sensor YAMAHA WR 450F 2016 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: WR 450F, Model: YAMAHA WR 450F 2016Pages: 426, PDF Size: 10.86 MB

Page 29 of 426

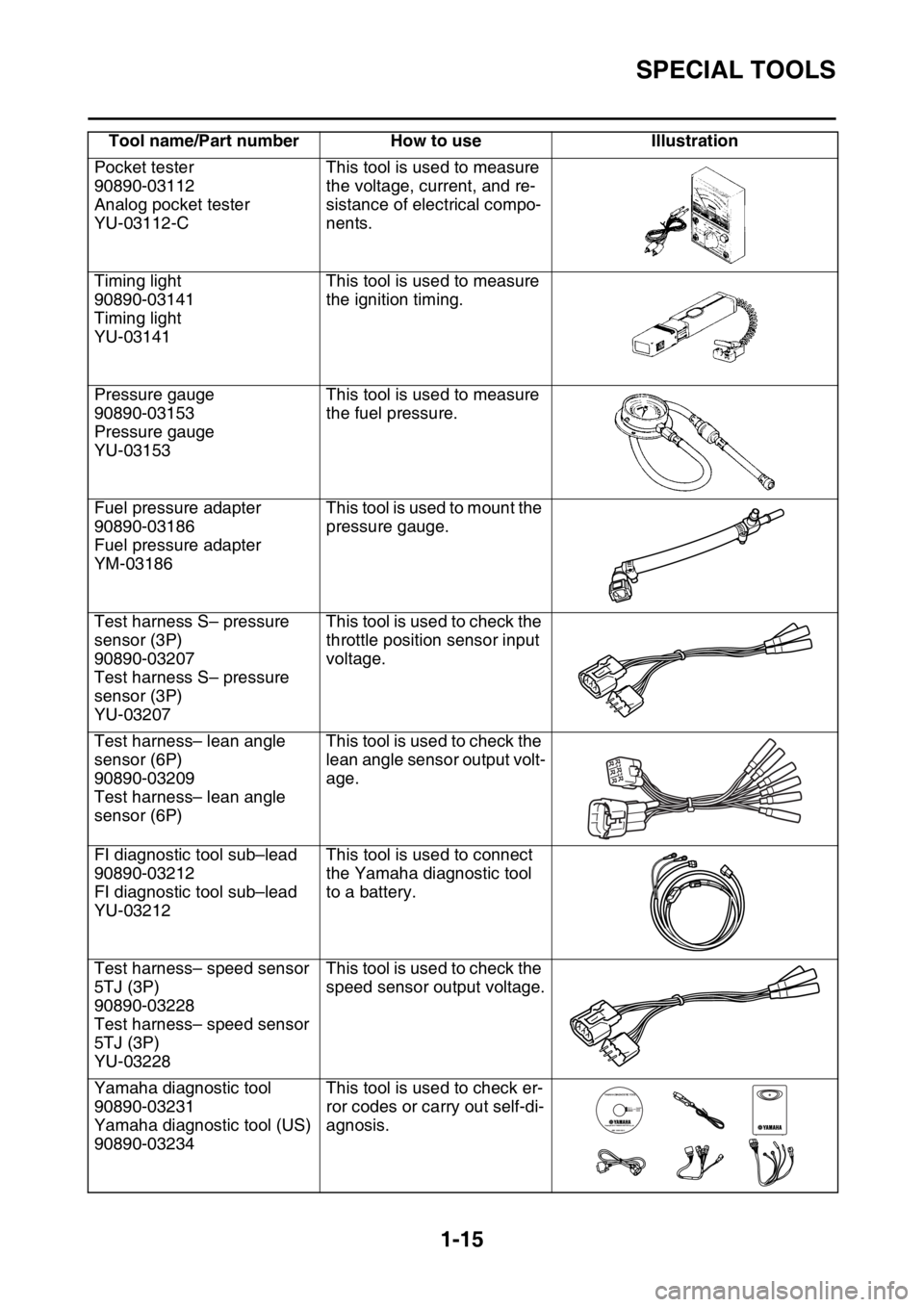

SPECIAL TOOLS

1-15

Pocket tester

90890-03112

Analog pocket tester

YU-03112-CThis tool is used to measure

the voltage, current, and re-

sistance of electrical compo-

nents.

Timing light

90890-03141

Timing light

YU-03141 This tool is used to measure

the ignition timing.

Pressure gauge

90890-03153

Pressure gauge

YU-03153 This tool is used to measure

the fuel pressure.

Fuel pressure adapter

90890-03186

Fuel pressure adapter

YM-03186 This tool is used to mount the

pressure gauge.

Test harness S– pressure

sensor (3P)

90890-03207

Test harness S– pressure

sensor (3P)

YU-03207 This tool is used to check the

throttle position sensor input

voltage.

Test harness– lean angle

sensor (6P)

90890-03209

Test harness– lean angle

sensor (6P) This tool is used to check the

lean angle sensor output volt-

age.

FI diagnostic tool sub–lead

90890-03212

FI diagnostic tool sub–lead

YU-03212 This tool is used to connect

the Yamaha diagnostic tool

to a battery.

Test harness– speed sensor

5TJ (3P)

90890-03228

Test harness– speed sensor

5TJ (3P)

YU-03228 This tool is used to check the

speed sensor output voltage.

Yamaha diagnostic tool

90890-03231

Yamaha diagnostic tool (US)

90890-03234 This tool is used to check er-

ror codes or carry out self-di-

agnosis.

