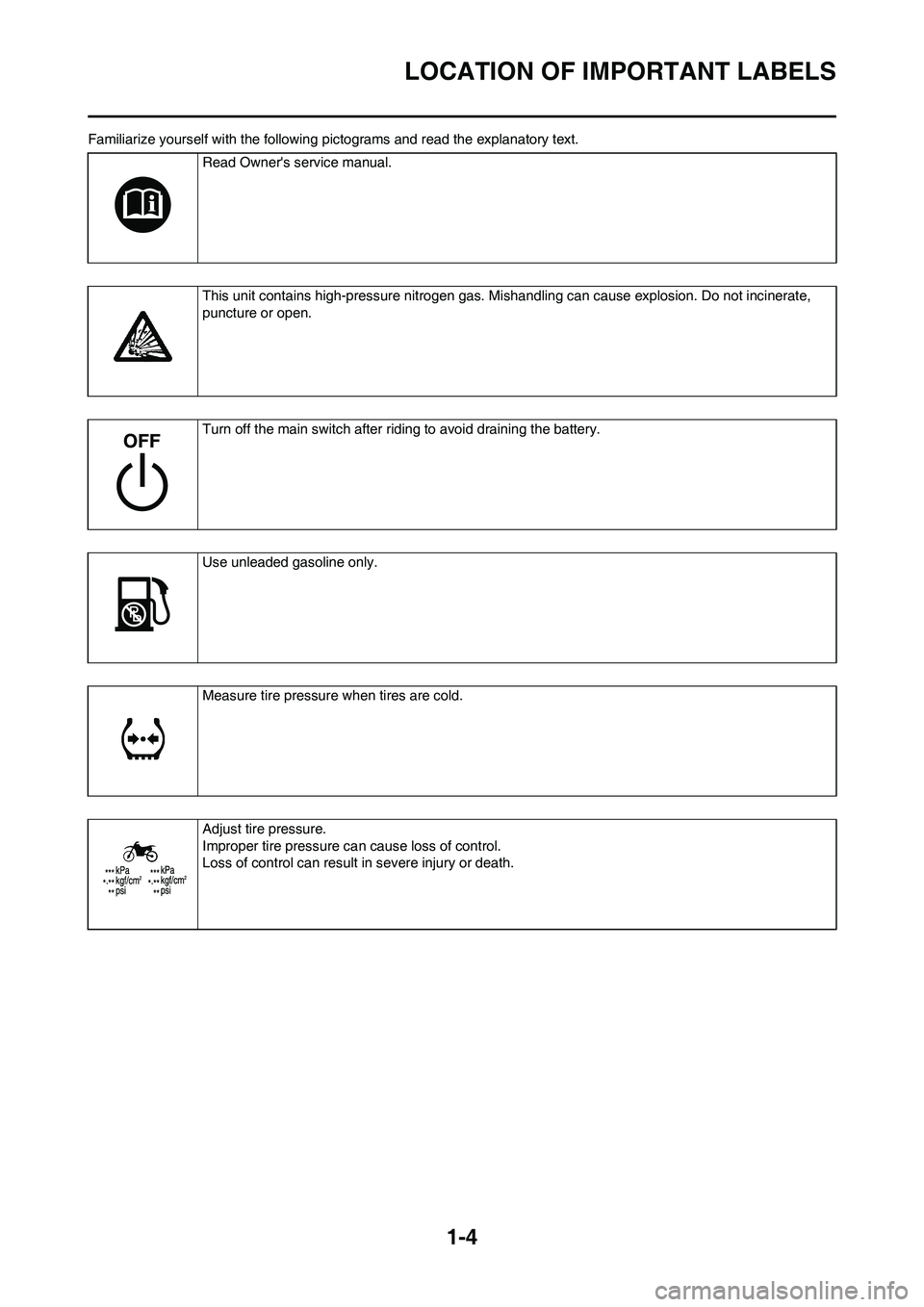

LOCATION OF IMPORTANT LABELS

Familiarize yourself with the following pictograms and read the explanatory text.

Read Owner's service manual.

This unit contains high-pressure nitrogen gas. Mi shandling can cause explosion. Do not incinerate,

puncture or open.

Turn off the main switch after riding to avoid draining the battery.

Use unleaded gasoline only.

Measure tire pressure when tires are cold.

Adjust tire pressure.

Improper tire pressure ca n cause loss of control.

Loss of control can result in severe injury or death.

