steering YAMAHA WR 450F 2016 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: WR 450F, Model: YAMAHA WR 450F 2016Pages: 426, PDF Size: 10.86 MB

Page 135 of 426

CHASSIS

3-37

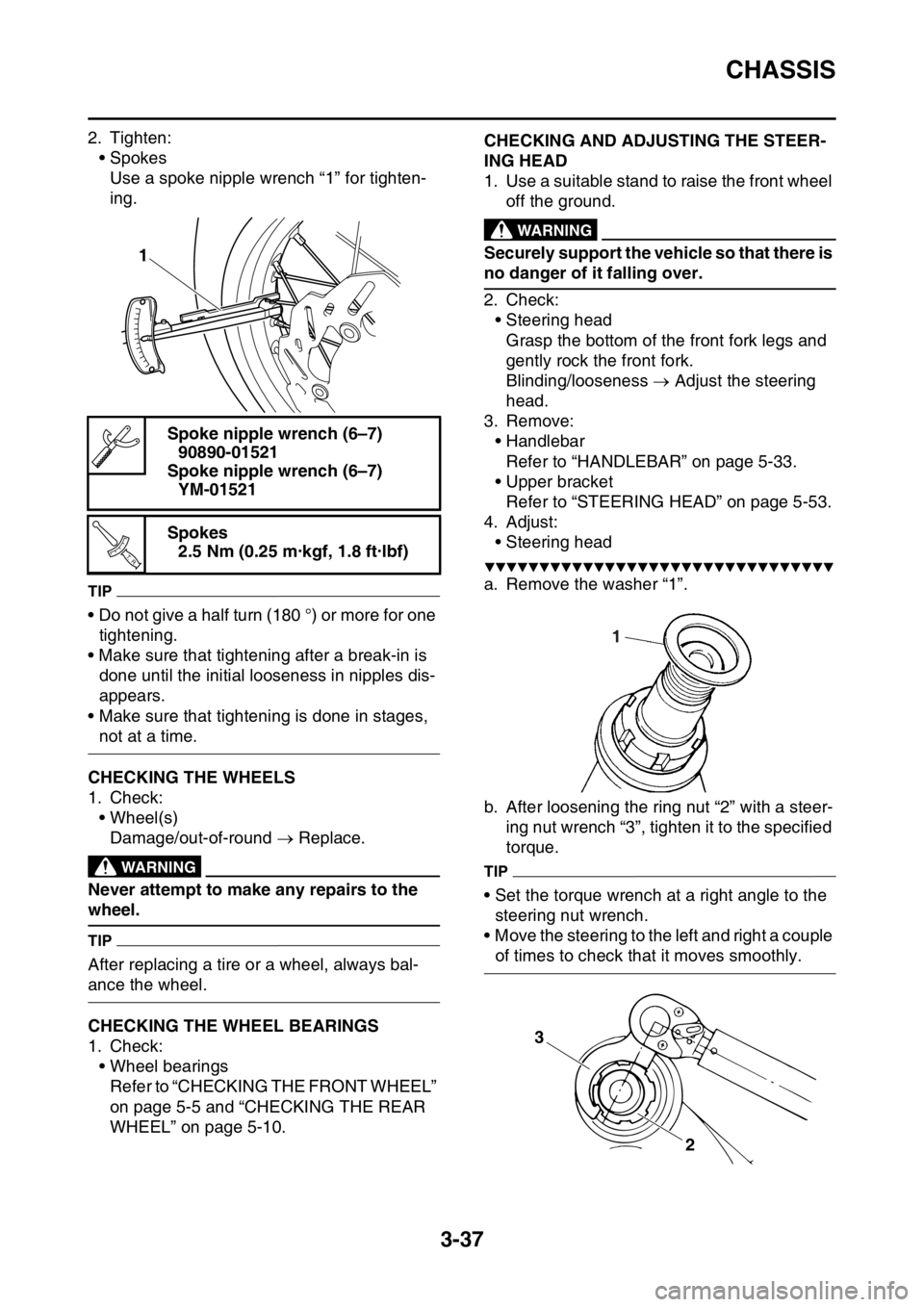

2. Tighten:• SpokesUse a spoke nipple wrench “1” for tighten-

ing.

TIP

• Do not give a half turn (180 °) or more for one tightening.

• Make sure that tightening after a break-in is done until the initial looseness in nipples dis-

appears.

• Make sure that tightening is done in stages,

not at a time.

EAS2GC1121CHECKING THE WHEELS

1. Check: • Wheel(s)Damage/out-of-round Replace.

EWA

WARNING

Never attempt to make any repairs to the

wheel.

TIP

After replacing a tire or a wheel, always bal-

ance the wheel.

EAS2GC1122CHECKING THE WHEEL BEARINGS

1. Check:

• Wheel bearingsRefer to “CHECKING THE FRONT WHEEL”

on page 5-5 and “CHECKING THE REAR

WHEEL” on page 5-10.

EAS2GC1123CHECKING AND ADJUSTING THE STEER-

ING HEAD

1. Use a suitable stand to raise the front wheel off the ground.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Check:• Steering head

Grasp the bottom of the front fork legs and

gently rock the front fork.

Blinding/looseness Adjust the steering

head.

3. Remove: • Handlebar

Refer to “HANDLEBAR” on page 5-33.

• Upper bracket Refer to “STEERING HEAD” on page 5-53.