Tool name/Part number

How to useIllustration

Page 57 of 426

ENGINE SPECIFICATIONS

2-6

Fuel pumpPump type Electrical

Fuel injector

Model/quantity 1010/1

Resistance 12

Throttle body

Type/quantity 30RA-A05U/1

ID mark 2GC1 00

Fuel line pressure (at idle) 300.0–390.0 kPa (3.00–3.90 kgf/cm

2, 43.5–

56.6 psi)

Throttle position sensor Resistance 6.30 k

Output voltage (at idle) 0.48–0.52 V

Fuel injection sensor Crankshaft position sensor resistance 228–342

Intake air pressure sensor output voltage 3.61–3.67 V at 101.3 kPa (3.61–3.67 V at 1.01 kgf/cm

2, 3.61–3.67 V at 14.7 psi)

Intake air temperature sensor resistance 290–390 at 80 °C (290–390 at 176 °F)

Coolant temperature sensor resistance 2512–2777 at 20 °C (2512–2777 at 68 °F)

210–220 at 100 °C (210–220 at 212 °F)

Idling condition

Engine idling speed 1900–2100 r/min

CO% 3.5–4.5 % (USA) (CAN)

Intake vacuum 32.8–36.8 kPa (246–276 mmHg, 9.7–10.9 inHg) (USA) (CAN)

Water temperature 70–90 °C (158–194 °F)

Oil temperature 70–80 °C (158–176 °F)

Throttle grip free play 3.0–6.0 mm (0.12–0.24 in)

Page 61 of 426

ELECTRICAL SPECIFICATIONS

2-10

EAS2GC1064

ELECTRICAL SPECIFICATIONS

VoltageSystem voltage 12 V

Ignition systemIgnition system TCI

Advancer type Digital

Ignition timing (B.T.D.C.) 10.0 ° at 2000 r/min

Engine control unitModel/manufacturer 2GC0/YAMAHA (USA) (CAN) 2GC1/YAMAHA (EUR) (AUS) (NZL) (ZAF)

Ignition coilMinimum ignition spark gap 6.0 mm (0.24 in)

Primary coil resistance 2.16–2.64

Secondary coil resistance 8.64–12.96 k

Spark plug cap

Resistance 7.50–12.50 k

Lean angle sensor output voltage

Operating angle 45 °

Output voltage up to operating angle 3.7–4.4 V

Output voltage over operating angle 0.4–1.4 V

AC magneto

Standard output 14.0 V, 160 W at 5000 r/min

Stator coil resistance 0.528–0.792 (W–W)

Rectifier/regulator

Regulator type Three-phase

No load regulated voltage 14.1–14.9 V

Rectifier capacity (DC) 35.0 A

BatteryModel YTZ7S (F)

Voltage, capacity 12 V, 6.0 Ah (10HR)

Specific gravity 1.31

Manufacturer GS YUASA

Ten hour rate charging current 0.60 A

Headlight

Bulb type Halogen bulb

Bulb voltage, wattage quantity

Headlight HS1, 35.0 W/35.0 W 1 (Hi)

Tail/brake light LED

Meter lighting EL (Electroluminescent)

Indicator light

Fuel level warning light 12 V, 1.7 W 1

Engine trouble warning light 12 V, 1.7 W 1

Electric starting system

System type Constant mesh

Page 66 of 426

TIGHTENING TORQUES

2-15

TIP

*1:Cylinder head bolt

First, tighten the cylinder head bolts to 30 Nm (3.0 m·kgf, 22 ft·lbf) in the proper tightening sequence

and remove them. Retighten the cylinder head bolts to 20 Nm (2.0 m·kgf, 14 ft·lbf) in the proper tight-

ening sequence, and then tighten the cylinder head bolts further to reach the specified angle 150° in

the proper tightening sequence.Kickstarter lever boss screw

M6 1 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Primary drive gear nut M20 1 100 Nm (10 m·kgf, 72 ft·lbf)

Clutch spring bolt M6 6 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Clutch boss nut M20 1 75 Nm (7.5 m·kgf, 54 ft·lbf)

Drive sprocket nut M20 1 75 Nm (7.5 m·kgf, 54 ft·lbf) Use a

lock

washer.

Drive axle oil seal stopper bolt M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Segment M8 1 30 Nm (3.0 m·kgf, 22 ft·lbf)

Shift guide bolt M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Stopper lever bolt M6 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Shift pedal bolt M6 1 12 Nm (1.2 m·kgf, 8.7 ft·lbf)

Rotor nut M12 1 65 Nm (6.5 m·kgf, 47 ft·lbf)

Stator screw M5 2 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Crankshaft position sensor bolt M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

AC magneto lead holder bolt M5 1 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Damper assembly cover bolt M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Starter clutch bolt M6 6 16 Nm (1.6 m·kgf, 12 ft·lbf)

Starter motor bolt M6 1 12 Nm (1.2 m·kgf, 8.7 ft·lbf)

Starter motor cover bolt M6 1 12 Nm (1.2 m·kgf, 8.7 ft·lbf)

Coolant temperature sensor M10 1 16 Nm (1.6 m·kgf, 12 ft·lbf)

Neutral switch bolt M5 2 3.5 Nm (0.35 m·kgf, 2.5 ft·lbf)

Intake air temperature sensor screw M5 1 1.5 Nm (0.15 m·kgf, 1.1 ft·lbf)

Rectifier/regulator bolt M6 2 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

ECU bolt M5 2 3.8 Nm (0.38 m·kgf, 2.8 ft·lbf)

Ignition coil bolt M6 2 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Throttle position sensor screw M5 2 3.4 Nm (0.34 m·kgf, 2.5 ft·lbf)

Intake air pressure sensor screw M6 1 5 Nm (0.5 m·kgf, 3.6 ft·lbf)