Page 15 of 230

1-5

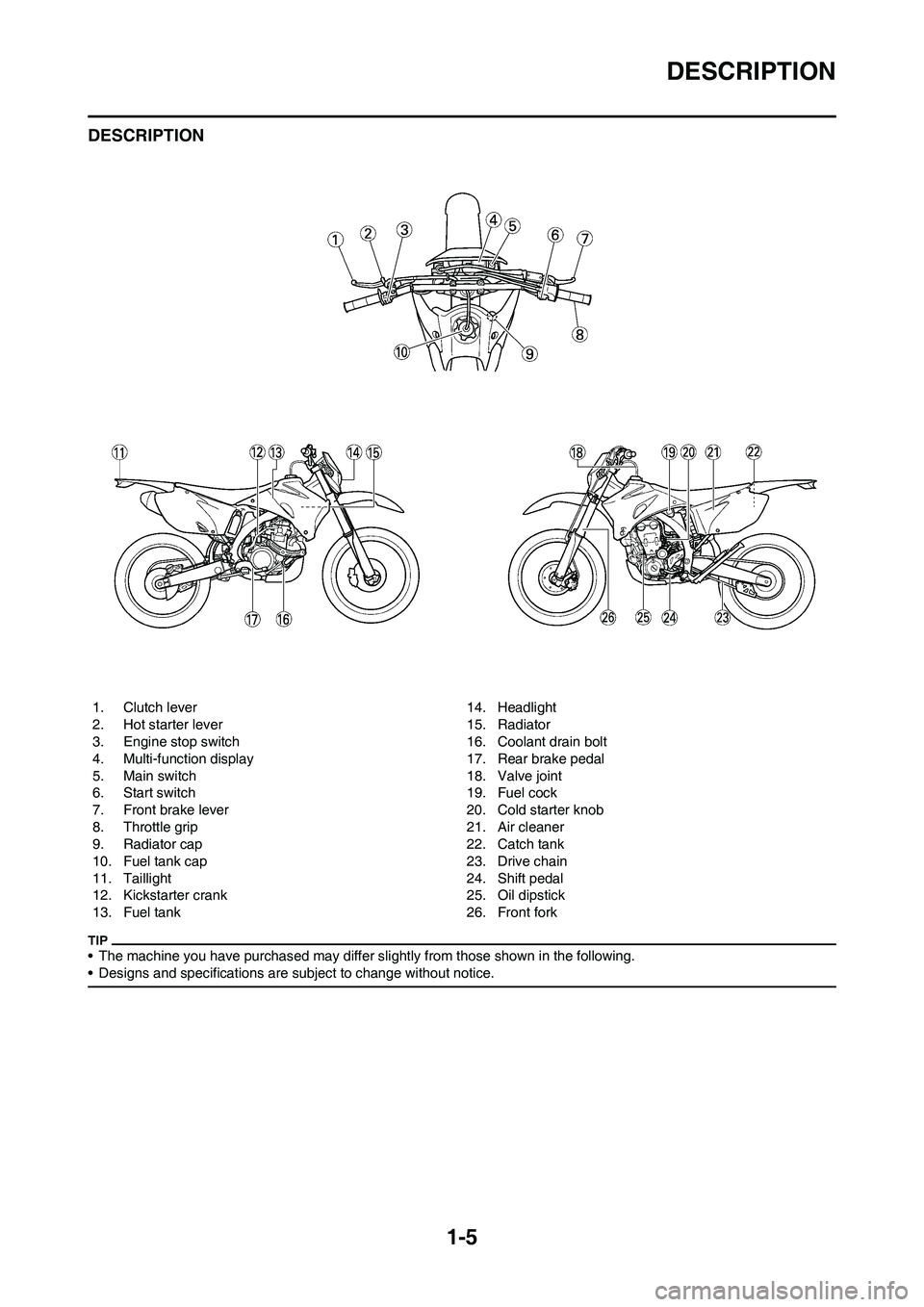

DESCRIPTION

DESCRIPTION

• The machine you have purchased may differ slightly from those shown in the following.

• Designs and specifications are subject to change without notice.