4. Adjust: • Steering head

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

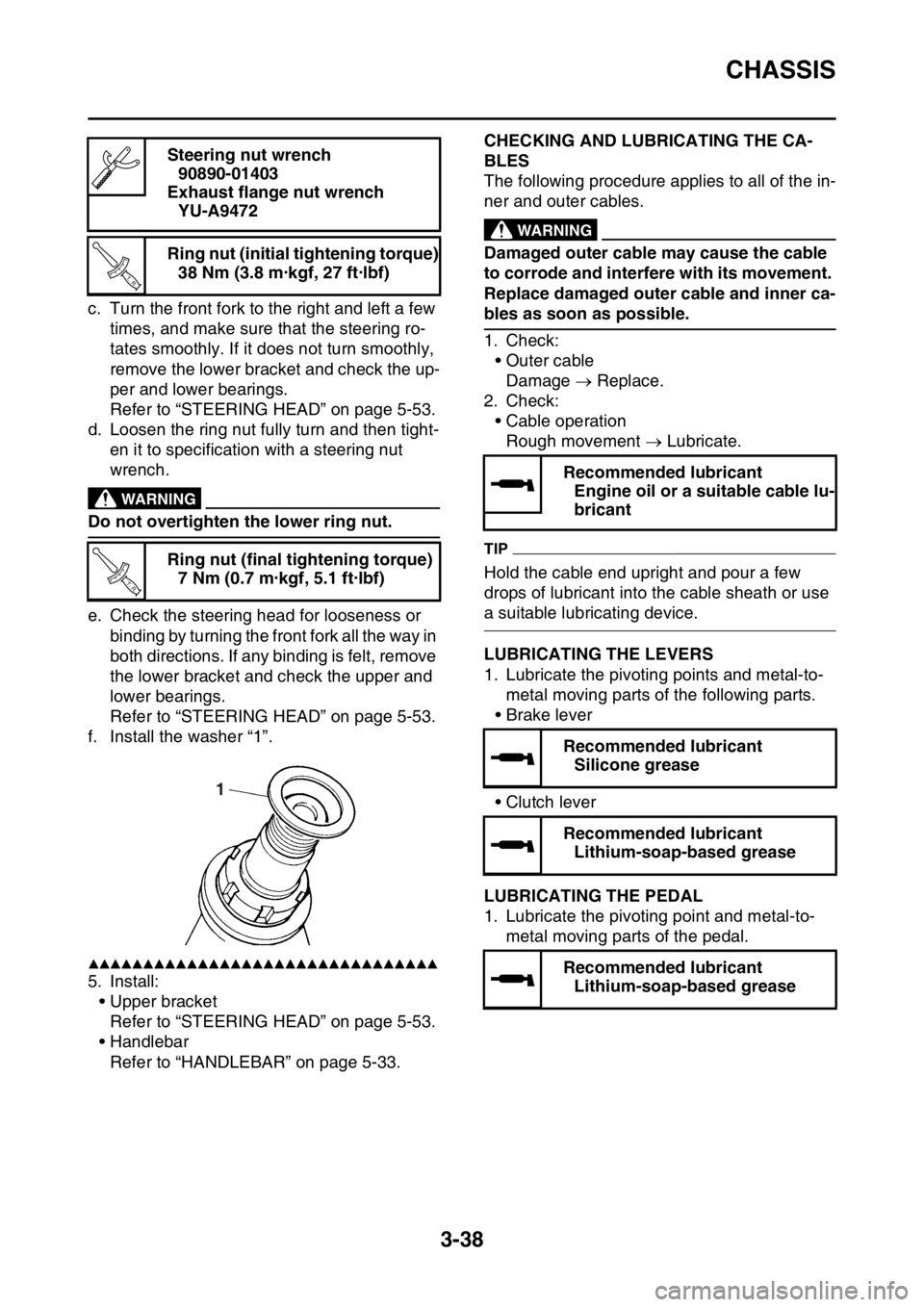

a. Remove the washer “1”.

b. After loosening the ring nut “2” with a steer- ing nut wrench “3”, tighten it to the specified

torque.

TIP

• Set the torque wrench at a right angle to the

steering nut wrench.

• Move the steering to the left and right a couple

of times to check that it moves smoothly.

Spoke nipple wrench (6–7)

90890-01521

Spoke nipple wrench (6–7) YM-01521

Spokes 2.5 Nm (0.25 m·kgf, 1.8 ft·lbf)

1

T R..

1

3

2

Page 136 of 426

CHASSIS

3-38

c. Turn the front fork to the right and left a few times, and make sure that the steering ro-

tates smoothly. If it does not turn smoothly,

remove the lower bracket and check the up-

per and lower bearings.

Refer to “STEERING HEAD” on page 5-53.

d. Loosen the ring nut fully turn and then tight- en it to specification with a steering nut

wrench.

EWA

WARNING

Do not overtighten the lower ring nut.

e. Check the steering head for looseness or binding by turning the front fork all the way in

both directions. If any binding is felt, remove

the lower bracket and check the upper and

lower bearings.

Refer to “STEERING HEAD” on page 5-53.

f. Install the washer “1”.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

5. Install: • Upper bracketRefer to “STEERING HEAD” on page 5-53.

• Handlebar

Refer to “HANDLEBAR” on page 5-33.

EAS2GC1124CHECKING AND LUBRICATING THE CA-

BLES

The following procedure applies to all of the in-

ner and outer cables.

EWA

WARNING

Damaged outer cable may cause the cable

to corrode and interfere with its movement.

Replace damaged outer cable and inner ca-

bles as soon as possible.

1. Check:• Outer cableDamage Replace.

2. Check: • Cable operationRough movement Lubricate.

TIP

Hold the cable end upright and pour a few

drops of lubricant into the cable sheath or use

a suitable lubricating device.

EAS2GC1125LUBRICATING THE LEVERS

1. Lubricate the pivoting points and metal-to-

metal moving parts of the following parts.

