wheel YAMAHA WR 450F 2013 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2013, Model line: WR 450F, Model: YAMAHA WR 450F 2013Pages: 98, PDF Size: 2.59 MB

Page 6 of 98

TABLE OF CONTENTSSAFETY INFORMATION .................. 1-1

DESCRIPTION .................................. 2-1

Left view .......................................... 2-1

Right view ........................................ 2-2

Controls and instrument s................. 2-3

INSTRUMENT AND CONTROL

FUNCTIONS ....................................... 3-1

Main switch ..................................... 3-1

Indicator lights and warning

lights ............................................ 3-1

Multi-function display ...................... 3-2

Handlebar switches ........................ 3-7

Clutch lever ..................................... 3-8

Shift pedal ...... ............................. .... 3-8

Brake lever ..................................... 3-8

Brake pedal .................................... 3-9

Fuel tank cap .................................. 3-9

Fuel ............................................... 3-10

Fuel tank breather hose ................ 3-11

Catalytic converter ........................ 3-11

Starter knob .................................. 3-12

Kickstarter ...... ............................. .. 3-12

Steering lock ................................. 3-13

Seat .............................................. 3-13

Adjusting the front fork .................. 3-14

Front fork bleeding ........................ 3-15

Adjusting the shock absorber assembly ................................... 3-16

Sidestand ...................................... 3-18 Ignition circuit cut-o

ff system ........ 3-19

FOR YOUR SAFETY –

PRE-OPERATION CHECKS ............. 4-1

OPERATION AND IMPORTANT

RIDING POINTS ................................. 5-1

Starting a cold engine .................... 5-1

Starting a warm engine .................. 5-3

Shifting ........................................... 5-3

Tips for reducing fuel

consumption ............................... 5-4

Engine break-in .............................. 5-4

Parking ........................................... 5-5

PERIODIC MAINTENANCE AND

ADJUSTMENT ................................... 6-1

Owner’s tool kit ............................... 6-2

Periodic maintenance chart for the emission contro l system ....... 6-3

General maintenance and lubrication chart .......................... 6-4

Removing and installing the

panel ........................................... 6-7

Checking the spark plug ................. 6-7

Engine oil and oil filter element ...... 6-8

Coolant ......................................... 6-12

Cleaning the air filter element

and check hose ......................... 6-14

Adjusting the engine idling speed ........................................ 6-17 Checking the throttle grip free

play ............................................ 6-17

Valve clearance ............................ 6-18

Tires .............................................. 6-18

Spoke wheels ............................... 6-20

Adjusting the clutch lever free play ............................................ 6-20

Checking the brake lever free

play ............................................ 6-21

Checking the shift pedal ............... 6-22

Brake light switches ...................... 6-22

Checking the front and rear brake pads ................................. 6-23

Checking the brake fluid level ....... 6-23

Changing the brake fluid ............... 6-24

Drive chain slack ........................... 6-25

Cleaning and lubricating the

drive chain ................................. 6-26

Checking and lubricating the cables ........................................ 6-27

Checking and lubricating the throttle grip and cable ................ 6-27

Checking and lubricating the

brake and clutch levers ............. 6-27

Checking and lubricating the

brake pedal ................................ 6-28

Checking and lubricating the sidestand ................................... 6-28

Lubricating the swingarm pivots ......................................... 6-29

Checking the front fork .................. 6-291DX-9-E1.book 1 ページ 2012年7月31日 火曜日 午前9時31分

Page 7 of 98

TABLE OF CONTENTS

Checking the steering ................... 6-30

Checking the wheel bearings ....... 6-30

Battery .......................................... 6-30

Replacing the fuse ........................ 6-32

Replacing the headlight bulb ........ 6-32

Tail/brake light .............................. 6-34

Replacing a turn signal light bulb ........................................... 6-34

Replacing the license plate light bulb .................................... 6-35

Replacing an auxiliary light

bulb ........................................... 6-35

Supporting the motor cycle ............ 6-36

Front wheel ................................... 6-37

Rear wheel ................................... 6-38

Troubleshooting ............................ 6-40

Troubleshooting charts ................. 6-41

MOTORCYCLE CARE AND

STORAGE .......................................... 7-1

Matte color caution ......................... 7-1

Care ................................................ 7-1

Storage ........................................... 7-3

SPECIFICATIONS ............................. 8-1

CONSUMER INFORMATION ............. 9-1

Identification numbers .................... 9-1

1DX-9-E1.book 2 ページ 2012年7月31日 火曜日 午前9時31分

Page 9 of 98

1-2

1

SAFETY INFORMATION

motorist’s blind spot.

