ABS YAMAHA WR 450F 2016 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: WR 450F, Model: YAMAHA WR 450F 2016Pages: 426, PDF Size: 10.86 MB

Page 107 of 426

PRE-OPERATION INSPECTION AND MAINTENANCE

3-9

EAS2GC1079

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating

condition.

Before using this machine, check the following points.

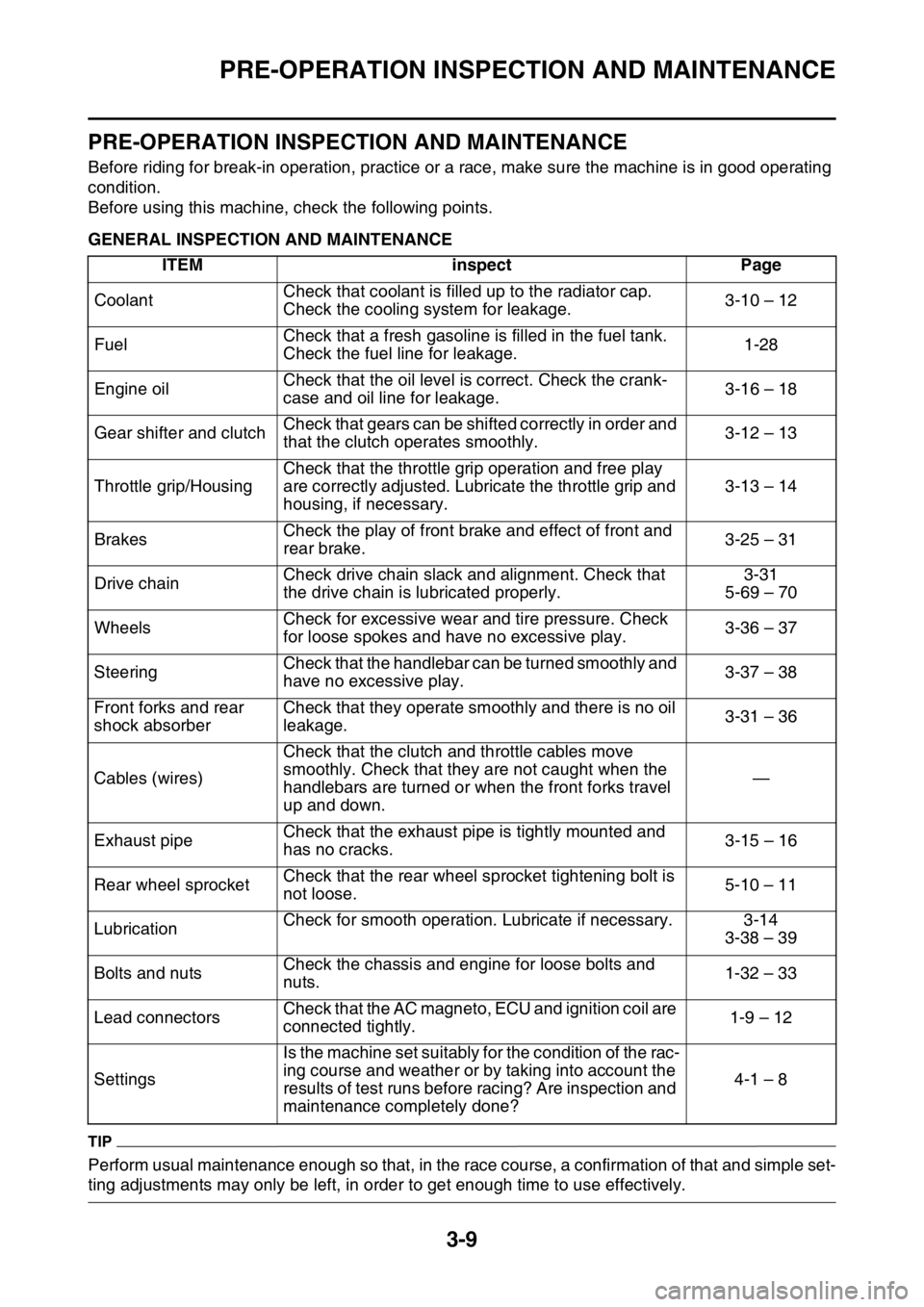

EAS2GC1080GENERAL INSPECTION AND MAINTENANCE

TIP

Perform usual maintenance enough so that, in the race course, a confirmation of that and simple set-

ting adjustments may only be left, in order to get enough time to use effectively.ITEM inspect Page

Coolant Check that coolant is filled up to the radiator cap.

Check the cooling system for leakage. 3-10 – 12

Fuel Check that a fresh gasoline is filled in the fuel tank.

Check the fuel line for leakage. 1-28

Engine oil Check that the oil level is correct. Check the crank-

case and oil line for leakage. 3-16 – 18

Gear shifter and clutch Check that gears can be shifted correctly in order and

that the clutch operates smoothly. 3-12 – 13

Throttle grip/Housing Check that the throttle grip operation and free play

are correctly adjusted. Lubricate the throttle grip and

housing, if necessary. 3-13 – 14

Brakes Check the play of front brake and effect of front and

rear brake. 3-25 – 31

Drive chain Check drive chain slack and alignment. Check that

the drive chain is lubricated properly. 3-31

5-69 – 70

Wheels Check for excessive wear and tire pressure. Check

for loose spokes and have no excessive play. 3-36 – 37

Steering Check that the handlebar can be turned smoothly and

have no excessive play. 3-37 – 38

Front forks and rear

shock absorber Check that they operate smoothly and there is no oil

leakage.

3-31 – 36

Cables (wires) Check that the clutch and throttle cables move

smoothly. Check that they are not caught when the

handlebars are turned or when the front forks travel

up and down.

—

Exhaust pipe Check that the exhaust pipe is tightly mounted and

has no cracks. 3-15 – 16

Rear wheel sprocket Check that the rear wheel sprocket tightening bolt is

not loose. 5-10 – 11

Lubrication Check for smooth operation. Lubricate if necessary. 3-14

3-38 – 39

Bolts and nuts Check the chassis and engine for loose bolts and

nuts. 1-32 – 33

Lead connectors Check that the AC magneto, ECU and ignition coil are

connected tightly. 1-9 – 12

Settings Is the machine set suitably for the condition of the rac-

ing course and weather or by taking into account the

results of test runs before racing? Are inspection and

maintenance completely done?

4-1 – 8

Page 132 of 426

CHASSIS

3-34

EAS2GC1116CHECKING THE SWINGARM OPERATION

1. Check:• Swingarm smooth action

• Swingarm free playRefer to “SWINGARM” on page 5-65.