ITEM

Thread

size Q’ty TIGHTENING TORQUES Remarks

E

E

LT

LT

LT

LT

LT

LT

LT

LT

Page 70 of 426

TIGHTENING TORQUES

2-19

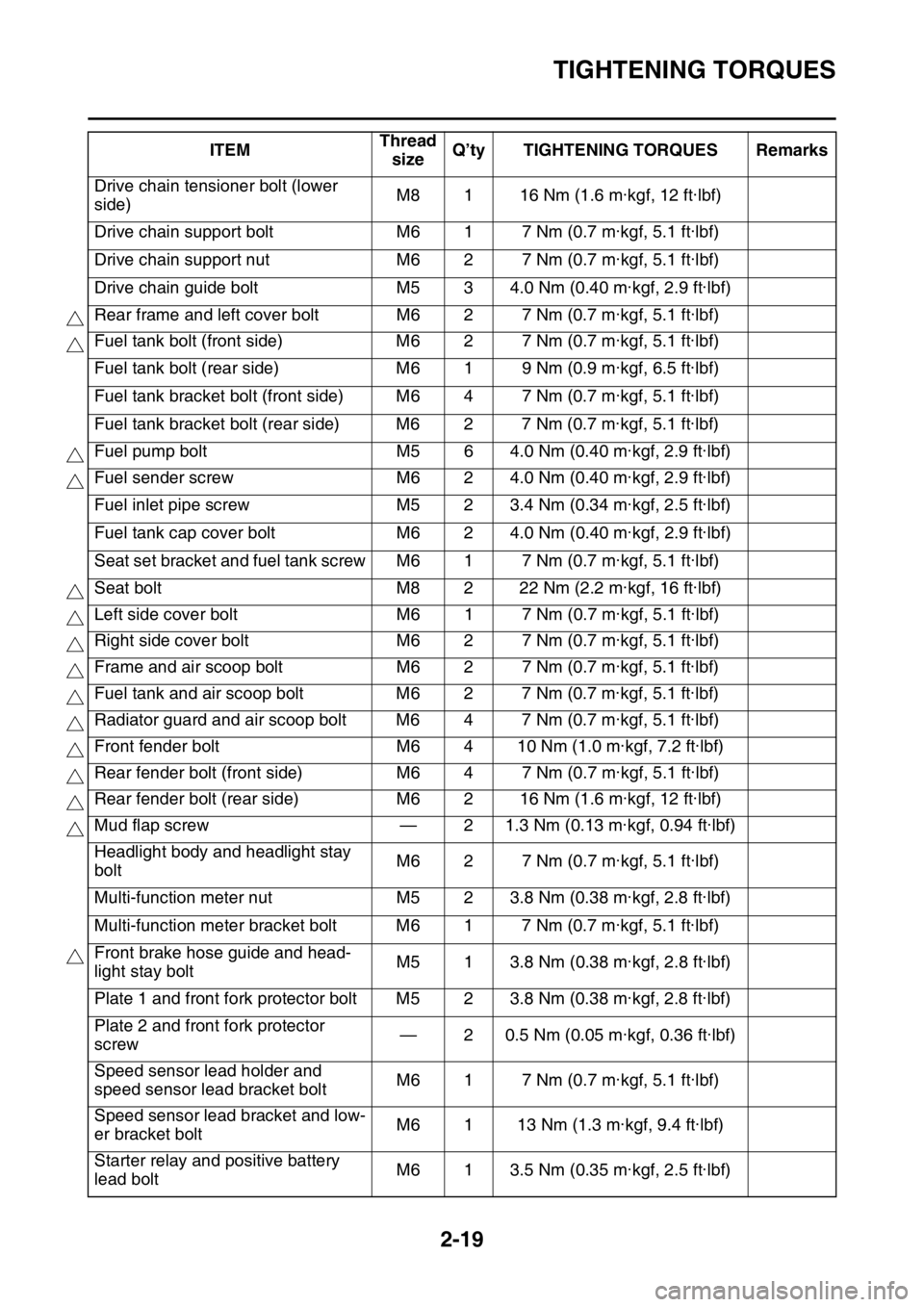

Drive chain tensioner bolt (lower

side)M8 1 16 Nm (1.6 m·kgf, 12 ft·lbf)

Drive chain support bolt M6 1 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Drive chain support nut M6 2 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Drive chain guide bolt M5 3 4.0 Nm (0.40 m·kgf, 2.9 ft·lbf)

Rear frame and left cover bolt M6 2 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Fuel tank bolt (front side) M6 2 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Fuel tank bolt (rear side) M6 1 9 Nm (0.9 m·kgf, 6.5 ft·lbf)

Fuel tank bracket bolt (front side) M6 4 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Fuel tank bracket bolt (rear side) M6 2 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Fuel pump bolt M5 6 4.0 Nm (0.40 m·kgf, 2.9 ft·lbf)

Fuel sender screw M6 2 4.0 Nm (0.40 m·kgf, 2.9 ft·lbf)

Fuel inlet pipe screw M5 2 3.4 Nm (0.34 m·kgf, 2.5 ft·lbf)

Fuel tank cap cover bolt M6 2 4.0 Nm (0.40 m·kgf, 2.9 ft·lbf)

Seat set bracket and fuel tank screw M6 1 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Seat bolt M8 2 22 Nm (2.2 m·kgf, 16 ft·lbf)

Left side cover bolt M6 1 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Right side cover bolt M6 2 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Frame and air scoop bolt M6 2 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Fuel tank and air scoop bolt M6 2 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Radiator guard and air scoop bolt M6 4 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Front fender bolt M6 4 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Rear fender bolt (front side) M6 4 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Rear fender bolt (rear side) M6 2 16 Nm (1.6 m·kgf, 12 ft·lbf)

Mud flap screw — 2 1.3 Nm (0.13 m·kgf, 0.94 ft·lbf)

Headlight body and headlight stay

bolt M6 2 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Multi-function meter nut M5 2 3.8 Nm (0.38 m·kgf, 2.8 ft·lbf)

Multi-function meter bracket bolt M6 1 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Front brake hose guide and head-

light stay bolt M5 1 3.8 Nm (0.38 m·kgf, 2.8 ft·lbf)

Plate 1 and front fork protector bolt M5 2 3.8 Nm (0.38 m·kgf, 2.8 ft·lbf)

Plate 2 and front fork protector

screw — 2 0.5 Nm (0.05 m·kgf, 0.36 ft·lbf)

Speed sensor lead holder and

speed sensor lead bracket bolt M6 1 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Speed sensor lead bracket and low-

er bracket bolt M6 1 13 Nm (1.3 m·kgf, 9.4 ft·lbf)

Starter relay and positive battery

lead bolt M6 1 3.5 Nm (0.35 m·kgf, 2.5 ft·lbf)