Never maintain a motorcycle without proper knowledge. Con-

tact an authorized motorcycle

dealer to inform you on basic

motorcycle maintenance. Cer-

tain maintenance can only be

carried out by certified staff.

Many accidents involve inexperi-

enced operators.

Make sure that you are qualifiedand that you only lend your mo-

torcycle to other qualified opera-

tors.

Know your skills and limits. Staying within your limits may

help you to avoid an accident.

We recommend that you prac- tice riding your motorcycle until

you have become thoroughly fa-

miliar with the motorcycle and all

of its controls.

Many accidents have been caused

by error of the motorcycle opera-

tor. A typical error made by the op-

erator is veering wide on a turn

due to excessive speed or under-

cornering (insufficient lean angle

for the speed). Always obey the speed limit and

never travel faster than warrant-

ed by road and traffic conditions.

Always signal before turning or changing lanes. Make sure that

other motorists can see you.

Ride cautiously in unfamiliar ar-

eas. You may encounter hidden

obstacles that could cause an ac-

cident.

The posture of the operator is im-

portant for proper control. The op-

erator should keep both hands on

the handlebar and both feet on the

operator footrests during operation

to maintain control of the motorcy-

cle.

Never ride under the influence of

alcohol or other drugs.

Protective Apparel

The majority of fatalities from motorcy-

cle accidents are the result of head in-

juries. The use of a safety helmet is the

single most critical factor in the preven-

tion or reduction of head injuries.

Always wear an approved helmet.

Wear a face shield or goggles.

Wind in your unprotected eyes could contribute to an impairment

of vision that could delay seeing a

hazard.

The use of a jacket, heavy boots,

trousers, gloves, etc., is effective in

preventing or reducing abrasions

or lacerations.

Never wear loose-fitting clothes,

otherwise they could catch on the

control levers, footrests, or wheels

and cause injury or an accident.

Always wear protective clothing

that covers your legs, ankles, and

feet. The engine or exhaust sys-

tem become very hot during or af-

ter operation and can cause burns.

Avoid Carbon Monoxide Poisoning

All engine exhaust contains carbon

monoxide, a deadly gas. Breathing car-

bon monoxide can cause headaches,

dizziness, drowsiness, nausea, confu-

sion, and eventually death.

Carbon Monoxide is a colorless, odor-

less, tasteless gas which may be

present even if you do not see or smell

any engine exhaust. Deadly levels of

carbon monoxide can collect rapidly

and you can quickly be overcome and

1DX-9-E1.book 2 ページ 2012年7月31日 火曜日 午前9時31分

Page 11 of 98

1-4

1

SAFETY INFORMATION

mended by Yamaha, even if sold and

installed by a Yamaha dealer.

Aftermarket Parts, Accessories,

and Modifications

While you may find aftermarket prod-

ucts similar in design and quality to

genuine Yamaha accessories, recog-

nize that some aftermarket accessories

or modifications are not suitable be-

cause of potential safety hazards to you

or others. Installing aftermarket prod-

ucts or having other modifications per-

formed to your vehicle that change any

of the vehicle’s design or operation

characteristics can put you and others

at greater risk of serious injury or death.

You are responsible for injuries related

to changes in the vehicle.

Keep the following guidelines in mind,

as well as those provided under “Load-

ing” when mounting accessories.

Never install accessories that

would impair the performance of

your motorcycle. Carefully inspect

the accessory before using it to

make sure that it does not in any

way reduce ground clearance or

cornering clearance, limit suspen-sion travel, steering travel or con-

trol operation, or obscure lights or

reflectors.

