ABS YAMAHA WR 450F 2010 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2010, Model line: WR 450F, Model: YAMAHA WR 450F 2010Pages: 230, PDF Size: 13.87 MB

Page 10 of 230

CONTENTS

CHAPTER 1

GENERAL INFOR-

MATION

LOCATION OF

IMPORTANT LABELS ..... 1-1

DESCRIPTION ................. 1-5

CONSUMER

INFORMATION................. 1-6

INCLUDED PARTS .......... 1-6

IMPORTANT

INFORMATION................. 1-6

CHECKING OF

CONNECTION .................. 1-7

SPECIAL TOOLS ............. 1-8

CONTROL

FUNCTIONS ................... 1-12

MULTI-FUNCTION

DISPLAY ........................ 1-13

STARTING AND

BREAK-IN ...................... 1-18

TORQUE-CHECK

POINTS........................... 1-20

CLEANING AND

STORAGE ...................... 1-21

CHAPTER 2

SPECIFICATIONS

GENERAL

SPECIFICATIONS ............ 2-1

MAINTENANCE

SPECIFICATIONS ............ 2-3

TIGHTENING

TORQUES ...................... 2-12

LUBRICATION

DIAGRAMS .................... 2-19

CABLE ROUTING

DIAGRAM ....................... 2-21

CHAPTER 3

REGULAR INSPEC-

TION AND AD-JUSTMENTS

PERIODIC MAINTENANCE

CHART FOR THE EMISSION

CONTROL SYSTEM (For

Canada) ............................ 3-1

GENERAL MAINTENANCE

AND LUBRICATION CHART

(For Canada) .................... 3-2

MAINTENANCE

INTERVALS FOR

COMPETITION USE ......... 3-3

PRE-OPERATION

INSPECTION AND

MAINTENANCE................ 3-7

ENGINE ............................ 3-8

CHASSIS ........................ 3-19

ELECTRICAL ................. 3-29

CHAPTER 4 TUNING

ENGINE

(Except for Canada) ........ 4-1

CHASSIS .......................... 4-5

CHAPTER 5

ENGINE

RADIATOR ....................... 5-1

CARBURETOR................. 5-4

AIR INDICTOIN

SYSTEM ......................... 5-13

CAMSHAFTS.................. 5-15

CYLINDER HEAD........... 5-20

VALVES AND VALVE

SPRINGS ........................ 5-23

CYLINDER AND

PISTON ........................... 5-27

CLUTCH ......................... 5-30 OIL FILTER ELEMENT

AND WATER PUMP .......5-34

BALANCER ....................5-38

OIL PUMP .......................5-40

KICK SHAFT AND SHIFT

SHAFT ............................5-43

AC MAGNETO AND

STARTER CLUTCH........5-48

ENGINE REMOVAL........5-53

CRANKCASE AND

CRANKSHAFT ...............5-57

TRANSMISSION,

SHIFT CAM AND

SHIFT FORK ...................5-63

CHAPTER 6

CHASSIS

FRONT WHEEL AND REAR

WHEEL .............................6-1

FRONT BRAKE AND REAR

BRAKE..............................6-6

FRONT FORK .................6-16

HANDLEBAR..................6-23

STEERING ......................6-27

SWINGARM ....................6-31

REAR SHOCK

ABSORBER ....................6-36

CHAPTER 7

ELECTRICAL

ELECTRICAL

COMPONENTS AND

WIRING DIAGRAM ...........7-1

IGNITION SYSTEM...........7-3

ELECTRIC STARTING

SYSTEM............................7-5

CHARGING SYSTEM .....7-13

THROTTLE POSITION

SENSOR SYSTEM .........7-15

LIGHTING SYSTEM .......7-18

SIGNALING SYSTEM.....7-20

Page 23 of 230

1-13

MULTI-FUNCTION DISPLAY

COLD STARTER KNOB

When cold, the engine requires a

richer air-fuel mixture for starting. A

separate starter circuit, which is con-

trolled by the cold starter knob "1",

supplies this mixture. Pull the cold

starter knob out to open the circuit for

starting. When the engine has

warmed up, push it in to close the cir-

cuit.

HOT STARTER LEVER

The hot starter lever "1" is used when

starting a warm engine. Use the hot

starter lever when starting the engine

again immediately after it was

stopped (the engine is still warm).

Pulling the hot starter lever injects

secondary air to thin the air-fuel mix-

ture temporarily, allowing the engine

to be started more easily.

SIDESTAND

This sidestand "1" is used to support

only the machine when standing or

transporting it.

• Never apply additional force to the sidestand.

• Hold up the sidestand before

starting out.