EAS2GC1117CHECKING THE REAR SUSPENSION

1. Stand the vehicle upright on a level surface.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Check:• Rear shock absorber assemblyGas leaks/oil leaks Replace the rear

shock absorber assembly.

Refer to “REAR SHOCK ABSORBER AS-

SEMBLY” on page 5-58.

3. Check: • Rear shock absorber assembly smooth ac-tion

• Rear suspension link smooth action Sit astride the seat and shake your body up

and down several times to check whether

the rear shock absorber assembly operates

smoothly.

Unsmooth operation Correct or replace.

Refer to “REAR SHOCK ABSORBER AS-

SEMBLY” on page 5-58.

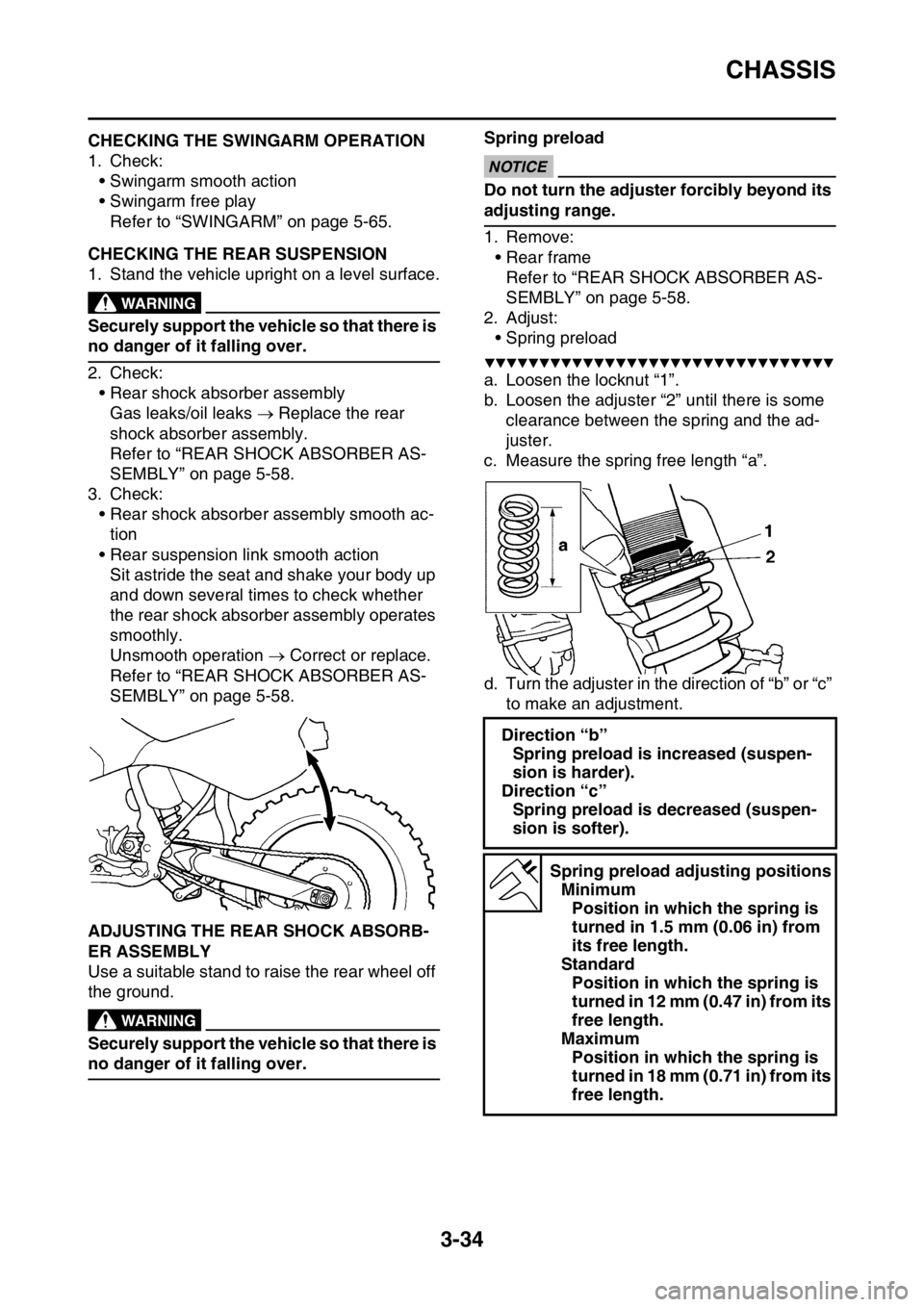

EAS2GC1118ADJUSTING THE REAR SHOCK ABSORB-

ER ASSEMBLY

Use a suitable stand to raise the rear wheel off

the ground.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over. Spring preload

ECA

NOTICE

Do not turn the adjuster forcibly beyond its

adjusting range.

1. Remove:

• Rear frameRefer to “REAR SHOCK ABSORBER AS-

SEMBLY” on page 5-58.

2. Adjust: • Spring preload

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Loosen the locknut “1”.

b. Loosen the adjuster “2” until there is some clearance between the spring and the ad-

juster.

c. Measure the spring free length “a”.

d. Turn the adjuster in the direction of “b” or “c” to make an adjustment.

Direction “b”Spring preload is increased (suspen-

sion is harder).

Direction “c” Spring preload is decreased (suspen-

sion is softer).

Spring preload adjusting positionsMinimum Position in which the spring is

turned in 1.5 mm (0.06 in) from

its free length.

Standard Position in which the spring is

turned in 12 mm (0.47 in) from its

free length.

Maximum Position in which the spring is

turned in 18 mm (0.71 in) from its

free length.