•Brake lever

• Clutch lever

EAS2GC1126LUBRICATING THE PEDAL

1. Lubricate the pivoting point and metal-to-

metal moving parts of the pedal.

Steering nut wrench

90890-01403

Exhaust flange nut wrench YU-A9472

Ring nut (initial tightening torque) 38 Nm (3.8 m·kgf, 27 ft·lbf)

Ring nut (final tightening torque) 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

T R..

T R..

1

Recommended lubricantEngine oil or a suitable cable lu-

bricant

Recommended lubricant Silicone grease

Recommended lubricant Lithium-soap-based grease

Recommended lubricant Lithium-soap-based grease

Page 152 of 426

HANDLEBAR................................................................................................. 5-33

REMOVING THE HANDLEBAR ............................................................... 5-35

CHECKING THE HANDLEBAR ............................................................... 5-35

INSTALLING THE HANDLEBAR ............................................................. 5-35

FRONT FORK ................................................................................................. 5-40

REMOVING THE FRONT FORK LEGS ................................................... 5-42

DISASSEMBLING THE FRONT FO RK LEGS ......................................... 5-42

CHECKING THE FRONT FORK LEGS ................................................... 5-43

ASSEMBLING THE FRONT FORK LEGS ............................................... 5-44

INSTALLING THE FRONT FORK LEGS ................................................. 5-50

STEERING HEAD ........................................................................................... 5-53

REMOVING THE LOWER BRACKET...................................................... 5-55

CHECKING THE STEERING HEAD ........................................................ 5-55

INSTALLING THE STEERING HEAD ...................................................... 5-55

REAR SHOCK ABSORBER ASSEMBLY ..................................................... 5-58

HANDLING THE REAR SHOCK ABSORBER ......................................... 5-61

