ABS YAMAHA WR 450F 2016 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: WR 450F, Model: YAMAHA WR 450F 2016Pages: 426, PDF Size: 10.86 MB

Page 169 of 426

FRONT BRAKE

5-17

EAS2GC1168INTRODUCTIONEWA

WARNING

If you need to disassemble the disc brake

components, observe the following precau-

tions.

• Never disassemble the brake components unless absolutely necessary.

• If there is any problem with connections on the hydraulic brake system, perform

the following jobs.

Disassemble the brake system, drain the

brake fluid, and clean it. After that, add a

suitable amount of brake fluid. Then, bleed

it after reassembly.

• Use only brake fluid for washing brake

components.

• Use new brake fluid for cleaning the brake components.

• Immediately wipe off the spilled brake fluid to avoid damage to painted surfaces or

plastic parts.

• Handle brake fluid with special care not to let it enter your eyes so that you may not

lost your eyesight.

• FIRST AID FOR BRAKE FLUID ENTERING THE EYES:

• Flush with water for 15 minutes and get

immediate medical attention.

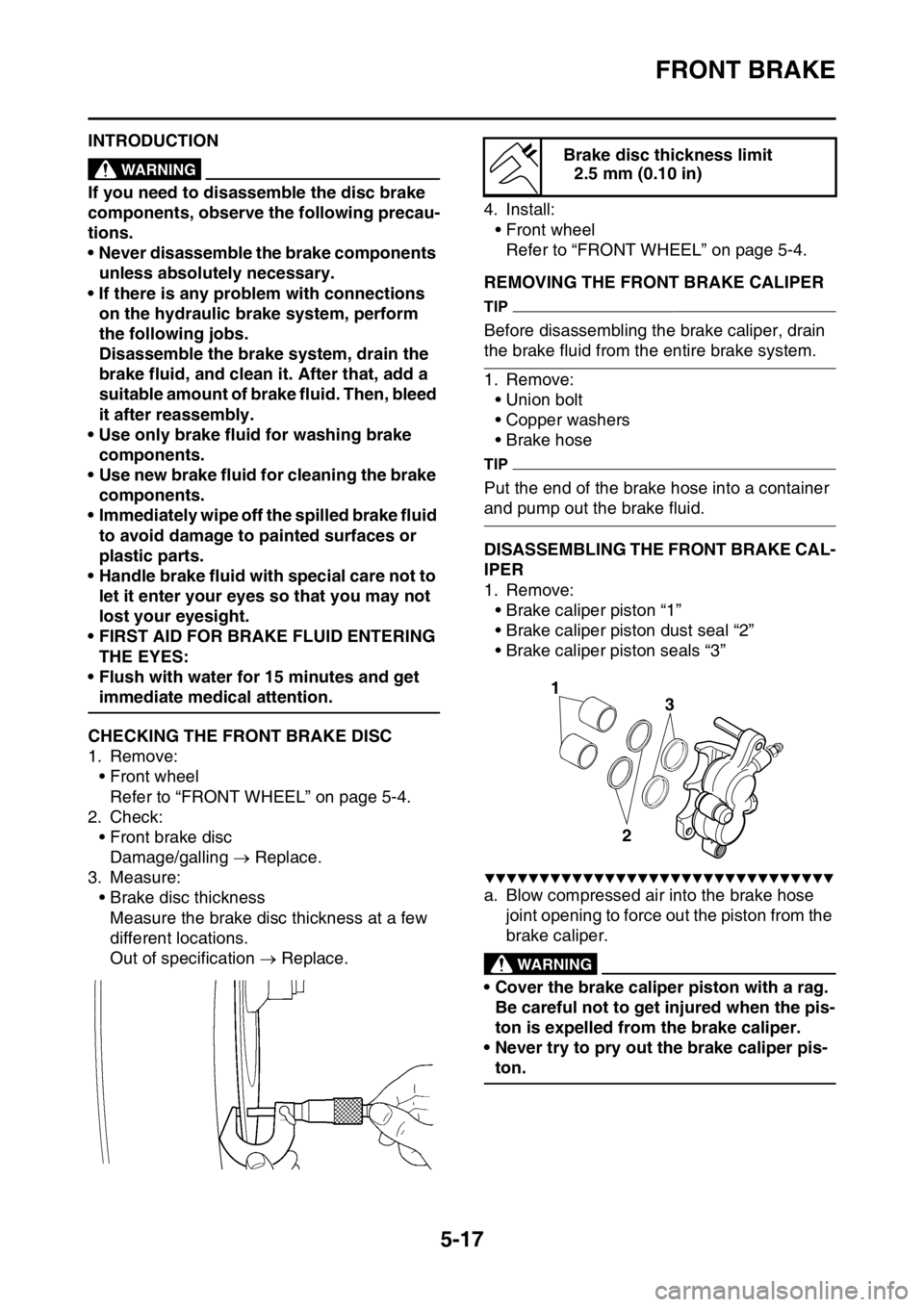

EAS2GC1169CHECKING THE FRONT BRAKE DISC

1. Remove: • Front wheel

Refer to “FRONT WHEEL” on page 5-4.

2. Check: • Front brake disc

Damage/galling Replace.

3. Measure: • Brake disc thickness

Measure the brake disc thickness at a few

different locations.

Out of specification Replace. 4. Install:

• Front wheelRefer to “FRONT WHEEL” on page 5-4.

EAS2GC1170REMOVING THE FRONT BRAKE CALIPER

TIP

Before disassembling the brake caliper, drain

the brake fluid from the entire brake system.

1. Remove:• Union bolt

• Copper washers

• Brake hose

TIP

Put the end of the brake hose into a container

and pump out the brake fluid.

EAS2GC1171DISASSEMBLING THE FRONT BRAKE CAL-

IPER

1. Remove:• Brake caliper piston “1”

• Brake caliper piston dust seal “2”

• Brake caliper piston seals “3”

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Blow compressed air into the brake hose

joint opening to force out the piston from the

brake caliper.

EWA

WARNING

• Cover the brake caliper piston with a rag. Be careful not to get injured when the pis-

ton is expelled from the brake caliper.

• Never try to pry out the brake caliper pis-

ton.

Brake disc thickness limit 2.5 mm (0.10 in)

3

2

1

Page 179 of 426

REAR BRAKE

5-27

EAS2GC1181INTRODUCTIONEWA

WARNING

If you need to disassemble the disc brake

components, observe the following precau-

tions.

• Never disassemble the brake components unless absolutely necessary.

• If there is any problem with connections on the hydraulic brake system, perform

the following jobs.

Disassemble the brake system, drain the

brake fluid, and clean it. After that, add a

suitable amount of brake fluid. Then, bleed

it after reassembly.

• Use only brake fluid for washing internal

brake components.