ITEM

Thread

size Q’ty TIGHTENING TORQUES Remarks

Page 71 of 426

TIGHTENING TORQUES

2-20

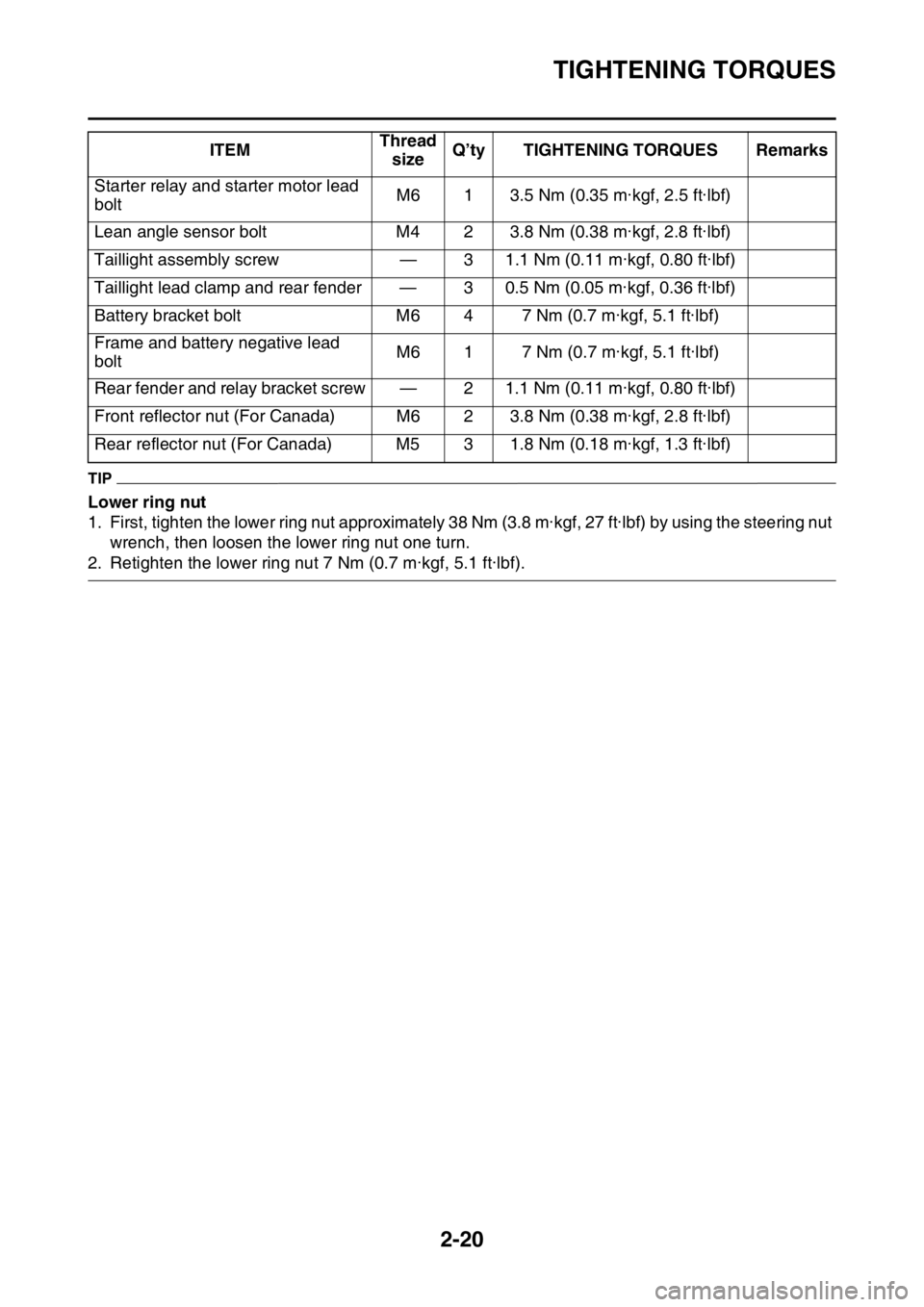

TIP

Lower ring nut

1. First, tighten the lower ring nut approximately 38 Nm (3.8 m·kgf, 27 ft·lbf) by using the steering nut wrench, then loosen the lower ring nut one turn.

2. Retighten the lower ring nut 7 Nm (0.7 m·kgf, 5.1 ft·lbf).Starter relay and starter motor lead

bolt

M6 1 3.5 Nm (0.35 m·kgf, 2.5 ft·lbf)

Lean angle sensor bolt M4 2 3.8 Nm (0.38 m·kgf, 2.8 ft·lbf)

Taillight assembly screw — 3 1.1 Nm (0.11 m·kgf, 0.80 ft·lbf)

Taillight lead clamp and rear fender — 3 0.5 Nm (0.05 m·kgf, 0.36 ft·lbf)

Battery bracket bolt M6 4 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Frame and battery negative lead

bolt M6 1 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Rear fender and relay bracket screw — 2 1.1 Nm (0.11 m·kgf, 0.80 ft·lbf)

Front reflector nut (For Canada) M6 2 3.8 Nm (0.38 m·kgf, 2.8 ft·lbf)