1. Clutch lever

2. Hot starter lever

3. Engine stop switch

4. Multi-function display

5. Main switch

6. Start switch

7. Front brake lever

8. Throttle grip

9. Radiator cap

10. Fuel tank cap

11. Taillight

12. Kickstarter crank

13. Fuel tank 14. Headlight

15. Radiator

16. Coolant drain bolt

17. Rear brake pedal

18. Valve joint

19. Fuel cock

20. Cold starter knob

21. Air cleaner

22. Catch tank

23. Drive chain

24. Shift pedal

25. Oil dipstick

26. Front fork

Page 16 of 230

1-6

CONSUMER INFORMATION

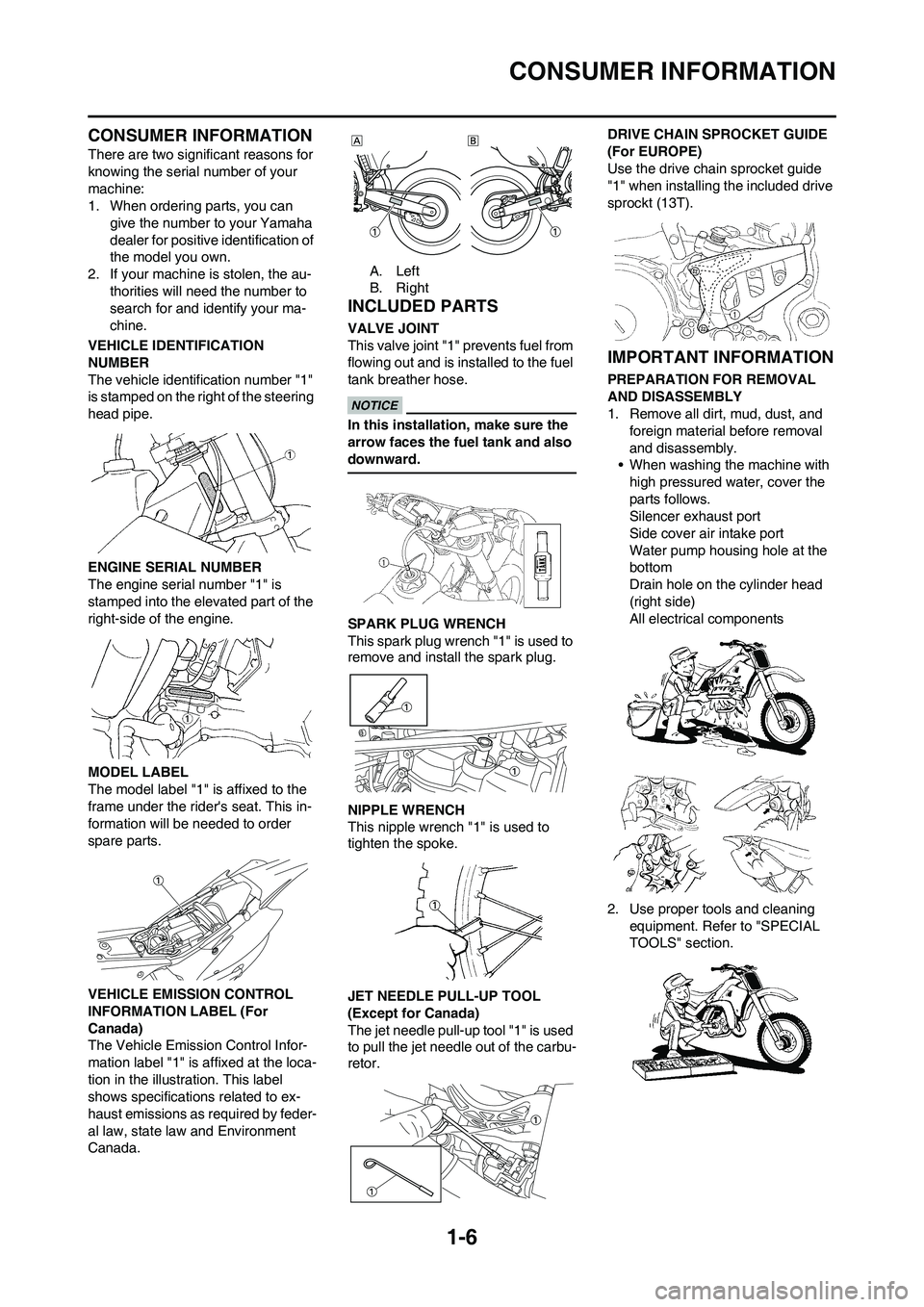

CONSUMER INFORMATION

There are two significant reasons for

knowing the serial number of your

machine:

1. When ordering parts, you can give the number to your Yamaha

dealer for positive identification of

the model you own.

2. If your machine is stolen, the au-

thorities will need the number to

search for and identify your ma-

chine.

VEHICLE IDENTIFICATION

NUMBER

The vehicle identification number "1"

is stamped on the ri ght of the steering

head pipe.

ENGINE SERIAL NUMBER

The engine serial number "1" is

stamped into the elevated part of the

right-side of the engine.

MODEL LABEL

The model label "1" is affixed to the

frame under the rider's seat. This in-

formation will be needed to order

spare parts.