• Use new brake fluid for cleaning the brake components.

• Immediately wipe off the spilled brake fluid to avoid damage to painted surfaces or

plastic parts.

• Handle brake fluid with special care not to let it enter your eyes so that you may not

lost your eyesight.

• FIRST AID FOR BRAKE FLUID ENTERING THE EYES:

• Flush with water for 15 minutes and get

immediate medical attention.

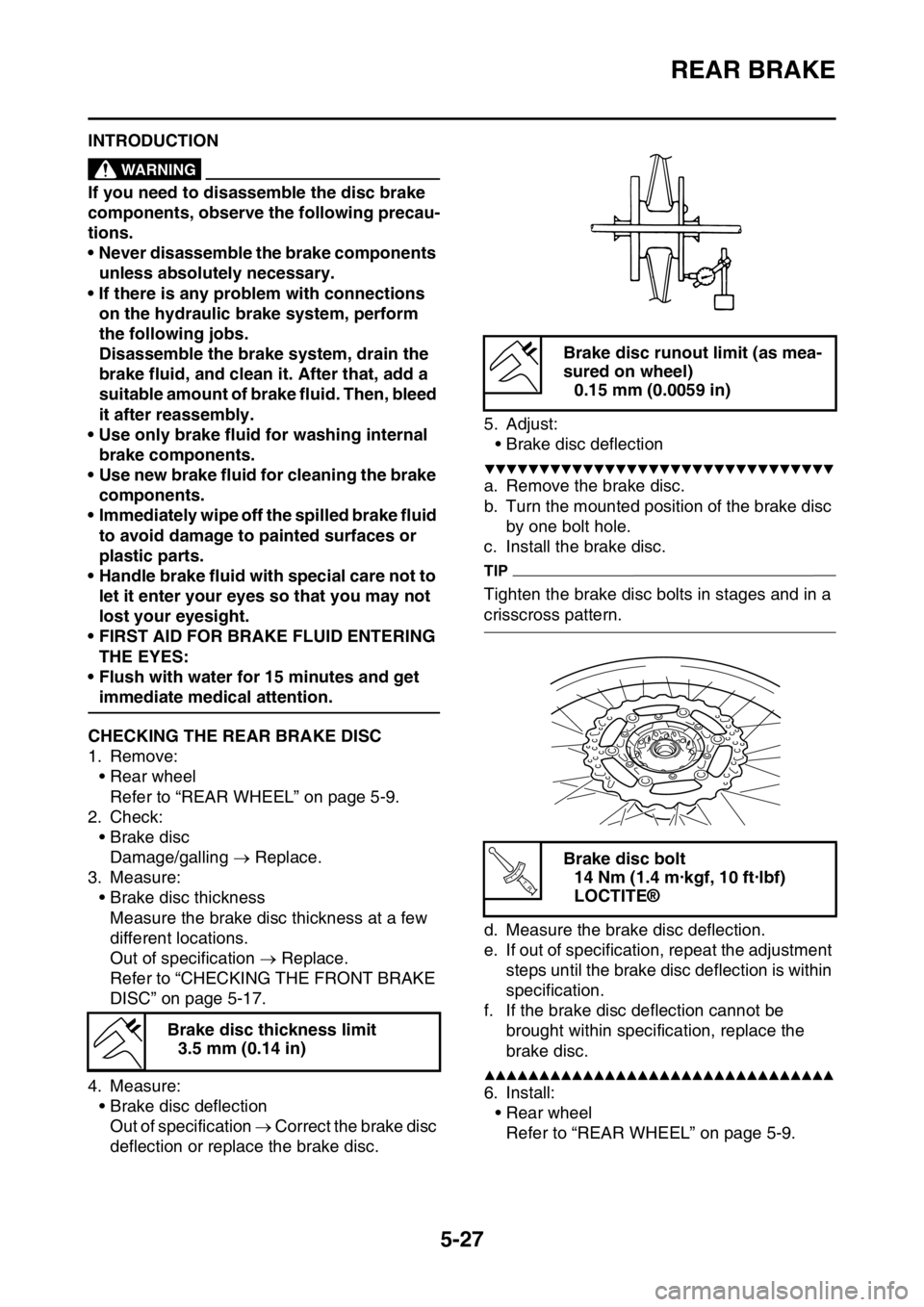

EAS2GC1182CHECKING THE REAR BRAKE DISC

1. Remove: • Rear wheel

Refer to “REAR WHEEL” on page 5-9.

2. Check: • Brake disc

Damage/galling Replace.

3. Measure: • Brake disc thickness

Measure the brake disc thickness at a few

different locations.

Out of specification Replace.

Refer to “CHECKING THE FRONT BRAKE

DISC” on page 5-17.

4. Measure: • Brake disc deflection

Out of specification Correct the brake disc

deflection or replace the brake disc. 5. Adjust:

• Brake disc deflection

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the brake disc.

b. Turn the mounted position of the brake disc by one bolt hole.

c. Install the brake disc.

TIP

Tighten the brake disc bolts in stages and in a

crisscross pattern.

d. Measure the brake disc deflection.

e. If out of specification, repeat the adjustment steps until the brake disc deflection is within

specification.

f. If the brake disc deflection cannot be

brought within specification, replace the

brake disc.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

6. Install:• Rear wheel

Refer to “REAR WHEEL” on page 5-9.

Brake disc thickness limit

3.5 mm (0.14 in)

Brake disc runout limit (as mea-

sured on wheel) 0.15 mm (0.0059 in)

Brake disc bolt 14 Nm (1.4 m·kgf, 10 ft·lbf)

LOCTITE®

T R..