Page 133 of 426

CHASSIS

3-35

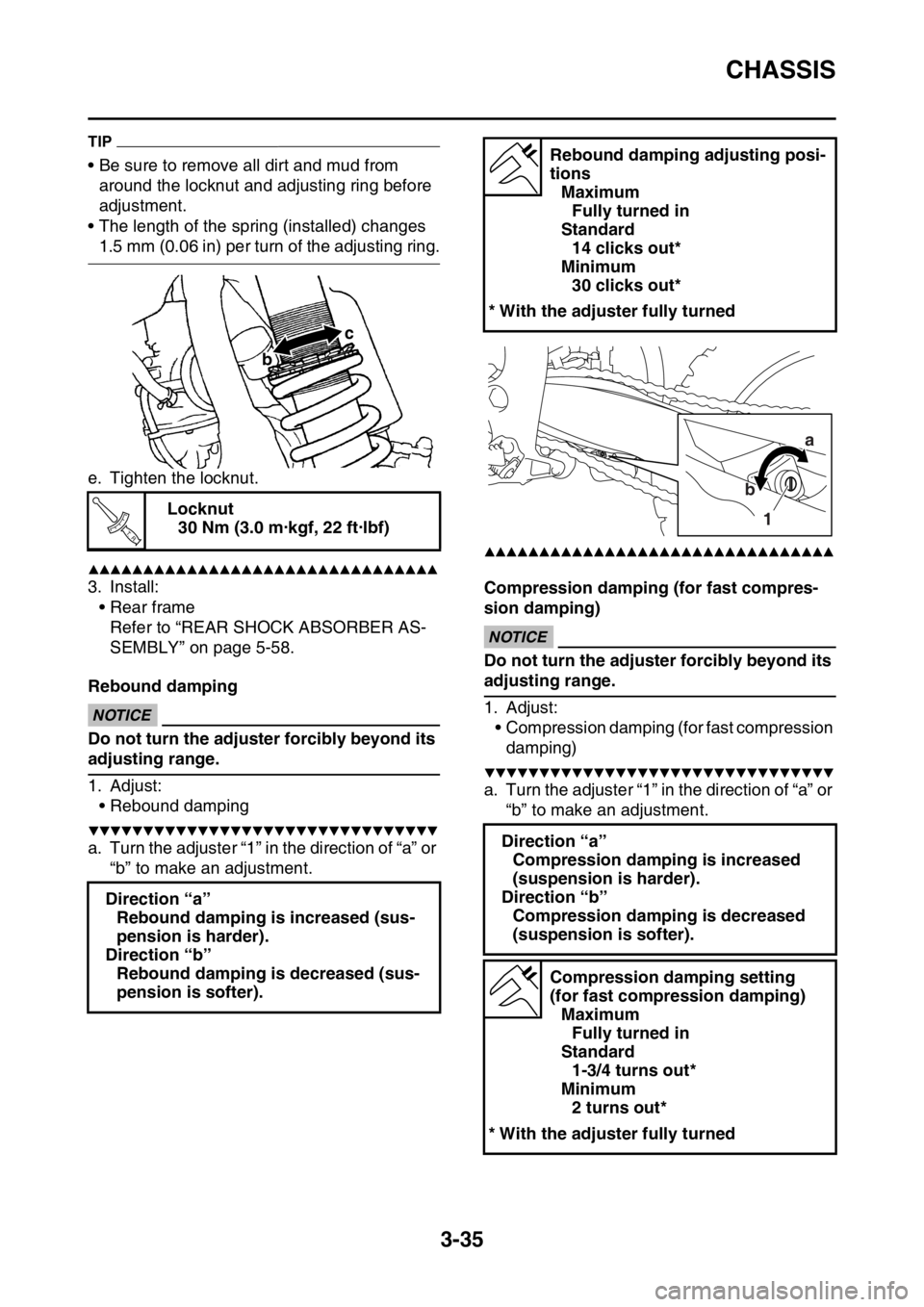

TIP

• Be sure to remove all dirt and mud from around the locknut and adjusting ring before

adjustment.

• The length of the spring (installed) changes

1.5 mm (0.06 in) per turn of the adjusting ring.

e. Tighten the locknut.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

3. Install: • Rear frameRefer to “REAR SHOCK ABSORBER AS-

SEMBLY” on page 5-58.

Rebound damping

ECA

NOTICE

Do not turn the adjuster forcibly beyond its

adjusting range.

1. Adjust: • Rebound damping

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the adjuster “1” in the direction of “a” or “b” to make an adjustment.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Compression damping (for fast compres-

sion damping)

ECA

NOTICE

Do not turn the adjuster forcibly beyond its

adjusting range.

1. Adjust:

• Compression damping (for fast compression damping)

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the adjuster “1” in the direction of “a” or “b” to make an adjustment.

Locknut

30 Nm (3.0 m·kgf, 22 ft·lbf)

Direction “a” Rebound damping is increased (sus-

pension is harder).

Direction “b” Rebound damping is decreased (sus-

pension is softer).

c

b

T R..

Rebound damping adjusting posi-

tions Maximum Fully turned in

Standard 14 clicks out*

Minimum 30 clicks out*

* With the adjuster fully turned

Direction “a”Compression damping is increased

(suspension is harder).

Direction “b” Compression damping is decreased

(suspension is softer).

Compression damping setting

(for fast compression damping)Maximum Fully turned in

Standard 1-3/4 turns out*

Minimum 2 turns out*

* With the adjuster fully turned

a

b

1

Page 141 of 426

4

TUNING

CHASSIS.......................................................................................................... 4-1

SELECTION OF THE SECONDARY REDUCTION RATIO

(SPROCKET) ............................................................................................ 4-1

DRIVE AND REAR WHEEL SPROCKETS SETTING PARTS .................. 4-1

TIRE PRESSURE............................. .......................................................... 4-1

FRONT FORK SETTING............................................................................ 4-2

CHANGE IN AMOUNT AND CHARACTERISTICS OF FORK OIL............ 4-2

SETTING OF SPRING AFTER REPLACEMENT ...................................... 4-2

FRONT FORK SETTING PARTS............................................................... 4-3

REAR SUSPENSION SETTING ................................................................ 4-3

CHOOSING SET LENGTH ........................................................................ 4-3

SETTING OF SPRING AFTER REPLACEMENT ...................................... 4-4

REAR SHOCK ABSORBER SETT ING PARTS ......................................... 4-4

SUSPENSION SETTING (FRONT FORK)................................................. 4-6

SUSPENSION SETTING (REAR SHOCK ABSORBER) ........................... 4-7

Page 144 of 426

CHASSIS

4-3

TIP

Generally a stiff spring gives a stiff riding feel-

ing. Rebound damping tends to become weak-

er, resulting in lack of a sense of contact with

the road surface or in a vibrating handlebar.