Accessories fitted to the handle-

bar or the front fork area can

create instability due to improper

weight distribution. If accesso-

ries are added to the handlebar

or front fork area, they must be

as lightweight as possible and

should be kept to a minimum.

Bulky or large accessories may seriously affect the stability of

the motorcycle. Wind may at-

tempt to lift the motorcycle, or

the motorcycle may become un-

stable in cross winds.

Certain accessories can dis- place the operator from his or

her normal riding position. This

improper position limits the free-

dom of movement of the opera-

tor and may limit control ability,

therefore, such accessories are

not recommended.

Use caution when adding electri-

cal accessories. If electrical acces-

sories exceed the capacity of the

motorcycle’s electr ical system, an electric failure could result, which

could cause a dangerous loss of

lights or engine power.

Aftermarket Tires and Rims

The tires and rims that came with your

motorcycle were designed to match the

performance capabilities and to provide

the best combination of handling, brak-

ing, and comfort. Other tires, rims, siz-

es, and combinations may not be

appropriate. Refer to page 6-18 for tire

specifications and more information on

replacing your tires.

Transporting the Motorcycle

Be sure to observe following instruc-

tions before transporting the motorcy-

cle in another vehicle.

Remove all loose items from the

motorcycle.

Point the front wheel straight

ahead on the trailer or in the truck

bed, and choke it in a rail to pre-

vent movement.

Shift the transmission in gear (for

models with a manual transmis-

sion).

Secure the motorcycle with

1DX-9-E1.book 4 ページ 2012年7月31日 火曜日 午前9時31分

Page 21 of 98

INSTRUMENT AND CONTROL FUNCTIONS

3-6

234

5

6

7

8

9

ton together again.

TIPThe stopwatch will continue counting

when the vehicle is stopped. To stop

and/or resume counting, repeat steps 3and 4.

Measurement mode (for calibrating

the distance-compensation tripme-

ter’s reading)

The distance-compensation tripmeter

is a feature intended to provide a more

accurate tripmeter reading for enduro

riding. Calibrating this meter in accor-

dance with the distances specified on

the enduro course map will help famil-

iarize the rider with the course. In addi-

tion, calibrating the meter may also be

necessary when using tire, wheel,

chain sprocket sizes, etc. other than

specified. For further information con-

cerning the use of this meter, please

consult your nearby Yamaha dealer.

Calibrate the distance-compensation

tripmeter as follows.

To increase the reading, push the

“SLCT 1” button. To decrease the read-

ing, push the “SLCT 2” button. Pushing and holding either button will increase

or decrease the reading continuously

until the button is released.

TIPCalibrating the reading of the dis-

tance-compensation tripmeter is possi-

ble regardless of the stopwatchoperation.

Resetting the distance-compensa-

tion tripmeter or the distance-com-

pensation tripmeter in combination

with the stopwatchTIPResetting can be made only to the dis-

tance-compensation tripmeter or to the

distance-compensation tripmeter incombination with the stopwatch.

Resetting the distance-compensationtripmeter1. Check that the stopwatch mea-

surement is in operation.

2. Reset the distance-compensation tripmeter to zero by pushing the

“RST” button for at least two sec-

onds. Resetting the distance-compensation

tripmeter in combination with the stop-watch1. Stop the stopwatch.

2. Reset the distance-compensation

tripmeter and the stopwatch to

zero by pushing the “RST” button

for at least two seconds.

1DX-9-E1.book 6 ページ 2012年7月31日 火曜日 午前9時31分

Page 30 of 98

INSTRUMENT AND CONTROL FUNCTIONS

3-15

1

23

4

5

6

7

8

9each fork leg in direction (b).

TIPAlthough the total number of clicks of a

damping force adjusting mechanism

may not exactly match the above spec-

ifications due to small differences in

production, the actual number of clicks

always represents the entire adjusting range. To obtain a precise adjustment,

it would be advisable to check the num-

ber of clicks of each damping force ad-

justing mechanism and to modify the

specifications as necessary.

EAU14793

Front fork bleeding

WARNING

EWA10200

Always bleed both fork legs, other-

wise poor handling and loss of sta-bility may result.