Page 210 of 426

REAR SHOCK ABSORBER ASSEMBLY

5-58

EAS2GC1207

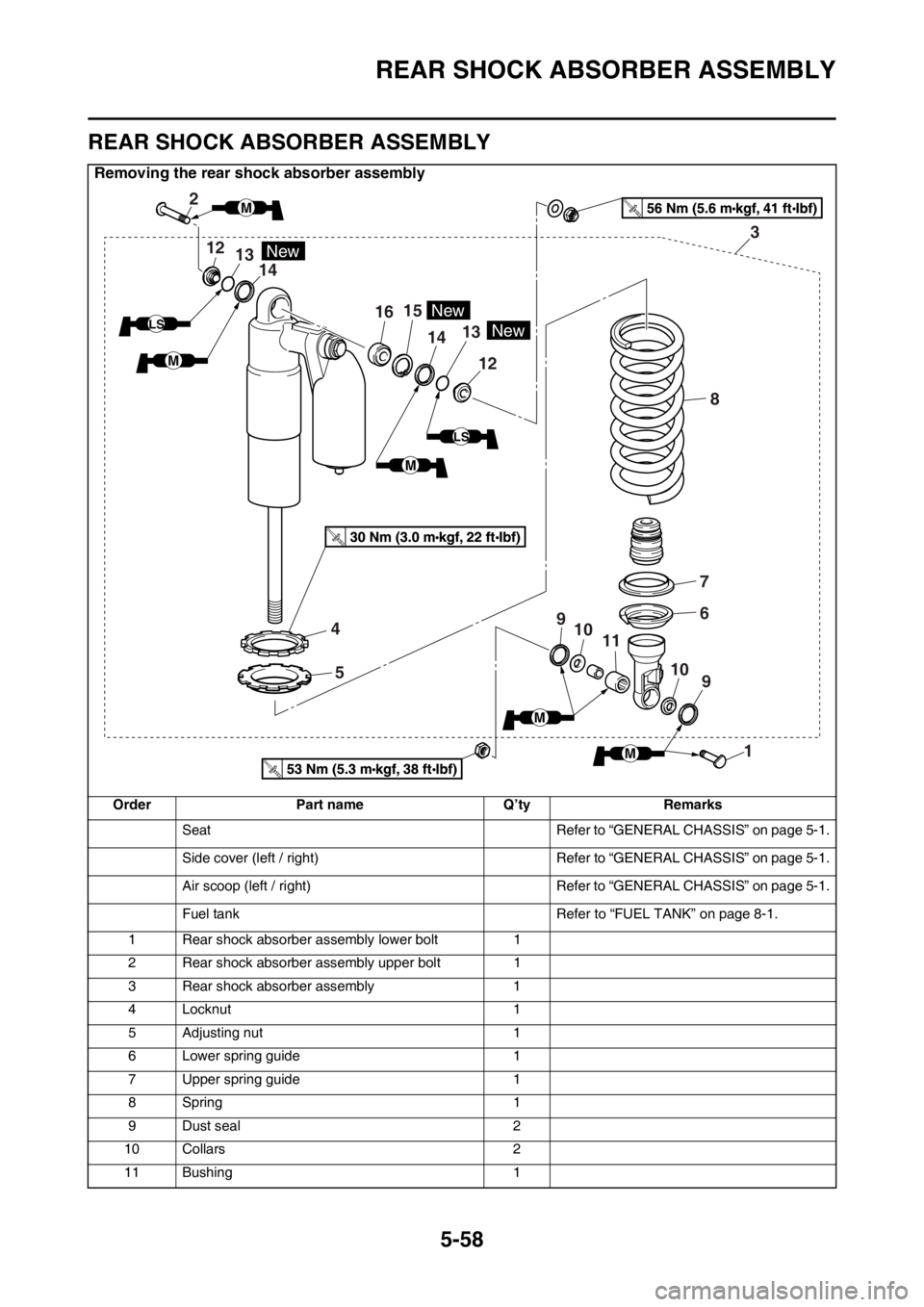

REAR SHOCK ABSORBER ASSEMBLY

Removing the rear shock absorber assembly

OrderPart name Q’tyRemarks

Seat Refer to “GENERAL CHASSIS” on page 5-1.

Side cover (left / right) Refer to “GENERAL CHASSIS” on page 5-1.

Air scoop (left / right) Refer to “GENERAL CHASSIS” on page 5-1.

Fuel tank Refer to “FUEL TANK” on page 8-1.