VEHICLE EMISSION CONTROL

INFORMATION LABEL (For

Canada)

The Vehicle Emission Control Infor-

mation label "1" is affixed at the loca-

tion in the illustration. This label

shows specifications related to ex-

haust emissions as required by feder-

al law, state law and Environment

Canada. A. Left

B. Right

INCLUDED PARTS

VALVE JOINT

This valve joint "1" prevents fuel from

flowing out and is installed to the fuel

tank breather hose.

In this installation, make sure the

arrow faces the fuel tank and also

downward.

SPARK PLUG WRENCH

This spark plug wrench "1" is used to

remove and install the spark plug.

NIPPLE WRENCH

This nipple wrench "1" is used to

tighten the spoke.

JET NEEDLE PULL-UP TOOL

(Except for Canada)

The jet needle pull-up tool "1" is used

to pull the jet needle out of the carbu-

retor.DRIVE CHAIN SPROCKET GUIDE

(For EUROPE)

Use the drive chain sprocket guide

"1" when installing the included drive

sprockt (13T).

IMPORTANT INFORMATION

PREPARATION FOR REMOVAL

AND DISASSEMBLY

1. Remove all dirt, mud, dust, and

foreign material before removal

and disassembly.

• When washing the machine with

high pressured water, cover the

parts follows.

Silencer exhaust port

Side cover air intake port

Water pump housing hole at the

bottom

Drain hole on the cylinder head

(right side)

All electrical components

2. Use proper tools and cleaning equipment. Refer to "SPECIAL

TOOLS" section.