When riding in extremely rough condi-

tions, the air temperature and pressure

in the front fork will rise. This will in-

crease the spring preload and harden

the front suspension. If this occurs,

bleed the front fork as follows.

1. Lift the front wheel off the ground according to the procedure on

page 6-36.TIPWhen bleeding the front fork, there

should be no weight on the front end ofthe vehicle.

2. Remove the bleed screws and al- low all of the air to escape from

each fork leg.

1. Compression damping force adjusting screwCompression damping setting:Minimum (soft):

20 click(s) in direction (b)*

Standard: 14 click(s) in direction (b)*

Maximum (hard): 0 click(s) in direction (b)*

* With the adjusting screw fully turned

in direction (a)

(a)(b)

1

1DX-9-E1.book 15 ページ 2012年7月31日 火曜日 午前9時31分

Page 31 of 98

INSTRUMENT AND CONTROL FUNCTIONS

3-16

234

5

6

7

8

9

3. Install the bleed screws.

4. Lower the front wheel so that it is

on the ground, and then put the

sidestand down.

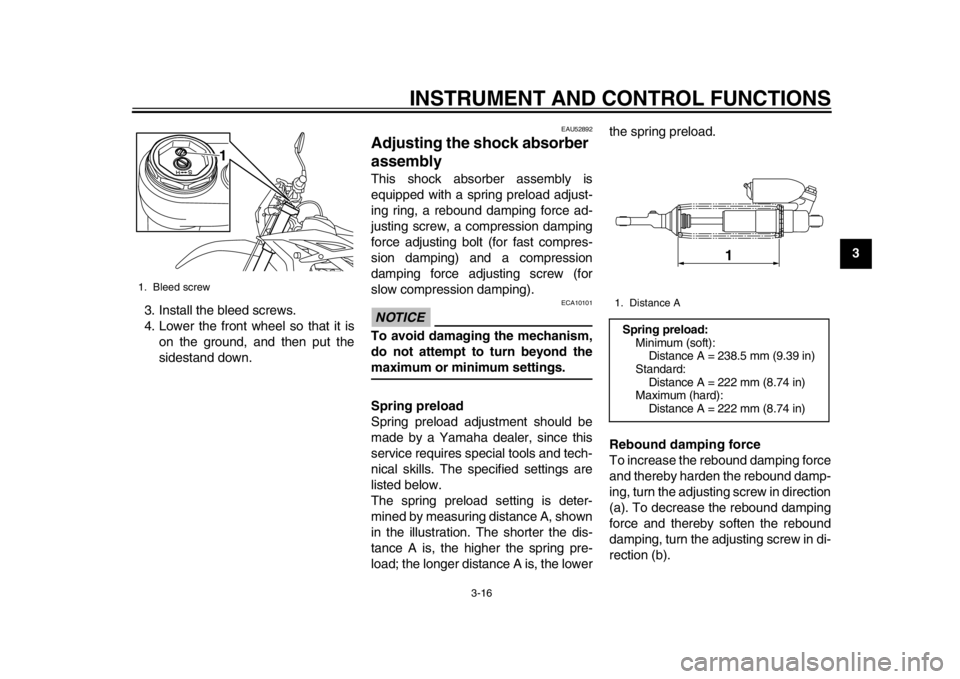

EAU52892

Adjusting the shock absorber

assembly This shock absorber assembly is

equipped with a spring preload adjust-

ing ring, a rebound damping force ad-

justing screw, a compression damping

force adjusting bolt (for fast compres-

sion damping) and a compression

damping force adjusting screw (for

slow compression damping).NOTICE

ECA10101

To avoid damaging the mechanism,

do not attempt to turn beyond themaximum or minimum settings.

Spring preload

Spring preload adjustment should be

made by a Yamaha dealer, since this

service requires special tools and tech-

nical skills. The specified settings are

listed below.

The spring preload setting is deter-

mined by measuring distance A, shown

in the illustration. The shorter the dis-

tance A is, the higher the spring pre-

load; the longer distance A is, the lower the spring preload.