Rear reflector nut (For Canada) M5 3 1.8 Nm (0.18 m·kgf, 1.3 ft·lbf) ITEM

Thread

size Q’ty TIGHTENING TORQUES Remarks

Page 85 of 426

CABLE ROUTING DIAGRAM

2-34

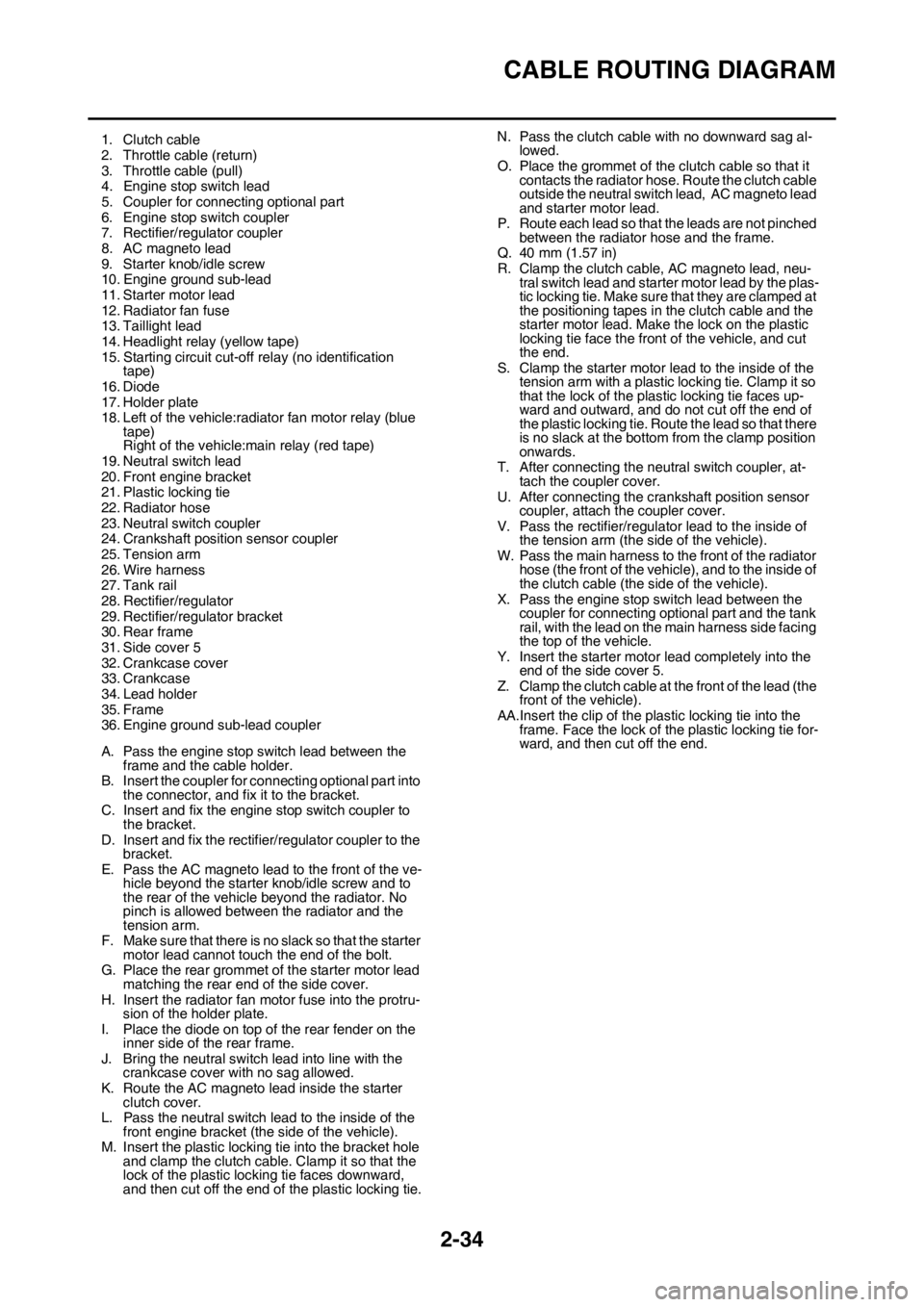

1. Clutch cable

2. Throttle cable (return)

3. Throttle cable (pull)

4. Engine stop switch lead

5. Coupler for connecting optional part

6. Engine stop switch coupler

7. Rectifier/regulator coupler

8. AC magneto lead

9. Starter knob/idle screw

10. Engine ground sub-lead

11. Starter motor lead

12. Radiator fan fuse

13. Taillight lead

14. Headlight relay (yellow tape)

15. Starting circuit cut-off relay (no identification tape)

16. Diode

17. Holder plate

18. Left of the vehicle:radiator fan motor relay (blue tape)

Right of the vehicle:main relay (red tape)

19. Neutral switch lead

20. Front engine bracket

21. Plastic locking tie

22. Radiator hose

23. Neutral switch coupler

24. Crankshaft position sensor coupler

25. Tension arm

26. Wire harness

27. Tank rail

28. Rectifier/regulator

29. Rectifier/regulator bracket

30. Rear frame

31. Side cover 5

32. Crankcase cover

33. Crankcase

34. Lead holder

35. Frame

36. Engine ground sub-lead coupler

A. Pass the engine stop switch lead between the frame and the cable holder.

B. Insert the coupler for connecting optional part into the connector, and fix it to the bracket.

C. Insert and fix the engine stop switch coupler to the bracket.

D. Insert and fix the rectifie r/regulator coupler to the

bracket.

E. Pass the AC magneto lead to the front of the ve- hicle beyond the starter knob/idle screw and to

the rear of the vehicle beyond the radiator. No

pinch is allowed between the radiator and the

tension arm.

F. Make sure that there is no slack so that the starter motor lead cannot touch the end of the bolt.

G. Place the rear grommet of the starter motor lead matching the rear end of the side cover.

H. Insert the radiator fan motor fuse into the protru- sion of the holder plate.

I. Place the diode on top of the rear fender on the inner side of the rear frame.

J. Bring the neutral switch lead into line with the crankcase cover with no sag allowed.

K. Route the AC magneto lead inside the starter clutch cover.

L. Pass the neutral switch l ead to the inside of the

front engine bracket (the side of the vehicle).

M. Insert the plastic locking tie into the bracket hole and clamp the clutch cable. Clamp it so that the

lock of the plastic locking tie faces downward,

and then cut off the end of the plastic locking tie. N. Pass the clutch cable

with no downward sag al-

lowed.

O. Place the grommet of the clutch cable so that it contacts the radiator hose. Route the clutch cable

outside the neutral switch lead, AC magneto lead

and starter motor lead.

P. Route each lead so that the leads are not pinched

between the radiator hose and the frame.

Q. 40 mm (1.57 in)

R. Clamp the clutch cable, AC magneto lead, neu- tral switch lead and starter motor lead by the plas-

tic locking tie. Make sure that they are clamped at

the positioning tapes in the clutch cable and the

starter motor lead. Make the lock on the plastic

locking tie face the front of the vehicle, and cut

the end.

S. Clamp the starter motor lead to the inside of the tension arm with a plastic locking tie. Clamp it so

that the lock of the plastic locking tie faces up-

ward and outward, and do not cut off the end of

the plastic locking tie. R oute the lead so that there

is no slack at the bottom from the clamp position

onwards.