Page 17 of 230

1-7

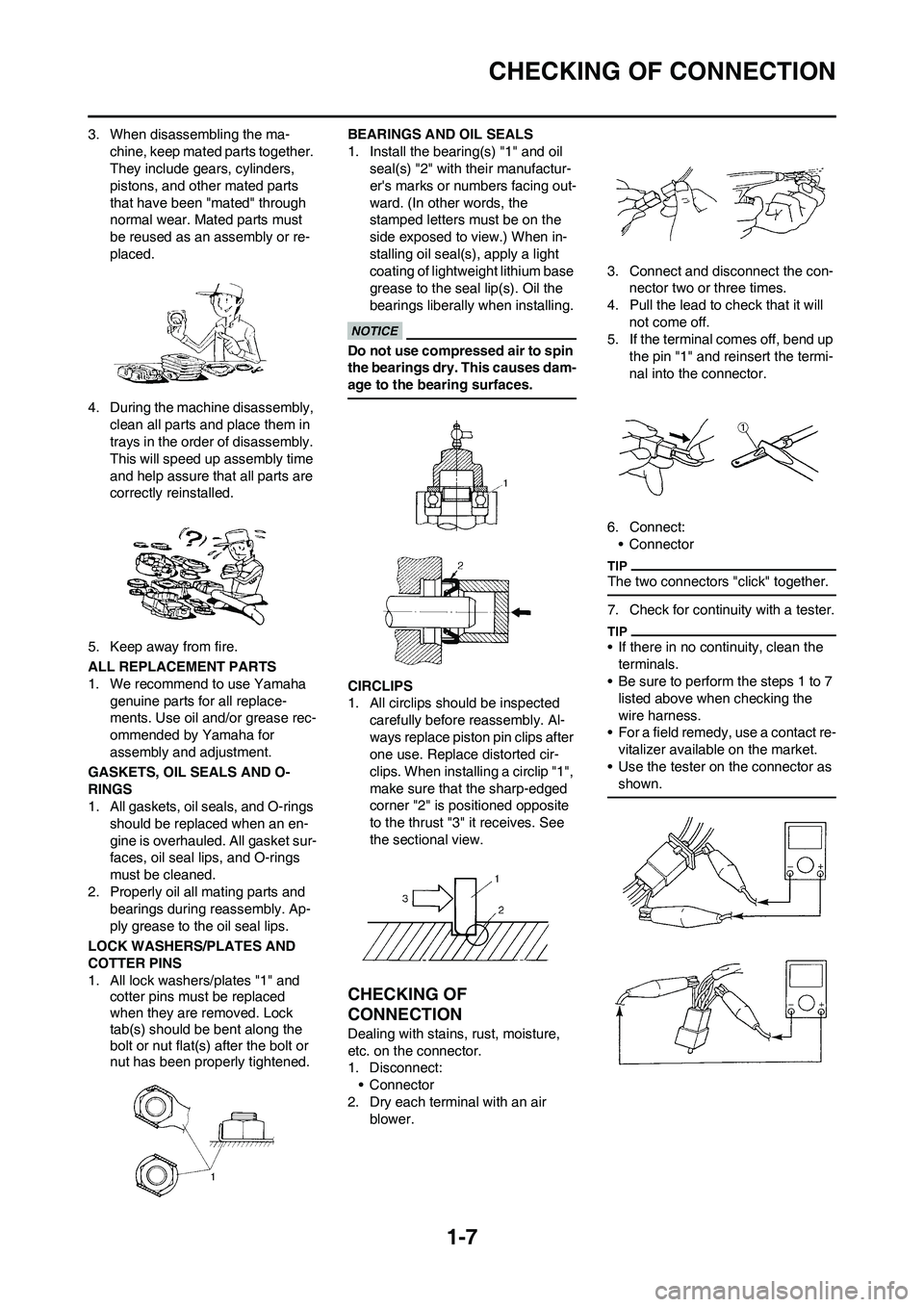

CHECKING OF CONNECTION

3. When disassembling the ma-chine, keep mated parts together.

They include gears, cylinders,

pistons, and other mated parts

that have been "mated" through

normal wear. Mated parts must

be reused as an assembly or re-

placed.

4. During the machine disassembly, clean all parts and place them in

trays in the order of disassembly.

This will speed up assembly time

and help assure that all parts are

correctly reinstalled.

5. Keep away from fire.

ALL REPLACEMENT PARTS

1. We recommend to use Yamaha genuine parts for all replace-

ments. Use oil and/or grease rec-

ommended by Yamaha for

assembly and adjustment.

GASKETS, OIL SEALS AND O-

RINGS

1. All gaskets, oil seals, and O-rings should be replaced when an en-

gine is overhauled. All gasket sur-

faces, oil seal lips, and O-rings

must be cleaned.

2. Properly oil all mating parts and bearings during reassembly. Ap-

ply grease to the oil seal lips.

LOCK WASHERS/PLATES AND

COTTER PINS

1. All lock washers/plates "1" and cotter pins must be replaced

when they are removed. Lock

tab(s) should be bent along the

bolt or nut flat(s) after the bolt or

nut has been properly tightened. BEARINGS AND OIL SEALS

1. Install the bearing(s) "1" and oil

seal(s) "2" with their manufactur-

er's marks or numbers facing out-

ward. (In other words, the

stamped letters must be on the

side exposed to view.) When in-

stalling oil seal(s), apply a light

coating of lightweight lithium base

grease to the seal lip(s). Oil the

bearings liberally when installing.

Do not use compressed air to spin

the bearings dry. This causes dam-

age to the bearing surfaces.

CIRCLIPS

1. All circlips should be inspected carefully before reassembly. Al-

ways replace piston pin clips after

one use. Replace distorted cir-

clips. When installing a circlip "1",

make sure that the sharp-edged

corner "2" is positioned opposite

to the thrust "3" it receives. See

the sectional view.

CHECKING OF

CONNECTION

Dealing with stains, rust, moisture,

etc. on the connector.

1. Disconnect:• Connector

2. Dry each terminal with an air blower. 3. Connect and disconnect the con-

nector two or three times.

4. Pull the lead to check that it will not come off.

5. If the terminal comes off, bend up

the pin "1" and reinsert the termi-

nal into the connector.

6. Connect: • Connector

The two connectors "click" together.

7. Check for continuity with a tester.

• If there in no continuity, clean the terminals.

• Be sure to perform the steps 1 to 7 listed above when checking the

wire harness.

• For a field remedy, use a contact re- vitalizer available on the market.

• Use the tester on the connector as shown.