Rebound damping force

To increase the rebound damping force

and thereby harden the rebound damp-

ing, turn the adjusting screw in direction

(a). To decrease the rebound damping

force and thereby soften the rebound

damping, turn the adjusting screw in di-

rection (b).

1. Bleed screw

1

1. Distance ASpring preload:

Minimum (soft):

Distance A = 238.5 mm (9.39 in)

Standard: Distance A = 222 mm (8.74 in)

Maximum (hard): Distance A = 222 mm (8.74 in)

1

1DX-9-E1.book 16 ページ 2012年7月31日 火曜日 午前9時31分

Page 37 of 98

FOR YOUR SAFETY – PRE-OPERATION CHECKS

4-2

2

345

6

7

8

9

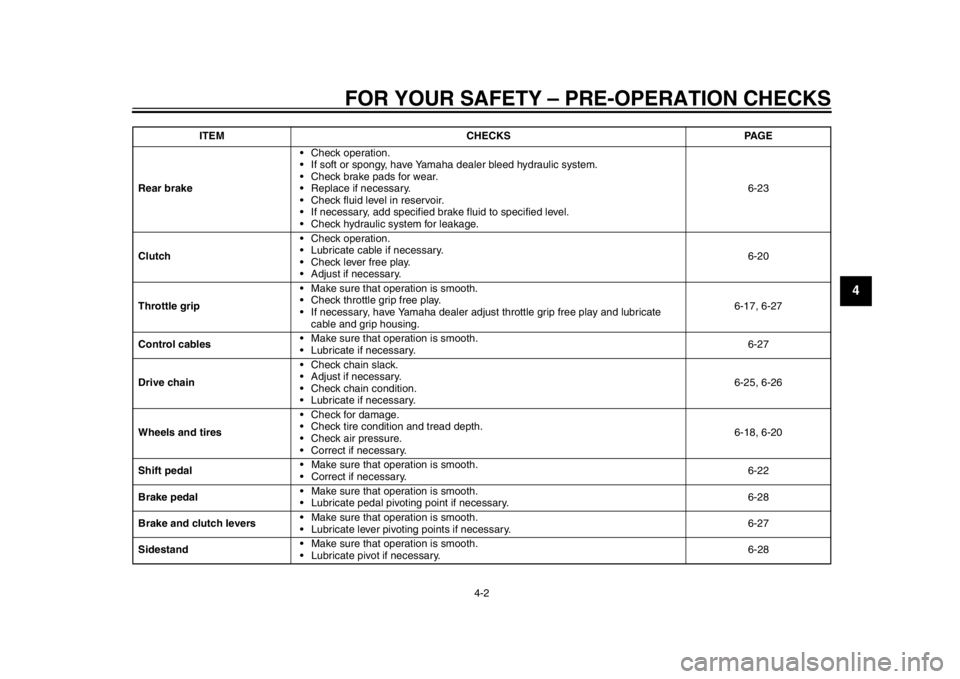

Rear brake Check operation.

If soft or spongy, have Yamaha dealer bleed hydraulic system.

Check brake pads for wear.

Replace if necessary.

Check fluid level in reservoir.

If necessary, add specified brak

e fluid to specified level.

Check hydraulic system for leakage. 6-23

Clutch Check operation.

Lubricate cable if necessary.

Check lever free play.

Adjust if necessary. 6-20

Throttle grip Make sure that operation is smooth.

Check throttle grip free play.

If necessary, have Yamaha dealer adjust

throttle grip free play and lubricate

cable and grip housing. 6-17, 6-27

Control cables Make sure that operation is smooth.

Lubricate if necessary. 6-27

Drive chain Check chain slack.

Adjust if necessary.

Check chain condition.

Lubricate if necessary. 6-25, 6-26

Wheels and tires Check for damage.

Check tire condition and tread depth.

Check air pressure.

Correct if necessary. 6-18, 6-20

Shift pedal Make sure that operation is smooth.

Correct if necessary. 6-22

Brake pedal Make sure that operation is smooth.

Lubricate pedal pivoting point if necessary. 6-28

Brake and clutch levers Make sure that operation is smooth.