T. After connecting the neutral switch coupler, at- tach the coupler cover.

U. After connecting the crankshaft position sensor coupler, attach the coupler cover.

V. Pass the rectifier/regulator lead to the inside of the tension arm (the side of the vehicle).

W. Pass the main harness to the front of the radiator

hose (the front of the vehicle), and to the inside of

the clutch cable (the side of the vehicle).

X. Pass the engine stop switch lead between the coupler for connecting optional part and the tank

rail, with the lead on the main harness side facing

the top of the vehicle.

Y. Insert the starter motor lead completely into the end of the side cover 5.

Z. Clamp the clutch cable at the front of the lead (the

front of the vehicle).

AA.Insert the clip of the pl astic locking tie into the

frame. Face the lock of the plastic locking tie for-

ward, and then cut off the end.

Page 87 of 426

CABLE ROUTING DIAGRAM

2-36

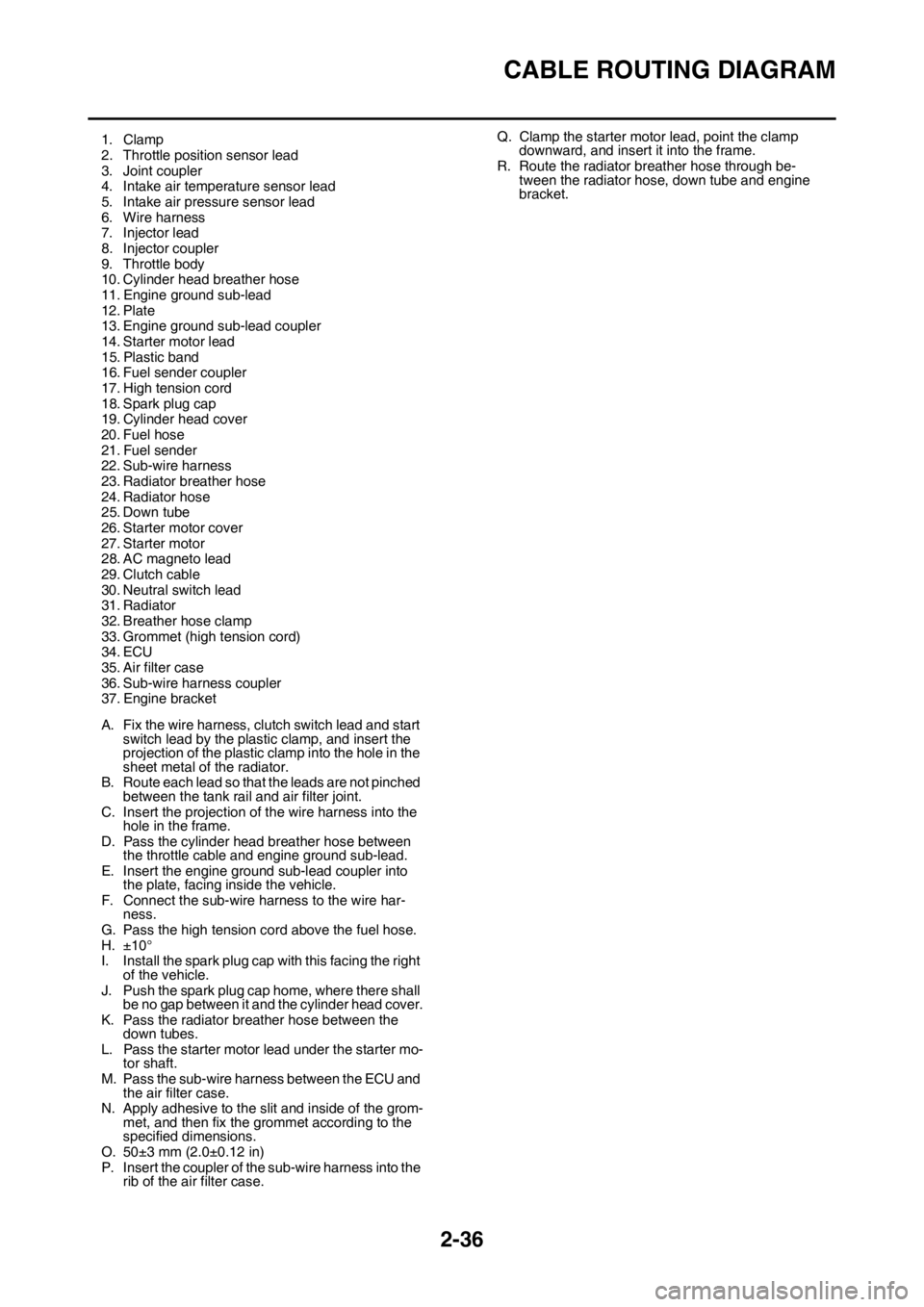

1. Clamp

2. Throttle position sensor lead

3. Joint coupler

4. Intake air temperature sensor lead

5. Intake air pressure sensor lead

6. Wire harness

7. Injector lead

8. Injector coupler

9. Throttle body

10. Cylinder head breather hose

11. Engine ground sub-lead

12. Plate

13. Engine ground sub-lead coupler

14. Starter motor lead

15. Plastic band

16. Fuel sender coupler

17. High tension cord

18. Spark plug cap

19. Cylinder head cover

20. Fuel hose

21. Fuel sender

22. Sub-wire harness

23. Radiator breather hose

24. Radiator hose

25. Down tube

26. Starter motor cover

27. Starter motor

28. AC magneto lead

29. Clutch cable

30. Neutral switch lead

31. Radiator

32. Breather hose clamp

33. Grommet (high tension cord)

34. ECU

35. Air filter case

36. Sub-wire harness coupler

37. Engine bracket

A. Fix the wire harness, clutch switch lead and start switch lead by the plasti c clamp, and insert the

projection of the plastic clamp into the hole in the

sheet metal of the radiator.

B. Route each lead so that the leads are not pinched between the tank rail and air filter joint.

C. Insert the projection of the wire harness into the hole in the frame.

D. Pass the cylinder head breather hose between the throttle cable and engine ground sub-lead.

E. Insert the engine ground sub-lead coupler into the plate, facing inside the vehicle.

F. Connect the sub-wire harness to the wire har- ness.

G. Pass the high tension cord above the fuel hose.

H. ±10°

I. Install the spark plug cap with this facing the right

of the vehicle.