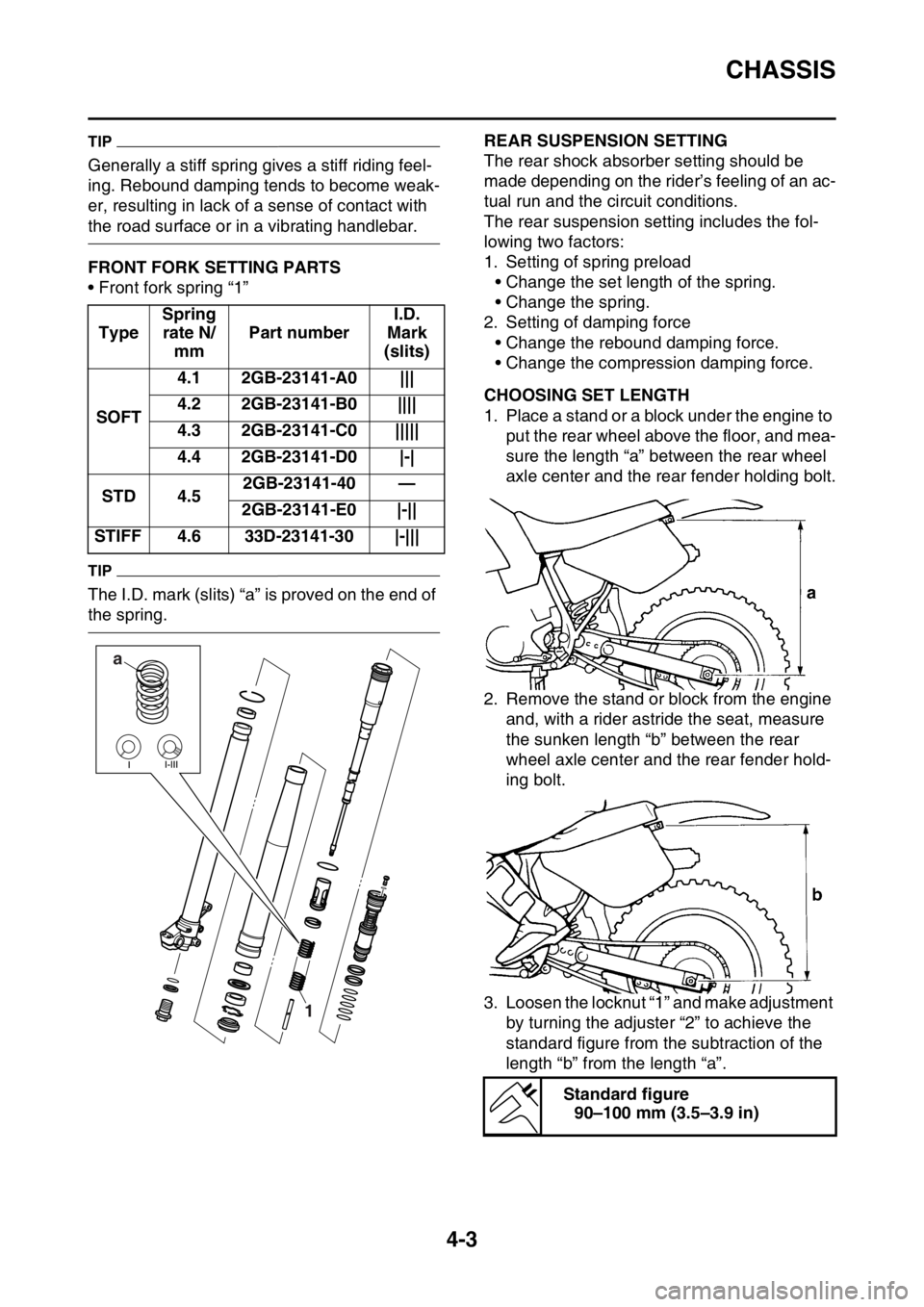

EAS2GC1143FRONT FORK SETTING PARTS

• Front fork spring “1”

TIP

The I.D. mark (slits) “a” is proved on the end of

the spring.

EAS2GC1144REAR SUSPENSION SETTING

The rear shock absorber setting should be

made depending on the rider’s feeling of an ac-

tual run and the circuit conditions.

The rear suspension setting includes the fol-

lowing two factors:

1. Setting of spring preload • Change the set length of the spring.

• Change the spring.

2. Setting of damping force

• Change the rebound damping force.

• Change the compression damping force.

EAS2GC1145CHOOSING SET LENGTH

1. Place a stand or a block under the engine to put the rear wheel above the floor, and mea-

sure the length “a” between the rear wheel

axle center and the rear fender holding bolt.

2. Remove the stand or block from the engine and, with a rider astride the seat, measure

the sunken length “b” between the rear

wheel axle center and the rear fender hold-

ing bolt.

3. Loosen the locknut “1” and make adjustment by turning the adjuster “2” to achieve the

standard figure from the subtraction of the

length “b” from the length “a”.

Type

Spring

rate N/ mm Part number I.D.

Mark

(slits)

SOFT 4.1 2GB-23141-A0 |||

4.2 2GB-23141-B0 ||||

4.3 2GB-23141-C0 |||||

4.4 2GB-23141-D0 |-|

STD 4.5 2GB-23141-40 —

2GB-23141-E0 |-||

STIFF 4.6 33D-23141-30 |-|||

a

1

Standard figure90–100 mm (3.5–3.9 in)

Page 145 of 426

CHASSIS

4-4

TIP

• If the machine is new and after it is broken in, the same set length of the spring may change

because of the initial fatigue, etc. of the

spring. Therefore, be sure to make reevalua-

tion.

• If the standard figure cannot be achieved by adjusting the adjuster and changing the set

length, replace the spri ng with an optional one

and make readjustment.