Lubricate lever pivoting

points if necessary. 6-27

Sidestand Make sure that operation is smooth.

Lubricate pivot if necessary. 6-28

ITEM CHECKS PAGE

1DX-9-E1.book 2 ページ 2012年7月31日 火曜日 午前9時31分

Page 47 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-4

2

3

4

567

8

9

EAU52581

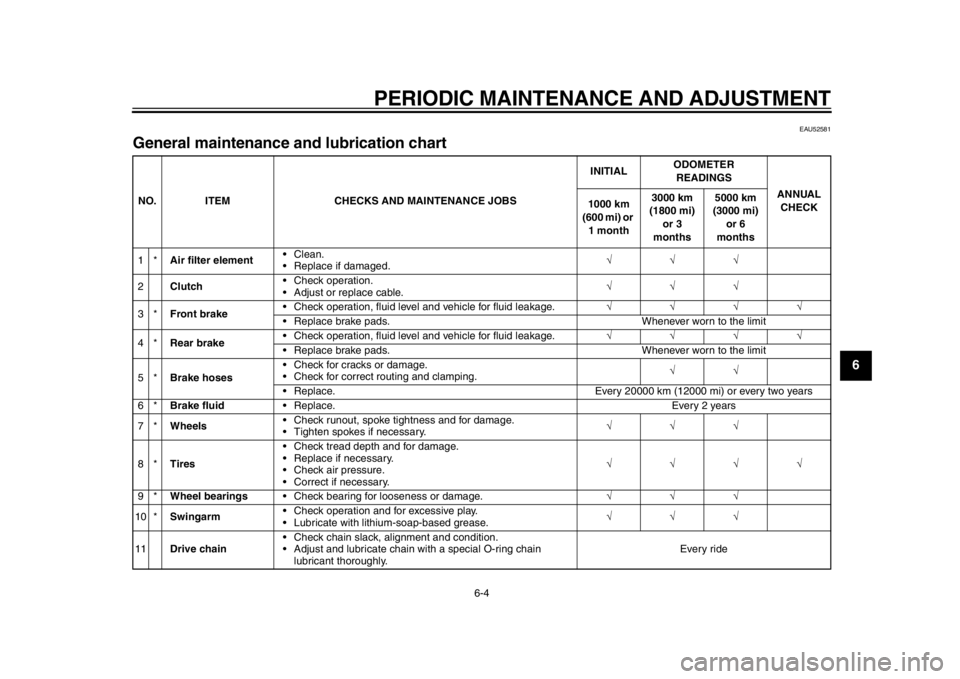

General maintenance and lubrication chart NO. ITEM CHECKS AND MAINTENANCE JOBS INITIAL

ODOMETER

READINGS

ANNUAL CHECK

1000 km

(600 mi) or 1 month 3000 km

(1800 mi) or 3

months 5000 km

(3000 mi) or 6

months

1* Air filter element Clean.

Replace if damaged.

2 Clutch Check operation.

Adjust or replace cable.

3* Front brake Check operation, fluid level

and vehicle for fluid leakage.

Replace brake pads. Whenever worn to the limit

4* Rear brake Check operation, fluid level

and vehicle for fluid leakage.

Replace brake pads. Whenever worn to the limit

5* Brake hoses Check for cracks or damage.

Check for correct routing and clamping.

Replace. Every 20000 km (12000 mi) or every two years

6* Brake fluid Replace. Every 2 years

7* Wheels Check runout, spoke tightness and for damage.

Tighten spokes if necessary.

8* Tires Check tread depth and for damage.

Replace if necessary.

Check air pressure.

Correct if necessary.

9* Wheel bearings Check bearing for looseness or damage.

10 * Swingarm Check operation and for excessive play.

Lubricate with lithium-soap-based grease.