J. Push the spark plug cap home, where there shall be no gap between it and the cylinder head cover.

K. Pass the radiator breather hose between the down tubes.

L. Pass the starter motor lead under the starter mo- tor shaft.

M. Pass the sub-wire harness between the ECU and the air filter case.

N. Apply adhesive to the s lit and inside of the grom-

met, and then fix the grommet according to the

specified dimensions.

O. 50±3 mm (2.0±0.12 in)

P. Insert the coupler of the sub-wire harness into the

rib of the air filter case. Q. Clamp the starter motor lead, point the clamp

downward, and insert it into the frame.

R. Route the radiator breather hose through be- tween the radiator hose, down tube and engine

bracket.

Page 89 of 426

CABLE ROUTING DIAGRAM

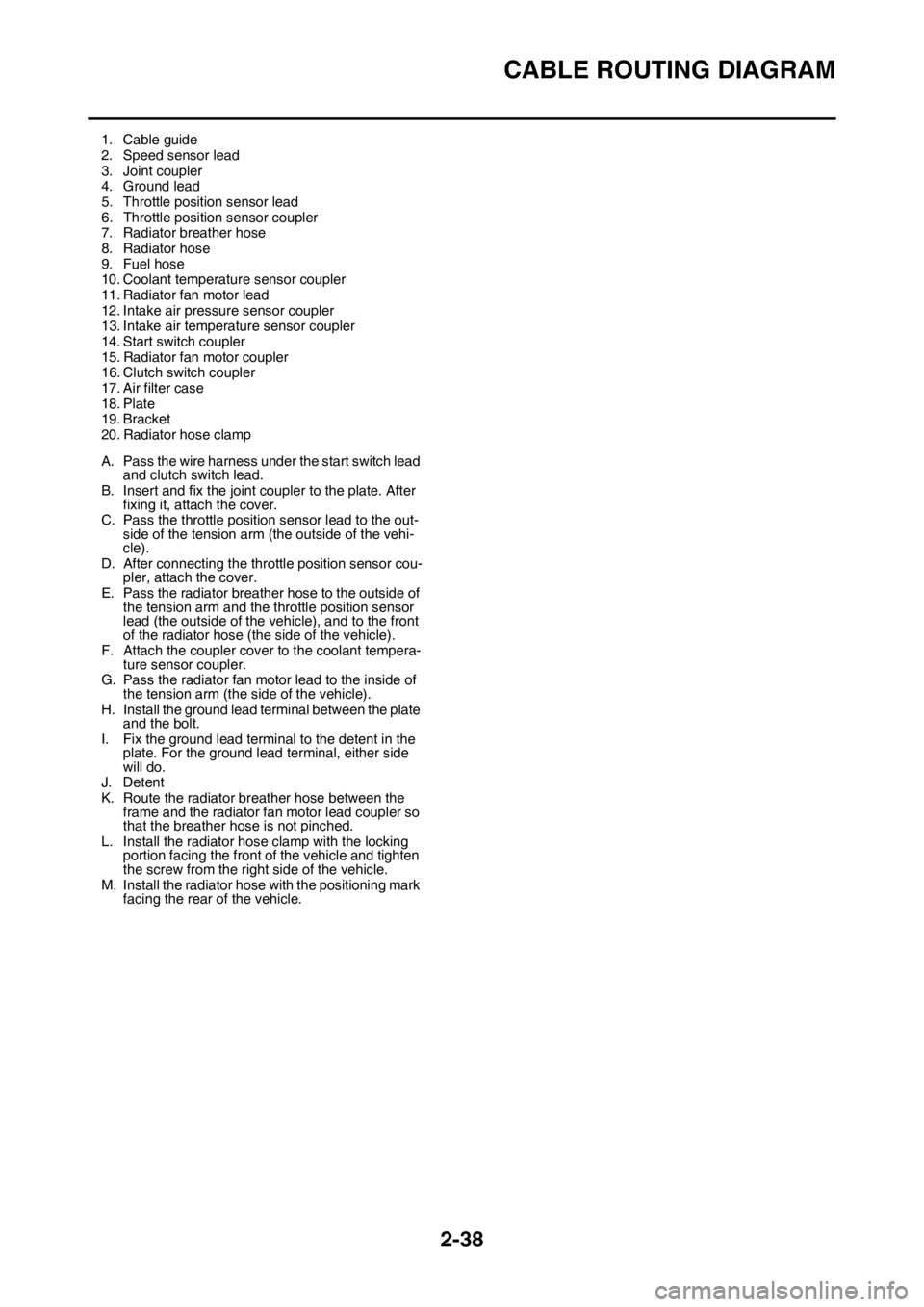

2-38

1. Cable guide

2. Speed sensor lead

3. Joint coupler

4. Ground lead

5. Throttle position sensor lead

6. Throttle position sensor coupler

7. Radiator breather hose

8. Radiator hose

9. Fuel hose

10. Coolant temperature sensor coupler

11. Radiator fan motor lead

12. Intake air pressure sensor coupler

13. Intake air temperature sensor coupler

14. Start switch coupler

15. Radiator fan motor coupler

16. Clutch switch coupler

17. Air filter case

18. Plate

19. Bracket

20. Radiator hose clamp

A. Pass the wire harness under the start switch lead

and clutch switch lead.

B. Insert and fix the joint co upler to the plate. After

fixing it, attach the cover.

C. Pass the throttle position sensor lead to the out- side of the tension arm (the outside of the vehi-

cle).

D. After connecting the throttle position sensor cou- pler, attach the cover.

E. Pass the radiator breather hose to the outside of the tension arm and the throttle position sensor

lead (the outside of the vehicle), and to the front

of the radiator hose (the side of the vehicle).

F. Attach the coupler cover to the coolant tempera- ture sensor coupler.

G. Pass the radiator fan motor lead to the inside of the tension arm (the side of the vehicle).

H. Install the ground lead terminal between the plate and the bolt.

I. Fix the ground lead terminal to the detent in the plate. For the ground lead terminal, either side

will do.