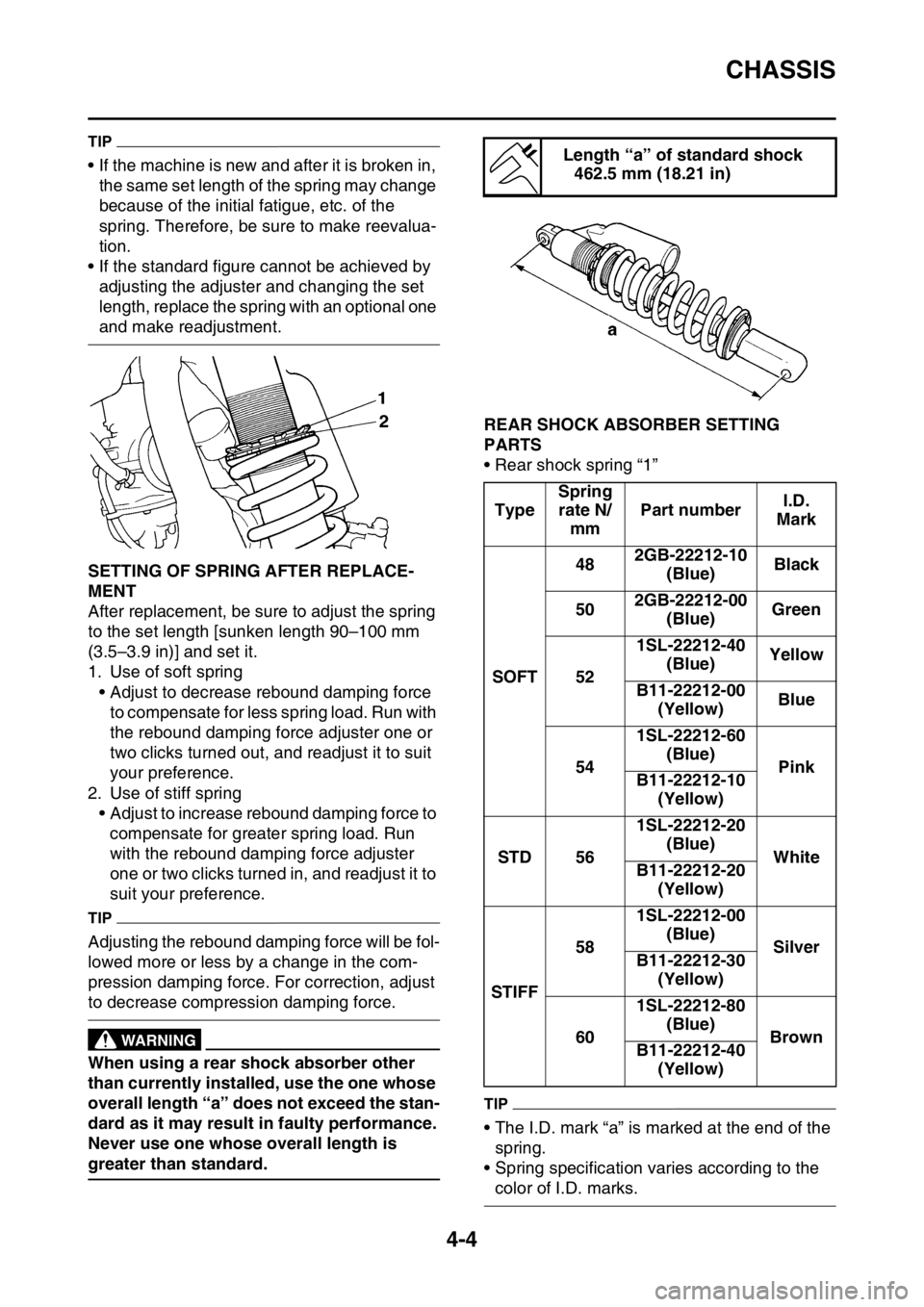

EAS2GC1146SETTING OF SPRING AFTER REPLACE-

MENT

After replacement, be sure to adjust the spring

to the set length [sunken length 90–100 mm

(3.5–3.9 in)] and set it.

1. Use of soft spring

• Adjust to decrease rebound damping force to compensate for less spring load. Run with

the rebound damping force adjuster one or

two clicks turned out, and readjust it to suit

your preference.

2. Use of stiff spring • Adjust to increase rebound damping force to

compensate for greater spring load. Run

with the rebound damping force adjuster

one or two clicks turned in, and readjust it to

suit your preference.

TIP

Adjusting the rebound damping force will be fol-

lowed more or less by a change in the com-

pression damping force. For correction, adjust

to decrease compression damping force.

EWA

WARNING

When using a rear shock absorber other

than currently installed, use the one whose

overall length “a” does not exceed the stan-

dard as it may result in faulty performance.

Never use one whose overall length is

greater than standard.

EAS2GC1147REAR SHOCK ABSORBER SETTING

PARTS

• Rear shock spring “1”

TIP

• The I.D. mark “a” is marked at the end of the spring.

• Spring specification varies according to the

color of I.D. marks.

Length “a” of standard shock 462.5 mm (18.21 in)

Type Spring

rate N/ mm Part number

I.D.

Mark

SOFT 48

2GB-22212-10

(Blue) Black

50 2GB-22212-00

(Blue) Green

52 1SL-22212-40

(Blue) Yellow

B11-22212-00 (Yellow) Blue

54 1SL-22212-60

(Blue) Pink

B11-22212-10

(Yellow)

STD 56 1SL-22212-20

(Blue) White

B11-22212-20

(Yellow)

STIFF 58

1SL-22212-00

(Blue) Silver

B11-22212-30

(Yellow)

60 1SL-22212-80

(Blue) Brown

B11-22212-40

(Yellow)