1 Rear shock absorber assembly lower bolt 1

2 Rear shock absorber assembly upper bolt 1

3 Rear shock absorber assembly 1

4 Locknut 1

5 Adjusting nut 1

6 Lower spring guide 1

7 Upper spring guide 1

8Spring 1

9 Dust seal 2

10 Collars 2

11 Bushing 1

2

12

1615

14 13

12

14

4

5

7

6

8 3

9

9

10

10

11

1

New

New

13New

LS

LS

M

M

M

M

M

Page 211 of 426

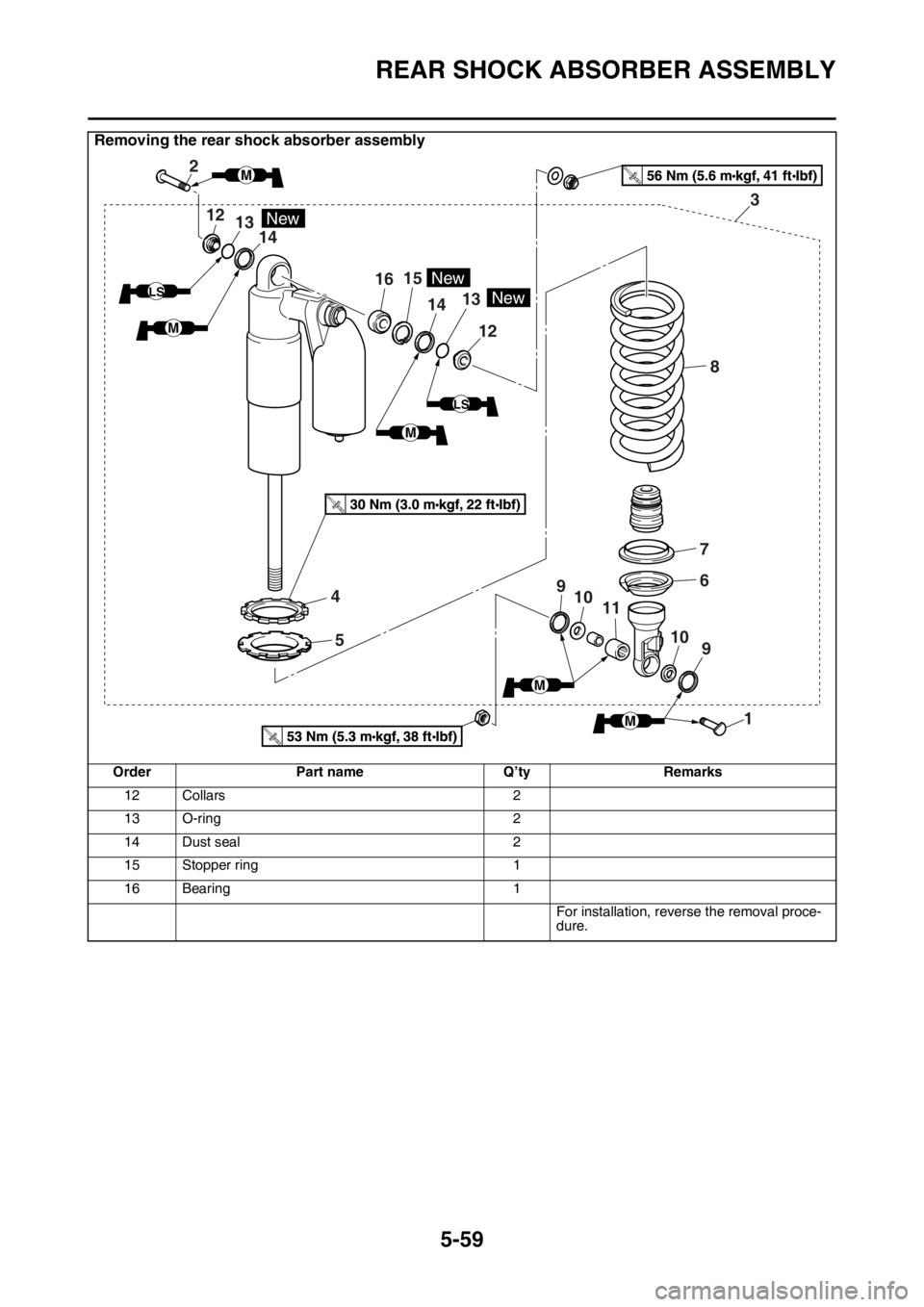

REAR SHOCK ABSORBER ASSEMBLY

5-59

12 Collars2

13 O-ring 2

14 Dust seal 2

15 Stopper ring 1

16 Bearing 1

For installation, reverse the removal proce-

dure.

Removing the rear shock absorber assembly

Order Part name Q’tyRemarks

2

12

1615

14 13

12

14

4

5

7

6

8 3

9

9

10

10

11

1

New

New

13New

LS

LS

M

M

M

M

M

Page 212 of 426

REAR SHOCK ABSORBER ASSEMBLY

5-60

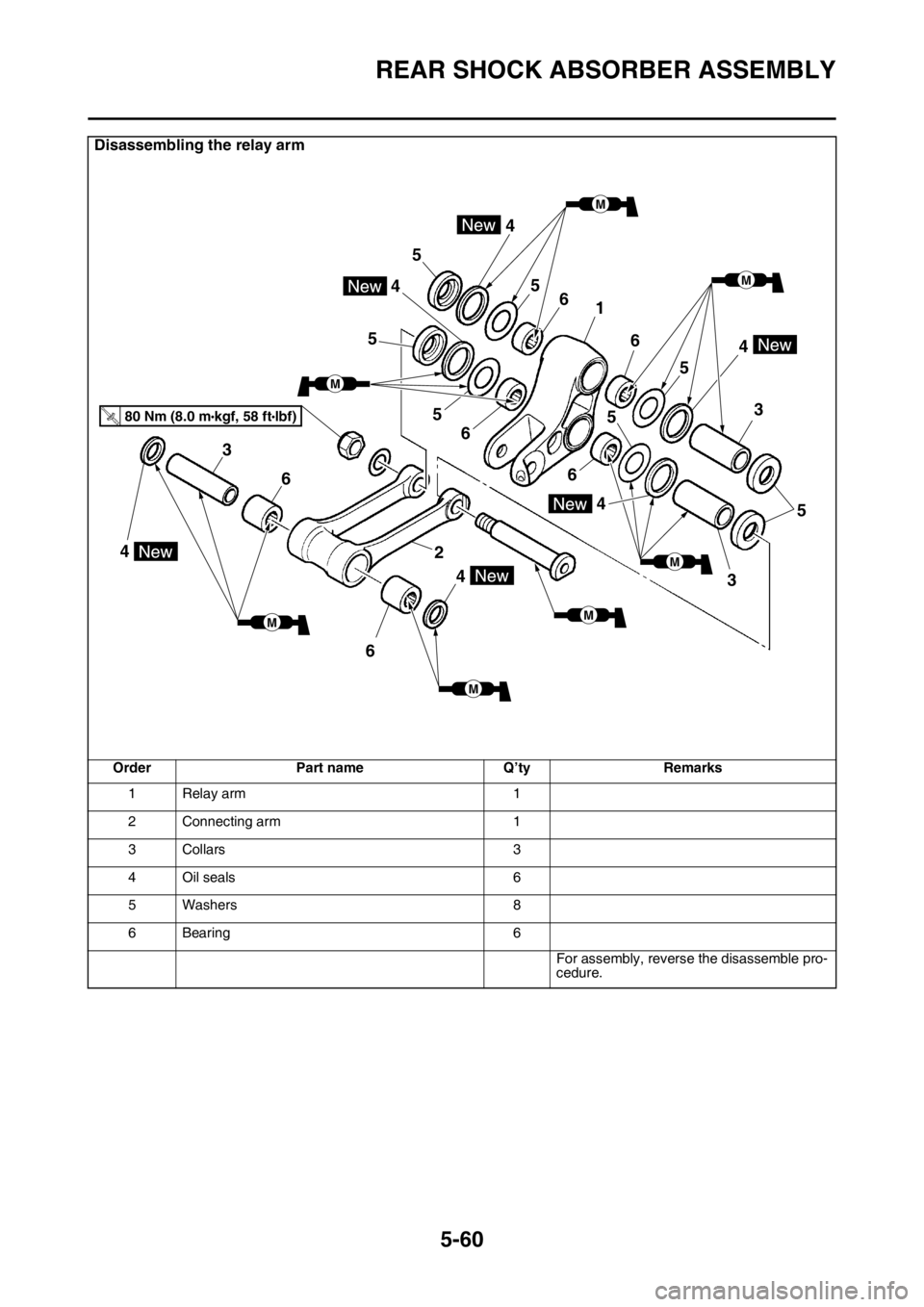

Disassembling the relay arm

OrderPart name Q’tyRemarks

1 Relay arm 1

2 Connecting arm 1

3Collars 3

4Oil seals 6

5Washers 8

6 Bearing 6

For assembly, reverse the disassemble pro-

cedure.

5

3

5

6

165

4

5

5

4

56

6

5

4

3

2

4

6

6

3

4

4

T.R.80 Nm (8.0 mlbf)

kgf, 58 ft

M

M

M

M

M

M M

Page 213 of 426

REAR SHOCK ABSORBER ASSEMBLY

5-61

EAS2GC1208HANDLING THE REAR SHOCK ABSORBEREWA

WARNING

This rear shock absorber contains highly

compressed nitrogen gas. Before handling

the rear shock absorber, read and make

sure that you understand the following in-

formation. The manufacturer cannot be held

responsible for property damage or person-

al injury that may result from improper han-

dling of the rear shock absorber.

• Do not tamper or attempt to open the rear shock absorber.

• Do not subject the rear shock absorber to an open flame or any other source of high

heat. High heat can cause an explosion

due to excessive gas pressure.

• Do not deform or damage the rear shock absorber in any way. Rear shock absorber

damage will result in poor damping perfor-

mance.

TIP

A break-in is required up to about 50 km of run-

ning.