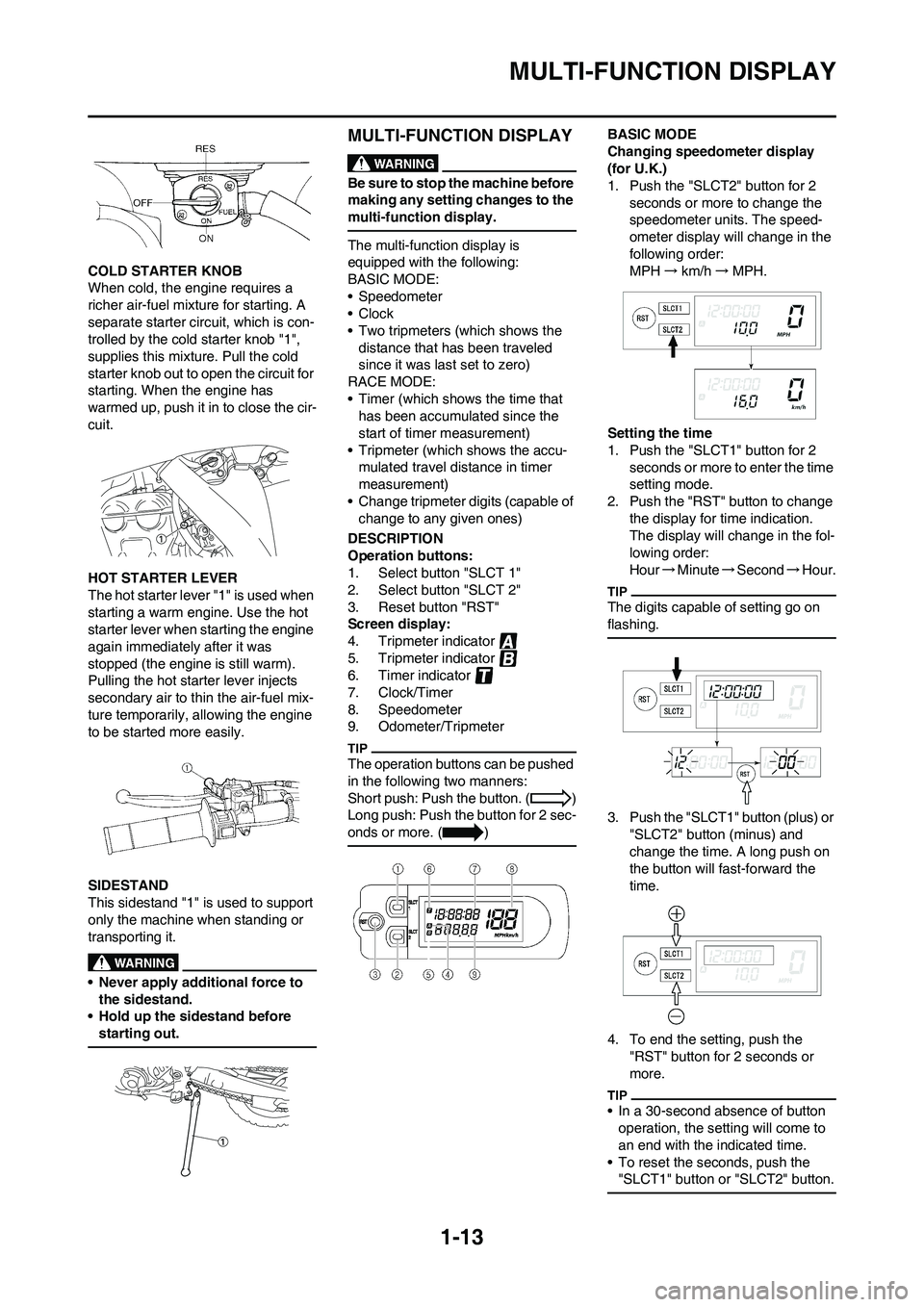

MULTI-FUNCTION DISPLAY

Be sure to stop the machine before

making any setting changes to the

multi-function display.

The multi-function display is

equipped with the following:

BASIC MODE:

• Speedometer

•Clock

• Two tripmeters (which shows the distance that has been traveled

since it was last set to zero)

RACE MODE:

• Timer (which shows the time that has been accumulated since the

start of timer measurement)

• Tripmeter (which shows the accu- mulated travel distance in timer

measurement)

• Change tripmeter digits (capable of change to any given ones)

DESCRIPTION

Operation buttons:

1. Select button "SLCT 1"

2. Select button "SLCT 2"

3. Reset button "RST"

Screen display:

4. Tripmeter indicator

5. Tripmeter indicator

6. Timer indicator

7. Clock/Timer

8. Speedometer

9. Odometer/Tripmeter

The operation buttons can be pushed

in the following two manners:

Short push: Push the button. ( )

Long push: Push the button for 2 sec-

onds or more. ( )

BASIC MODE

Changing speedometer display

(for U.K.)

1. Push the "SLCT2" button for 2 seconds or more to change the

speedometer units. The speed-

ometer display will change in the

following order:

MPH →km/h →MPH.

Setting the time

1. Push the "SLCT1" button for 2 seconds or more to enter the time

setting mode.

2. Push the "RST" button to change the display for time indication.

The display will change in the fol-

lowing order:

Hour →Minute →Second →Hour.

The digits capable of setting go on

flashing.

3. Push the "SLCT1" button (plus) or

"SLCT2" button (minus) and

change the time. A long push on

the button will fast-forward the

time.

4. To end the setting, push the "RST" button for 2 seconds or

more.

• In a 30-second absence of button operation, the setting will come to

an end with the indicated time.

• To reset the seconds, push the "SLCT1" button or "SLCT2" button.