DISPOSING OF A REAR SH OCK ABSORBER ...................................... 5-61

REMOVING THE REAR SHOCK ABSORBER ASSEMBLY.................... 5-61

REMOVING THE BEARING..................................................................... 5-61

CHECKING THE REAR SHOCK ABSORBER ASSEMBLY .................... 5-62

CHECKING THE CONNECTING ARM AND RELAY ARM ...................... 5-62

INSTALLING THE RELAY ARM............................................................... 5-62

INSTALLING THE REAR SHOCK ABSORBER ASSEMBLY .................. 5-63

SWINGARM .................................................................................................... 5-65

REMOVING THE SWINGARM................................................................. 5-66

REMOVING THE BEARING..................................................................... 5-66

CHECKING THE SWINGARM ................................................................. 5-66

INSTALLING THE SWINGARM ............................................................... 5-67

CHAIN DRIVE ................................................................................................. 5-68

REMOVING THE DRIVE CHAIN.............................................................. 5-69

CHECKING THE DRIVE CHAIN .............................................................. 5-69

CHECKING THE DRIVE SPROCKET...................................................... 5-70

CHECKING THE REAR WHEEL SPROCKET ......................................... 5-70

INSTALLING THE DRIVE CHAIN ............................................................ 5-70

Page 205 of 426

STEERING HEAD

5-53

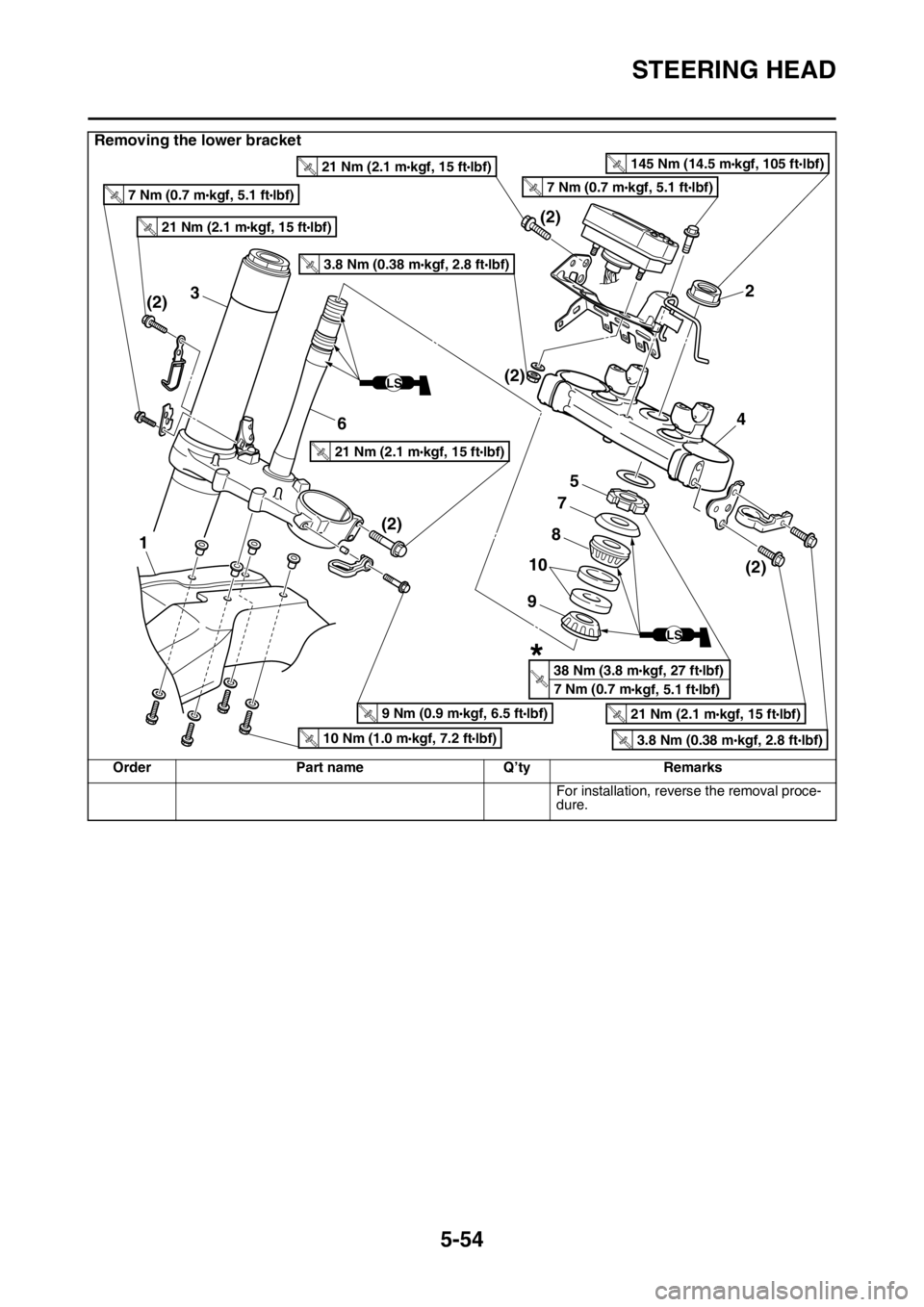

EAS2GC1203

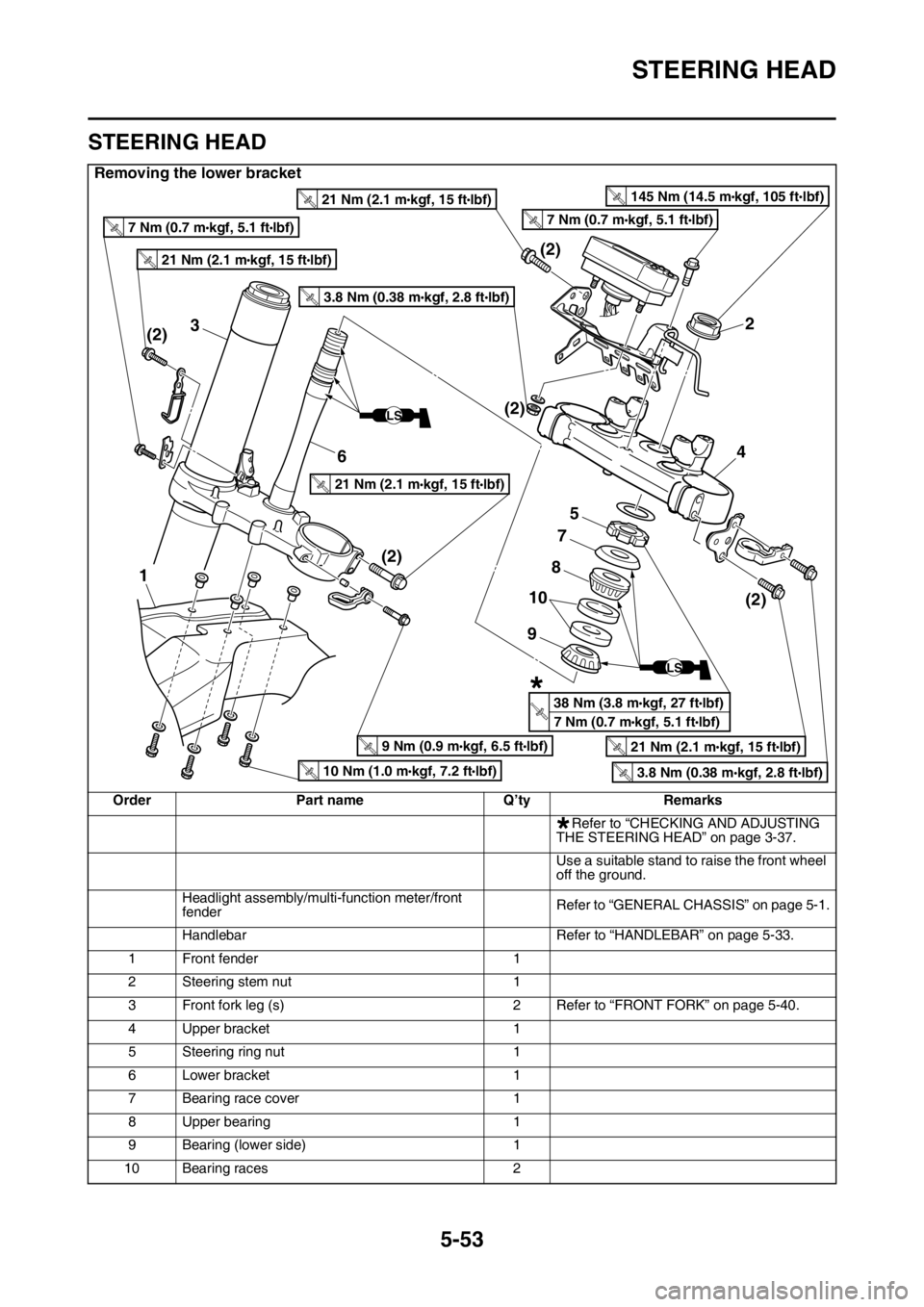

STEERING HEAD

Removing the lower bracket

OrderPart name Q’tyRemarks

Refer to “CHECKING AND ADJUSTING

THE STEERING HEAD” on page 3-37.

Use a suitable stand to raise the front wheel

off the ground.

Headlight assembly/multi -function meter/front

fender Refer to “GENERAL

CHASSIS” on page 5-1.