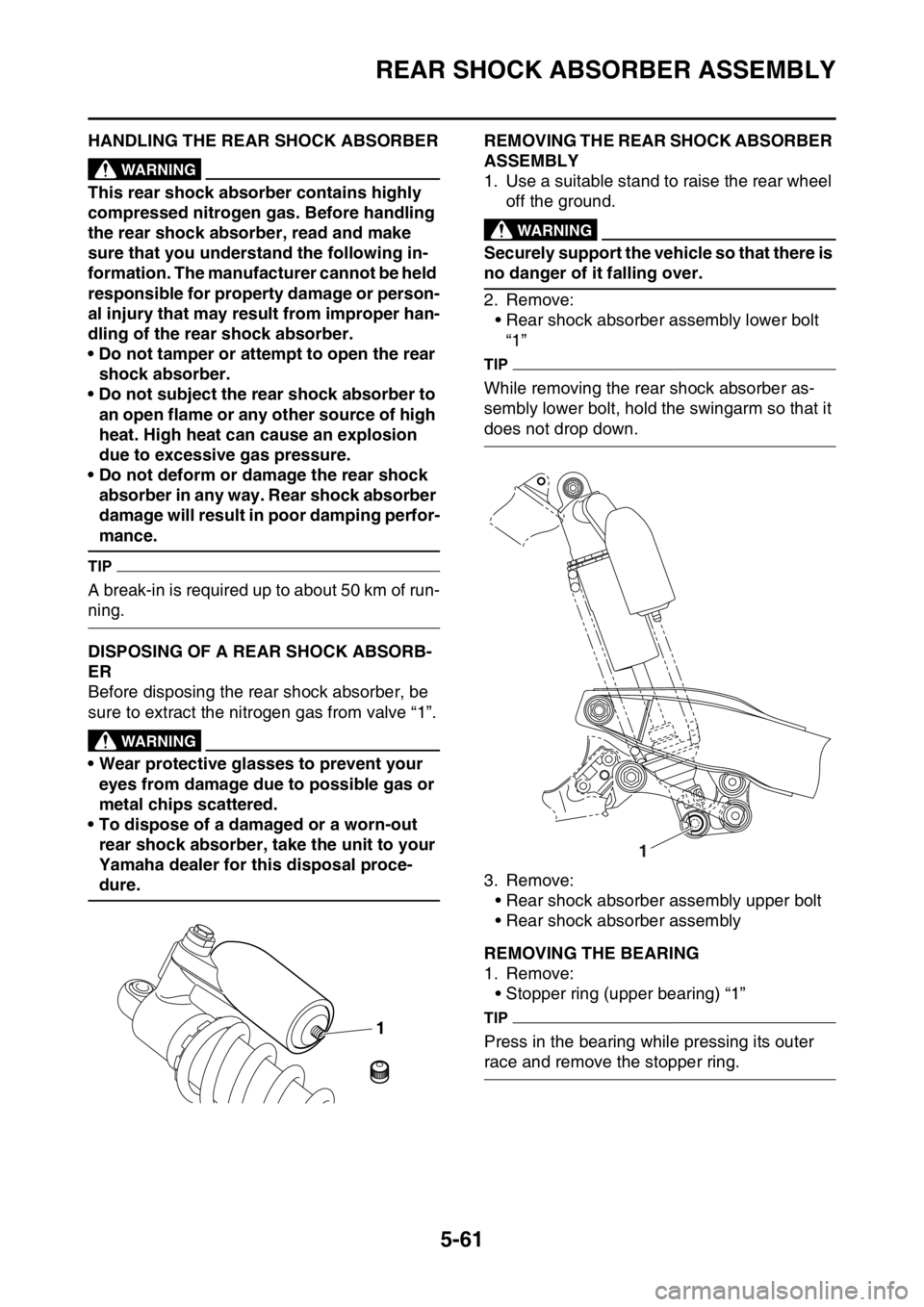

EAS2GC1209DISPOSING OF A REAR SHOCK ABSORB-

ER

Before disposing the rear shock absorber, be

sure to extract the nitrogen gas from valve “1”.

EWA

WARNING

• Wear protective glasses to prevent your

eyes from damage due to possible gas or

metal chips scattered.

• To dispose of a damaged or a worn-out rear shock absorber, take the unit to your

Yamaha dealer for this disposal proce-

dure.

EAS2GC1210REMOVING THE REAR SHOCK ABSORBER

ASSEMBLY

1. Use a suitable stand to raise the rear wheel off the ground.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Remove:• Rear shock absorber assembly lower bolt

“1”

TIP

While removing the rear shock absorber as-

sembly lower bolt, hold the swingarm so that it

does not drop down.