Page 30 of 230

1-20

TORQUE-CHECK POINTS

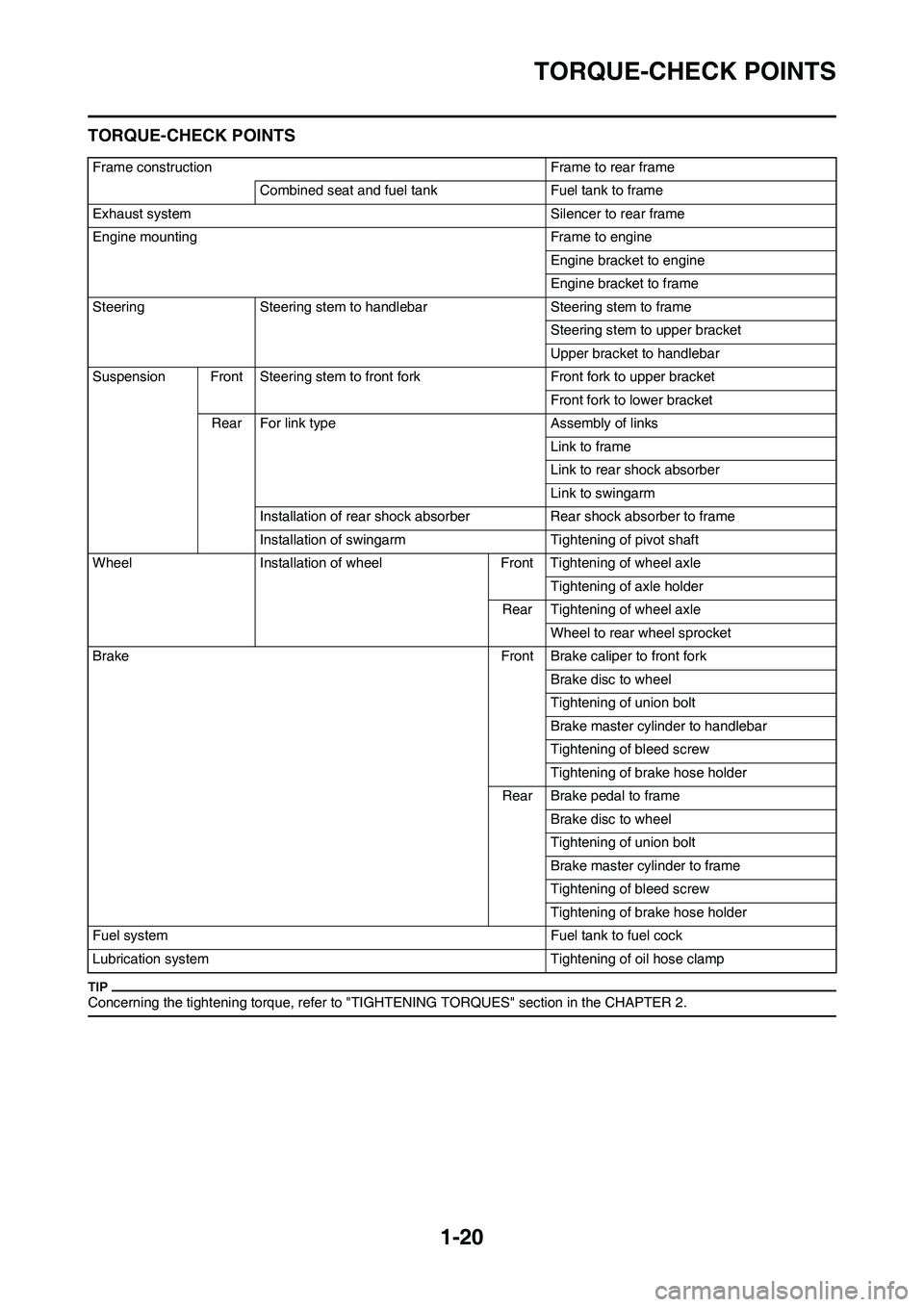

TORQUE-CHECK POINTS

Concerning the tightening torque, refer to "TIGHTENING TORQUES" section in the CHAPTER 2.

Frame construction Frame to rear frameCombined seat and fuel tank Fuel tank to frame

Exhaust system Silencer to rear frame

Engine mounting Frame to engine Engine bracket to engine

Engine bracket to frame

Steering Steering stem to handlebar Steering stem to frame Steering stem to upper bracket

Upper bracket to handlebar

Suspension Front Steering stem to front fork Front fork to upper bracket

Front fork to lower bracket

Rear For link type Assembly of links Link to frame

Link to rear shock absorber

Link to swingarm

Installation of rear shock absorber Rear shock absorber to frame

Installation of swingarm Tightening of pivot shaft

Wheel Installation of wheel Front Tightening of wheel axle Tightening of axle holder