Handlebar Refer to “HANDLEBAR” on page 5-33.

1 Front fender 1

2 Steering stem nut 1

3 Front fork leg (s) 2 Refer to “FRONT FORK” on page 5-40.

4 Upper bracket 1

5 Steering ring nut 1

6 Lower bracket 1

7 Bearing race cover 1

8 Upper bearing 1

9 Bearing (lower side) 1

10 Bearing races 2

2

4

5

7

3

(2) (2)

(2)

(2)

(2)

1

6

8

9

10

LS

LS

T

.R.21 Nm (2.1 mlbf)

kgf, 15 ft

T

.R.21 Nm (2.1 mlbf)

kgf, 15 ft

T

.R.21 Nm (2.1 mlbf)

kgf, 15 ft

T

.R.21 Nm (2.1 mlbf)

kgf, 15 ft

T

.R.3.8 Nm (0.38 mlbf)

kgf, 2.8 ft

T

.R.3.8 Nm (0.38 mlbf)

kgf, 2.8 ft

T

.R.9 Nm (0.9 mlbf)

kgf, 6.5 ft

T

.R.7 Nm (0.7 mlbf)

kgf, 5.1 ftT

.R.7 Nm (0.7 mlbf)

kgf, 5.1 ft

T

.R.10 Nm (1.0 mlbf)

kgf, 7.2 ft

T

.R.145 Nm (14.5 mlbf)

kgf, 105 ft

T

.R.38 Nm (3.8 mlbf)

kgf, 27 ft

7 Nm (0.7 m

lbf)

kgf, 5.1 ft

*

*

Page 206 of 426

STEERING HEAD

5-54

For installation, reverse the removal proce-

dure.

Removing the lower bracket

OrderPart name Q’tyRemarks

2

4

5

7

3

(2) (2)

(2)

(2)

(2)

1

6

8

9

10

LS

LS

T

.R.21 Nm (2.1 mlbf)

kgf, 15 ft

T

.R.21 Nm (2.1 mlbf)

kgf, 15 ft

T

.R.21 Nm (2.1 mlbf)

kgf, 15 ft

T

.R.21 Nm (2.1 mlbf)

kgf, 15 ft

T

.R.3.8 Nm (0.38 mlbf)

kgf, 2.8 ft

T

.R.3.8 Nm (0.38 mlbf)

kgf, 2.8 ft

T

.R.9 Nm (0.9 mlbf)

kgf, 6.5 ft

T

.R.7 Nm (0.7 mlbf)

kgf, 5.1 ftT

.R.7 Nm (0.7 mlbf)

kgf, 5.1 ft

T

.R.10 Nm (1.0 mlbf)

kgf, 7.2 ft

T

.R.145 Nm (14.5 mlbf)

kgf, 105 ft

T

.R.38 Nm (3.8 mlbf)

kgf, 27 ft

7 Nm (0.7 m

lbf)