Page 146 of 426

CHASSIS

4-5

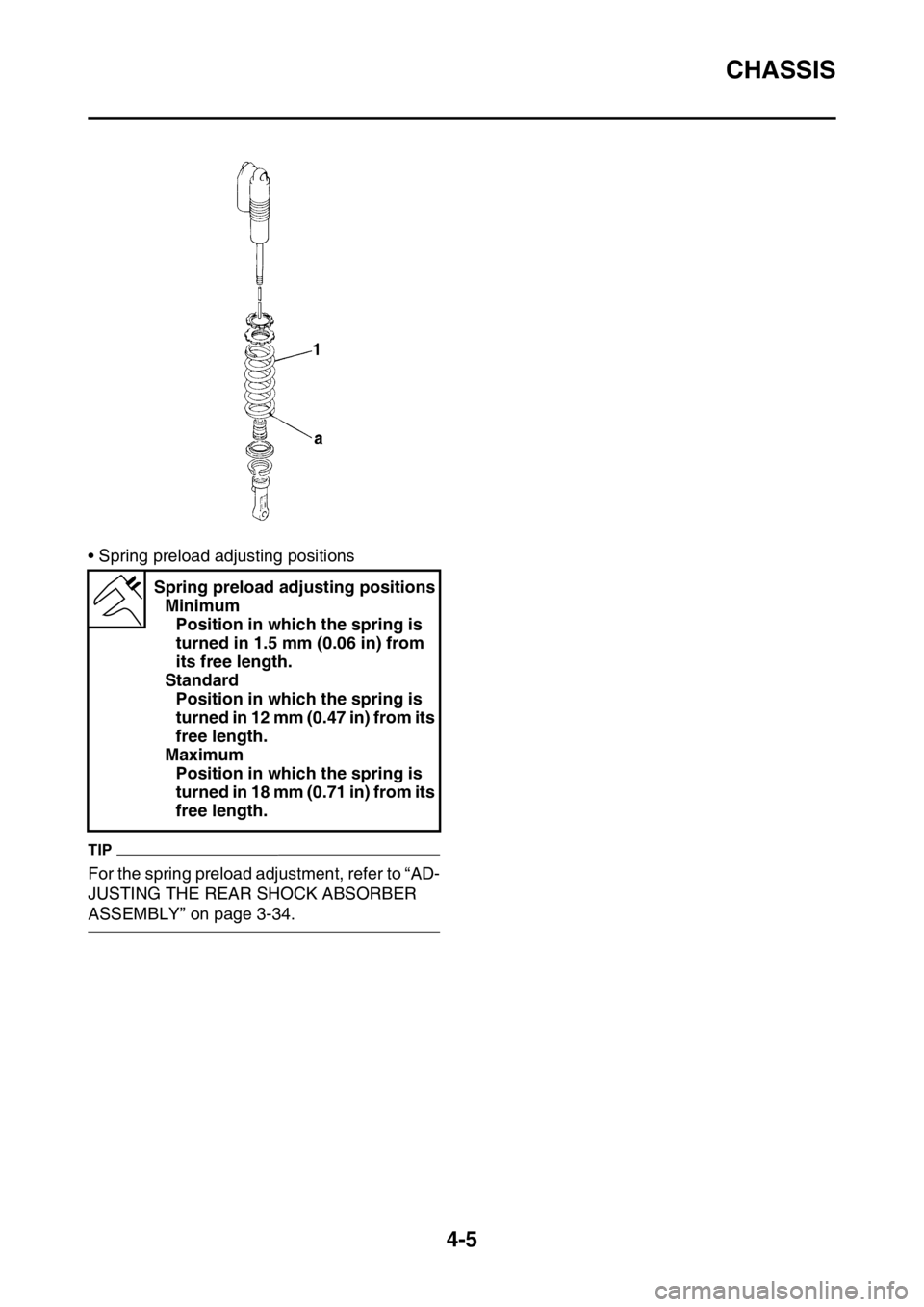

• Spring preload adjusting positions

TIP

For the spring preload adjustment, refer to “AD-

JUSTING THE REAR SHOCK ABSORBER

ASSEMBLY” on page 3-34.Spring preload adjusting positions

MinimumPosition in which the spring is

turned in 1.5 mm (0.06 in) from

its free length.

Standard Position in which the spring is

turned in 12 mm (0.47 in) from its

free length.

Maximum Position in which the spring is

turned in 18 mm (0.71 in) from its

free length.

Page 147 of 426

CHASSIS

4-6

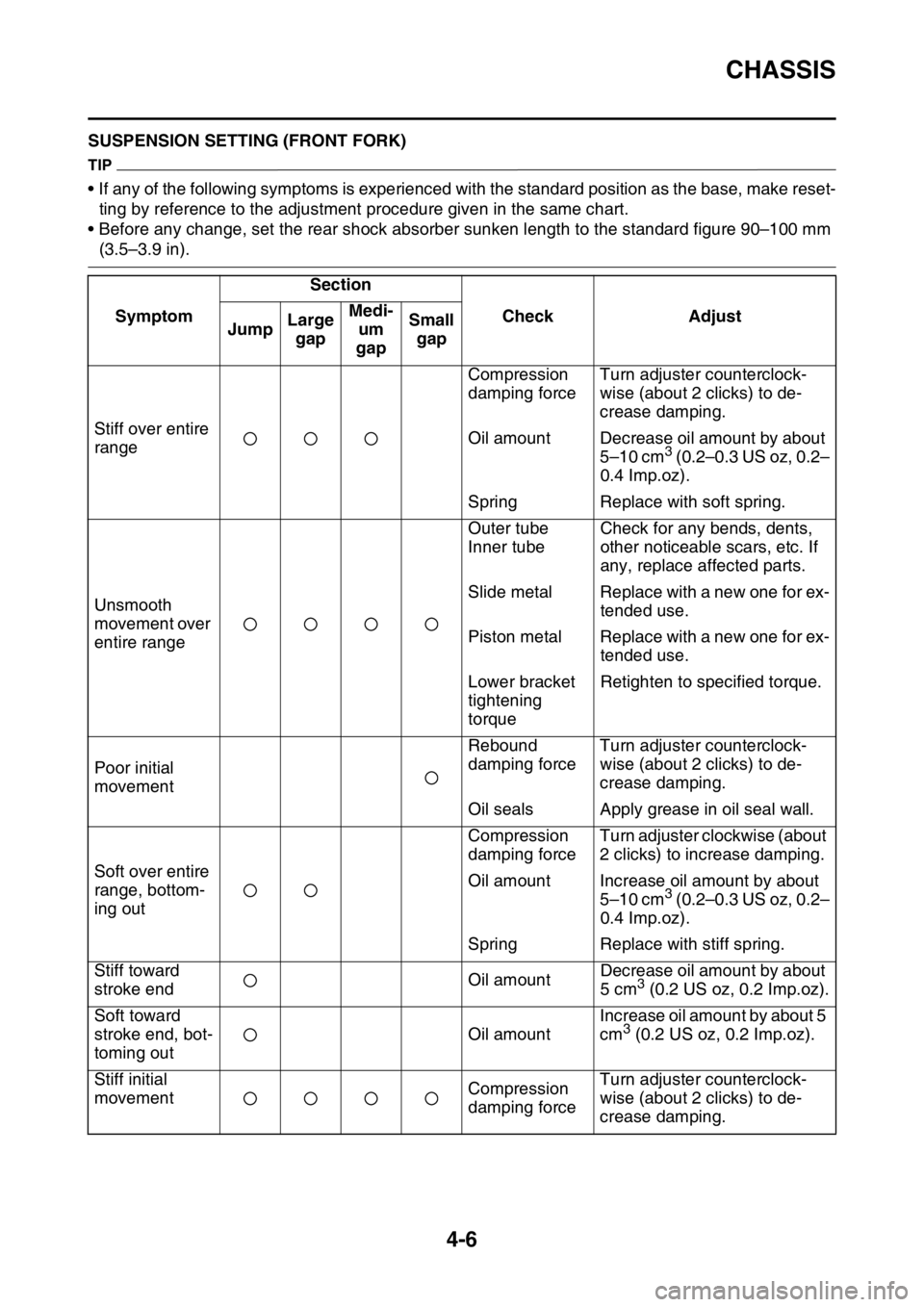

EAS2GC1148SUSPENSION SETTING (FRONT FORK)

TIP

• If any of the following symptoms is experienced with the standard position as the base, make reset-ting by reference to the adjustment procedure given in the same chart.

• Before any change, set the rear shock absor ber sunken length to the standard figure 90–100 mm

(3.5–3.9 in).

Symptom Section

CheckAdjust

Jump Large

gap Medi-

um

gap Small

gap

Stiff over entire

range Compression

damping force

Turn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Oil amount Decrease oil amount by about 5–10 cm

3 (0.2–0.3 US oz, 0.2–

0.4 Imp.oz).

Spring Replace with soft spring.