Rear Tightening of wheel axle Wheel to rear wheel sprocket

Brake Front Brake caliper to front fork Brake disc to wheel

Tightening of union bolt

Brake master cylinder to handlebar

Tightening of bleed screw

Tightening of brake hose holder

Rear Brake pedal to frame Brake disc to wheel

Tightening of union bolt

Brake master cylinder to frame

Tightening of bleed screw

Tightening of brake hose holder

Fuel system Fuel tank to fuel cock

Lubrication system Tighteni ng of oil hose clamp

Page 34 of 230

2-3

MAINTENANCE SPECIFICATIONS

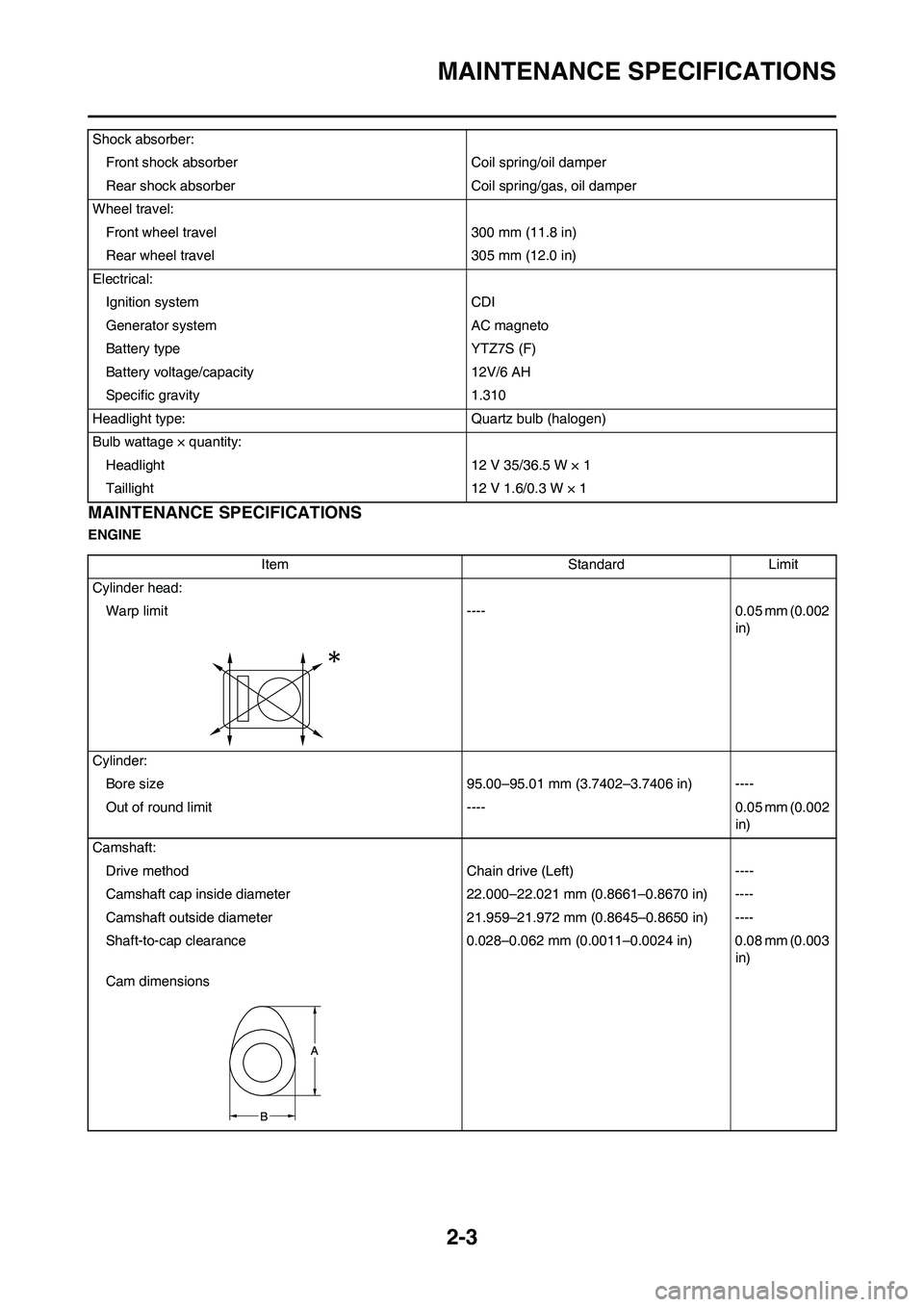

MAINTENANCE SPECIFICATIONS

ENGINEShock absorber:

Front shock absorber Coil spring/oil damper

Rear shock absorber Coil spring/gas, oil damper

Wheel travel:

Front wheel travel 300 mm (11.8 in)

Rear wheel travel 305 mm (12.0 in)

Electrical:

Ignition system CDI

Generator system AC magneto

Battery type YTZ7S (F)

Battery voltage/capacity 12V/6 AH

Specific gravity 1.310

Headlight type: Quartz bulb (halogen)

Bulb wattage × quantity:

Headlight 12 V 35/36.5 W × 1

Taillight 12 V 1.6/0.3 W × 1

Item Standard Limit

Cylinder head:

Warp limit ---- 0.05 mm (0.002

in)

Cylinder:

Bore size 95.00–95.01 mm (3.7402–3.7406 in) ----

Out of round limit ---- 0.05 mm (0.002

in)

Camshaft:

Drive method Chain drive (Left) ----

Camshaft cap inside diameter 22.000–22.021 mm (0.8661–0.8670 in) ----

Camshaft outside diameter 21.959–21.972 mm (0.8645–0.8650 in) ----

Shaft-to-cap clearance 0.028–0.062 mm (0.0011–0.0024 in) 0.08 mm (0.003

in)

Cam dimensions

Page 40 of 230

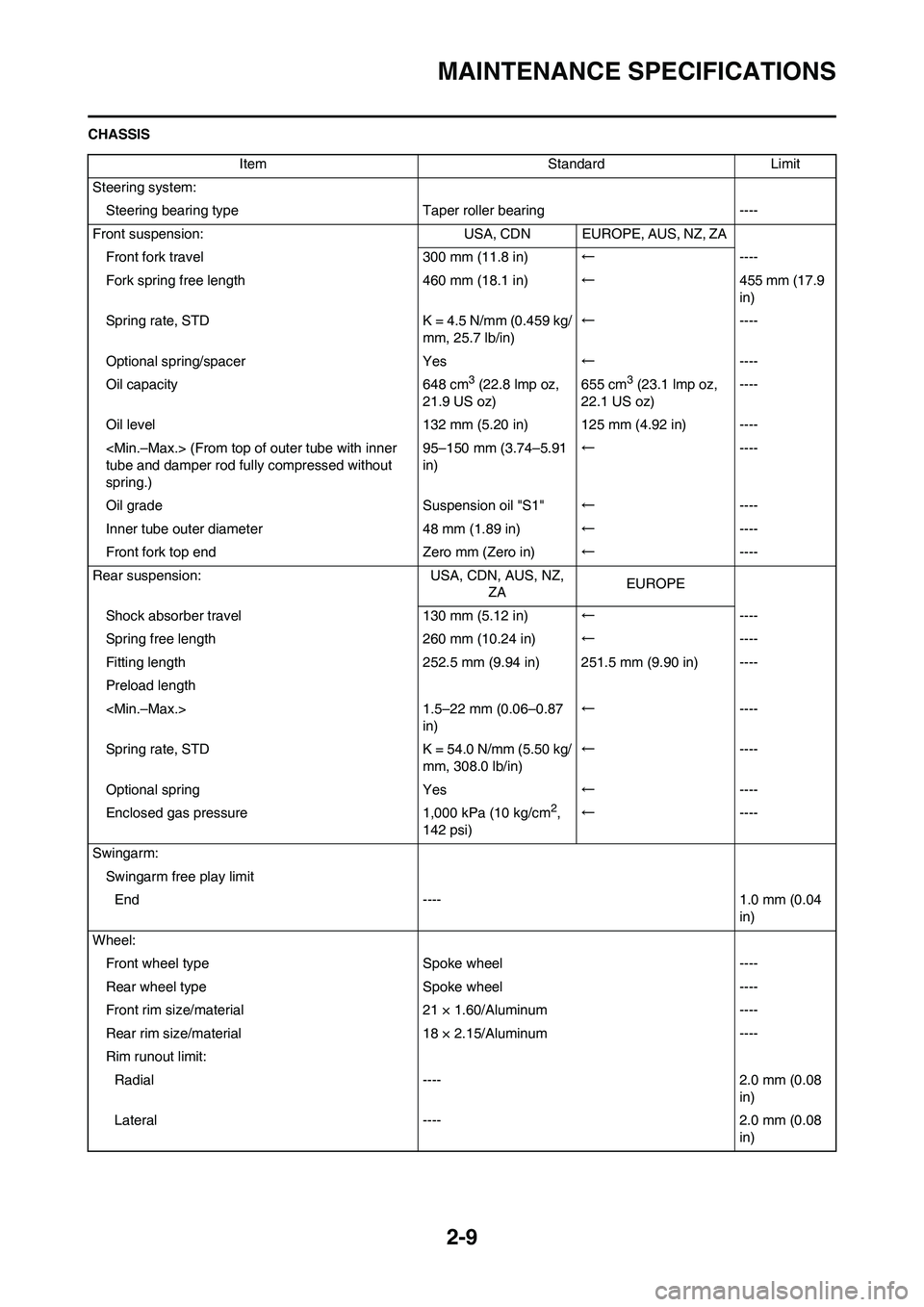

2-9

MAINTENANCE SPECIFICATIONS

CHASSIS

Item Standard Limit

Steering system:

Steering bearing typeTaper roller bearing ----

Front suspension: USA, CDN EUROPE, AUS, NZ, ZA

Front fork travel 300 mm (11.8 in)←----

Fork spring free length 460 mm (18.1 in)←455 mm (17.9

in)

Spring rate, STD K = 4.5 N/mm (0.459 kg/

mm, 25.7 lb/in)←----

Optional spring/spacer Yes←----

Oil capacity 648 cm

3 (22.8 lmp oz,

21.9 US oz)655 cm3 (23.1 lmp oz,

22.1 US oz)----

Oil level 132 mm (5.20 in) 125 mm (4.92 in) ----

tube and damper rod fully compressed without

spring.)95–150 mm (3.74–5.91

in)←----

Oil grade Suspension oil "S1"←----

Inner tube outer diameter 48 mm (1.89 in)←----

Front fork top end Zero mm (Zero in)←----

Rear suspension: USA, CDN, AUS, NZ,

ZAEUROPE

Shock absorber travel 130 mm (5.12 in)←----

Spring free length 260 mm (10.24 in)←----

Fitting length 252.5 mm (9.94 in) 251.5 mm (9.90 in) ----

Preload length

in)←----

Spring rate, STD K = 54.0 N/mm (5.50 kg/

mm, 308.0 lb/in)←----

Optional spring Yes←----

Enclosed gas pressure 1,000 kPa (10 kg/cm

2,

142 psi)←----

Swingarm:

Swingarm free play limit

End ---- 1.0 mm (0.04

in)

Wheel:

Front wheel type Spoke wheel ----

Rear wheel typeSpoke wheel ----

Front rim size/material 21 × 1.60/Aluminum ----

Rear rim size/material 18 × 2.15/Aluminum ----

Rim runout limit:

Radial ---- 2.0 mm (0.08

in)

Lateral ---- 2.0 mm (0.08

in)

Page 46 of 230

2-15

TIGHTENING TORQUES

△Driven sprocket and wheel hub M8 × 1.25 6 50 5.0 36

△Nipple (spoke) — 72 3 0.3 2.2

△Disc cover and rear brake caliper M6 × 1.0 2 10 1.0 7.2

△Protector and rear brake caliper M6 × 1.0 2 7 0.7 5.1

Chain puller adjust bolt and locknut M8 × 1.25 2 19 1.9 13

Engine mounting:

△Engine upper bracket and frame M10 × 1.25 4 55 5.5 40

△Engine lower bracket and frame M8 × 1.25 4 34 3.4 24

△Engine and engine bracket (lower) M10 × 1.25 1 53 5.3 38

△Engine and engine bracket (upper) M10 × 1.25 1 55 5.5 40

△Engine and frame (lower) M10 × 1.25 1 53 5.3 38

△Engine guard M6 × 1.0 3 7 0.7 5.1

Regulator mounting M6 × 1.0 2 7 0.7 5.1

△Pivot shaft and nut M16 × 1.5 1 85 8.5 61

△Relay arm and swingarm M14 × 1.5 1 70 7.0 50

△Relay arm and connecting rod M14 × 1.5 1 80 8.0 58

△Connecting rod and frame M14 × 1.5 1 80 8.0 58

△Rear shock absorber and frame M10 × 1.25 1 56 5.6 40

△Rear shock absorber and relay arm M10 × 1.25 1 53 5.3 38

△Rear frame and frame (upper) M8 × 1.25 1 38 3.8 27

△Rear frame and frame (lower) M8 × 1.25 2 32 3.2 23

△Swingarm and brake hose holder M5 × 0.8 4 2 0.2 1.4

Swingarm and patch M4 × 0.7 4 2 0.2 1.4

Drive chain tensioner mounting (upper) M8 × 1.25 1 16 1.6 11

Drive chain tensioner mounting (lower) M8 × 1.25 1 16 1.6 11

Chain support and swingarm M6 × 1.0 3 7 0.7 5.1

Seal guard and swingarm M5 × 0.8 4 6 0.6 4.3

△Fuel tank mounting M6 × 1.0 2 9 0.9 6.5

△Fuel tank and fuel cock M6 × 1.0 2 4 0.4 2.9

Fuel tank and seat set bracket M6 × 1.0 1 7 0.7 5.1

Fuel tank and fuel tank bracket M6 × 1.0 4 7 0.7 5.1

Seat mounting M8 × 1.25 2 22 2.2 16

△Side cover mounting M6 × 1.0 2 7 0.7 5.1

△Air scoop and fuel tank M6 × 1.0 6 7 0.7 5.1

△Air scoop and radiator panel (lower) M6 × 1.0 2 6 0.6 4.3

△Front fender mounting M6 × 1.0 4 7 0.7 5.1

△Rear fender mounting (front) M6 × 1.0 2 7 0.7 5.1

△Rear fender mounting (rear) M6 × 1.0 2 11 1.1 8.0

Multi-function display bracket mounting M6 × 1.0 2 7 0.7 5.1

Multi-function display mounting M5 × 0.8 2 4 0.4 2.9

Plate 1 and protector M5 × 0.8 2 4 0.4 2.9

Plate 2 and protector — 2 0.5 0.05 0.36

Speed sensor lead holder and under bracket M6 × 1.0 1 13 1.3 9.4

Headlight body and headlight unit — 2 1 0.1 0.7Part to be tightened Thread size Q'tyTightening torque

Nm m•kg ft•lb

Page 53 of 230

2-22

CABLE ROUTING DIAGRAM

A. Insert the end of the fuel tank

breather hose into the hole in

the steering stem.