3. Remove:• Rear shock absorber assembly upper bolt

• Rear shock absorber assembly

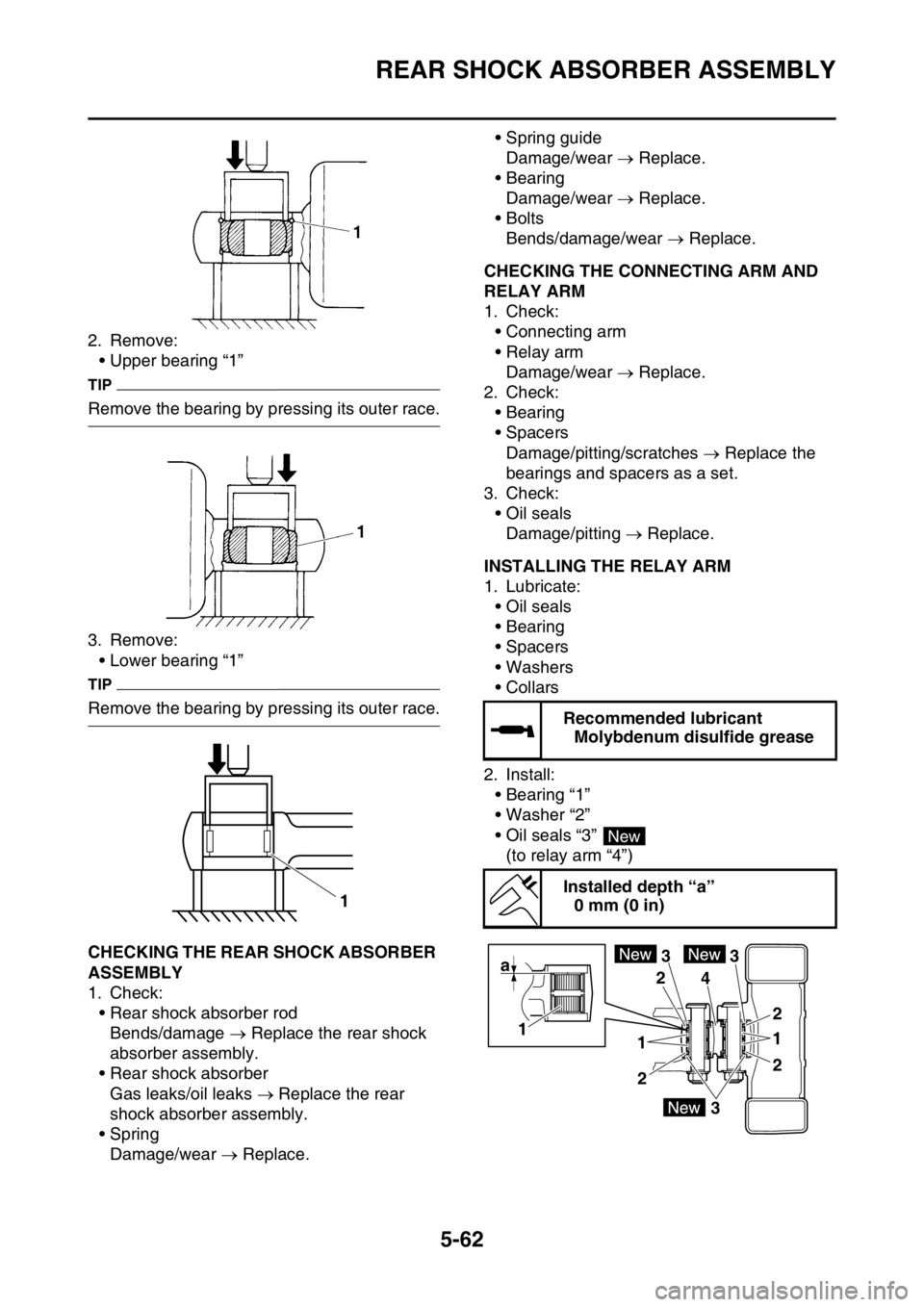

EAS2GC1211REMOVING THE BEARING

1. Remove:• Stopper ring (upper bearing) “1”

TIP

Press in the bearing while pressing its outer

race and remove the stopper ring.

1

1

Page 214 of 426

REAR SHOCK ABSORBER ASSEMBLY

5-62

2. Remove:• Upper bearing “1”

TIP

Remove the bearing by pressing its outer race.

3. Remove:

• Lower bearing “1”

TIP

Remove the bearing by pressing its outer race.

EAS2GC1212CHECKING THE REAR SHOCK ABSORBER

ASSEMBLY

1. Check:• Rear shock absorber rod

Bends/damage Replace the rear shock

absorber assembly.

• Rear shock absorber

Gas leaks/oil leaks Replace the rear

shock absorber assembly.

•Spring

Damage/wear Replace. • Spring guide

Damage/wear Replace.

• Bearing

Damage/wear Replace.

•Bolts Bends/damage/wear Replace.

EAS2GC1213CHECKING THE CONNECTING ARM AND

RELAY ARM

1. Check:

• Connecting arm

• Relay arm

Damage/wear Replace.

2. Check: • Bearing

• Spacers

Damage/pitting/scratches Replace the

bearings and spacers as a set.

3. Check: • Oil sealsDamage/pitting Replace.

EAS2GC1214INSTALLING THE RELAY ARM

1. Lubricate:

• Oil seals

• Bearing

• Spacers

• Washers

•Collars

2. Install: • Bearing “1”

• Washer “2”

• Oil seals “3” (to relay arm “4”)

1

Recommended lubricantMolybdenum disulfide grease

Installed depth “a” 0 mm (0 in)

New

3

3

43

2 2

2 2

a

1 1 1

Page 215 of 426

REAR SHOCK ABSORBER ASSEMBLY

5-63

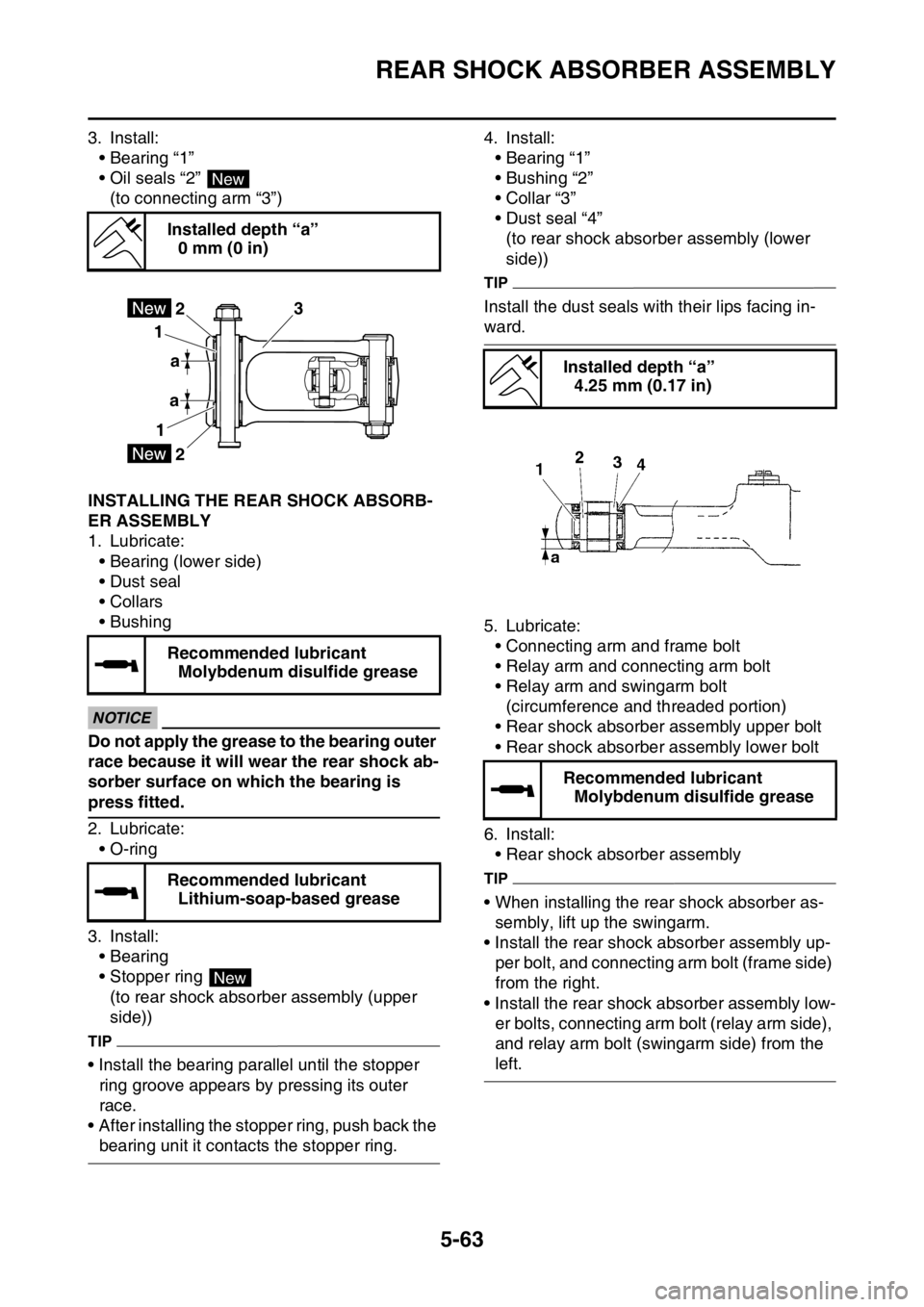

3. Install:• Bearing “1”

• Oil seals “2” (to connecting arm “3”)