kgf, 5.1 ft

*

Page 207 of 426

STEERING HEAD

5-55

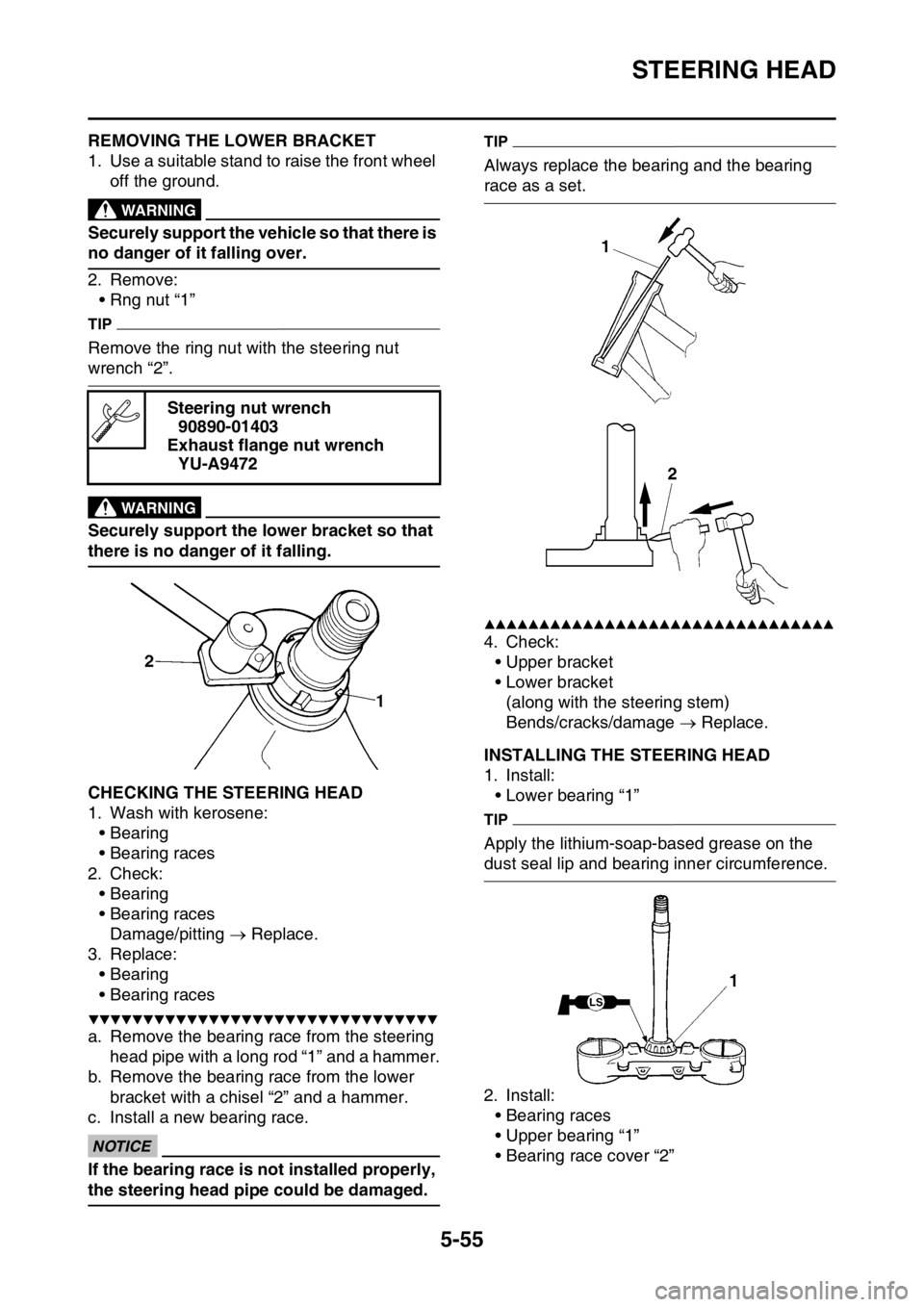

EAS2GC1204REMOVING THE LOWER BRACKET

1. Use a suitable stand to raise the front wheel off the ground.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Remove:• Rng nut “1”

TIP

Remove the ring nut with the steering nut

wrench “2”.

EWA

WARNING

Securely support the lower bracket so that

there is no danger of it falling.

EAS2GC1205CHECKING THE STEERING HEAD

1. Wash with kerosene:• Bearing

• Bearing races

2. Check: • Bearing

• Bearing races

Damage/pitting Replace.

3. Replace:

• Bearing

• Bearing races

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the bearing race from the steering head pipe with a long rod “1” and a hammer.

b. Remove the bearing race from the lower bracket with a chisel “2” and a hammer.

c. Install a new bearing race.

ECA

NOTICE

If the bearing race is not installed properly,

the steering head pipe could be damaged.

TIP

Always replace the bearing and the bearing

race as a set.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

4. Check: • Upper bracket

• Lower bracket

(along with the steering stem)

Bends/cracks/damage Replace.

EAS2GC1206INSTALLING THE STEERING HEAD

1. Install:

• Lower bearing “1”

TIP

Apply the lithium-soap-based grease on the

dust seal lip and bearing inner circumference.

2. Install:• Bearing races

• Upper bearing “1”

• Bearing race cover “2”