Page 18 of 230

1-8

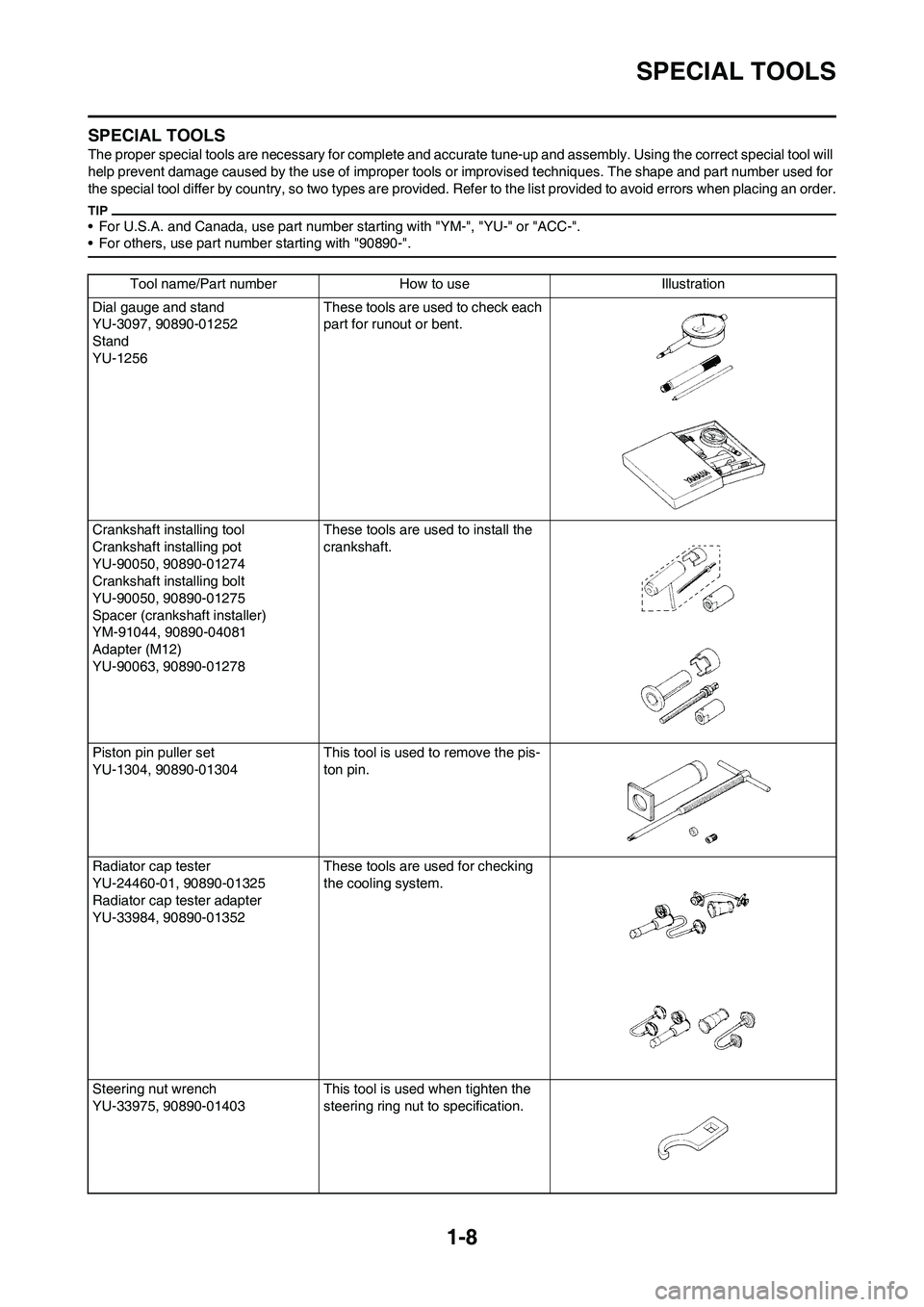

SPECIAL TOOLS

SPECIAL TOOLS

The proper special tools are necessary for complete and accurate tune-up and assembly. Using the correct special tool will

help prevent damage caused by the use of improper tools or improvised techniques. The shape and part number used for

the special tool differ by coun try, so two types are provided. Refer to the list provided to avoid errors when placing an order .

• For U.S.A. and Canada, use part number starting with "YM-", "YU-" or "ACC-".

• For others, use part num ber starting with "90890-".

Tool name/Part number How to use Illustration

Dial gauge and stand

YU-3097, 90890-01252

Stand

YU-1256 These tools are used to check each

part for runout or bent.

Crankshaft installing tool

Crankshaft installing pot

YU-90050, 90890-01274

Crankshaft installing bolt

YU-90050, 90890-01275

Spacer (crankshaft installer)

YM-91044, 90890-04081

Adapter (M12)

YU-90063, 90890-01278 These tools are used to install the

crankshaft.

Piston pin puller set

YU-1304, 90890-01304 This tool is used to remove the pis-

ton pin.

Radiator cap tester

YU-24460-01, 90890-01325

Radiator cap tester adapter

YU-33984, 90890-01352 These tools are used for checking

the cooling system.

Steering nut wrench

YU-33975, 90890-01403 This tool is used when tighten the

steering ring nut to specification.