J. Detent

K. Route the radiator breather hose between the frame and the radiator fan motor lead coupler so

that the breather hose is not pinched.

L. Install the radiator hose clamp with the locking portion facing the front of the vehicle and tighten

the screw from the right side of the vehicle.

M. Install the radiator hose with the positioning mark facing the rear of the vehicle.

Page 91 of 426

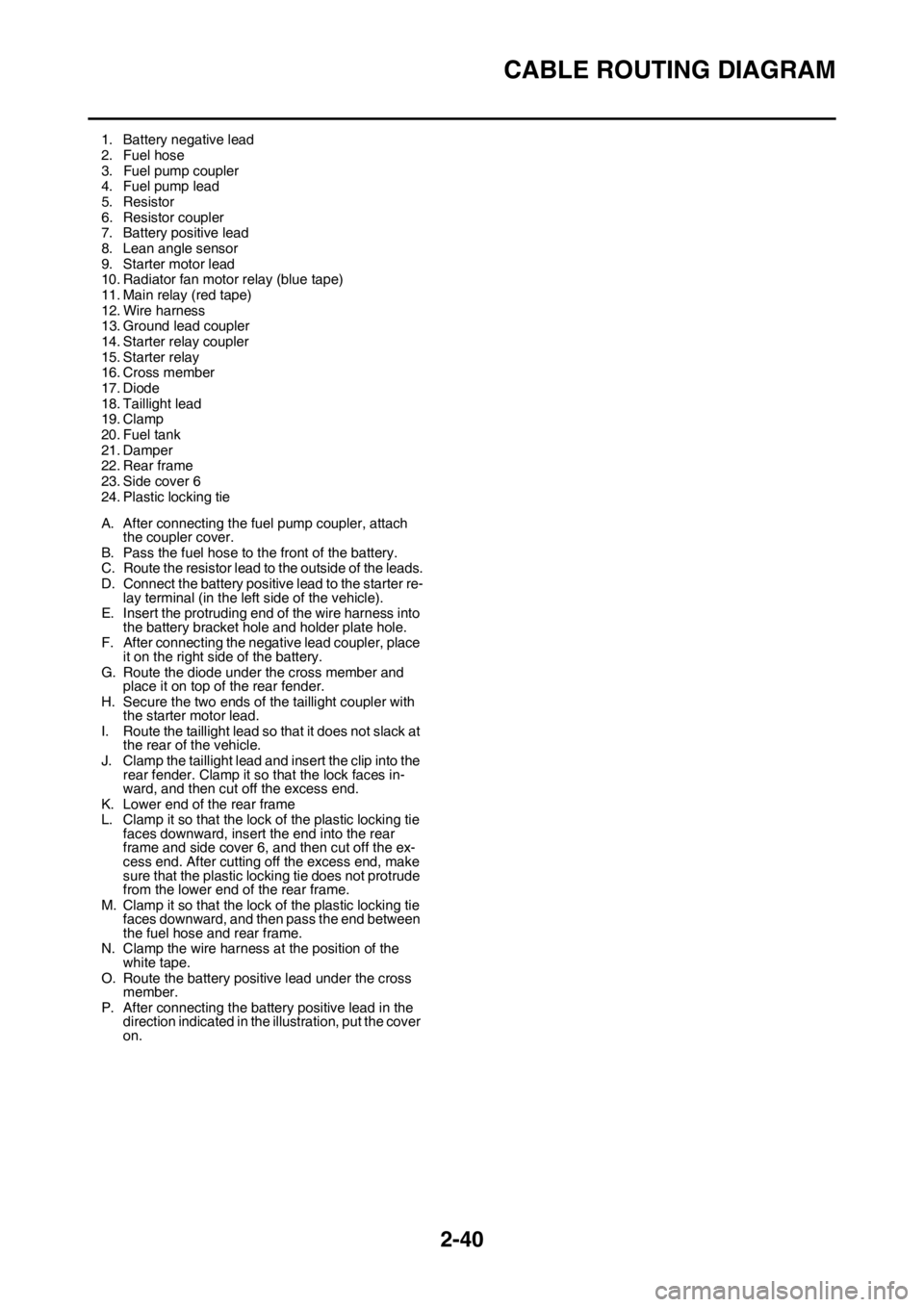

CABLE ROUTING DIAGRAM

2-40

1. Battery negative lead

2. Fuel hose

3. Fuel pump coupler

4. Fuel pump lead

5. Resistor

6. Resistor coupler

7. Battery positive lead

8. Lean angle sensor

9. Starter motor lead

10. Radiator fan motor relay (blue tape)

11. Main relay (red tape)

12. Wire harness

13. Ground lead coupler

14. Starter relay coupler

15. Starter relay

16. Cross member

17. Diode

18. Taillight lead

19. Clamp

20. Fuel tank

21. Damper

22. Rear frame

23. Side cover 6

24. Plastic locking tie

A. After connecting the fuel pump coupler, attach the coupler cover.

B. Pass the fuel hose to the front of the battery.

C. Route the resistor lead to the outside of the leads.

D. Connect the battery positive lead to the starter re- lay terminal (in the left side of the vehicle).

E. Insert the protruding end of the wire harness into

the battery bracket hole and holder plate hole.

F. After connecting the negative lead coupler, place it on the right side of the battery.

G. Route the diode under the cross member and place it on top of the rear fender.

H. Secure the two ends of the taillight coupler with the starter motor lead.

I. Route the taillight lead so that it does not slack at

the rear of the vehicle.

J. Clamp the taillight lead and insert the clip into the rear fender. Clamp it so that the lock faces in-

ward, and then cut off the excess end.

K. Lower end of the rear frame

L. Clamp it so that the lock of the plastic locking tie

faces downward, insert the end into the rear

frame and side cover 6, and then cut off the ex-

cess end. After cutting off the excess end, make

sure that the plastic locki ng tie does not protrude

from the lower end of the rear frame.

M. Clamp it so that the lock of the plastic locking tie

faces downward, and then pass the end between

the fuel hose and rear frame.

N. Clamp the wire harness at the position of the white tape.

O. Route the battery positive lead under the cross member.

P. After connecting the battery positive lead in the direction indicated in the illustration, put the cover

on.