Steering nut wrench

90890-01403

Exhaust flange nut wrench YU-A9472

Page 208 of 426

STEERING HEAD

5-56

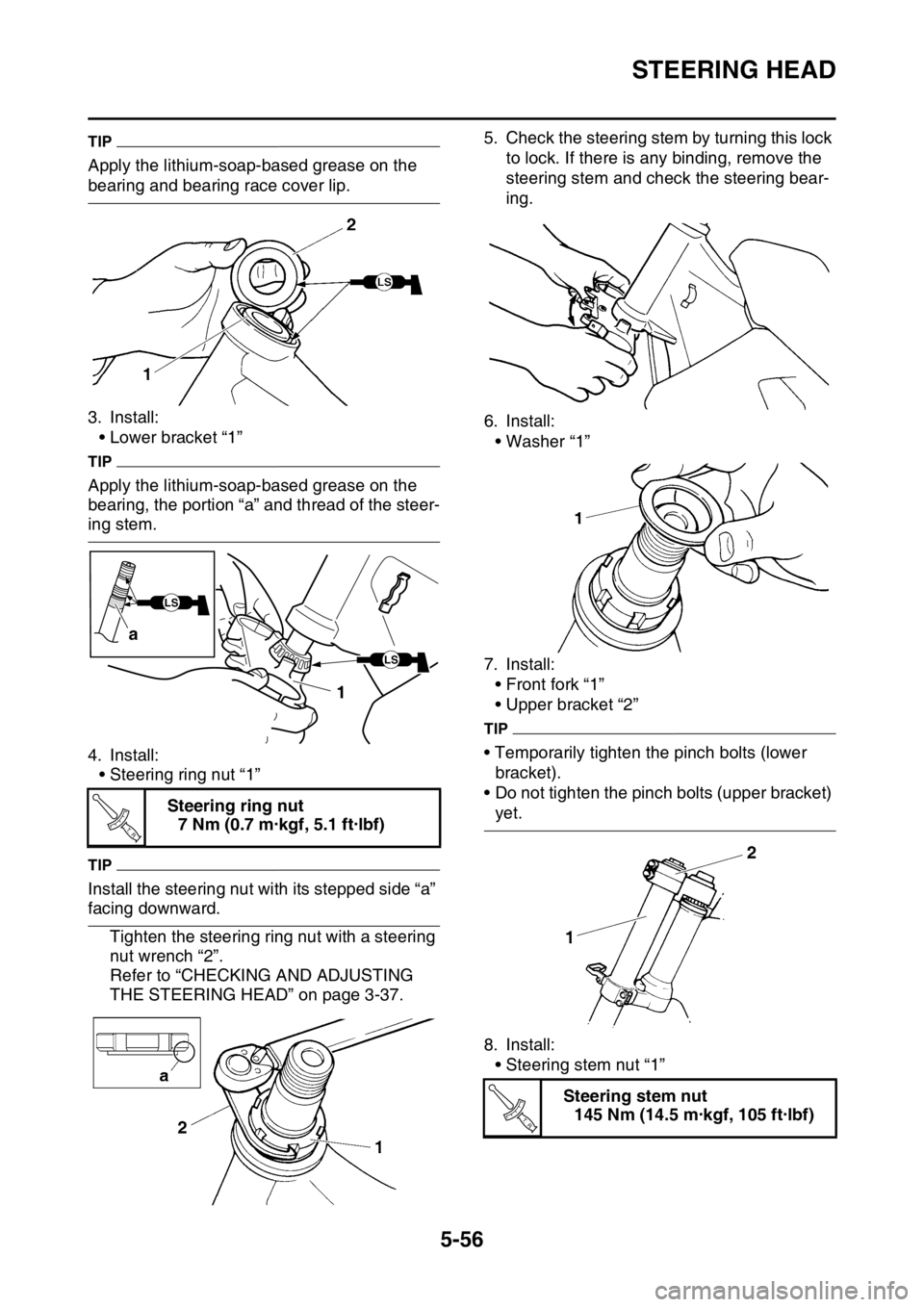

TIP

Apply the lithium-soap-based grease on the

bearing and bearing race cover lip.

3. Install:• Lower bracket “1”

TIP

Apply the lithium-soap-based grease on the

bearing, the portion “a” and thread of the steer-

ing stem.

4. Install:• Steering ring nut “1”

TIP

Install the steering nut with its stepped side “a”

facing downward.

Tighten the steering ring nut with a steering

nut wrench “2”.

Refer to “CHECKING AND ADJUSTING

THE STEERING HEAD” on page 3-37. 5. Check the steering stem by turning this lock

to lock. If there is any binding, remove the

steering stem and check the steering bear-

ing.

6. Install: • Washer “1”

7. Install: • Front fork “1”

• Upper bracket “2”

TIP

• Temporarily tighten the pinch bolts (lower bracket).

• Do not tighten the pinch bolts (upper bracket)

yet.

8. Install: • Steering stem nut “1”

Steering ring nut

7 Nm (0.7 m·kgf, 5.1 ft·lbf)

LS

1

a

LSLS

T R..

Steering stem nut

145 Nm (14.5 m·kgf, 105 ft·lbf)

T R..

Page 209 of 426

STEERING HEAD

5-57

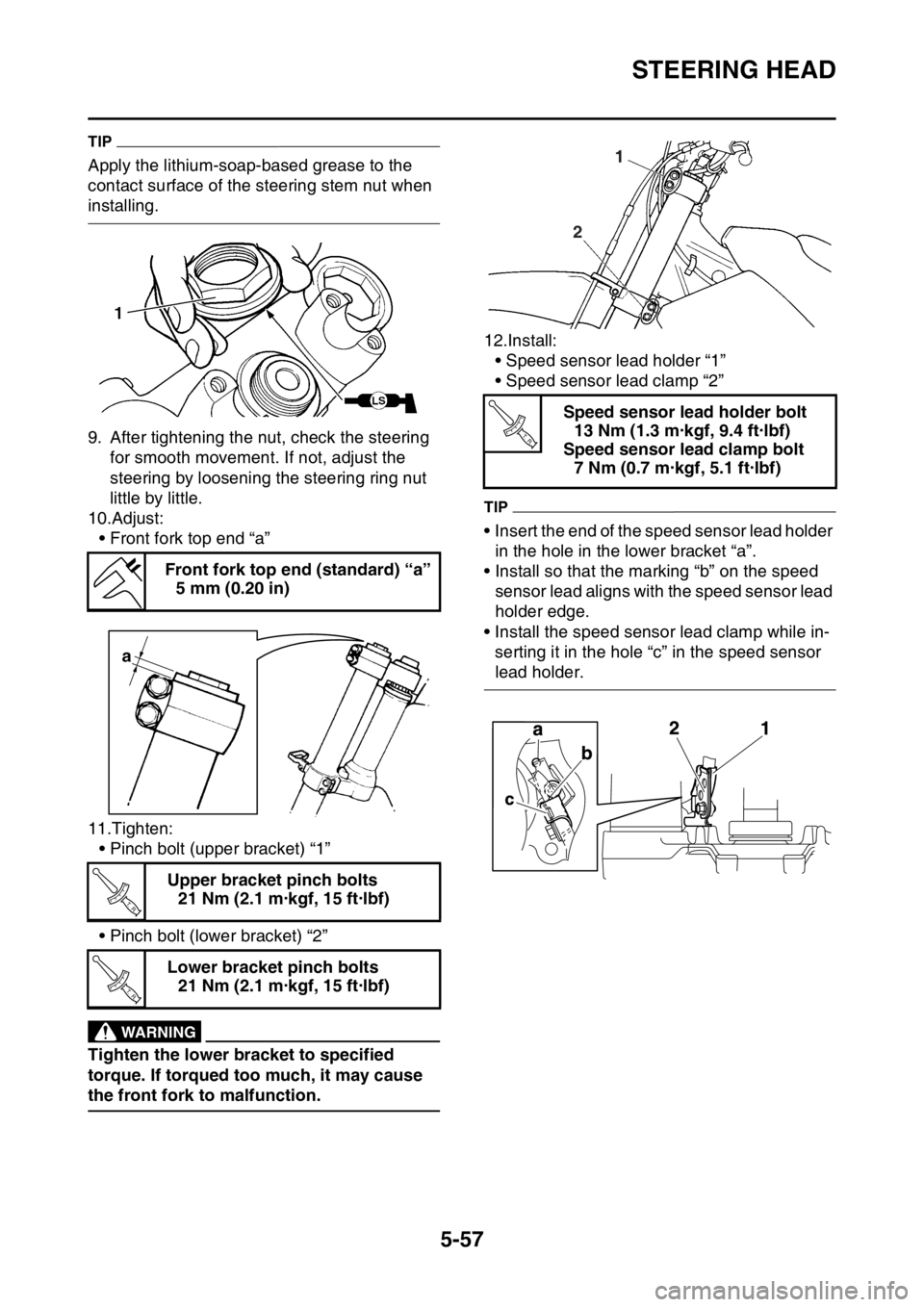

TIP

Apply the lithium-soap-based grease to the

contact surface of the steering stem nut when

installing.