Page 19 of 230

1-9

SPECIAL TOOLS

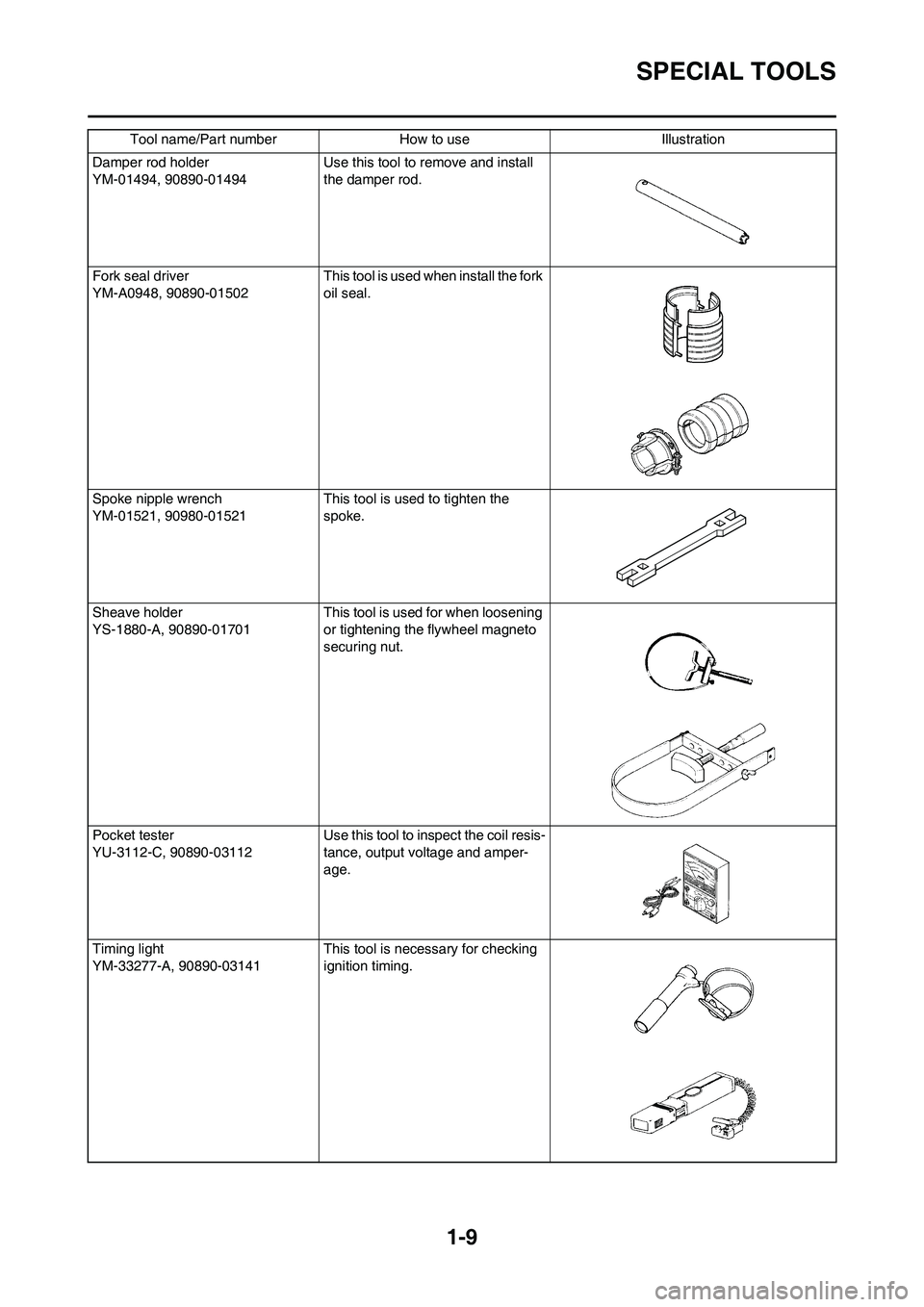

Damper rod holder

YM-01494, 90890-01494Use this tool to remove and install

the damper rod.

Fork seal driver

YM-A0948, 90890-01502 This tool is used when install the fork

oil seal.

Spoke nipple wrench

YM-01521, 90980-01521 This tool is used to tighten the

spoke.

Sheave holder

YS-1880-A, 90890-01701 This tool is used for when loosening

or tightening the flywheel magneto

securing nut.

Pocket tester

YU-3112-C, 90890-03112 Use this tool to inspect the coil resis-

tance, output voltage and amper-

age.

Timing light

YM-33277-A, 90890-03141 This tool is necessary for checking

ignition timing.