Unsmooth

movement over

entire range Outer tube

Inner tube

Check for any bends, dents,

other noticeable scars, etc. If

any, replace affected parts.

Slide metal Replace with a new one for ex- tended use.

Piston metal Replace with a new one for ex- tended use.

Lower bracket

tightening

torque Retighten to specified torque.

Poor initial

movement Rebound

damping force

Turn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Oil seals Apply grease in oil seal wall.

Soft over entire

range, bottom-

ing out Compression

damping force

Turn adjuster clockwise (about

2 clicks) to increase damping.

Oil amount Increase oil amount by about 5–10 cm

3 (0.2–0.3 US oz, 0.2–

0.4 Imp.oz).

Spring Replace with stiff spring.

Stiff toward

stroke end Oil amountDecrease oil amount by about

5 cm

3 (0.2 US oz, 0.2 Imp.oz).

Soft toward

stroke end, bot-

toming out Oil amountIncrease oil amount by about 5

cm

3 (0.2 US oz, 0.2 Imp.oz).

Stiff initial

movement Compression

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Page 148 of 426

CHASSIS

4-7

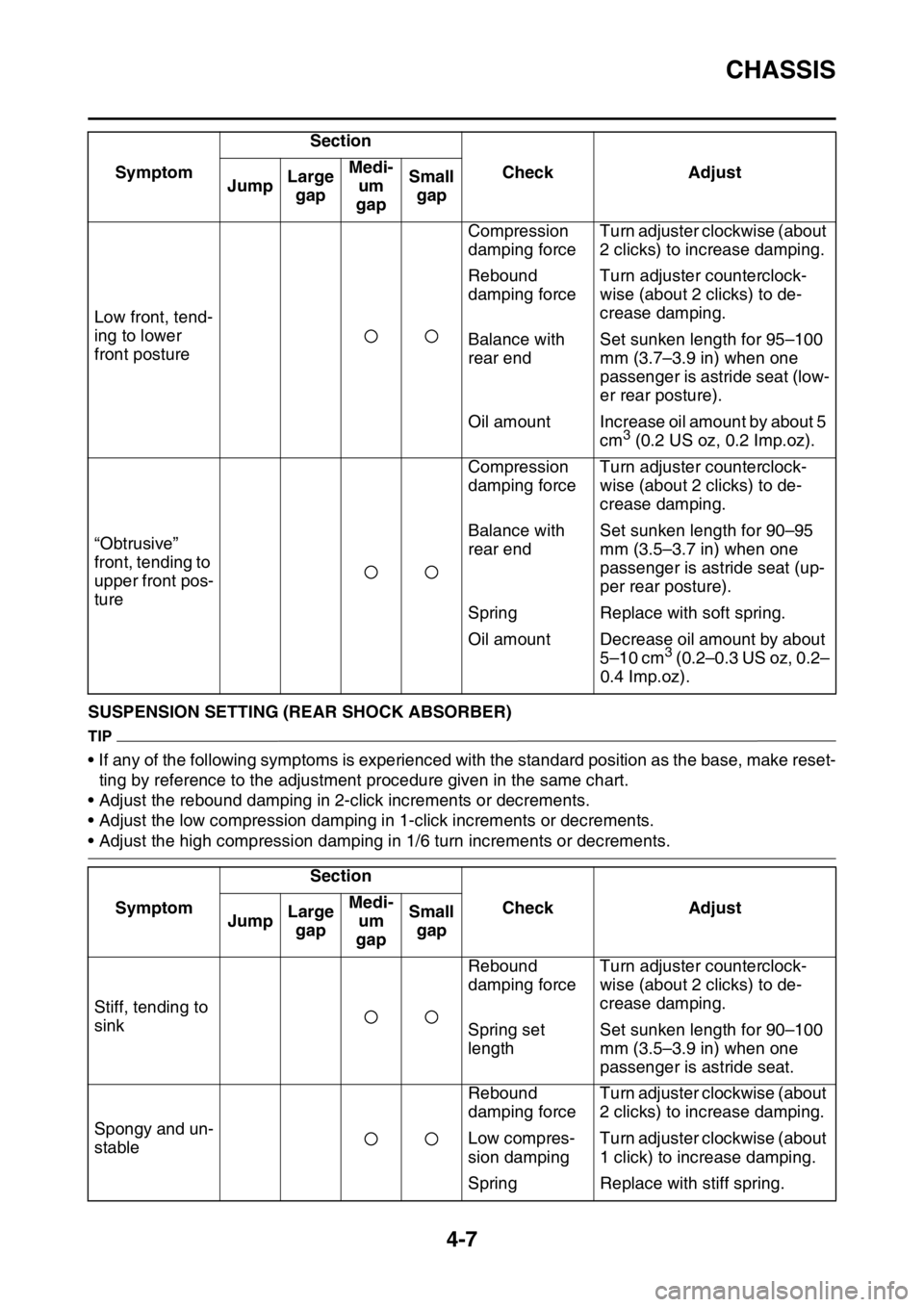

EAS2GC1149SUSPENSION SETTING (REAR SHOCK ABSORBER)

TIP

• If any of the following symptoms is experienced with the standard position as the base, make reset-ting by reference to the adjustment procedure given in the same chart.

• Adjust the rebound damping in 2- click increments or decrements.

• Adjust the low compression damping in 1-click increments or decrements.

• Adjust the high compression damping in 1/6 turn increments or decrements.Low front, tend-

ing to lower

front posture

Compression

damping force

Turn adjuster clockwise (about

2 clicks) to increase damping.

Rebound

damping force Turn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Balance with

rear end Set sunken length for 95–100

mm (3.7–3.9 in) when one

passenger is astride seat (low-

er rear posture).

Oil amount Increase oil amount by about 5 cm

3 (0.2 US oz, 0.2 Imp.oz).

“Obtrusive”

front, tending to

upper front pos-

ture Compression

damping force

Turn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Balance with

rear end Set sunken length for 90–95

mm (3.5–3.7 in) when one

passenger is astride seat (up-

per rear posture).

Spring Replace with soft spring.

Oil amount Decrease oil amount by about 5–10 cm

3 (0.2–0.3 US oz, 0.2–

0.4 Imp.oz).

Symptom Section

Check Adjust

Jump Large

gap Medi-

um

gap Small

gap

Stiff, tending to

sink Rebound

damping force

Turn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Spring set

length Set sunken length for 90–100

mm (3.5–3.9 in) when one

passenger is astride seat.