9. After tightening the nut, check the steering for smooth movement. If not, adjust the

steering by loosening the steering ring nut

little by little.

10.Adjust:

• Front fork top end “a”

11.Tighten: • Pinch bolt (upper bracket) “1”

• Pinch bolt (lower bracket) “2”

EWA

WARNING

Tighten the lower bracket to specified

torque. If torqued too much, it may cause

the front fork to malfunction. 12.Install:

• Speed sensor lead holder “1”

• Speed sensor lead clamp “2”

TIP

• Insert the end of the speed sensor lead holder

in the hole in the lower bracket “a”.

• Install so that the marking “b” on the speed sensor lead aligns with the speed sensor lead

holder edge.

• Install the speed sens or lead clamp while in-

serting it in the hole “c” in the speed sensor

lead holder.

Front fork top end (standard) “a”

5 mm (0.20 in)

Upper bracket pinch bolts 21 Nm (2.1 m·kgf, 15 ft·lbf)

Lower bracket pinch bolts 21 Nm (2.1 m·kgf, 15 ft·lbf)

a

T R..

T R..

Speed sensor lead holder bolt13 Nm (1.3 m·kgf, 9.4 ft·lbf)

Speed sensor lead clamp bolt 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

2 1

T R..

Page 416 of 426

TROUBLESHOOTING

10-3

Cooling system

1. Coolant• Low coolant level

2. Radiator • Damaged or leaking radiator

• Faulty radiator cap

• Bent or damaged radiator fin

3. Water pump • Damaged or faulty water pump

• Damaged hose

• Improperly connected hose

• Damaged pipe

• Improperly connected pipe

Fuel system

1. Throttle body • Damaged or loose throttle body joint

2. Air filter • Clogged air filter element

Chassis

1. Brake(s) • Dragging brake

Electrical system

1. Spark plug • Incorrect spark plug gap

• Incorrect spark plug heat range

2. Ignition system • Faulty ECU

• Faulty coolant temperature sensor

EAS2GC1417OVERCOOLING

Cooling system

1. Coolant temperature sensor• Faulty coolant temperature sensor

EAS2GC1418POOR BRAKING PERFORMANCE

Chassis

1. Brake(s)• Worn brake pad

• Worn brake disc

• Air in hydraulic brake system

• Leaking brake fluid

• Defective master cylinder kit

• Faulty brake caliper kit

• Faulty brake caliper seal

• Loose union bolt

• Damaged brake hose

• Oil or grease on the brake disc

• Oil or grease on the brake pad

• Incorrect brake fluid level

EAS2GC1419FRONT FORK OIL LEAKING

Chassis

1. Front fork• Bent, damaged, or rusty inner tube

• Cracked or damaged outer tube

• Improperly installed oil seal

• Damaged oil seal lip

• Incorrect oil level (high)

• Loose damper rod assembly bolt

• Damaged damper rod assembly bolt copper

washer

• Cracked or damaged cap bolt O-ring

EAS2GC1420FAULTY FRONT FORK LEGS

Chassis

1. Front fork • Bent or damaged inner tube

• Bent or damaged outer tube

• Broken fork spring

• Bent or damaged damper rod

• Incorrect oil viscosity

• Incorrect oil level

EAS2GC1421UNSTABLE HANDLING

Chassis

1. Handlebar• Bent or improperly installed handlebar

2. Steering head components • Improperly installed upper bracket

• Improperly installed lower bracket(improperly tightened ring nut)

• Bent steering stem

• Damaged ball bearing or bearing race

3. Front fork leg (s) • Uneven oil levels (both front fork legs)

• Unevenly tensioned fork spring (both front fork legs)

• Broken fork spring

• Bent or damaged inner tube

• Bent or damaged outer tube

4. Swingarm • Worn bearing or bushing

• Bent or damaged swingarm

5. Rear shock absorber assembly (-ies) • Faulty rear shock absorber spring

• Leaking oil or gas

6. Tire (s) • Uneven tire pressures (front and rear)

• Incorrect tire pressure

• Uneven tire wear

Page 417 of 426

TROUBLESHOOTING

10-4

7. Wheel (s)• Incorrect wheel balance

• Broken or loose spoke

• Damaged wheel bearing

• Bent or loose wheel axle

• Excessive wheel runout

8. Frame • Bent frame

• Damaged steering head pipe

• Improperly installed bearing race

EAS2GC1422HEADLIGHT DOES NOT COME ON

Electrical system

1. Headlight• Fuse open circuit

• Wrong headlight bulb

• Too many electrical accessories

• Hard charging

• Incorrect connection

• Improperly grounded circuit

• Poor contacts (start switch)

• Burnt-out headlight bulb

EAS2GC1423HEADLIGHT BULB BURNT OUT

Electrical system

1. Headlight

• Wrong headlight bulb

• Faulty battery

• Faulty rectifier/regulator

• Improperly grounded circuit

• Faulty start switch

• Headlight bulb life expired

EAS2GC1424TAILLIGHT DOES NOT COME ON

Electrical system

1. Taillight• Wrong taillight LED

• Too many electrical accessories

• Incorrect connection

• Faulty battery