B. Fasten the throttle cable, hot

starter cable and rectifier/regula-

tor lead onto the frame. Locate

the clamp under the throttle ca-

ble on the right side of the frame,

and face its ends, as well as the

tie ends, downward.

C. Fasten the diode (at the mark-

ing), throttle cable and hot start-

er cable onto the frame. Locate

the clamp end facing toward the

lower right of the frame and with

the tie end facing downward.

D. Fasten the wire harness, throttle

position sensor lead and clutch

cable onto the frame. Pass the

clamp through the hole in the

stay (air cut-off valve). Locate

the clamp end facing toward the

lower side of the frame and cut

off the tie end.

E. Pass the carburetor breather

hoses, carburetor overflow hose

and catch tank breather hose

between the connecting rod and

cross tube (frame).

F. Pass the neutral switch lead on

the inside of the engine bracket.

G. Fasten the neutral switch lead

and AC magneto lead onto the

frame. Locate the clamp end

facing toward the outside of the

frame and tie end facing toward

the rear of the frame.

H. Fasten the AC magneto lead

and neutral switch lead onto the

frame. Locate the clamp end

facing toward the rear of the

frame and cut off the tie end.

I. Pass the neutral switch lead and

AC magneto lead on the inside

of the wire harness.

J. Fasten the AC magneto lead

and neutral switch lead onto the

frame.

K. Pass the wire harness through

the cable guide.

L. Locate the couplers in the frame

recess.

M. Pass the carburetor breather

hoses, carburetor overflow hose

and catch tank breather hose so

that the hoses do not contact the

rear shock absorber.

N. Secure the coupler by pushing it

into the hole in the headlight

unit.

O. Fasten the throttle position sen-

sor lead and the hot starter ca-

ble.P. Locate the clamp between the

hot starter cable protector and

rubber cap.

Page 55 of 230

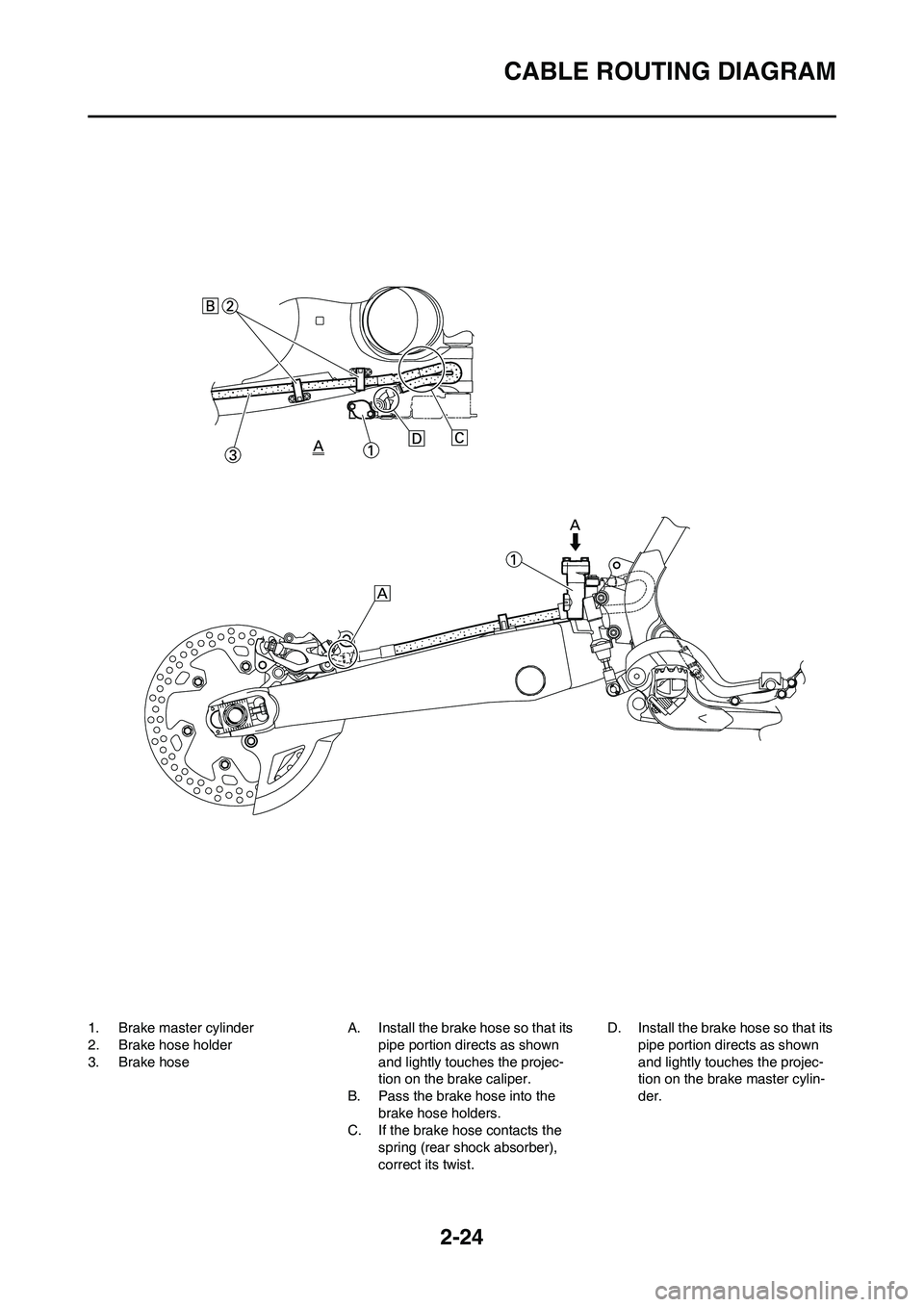

2-24

CABLE ROUTING DIAGRAM

1. Brake master cylinder

2. Brake hose holder

3. Brake hoseA. Install the brake hose so that its

pipe portion directs as shown

and lightly touches the projec-

tion on the brake caliper.