EAS2GC1215INSTALLING THE REAR SHOCK ABSORB-

ER ASSEMBLY

1. Lubricate:• Bearing (lower side)

•Dust seal

•Collars

• Bushing

ECA

NOTICE

Do not apply the grease to the bearing outer

race because it will wear the rear shock ab-

sorber surface on which the bearing is

press fitted.

2. Lubricate:• O-ring

3. Install: • Bearing

• Stopper ring (to rear shock absorber assembly (upper

side))

TIP

• Install the bearing parallel until the stopper ring groove appears by pressing its outer

race.

• After installing the stopper ring, push back the

bearing unit it contacts the stopper ring. 4. Install:

• Bearing “1”

• Bushing “2”

• Collar “3”

• Dust seal “4”(to rear shock absorber assembly (lower

side))

TIP

Install the dust seals with their lips facing in-

ward.

5. Lubricate:

• Connecting arm and frame bolt

• Relay arm and connecting arm bolt

• Relay arm and swingarm bolt(circumference and threaded portion)

• Rear shock absorber assembly upper bolt

• Rear shock absorber assembly lower bolt

6. Install: • Rear shock absorber assembly

TIP

• When installing the rear shock absorber as-sembly, lift up the swingarm.

• Install the rear shock absorber assembly up- per bolt, and connecting arm bolt (frame side)

from the right.

• Install the rear shock absorber assembly low- er bolts, connecting arm bolt (relay arm side),

and relay arm bolt (swingarm side) from the

left.

Installed depth “a”

0 mm (0 in)

Recommended lubricant Molybdenum disulfide grease

Recommended lubricant Lithium-soap-based grease

New

3

a

1

1 2

a

2

New

Installed depth “a” 4.25 mm (0.17 in)

Recommended lubricant Molybdenum disulfide grease

Page 216 of 426

REAR SHOCK ABSORBER ASSEMBLY

5-64

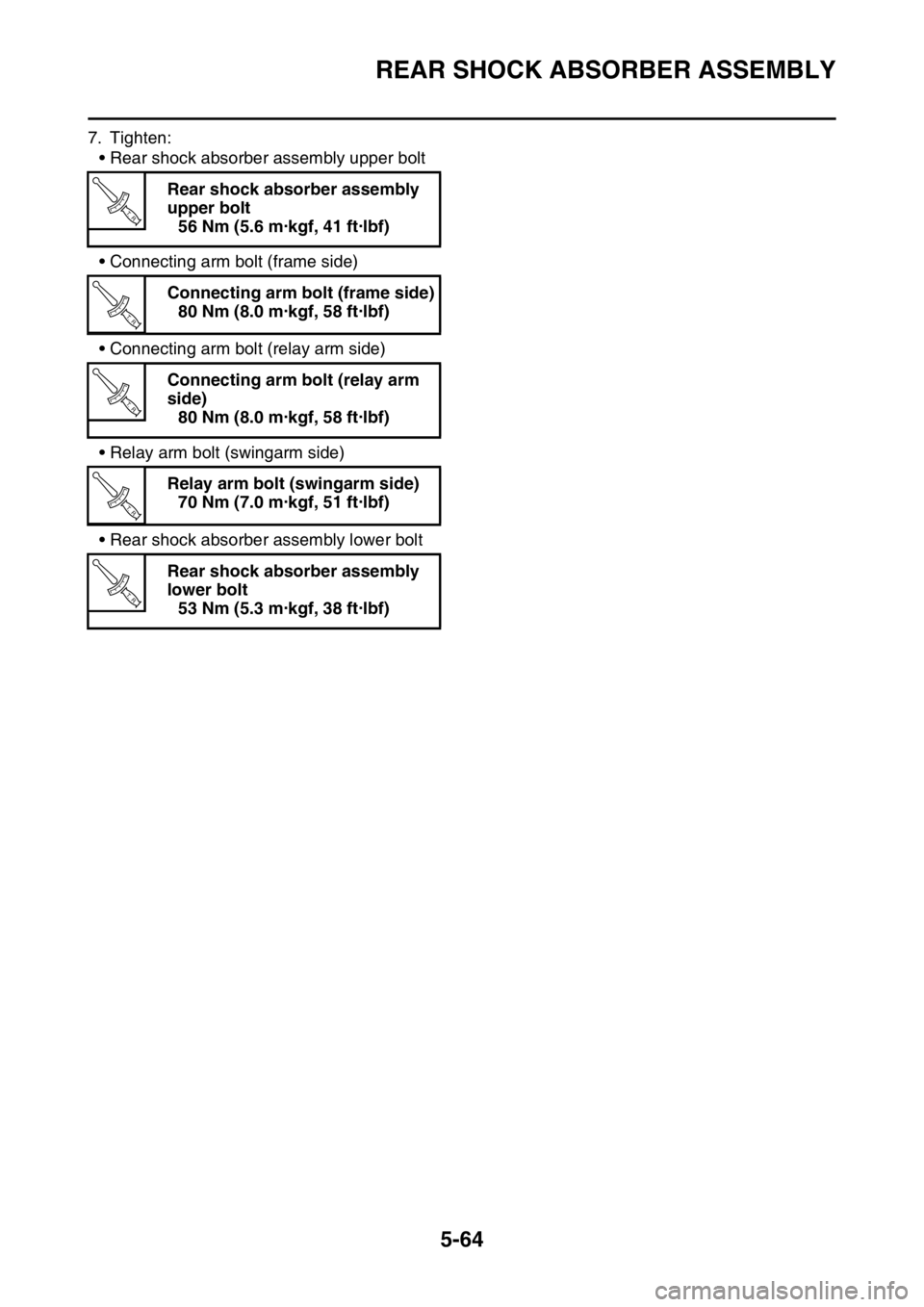

7. Tighten:• Rear shock absorber assembly upper bolt

• Connecting arm bolt (frame side)

• Connecting arm bolt (relay arm side)

• Relay arm bolt (swingarm side)

• Rear shock absorber assembly lower bolt Rear shock absorber assembly

upper bolt

56 Nm (5.6 m·kgf, 41 ft·lbf)

Connecting arm bolt (frame side) 80 Nm (8.0 m·kgf, 58 ft·lbf)

Connecting arm bolt (relay arm

side) 80 Nm (8.0 m·kgf, 58 ft·lbf)

Relay arm bolt (swingarm side) 70 Nm (7.0 m·kgf, 51 ft·lbf)

Rear shock absorber assembly

lower bolt 53 Nm (5.3 m·kgf, 38 ft·lbf)

T R..