11 Drive chain Check chain slack, alignment and condition.

Adjust and lubricate chain with a special O-ring chain

lubricant thoroughly. Every ride

1DX-9-E1.book 4 ページ 2012年7月31日 火曜日 午前9時31分

Page 62 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-19

1

2

3

4

56

7

8

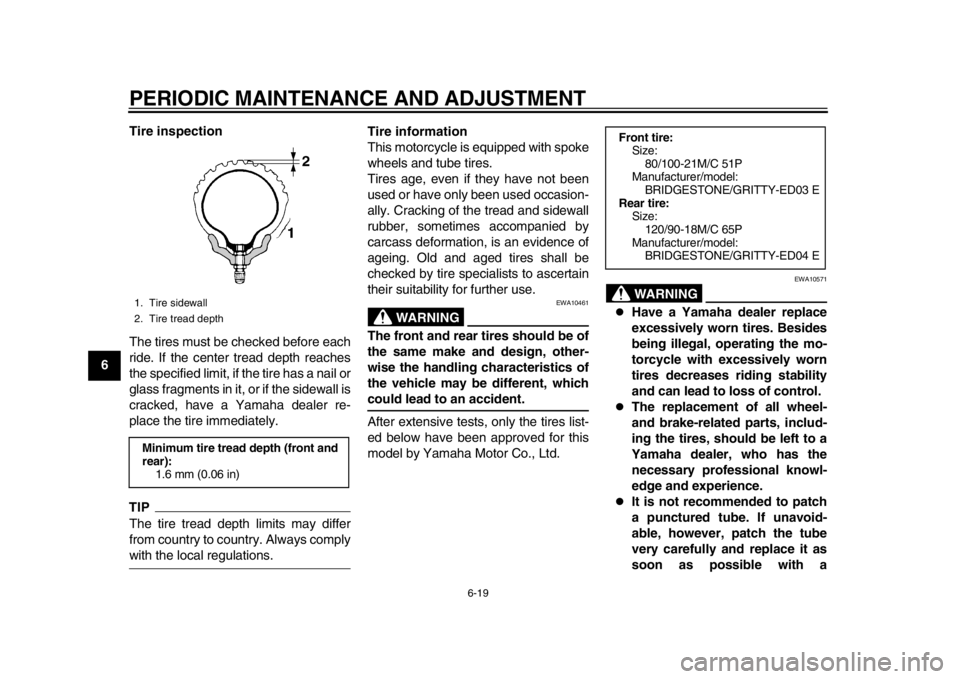

9Tire inspection

The tires must be checked before each

ride. If the center tread depth reaches

the specified limit, if the tire has a nail or

glass fragments in it, or if the sidewall is

cracked, have a Yamaha dealer re-

place the tire immediately.

TIPThe tire tread depth limits may differ

from country to country. Always complywith the local regulations. Tire information

This motorcycle is equipped with spoke

wheels and tube tires.

Tires age, even if they have not been

used or have only been used occasion-

ally. Cracking of the tread and sidewall

rubber, sometimes accompanied by

carcass deformation, is an evidence of

ageing. Old and aged tires shall be

checked by tire specialists to ascertain

their suitability for further use.

WARNING

EWA10461

The front and rear tires should be of

the same make and design, other-

wise the handling characteristics of

the vehicle may be different, whichcould lead to an accident.

After extensive tests, only the tires list-

ed below have been approved for this

model by Yamaha Motor Co., Ltd.

WARNING

EWA10571

Have a Yamaha dealer replace

excessively worn tires. Besides

being illegal, operating the mo-

torcycle with excessively worn

tires decreases riding stability

and can lead to loss of control.

The replacement of all wheel-

and brake-related parts, includ-

ing the tires, should be left to a

Yamaha dealer, who has the

necessary professional knowl-

edge and experience.

It is not recommended to patch

a punctured tube. If unavoid-

able, however, patch the tube

very carefully and replace it as

soon as possible with a

1. Tire sidewall

2. Tire tread depthMinimum tire tread depth (front and

rear):

1.6 mm (0.06 in)

Front tire: Size:80/100-21M/C 51P

Manufacturer/model:

BRIDGESTONE/GRITTY-ED03 E

Rear tire: Size:

120/90-18M/C 65P

Manufacturer/model: BRIDGESTONE/GRITTY-ED04 E

1DX-9-E1.book 19 ページ 2012年7月31日 火曜日 午前9時31分