B. Pass the brake hose into the

brake hose holders.

C. If the brake hose contacts the

spring (rear shock absorber),

correct its twist.D. Install the brake hose so that its

pipe portion directs as shown

and lightly touches the projec-

tion on the brake master cylin-

der.

Page 62 of 230

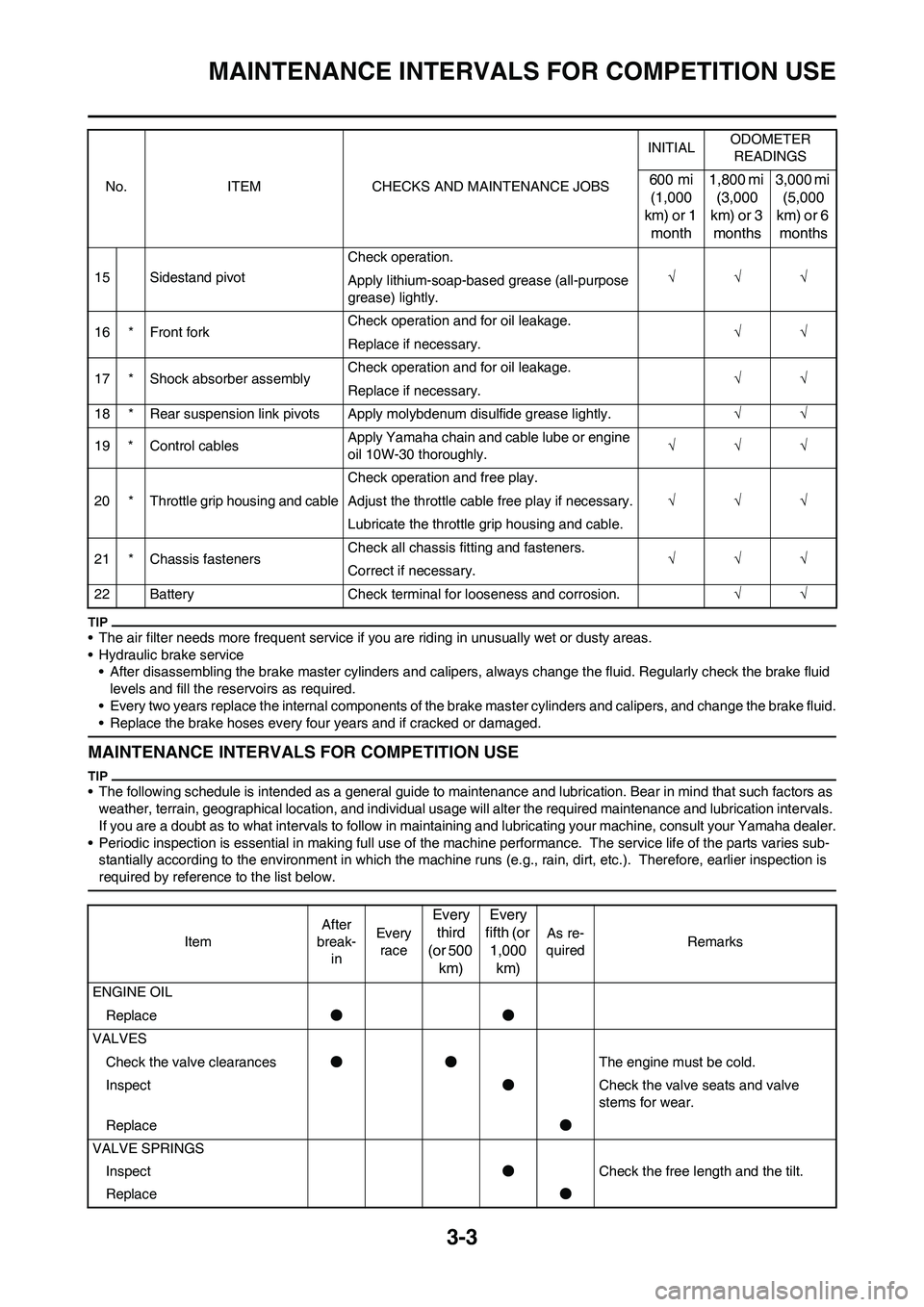

3-3

MAINTENANCE INTERVALS FOR COMPETITION USE

• The air filter needs more frequent service if you are riding in unusually wet or dusty areas.

• Hydraulic brake service

• After disassembling the brake master cylinders and calipers, always change the fluid. Regularly check the brake fluid

levels and fill the reservoirs as required.

• Every two years replace the internal components of the brake master cylinders and calipers, and change the brake fluid.

• Replace the brake hoses every four years and if cracked or damaged.

MAINTENANCE INTERVALS FOR COMPETITION USE

• The following schedule is intended as a general guide to maintenance and lubrication. Bear in mind that such factors as

weather, terrain, geographical location, and individual usage will alter the required maintenance and lubrication intervals.

If you are a doubt as to what intervals to follow in maintaining and lubricating your machine, consult your Yamaha dealer.

• Periodic inspection is essential in making full use of the machine performance. The service life of the parts varies sub-

stantially according to the environment in which the machine runs (e.g., rain, dirt, etc.). Therefore, earlier inspection is

required by reference to the list below.

15 Sidestand pivotCheck operation.

√√√

Apply lithium-soap-based grease (all-purpose

grease) lightly.

16 * Front forkCheck operation and for oil leakage.

√√

Replace if necessary.

17 * Shock absorber assemblyCheck operation and for oil leakage.

√√

Replace if necessary.

18 * Rear suspension link pivots Apply molybdenum disulfide grease lightly.√√

19 * Control cablesApply Yamaha chain and cable lube or engine

oil 10W-30 thoroughly.√√√

20 * Throttle grip housing and cableCheck operation and free play.

√√√ Adjust the throttle cable free play if necessary.

Lubricate the throttle grip housing and cable.

21 * Chassis fastenersCheck all chassis fitting and fasteners.

√√√

Correct if necessary.