T R..

T R..

T R..

T R..

Page 228 of 426

ENGINE REMOVAL

6-1

EAS2GC1225

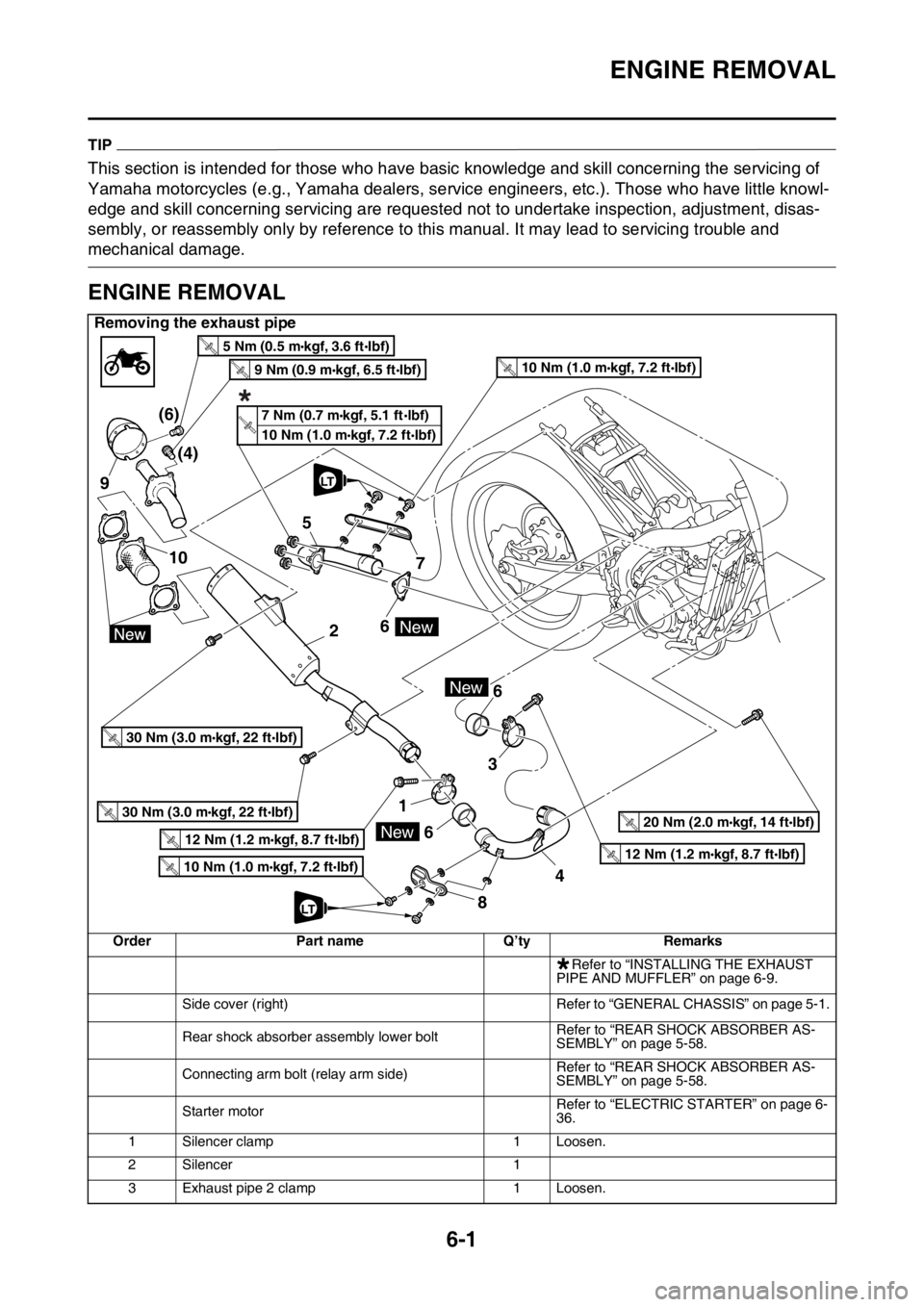

TIP

This section is intended for those who have basic knowledge and skill concerning the servicing of

Yamaha motorcycles (e.g., Yamaha dealers, serv ice engineers, etc.). Those who have little knowl-

edge and skill concerning servicing are requested not to undertake inspection, adjustment, disas-

sembly, or reassembly only by reference to this manual. It may lead to servicing trouble and

mechanical damage.

EAS2GC1226

ENGINE REMOVAL

Removing the exhaust pipe

OrderPart name Q’tyRemarks

Refer to “INSTALLING THE EXHAUST

PIPE AND MUFFLER” on page 6-9.

Side cover (right) Refer to “GENERAL CHASSIS” on page 5-1.

Rear shock absorber assembly lower bolt Refer to “REAR SHOCK ABSORBER AS-

SEMBLY” on page 5-58.

Connecting arm bolt (relay arm side) Refer to “REAR SHOCK ABSORBER AS-

SEMBLY” on page 5-58.

Starter motor Refer to “ELECTRIC STARTER” on page 6-

36.

1 Silencer clamp 1 Loosen.

2 Silencer 1

3 Exhaust pipe 2 clamp 1 Loosen.

105

9

26

1 6 6

3

8 4

7

(4)

(6)

30 Nm (3.0 m kgf, 22 ft Ibf)T

.R.

30 Nm (3.0 m kgf, 22 ft Ibf)T.R.

New

New

10 Nm (1.0 m kgf, 7.2 ft Ibf)T.R.

12 Nm (1.2 m kgf, 8.7 ft Ibf)T.R.12 Nm (1.2 m kgf, 8.7 ft Ibf)T.R.

20 Nm (2.0 m kgf, 14 ft Ibf)T.R.New

LT

LT

10 Nm (1.0 m kgf, 7.2 ft Ibf)T.R.9 Nm (0.9 m kgf, 6.5 ft Ibf)T .R.

5 Nm (0.5 m kgf, 3.6 ft Ibf)T.R.

T

.R.*kgf

7 Nm (0.7 m , 5.1 ft lbf)

10 Nm (1.0 m kgf, 7.2 ft Ibf)

*