Tool name/Part number How to use Illustration

Page 20 of 230

1-10

SPECIAL TOOLS

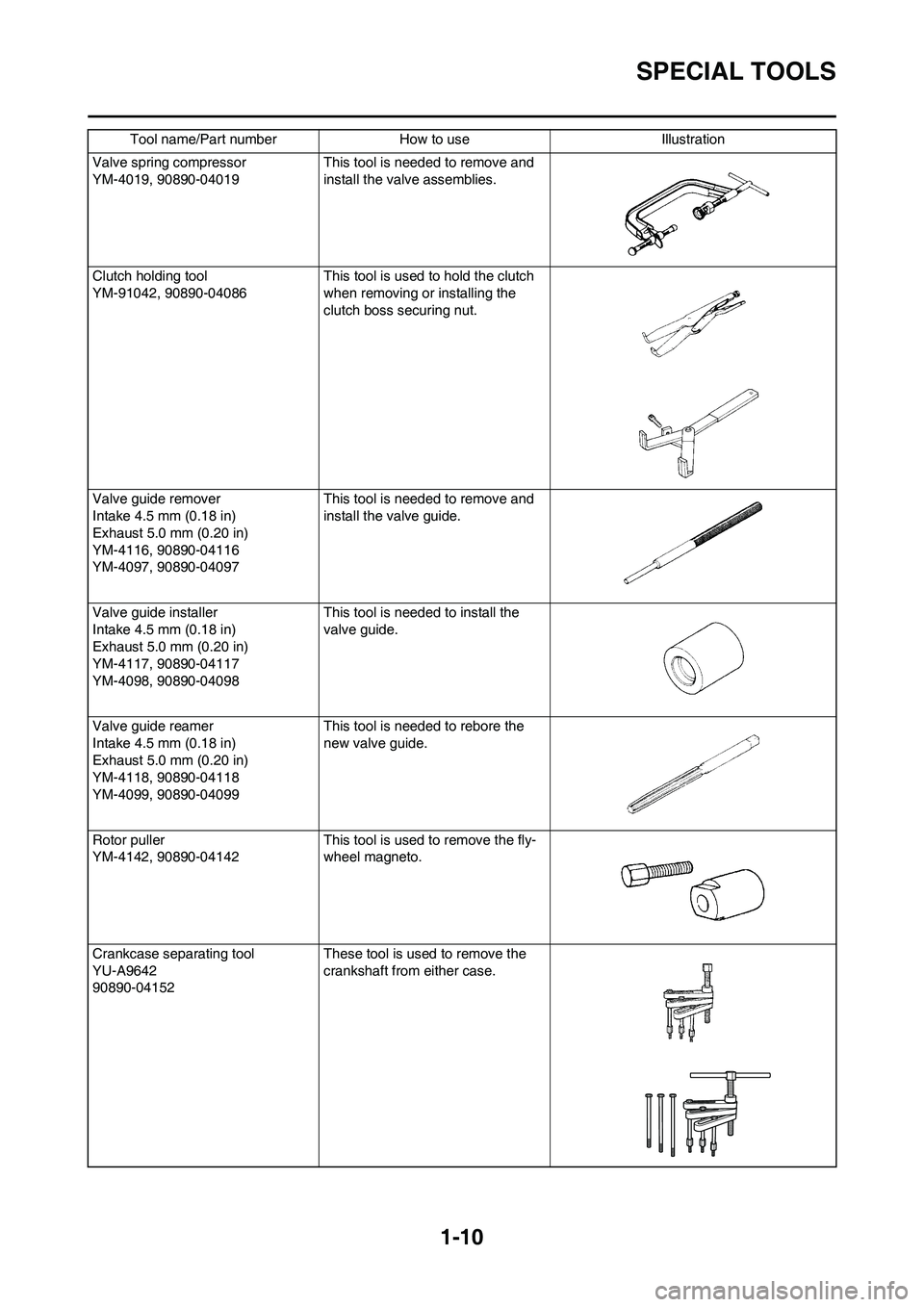

Valve spring compressor

YM-4019, 90890-04019 This tool is needed to remove and

install the valve assemblies.

Clutch holding tool

YM-91042, 90890-04086 This tool is used to hold the clutch

when removing or installing the

clutch boss securing nut.

Valve guide remover

Intake 4.5 mm (0.18 in)

Exhaust 5.0 mm (0.20 in)

YM-4116, 90890-04116

YM-4097, 90890-04097 This tool is needed to remove and

install the valve guide.

Valve guide installer

Intake 4.5 mm (0.18 in)

Exhaust 5.0 mm (0.20 in)

YM-4117, 90890-04117

YM-4098, 90890-04098 This tool is needed to install the

valve guide.

Valve guide reamer

Intake 4.5 mm (0.18 in)

Exhaust 5.0 mm (0.20 in)

YM-4118, 90890-04118

YM-4099, 90890-04099 This tool is needed to rebore the

new valve guide.

Rotor puller

YM-4142, 90890-04142 This tool is used to remove the fly-

wheel magneto.

Crankcase separating tool

YU-A9642

90890-04152 These tool is used to remove the

crankshaft from either case.

Tool name/Part number How to use Illustration