22 Battery Check terminal for looseness and corrosion.√√ No. ITEM CHECKS AND MAINTENANCE JOBSINITIALODOMETER

READINGS

600 mi

(1,000

km) or 1

month1,800 mi

(3,000

km) or 3

months3,000 mi

(5,000

km) or 6

months

ItemAfter

break-

inEvery

race

Every

third

(or 500

km)Every

fifth (or

1,000

km)

As re-

quiredRemarks

ENGINE OIL

Replace●●

VALVES

Check the valve clearances●●The engine must be cold.

Inspect●Check the valve seats and valve

stems for wear.

Replace●

VALVE SPRINGS

Inspect●Check the free length and the tilt.

Replace●

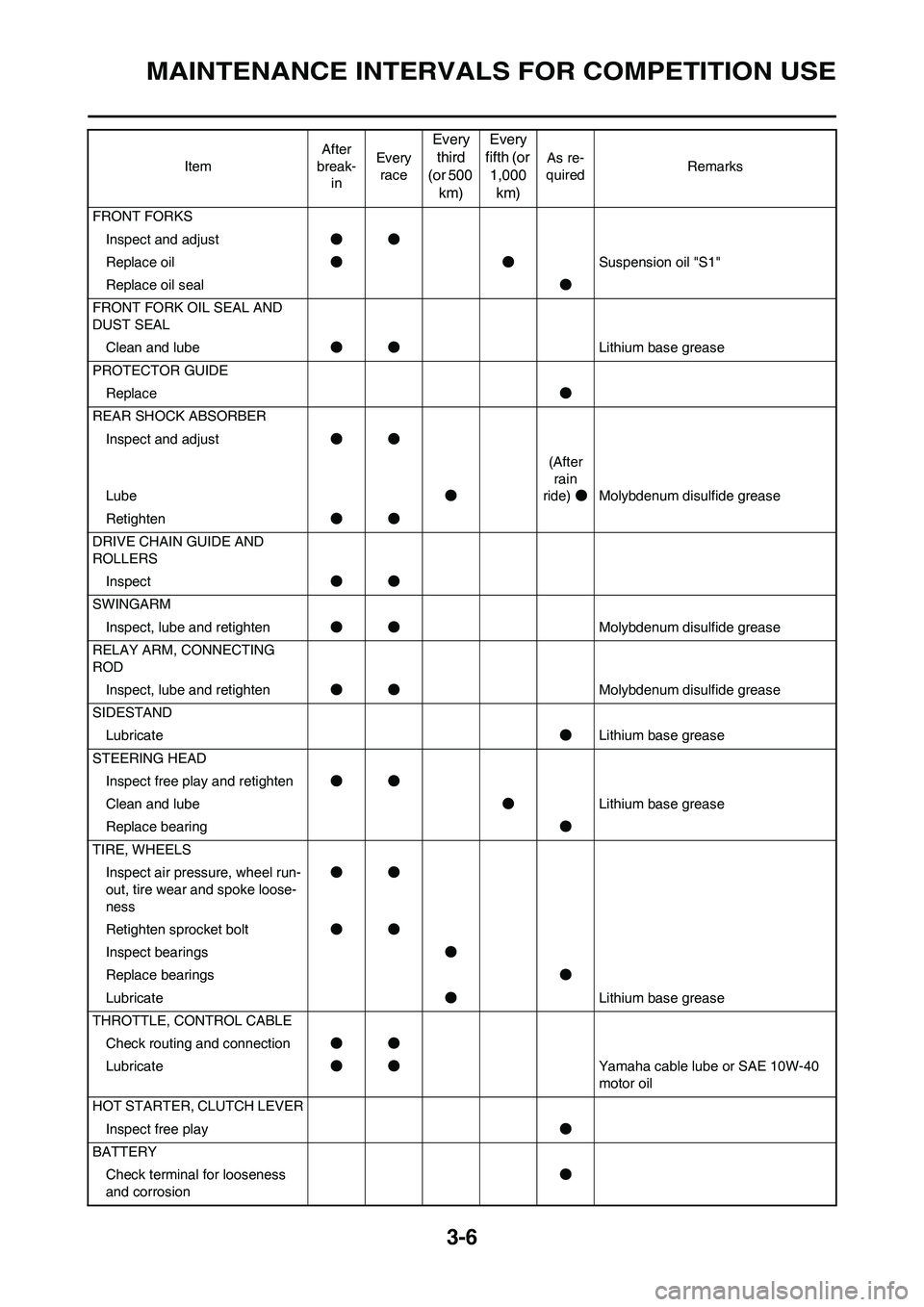

Page 65 of 230

3-6

MAINTENANCE INTERVALS FOR COMPETITION USE

FRONT FORKS

Inspect and adjust●●

Replace oil●●Suspension oil "S1"

Replace oil seal●

FRONT FORK OIL SEAL AND

DUST SEAL

Clean and lube●●Lithium base grease

PROTECTOR GUIDE

Replace●

REAR SHOCK ABSORBER

Inspect and adjust●●

Lube●(After

rain

ride)●Molybdenum disulfide grease

Retighten●●

DRIVE CHAIN GUIDE AND

ROLLERS

Inspect●●

SWINGARM

Inspect, lube and retighten●●Molybdenum disulfide grease

RELAY ARM, CONNECTING

ROD

Inspect, lube and retighten●●Molybdenum disulfide grease

SIDESTAND

Lubricate●Lithium base grease

STEERING HEAD

Inspect free play and retighten●●

Clean and lube●Lithium base grease

Replace bearing●

TIRE, WHEELS

Inspect air pressure, wheel run-

out, tire wear and spoke loose-

ness●●

Retighten sprocket bolt●●

Inspect bearings●

Replace bearings●

Lubricate●Lithium base grease

THROTTLE, CONTROL CABLE

Check routing and connection●●

Lubricate●●Yamaha cable lube or SAE 10W-40

motor oil

HOT STARTER, CLUTCH LEVER

Inspect free play●

BATTERY

Check terminal for looseness

and corrosion● ItemAfter

break-

inEvery

race

Every

third

(or 500

km)Every

fifth (or

1,000

km)

As re-

quiredRemarks