Spongy and un-

stable Rebound

damping force

Turn adjuster clockwise (about

2 clicks) to increase damping.

Low compres-

sion damping Turn adjuster clockwise (about

1 click) to increase damping.

Spring Replace with stiff spring.

Symptom

Section

Check Adjust

Jump Large

gap Medi-

um

gap Small

gap

Page 152 of 426

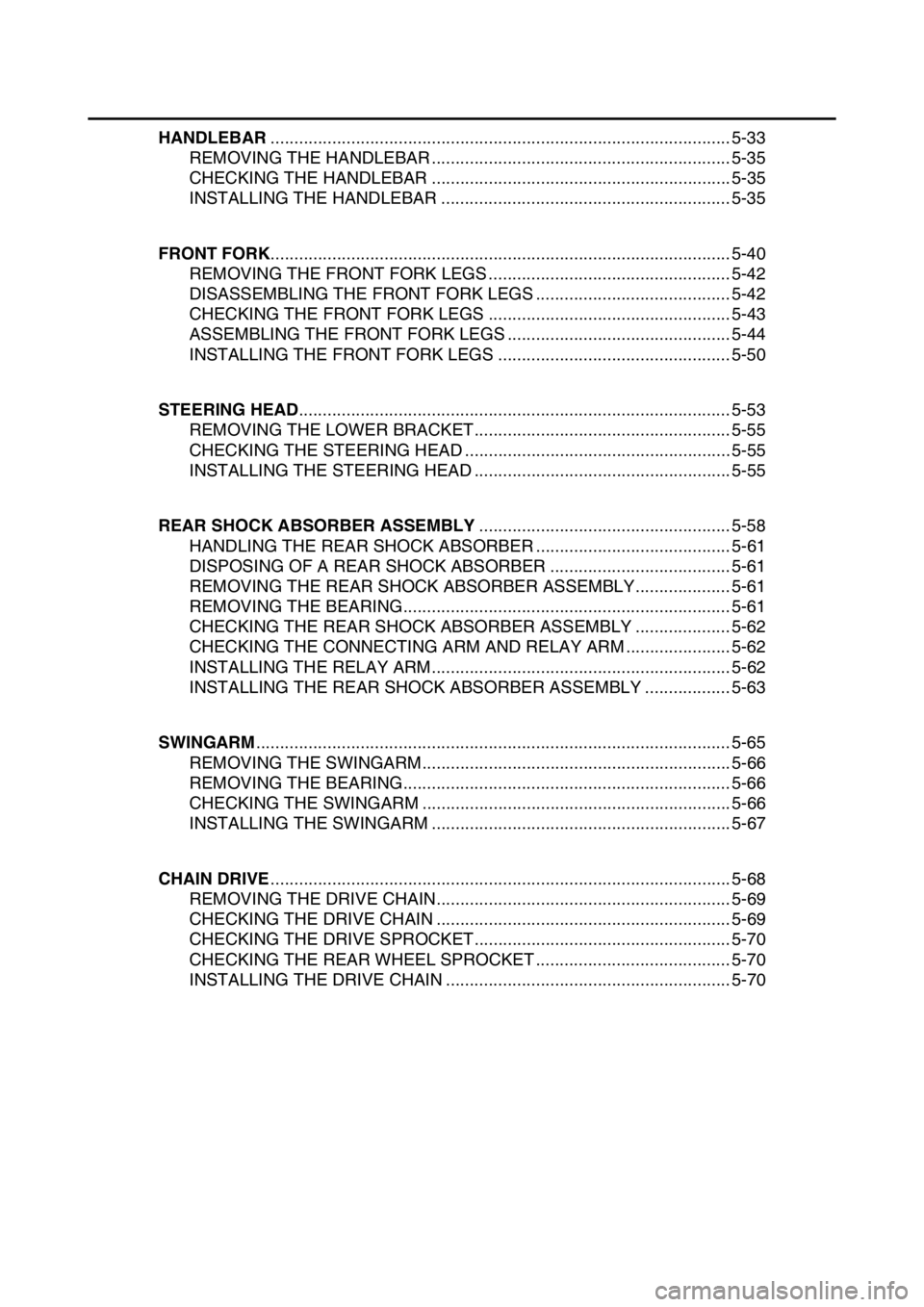

HANDLEBAR................................................................................................. 5-33

REMOVING THE HANDLEBAR ............................................................... 5-35

CHECKING THE HANDLEBAR ............................................................... 5-35

INSTALLING THE HANDLEBAR ............................................................. 5-35

FRONT FORK ................................................................................................. 5-40

REMOVING THE FRONT FORK LEGS ................................................... 5-42

DISASSEMBLING THE FRONT FO RK LEGS ......................................... 5-42

CHECKING THE FRONT FORK LEGS ................................................... 5-43

ASSEMBLING THE FRONT FORK LEGS ............................................... 5-44

INSTALLING THE FRONT FORK LEGS ................................................. 5-50

STEERING HEAD ........................................................................................... 5-53

REMOVING THE LOWER BRACKET...................................................... 5-55

CHECKING THE STEERING HEAD ........................................................ 5-55

INSTALLING THE STEERING HEAD ...................................................... 5-55

REAR SHOCK ABSORBER ASSEMBLY ..................................................... 5-58

HANDLING THE REAR SHOCK ABSORBER ......................................... 5-61

DISPOSING OF A REAR SH OCK ABSORBER ...................................... 5-61

REMOVING THE REAR SHOCK ABSORBER ASSEMBLY.................... 5-61

REMOVING THE BEARING..................................................................... 5-61

CHECKING THE REAR SHOCK ABSORBER ASSEMBLY .................... 5-62

CHECKING THE CONNECTING ARM AND RELAY ARM ...................... 5-62

INSTALLING THE RELAY ARM............................................................... 5-62

INSTALLING THE REAR SHOCK ABSORBER ASSEMBLY .................. 5-63

SWINGARM .................................................................................................... 5-65

REMOVING THE SWINGARM................................................................. 5-66

REMOVING THE BEARING..................................................................... 5-66

CHECKING THE SWINGARM ................................................................. 5-66

INSTALLING THE SWINGARM ............................................................... 5-67

CHAIN DRIVE ................................................................................................. 5-68

REMOVING THE DRIVE CHAIN.............................................................. 5-69

CHECKING THE DRIVE CHAIN .............................................................. 5-69

CHECKING THE DRIVE SPROCKET...................................................... 5-70

CHECKING THE REAR WHEEL SPROCKET ......................................... 5-70

INSTALLING THE DRIVE CHAIN ............................................................ 5-70